engine coolant LAND ROVER DEFENDER 1999 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 98 of 667

ENGINE

13

DESCRIPTION AND OPERATION CYLINDER BLOCK

The cylinders and crankcase are contained in a single cast iron construction. The cylinders are direct bored and

plateau honed with lubrication oil supplied via lubrication jets for piston and gudgeon pin lubrication and cooling. It

is not possible to rebore the cylinder block if the cylinders become worn or damaged. Three metal core plugs are

fitted to the three centre cylinders on the right hand side of the cylinder block.

Lubrication oil is distributed throughout the block via the main oil gallery to critical moving parts through channels

bored in the block which divert oil to the main and big-end bearings via oil holes machined into the crankshaft. Oil

is also supplied from the cylinder block main gallery to the five lubrication jets which cool and lubricate the piston

and gudgeon pins. Plugs are used to seal both ends of the main oil gallery at front and rear of the engine block.

An oil cooler is fitted to the LH side of the engine block; ports in the oil cooler assembly mate with ports in the

cylinder block to facilitate coolant flow. Oil is diverted through the oil cooler, centrifuge filter and full-flow filter

before supplying the main oil gallery. A tapping in the oil filter housing provides a lubrication source for the

turbocharger bearings and an oil pressure switch is included in a tapping in the oil cooler housing which

determines whether sufficient oil pressure is available to provide engine lubrication and cooling.

Cylinder cooling is achieved by water circulating through chambers in the engine block casting. A threaded coolant

jacket plug is located at the front RH side of the cylinder block.

Cast brackets are bolted to both sides of the engine block for mounting the engine to the chassis on the LH and

RH hydramount studs.

The gearbox bolts directly to the engine block; a gearbox shim plate is located between the adjoining faces of the

gearbox and the flywheel side of the engine block and is fixed to the rear of the engine block by two bolts. Two

hollow metal dowels locate the rear of the cylinder block to the shim plate. The gearbox casing provides the

mounting for the starter motor.

A port is included at the rear left hand side of the cylinder block which connects to the turbocharger oil drain pipe

to return lubrication oil to the sump. A plug sealing the lubrication cross-drilling gallery is located at the front right

hand side of the cylinder block and plugs for the main lubrication gallery are located at the front and rear of the

cylinder block. Two plastic dowels are used to locate the cylinder head to the cylinder block and must be replaced

every time the cylinder head is removed from the cylinder block.

ProCarManuals.com

Page 101 of 667

12ENGINE

16

DESCRIPTION AND OPERATION Oil cooler

1.Front oil gallery - full-flow filter to oil cooler matrix

2.Full-flow filter adaptor outlet port to oil cooler

(opens at 74°C)

3.Full-flow filter inlet port

4.Oil cooler housing

5.Full-flow filter outlet port to cylinder block

6.Coolant inlet port

7.Oil cooler banjo bolt seals (2 off)

8.Banjo bolts (2 off)

9.Banjo bolt oil holes - to oil cooler matrix

10.Rear oil gallery - full-flow filter / oil cooler outlet

to cylinder block11.Centre oil gallery - from pump to full-flow filter

12.Inlet port to centrifuge filter

13.Sealing ring - centrifuge filter housing to oil

cooler housing

14.Port - oil cooler matrix

15.Oil cooler matrix

16.Inlet port from pump via cylinder block to oil

cooler housing

17.Outlet port from oil cooler housing to cylinder

block

18.Rear view of oil cooler housing

ProCarManuals.com

Page 102 of 667

ENGINE

17

DESCRIPTION AND OPERATION The engine oil cooler assembly is located on the left hand side of the engine block behind the oil centrifuge and oil

filter. The housing is bolted to the engine block by seven bolts. A matrix is included in the oil cooler housing which

acts as a heat exchanger. Coolant flow circulates through the oil cooler housing under pressure from the coolant

pump and distributes the flow evenly around the matrix fins and then along the block into three core holes for

cylinder cooling. Coolant enters the oil cooler through a pipe with a rubber hose extension at the rear side of the

engine. The coolant hose is attached to the stub pipe of the oil cooler by a spring clip.

Oil, drawn from the sump by the oil pump, passes through the oil cooler via the cylinder block. The flow of coolant

around the exterior surface of the oil cooler matrix cools a proportion of the engine oil flow as it passes through the

oil cooler.

The oil cooler is sealed to the cylinder block by a gasket which must be replaced every time the oil cooler housing

is removed.

ProCarManuals.com

Page 110 of 667

ENGINE

25

DESCRIPTION AND OPERATION CYLINDER HEAD COMPONENTS

The cylinder head components are described below:

Cylinder head

The cylinder head is of aluminium construction. It is not possible to reface the cylinder head if it becomes worn or

damaged. An alloy camshaft carrier is bolted directly to the upper surface of the cylinder head. Two dowels are

included in the cylinder head upper face for correct location of the camshaft carrier.

The EU3 cylinder head has a single internal fuel rail for delivering fuel to the injectors and an external fuel pipe for

returning spill fuel back to the fuel connector block. Therefore, pre EU3 and EU3 cylinder heads are not

interchangeable.

CAUTION: The cylinder head incorporates drillings for the fuel injection system, any

contamination which enters these drillings could cause engine running problems or injector

failure. It is therefore, essential that absolute cleanliness is maintained when carrying out work on

the cylinder head.

The camshaft carrier and cylinder head assembly is attached to the cylinder block by twelve cylinder head

retaining bolts which pass through the camshaft carrier and the cylinder head to secure the assembly to the

cylinder block.

CAUTION: The valve heads, tips of the injectors and glow plugs protrude below the face of the

cylinder head and will be damaged if the cylinder head is stored face down.

The camshaft is located between the cylinder head and the camshaft carrier, and the bearing journals are line

bored between the two components to form a matched pair.

CAUTION: Always fit plugs to open connections to prevent contamination.

The valve guides and valve seat inserts are sintered components which are an interference fit to the cylinder

head. The cylinder head machining also provide the locations for the electronic unit injectors, glow plugs, hydraulic

lash adjusters, finger followers and low pressure fuel rail.

Cooling to the cylinder head is provided by coolant flow through a water jacket machined into the cylinder head.

Drillings through the block provide lubrication channels for pressurised oil supply to cylinder head components

such as the lash adjusters, finger followers, rocker arms and camshaft bearings.

A coolant outlet elbow is fitted to the front LH side of the cylinder head to allow flow of coolant from the cylinder

head back to the radiator. A metal gasket is used to seal the joint between the water outlet elbow and the cylinder

head. A coolant temperature sensor is located in a port in the side of the water outlet elbow for monitoring coolant

temperature.

A stub pipe is connected at the front RH side of the cylinder block above the timing cover which connects a pipe to

supply oil to the vacuum pump. The timing chain tensioner adjuster is screwed in a thread in the cylinder head at a

location on the front RH side of the engine below the oil feed port for the vacuum pump.

An access hole for the camshaft gear is included at the front of the cylinder head which is sealed with a plastic

plug and rubber’O’ring. A press-fit core plug for the chain chest is located on the front face of the cylinder head.

A press-fit core plug for the cylinder head water jacket is located at the rear of the cylinder head and a threaded

brass plug for the water jacket is located on the LH side of the cylinder head beneath the exhaust manifold

assembly.

ProCarManuals.com

Page 131 of 667

12ENGINE

6

REPAIR GASKET - CYLINDER HEAD

Service repair no - 12.29.02

Remove

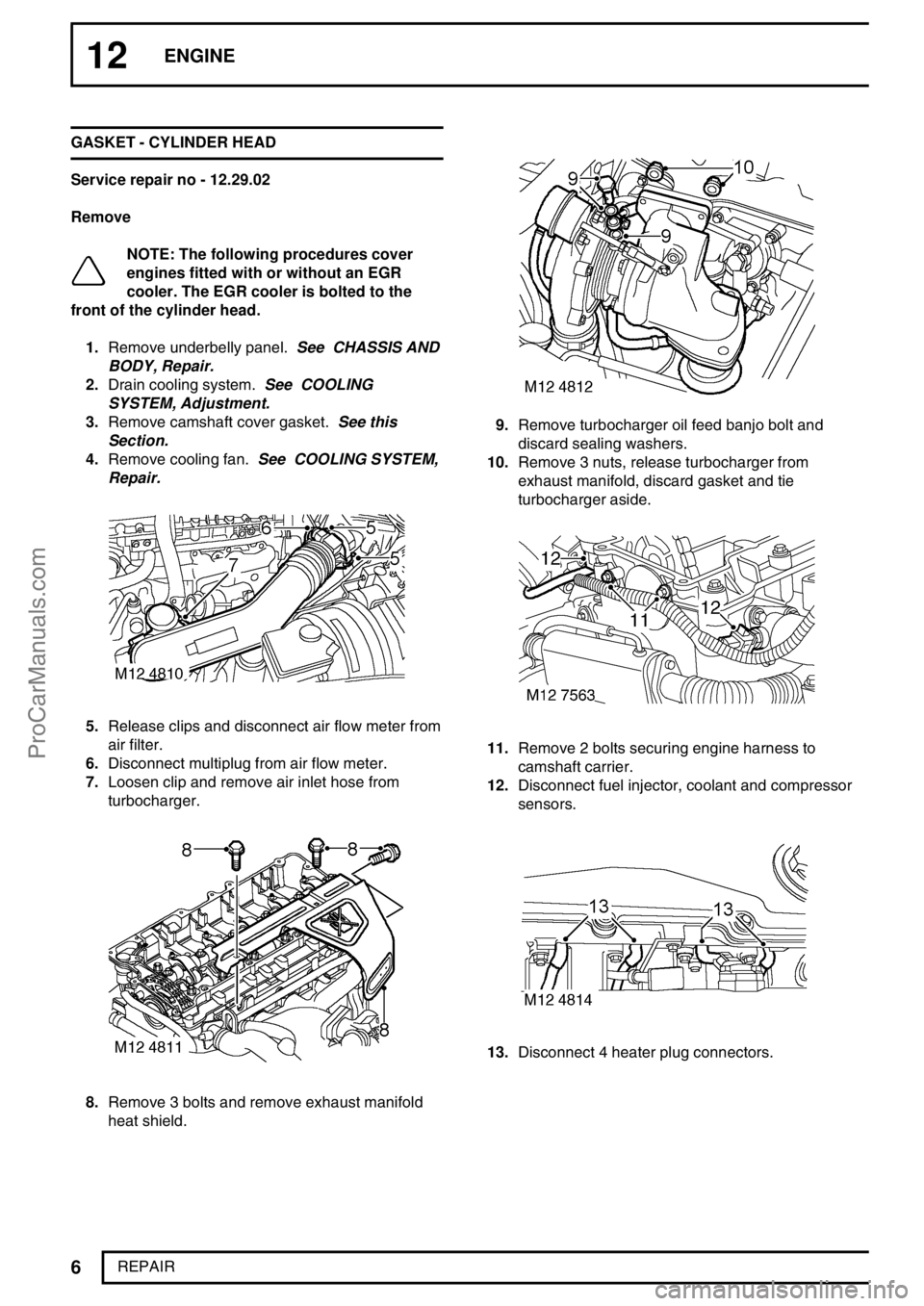

NOTE: The following procedures cover

engines fitted with or without an EGR

cooler. The EGR cooler is bolted to the

front of the cylinder head.

1.Remove underbelly panel.See CHASSIS AND

BODY, Repair.

2.Drain cooling system.See COOLING

SYSTEM, Adjustment.

3.Remove camshaft cover gasket.See this

Section.

4.Remove cooling fan.See COOLING SYSTEM,

Repair.

5.Release clips and disconnect air flow meter from

air filter.

6.Disconnect multiplug from air flow meter.

7.Loosen clip and remove air inlet hose from

turbocharger.

8.Remove 3 bolts and remove exhaust manifold

heat shield.

9.Remove turbocharger oil feed banjo bolt and

discard sealing washers.

10.Remove 3 nuts, release turbocharger from

exhaust manifold, discard gasket and tie

turbocharger aside.

11.Remove 2 bolts securing engine harness to

camshaft carrier.

12.Disconnect fuel injector, coolant and compressor

sensors.

13.Disconnect 4 heater plug connectors.

ProCarManuals.com

Page 132 of 667

ENGINE

7

REPAIR

14.Disconnect MAP sensor multiplug from inlet

manifold.

15.Position engine harness clear of inlet manifold.

16.Disconnect vacuum hose from EGR valve.

17.Loosen clip screw and disconnect air intake

hose from EGR valve.

18.Release 3 clips and disconnect coolant hoses

from fuel cooler.

19.Disconnect fuel hoses, tank to fuel cooler and

connector block on cylinder head.

CAUTION: Plug the connections.

20.Disconnect fuel hose from fuel cooler and secure

to connector block on cylinder head. This is to

prevent contamination of the fuel injection

system.

ProCarManuals.com

Page 133 of 667

12ENGINE

8

REPAIR

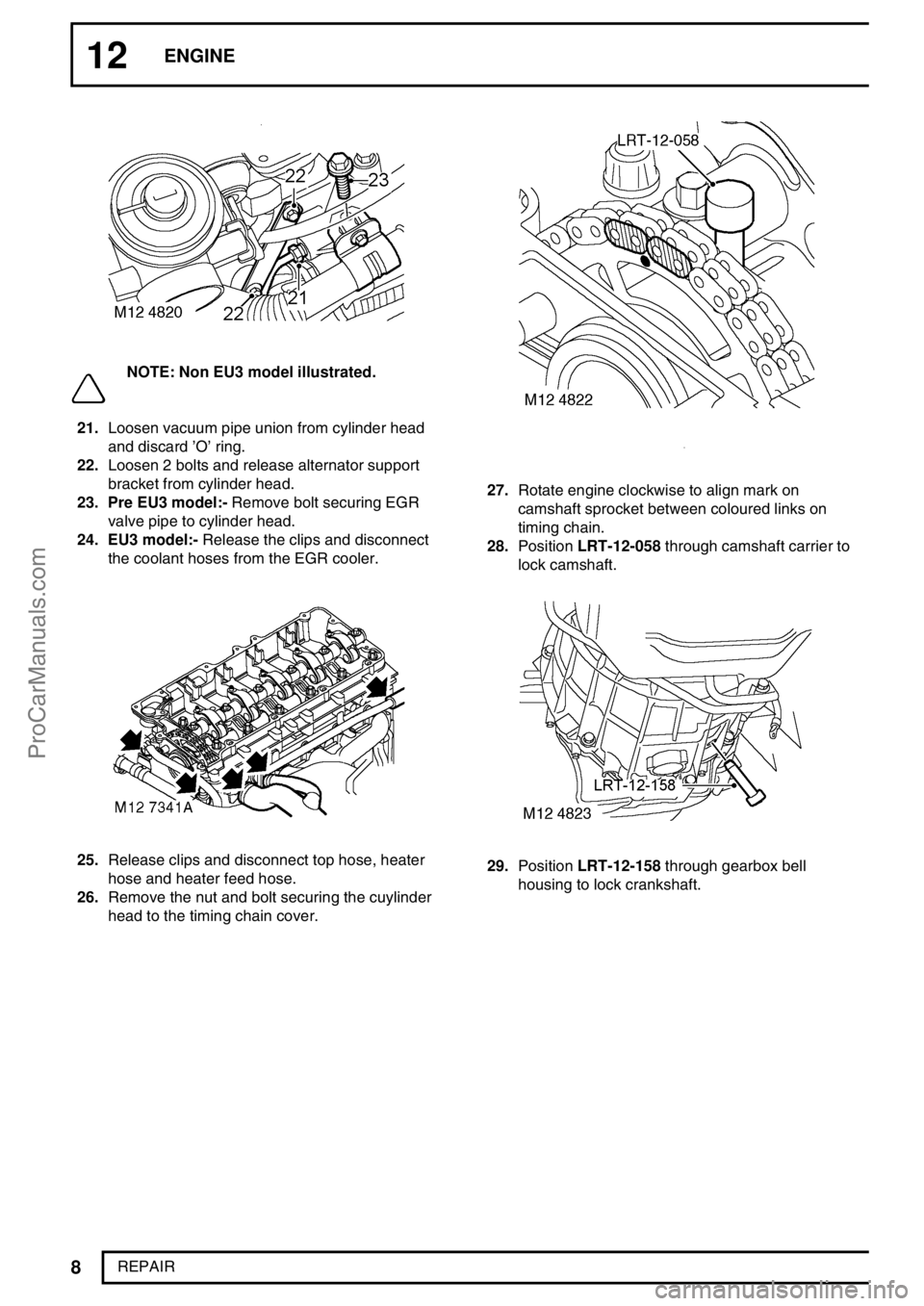

NOTE: Non EU3 model illustrated.

21.Loosen vacuum pipe union from cylinder head

and discard’O’ring.

22.Loosen 2 bolts and release alternator support

bracket from cylinder head.

23. Pre EU3 model:-Remove bolt securing EGR

valve pipe to cylinder head.

24. EU3 model:-Release the clips and disconnect

the coolant hoses from the EGR cooler.

25.Release clips and disconnect top hose, heater

hose and heater feed hose.

26.Remove the nut and bolt securing the cuylinder

head to the timing chain cover.

27.Rotate engine clockwise to align mark on

camshaft sprocket between coloured links on

timing chain.

28.PositionLRT-12-058through camshaft carrier to

lock camshaft.

29.PositionLRT-12-158through gearbox bell

housing to lock crankshaft.

ProCarManuals.com

Page 135 of 667

12ENGINE

10

REPAIR Refit

39.Clean mating faces of cylinder head and cylinder

block.

40.Check cylinder head for warping, across centre

and from corner to corner:

Maximum warp = 0.10 mm (0.004 in)

CAUTION: Cylinder heads may not be

refaced, replace cylinder head assembly if

warping exceeds figure given.

41.Ensure coolant and oil passages are clean.

42.Clean dowel holes and fit new dowels.

43.Fit new cylinder head gasket of the correct

thickness with the word’TOP’uppermost.

44.Using assistance, fit cylinder head and locate on

to dowels.

45.Carefully enter new cylinder head bolts together

with their captive washers,DO NOT DROP.

Lightly tighten bolts.

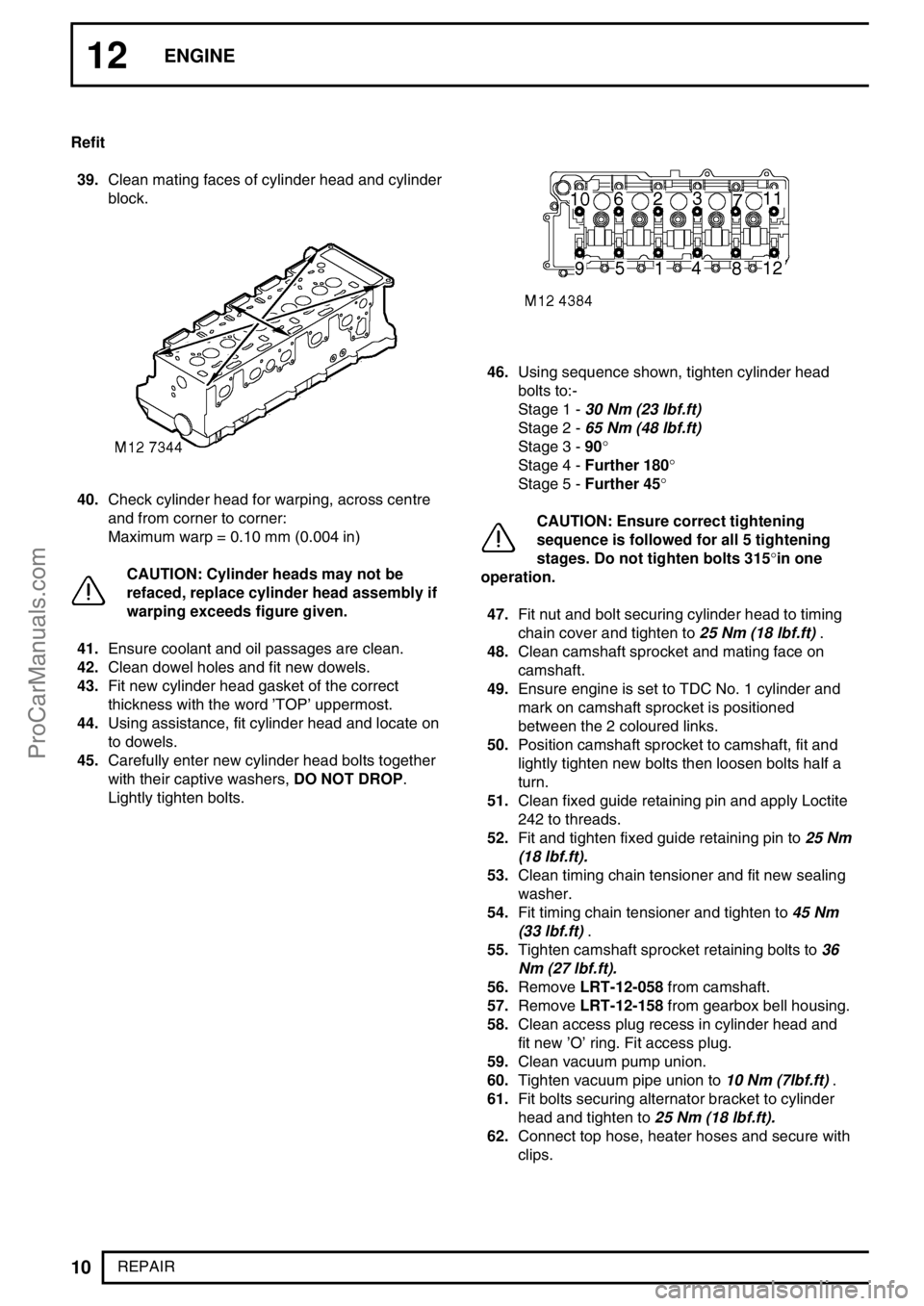

46.Using sequence shown, tighten cylinder head

bolts to:-

Stage 1 -30 Nm (23 lbf.ft)

Stage 2 -65 Nm (48 lbf.ft)

Stage 3 -90°

Stage 4 -Further 180°

Stage 5 -Further 45°

CAUTION: Ensure correct tightening

sequence is followed for all 5 tightening

stages. Do not tighten bolts 315°in one

operation.

47.Fit nut and bolt securing cylinder head to timing

chain cover and tighten to25 Nm (18 lbf.ft).

48.Clean camshaft sprocket and mating face on

camshaft.

49.Ensure engine is set to TDC No. 1 cylinder and

mark on camshaft sprocket is positioned

between the 2 coloured links.

50.Position camshaft sprocket to camshaft, fit and

lightly tighten new bolts then loosen bolts half a

turn.

51.Clean fixed guide retaining pin and apply Loctite

242 to threads.

52.Fit and tighten fixed guide retaining pin to25 Nm

(18 lbf.ft).

53.Clean timing chain tensioner and fit new sealing

washer.

54.Fit timing chain tensioner and tighten to45 Nm

(33 lbf.ft).

55.Tighten camshaft sprocket retaining bolts to36

Nm (27 lbf.ft).

56.RemoveLRT-12-058from camshaft.

57.RemoveLRT-12-158from gearbox bell housing.

58.Clean access plug recess in cylinder head and

fit new’O’ring. Fit access plug.

59.Clean vacuum pump union.

60.Tighten vacuum pipe union to10 Nm (7lbf.ft).

61.Fit bolts securing alternator bracket to cylinder

head and tighten to25 Nm (18 lbf.ft).

62.Connect top hose, heater hoses and secure with

clips.

ProCarManuals.com

Page 136 of 667

ENGINE

11

REPAIR 63. Pre EU3 model:-Fit bolt, EGR valve pipe to

cylinder head and tighten to25 Nm (18 lbf.ft).

64. EU3 model:-Connect coolant hoses to EGR

cooler and secure with clips.

65.Position air intake hose to EGR valve and

tighten clip screw.

66.Disconnect fuel hose from connector block and

connect to fuel cooler.

67.Connect fuel hoses to fuel cooler and connector

block on cylinder head.

68.Connect coolant hoses to fuel cooler and secure

clips.

69.Connect vacuum hose to EGR valve.

70.Position engine harness and connect multiplugs

and heater plug connectors.

71.Fit and tighten bolts, engine harness to camshaft

carrier.

72.Clean exhaust manifold and mating face.

73.Fit new gasket to exhaust manifold, position

turbocharger and tighten nuts to30 Nm (22 lbf.

ft).

74.Clean turbocharger feed hose bolt.

75.Position feed hose using new sealing washers,

tighten bolt to25 Nm (18 lbf.ft).

76.Position exhaust manifold heat shield, and

tighten M6 bolts to10 Nm (7 lbf.ft)and M8 bolt

to25 Nm (18 lbf.ft).

77.Position air inlet hose to turbocharger and

tighten clip screw.

78.Connect air flow meter to air filter and secure

clips.

79.Connect air flow meter multiplug.

80.Fit cooling fan.See COOLING SYSTEM,

Repair.

81.Fit camshaft cover gasket.See this Section.

82.Refill cooling system.See COOLING SYSTEM,

Adjustment.

83.Fit underbelly panel.See CHASSIS AND

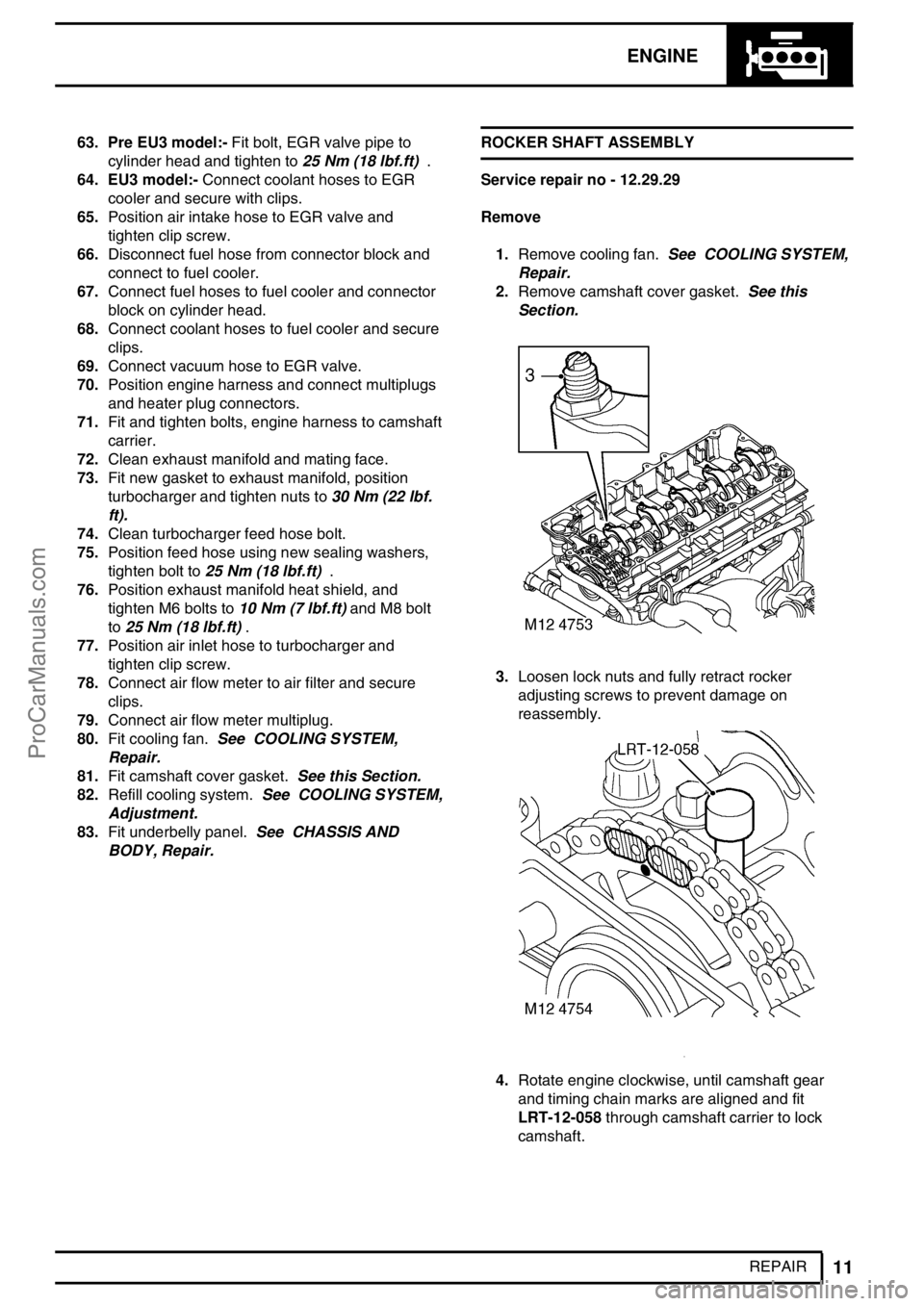

BODY, Repair.ROCKER SHAFT ASSEMBLY

Service repair no - 12.29.29

Remove

1.Remove cooling fan.See COOLING SYSTEM,

Repair.

2.Remove camshaft cover gasket.See this

Section.

3.Loosen lock nuts and fully retract rocker

adjusting screws to prevent damage on

reassembly.

4.Rotate engine clockwise, until camshaft gear

and timing chain marks are aligned and fit

LRT-12-058through camshaft carrier to lock

camshaft.

ProCarManuals.com

Page 139 of 667

12ENGINE

14

REPAIR

9. Not EU3 model:-Apply two 3 mm diameter

beads of sealant, Part No.STC 5433 to areas’A’

shown on illustration.

CAUTION: Excessive use of sealant could

result in blockage of oil drain hole,

arrowed’B’in illustration.

10.Fit new gasket to camshaft cover. fit cover and

tighten bolts to10 Nm (7 lbf.ft).

11.Position breather hose and secure clip.

12.Fit engine acoustic cover.

13.Reconnect battery negative lead.

14.Fit battery cover.ENGINE AND ANCILLARIES

Service repair no - 12.41.01.99

Remove

1.Remove underbelly panel.See CHASSIS AND

BODY, Repair.

2.Drain engine oil.

3.Remove radiator.See COOLING SYSTEM,

Repair.

4.Remove turbocharger.See FUEL SYSTEM,

Repair.

5.Remove starter motor.See ELECTRICAL,

Repair.

6.Remove air filter.See FUEL SYSTEM, Repair.

7.Loosen clip screw and release air intake hose

from intake elbow.

8.Release clips and disconnect coolant hoses

from fuel cooler and coolant rail.

ProCarManuals.com