heater LAND ROVER DISCOVERY 1999 Owner's Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 991 of 1529

SCREENS

76-4-2 REPAIRS

Windscreen

$% 76.81.01

Introduction

The following equipment is required:

lCutting wire and handles.

lKent cutting knife.

lGlazing knife.

lWindscreen repair kit.

lSealant applicator gun.

lSuction cups.

lA felt covered table or stand to support glass.

WARNING: Wear protective gloves when

handling glass, solvents and primers.

WARNING: Wear suitable eye protection when

removing and refitting glass.

WARNING: If glass has splintered, protect eyes

and operate demister blower to remove glass

from heater ducts. Use a vacuum cleaner to

remove glass from fascia, carpet and seats.Remove

1.Remove air intake plenum.

+ HEATING AND VENTILATION,

REPAIRS, Plenum Air Intake.

2.If fitted, disconnect screen heater multiplugs.

3.Remove top corner trim finishers from body.

4.Remove windscreen top finisher and discard.

5.Release interior mirror from slug and tie aside.

6.Fit protection to exterior body work adjacent to

screen.

7.Cover body panels adjacent to glass.

8.Cover heater ducts with masking tape.

9.Cover interior of vehicle with protective sheet.

Page 993 of 1529

SCREENS

76-4-4 REPAIRS

15.Apply a continuous bead of sealant to sealant

face on screen as shown.

16.With assistance, lift screen into place and align

to screen supports and tape. Ensure top

finisher is located into correct position. Lightly

press glass to fully seat sealer.

CAUTION: Do not apply heavy pressure to

the sides of the windscreen. Lightly press

windscreen from centre outwards until

edges are to required gap. Pushing sides

into position can bend windscreen and lead

to cracking in service.

17.Remove protective covers and tape.

18.Test sealer for leaks, apply additional sealer if

necessary. If water is used, allow sealer to dry

before testing. Spray water around glass and

check for leaks. Mark any area that leaks. Dry

glass and sealer then apply additional sealer.

19.Fit interior mirror to slug.

20.If applicable, connect screen heater multiplugs.

21.Fit air intake plenum.

+ HEATING AND VENTILATION,

REPAIRS, Plenum Air Intake.

CAUTION: A curing time of 6 hours is

desirable. During this time leave a window

open to ventilate the vehicle interior. If the

vehicle must be used before the curing time

has elapsed, do not drive at speed or slam

the doors with the windows closed.

CAUTION: Vehicles fitted with a passenger

airbag should not be driven for 24 hours.

Glass - body side - rear

$% 76.81.18

Introduction

The following equipment is required:

lCutting wire and handles.

lKent cutting knife.

lGlazing knife.

lWindscreen repair kit.

lSealant applicator gun.

lSuction cups.

lA felt covered table or stand to support glass.

WARNING: Wear protective gloves when

handling glass, solvents and primers.

WARNING: Wear suitable eye protection when

removing and refitting glass.

Remove

1.If fitted, disconnect coaxial cable from terminal

on glass.

2.Fit protection to exterior body work adjacent to

glass.

3.Cover body panels adjacent to glass.

4.Fit protection to internal trim adjacent to glass.

5.Cover interior of vehicle with protective sheet.

Page 1006 of 1529

SEATS

DESCRIPTION AND OPERATION 76-5-9

DESCRIPTION AND OPERAT ION

Heated seat component location

1Heater module2Seat heater switches

Page 1007 of 1529

SEATS

76-5-10 DESCRIPTION AND OPERATION

Heated seat block diagram (electric

seats)

1Passenger compartment fuse box

2Left seat heater switch

3Left seat heater module

4Left seat cushion heater element

5Left seat squab heater element 6Right seat heater switch

7Right seat heater module

8Right seat cushion heater element

9Right seat squab heater element

Page 1008 of 1529

SEATS

DESCRIPTION AND OPERATION 76-5-11

Description - heated seats

Heated seats

The heated seat system is available on both manual seats and electric seats. The electrical sub-system consists of

the following components:

lSeat heater switches.

lSeat heater elements.

lTemperature control unit (if electric seats are fitted).

lTemperature sensor (if electric seats are fitted).

lThermostat (if manual seats are fitted).

Seat heater switches

The seat heater switches supply an ignition feed to either the temperature control unit (vehicles with electric seats) or

directly to the seat heater elements (vehicles with manual seats). When a seat heater switch is operated, current flows

to the seat heater elements causing them to heat the seat.

The ignition feed comes from fuse 15 in the passenger compartment fuse box.

Seat heater elements

The seat heater elements are located in the seat cushion and squab. The cushion and squab heater elements are

wired in series. Total power consumption at 13.5 volts is approximately 115 Watts.

The cushion heater element has an input feed from the temperature control unit or heater switch and an output to the

squab heater element, which outputs to earth.

Page 1009 of 1529

SEATS

76-5-12 DESCRIPTION AND OPERATION

Temperature control unit

The temperature control unit is only fitted to vehicles with electric seats. Feed back of the seat temperature is via a

Negative Temperature Coefficient (NTC) sensor within the seat cushion. Resistance of this sensor changes with the

temperature of the seat cushion allowing the temperature control unit to lower or raise the voltage to the seat heater

elements to raise or lower their temperature.

An ignition feed is supplied via the seat heater switch. The temperature sensor supplies an input. Output is a supply

to the cushion heater element and an earth.

Thermostat

On vehicles with non electric seats, the temperature is controlled by a thermostat located in the seat cushion. The

thermostat interrupts the power supply when it reaches a pre-determined temperature.

Page 1010 of 1529

SEATS

DESCRIPTION AND OPERATION 76-5-13

Operation - heated seats

When the seat heater switch is operated, power is supplied to the heater elements in the seat, causing the seat to

heat up. On vehicles fitted with non electric seats, the thermostat switches the power supply to the heater elements

on and off. On vehicles fitted with electric seats, the temperature control unit senses seat temperature via the sensor

in the cushion and regulates voltage to the seat heater elements to maintain a constant temperature.

On both electric and non electric seats, the heater elements increase and then maintain the seat at a temperature

between 26 and 36 °C (79 and 97 °F).

Page 1017 of 1529

SEATS

76-5-20 REPAIRS

Cover - cushion - front seat

$% 78.30.01/81

Remove

1.Remove front seat.

+ SEATS, REPAIRS, Seat - front.

2.Place seat on a suitable work bench.

3.Remove 2 screws securing outer edge trim

casing to seat frame.

4.Remove trim casing.

5.Release inner edge trim casing from seat

frame.

6.Remove trim casing.

7.Position seat upside down on table.

8.Release clip securing front edge of cushion

cover to seat frame.

9.Release clips securing side edges of cushion

cover to seat frame. 10.Release clip securing lower edge of squab

cover to seat frame.

11.Remove 2 end clips securing rear edge of

cushion cover to seat frame.

12.Release main central clip securing rear edge of

cushion cover to seat frame.

13. Models with seat heaters: Disconnect seat

heater multiplug.

14.Release bonded rear edge of cushion from

seat frame.

15.Remove seat cushion and cover assembly.

16.Release outer edges of cover from cushion to

gain access to hog rings.

17.Remove 12 hog rings securing cover to

cushion.

18.Remove cover.

Page 1018 of 1529

SEATS

REPAIRS 76-5-21

Refit

1.Fit cover to cushion.

2.Fit and clamp hog rings securing cover to

cushion.

3.Fit outer edges of cover over cushion.

4.Fit cushion and cover assembly to seat frame.

5. Models with seat heaters: Connect seat

heater multiplug.

6.Secure rear edge of cushion cover with clip.

7.Fit end clips over rear edge of cushion cover.

8.Secure lower edge of squab cover to seat

frame.

9.Secure edges of cushion cover with clips.

10.Secure front edge of cushion cover with clip.

11.Position seat correct way up on work bench.

12.Secure inner edge trim casing to seat frame.

13.Fit outer edge trim casing to seat frame and

secure with screws.

14.Fit front seat.

+ SEATS, REPAIRS, Seat - front.

Heating element - cushion - front seat

$% 78.30.24

Remove

1.Remove front seat cushion cover.

+ SEATS, REPAIRS, Cover - cushion

- front seat.

2.Carefully release heating element from

cushion pad, ensuring adhesive does not tear

cushion pad.

Refit

1.Ensure cushion pad is free of adhesive.

2.Remove adhesive cover from new heating

element, position element and secure to

cushion pad.

3.Fit front seat cushion cover.

+ SEATS, REPAIRS, Cover - cushion

- front seat.

Page 1158 of 1529

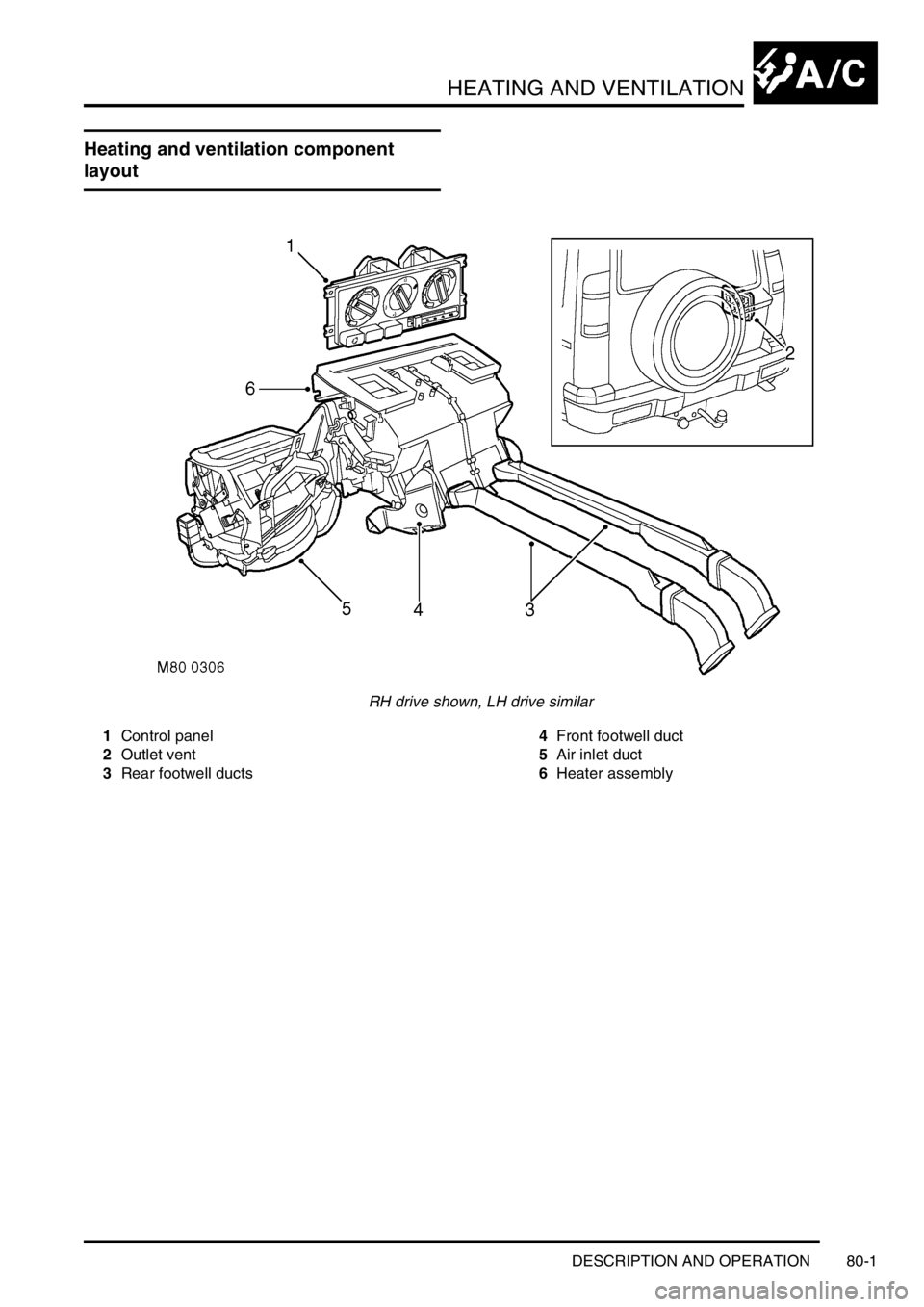

HEATING AND VENTILATION

DESCRIPTION AND OPERATION 80-1

HEATING A ND VENT ILATION DESCRIPTION AND OPERAT ION

Heating and ventilation component

layout

RH drive shown, LH drive similar

1Control panel

2Outlet vent

3Rear footwell ducts4Front footwell duct

5Air inlet duct

6Heater assembly