JEEP YJ 1995 Service And Workshop Manual

Manufacturer: JEEP, Model Year: 1995, Model line: YJ, Model: JEEP YJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 51 of 2158

(2) Note any indication of drum/rotor overheating,

wheel dragging or the vehicle pulling to one side

when the brakes are applied.

(3) Evaluate any performance complaints received

from the owner/operator.

(4) Repair the brake system as necessary. Refer to

Group, 5 Brakes for additional information and ser-

vice procedures.

TIRES

RECOMMENDED MAINTENANCE

The general condition of the tires and the inflation

pressures should be inspected at the same time the

engine oil is changed and the oil filter is replaced.

In addition, the tires/wheels should be rotated at

the intervals described in the Maintenance Schedules

section of this group.

INSPECTION

Inspect the tires for excessive wear, damage, etc.

Test the tires for the recommended inflation pres-sure. Refer to the tire inflation pressure decal located

on the inside of the glove box door, and also to Group

22, Tires And Wheels.

ROTATION

Refer to Group 22, Tires And Wheels for the recom-

mended method of tire/wheel rotation for a Jeep ve-

hicle.

BODY COMPONENTS

LUBRICATION REQUIREMENTS

All Jeep operating mechanisms and linkages

should be lubricated when necessary. The door

weatherstrip seals should be lubricated to prolong

their life as well as to improve door sealing.

LUBRICANT SPECIFICATIONS

All applicable exterior and interior vehicle operat-

ing mechanisms should be:

²Inspected

²Cleaned

²Pivot/sliding contact areas on the mechanisms

should then be lubricated.

Multi-purpose NLGI GC-LB MOPAR Multi-Mileage

Lubricant or an equivalent, should be used to lubri-

cate the mechanisms. The door weatherstrip seals

should be lubricated with silicone lubricant spray.

Refer to the Body Lubricant Specifications chart be-

low for additional lubricant applications.

LUBRICATION

All pivoting and sliding contact areas, should be lu-

bricated periodically to ensure quiet, easy operation

and to protect against wear and corrosion. Areas in-

clude:

²Seat tracks.

²Door hinges/latches/strikers.

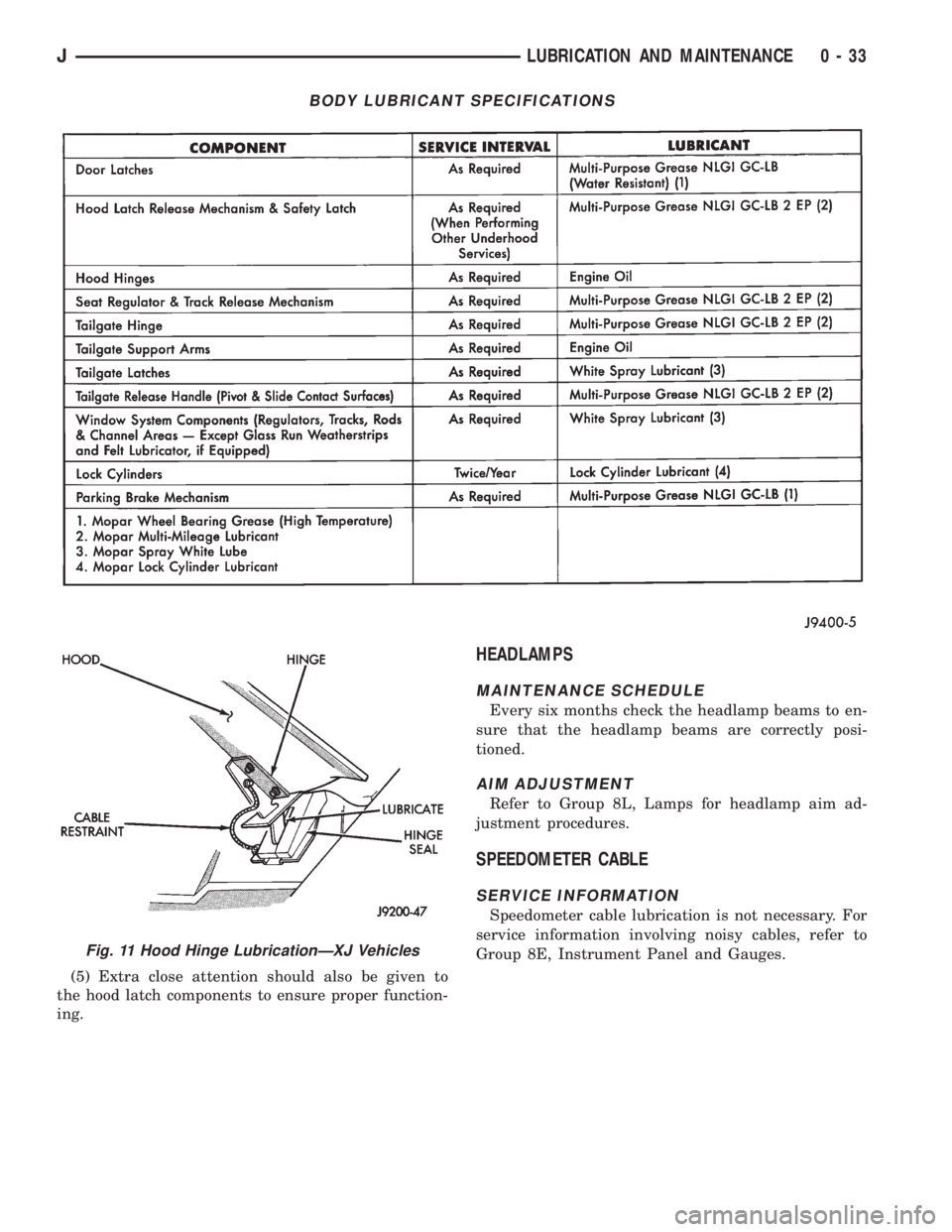

²Liftgate/tailgate/hood hinges (Fig. 11).

(1) As required, lubricate the body components

with the specified lubricants.

(2) Apply silicone lubricant to a cloth and wipe it

on door seals to avoid over-spray that can soil pas-

senger clothing.

(3) Before applying lubricant, the component

should be wiped clean. After lubrication, any excess

lubricant should be removed.

(4) The door lock cylinders should be lubricated 2

times each year (preferably autumn and spring):

²Spray a small amount of lock cylinder lubricant di-

rectly into the lock cylinder.

²Apply a small amount to the key and insert it into

the lock cylinder.

²Rotate it to the locked position and then back to

the unlocked position several times.

²Remove the key. Wipe the lubricant from it with a

clean cloth to avoid soiling of clothing.

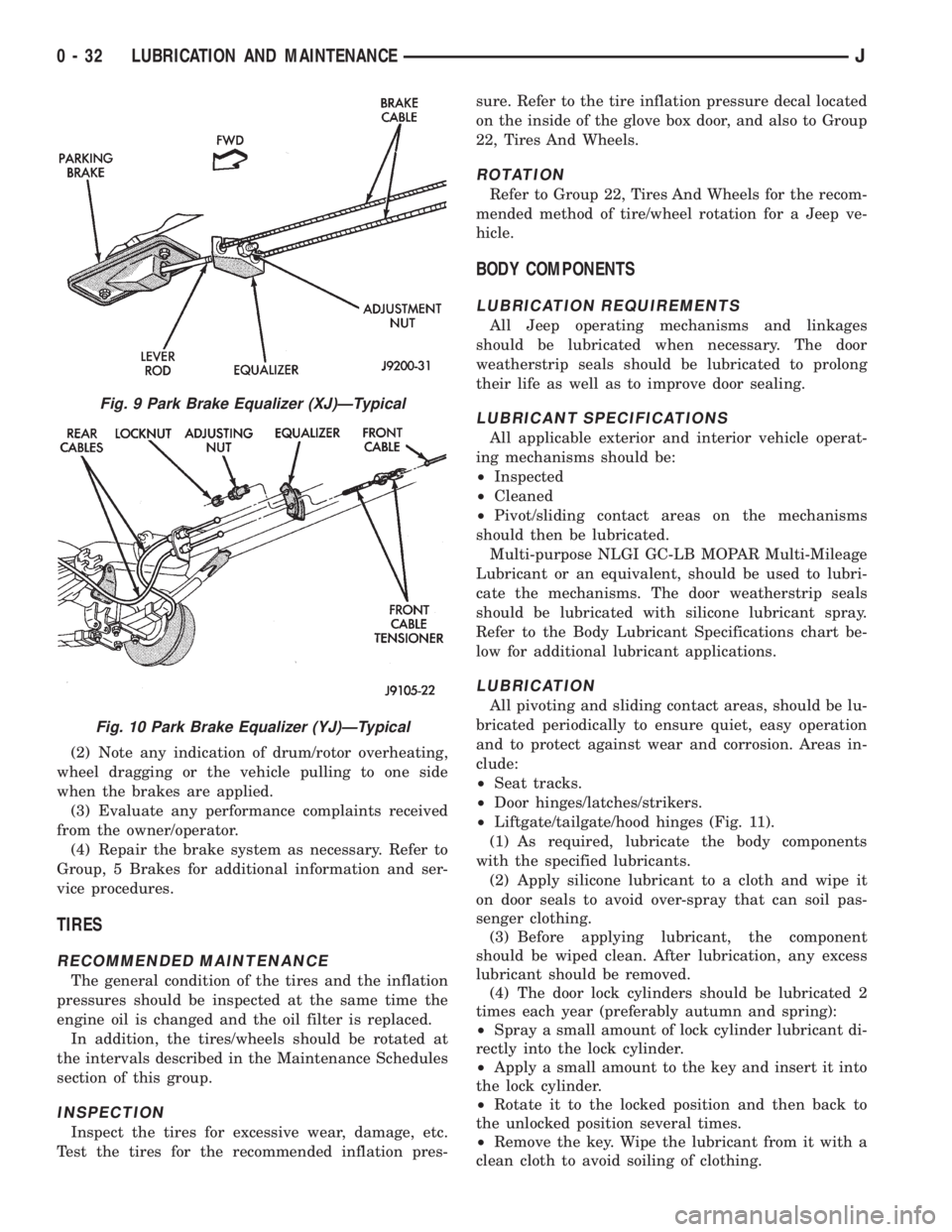

Fig. 9 Park Brake Equalizer (XJ)ÐTypical

Fig. 10 Park Brake Equalizer (YJ)ÐTypical

0 - 32 LUBRICATION AND MAINTENANCEJ

Page 52 of 2158

(5) Extra close attention should also be given to

the hood latch components to ensure proper function-

ing.

HEADLAMPS

MAINTENANCE SCHEDULE

Every six months check the headlamp beams to en-

sure that the headlamp beams are correctly posi-

tioned.

AIM ADJUSTMENT

Refer to Group 8L, Lamps for headlamp aim ad-

justment procedures.

SPEEDOMETER CABLE

SERVICE INFORMATION

Speedometer cable lubrication is not necessary. For

service information involving noisy cables, refer to

Group 8E, Instrument Panel and Gauges.

BODY LUBRICANT SPECIFICATIONS

Fig. 11 Hood Hinge LubricationÐXJ Vehicles

JLUBRICATION AND MAINTENANCE 0 - 33

Page 53 of 2158

FRONT SUSPENSION AND AXLE

CONTENTS

page page

AXLE NOISE/VIBRATION DIAGNOSIS........ 18

AXLE SPECIFICATIONS................... 49

FRONT WHEEL ALIGNMENT................ 5

GENERAL INFORMATION.................. 1MODEL 30 AXLE AND TUBE AXLE (2WD).... 22

TORQUE SPECIFICATIONS................ 49

XJ FRONT SUSPENSION.................. 11

YJ FRONT SUSPENSION.................. 15

GENERAL INFORMATION

FRONT SUSPENSION

XJ VEHICLES

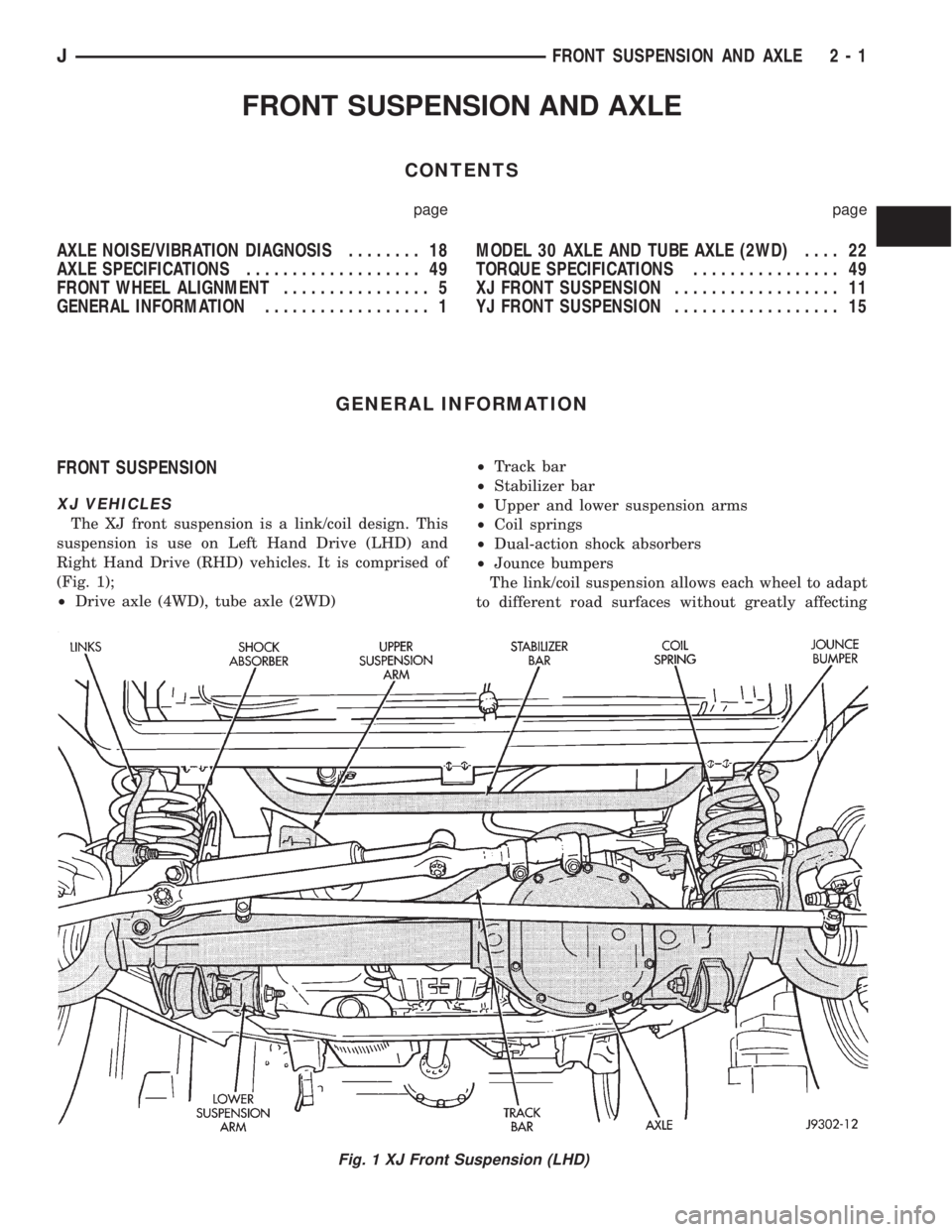

The XJ front suspension is a link/coil design. This

suspension is use on Left Hand Drive (LHD) and

Right Hand Drive (RHD) vehicles. It is comprised of

(Fig. 1);

²Drive axle (4WD), tube axle (2WD)²Track bar

²Stabilizer bar

²Upper and lower suspension arms

²Coil springs

²Dual-action shock absorbers

²Jounce bumpers

The link/coil suspension allows each wheel to adapt

to different road surfaces without greatly affecting

Fig. 1 XJ Front Suspension (LHD)

JFRONT SUSPENSION AND AXLE 2 - 1

Page 54 of 2158

the opposite wheel. Wheels are attached to a hub/

bearings which bolts to the knuckles. The hub/bear-

ing is not serviceable and is replaced as a unit.

Steering knuckles pivot on replaceable ball studs at-

tached to the axle tube yokes.

The upper and lower suspension arms are different

lengths, with bushings at both ends. They bolt the

axle assembly to the body. The lower arms uses

shims at the body mount to allow for adjustment of

caster and drive shaft pinion angle. The suspension

arm travel is limited through the use of jounce

bumpers in compression and shocks absorbers in re-

bound.

Suspension components which use rubber bushings

should be tightened at vehicle ride height. This will

prevent premature failure of the bushing and main-

tain ride comfort. Bushings must never be lubricated.

The coil springs control ride quality and maintain

proper ride height. The coil springs mount up in the

fender shield which is part of the unitized body

bracket. A rubber isolator is located between the top

of the spring and the frame. The bottom of the spring

seats on a axle pad and is retained with a clip.

The shock absorbers dampen jounce and rebound of

the vehicle over various road conditions. The top of

the shock absorbers are bolted to the body. The bot-

tom of the shocks are bolted to the axle spring

bracket.

The stabilizer bar is used to minimize vehicle body

roll during turns. The spring steel bar helps to con-

trol the vehicle body in relationship to the suspen-

sion. The bar extends across the front underside of

the chassis and connects to the body rails. Links are

connected from the bar to the axle brackets. Stabi-

lizer bar mounts are isolated by rubber bushings.

The track bar is used to minimize front axle side-

to-side movement. The bar is attached to a frame rail

bracket with a ball stud and isolated with a bushing

at the axle bracket.

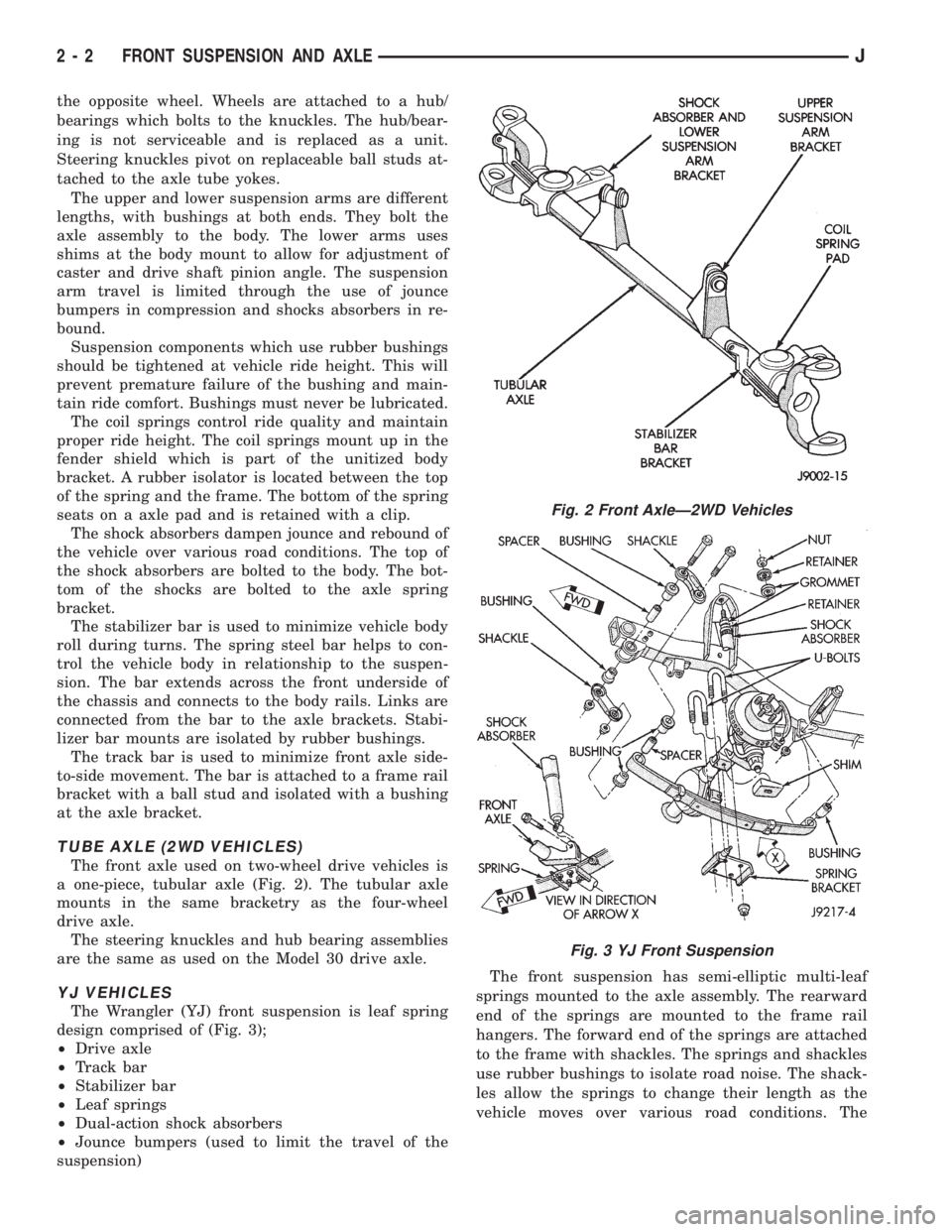

TUBE AXLE (2WD VEHICLES)

The front axle used on two-wheel drive vehicles is

a one-piece, tubular axle (Fig. 2). The tubular axle

mounts in the same bracketry as the four-wheel

drive axle.

The steering knuckles and hub bearing assemblies

are the same as used on the Model 30 drive axle.

YJ VEHICLES

The Wrangler (YJ) front suspension is leaf spring

design comprised of (Fig. 3);

²Drive axle

²Track bar

²Stabilizer bar

²Leaf springs

²Dual-action shock absorbers

²Jounce bumpers (used to limit the travel of the

suspension)The front suspension has semi-elliptic multi-leaf

springs mounted to the axle assembly. The rearward

end of the springs are mounted to the frame rail

hangers. The forward end of the springs are attached

to the frame with shackles. The springs and shackles

use rubber bushings to isolate road noise. The shack-

les allow the springs to change their length as the

vehicle moves over various road conditions. The

Fig. 2 Front AxleÐ2WD Vehicles

Fig. 3 YJ Front Suspension

2 - 2 FRONT SUSPENSION AND AXLEJ

Page 55 of 2158

spring and axle travel (jounce or rebound) is limited

through use of rubber bumpers mounted on the

frame.

Suspension components which use rubber bushings

should be tightened at vehicle ride height. This will

prevent premature failure of the bushing and main-

tain ride comfort. The bushings should never be lu-

bricated.

The shocks absorbers dampen jounce and rebound

of the vehicle over various road conditions. The top of

the shock absorbers bolt to the frame. The bottom of

the shocks bolt to the axle brackets.

The stabilizer bar is used to minimize vehicle front

sway during turns. The spring steel bar helps control

vehicle body in relationship to the suspension move-

ment. The bar extends across the front underside of

the chassis and connects to the frame rails. Links

connect the bar to the axle brackets. Stabilizer bar

mounts are isolated by rubber bushings.

The track bar is used to minimize front axle side-

to-side movement. The track bar is attached to a

frame rail bracket and axle bracket. The bar uses

bushings at both ends.

FRONT DRIVE AXLE

It is not necessary to remove the complete axle

from the vehicle for routine differential service. If the

differential housing or axle shaft tubes are damaged,

the complete axle assembly can be removed and ser-

viced.

For complete drive axle assembly removal and in-

stallation refer to Drive Axle Assembly Replacement

in this Group.

The removable cover provides for servicing without

removing axle from vehicle.

The integral type housing, hypoid gear design has

the centerline of the pinion set above the centerline

of the ring gear.

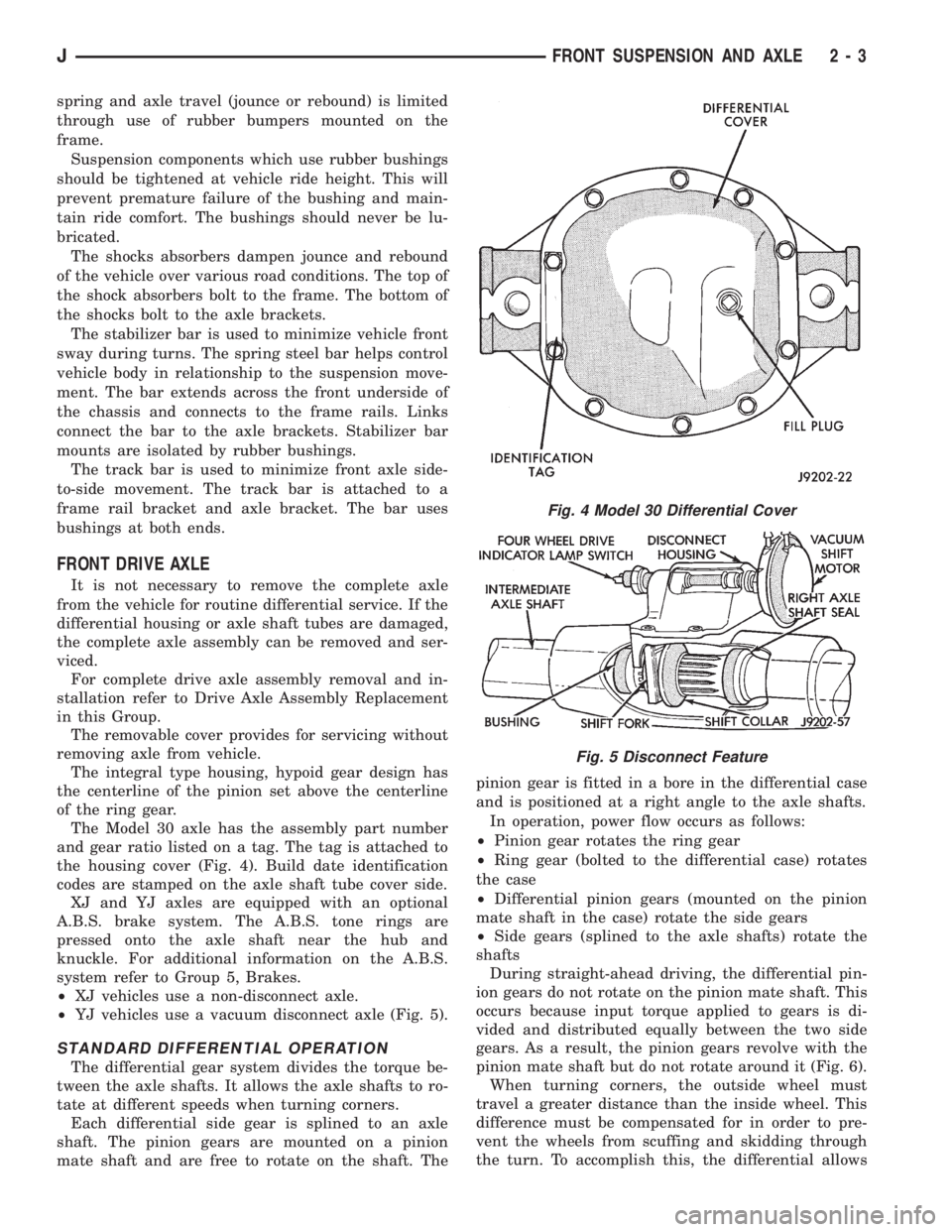

The Model 30 axle has the assembly part number

and gear ratio listed on a tag. The tag is attached to

the housing cover (Fig. 4). Build date identification

codes are stamped on the axle shaft tube cover side.

XJ and YJ axles are equipped with an optional

A.B.S. brake system. The A.B.S. tone rings are

pressed onto the axle shaft near the hub and

knuckle. For additional information on the A.B.S.

system refer to Group 5, Brakes.

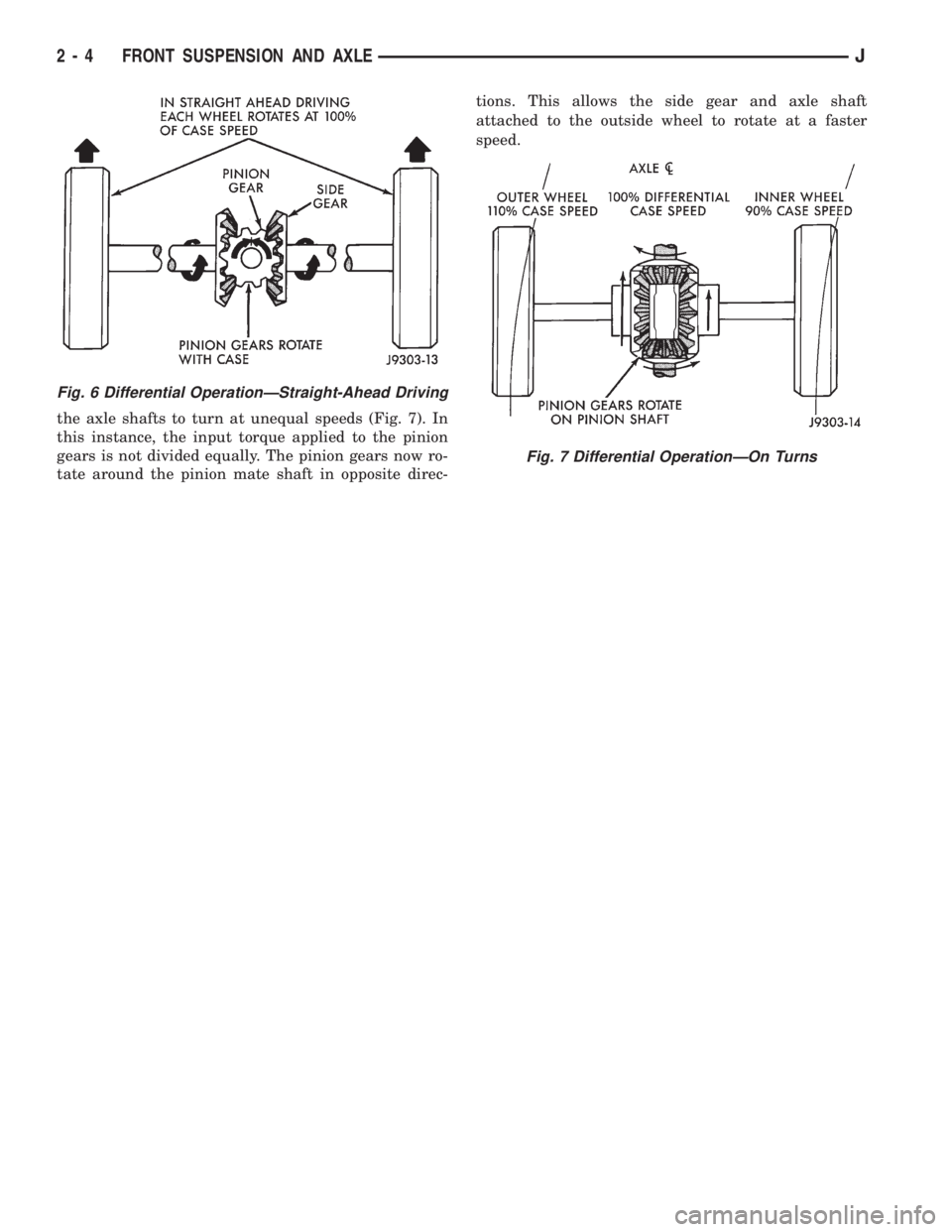

²XJ vehicles use a non-disconnect axle.

²YJ vehicles use a vacuum disconnect axle (Fig. 5).

STANDARD DIFFERENTIAL OPERATION

The differential gear system divides the torque be-

tween the axle shafts. It allows the axle shafts to ro-

tate at different speeds when turning corners.

Each differential side gear is splined to an axle

shaft. The pinion gears are mounted on a pinion

mate shaft and are free to rotate on the shaft. Thepinion gear is fitted in a bore in the differential case

and is positioned at a right angle to the axle shafts.

In operation, power flow occurs as follows:

²Pinion gear rotates the ring gear

²Ring gear (bolted to the differential case) rotates

the case

²Differential pinion gears (mounted on the pinion

mate shaft in the case) rotate the side gears

²Side gears (splined to the axle shafts) rotate the

shafts

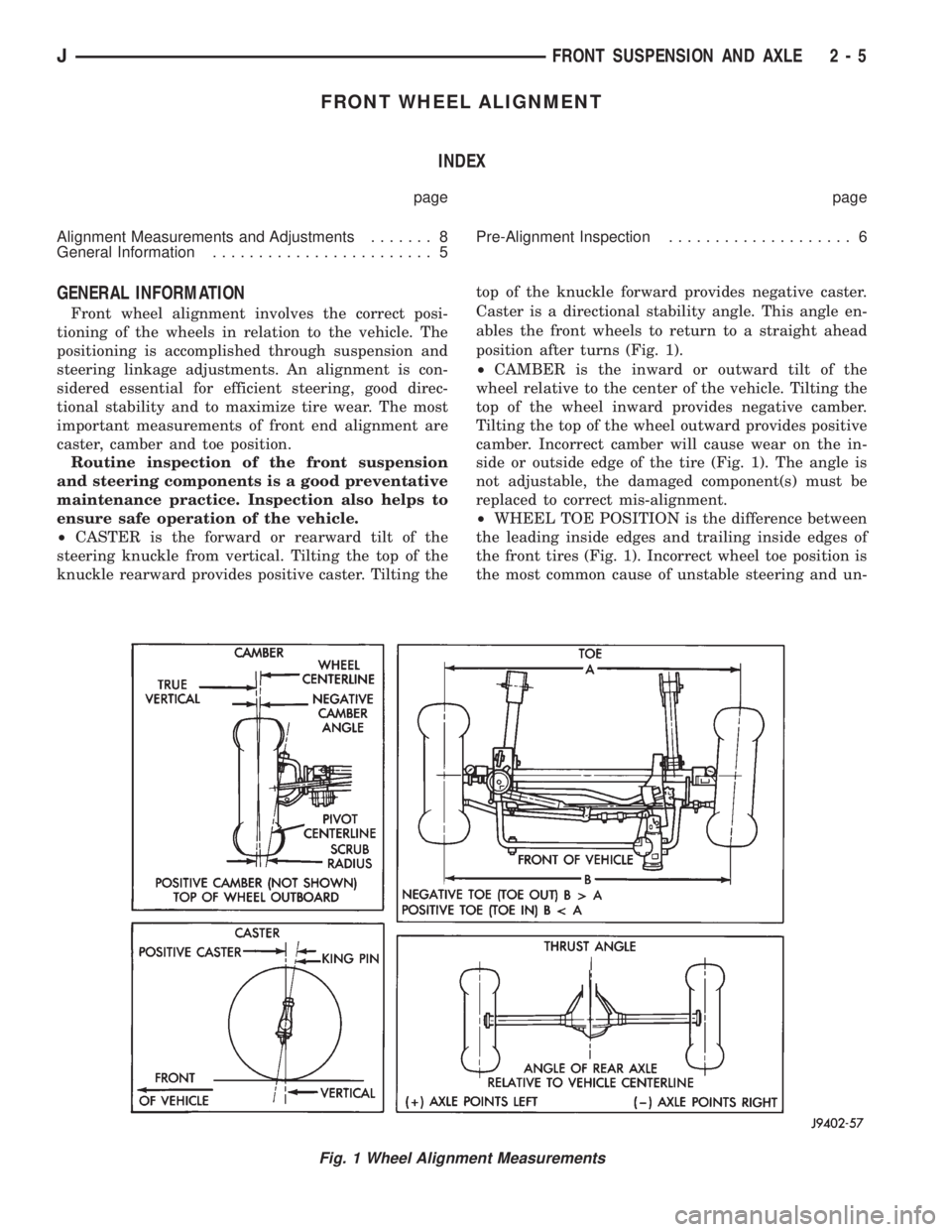

During straight-ahead driving, the differential pin-

ion gears do not rotate on the pinion mate shaft. This

occurs because input torque applied to gears is di-

vided and distributed equally between the two side

gears. As a result, the pinion gears revolve with the

pinion mate shaft but do not rotate around it (Fig. 6).

When turning corners, the outside wheel must

travel a greater distance than the inside wheel. This

difference must be compensated for in order to pre-

vent the wheels from scuffing and skidding through

the turn. To accomplish this, the differential allows

Fig. 4 Model 30 Differential Cover

Fig. 5 Disconnect Feature

JFRONT SUSPENSION AND AXLE 2 - 3

Page 56 of 2158

the axle shafts to turn at unequal speeds (Fig. 7). In

this instance, the input torque applied to the pinion

gears is not divided equally. The pinion gears now ro-

tate around the pinion mate shaft in opposite direc-tions. This allows the side gear and axle shaft

attached to the outside wheel to rotate at a faster

speed.

Fig. 6 Differential OperationÐStraight-Ahead Driving

Fig. 7 Differential OperationÐOn Turns

2 - 4 FRONT SUSPENSION AND AXLEJ

Page 57 of 2158

FRONT WHEEL ALIGNMENT

INDEX

page page

Alignment Measurements and Adjustments....... 8

General Information........................ 5Pre-Alignment Inspection.................... 6

GENERAL INFORMATION

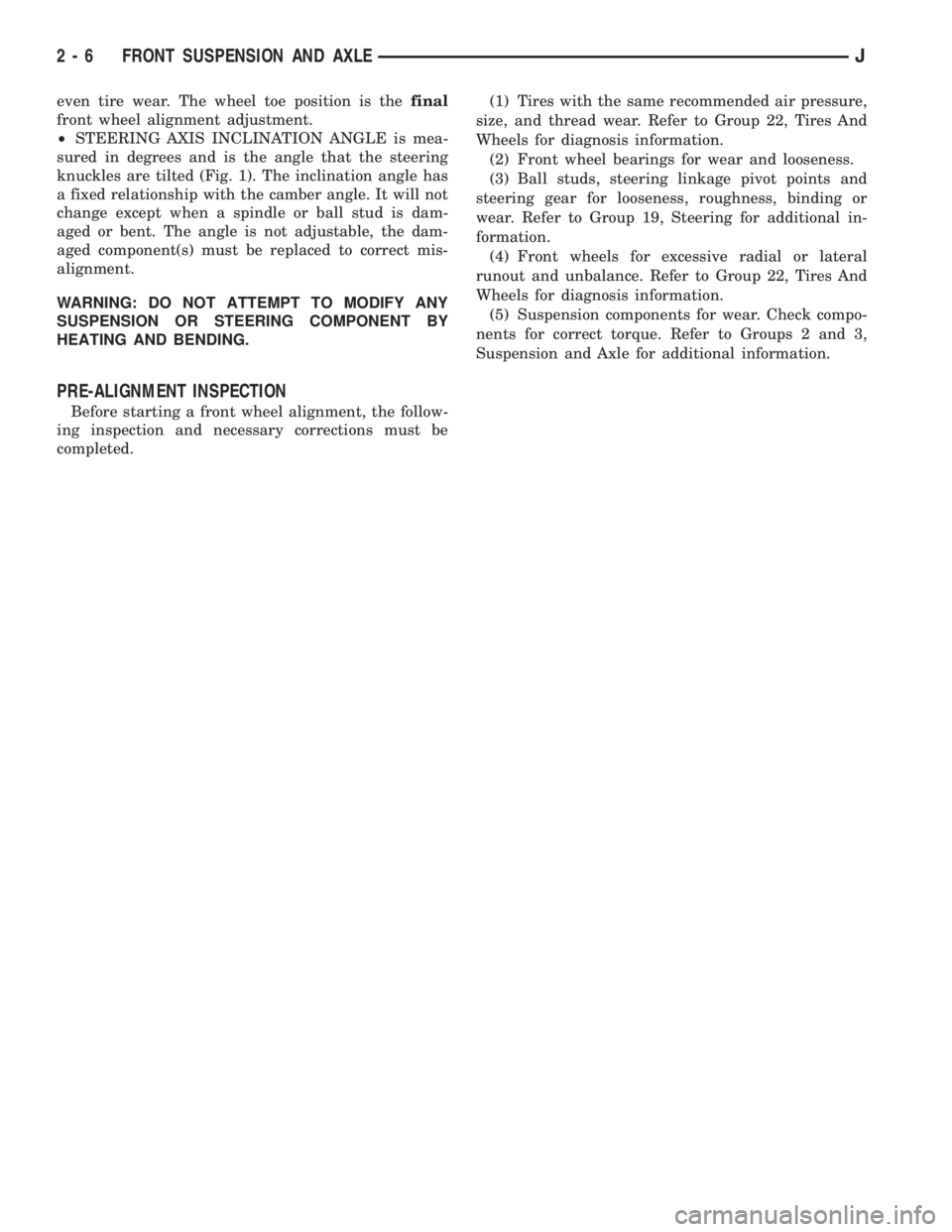

Front wheel alignment involves the correct posi-

tioning of the wheels in relation to the vehicle. The

positioning is accomplished through suspension and

steering linkage adjustments. An alignment is con-

sidered essential for efficient steering, good direc-

tional stability and to maximize tire wear. The most

important measurements of front end alignment are

caster, camber and toe position.

Routine inspection of the front suspension

and steering components is a good preventative

maintenance practice. Inspection also helps to

ensure safe operation of the vehicle.

²CASTER is the forward or rearward tilt of the

steering knuckle from vertical. Tilting the top of the

knuckle rearward provides positive caster. Tilting thetop of the knuckle forward provides negative caster.

Caster is a directional stability angle. This angle en-

ables the front wheels to return to a straight ahead

position after turns (Fig. 1).

²CAMBER is the inward or outward tilt of the

wheel relative to the center of the vehicle. Tilting the

top of the wheel inward provides negative camber.

Tilting the top of the wheel outward provides positive

camber. Incorrect camber will cause wear on the in-

side or outside edge of the tire (Fig. 1). The angle is

not adjustable, the damaged component(s) must be

replaced to correct mis-alignment.

²WHEEL TOE POSITION is the difference between

the leading inside edges and trailing inside edges of

the front tires (Fig. 1). Incorrect wheel toe position is

the most common cause of unstable steering and un-

Fig. 1 Wheel Alignment Measurements

JFRONT SUSPENSION AND AXLE 2 - 5

Page 58 of 2158

even tire wear. The wheel toe position is thefinal

front wheel alignment adjustment.

²STEERING AXIS INCLINATION ANGLE is mea-

sured in degrees and is the angle that the steering

knuckles are tilted (Fig. 1). The inclination angle has

a fixed relationship with the camber angle. It will not

change except when a spindle or ball stud is dam-

aged or bent. The angle is not adjustable, the dam-

aged component(s) must be replaced to correct mis-

alignment.

WARNING: DO NOT ATTEMPT TO MODIFY ANY

SUSPENSION OR STEERING COMPONENT BY

HEATING AND BENDING.

PRE-ALIGNMENT INSPECTION

Before starting a front wheel alignment, the follow-

ing inspection and necessary corrections must be

completed.(1) Tires with the same recommended air pressure,

size, and thread wear. Refer to Group 22, Tires And

Wheels for diagnosis information.

(2) Front wheel bearings for wear and looseness.

(3) Ball studs, steering linkage pivot points and

steering gear for looseness, roughness, binding or

wear. Refer to Group 19, Steering for additional in-

formation.

(4) Front wheels for excessive radial or lateral

runout and unbalance. Refer to Group 22, Tires And

Wheels for diagnosis information.

(5) Suspension components for wear. Check compo-

nents for correct torque. Refer to Groups 2 and 3,

Suspension and Axle for additional information.

2 - 6 FRONT SUSPENSION AND AXLEJ

Page 59 of 2158

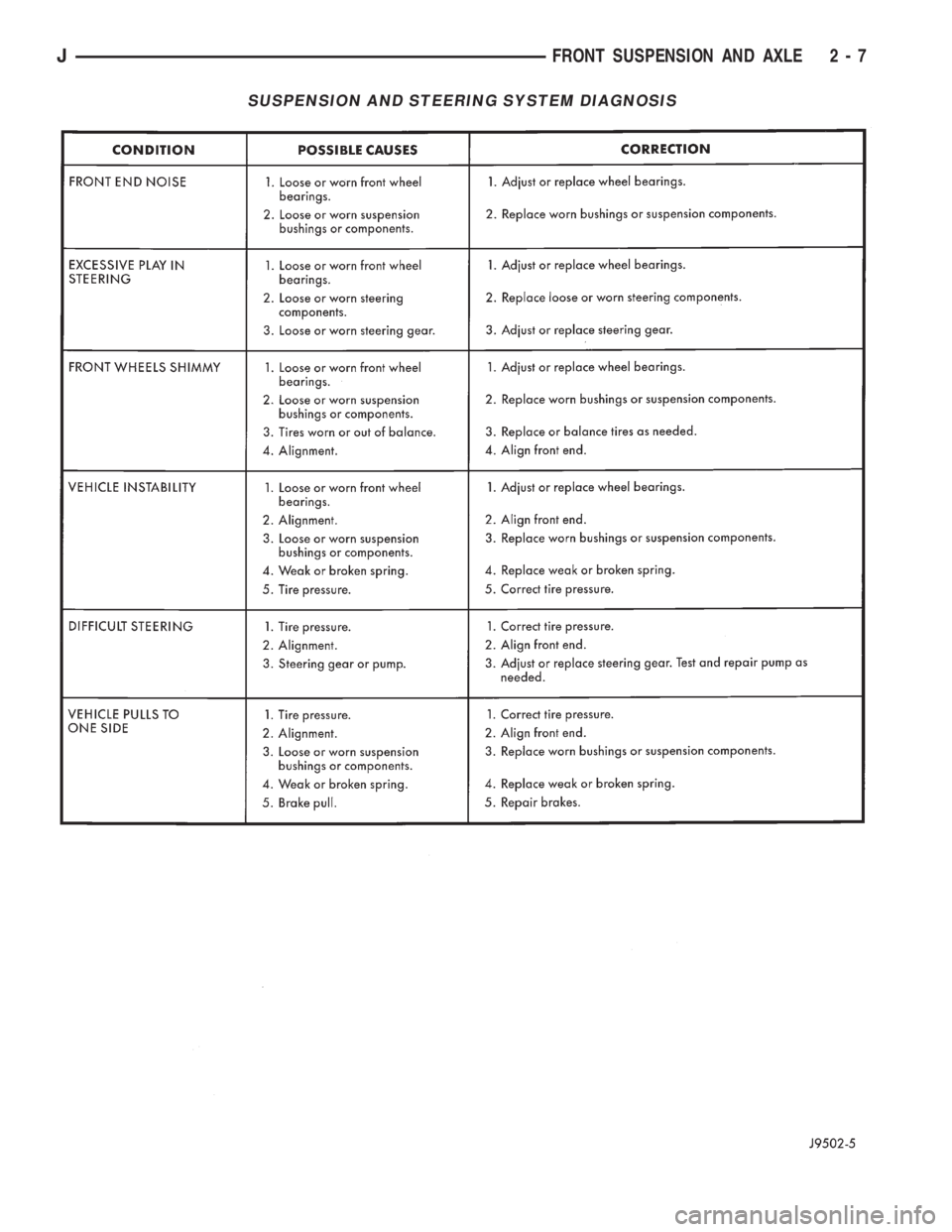

SUSPENSION AND STEERING SYSTEM DIAGNOSIS

JFRONT SUSPENSION AND AXLE 2 - 7

Page 60 of 2158

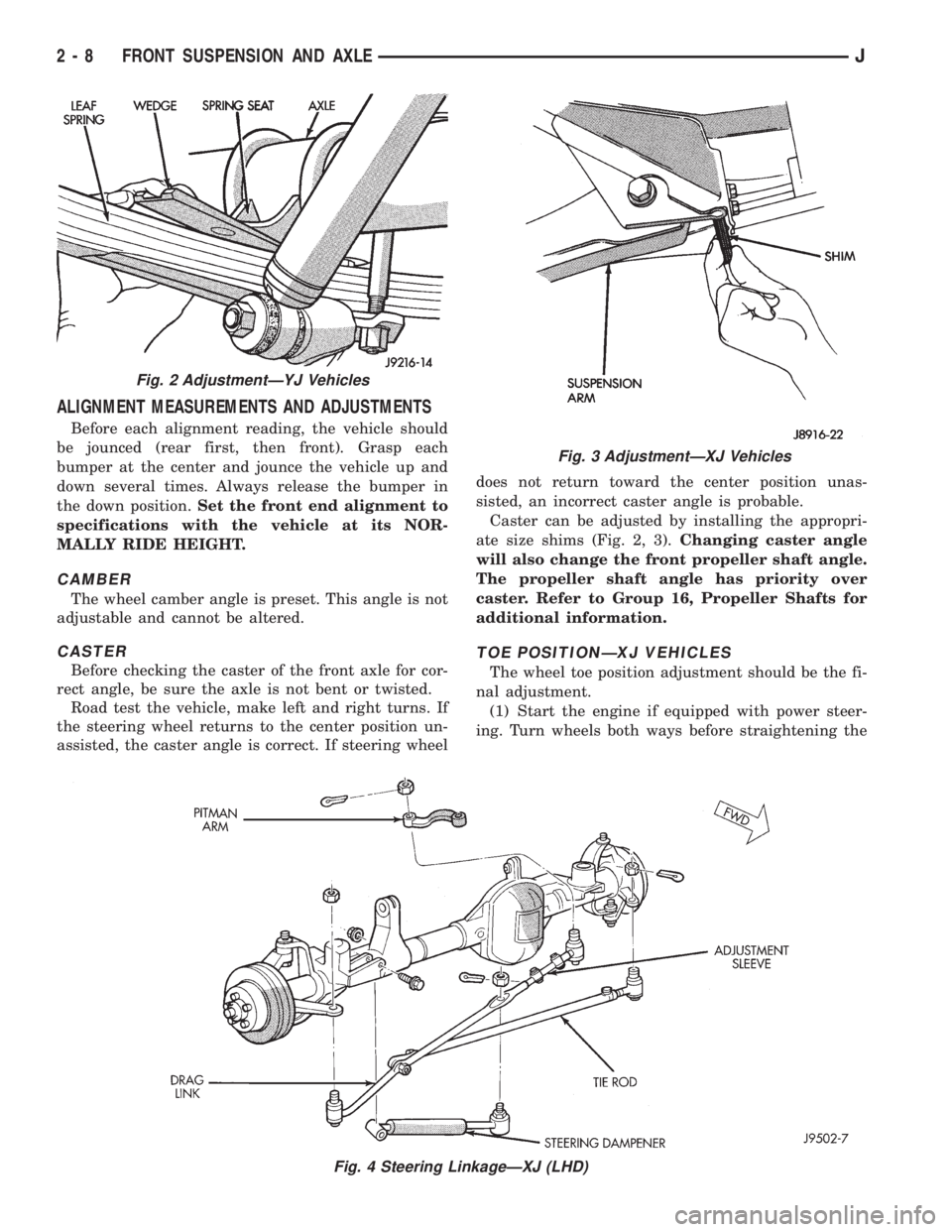

ALIGNMENT MEASUREMENTS AND ADJUSTMENTS

Before each alignment reading, the vehicle should

be jounced (rear first, then front). Grasp each

bumper at the center and jounce the vehicle up and

down several times. Always release the bumper in

the down position.Set the front end alignment to

specifications with the vehicle at its NOR-

MALLY RIDE HEIGHT.

CAMBER

The wheel camber angle is preset. This angle is not

adjustable and cannot be altered.

CASTER

Before checking the caster of the front axle for cor-

rect angle, be sure the axle is not bent or twisted.

Road test the vehicle, make left and right turns. If

the steering wheel returns to the center position un-

assisted, the caster angle is correct. If steering wheeldoes not return toward the center position unas-

sisted, an incorrect caster angle is probable.

Caster can be adjusted by installing the appropri-

ate size shims (Fig. 2, 3).Changing caster angle

will also change the front propeller shaft angle.

The propeller shaft angle has priority over

caster. Refer to Group 16, Propeller Shafts for

additional information.

TOE POSITIONÐXJ VEHICLES

The wheel toe position adjustment should be the fi-

nal adjustment.

(1) Start the engine if equipped with power steer-

ing. Turn wheels both ways before straightening the

Fig. 2 AdjustmentÐYJ Vehicles

Fig. 3 AdjustmentÐXJ Vehicles

Fig. 4 Steering LinkageÐXJ (LHD)

2 - 8 FRONT SUSPENSION AND AXLEJ