ignition LAND ROVER DISCOVERY 2002 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 353 of 1672

EMISSION CONTROL - V8

17-2-16 DESCRIPTION AND OPERATION

Fuel leak detection system (vacuum type) – NAS only

The advanced evaporative loss control system equipped with a vacuum type, fuel evaporation leak detection

capability is similar to the standard evaporative loss system, but also includes additional components to enable the

engine control module (ECM) to perform a fuel evaporation leak detection test. The system includes an EVAPs

canister and purge valve, and in addition, a canister vent solenoid (CVS) valve and a fuel tank pressure sensor.

The function of the CVS valve is to block the atmospheric vent side of the EVAP canister under the control of the ECM

so that an evaporation system leak check can be performed. The test is carried out when the vehicle is stationary and

the engine is running at idle speed. The system test uses the natural rate of fuel evaporation and engine manifold

depression. Failure of the leak check will result in illumination of the Malfunction Indicator Lamp (MIL).

The fuel evaporation leak detection is part of the On-Board Diagnostics (OBD) strategy and it is able to determine

vapour leaks from holes or breaks greater than 1 mm (0.04 in.) in diameter. Any fuel evaporation system leaks which

occur between the output of the purge valve and the connection to the inlet manifold cannot be determined using this

test, but these will be detected through the fuelling adaption diagnostics.

Fuel leak detection system (positive pressure type) – NAS only

The evaporative loss control system equipped with a positive pressure type, fuel evaporation leak detection capability

is similar to the vacuum type, but it is capable of detecting smaller leaks by placing the evaporation system under the

influence of positive air pressure. The system includes an EVAPs canister and purge valve, and in addition, a leak

detection pump comprising a motor and solenoid valve.

The solenoid valve contained in the leak detection pump assembly performs a similar function to the CVS valve

utilised on the vacuum type pressure test. The solenoid valve is used to block the atmospheric vent side of the EVAP

canister under the control of the ECM so that an EVAP system leak check can be performed. At the same time,

pressurised air from the pump is allowed past the valve into the EVAP system to set up a positive pressure. The test

is carried out at the end of a drive cycle when the vehicle is stationary and the ignition is switched off. The test is

delayed for a brief period (approximately 10 seconds) after the engine is switched off to allow any slosh in the fuel

tank to stabilise. Component validity checks and pressure signal reference checking takes a further 10 seconds before

the pressurised air is introduced into the EVAP system.

During reference checking, the purge valve is closed and the leak detection pump solenoid valve is not energised,

while the leak detection pump is operated. The pressurised air is bypassed through a restrictor which corresponds to

a 0.5 mm (0.02 in) leak while the current consumption of the leak detection pump motor is monitored.

The system test uses the leak detection pump to force air into the EVAP system when the purge valve and solenoid

valves are both closed (solenoid valve energised), to put the evaporation lines, components and fuel tank under the

influence of positive air pressure. Air is drawn into the pump through an air filter which is located in the engine

compartment.

The fuel leak detection pump current consumption is monitored by the ECM while the EVAP system is under pressure,

and compared to the current noted during the reference check. A drop in the current drawn by the leak detection pump

motor, indicates that air is being lost through holes or leaks in the system which are greater than the reference value

of 0.5 mm (0.02 in). An increase in the current drawn by the leak detection pump motor, indicates that the EVAP

system is well sealed and that there are no leaks present which are greater than 0.5 mm (0.02 in).

The presence of leakage points indicates the likelihood of hydrocarbon emissions to atmosphere from the

evaporation system outside of test conditions and the necessity for rectification work to be conducted to seal the

system. Failure of the leak check will result in illumination of the Malfunction Indicator Lamp (MIL).

C0637-9 Fuel tank pressure sensor (NAS vehicles

with vacuum type EVAP system leak

detection only)Output reference 5V

C0637-12 Analogue fuel level (NAS vehicles with

positive pressure type EVAP system leak

detection only)Input Analogue 0 - 5V

C0637-14 Fuel tank pressure sensor (NAS vehicles

with vacuum type EVAP system leak

detection only)Input signal Analogue 0 - 5V

C0637-20 MIL "ON" Output drive Switch to ground Connector / Pin No. Function Signal type Control

Page 361 of 1672

EMISSION CONTROL - V8

17-2-24 DESCRIPTION AND OPERATION

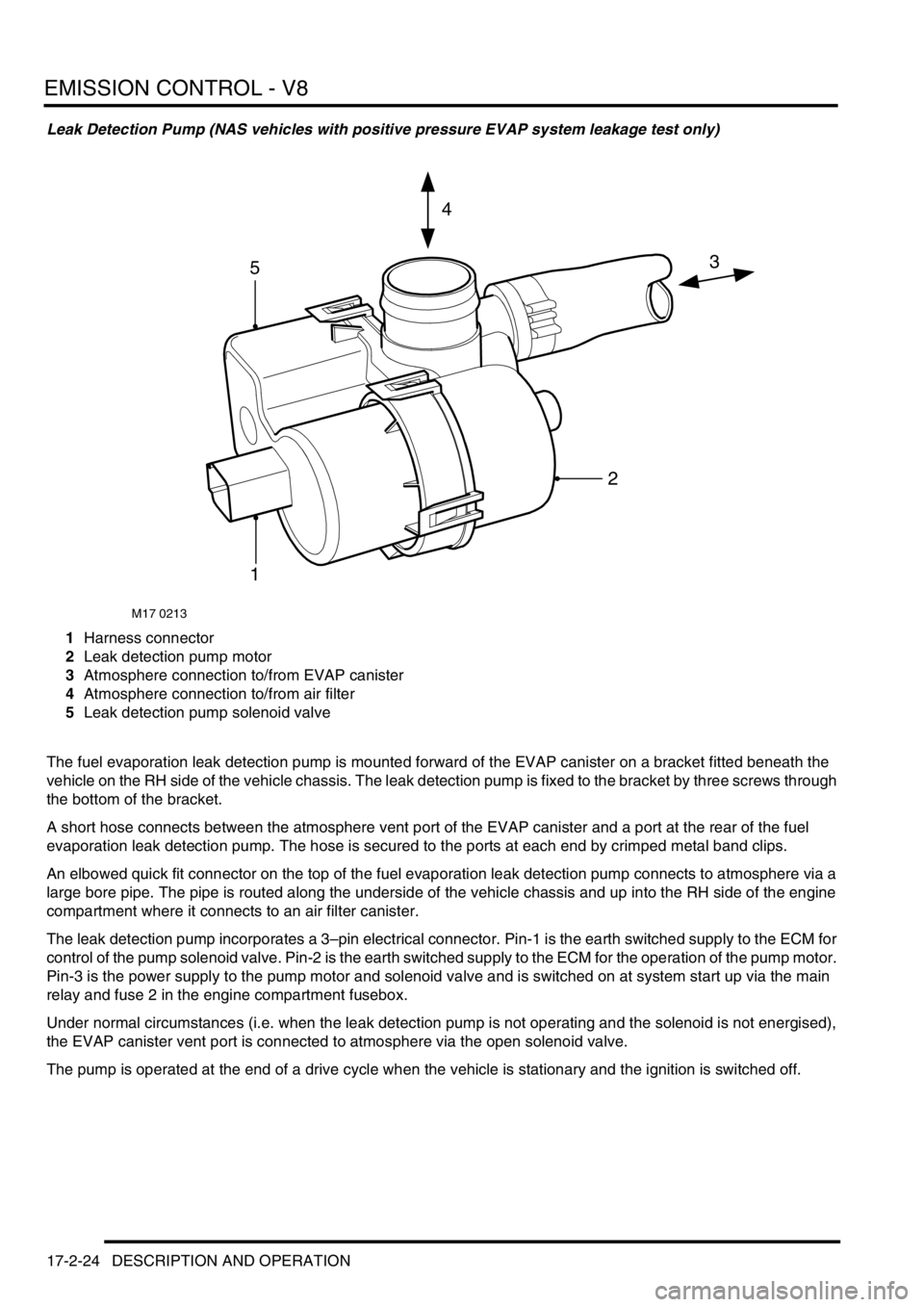

Leak Detection Pump (NAS vehicles with positive pressure EVAP system leakage test only)

1Harness connector

2Leak detection pump motor

3Atmosphere connection to/from EVAP canister

4Atmosphere connection to/from air filter

5Leak detection pump solenoid valve

The fuel evaporation leak detection pump is mounted forward of the EVAP canister on a bracket fitted beneath the

vehicle on the RH side of the vehicle chassis. The leak detection pump is fixed to the bracket by three screws through

the bottom of the bracket.

A short hose connects between the atmosphere vent port of the EVAP canister and a port at the rear of the fuel

evaporation leak detection pump. The hose is secured to the ports at each end by crimped metal band clips.

An elbowed quick fit connector on the top of the fuel evaporation leak detection pump connects to atmosphere via a

large bore pipe. The pipe is routed along the underside of the vehicle chassis and up into the RH side of the engine

compartment where it connects to an air filter canister.

The leak detection pump incorporates a 3–pin electrical connector. Pin-1 is the earth switched supply to the ECM for

control of the pump solenoid valve. Pin-2 is the earth switched supply to the ECM for the operation of the pump motor.

Pin-3 is the power supply to the pump motor and solenoid valve and is switched on at system start up via the main

relay and fuse 2 in the engine compartment fusebox.

Under normal circumstances (i.e. when the leak detection pump is not operating and the solenoid is not energised),

the EVAP canister vent port is connected to atmosphere via the open solenoid valve.

The pump is operated at the end of a drive cycle when the vehicle is stationary and the ignition is switched off.

M17 0213

3

4

5

1

2

Page 363 of 1672

EMISSION CONTROL - V8

17-2-26 DESCRIPTION AND OPERATION

Secondary air injection system

The secondary air injection (SAI) system comprises the following components:

lSecondary air injection pump

lSAI vacuum solenoid valve

lSAI control valves (2 off, 1 for each bank of cylinders)

lSAI pump relay

lVacuum reservoir

lVacuum harness and pipes

The secondary air injection system is used to limit the emission of carbon monoxide (CO) and hydrocarbons (HCs)

that are prevalent in the exhaust during cold starting of a spark ignition engine. The concentration of hydrocarbons

experienced during cold starting at low temperatures are particularly high until the engine and catalytic converter

reach normal operating temperature. The lower the cold start temperature, the greater the prevalence of

hydrocarbons emitted from the engine.

There are several reasons for the increase of HC emissions at low cold start temperatures, including the tendency for

fuel to be deposited on the cylinder walls, which is then displaced during the piston cycle and expunged during the

exhaust stroke. As the engine warms up through operation, the cylinder walls no longer retain a film of fuel and most

of the hydrocarbons will be burnt off during the combustion process.

The SAI pump is used to provide a supply of air into the exhaust ports in the cylinder head, onto the back of the

exhaust valves, during the cold start period. The hot unburnt fuel particles leaving the combustion chamber mix with

the air injected into the exhaust ports and immediately combust. This subsequent combustion of the unburnt and

partially burnt CO and HC particles help to reduce the emission of these pollutants from the exhaust system. The

additional heat generated in the exhaust manifold also provides rapid heating of the exhaust system catalytic

converters. The additional oxygen which is delivered to the catalytic converters also generate an exothermic reaction

which causes the catalytic converters to 'light off' quickly.

The catalytic converters only start to provide effective treatment of emission pollutants when they reach an operating

temperature of approximately 250

°C (482°F) and need to be between temperatures of 400°C (752°F) and 800°C

(1472

°F) for optimum efficiency. Consequently, the heat produced by the secondary air injection “afterburning”,

reduces the time delay before the catalysts reach an efficient operating temperature.

The engine control module (ECM) checks the engine coolant temperature when the engine is started, and if it is below

60º C (131

°F), the SAI pump is started. Secondary air injection will remain operational for a period controlled by the

ECM (76 seconds for NAS vehicles, 64 seconds for EU-3 vehicles). The SAI pump operation can be cut short due to

excessive engine speed or load.

Air from the SAI pump is supplied to the SAI control valves via pipework and an intermediate T-piece which splits the

air flow evenly to each bank.

At the same time the secondary air pump is started, the ECM operates a SAI vacuum solenoid valve, which opens to

allow vacuum from the reservoir to be applied to the vacuum operated SAI control valves on each side of the engine.

When the vacuum is applied to the SAI control valves, they open simultaneously to allow the air from the SAI pump

through to the exhaust ports. Secondary air is injected into the inner most exhaust ports on each bank.

When the ECM breaks the ground circuit to de-energise the SAI vacuum solenoid valve, the vacuum supply to the

SAI control valves is cut off and the valves close to prevent further air being injected into the exhaust manifold. At the

same time as the SAI vacuum solenoid valve is closed, the ECM opens the ground circuit to the SAI pump relay, to

stop the SAI pump.

A vacuum reservoir is included in the vacuum line between the intake manifold and the SAI vacuum solenoid valve.

This prevents changes in vacuum pressure from the intake manifold being passed on to cause fluctuations of the

secondary air injection solenoid valve. The vacuum reservoir contains a one way valve and ensures a constant

vacuum is available for the SAI vacuum solenoid valve operation. This is particularly important when the vehicle is at

high altitude.

Page 365 of 1672

EMISSION CONTROL - V8

17-2-28 DESCRIPTION AND OPERATION

The SAI pump is attached to a bracket at the rear RH side of the engine compartment and is fixed to the bracket by

three studs and nuts. The pump is electrically powered from a 12V battery supply via a dedicated relay and supplies

approximately 35kg/hr of air when the vehicle is at idle in Neutral/Park on a start from 20

°C (68°F).

Air is drawn into the pump through vents in its front cover and is then passed through a foam filter to remove

particulates before air injection. The air is delivered to the exhaust manifold on each side of the engine through a

combination of plastic and metal pipes.

The air delivery pipe is a flexible plastic type, and is connected to the air pump outlet via a plastic quick-fit connector.

The other end of the flexible plastic pipe connects to the fixed metal pipework via a short rubber hose. The part of the

flexible plastic pipe which is most vulnerable to engine generated heat is protected by heat reflective sleeving. The

metal delivery pipe has a fabricated T-piece included where the pressurised air is split for delivery to each exhaust

manifold via the SAI control valves.

The pipes from the T-piece to each of the SAI control valves are approximately the same length, so that the pressure

and mass of the air delivered to each bank will be equal. The ends of the pipes are connected to the inlet port of each

SAI control valve through short rubber hose connections.

The T-piece is mounted at the rear of the engine (by the ignition coils) and features a welded mounting bracket which

is fixed to the engine by two studs and nuts.

The foam filter in the air intake of the SAI pump provides noise reduction and protects the pump from damage due to

particulate contamination. In addition, the pump is fitted on rubber mountings to help prevent noise which is generated

by pump operation from being transmitted through the vehicle body into the passenger compartment.

If the secondary air injection pump malfunctions, the following fault codes may be stored in the ECM diagnostic

memory, which can be retrieved using 'Testbook':

Secondary air injection (SAI) pump relay

The secondary air injection pump relay is located in the engine compartment fusebox. The engine control module

(ECM) is used to control the operation of the SAI pump via the SAI pump relay. Power to the coil of the relay is supplied

from the vehicle battery via the main relay and the ground connection to the coil is via the ECM.

Power to the SAI pump relay contacts is via fusible link FL2 which is located in the engine compartment fusebox.

P-code Description

P0418Secondary air injection pump powerstage fault (e.g. - SAI pump relay fault / SAI

pump or relay not connected / open circuit / harness damage).

Page 371 of 1672

EMISSION CONTROL - V8

17-2-34 DESCRIPTION AND OPERATION

Exhaust emission control operation

The oxygen content of the exhaust gas is monitored by heated oxygen sensors using either a four sensor (NAS only)

or two sensor setup, dependent on market destination and legislative requirements. Signals from the heated oxygen

sensors are input to the engine management ECM which correspond to the level of oxygen detected in the exhaust

gas. From ECM analysis of the data, necessary changes to the air:fuel mixture and ignition timing can be made to

bring the emission levels back within acceptable limits under all operating conditions.

Changes to the air:fuel ratio are needed when the engine is operating under particular conditions such as cold starting,

idle, cruise, full throttle or altitude. In order to maintain an optimum air:fuel ratio for differing conditions, the engine

management control system uses sensors to determine data which enable it to select the ideal ratio by increasing or

decreasing the air to fuel ratio. Improved fuel economy can be arranged by increasing the quantity of air to fuel to

create a lean mixture during part-throttle conditions, however lean running conditions are not employed on closed loop

systems where the maximum is

λ = 1. Improved performance can be established by supplying a higher proportion of

fuel to create a rich mixture during idle and full-throttle operation. Rich running at wide open throttle (WOT) for

performance and at high load conditions helps to keep the exhaust temperature down to protect the catalyst and

exhaust valves.

The voltage of the heated oxygen sensors at

λ = 1 is between 450 and 500 mV. The voltage decreases to 100 to 500

mV if there is an increase in oxygen content (

λ > 1) indicating a lean mixture. The voltage increases to 500 to 1000

mV if there is a decrease in oxygen content (

λ < 1), signifying a rich mixture.

The heated oxygen sensor needs to operate at high temperatures in order to function correctly (

≥ 350° C). To achieve

this the sensors are fitted with heater elements which are controlled by a pulse width modulated (PWM) signal from

the engine management ECM. The heater element warms the sensor's ceramic layer from the inside so that the

sensor is hot enough for operation. The heater elements are supplied with current immediately following engine start

and are ready for closed loop control within about 20 to 30 seconds (longer at cold ambient temperatures less than

0

°C (32°F)). Heating is also necessary during low load conditions when the temperature of the exhaust gases is

insufficient to maintain the required sensor temperatures. The maximum tip temperature is 930

° C.

A non-functioning heater element will delay the sensor's readiness for closed loop control and influences emissions.

A diagnostic routine is utilised to measure both sensor heater current and the heater supply voltage so its resistance

can be calculated. The function is active once per drive cycle, as long as the heater has been switched on for a pre-

defined period and the current has stabilised. The PWM duty cycle is carefully controlled to prevent thermal shock to

cold sensors.

The heated oxygen sensors age with mileage, causing an increase in the response time to switch from rich to lean

and lean to rich. This increase in response time influences the closed loop control and leads to progressively

increased emissions. The response time of the pre-catalytic converter sensors are monitored by measuring the period

of rich to lean and lean to rich switching. The ECM monitors the switching time, and if the threshold period is exceeded

(200 milliseconds), the fault will be detected and stored in the ECM as a fault code (the MIL light will be illuminated

on NAS vehicles). NAS vehicle engine calibration uses downstream sensors to compensate for aged upstream

sensors, thereby maintaining low emissions.

Diagnosis of electrical faults is continuously monitored for both the pre-catalytic converter sensors and the post-

catalytic converter sensors (NAS only). This is achieved by checking the signal against maximum and minimum

threshold for open and short circuit conditions. For NAS vehicles, should the pre- and post-catalytic converters be

inadvertently transposed, the lambda signals will go to maximum but opposite extremes and the system will

automatically revert to open loop fuelling. The additional sensors for NAS vehicles provide mandatory monitoring of

the catalyst conversion efficiency and long term fuelling adaptations.

Note that some markets do not legislate for closed loop fuelling control and in this instance no heated oxygen

sensors will be fitted to the exhaust system.

Page 378 of 1672

EMISSION CONTROL - V8

DESCRIPTION AND OPERATION 17-2-41

Following the test, the system returns to normal purge operation after the canister vent solenoid opens. Possible

reasons for an EVAP system leak test failure are listed below:

lFuel filler not tightened or cap missing.

lSensor or actuator open circuit.

lShort circuit to vehicle supply or ground.

lEither purge or CVS valve stuck open.

lEither purge or CVS valve stuck shut or blocked pipe.

lPiping broken or not connected.

lLoose or leaking connection.

If the piping is broken forward of the purge valve or is not connected, the engine may run rough and fuelling adaptions

will drift. The fault will not be detected by the leak detection diagnostic, but it will be determined by the engine

management ECM through the fuelling adaption diagnostics.

The evaluation of leakage is dependent on the differential pressure between the fuel tank and ambient atmospheric

pressure, the diagnostic is disabled above altitudes of 9500 ft. (2800 m) to avoid false detection of fuel leaks due to

the change in atmospheric pressure at altitude.

Fuel leak detection system (positive pressure leak detection type) – NAS only

The EVAP system with positive pressure leak detection capability used on NAS vehicles is similar to the standard

system, but also includes a fuel evaporation leak detection pump with integral solenoid valve. It is capable of detecting

holes in the EVAP system down to 0.5 mm (0.02 in.). The test is carried out at the end of a drive cycle, when the

vehicle is stationary and the ignition switch has been turned off. The ECM maintains an earth supply to the Main relay

to hold it on, so that power can be supplied to the leak detection pump.

First a reference measurement is established by passing the pressurised air through a by-pass circuit containing a

fixed sized restriction. The restriction assimilates a 0.5 mm (0.02 in) hole and the current drawn by the pump motor

during this procedure is recorded for comparison against the value to be obtained in the system test. The purge valve

is held closed, and the reversing valve in the leak detection pump module is not energised while the leak detection

pump is switched on. The pressurised air from the leak detection pump is forced through an orifice while the current

drawn by the pump motor is monitored.

Next the EVAP system diagnostic is performed; the solenoid valve is energised so that it closes off the EVAP system's

vent line to atmosphere, and opens a path for the pressurised air from the leak detection pump to be applied to the

closed EVAP system.

The current drawn by the leak detection pump is monitored and checked against that obtained during the reference

measurement. If the current is less than the reference value, this infers there is a hole in the EVAP system greater

than 0.5 mm (0.02 in) which is allowing the positive air pressure to leak out. If the current drawn by the pump motor

is greater than the value obtained during the reference check, the system is sealed and free from leaks. If an EVAP

system leak is detected, the ECM stores the fault in diagnostic memory and the MIL light on the instrument pack is

illuminated.

On NAS vehicles, the ECM works on a 2 trip cycle before illuminating the MIL. On EU-3 vehicles, the ECM works on

a 3 trip cycle before illuminating the MIL.

Following the test, the solenoid valve is opened to normalise the EVAP system pressure and the system returns to

normal purge operation at the start of the next drive cycle. Possible reasons for an EVAP system leak test failure are

listed below:

lFuel filler not tightened or cap missing.

lSensor or actuator open circuit.

lShort circuit to vehicle supply or ground.

lEither purge or solenoid valve stuck open.

lEither purge or solenoid valve stuck shut.

lBlocked pipe or air filter.

lPiping broken or not connected.

lLoose or leaking connection.

If the piping is broken forward of the purge valve or is not connected, the engine may run rough and fuelling adaptions

will drift. The fault will not be detected by the leak detection test, but will be determined by the engine management

ECM through the fuelling adaption diagnostics. This test can be run from TestBook.

Page 402 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

DESCRIPTION AND OPERATION 18-1-9

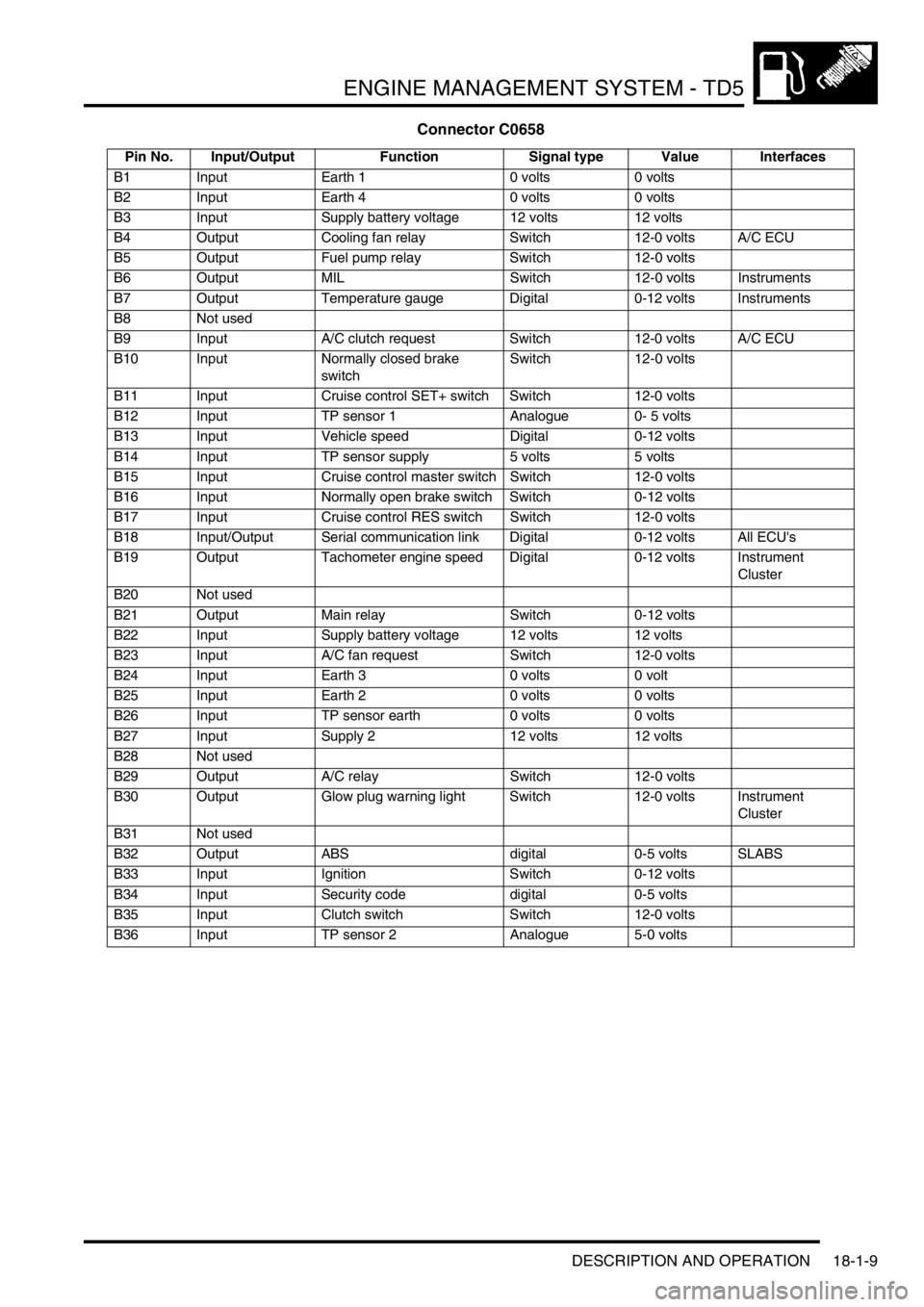

Connector C0658

Pin No. Input/Output Function Signal type Value Interfaces

B1 Input Earth 1 0 volts 0 volts

B2 Input Earth 4 0 volts 0 volts

B3 Input Supply battery voltage 12 volts 12 volts

B4 Output Cooling fan relay Switch 12-0 volts A/C ECU

B5 Output Fuel pump relay Switch 12-0 volts

B6 Output MIL Switch 12-0 volts Instruments

B7 Output Temperature gauge Digital 0-12 volts Instruments

B8 Not used

B9 Input A/C clutch request Switch 12-0 volts A/C ECU

B10 Input Normally closed brake

switchSwitch 12-0 volts

B11 Input Cruise control SET+ switch Switch 12-0 volts

B12 Input TP sensor 1 Analogue 0- 5 volts

B13 Input Vehicle speed Digital 0-12 volts

B14 Input TP sensor supply 5 volts 5 volts

B15 Input Cruise control master switch Switch 12-0 volts

B16 Input Normally open brake switch Switch 0-12 volts

B17 Input Cruise control RES switch Switch 12-0 volts

B18 Input/Output Serial communication link Digital 0-12 volts All ECU's

B19 Output Tachometer engine speed Digital 0-12 volts Instrument

Cluster

B20 Not used

B21 Output Main relay Switch 0-12 volts

B22 Input Supply battery voltage 12 volts 12 volts

B23 Input A/C fan request Switch 12-0 volts

B24 Input Earth 3 0 volts 0 volt

B25 Input Earth 2 0 volts 0 volts

B26 Input TP sensor earth 0 volts 0 volts

B27 Input Supply 2 12 volts 12 volts

B28 Not used

B29 Output A/C relay Switch 12-0 volts

B30 Output Glow plug warning light Switch 12-0 volts Instrument

Cluster

B31 Not used

B32 Output ABS digital 0-5 volts SLABS

B33 Input Ignition Switch 0-12 volts

B34 Input Security code digital 0-5 volts

B35 Input Clutch switch Switch 12-0 volts

B36 Input TP sensor 2 Analogue 5-0 volts

Page 411 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

18-1-18 DESCRIPTION AND OPERATION

Throttle Position (TP) sensor – Up to VIN 297136

The TP sensor is located on the throttle pedal assembly. It detects throttle pedal movement and position. It uses two

position sensors to provide the ECM with the exact throttle pedal position. As the pedal operates the voltage of one

position sensor increases as the other decreases.

Input/Output

The ECM provides the throttle position sensor with a 5 volt reference feed. Both position sensors send an analogue

signal back to the ECM.

lSensor one, 0 to 5 volts variable.

lSensor two, 5 to 0 volts variable.

Input to the throttle pedal position sensor is via pin 14 of the ECM connector C0658. Output from sensor one is

measured via pin 12 of the ECM connector C0658. Output from sensor two is measured via pin 36 of the ECM

connector C0658. The earth path is via pin 26 of ECM connector C0658.

The TP sensor can fail the following ways or supply incorrect signal:

lSensor open circuit.

lShort circuit to vehicle supply.

lShort circuit to vehicle earth.

lWater ingress.

lSensor incorrectly fitted.

In the event of a TP sensor signal failure any of the following symptoms may be observed:

lEngine performance concern.

lDelayed throttle response.

lFailure of emission control.

If the TP sensor fails, the engine will only run at idle and the MIL will remain on until the fault is eliminated. Turning

the ignition off/on can reset the MIL provided that the fault has been rectified.

Page 418 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

DESCRIPTION AND OPERATION 18-1-25

Main relay

The main relay is located in the engine compartment fuse box and supplies battery voltage to the following:

lECM.

lMAF.

lFuel pump relay.

lCruise control master switch.

lCruise control RES switch.

lCruise control SET+ switch.

It is a 4 pin normally open relay and must be energised to provide voltage to the ECM.

Input/Output

The earth path for the main relay is via a transistor within the ECM. When the earth path is completed, the main relay

energises to supply battery voltage to the ECM. Interrupting this earth path de-energises the main relay, preventing

battery voltage reaching the ECM.

Input to the main relay is via pin 1 of connector C0632, located at the engine compartment fuse box. Output from the

main relay is via fuse 1 to the ECM connector C0658 pins 3, 22 and 27. The earth path is via pin 21 of ECM connector

C0658.

The main relay can fail in the following ways:

lRelay open circuit.

lShort circuit to vehicle supply.

lShort circuit to vehicle earth.

lBroken return spring.

In the event of a main relay failure any of the following symptoms may be observed:

lEngine will crank but not start.

lIf the engine is running it will stop.

For the ECM start up to take place the ignition 'on' (position II) voltage must be greater than 6.0 volts.

Page 422 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

DESCRIPTION AND OPERATION 18-1-29

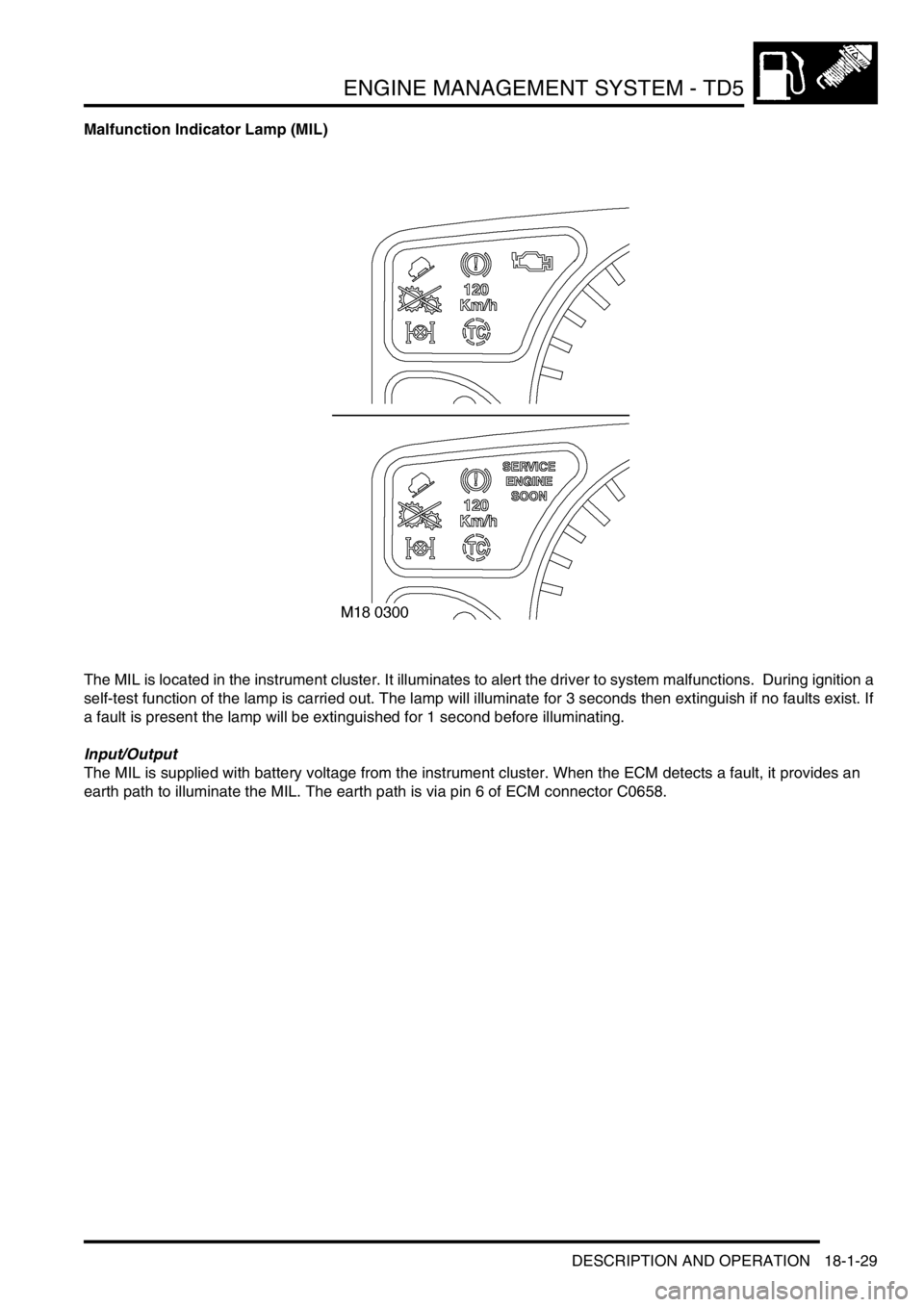

Malfunction Indicator Lamp (MIL)

The MIL is located in the instrument cluster. It illuminates to alert the driver to system malfunctions. During ignition a

self-test function of the lamp is carried out. The lamp will illuminate for 3 seconds then extinguish if no faults exist. If

a fault is present the lamp will be extinguished for 1 second before illuminating.

Input/Output

The MIL is supplied with battery voltage from the instrument cluster. When the ECM detects a fault, it provides an

earth path to illuminate the MIL. The earth path is via pin 6 of ECM connector C0658.