oil pressure LAND ROVER DISCOVERY 1995 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 139 of 873

![LAND ROVER DISCOVERY 1995 Owners Manual 4.0 V8

3

REPAIR ENGINE ASSEMBLY

Service repair no - 12.41.01/99

Remove

1.Position vehicle on ramp.

2.Remove bonnet.

See CHASSIS AND BODY,Repair, Bonnet [Hood]

3.Remove radiator.See COOLING SYSTEM,

Rep LAND ROVER DISCOVERY 1995 Owners Manual 4.0 V8

3

REPAIR ENGINE ASSEMBLY

Service repair no - 12.41.01/99

Remove

1.Position vehicle on ramp.

2.Remove bonnet.

See CHASSIS AND BODY,Repair, Bonnet [Hood]

3.Remove radiator.See COOLING SYSTEM,

Rep](/img/64/57248/w960_57248-138.png)

4.0 V8

3

REPAIR ENGINE ASSEMBLY

Service repair no - 12.41.01/99

Remove

1.Position vehicle on ramp.

2.Remove bonnet.

See CHASSIS AND BODY,Repair, Bonnet [Hood]

3.Remove radiator.See COOLING SYSTEM,

Repair, Radiator

4.Remove plenum chamber.See FUEL SYSTEM

SFI, Repair, Plenum Chamber

5.Remove mass air flow sensor.See FUEL

SYSTEM SFI, Repair, Mass Air Flow Sensor

(MAF Sensor)

6.Slacken hose clip securing bottom hose to

expansion tank.

7.Disconnect hose.

8.Remove 2 nuts securing expansion tank.

9.Remove nut and bolt securing expansion tank.

10.Remove expansion tank.

11.Disconnect servo vacuum hose from ram

housing.

12.Disconnect battery sensing lead Lucar from

generator.

13.Remove generator terminal cover.

14.Remove 2 terminal nuts and release leads from

terminals.

15.Release purge hose from ram pipe housing.

16.Position cloth to absorb fuel spillage.

17.Slacken clip securing fuel return hose to fuel rail.

18.Disconnect hose.

19.Plug connections.

20.Disconnect fuel feed hose union.

21.Plug connections. Position hoses aside.

22.Slacken clip securing heater return hose to pipe.

23.Disconnect hose.24.Slacken clip securing heater feed adaptor hose

to inlet manifold.

25.Remove bolt securing pipe bracket.

26.Disconnect feed hose from inlet manifold.

27.Disconnect hose/pipe assembly.

28.Disconnect leads from spark plugs and remove

ignition coils.

See FUEL SYSTEM SFI, Repair,

Ignition Coils

29.Disconnect fuel temperature sensor multiplug.

30.Disconnect coolant sensor multiplug.

31.Disconnect temperature gauge sensor lead.

32.Release camshaft sensor multiplug from bracket

and disconnect multiplug.

33.Disconnect oil pressure switch Lucar.

34.Disconnect air intake temperature sensor

multiplug.

35.Disconnect 8 injector multiplugs.

36.Remove 4 nuts securing harness brackets to

inlet manifold.

37.Release harness brackets.

38.Remove bolts securing gearbox breather pipes

to engine lifting bracket.

Page 143 of 873

4.0 V8

7

REPAIR 171.Route drive belt around pulleys.

172.Pivot tensioner downwards.

173.Align belt to tensioner and release tensioner.

174.Connect battery positive lead and tighten.

175.Secure terminal cover.

176.Align gearbox breather pipe, clip to engine lifting

eye and fit bolt. Tighten to

9 Nm.

177.Align and secure engine harness brackets to

inlet manifold and fit nuts. Tighten to

9 Nm.

178.Connect injector multiplugs.

179.Connect air intake temperature sensor multiplug.

180.Connect fuel temperature sensor multiplug.

181.Connect coolant temperature multiplug.

182.Connect temperature gauge connector.

183.Connect oil pressure switch Lucar.

184.Connect camshaft sensor multiplug and secure

to bracket.

185.Fit ignition coil bracket.

See FUEL SYSTEM

SFI, Repair, Ignition Coils

186.Position heater hose/pipe assembly.

187.Connect hose to inlet manifold.

188.Align pipe to bracket and fit bolt. Tighten to

9

Nm.

189.Tighten hose clip.

190.Connect heater return hose and tighten clip.

191.Remove plugs from fuel feed and return hose

connections.

192.Clean feed unions.

193.Connect return hose and tighten clip.

194.Connect feed hose union and tighten.

195.Remove cloth.

196.Connect purge hose.

197.Connect leads to generator, tighten terminal nuts

and fit cover.

198.Connect sensing Lucar.

199.Connect servo vacuum hose.

200.Position expansion tank and secure with fixings.

201.Connect hose and tighten clip.

202.Lower ramp.

203.Fit mass air flow sensor.

See FUEL SYSTEM

SFI, Repair, Mass Air Flow Sensor (MAF

Sensor)

204.Fit plenum chamber.See FUEL SYSTEM SFI,

Repair, Plenum Chamber

205.Fit radiator.See COOLING SYSTEM, Repair,

Radiator

206.Fit bonnet.See CHASSIS AND BODY, Repair,

Bonnet [Hood]

207.Reconnect battery negative lead.

208.Bleed power steering system.

See STEERING,

Repair, Power Steering System - Bleed

209.Drain engine oil and refill.See LUBRICANTS,

FLUIDS AND CAPACITIES, Information,

Recommended Lubricants and Fluids - USA

Vehicles

210.Start engine. Check for fuel, coolant and oil

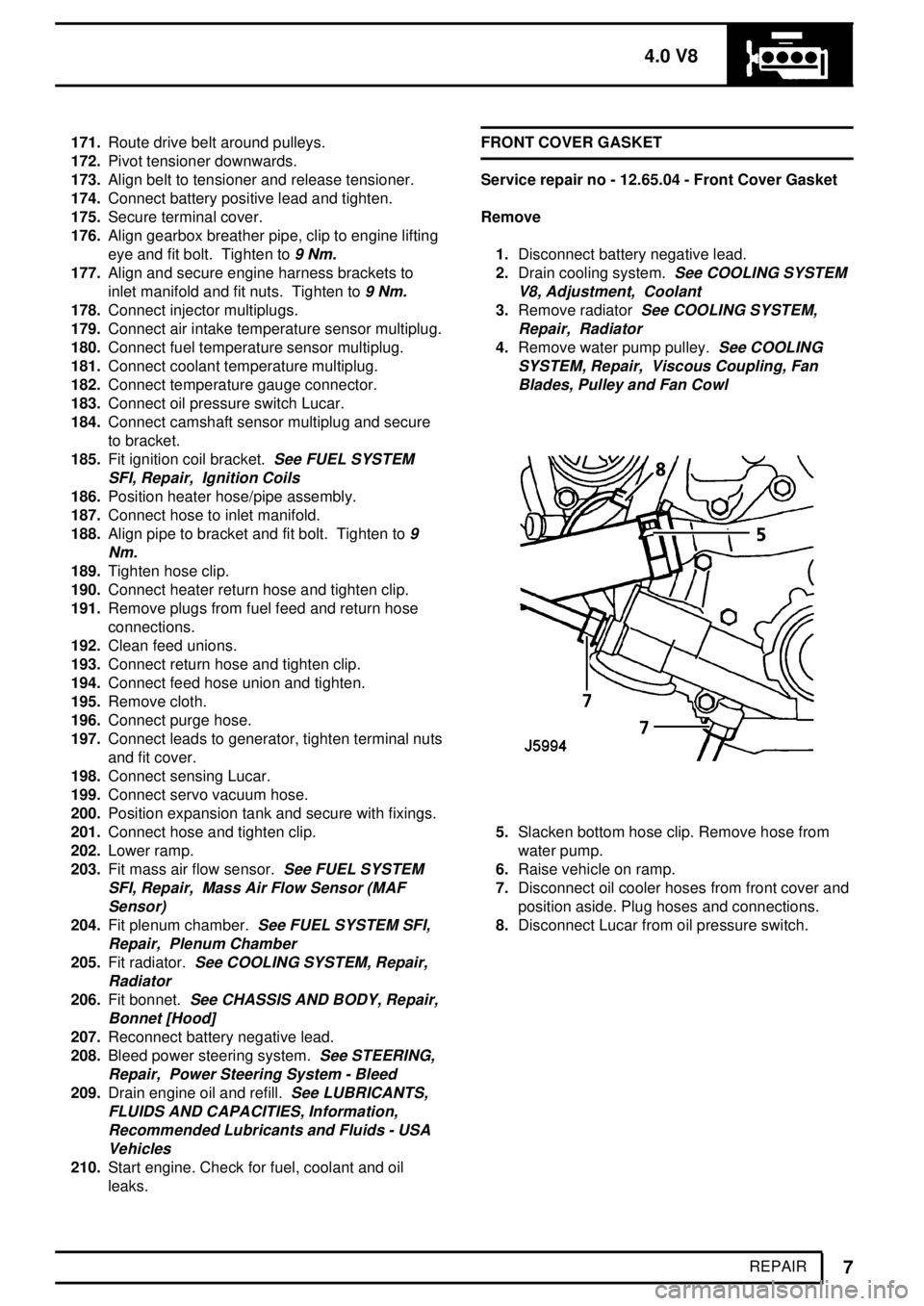

leaks.FRONT COVER GASKET

Service repair no - 12.65.04 - Front Cover Gasket

Remove

1.Disconnect battery negative lead.

2.Drain cooling system.

See COOLING SYSTEM

V8, Adjustment, Coolant

3.Remove radiatorSee COOLING SYSTEM,

Repair, Radiator

4.Remove water pump pulley.See COOLING

SYSTEM, Repair, Viscous Coupling, Fan

Blades, Pulley and Fan Cowl

5.Slacken bottom hose clip. Remove hose from

water pump.

6.Raise vehicle on ramp.

7.Disconnect oil cooler hoses from front cover and

position aside. Plug hoses and connections.

8.Disconnect Lucar from oil pressure switch.

Page 145 of 873

4.0 V8

9

REPAIR 28.Remove alignment tool LRT-12-090.

29.Apply a small amount of Loctite 242 to threads

and refit front cover bolts. Tighten to

22 Nm.

30.Fit sump bolts. Tighten to23 Nm.

31.Connect camshaft sensor multiplug.

32.Connect Lucar to oil pressure switch terminal.

33.Remove plugs from oil cooler pipes and cover.

34.Fit new 'O' ring seals, reconnect oil cooler pipes.

Tighten to

15 Nm.

CAUTION: Over tightening of oil cooler

pipe unions can crack front cover.

35.Refit bottom hose to water pump. Tighten clip.

36.Refit water pump pulley.

See COOLING

SYSTEM, Repair, Viscous Coupling, Fan

Blades, Pulley and Fan Cowl

37.Refit radiator assembly.See COOLING

SYSTEM, Repair, Radiator

38.Refill cooling system.See COOLING SYSTEM

V8, Adjustment, Coolant

39.Check/top-up engine oil.

40.Lower ramp.

41.Reconnect battery negative lead.

Page 153 of 873

Mpi

3

DESCRIPTION AND OPERATION Lubrication

Oil is drawn from the pressed steel sump through a

strainer (1) and into the oil pump (2); excess pressure

being relieved by a pressure relief valve (3) integral

with the pump. The low oil pressure sensor (4)

registers the oil pressure in the main oil gallery on the

outflow side of the filter. Pressurised oil passes

through the full flow oil filter (5) to internal drillings in

the crankshaft where it is directed to each main

bearing and to the big end bearings via Nos. 1, 3 and

5 main bearings (6). An internal drilling in the cylinder

block directs oil, via a restrictor (7) to the cylinder

head where it passes through further internal drillings

to the hydraulic tappets and camshaft journals (8).

Gudgeon pin and small-end bush lubrication is by

splash from the big-end bearings.Crankcase ventilation

With the exception of two hoses connected from the

inlet camshaft cover to the inlet manifold and throttle

housing all crankcase ventilation is via internal voids

in the cylinder head and block. The inlet camshaft

cover carries a wire gauze flame trap located over the

breather pipe connections.

Page 154 of 873

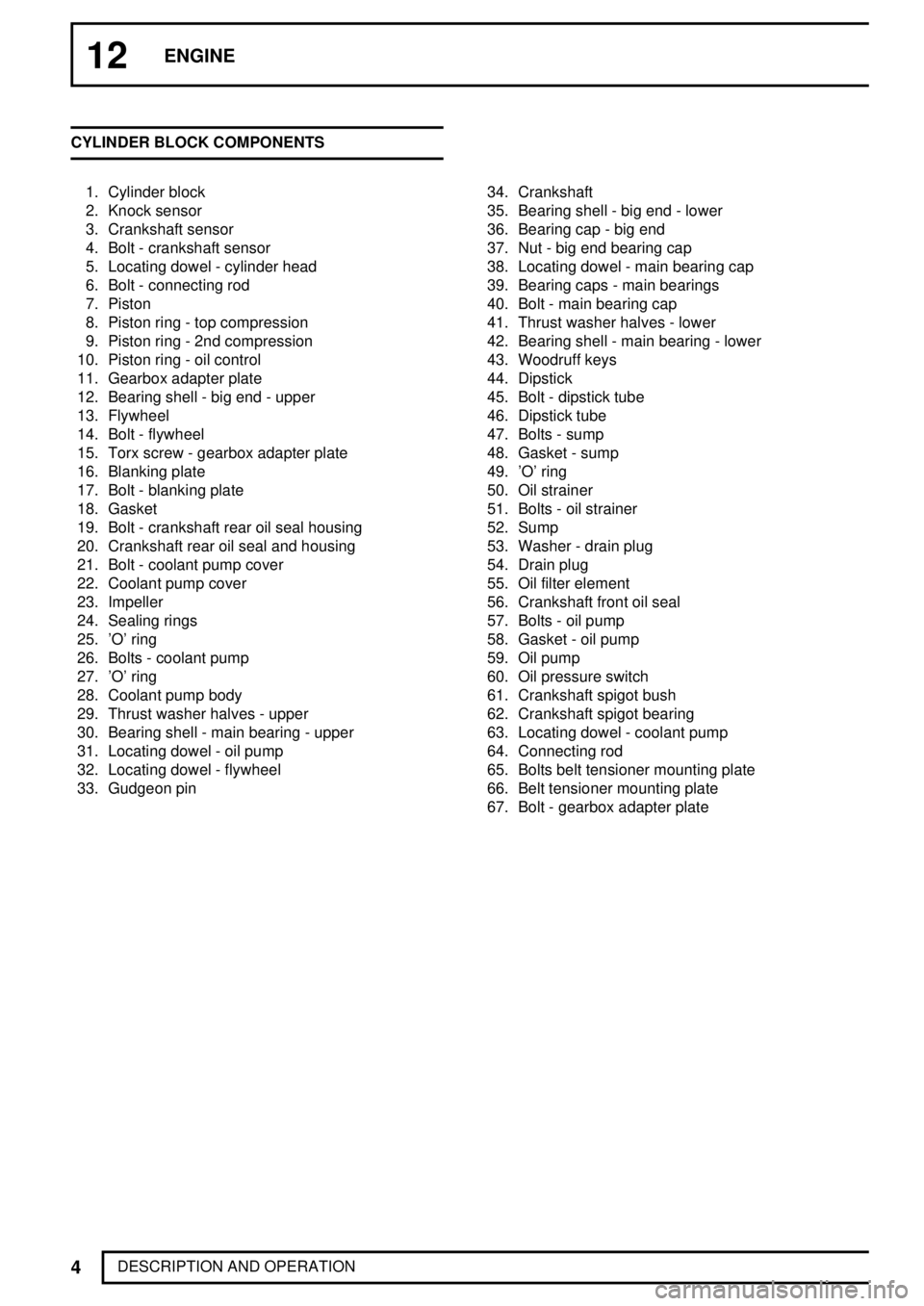

12ENGINE

4

DESCRIPTION AND OPERATION CYLINDER BLOCK COMPONENTS

1. Cylinder block

2. Knock sensor

3. Crankshaft sensor

4. Bolt - crankshaft sensor

5. Locating dowel - cylinder head

6. Bolt - connecting rod

7. Piston

8. Piston ring - top compression

9. Piston ring - 2nd compression

10. Piston ring - oil control

11. Gearbox adapter plate

12. Bearing shell - big end - upper

13. Flywheel

14. Bolt - flywheel

15. Torx screw - gearbox adapter plate

16. Blanking plate

17. Bolt - blanking plate

18. Gasket

19. Bolt - crankshaft rear oil seal housing

20. Crankshaft rear oil seal and housing

21. Bolt - coolant pump cover

22. Coolant pump cover

23. Impeller

24. Sealing rings

25. 'O' ring

26. Bolts - coolant pump

27. 'O' ring

28. Coolant pump body

29. Thrust washer halves - upper

30. Bearing shell - main bearing - upper

31. Locating dowel - oil pump

32. Locating dowel - flywheel

33. Gudgeon pin34. Crankshaft

35. Bearing shell - big end - lower

36. Bearing cap - big end

37. Nut - big end bearing cap

38. Locating dowel - main bearing cap

39. Bearing caps - main bearings

40. Bolt - main bearing cap

41. Thrust washer halves - lower

42. Bearing shell - main bearing - lower

43. Woodruff keys

44. Dipstick

45. Bolt - dipstick tube

46. Dipstick tube

47. Bolts - sump

48. Gasket - sump

49. 'O' ring

50. Oil strainer

51. Bolts - oil strainer

52. Sump

53. Washer - drain plug

54. Drain plug

55. Oil filter element

56. Crankshaft front oil seal

57. Bolts - oil pump

58. Gasket - oil pump

59. Oil pump

60. Oil pressure switch

61. Crankshaft spigot bush

62. Crankshaft spigot bearing

63. Locating dowel - coolant pump

64. Connecting rod

65. Bolts belt tensioner mounting plate

66. Belt tensioner mounting plate

67. Bolt - gearbox adapter plate

Page 164 of 873

![LAND ROVER DISCOVERY 1995 Owners Manual 12ENGINE

6

REPAIR ENGINE

Service repair no - 12.41.01

Remove

1.Site vehicle onto ramp [hoist].

2.Remove the drive belt.

See SECTION 10,

Maintenance, Under Bonnet [Hood]

Maintenance

3.Remove radiator.S LAND ROVER DISCOVERY 1995 Owners Manual 12ENGINE

6

REPAIR ENGINE

Service repair no - 12.41.01

Remove

1.Site vehicle onto ramp [hoist].

2.Remove the drive belt.

See SECTION 10,

Maintenance, Under Bonnet [Hood]

Maintenance

3.Remove radiator.S](/img/64/57248/w960_57248-163.png)

12ENGINE

6

REPAIR ENGINE

Service repair no - 12.41.01

Remove

1.Site vehicle onto ramp [hoist].

2.Remove the drive belt.

See SECTION 10,

Maintenance, Under Bonnet [Hood]

Maintenance

3.Remove radiator.See COOLING SYSTEM,

Repair, Radiator - Mpi

4.Remove bonnet [hood].See CHASSIS AND

BODY, Repair, Bonnet [Hood]

5.Drain engine oil.

6.Position absorbent cloth around fuel pipe to fuel

rail union.

Unscrew union to relieve pressure.

CAUTION: Plug the connections

7.Release clip and disconnect hose from coolant

pump.

8.Release clip and disconnect hose from heater

rail.

Page 167 of 873

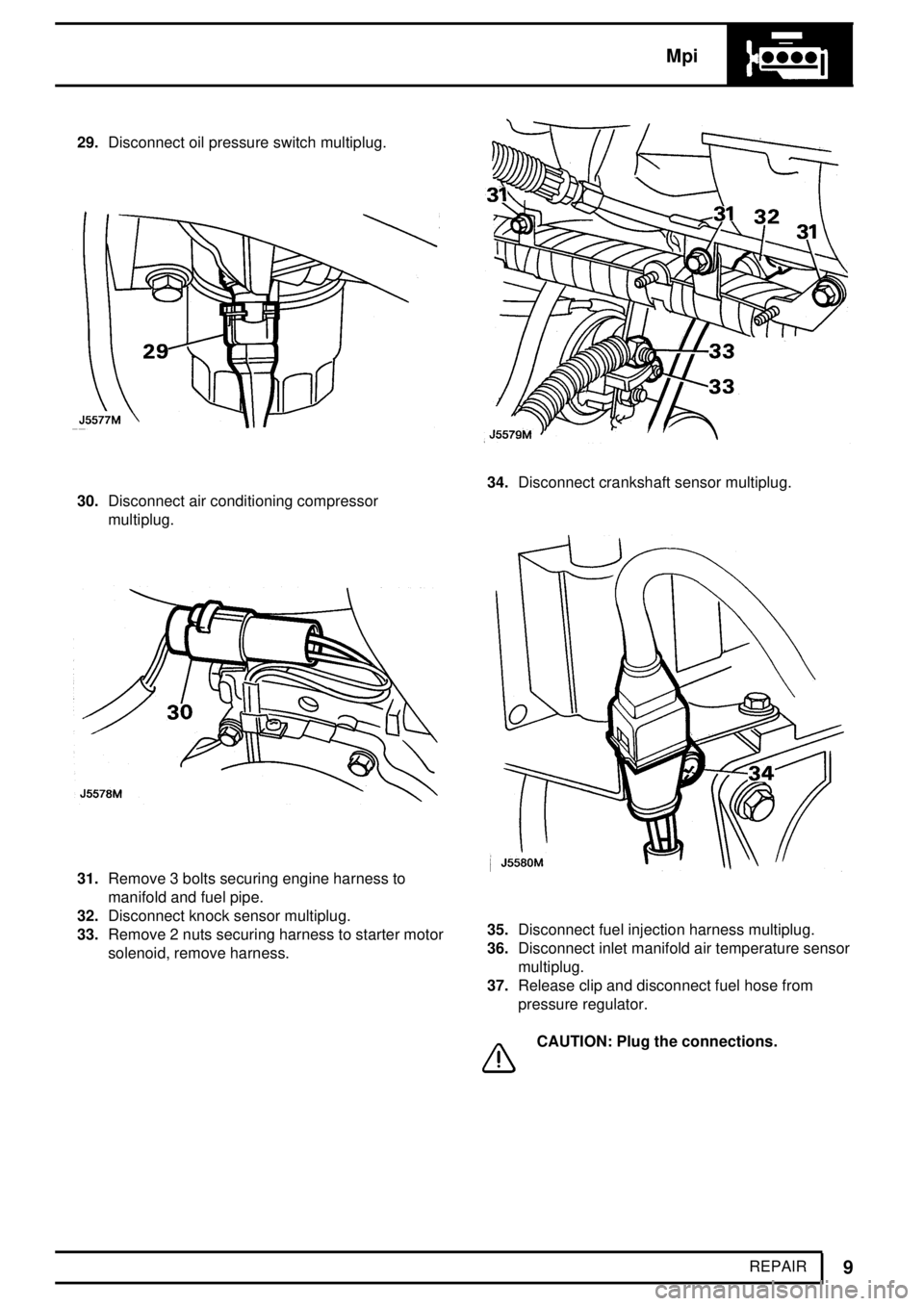

Mpi

9

REPAIR 29.Disconnect oil pressure switch multiplug.

30.Disconnect air conditioning compressor

multiplug.

31.Remove 3 bolts securing engine harness to

manifold and fuel pipe.

32.Disconnect knock sensor multiplug.

33.Remove 2 nuts securing harness to starter motor

solenoid, remove harness.

34.Disconnect crankshaft sensor multiplug.

35.Disconnect fuel injection harness multiplug.

36.Disconnect inlet manifold air temperature sensor

multiplug.

37.Release clip and disconnect fuel hose from

pressure regulator.

CAUTION: Plug the connections.

Page 171 of 873

Mpi

13

REPAIR 19.Connect crankshaft sensor, knock sensor, air

conditioning compressor, fuel injector harness,

inlet manifold air temperature and fuel

temperature sensor multiplugs.

20.Connect fuel hose to pressure regulator and

secure with clip.

21.Fit and tighten fuel pipe to fuel rail union.

22.Connect multiplugs to throttle housing.

23.Connect vacuum hose to manifold.

24.Connect oil pressure switch multiplug.

25.Connect brake servo hose to manifold, secure

with clip.

26.Connect throttle cable to cam.

27.Position engine harness and connect breather

hose to inlet manifold, secure with clip.

28.Connect coolant temperature sensor multiplugs,

secure harness with cable tie.

29.Connect oxygen sensor multiplug, secure

harness with cable tie.

30.Connect alternator harness.

31.Connect heater hose to heater rail and secure

with clip.

32.Connect hose to coolant pump and secure with

clip.

33.Connect inlet hose to power steering pump and

secure with clip.

34.Fit and tighten outlet pipe union to power

steering pump.

35.Connect bypass and top hose, secure with clip.

36.Connect air cleaner to throttle housing hose and

secure with clip.

37.Remove engine lifting bracket.

38.Position spark plug cover and secure with

screws.

39.Fill engine with oil.

40.Fit bonnet [hood].

See CHASSIS AND BODY,

Repair, Bonnet [Hood]

41.Fit radiator.See COOLING SYSTEM, Repair,

Radiator - Mpi

42.Adjust throttle cable.See FUEL SYSTEM,

Adjustment, Throttle Cable Adjustment

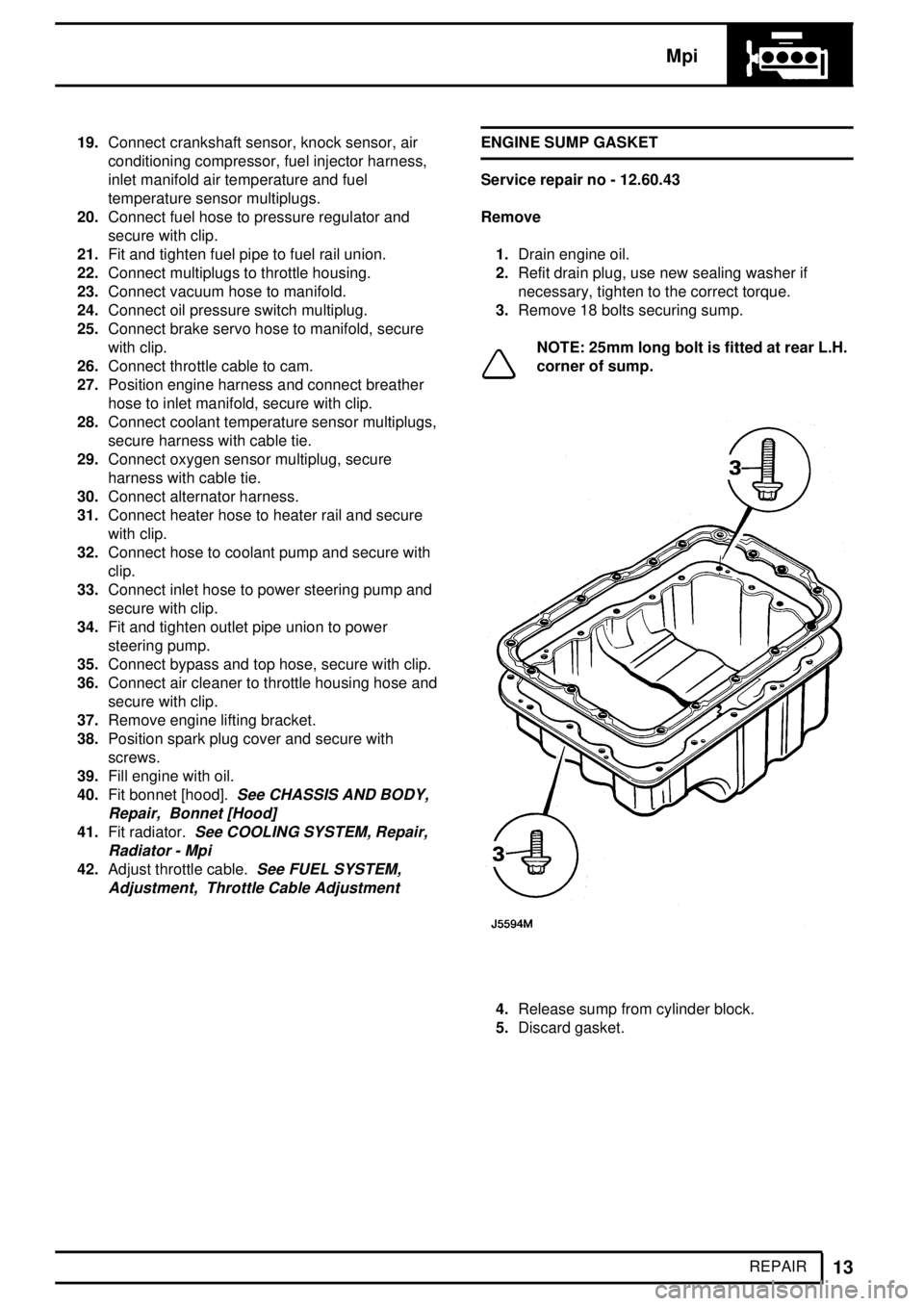

ENGINE SUMP GASKET

Service repair no - 12.60.43

Remove

1.Drain engine oil.

2.Refit drain plug, use new sealing washer if

necessary, tighten to the correct torque.

3.Remove 18 bolts securing sump.

NOTE: 25mm long bolt is fitted at rear L.H.

corner of sump.

4.Release sump from cylinder block.

5.Discard gasket.

Page 172 of 873

12ENGINE

14

REPAIR Refit

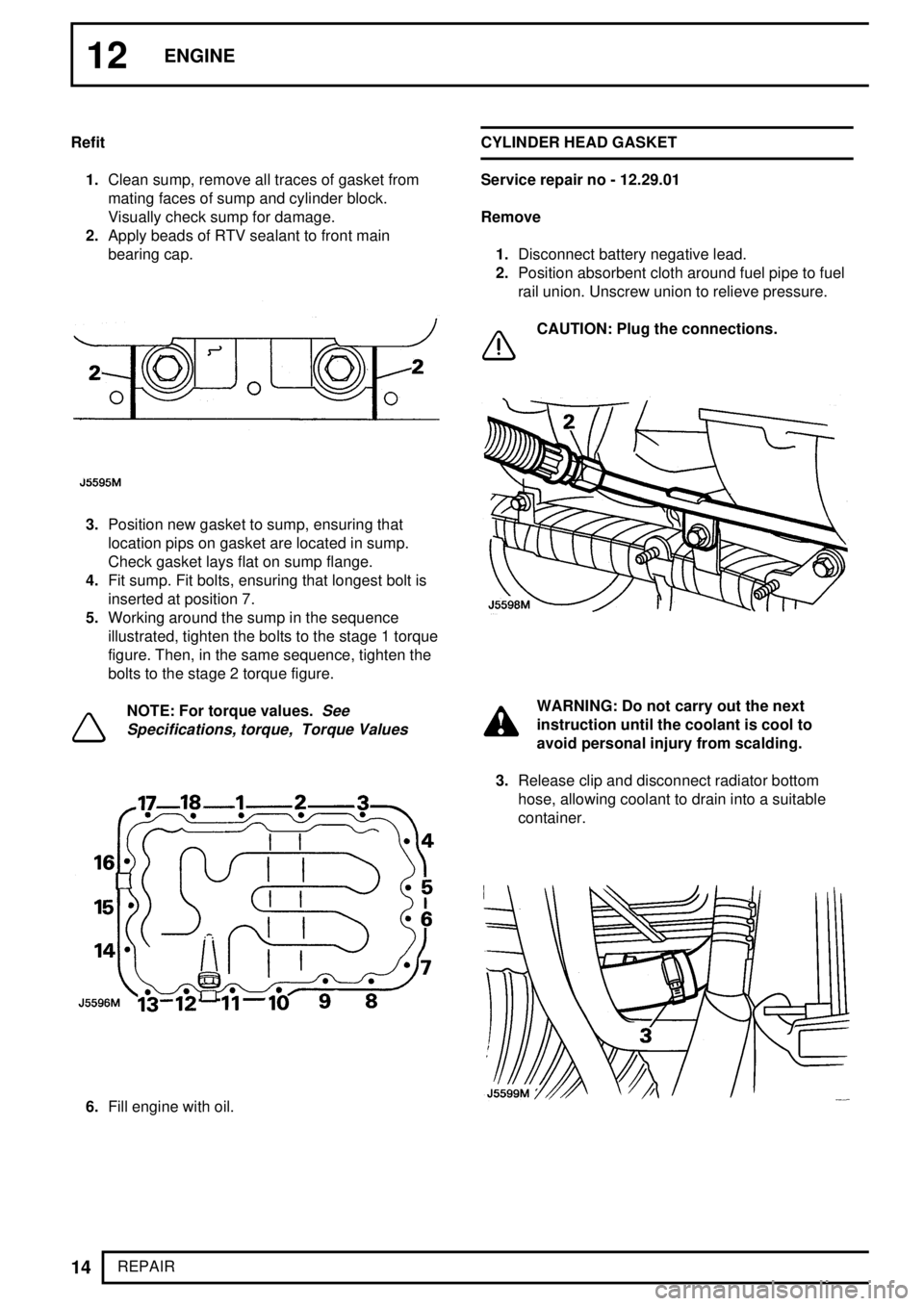

1.Clean sump, remove all traces of gasket from

mating faces of sump and cylinder block.

Visually check sump for damage.

2.Apply beads of RTV sealant to front main

bearing cap.

3.Position new gasket to sump, ensuring that

location pips on gasket are located in sump.

Check gasket lays flat on sump flange.

4.Fit sump. Fit bolts, ensuring that longest bolt is

inserted at position 7.

5.Working around the sump in the sequence

illustrated, tighten the bolts to the stage 1 torque

figure. Then, in the same sequence, tighten the

bolts to the stage 2 torque figure.

NOTE: For torque values.See

Specifications, torque, Torque Values

6.Fill engine with oil.CYLINDER HEAD GASKET

Service repair no - 12.29.01

Remove

1.Disconnect battery negative lead.

2.Position absorbent cloth around fuel pipe to fuel

rail union. Unscrew union to relieve pressure.

CAUTION: Plug the connections.

WARNING: Do not carry out the next

instruction until the coolant is cool to

avoid personal injury from scalding.

3.Release clip and disconnect radiator bottom

hose, allowing coolant to drain into a suitable

container.

Page 182 of 873

Mpi

1

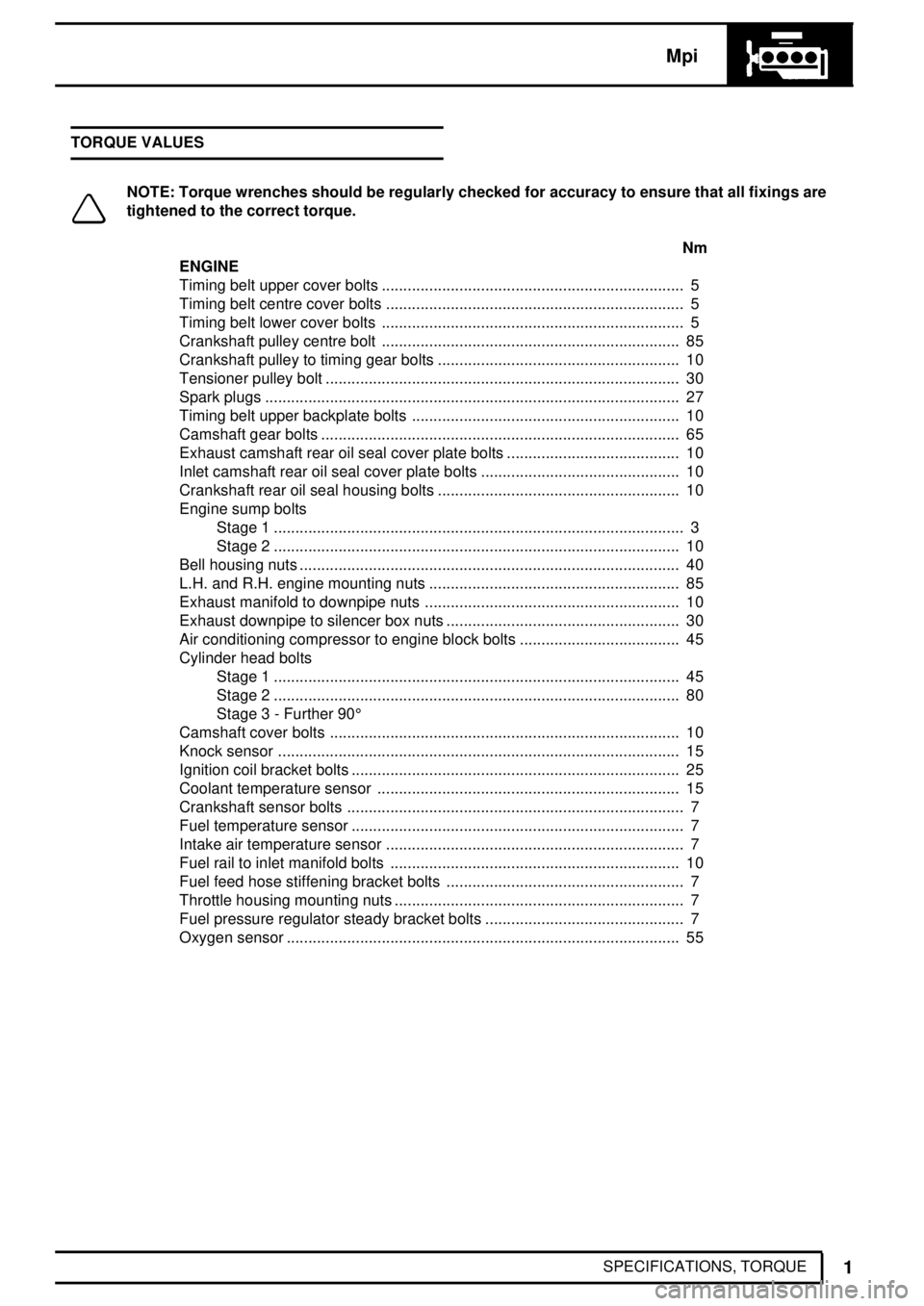

SPECIFICATIONS, TORQUE TORQUE VALUES

NOTE: Torque wrenches should be regularly checked for accuracy to ensure that all fixings are

tightened to the correct torque.

Nm

ENGINE

Timing belt upper cover bolts 5......................................................................

Timing belt centre cover bolts 5.....................................................................

Timing belt lower cover bolts 5......................................................................

Crankshaft pulley centre bolt 85.....................................................................

Crankshaft pulley to timing gear bolts 10........................................................

Tensioner pulley bolt 30..................................................................................

Spark plugs 27................................................................................................

Timing belt upper backplate bolts 10..............................................................

Camshaft gear bolts 65...................................................................................

Exhaust camshaft rear oil seal cover plate bolts 10........................................

Inlet camshaft rear oil seal cover plate bolts 10..............................................

Crankshaft rear oil seal housing bolts 10........................................................

Engine sump bolts

Stage 1 3...............................................................................................

Stage 2 10..............................................................................................

Bell housing nuts 40........................................................................................

L.H. and R.H. engine mounting nuts 85..........................................................

Exhaust manifold to downpipe nuts 10...........................................................

Exhaust downpipe to silencer box nuts 30......................................................

Air conditioning compressor to engine block bolts 45.....................................

Cylinder head bolts

Stage 1 45..............................................................................................

Stage 2 80..............................................................................................

Stage 3 - Further 90°

Camshaft cover bolts 10.................................................................................

Knock sensor 15.............................................................................................

Ignition coil bracket bolts 25............................................................................

Coolant temperature sensor 15......................................................................

Crankshaft sensor bolts 7..............................................................................

Fuel temperature sensor 7.............................................................................

Intake air temperature sensor 7.....................................................................

Fuel rail to inlet manifold bolts 10...................................................................

Fuel feed hose stiffening bracket bolts 7.......................................................

Throttle housing mounting nuts 7...................................................................

Fuel pressure regulator steady bracket bolts 7..............................................

Oxygen sensor 55...........................................................................................