engine coolant KIA Optima Hybrid 2014 3.G User Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2014, Model line: Optima Hybrid, Model: KIA Optima Hybrid 2014 3.GPages: 474, PDF Size: 12.73 MB

Page 366 of 474

73

Maintenance

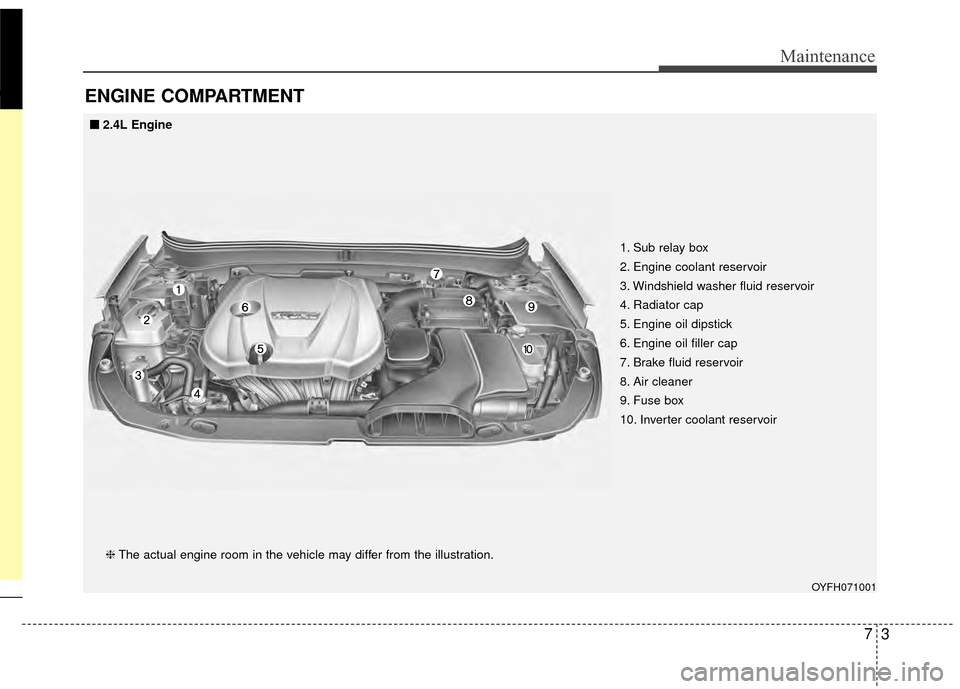

ENGINE COMPARTMENT

OYFH071001

❈The actual engine room in the vehicle may differ from the illustration. 1. Sub relay box

2. Engine coolant reservoir

3. Windshield washer fluid reservoir

4. Radiator cap

5. Engine oil dipstick

6. Engine oil filler cap

7. Brake fluid reservoir

8. Air cleaner

9. Fuse box

10. Inverter coolant reservoir

■

■

2.4L Engine

Page 369 of 474

Maintenance

67

OWNER MAINTENANCE

The following lists are vehicle checks

and inspections that should be per-

formed by the owner or an author-

ized Kia dealer at the frequencies

indicated to help ensure safe,

dependable operation of your vehi-

cle.

Any adverse conditions should be

brought to the attention of your deal-

er as soon as possible.

These Owner Maintenance Checks

are generally not covered by war-

ranties and you may be charged for

labor, parts and lubricants used.Owner maintenance schedule

When you stop for fuel:

Check the engine oil level.

Check the coolant level in coolantreservoir.

Check the windshield washer fluid level.

Look for low or under-inflated tires.

While operating your vehicle:

Note any changes in the sound of the exhaust or any smell of

exhaust fumes in the vehicle.

Check for vibrations in the steering wheel. Notice any increased steer-

ing effort or looseness in the steer-

ing wheel, or change in its straight-

ahead position.

Notice if your vehicle constantly turns slightly or “pulls” to one side

when traveling on smooth, level

road.

When stopping, listen and check for unusual sounds, pulling to one

side, increased brake pedal travel

or “hard-to-push” brake pedal.

If any slipping or changes in the operation of your transaxle occurs,

check the transaxle fluid level.

Check the automatic transaxle P (Park) function.

Check the parking brake.

Check for fluid leaks under your vehicle (water dripping from the air

conditioning system during or after

use is normal).

WARNING - Hot coolant

Be careful when checking your

engine coolant level when the

engine is hot. Scalding hot

coolant and steam may blow

out under pressure.

Page 370 of 474

77

Maintenance

At least monthly:

Check the coolant level in theengine coolant reservoir.

Check the operation of all exterior lights, including the stoplights, turn

signals and hazard warning flash-

ers.

Check the inflation pressures of all tires including the spare.

At least twice a year

(i.e., every Spring and Fall) :

Check the radiator, heater and air conditioning hoses for leaks or

damage.

Check the windshield washer spray and wiper operation. Clean

the wiper blades with clean cloth

dampened with washer fluid.

Check the headlight alignment.

Check the muffler, exhaust pipes, shields and clamps.

Check the lap/shoulder belts for wear and function.

Check for worn tires and loose wheel lug nuts.

At least once a year :

Clean the body and door drainholes.

Lubricate the door hinges and check the hood hinges.

Lubricate the door and hood locks and latches.

Lubricate the door rubber weather- strips.

Check the air conditioning system.

Check the power steering fluid level.

Inspect and lubricate automatic transaxle linkage and controls.

Clean the battery and terminals.

Check the brake fluid level.

Page 380 of 474

717

Maintenance

NORMAL MAINTENANCE SCHEDULE (CONT.)

192,000 km or 96 months

❑Inspect air conditioning refrigerant

❑Inspect brake fluid

❑Inspect brake hoses and lines

❑Inspect drive shafts and boots

❑Inspect exhaust pipe and muffler

❑Inspect front brake disc/pads, calipers and rotors

❑Inspect fuel filter *2

❑Inspect fuel lines, fuel hoses and connections

❑Inspect fuel tank air filter (if equipped) *2

❑Inspect parking brake

❑Inspect rear brake disc/pads

❑Inspect steering gear box, linkage & boots/lower arm ball

joint, upper arm ball joint

❑ Inspect suspension mounting bolts

❑Inspect vacuum hose

❑Inspect vapor hose and fuel filler cap

❑Inspect valve clearance *4

❑Inspect W/pump belt (auto-tensioner, HSG, w/pump)

(First, 96,000 km or 72 months after every 24,000 km or 24

months)

❑ Replace air cleaner filter

❑Replace climate control air filter

(for evaporator and blower unit)

(Continued)

(Continued)

❑Replace engine coolant (First, 192,000 km or 120 months

after every 48,000 km or 24 months)

❑Replace inverter coolant (First, 192,000 km or 120 months

after every 48,000 km or 24 months)

❑Replace engine oil and filter (192,000 km or 192 months)

❑Replace HSG belt (192,000 km or 96 months)

❑Add fuel additive *1 (Every 12,000 km or 12 months)

❈ Inspect : Inspect and if necessary, adjust, correct, clean or replace.

Page 382 of 474

719

Maintenance

240,000 km or 120 months

❑Inspect air conditioning refrigerant

❑Inspect brake fluid

❑Inspect brake hoses and lines

❑Inspect drive shafts and boots

❑Inspect exhaust pipe and muffler

❑Inspect front brake disc/pads, calipers and rotors

❑Inspect fuel filter *2

❑Inspect fuel lines, fuel hoses and connections

❑Inspect fuel tank air filter (if equipped) *2

❑Inspect HSG belt (240,000 km or 240 months)

❑ Inspect parking brake

❑Inspect rear brake disc/pads

❑Inspect steering gear box, linkage & boots/lower arm ball

joint, upper arm ball joint

❑ Inspect suspension mounting bolts

❑Inspect vacuum hose

❑Inspect vapor hose and fuel filler cap

❑Inspect W/pump belt (auto-tensioner, HSG, w/pump)

(First, 96,000 km or 72 months after every 24,000 km or

24 months)

❑ Replace climate control air filter (for evaporator and blower unit)

❑ Replace air cleaner filter

(Continued)

(Continued)

❑Replace engine oil and filter (240,000 km or 240 months)

❑Replace engine coolant (First, 192,000 km or 120 months

after every 48,000 km or 24 months)

❑Replace inverter coolant (First, 192,000 km or 120 months

after every 48,000 km or 24 months)

❑Add fuel additive *1 (Every 12,000 km or 12 months)

NORMAL MAINTENANCE SCHEDULE (CONT.)

No check, No service required

❑ Automatic transaxle fluid

❈ Inspect : Inspect and if necessary, adjust, correct, clean or replace.

Page 385 of 474

Maintenance

22

7

Vacuum crankcase ventilation

hoses

Inspect the surface of hoses for evi-

dence of heat and/or mechanical

damage. Hard and brittle rubber,

cracking, tears, cuts, abrasions, and

excessive swelling indicate deterio-

ration. Particular attention should be

paid to examine those hose surfaces

nearest to high heat sources, such

as the exhaust manifold.

Inspect the hose routing to assure

that the hoses do not come in con-

tact with any heat source, sharp

edges or moving component which

might cause heat damage or

mechanical wear. Inspect all hose

connections, such as clamps and

couplings, to make sure they are

secure, and that no leaks are pres-

ent. Hoses should be replaced

immediately if there is any evidence

of deterioration or damage.

Air cleaner filter

A Genuine Kia air cleaner filter is

recommended when the filter is

replaced.

Spark plugs

Make sure to install new spark plugs

of the correct heat range.

Valve clearance

Inspect excessive valve noise and/or

engine vibration and adjust if neces-

sary. An authorized Kia dealer

should perform the operation.

Cooling system

Check cooling system components,

such as radiator, coolant reservoir,

hoses and connections for leakage

and damage. Replace any damaged

parts.

Coolant

The engine and inverter coolant

should be changed at the intervals

specified in the maintenance sched-

ule.

Page 390 of 474

727

Maintenance

COOLANT

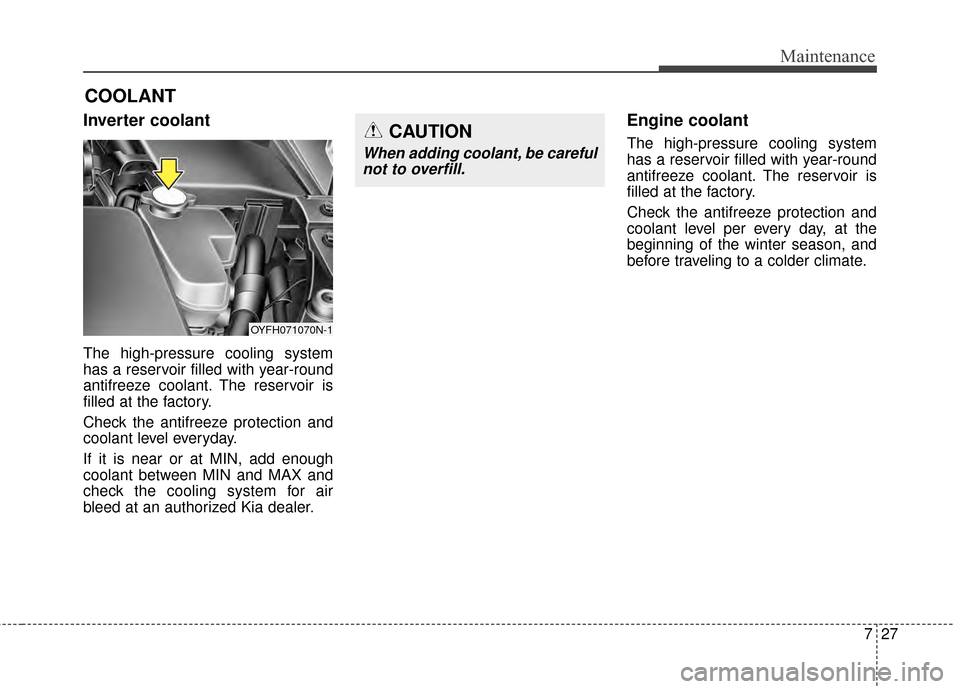

Inverter coolant

The high-pressure cooling system

has a reservoir filled with year-round

antifreeze coolant. The reservoir is

filled at the factory.

Check the antifreeze protection and

coolant level everyday.

If it is near or at MIN, add enough

coolant between MIN and MAX and

check the cooling system for air

bleed at an authorized Kia dealer.

Engine coolant

The high-pressure cooling system

has a reservoir filled with year-round

antifreeze coolant. The reservoir is

filled at the factory.

Check the antifreeze protection and

coolant level per every day, at the

beginning of the winter season, and

before traveling to a colder climate.

OYFH071070N-1

CAUTION

When adding coolant, be carefulnot to overfill.

Page 391 of 474

Maintenance

28

7

Checking the coolant level

WARNING

Removing radiator

cap and inverter

coolant cap

Never attempt to remove the radiator cap and/or inveter

coolant cap while the engine

is operating or hot. Doing so

might lead to cooling system

and engine damage and could

result in serious personal

injury from escaping hot

coolant or steam.

The engine coolant and/or inverter coolant level is influ-

enced by hybrid system tem-

perature. Before filling the

engine coolant and/or inverter

coolant, turn the hybrid vehi-

cle off, fill the engine coolant

and/or inverter coolant care-

fully.

(Continued)

(Continued)

Turn the engine off and waituntil it cools down. Use

extreme care when removing

the radiator cap. Wrap a thick

towel around it, and turn it

counterclockwise slowly to

the first stop. Step back while

the pressure is released from

the cooling system. When you

are sure all the pressure has

been released, press down on

the cap, using a thick towel,

and continue turning counter-

clockwise to remove it.

Even if the engine is not oper- ating, do not remove the radi-

ator cap and/or inverter or the

drain plug while the engine

and radiator are hot. Hot

coolant and steam may still

blow out under pressure,

causing serious injury.WARNING

The electronic motor

(cooling fan) is con-

trolled by engine

coolant temperature,

refrigerant pressure

and vehicle speed. It may some-

times operate even when the

engine is not running. Use

extreme caution when working

near the blades of the cooling

fan so that you are not injured

by the rotating fan blades. As

the engine coolant temperature

decreases, the electric motor

will automatically shut off. This

is a normal condition.

Page 392 of 474

729

Maintenance

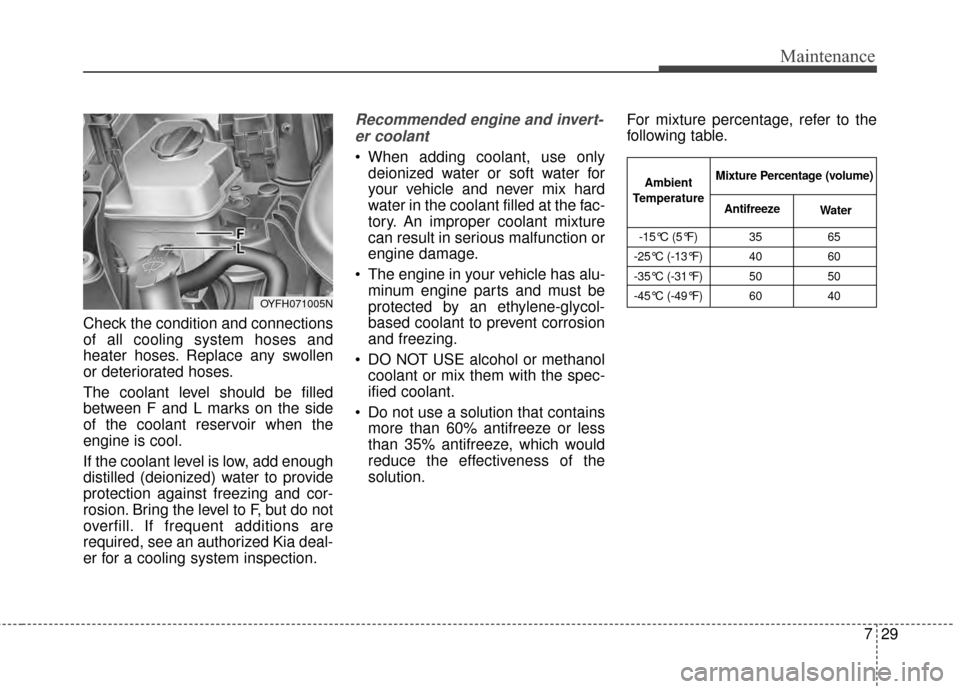

Check the condition and connections

of all cooling system hoses and

heater hoses. Replace any swollen

or deteriorated hoses.

The coolant level should be filled

between F and L marks on the side

of the coolant reservoir when the

engine is cool.

If the coolant level is low, add enough

distilled (deionized) water to provide

protection against freezing and cor-

rosion. Bring the level to F, but do not

overfill. If frequent additions are

required, see an authorized Kia deal-

er for a cooling system inspection.

Recommended engine and invert-er coolant

When adding coolant, use only deionized water or soft water for

your vehicle and never mix hard

water in the coolant filled at the fac-

tory. An improper coolant mixture

can result in serious malfunction or

engine damage.

The engine in your vehicle has alu- minum engine parts and must be

protected by an ethylene-glycol-

based coolant to prevent corrosion

and freezing.

DO NOT USE alcohol or methanol coolant or mix them with the spec-

ified coolant.

Do not use a solution that contains more than 60% antifreeze or less

than 35% antifreeze, which would

reduce the effectiveness of the

solution. For mixture percentage, refer to the

following table.

-15°C (5°F) 35

65

-25°C (-13°F) 40 60

-35°C (-31°F) 50 50

-45°C (-49°F) 60 40

Ambient

Temperature Mixture Percentage (volume)

Antifreeze Water

OYFH071005N

Page 393 of 474

Maintenance

30

7

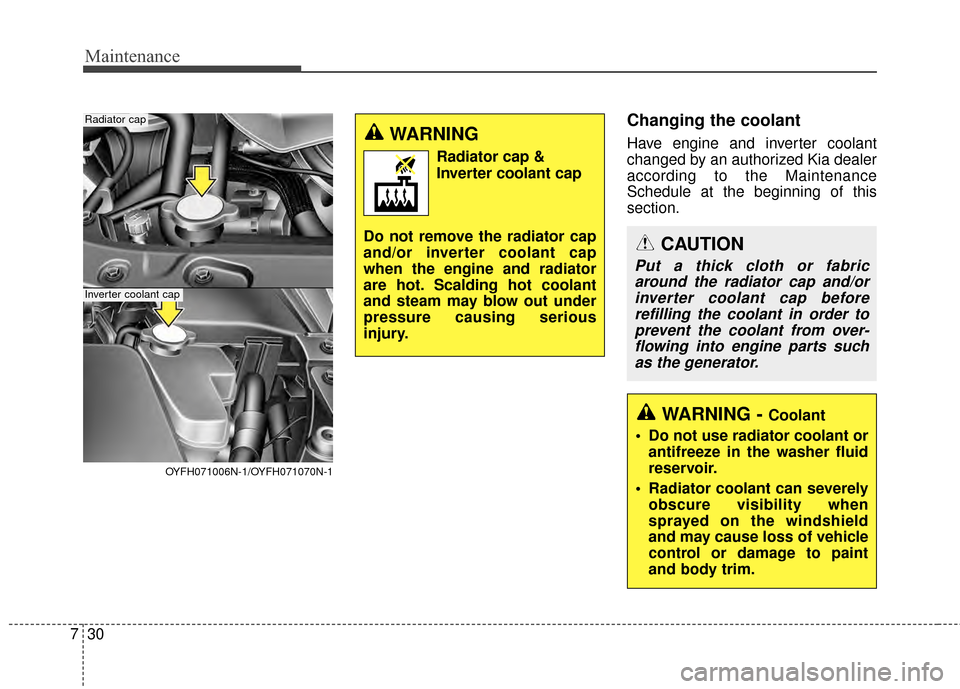

Changing the coolant

Have engine and inverter coolant

changed by an authorized Kia dealer

according to the Maintenance

Schedule at the beginning of this

section.

WARNING - Coolant

Do not use radiator coolant or antifreeze in the washer fluid

reservoir.

Radiator coolant can severely obscure visibility when

sprayed on the windshield

and may cause loss of vehicle

control or damage to paint

and body trim.

CAUTION

Put a thick cloth or fabricaround the radiator cap and/orinverter coolant cap beforerefilling the coolant in order toprevent the coolant from over-flowing into engine parts suchas the generator.

OYFH071006N-1/OYFH071070N-1

Radiator cap

Inverter coolant cap

WARNING

Radiator cap &

Inverter coolant cap

Do not remove the radiator cap

and/or inverter coolant cap

when the engine and radiator

are hot. Scalding hot coolant

and steam may blow out under

pressure causing serious

injury.