wheel bolts LAND ROVER DISCOVERY 1995 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 618 of 873

70BRAKES

16

REPAIR 13.Apply brake fluid to new seal. Fit seal into

groove in bore. When seal is seated it feels

raised to touch at edge furthest away from

mouth of bore.

14.Coat piston with brake fluid. Insert it squarely

into bore. Do not tilt piston during insertion and

leave 8mm projecting from bore.

15.Coat a new wiper seal with brake fluid and fit to

new seal retainer. Slide assembly, seal first, over

protruding piston into bore recess.

16.Using special tool LRT-70-500 - piston clamp,

press home seal retainer and piston.

Mounting inboard piston

17.Carry out same procedure as for removing and

fitting outboard piston and seals, instructions 8 to

16.

Fit calipers and pads to vehicle

18.Fit caliper to axle, tighten two bolts evenly to

82

Nm.

19.Connect brake pipe to caliper. Tighten to15Nm.

20.Remove clamp from flexible brake hose.

21.Insert pads and retaining springs, secure in

position with new retaining pins and spread

ends. Note correct position of retaining springs.

22.Bleed brake system.See Brake System Bleed

23.Press brake pedal firmly several times to locate

pads.

24.Fit road wheels, remove axle stands and finally

tighten road wheel nuts,

25.Road test vehicle. Note new brake pads require

'bedding-in', for several hundred miles before

brakes are at maximum efficiency.

PARKING BRAKE ADJUST

See SECTION 10,

Maintenance, Vehicle Interior

Page 664 of 873

SUPPLEMENTARY RESTRAINT SYSTEM

19

REPAIR

9.Press both operating buttons to deploy airbag

module.

10. DO NOTreturn to airbag module for 30 minutes.

11.Using gloves and face mask, remove airbag

module from tool, place airbag module in plastic

bag and seal bag.

12.Wipe down tool with damp cloth.

13.Transport deployed airbag module to designated

area for incineration.

NOTE: DO NOT transport airbag module in

the vehicle passenger compartment. DO

NOT re-use or salvage any parts of the

airbag system including steering wheel or

steering column.Passenger's Airbag Module

1.Carry out deployment tool self test.

2.Remove airbag module from fascia.

See

passenger's airbag module.

3.Position toolSMD 4082/6in vice, ensuring that

vice jaws grip tool above bottom flange to

prevent possibility of tool being forced upwards

from vice. Tighten vice.

4.Position bracketsSMD 4082/7to tool; lightly

tighten bolts.

Page 678 of 873

CHASSIS AND BODY

11

REPAIR

11.Remove the two bolts, spring and plain washers

securing the door frame to the edge of the door.

12.Lift out the door frame complete with glass and

remove to a suitable workbench.

13.Remove the tape and slide the glass out of the

door frame channel.

Refit

14.Reverse removal procedure.

NOTE: When refitting the door glass frame

ensure that it is adjusted to suit the door

opening before fully tightening the

securing bolts.REAR DOOR

Service repair no - 76.28.19

Remove

1.Remove the spare wheel from the exterior of the

door.

2.Remove the trim panel from inside the rear door.

See rear door trim panel.

3.Release the convoluted grommet from the door

post, expose the door harness connectors and

multiplugs and disconnect.

4.Remove the circlip and washer from the check

stay pivot on the body.

WARNING: Instruction 5 MUST BE carried

out with assistance.

5.Suitably support the door, remove the four bolts

securing the hinges to the door and with

assistance slide the door off the hinges.

Refit

6.Reverse removal procedure.

Page 697 of 873

76CHASSIS AND BODY

30

REPAIR

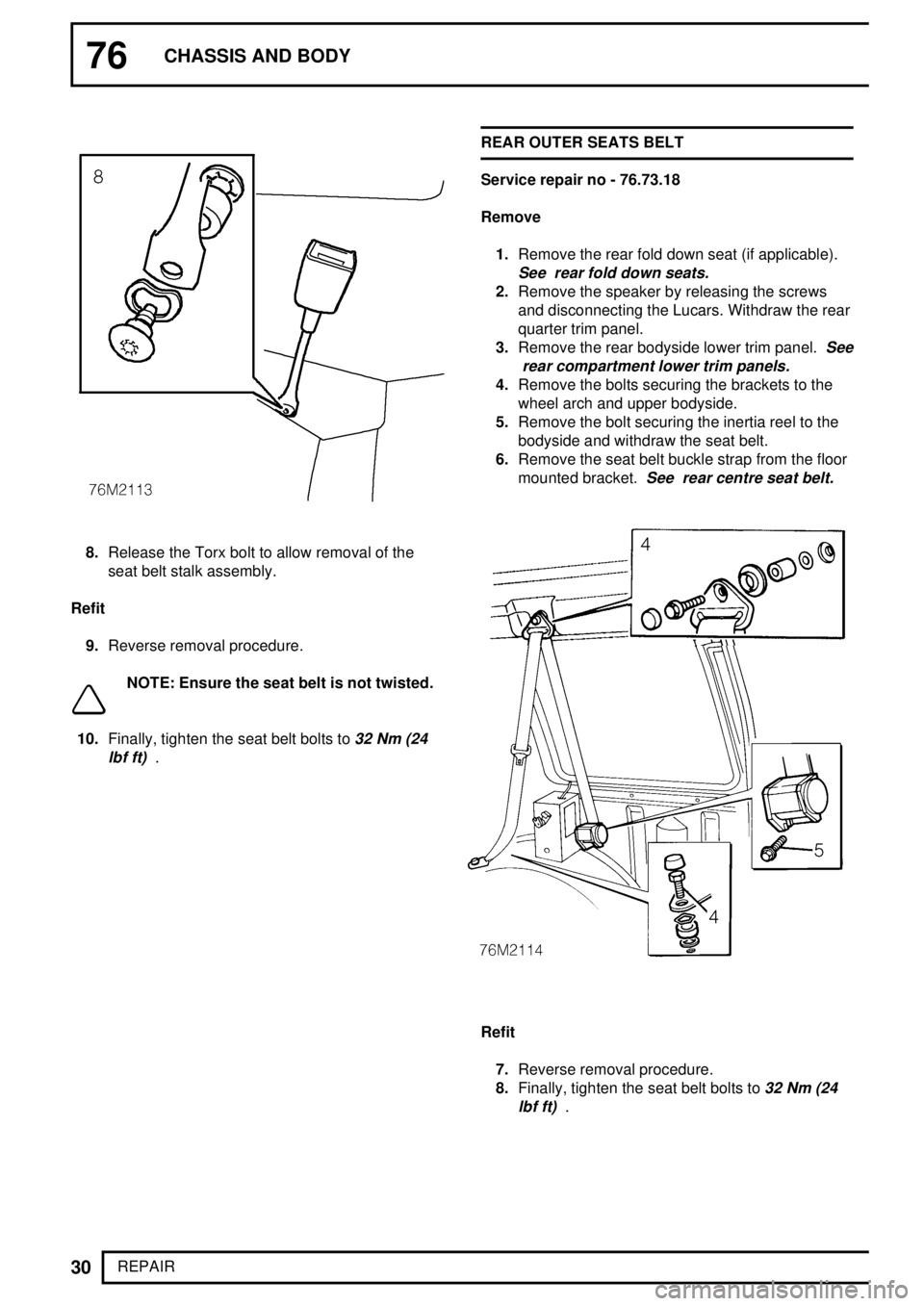

8.Release the Torx bolt to allow removal of the

seat belt stalk assembly.

Refit

9.Reverse removal procedure.

NOTE: Ensure the seat belt is not twisted.

10.Finally, tighten the seat belt bolts to

32 Nm (24

lbf ft)

.REAR OUTER SEATS BELT

Service repair no - 76.73.18

Remove

1.Remove the rear fold down seat (if applicable).

See rear fold down seats.

2.Remove the speaker by releasing the screws

and disconnecting the Lucars. Withdraw the rear

quarter trim panel.

3.Remove the rear bodyside lower trim panel.

See

rear compartment lower trim panels.

4.Remove the bolts securing the brackets to the

wheel arch and upper bodyside.

5.Remove the bolt securing the inertia reel to the

bodyside and withdraw the seat belt.

6.Remove the seat belt buckle strap from the floor

mounted bracket.

See rear centre seat belt.

Refit

7.Reverse removal procedure.

8.Finally, tighten the seat belt bolts to

32 Nm (24

lbf ft)

.

Page 759 of 873

82AIR CONDITIONING

4

FAULT DIAGNOSISFAULT CAUSE REMEDY

E.

NOISY

EXPANSION

VALVE

(steady hissing)1. Low refrigerant charge; evident by

bubbles in sight glass.1. Leak test. Repair or replace

components as required.

F.1. Expansion valve not operating 1. Refer to C-2, C-3, D-1

INSUFFICIENTproperly. and E.

COOLING2. Low refrigerant charge-evident 2. Refer to B-1 and E.

by bubbles in sight glass.

3. Compressor not pumping. 3. Refer to B-2 and B-3

G.1. Belt tension. 1. Adjust belt tension.

COMPRESSOR2. Excessive head pressure. 2. Refer to A-1 through

BELTA-4 and C-6.

SLIPPING3. Incorrect alignment of pulleys 3. Repair as needed.

or worn belt not riding properly.

4. Nicked or broken pulley. 4. Replace as needed.

5. Seized compressor. 5. Replace compressor.

1. Loose or missing mounting bolts. 1. Repair as necessary.

2. Broken mounting bracket. 2. Replace bracket.

3. Loose flywheel or clutch 3. Repair as necessary.

retaining bolt.

H.4. Rough idler pulley bearing. 4. Replace bearing.

ENGINE5. Bent, loose, or improperly 5. Repair as necessary.

NOISEmounted engine drive pulley.

AND/OR6. Defective compressor bearing. 6. Replace bearing.

VIBRATION7. Insecure mountings of 7. Repair as necessary.

accessories; generator, power

steering, air filter, etc.

8. Excessive head pressure. 8. Refer to A-1, A-2, A-3

A-4 and C-6.

9. Incorrect compressor oil level. 9. Refer to compressor Oil

Level Check.

HEATER AND AIR CONDITIONING - CIRCUIT

DIAGRAMS

1.For details of heating and air conditioning

electrics

See Electrical Trouble Shooting

Manual.

Page 777 of 873

82AIR CONDITIONING

12

REPAIR

7.Remove nut securing rear fold down seat

mounting frame to wheel arch.

8.Remove 5 bolts securing rear fold down seat

mounting frame.

NOTE: The rear fold down seat mounting

frame retaining nut is located in the LH

rear wheel arch.

9.Remove mounting frame.

10.Disconnect 2, main to rear air conditioning unit

harness multiplugs.

11.Remove 3 bolts securing evaporator/blower

motor assembly to body.

12.Release evaporator/blower motor assembly

pipes from body grommets.

13.Remove evaporator/blower motor assembly.Refit

14.Lubricate body grommets to aid fitment of

evaporator/blower motor assembly pipe unions.

15.Fit evaporator/blower motor assembly, feed pipe

unions through grommets and align to fittings.

16.Fit bolts securing evaporator/blower motor

assembly to body and tighten to

25 Nm.

17.Connect, main to rear air conditioning unit,

harness multiplugs.

18.Position and align rear fold down seat mounting

frame to fittings, fit nut and bolts and tighten to

25 Nm.

19.Lubricate NEW 'O' rings with refrigerant oil, and

fit to pipe unions.

20.Remove plugs, align unions, and tighten to;

High pressure pipe:

14 Nm

Low pressure pipe:22 Nm.

CAUTION: Use 2 spanners when loosening

or tightening air conditioning pipe unions.

21.Fit LH rear mud flap.

See CHASSIS AND

BODY, Repair, mud flap - rear - lh; Refit

22.Fit evaporator to alpine light duct.See

evaporator to alpine light duct; Refit

23.Evacuate and recharge air conditioning system.

See Adjustment, refrigerant recovery

recycling recharging

Page 797 of 873

WIPERS AND WASHERS

1

REPAIR WASHER RESERVOIR

Service repair no - 84.10.03.

Remove

1.Remove two bolts securing top of reservoir.

2.From underneath the wheelarch remove two

bolts securing base of reservoir.

3.Withdraw reservoir and disconnect tubing from

washer pumps and power wash.

4.Disconnect electrical leads from pumps.

Refit

5.Reverse removal procedure. 1 to 4.WASHER PUMP - WINDSCREEN, REAR WINDOW

OR POWER WASH

Service repair no - 84.20.21.

Remove

1.Remove washer reservoir.See Washer

reservoir

2.Disconnect washer tubing from pump.

3.Disconnect electrical leads from pump.

4.Pull top of pump away from its location in

reservoir and remove pump.

Note position of sealing gasket in reservoir.

Refit

5.Reverse removal procedure. 1 to 4.

Page 802 of 873

84WIPERS AND WASHERS

6

REPAIR Refit

16.Reverse removal procedure.

17.Fit wiper motor to support plate using new

sealing bushes at the motor spindle as

necessary.

18.When positioning assembled motor and support

plate use a new seal and bushes, if necessary.

REAR DOOR WIPER MOTOR

Service repair no - 84.35.12.

Remove

1.Disconnect battery negative lead.

2.Remove rear door trim panel.

3.Remove spare wheel.

4.Remove wiper arm and grommet.

5.Remove nut, plain washer and seal from drive

spindle.

6.From inside the door, disconnect wiper motor

leads from door harness at multi-plug.

7.Remove bolts securing wiper motor mounting

bracket and negative lead to inner door panel.

8.Withdraw motor spindle from outer door panel

and manoeuvre wiper motor from door casing

complete with the spindle spacer.

9.Remove two rubber mounted nuts securing

mounting bracket to motor and detach bracket.

Refit

10.Reverse removal procedure. 1 to 9.

NOTE: If a new wiper motor assembly has

been fitted, before fitting the wiper arm.

Reconnect battery negative lead. Operate

wiper motor to ensure that motor spindle is in

park position.

Page 866 of 873

86ELECTRICAL

46

REPAIR STARTER MOTOR - 4.0 V8

Service repair no - 86.60.01

Remove

1.Disconnect battery negative lead.

2.Raise vehicle on ramp.

3.Remove heated oxygen sensor from RH front

exhaust pipe.

See EMISSION CONTROL,

Repair, Heated Oxygen Sensor (HO2S) - 4.0

V8

4.Mark front propeller shaft and drive flanges for

assembly reference.

5.Remove 4 nuts and bolts securing propeller

shaft flange.

NOTE: Raise 1 front road wheel and rotate

propeller shaft to gain access to all

fixings.

6.Tie propeller shaft aside.

7.Position starter motor heat shield above motor.

See Starter Motor Heat Shield - 4.0 V8

8.Disconnect Lucar from solenoid.

9.Remove nut securing feed wires to starter

solenoid and disconnect from terminal.