air filter LAND ROVER DISCOVERY 1995 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 107 of 873

Tdi

3

SPECIFICATIONS, TORQUE Turbo charger oil drain adaptor to block 42....................................................

Oil drain pipe to turbocharger 25....................................................................

Turbocharger oil drain pipe to adaptor 38.......................................................

Turbocharger oil feed pipe adaptor to block 25...............................................

Turbocharger oil feed pipe to adaptor 25........................................................

Oil feed pipe to turbocharger 19.....................................................................

Turbocharger to cylinder head (stud) 10.........................................................

Turbocharger to cylinder head (nut) 45...........................................................

Turbocharger to blanking plate 25..................................................................

Turbocharger to EGR valve 25.......................................................................

EGR delivery tube to valve 25........................................................................

EGR delivery tube to mixing tube 25..............................................................

Fuel lift pump to filter (union) 15.....................................................................

Fuel filter from lift pump (banjo bolt) 33...........................................................

Fuel filter to fuel injection pump (banjo bolt) 33..............................................

Fuel injection pump from fuel filter (banjo bolt) 25..........................................

Injector pipes to injectors and fuel injection pump 29.....................................

Spill rail to injectors (banjo bolt) 10.................................................................

Spill rail to injection pump (banjo bolt) 25.......................................................

Boost pipe injection pump (banjo bolt) 10.......................................................

Plug, rear of injection pump 29.......................................................................

PAS pump to mounting plate 25.....................................................................

PAS pump mounting plate to auxiliaries mounting bracket 25........................

PAS pump pulley to hub 25............................................................................

Generator to auxiliaries mounting bracket 25.................................................

Starter motor (bolt and nut) 45........................................................................

Tachometer electrical connection 4...............................................................

Air conditioning compressor

Compressor mounting bracket to front cover 45.............................................

Compressor to mounting bracket (stud) 8......................................................

Compressor to mounting bracket (nut) 25......................................................

Belt tensioner pulley to tensioner arm 45........................................................

Belt tensioner assembly to front cover plate 25..............................................

Idler pulley to front cover plate 45...................................................................

Compressor belt guard (nut) 25......................................................................

Sensors to water outlet elbow (air/con) 25......................................................

Blanking plug, water outlet elbow (air/con) 25................................................

Generator mounting bracket to front cover 45................................................

Generator to mounting bracket 85..................................................................

Generator pulley to hub 95.............................................................................

Generator belt guard 25..................................................................................

Page 111 of 873

V8i

3

DESCRIPTION AND OPERATION

1. Cylinder heads (2)

2. Rocker covers (2)

3. PCV filter

4. Rocker shafts (2)

5. Hydraulic tappets (8)

6. Pushrods (8)

7. Rocker brackets (8)

8. Rocker arms (4) left and (4) right

9. Rocker shaft springs (6)

10. Inlet manifold

11. Plenum chamber lower

12. Ram pipes (8)13. Plenum chamber upper

14. PCV air intake filter

15. Oil filler

16. Thermostat

17. Thermostat cover

18. Inlet valve seal, spring, cap and collets (8)

19. Exhaust valve seal, spring, cap and collets (8)

20. Inlet valve and seat (8)

21. Exhaust valve and seat (8)

22. Inlet manifold gasket and seals

23. Cylinder head gaskets (2)

24. Valve guides (16)

Page 115 of 873

12ENGINE

2

FAULT DIAGNOSIS ENGINE NOISES

Excessive or obtrusive noise from the engine

compartment originates from three main sources:

A. The exhaust system, which makes an

unmistakable and easy to diagnose noise.

B. External components emit the greatest variety of

noises, but are also easy to diagnose by simply

removing the drive belt.

C. Engine internal mechanical noises which can

vary in volume and pitch and may be a

combination of, tapping - knocking or rumbling,

are the most difficult to diagnose. The following

is therefore a guide to diagnosis of engine

internal mechanical noises only.

Engine internal mechanical noises.

Single or multiple, light tapping noise, particularly

when engine is cold.

See Description and

operation, Description

1.Is engine oil level correct?

NO - Top up to correct level.

See

LUBRICANTS, FLUIDS AND

CAPACITIES, Information,

Recommended Lubricants and Fluids

YES - Continue.

2.Is the lubricating pressure correct?

NO -

See Engine Oil Pressure Test

YES - Suspect valve operating mechanism.

3.To confirm diagnosis, remove the rocker covers

and with the engine idling, insert a feeler gauge

of 0,015mm between each rocker and valve

stem. A faulty valve operating mechanism will

emit a different noise when the feeler gauge is

inserted.

See Repair, Rocker Shaft Renew

Heavy knocking noise (particularly on load and

when engine is hot).

See Description and

operation, Description

1.Is engine oil level correct?

NO - Top up to correct level.

See

LUBRICANTS, FLUIDS AND

CAPACITIES, Information,

Recommended Lubricants and Fluids

YES - Continue.

2.Is the lubricating pressure correct?

NO -

See Engine Oil Pressure Test

YES - Drain engine oil and filter, and examine

for metallic contamination.

3.Is the oil contaminated with metal particles?

YES - Suspect faulty big end bearings. To

confirm diagnosis, short out the ignition to

each spark plug in turn. The noise will

disappear or be reduced when the

cylinder with the faulty big end is shorted

out.

4.If noise is not conclusively diagnosed, check the

security of the flywheel and crankshaft front

pulley. Temporarily release the drive belt to

reduce general noise level and use a

stethoscope to locate source of noise.

Heavy rumbling noise (particularly during hard

acceleration).

See Description and operation,

Description

1.Is engine oil level correct?

NO - Top up to correct level.

See

LUBRICANTS, FLUIDS AND

CAPACITIES, Information,

Recommended Lubricants and Fluids

YES - Continue.

2.Is the lubricating pressure correct?

NO -

See Engine Oil Pressure Test

YES - Drain engine oil and filter, and examine

for metallic contamination.

3.Is the oil contaminated with metal particles?

YES - Suspect faulty main bearings. If noise is

not conclusively diagnosed, check the

security of the flywheel and crankshaft

front pulley. Temporarily release the drive

belt to reduce general noise level and use

a stethoscope to locate source of noise.

Page 116 of 873

V8i

3

FAULT DIAGNOSIS ENGINE STARTING PROBLEMS

Engine fails to crank in park or neutral (Automatic

Transmission)

1.Is battery in good state of charge?

NO -

See INTRODUCTION, Information,

Jump Starting

YES - Continue.

2.Is automatic transmission inhibitor switch faulty

or gear selection linkage incorrectly adjusted?

YES -

See AUTOMATIC GEARBOX, Repair,

Inhibitor Switch

,

NO -

See Electrical Trouble Shooting

Manual.

If problem is not diagnosed repeat tests, starting

at 1.

Engine fails to crank (Manual Transmission)

1.Is battery in good state of charge?

NO -

See INTRODUCTION, Information,

Jump Starting

YES -See Electrical Trouble Shooting

Manual.

If problem is not diagnosed repeat tests, starting

at 1.

Engine cranks but fails to start

1.Is the cranking speed fast enough (120 rpm)?

NO -

See INTRODUCTION, Information,

Jump Starting

If necessary also.See Electrical Trouble

Shooting Manual.

YES - Continue.

2.Is there combustion in any cylinder?

NO -

See ELECTRICAL, Fault diagnosis,

Lucas Constant Energy Ignition

System - V8i See Electrical Trouble

Shooting Manual.

YES - Continue.

3.Are the fuel supply, tank, pump, ventilation and

emission control systems in correct working

order or the fuel contaminated?

NO -

See FUEL SYSTEM, Repair, Fuel

Filter See FUEL SYSTEM, Repair,

Fuel Tank See FUEL SYSTEM, Repair,

Fuel pump and Sender Unit See

EMISSION CONTROL, Description and

operation, Emission control

If problem is not diagnosed repeat tests, starting

at 2.ENGINE RUNNING PROBLEMS

Engine runs at high speed but will not idle (stops)

Engine idle speed erratic Engine starts but stops

immediately

Engine stalls Engine misfires/hesitation

1.Multiport fuel injection.

See Electrical Trouble

Shooting Manual. See ELECTRICAL, Fault

diagnosis, Lucas Constant Energy Ignition

System - V8i

Check brake vacuum connections.See

BRAKES, Description and operation, Brake

Servo Unit

Check heater/ventilation unit vacuum

connections.

See HEATING AND

VENTILATION, Description and operation,

Heating and Ventilation Unit

If problem is not diagnosed continue.

2.Are HT leads correctly routed and clipped?

NO -

See ELECTRICAL, Repair, Distributor

- V8i

YES - Continue.

3.Is fuel supply, tank, pump, ventilation and

emission control systems in correct working

order or the fuel contaminated?

NO -

See FUEL SYSTEM, Repair, Fuel

Filter See FUEL SYSTEM, Repair,

Fuel Tank See FUEL SYSTEM, Repair,

Fuel Pump and Sender Unit See

EMISSION CONTROL, Description and

operation, Emission Control

If problem is not diagnosed repeat tests, starting

at 1.

Engine lacks power/poor performance

1.Is throttle travel restricted or cable incorrectly

adjusted?

YES - Check thickness of carpets.

See FUEL

SYSTEM, Repair, Throttle Cable See

FUEL SYSTEM, Repair, Accelerator

Pedal

NO - Continue.

2.Are the Ignition and Multiport Fuel Injection

systems in order?

NO -

See Electrical Trouble Shooting

Manual.A1 See ELECTRICAL, Fault

diagnosis, Lucas Constant Energy

Ignition System - V8i See

ELECTRICAL, Repair, Distributor - V8i

YES - Continue.

Page 117 of 873

12ENGINE

4

FAULT DIAGNOSIS 3.Are fuel supply, tank, pump, ventilation and

emission control systems in correct working

order or the fuel contaminated?

NO -

See FUEL SYSTEM, Repair, Fuel

Filter See FUEL SYSTEM, Repair,

Fuel Tank See FUEL SYSTEM, Repair,

Fuel Pump and Sender Unit

YES - Suspect valves held open by hydraulic

tappets due to high oil pressure.

See

Engine Oil Pressure Test

4.Is oil pressure high?

YES - Remove oil filter and cooler adaptor and

check pressure relief valve strainer gauze

for blockage and that the relief valve is

not stuck closed.

See Description and

operation, Description

NO - Carry out cylinder compression tests to

determine condition of head gaskets and

valves.

See Cylinder Compression -

Test

5.Are cylinder compressions satisfactory?

NO -

See Repair, Cylinder Heads - Renew

YES - Check brake vacuum connections.See

BRAKES, Description and operation,

Brake Servo Unit

Check heater/ventilation unit vacuum connections.

See HEATING AND VENTILATION, Description and

operation, Heating and Ventilation Unit

If problem is not diagnosed: Continue.

6.Are the brakes binding?

YES - Investigate cause of binding.

NO - Continue.

7.Automatic Transmission only. Is the Torque

Converter and Transmission operating correctly?

Carry out Road test, Static tests and Stall tests

to determine condition of Automatic

transmission.

If problem is not diagnosed: repeat tests starting at 1.Engine backfires into exhaust system

1.Are there any leaking joints/connections or holes

in the exhaust system?

YES -

See MANIFOLD AND EXHAUST

SYSTEM, Repair, Exhaust System

Complete

NO - Continue.

2.Is distributor fitted correctly, HT leads in correct

firing order and routed correctly?

NO -

See ELECTRICAL, Repair, Distributor

- V8i

YES - Continue.

3.Is air fuel ratio correct?

NO - Check multiport fuel injection.

See

Electrical Trouble Shooting Manual.

Check brake vacuum connections.See

BRAKES, Description and operation, Brake

Servo Unit

Check heater/ventilation unit vacuum

connections.

See HEATING AND

VENTILATION, Description and operation,

Heating and Ventilation Unit

Check the crank case and fuel tank ventilation

system.

See EMISSION CONTROL,

Description and operation, Emission Control

YES - Continue.

4.Are cylinder compressions satisfactory?

NO - Carry out compression test to check for

leaking gaskets valves etc.

See

Cylinder Compression - Test

See Repair, Cylinder Heads - Renew

If problem is not diagnosed: repeat tests starting

at 1.

Page 187 of 873

EMISSION CONTROL

1

DESCRIPTION AND OPERATION REV: 09/95 EMISSION CONTROL

Three systems are used to control the vehicle

atmospheric emissions these are:

Engine crankcase fume emissions.

Fuel tank Evaporative emissions

Engine exhaust gas emissions.

Crankcase ventilation system - 3.9 MFi models

only

The crankcase ventilation system which is an integral

part of the air supply to the engine combustion

chambers, is often overlooked when diagnosing

problems associated with engine performance. A

blocked ventilation pipe or filter or excessive air leak

into the inlet system through a damaged pipe or

leaking gasket can effect the mixture, performance

and economy of the engine.

1. Three way connector

2. Air filter

3. Oil separatorThe purpose of the crankcase ventilation system is to

ensure that any noxious gas generated in the engine

crankcase is rendered harmless by burning in the

combustion chambers as follows:

Oil laden noxious gas in the engine crankcase is

drawn through an oil separator 3 located on the right

cylinder head rocker cover, where the oil is separated

and returned to the sump. The gas flows through a

restrictor in the three way connection 1 and into the

inlet plenum chamber where it is drawn into the

combustion chambers and burned. The volume of

fresh air which is drawn from the atmospheric side of

the throttle butterfly to mix with the gas, depends on

the position of the throttle and the engine speed.

The air filter 2 fitted to the left cylinder head rocker

cover, must be maintained in clean condition to

ensure sufficient air enters the crankcase under

varying throttle openings and manifold depression, to

prevent excessive crankcase pressure or depression

developing.

Page 194 of 873

17EMISSION CONTROL

8

DESCRIPTION AND OPERATION ADD: 09/95 System operation

The system is designed to prevent fuel vapour

escaping to atmosphere, and consists of four roll-over

valves fitted internally in the fuel tank, connected to

the liquid/vapour separator by a nylon line. The

separator is mounted to the side of the filler neck. An

EVAP canister is positioned in the engine

compartment mounted on the right front side valance.

The liquid/vapour separator and EVAP canister are

connected by a nylon line which runs the length of the

chassis.

Pressure/vacuum relief valves are incorporated into

the fuel filler cap and are designed to protect the fuel

tank from permanent deformation in the event of

system pressure or vacuum exceeding the system

operating parameters. There are no other relief or

one-way valves in the system.

A vent line flow restrictor known as an anti-trickle fill

valve is fitted to the filler pipe in the line between the

tank and EVAP canister. The function of this valve is

to prevent overfilling the tank by trickling fuel in,

thereby preserving the vapour space in the tank to

allow for fuel expansion during hot weather.

The valve achieves this by blocking the vent line

during the fuel filling process. The valve is operated

by the action of inserting the filler gun so that when

the fuel in the tank reaches the level of the filling

breather, flow cut off occurs due to fuel filling the filler

pipe.During normal vehicle operation and when the engine

is switched off, the venting system between the fuel

tank and EVAP canister is open to allow the free

passage of vapour.

The EVAP canister, which is connected by a nylon

hose to the plenum chamber, absorbs and stores the

fuel vapour from the fuel tank when the engine is not

running. With the engine running, vapour is purged

from the EVAP canister by allowing outside air to be

drawn through the EVAP canister vent solenoid and

link pipe by the influence of manifold vacuum to the

EVAP canister purge connection on the canister.

Filter pads are fitted above and below the charcoal

and in the EVAP canister vent solenoid to prevent the

ingress of foreign matter into the purge line.

The EVAP canister purge valve, which is fitted in the

line from the EVAP canister to the plenum, is

controlled by the ECM which determines the most

emission acceptable time at which purging should

take place. This will normally be at engine speeds

above idle and when the vehicle is in motion.

The EVAP canister vent solenoid is mounted on the

side of the EVAP canister bracket and is connected to

the EVAP canister by a length of large bore hose. The

ECVS is controlled by the ECM and is normally open.

The function of the ECVS is to block the air intake

side of the EVAP canister. When the system receives

an ECM signal the valve closes; this allows the

system leak check to take place. The leak check only

occurs when pre-determined vehicle operating

conditions are met.

Page 197 of 873

EMISSION CONTROL

1

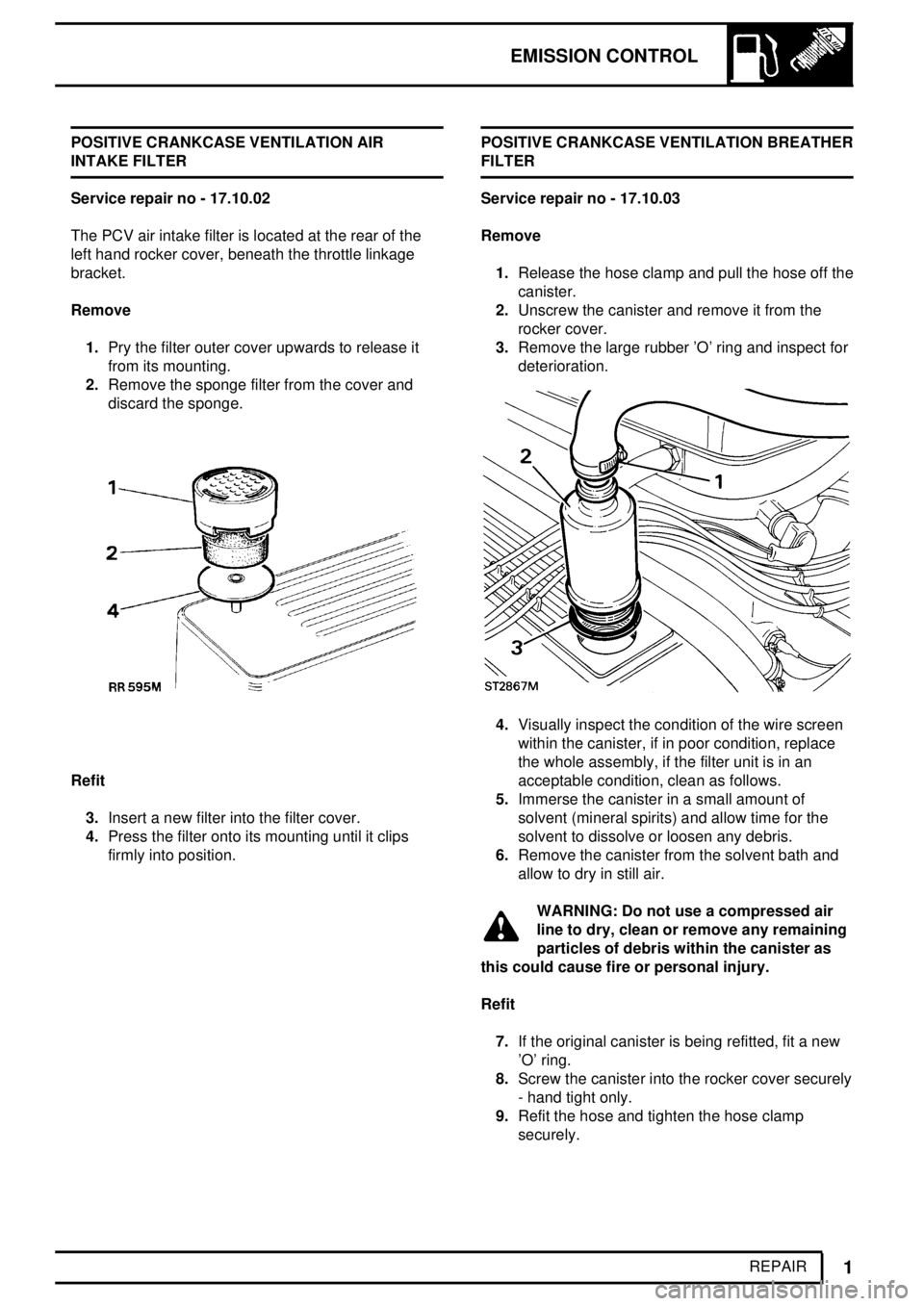

REPAIR POSITIVE CRANKCASE VENTILATION AIR

INTAKE FILTER

Service repair no - 17.10.02

The PCV air intake filter is located at the rear of the

left hand rocker cover, beneath the throttle linkage

bracket.

Remove

1.Pry the filter outer cover upwards to release it

from its mounting.

2.Remove the sponge filter from the cover and

discard the sponge.

Refit

3.Insert a new filter into the filter cover.

4.Press the filter onto its mounting until it clips

firmly into position.POSITIVE CRANKCASE VENTILATION BREATHER

FILTER

Service repair no - 17.10.03

Remove

1.Release the hose clamp and pull the hose off the

canister.

2.Unscrew the canister and remove it from the

rocker cover.

3.Remove the large rubber 'O' ring and inspect for

deterioration.

4.Visually inspect the condition of the wire screen

within the canister, if in poor condition, replace

the whole assembly, if the filter unit is in an

acceptable condition, clean as follows.

5.Immerse the canister in a small amount of

solvent (mineral spirits) and allow time for the

solvent to dissolve or loosen any debris.

6.Remove the canister from the solvent bath and

allow to dry in still air.

WARNING: Do not use a compressed air

line to dry, clean or remove any remaining

particles of debris within the canister as

this could cause fire or personal injury.

Refit

7.If the original canister is being refitted, fit a new

'O' ring.

8.Screw the canister into the rocker cover securely

- hand tight only.

9.Refit the hose and tighten the hose clamp

securely.

Page 206 of 873

Tdi

1

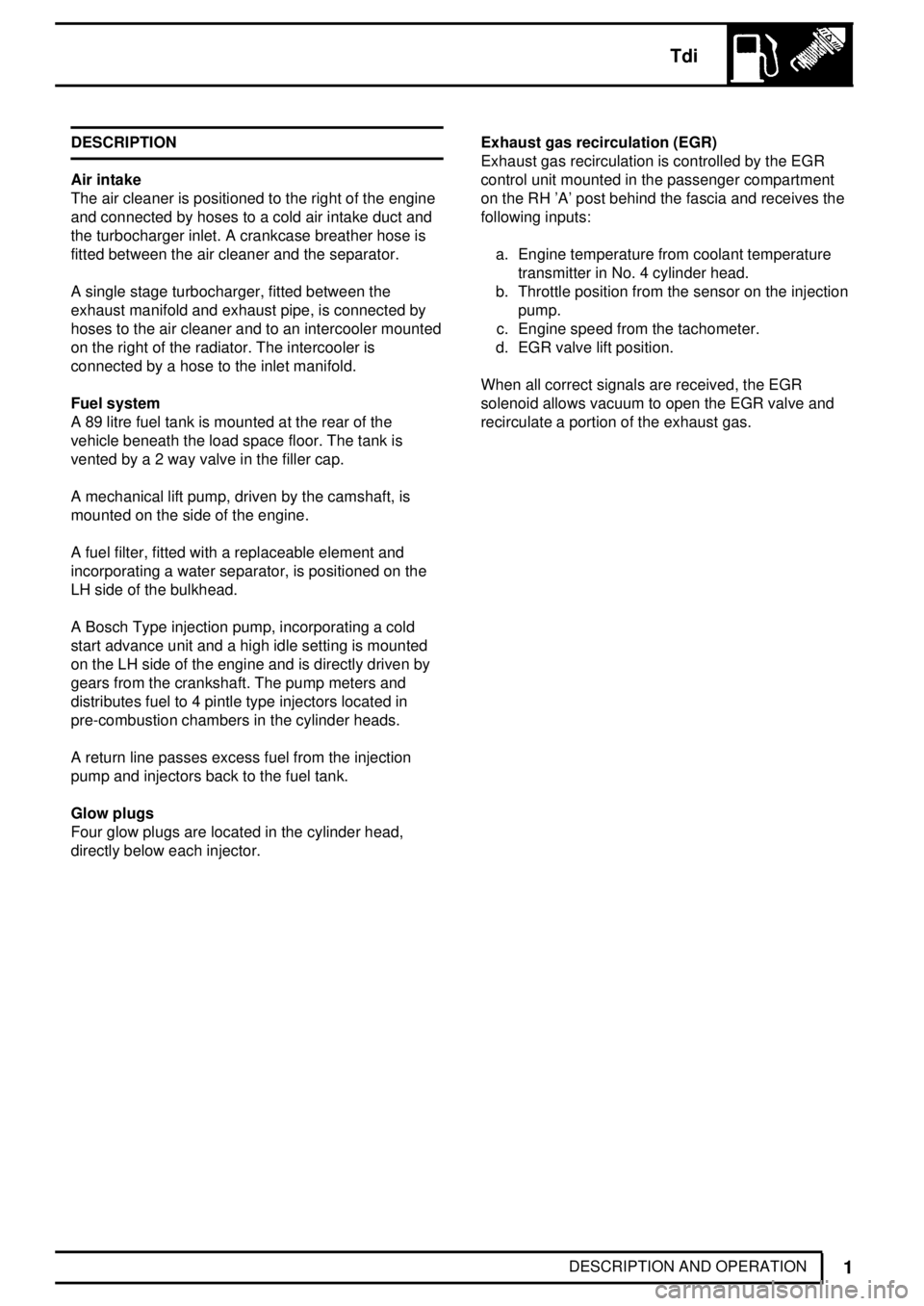

DESCRIPTION AND OPERATION DESCRIPTION

Air intake

The air cleaner is positioned to the right of the engine

and connected by hoses to a cold air intake duct and

the turbocharger inlet. A crankcase breather hose is

fitted between the air cleaner and the separator.

A single stage turbocharger, fitted between the

exhaust manifold and exhaust pipe, is connected by

hoses to the air cleaner and to an intercooler mounted

on the right of the radiator. The intercooler is

connected by a hose to the inlet manifold.

Fuel system

A 89 litre fuel tank is mounted at the rear of the

vehicle beneath the load space floor. The tank is

vented by a 2 way valve in the filler cap.

A mechanical lift pump, driven by the camshaft, is

mounted on the side of the engine.

A fuel filter, fitted with a replaceable element and

incorporating a water separator, is positioned on the

LH side of the bulkhead.

A Bosch Type injection pump, incorporating a cold

start advance unit and a high idle setting is mounted

on the LH side of the engine and is directly driven by

gears from the crankshaft. The pump meters and

distributes fuel to 4 pintle type injectors located in

pre-combustion chambers in the cylinder heads.

A return line passes excess fuel from the injection

pump and injectors back to the fuel tank.

Glow plugs

Four glow plugs are located in the cylinder head,

directly below each injector.Exhaust gas recirculation (EGR)

Exhaust gas recirculation is controlled by the EGR

control unit mounted in the passenger compartment

on the RH 'A' post behind the fascia and receives the

following inputs:

a. Engine temperature from coolant temperature

transmitter in No. 4 cylinder head.

b. Throttle position from the sensor on the injection

pump.

c. Engine speed from the tachometer.

d. EGR valve lift position.

When all correct signals are received, the EGR

solenoid allows vacuum to open the EGR valve and

recirculate a portion of the exhaust gas.

Page 207 of 873

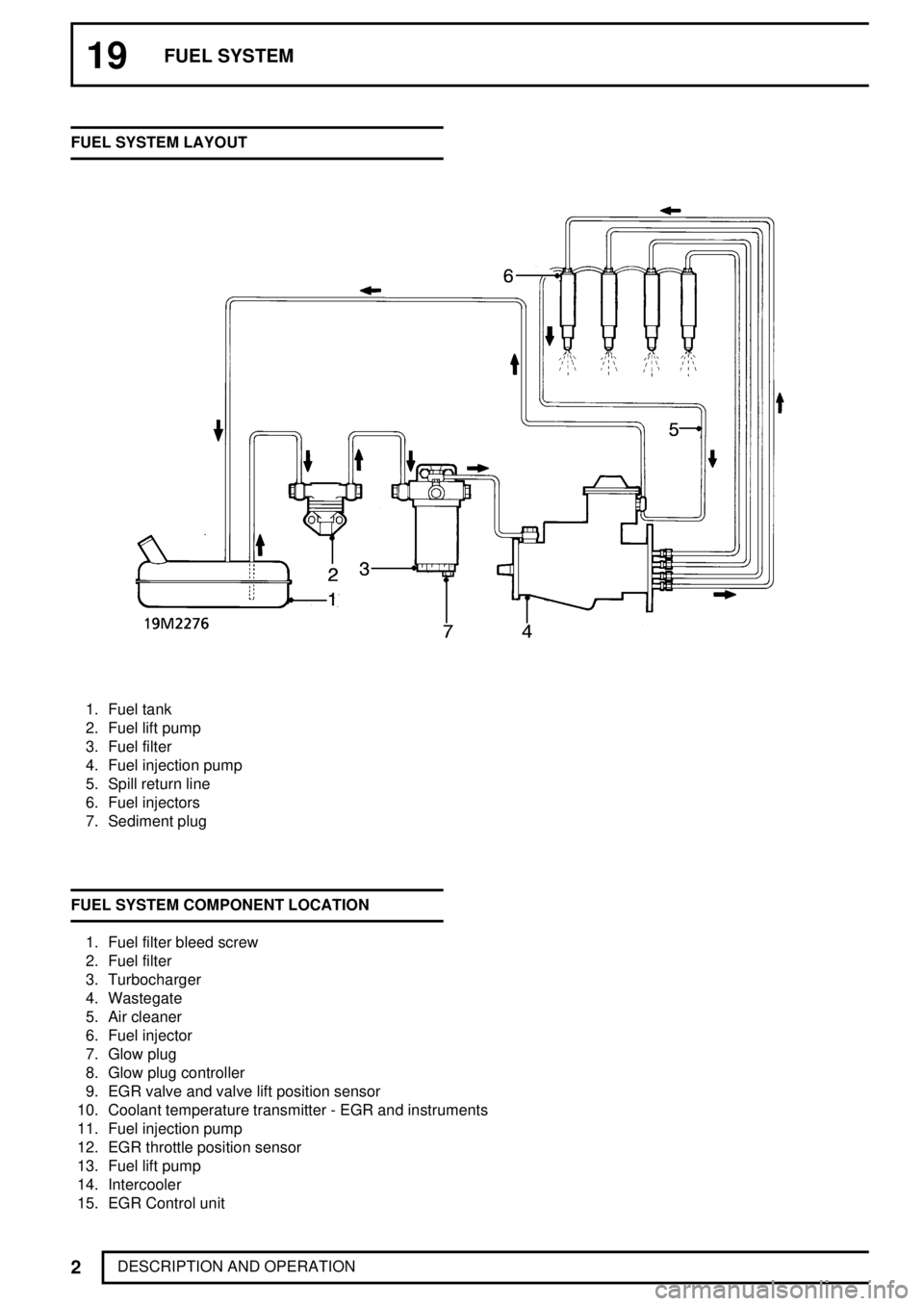

19FUEL SYSTEM

2

DESCRIPTION AND OPERATION FUEL SYSTEM LAYOUT

1. Fuel tank

2. Fuel lift pump

3. Fuel filter

4. Fuel injection pump

5. Spill return line

6. Fuel injectors

7. Sediment plug

FUEL SYSTEM COMPONENT LOCATION

1. Fuel filter bleed screw

2. Fuel filter

3. Turbocharger

4. Wastegate

5. Air cleaner

6. Fuel injector

7. Glow plug

8. Glow plug controller

9. EGR valve and valve lift position sensor

10. Coolant temperature transmitter - EGR and instruments

11. Fuel injection pump

12. EGR throttle position sensor

13. Fuel lift pump

14. Intercooler

15. EGR Control unit