check oil LAND ROVER DISCOVERY 1995 Owner's Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 295 of 873

19FUEL SYSTEM

12

REPAIR Refit

15.Ensure locations on fuel pressure regulator and

fuel rail are clean.

16.Fit new spacer ring and 'O' ring to fuel pressure

regulator. Lubricate 'O' ring with silicone grease.

17.Fit pressure regulator assembly to fuel rail.

18.Secure regulator connecting pipe in clip.

19.Secure with bolts. Tighten to

10 Nm.

20.Align ignition coil bracket to inlet manifold studs.

21.Secure ignition coil bracket and fuel rail to inlet

manifold with nuts. Tighten to

8 Nm.

22.Remove plugs.

23.Connect return pipe to regulator connecting pipe.

Secure with clip.

24.Connect vacuum hose to fuel pressure regulator.

25.Remove cloth.

26.Reconnect battery negative lead.

27.Start engine. Check for leaks around fuel

pressure regulator, fuel feed and fuel return

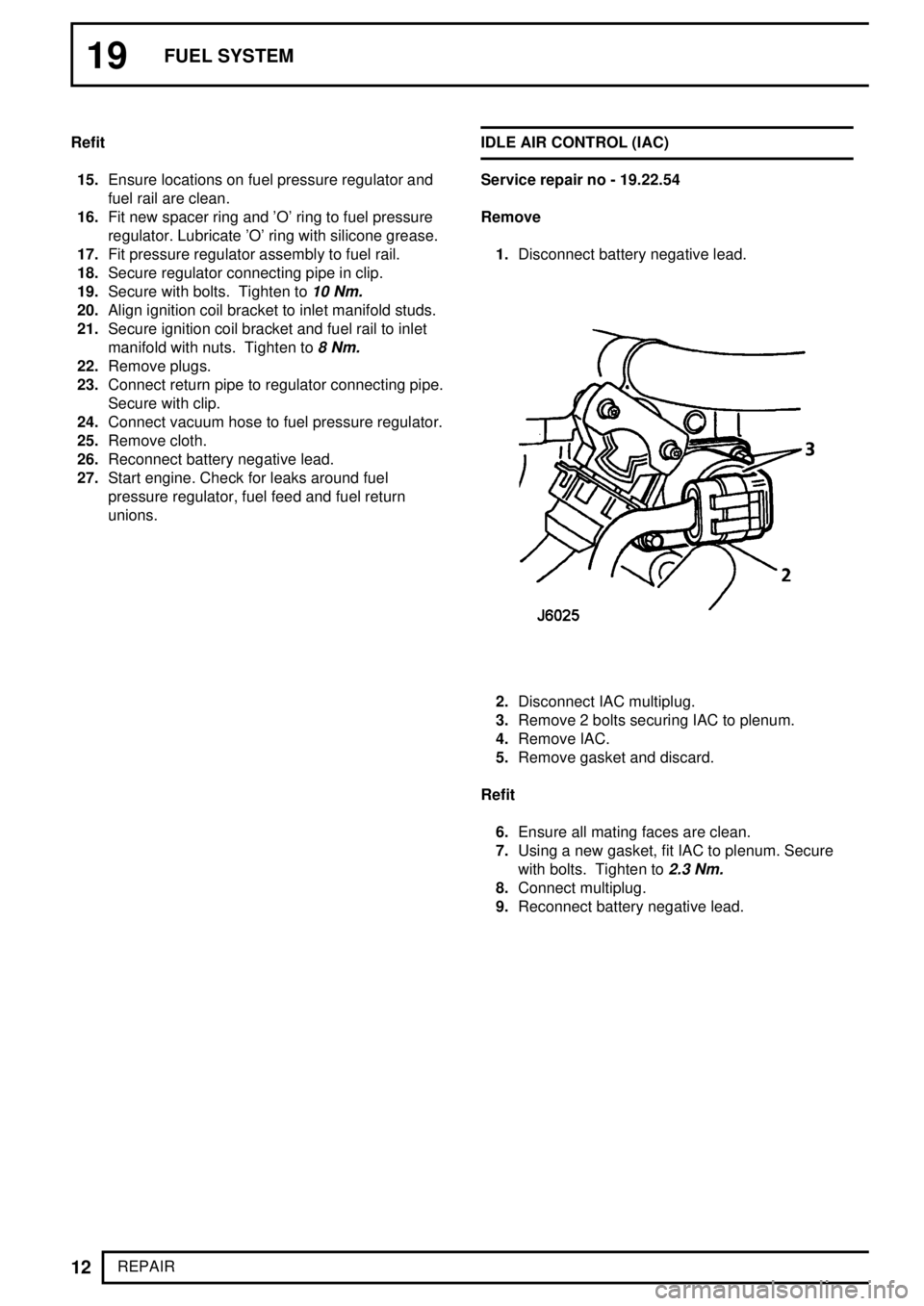

unions.IDLE AIR CONTROL (IAC)

Service repair no - 19.22.54

Remove

1.Disconnect battery negative lead.

2.Disconnect IAC multiplug.

3.Remove 2 bolts securing IAC to plenum.

4.Remove IAC.

5.Remove gasket and discard.

Refit

6.Ensure all mating faces are clean.

7.Using a new gasket, fit IAC to plenum. Secure

with bolts. Tighten to

2.3 Nm.

8.Connect multiplug.

9.Reconnect battery negative lead.

Page 316 of 873

19FUEL SYSTEM

4

DESCRIPTION AND OPERATION

Injectors

The four fuel injectors are fitted between the

pressurised fuel rail and inlet manifold. Each injector

comprises of a solenoid operated needle valve and a

specially designed nozzle to ensure good fuel

atomisation.

Engine coolant temperature sensor

The coolant temperature sensor is mounted in the

thermostat housing and is immersed in the engine

coolant. The sensor is a resistive device in which the

resistance varies with temperature

Throttle housing

The throttle housing is attached to the inlet manifold

via a rubber sandwich plate and incorporates a throttle

disc which is connected to the throttle pedal via the

throttle lever and a cable.

There are two breather pipes; one either side of the

throttle disc. When the engine is running with the

throttle disc open, both pipes are subject to manifold

depression and draw crankcase fumes into the

manifold. When the throttle disc is closed, only the

pipe on the inlet manifold side of the disc is subject to

manifold depression. This pipe incorporates a

restrictor to prevent engine oil being drawn into the

engine by the substantially greater manifold

depression.

Also incorporated in the throttle housing are the

throttle potentiometer and stepper motor.

Throttle potentiometer

The throttle potentiometer is mounted in front of the

throttle housing and is directly coupled to the throttle

disc shaft.

Three wires connect the throttle potentiometer to the

ECM; a 5 volt supply to the potentiometer, an earth

return to the ECM and an output voltage to the ECM

which indicates the rate of throttle disc movement.

Stepper motor

The stepper motor is contained within the throttle

housing and operates a cam and push rod via a

reduction gear. The push rod is in direct contact with

the throttle lever and moves the throttle disc to control

idle and fast idle speed. The stepper motor maximum

movement is 3.75 revolutions accomplished in steps

of 7.5°. The reduction gear converts this into 180°of

cam movement.

The throttle lever has a throttle position setting screw

which rests on the stepper motor operating pin when

the throttle pedal is released and is used to set the

relationship between engine speed and stepper motor

position.

In the side of the throttle housing is a throttle air

bypass bleed screw to provide easier and more

sensitive setting of the stepper motor position at idle.

The stepper motor position is checked using Testbook

and should be within the range of 20 to 40 steps when

the engine is run in. If it is identified as being outside

this range it can be adjusted to within range by turning

the throttle air bypass bleed screw. It is important to

follow Testbook setting procedure when adjusting this

screw to prevent mismatching of throttle body

settings. This ensures that the stepper motor is at the

optimum position within its range for providing further

movement to compensate for changes in engine load

or temperature in accordance with signals from the

ECM

NOTE: The stepper motor and throttle

position setting screws must only be

adjusted when Testbook identifies the

requirement.

Page 350 of 873

Tdi

1

FAULT DIAGNOSIS ENGINE OVERHEATING

Before conducting any cooling system diagnosis:

See

Description and operation, Engine Cooling

1.Is coolant level correct?

NO - Allow engine to cool, top up level to

expansion tank seam.

YES - Continue.

2.Is drive belt tension correct?

NO -

See ENGINE, Repair, Compressor

Drive Belt

YES - Continue.

3.Is coolant in radiator frozen?

YES - Slowly thaw and drain system.

See

Adjustment, Coolant

NO - Continue.

4.Is air flow through radiator restricted or blocked?

YES - Apply air pressure from engine side of

radiator to clear obstruction.

NO - Continue.

5.Are there any external leaks, from water pump,

engine gaskets, fast idle thermostat or the heater

unit?

YES - Investigate and rectify.

See Adjustment,

Coolant

NO - Continue.

6.Are fan blades fitted correct way round, concave

side towards engine?

NO - Rectify.

YES - Continue

7.Is viscous unit operating correctly?

See

Description and operation, Viscous Fan

NO - Renew.See Repair, Viscous

Coupling, Fan Blades, Pulley and Fan

Cowl

YES - Carry out a pressure test on radiator cap

and system. Check thermostat type,

operation and correct fitting.

See Repair,

Thermostat

If pressure test leads you to suspect coolant

leakage across gaskets, go to check 10,

otherwise: Continue.8.Are the air conditioning fans operating correctly?

See Electrical Trouble Shooting Manual.

NO - Rectify.

YES - Continue.

9.Is temperature sender and gauge giving

accurate readings?

NO - Sustitute parts and compare readings.

YES - Continue.

10.Carry out cylinder pressure test to determine if

pressure is leaking into cooling system causing

over pressurising and loss of coolant.

If problem is not diagnosed, check the coolant system

for engine oil contamination and engine lubrication

system for coolant contamination.

If only the coolant system is contaminated suspect a

cylinder head gasket.

If both systems are contaminated, suspect the

radiator.

If only the lubrication system is contaminated with

coolant, suspect leakage past cylinder liner seals or

cylinder head gasket.

Page 354 of 873

26COOLING SYSTEM

2

REPAIR WATER PUMP

Service repair no - 26.50.01

Remove

WARNING: Disconnect battery negative

terminal to prevent engine being started

before removing drive belts.

1.Drain engine cooling system.

See Adjustment,

Coolant

2.Remove top hose radiator to thermostat.

3.Remove top hose intercooler to induction

manifold.

4.Slacken water pump and power steering pump

pully retaining bolts.

5.Remove drive belt.

6.Remove centre nut from belt tensioner.

7.Manoeuvre pulley upwards and withdraw

tensioner from retaining stud.

8.Disconnect hose thermostat to bottom hose,

release hose from clip on water pump and move

aside.

9.Remove water pump pulley.

10.Remove power steering pump pulley.

11.Remove 8 bolts securing water pump, noting

location of 3 through bolts.

12.Withdraw pump and gasket, clean all gasket

material from mating surfaces.

Refit

13.Refit water pump in reverse order to removal

using new gasket.RADIATOR

Service repair no - 26.40.01

Remove

1.Drain cooling system.

See Adjustment,

Coolant

2.Disconnect radiator top hose.

3.Remove fan blade assembly.

4.Remove cowl.

5.Disconnect engine oil cooler connections and

turbo intercooler connections from radiator ends.

NOTE: Oil spillage will occur when

connections are loosened. Blank off

exposed oil connections.

6.Disconnect expansion tank bleed hose from

radiator.

7.Remove radiator securing brackets from each

side.

8.Remove radiator unit by lifting from its location.

Check condition of rubber mounting pads.

Refit

9.Check radiator sealing strips are securely

located.

10.Transfer oil cooler adaptors if fitting new radiator.

11.Reverse removal procedure. Tighten oil cooler

connections to

30 Nmbefore fitting fan blades

and cowl.

12.Check all connections for leaks.

Page 360 of 873

V8i

1

FAULT DIAGNOSIS ENGINE OVERHEATING

Before conducting any cooling system diagnosis:

See

Description and operation, Engine Cooling

1.Is coolant level correct?

NO - Allow engine to cool, top up level to

expansion tank seam.

YES - Continue.

2.Is drive belt tension correct?

NO -

See ENGINE, Repair, Drive Belt -

Check Tension

YES - Continue.

3.Is ignition timing correct?

NO -

See ELECTRICAL, Adjustment,

Ignition Timing

YES - Continue.

4.Is coolant in radiator frozen?

YES - Slowly thaw and drain system.

See

Adjustment, Coolant Requirements

NO - Continue.

5.Is air flow through radiator restricted or blocked?

YES - Apply air pressure from engine side of

radiator to clear obstruction.

NO - Continue.

6.Are there any external leaks, from water pump,

engine gaskets or the heater unit?

YES - Investigate and rectify.

See Adjustment,

Coolant Requirements

NO - Continue.

7.Are fan blades fitted correct way round, concave

side towards engine?

NO - Rectify.

YES - Continue.8.Is viscous unit operating correctly?

See

Description and operation, Viscous Fan

NO - Renew.See Repair, Viscous

Coupling, Fan Blades, Pulley and Fan

Cowl

YES - Carry out a pressure test on radiator cap

and system. Check thermostat type,

operation and correct fitting

See Repair,

Thermostat

If pressure test leads you to suspect coolant

leakage across gaskets, go to check 11,

otherwise: Continue.

9.Are the air conditioning fans operating correctly?

See Electrical Trouble Shooting Manual.K5

NO - Rectify.

YES - Continue.

10.Is temperature sender and gauge giving

accurate readings?

NO - Substitute parts and compare readings.

YES - Continue.

11.Carry out cylinder pressure test to determine if

pressure is leaking into cooling system causing

over pressurising and loss of coolant.

If problem is not diagnosed, check the coolant system

for engine oil contamination and engine lubrication

system for coolant contamination.

If the coolant only, or both systems are contaminated,

suspect cylinder head gaskets or radiator.

If only the lubrication stystem is contaminated with

coolant, suspect inlet manifold or front cover gaskets.

Page 367 of 873

26COOLING SYSTEM

4

REPAIR RADIATOR

Service repair no - 26.40.01

Remove

1.Drain cooling system.

See Adjustment,

Coolant

2.Remove viscous coupling and fan assembly.

See Viscous Coupling, Fan Blades, Pulley

and Fan Cowl

3.Release 2 clips and remove fan cowl.

4.Disconnect radiator top hoses.

5.Disconnect four transmission and engine oil

cooler connections to radiator end tanks. Note oil

spillage will occur when connections are

loosened. Blank off exposed oil connections.

6.Disconnect transmission oil temperature sensor.

7.Remove radiator securing brackets from each

side.

8.Remove radiator unit by lifting from its location.

Check condition of rubber mounting pads.Refit

9.Reverse removal procedure.

10.Clean unions and apply sealant.

11.Lubricate new 'O' rings before fitting.

12.Check radiator sealing strips are securely

located.

13.Transfer oil cooler adaptors if fitting new radiator.

14.Ensure that oil cooler connections are tightened

to

30 Nm.before fitting fan blades and cowl.

15.Clean coolant/oil spillage from vehicle.

16.Check all connections for coolant/oil leaks.

Page 370 of 873

V8i

1

SPECIFICATIONS, TORQUE TORQUE VALUES

NOTE: Torque wrenches should be regularly checked for accuracy to ensure that all fixings are

tightened to the correct torque.

Nm

Oil cooler pipes 30..........................................................................................

Radiator filler plug (plastic) 6.........................................................................

Page 380 of 873

30MANIFOLD AND EXHAUST SYSTEM

4

REPAIR EXHAUST MANIFOLD - Tdi

Service repair no - 30.15.10

Remove

1.Disconnect battery negative lead.

2.Remove heat shield from rear of air intake

manifold.

3.Release dip stick tube from cylinder block.

4.Disconnect the intake hose from the manifold.

5.Remove the two bolts and two nuts securing the

intake manifold to the cylinder head and

withdraw the inlet manifold.

6.Remove air filter inlet pipe to turbo unit.

7.Remove intercooler pipe from turbo to

intercooler.

8.Disconnect the EGR pipe from the inlet manifold

hose.

9.Remove the three fixings at the exhaust pipe

flange.

10.Release the turbo charger oil pipes from the

cylinder block.

11.Remove the turbo boost pipes.

12.Remove seven bolts securing the exhaust

manifold, release the heater rail and remove the

manifold gasket, complete with turbo unit.

13.Remove four bolts and disconnect diaphragm

rod from manifold, and remove turbo charger if

necessary.

Refit

14.Reverse removal procedure. 1 to 12. Use a new

manifold and exhaust flange gaskets.

15.Reconnect battery negative lead. Start engine

and check for leaks.

Page 391 of 873

33CLUTCH

2

FAULT DIAGNOSIS FAULT/SYMPTOM CHART

Symptoms

Slip Spin/Drag Judder/Fierce Fault Item

* * * Worn or oil on clutch linings 2

* * * Mechanical damage45678

* * Distorted clutch plate 2

* Failed or air in hydraulic system 12 13

* * Primary shaft tight fit in crankshaft bush 15 17

* Clutch splines sticking 2 15

* Weak clutch plate springs or insecure/worn

engine/gearbox mountings6

* Insecure/worn propeller shafts

* Insecure/worn suspension components/rubber

bushes

For items refered to in this chart.See Description and operation, Description

CLUTCH NOISE - MECHANICAL FAULTS

Noise from clutch or gearbox in neutral, which

disappears when clutch is depressed.

Suspect gearbox input/primary shaft bearings.

See MANUAL GEARBOX, Fault diagnosis,

Manual Gearbox

- Noise from gearbox in neutral, which

disappears when clutch is depressed

Noise from clutch or gearbox in neutral, which

changes tone or becomes worse when the clutch

is depressed.

Suspect worn release bearing.

Knocking/rattling from clutch or gearbox in

neutral, which is reduced or disappears when the

clutch is depressed.

Suspect worn/weak release lever retainer or

clutch unit.

Noise from clutch or gearbox in neutral, which

disappears when clutch is depressed.

Suspect gearbox fault.

See MANUAL GEARBOX, Fault diagnosis,

Manual Gearbox

- Noise from gearbox in neutral, which

disappears when clutch is depressed.HYDRAULIC FAULTS

Unable to dis-engage clutch, little or no pedal

resistance.

1.Check condition, specification and level of fluid.

2.Check pipes and cylinders for leaks.

3.Check that air vent in reservoir lid is clear.

Suspect faulty master cylinder if no fluid leaks

present.

See Repair, Master Cylinder

Spongy pedal operation

1.Check condition, specification and level of fluid.

2.Check that air vent in reservoir lid is clear.

Suspect air in fluid.

See Repair, Bleed Hydraulic System

Clutch is difficult to dis-engage and/or does not

immediately re-engage when pedal is released.

1.Check condition, specification and level of fluid.

2.Check that air vent in reservoir lid is clear.

Suspect pedal pivot, master cylinder or slave

cylinder seizure.

See Repair, Master Cylinder

Page 405 of 873

R380

3

REPAIR Assembling transfer gearbox to main gearbox

45.Clean extension housing and transfer gearbox

mating faces.

46.Ensuring loose upper dowel is fitted, hoist

transfer gearbox into position.

47.Fit and tighten nut and bolts to

34Nm.

48.Connect high/low operating rod, fit and tighten

locknut.

49.Fit link to differential lock lever and secure with 2

clips

50.Align lever to high/low shaft, position washer, fit

bolt and new Nyloc nut. Tighten to

2Nm.

51.Position breather pipes, secure pipe unions

using new sealing washers. Tighten unions to

15Nm.

Fitting transfer gearbox and main gearbox

assembly to engine

52.Position transmission assembly to hoist cradle.

53.Clean bell housing and engine mating faces.

54.Temporarily fit gear lever and select any gear in

main gearbox to facilitate entry of gearbox input

shaft.

55.Position and raise hoist, and fit transmission to

engine whilst keeping wires and pipes clear to

prevent trapping.

56.Fit and tighten nuts securing transmission to

engine.

57.Connect reverse lamp switch connectors and

differential lock switch connectors.

58.Secure breather pipes to harness with clips.

59.Position temporary support.

60.Remove 2 bolts securing lifting cradle to

transmission and remove hoist. Apply Loctite

290 to bolts and refit bolts.

61.Position cross-member, loosely fit nuts and bolts

securing cross-member mountings to

transmission.62.Raise transmission, align cross-member and

loosely fit nuts and bolts securing cross-member

to chassis.

63.Tighten all securing nuts and bolts. Remove

supporting jack from under sump.

64.Remove temporary support.

65.Fit handbrake cable through transmission tunnel

and secure gaiter.

66.Connect speedometer cable to transfer gearbox.

67.Line up marks and connect front and rear

propeller shafts.

68.Clean spacer, clutch slave cylinder and gearbox

mating faces.

69.Position spacer and slave cylinder, fit bolts.

Tighten to

25Nm.

70.Untie intermediate exhaust pipe(s) and refit

exhaust front pipe(s).

See MANIFOLD AND

EXHAUST SYSTEM, Repair, Exhaust System

Complete

71.Refill main gearbox and transfer gearbox with oil.

See SECTION 10, Maintenance, Under

Vehicle Maintenance

72.Lower ramp [hoist].

73.Fit fan cowl, fit and tighten bolts.

74.Align breather pipe clip to cylinder block, fit and

tighten bolts.

75.Fit handbrake cable adjuster and secure with 'C'

clip.

76.Align cable trunnion to handbrake lever, fit clevis

pin and secure with clip.

77.Check handbrake adjustment.

See SECTION

10, Maintenance, Vehicle Interior

78.Fit upper gear lever, fit and tighten bolt.

79.Fit gear selector lever and high/low selector

lever draft excluders.

80.Position draft excluder clamp rings, fit and

tighten screws.

81.Refit sound insulation.

82.Refit centre console.

See CHASSIS AND

BODY, Repair, Centre Console

83.Connect battery earth lead.