ABS LAND ROVER FRELANDER 2 2006 Service Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 297 of 3229

If a fault occurs i n t he Terrai n Res pons e rot ary cont rol, al l rotary cont rol i con amber Light Emi tt ing Di odes (LED's ) wil l bet urned off and rotat ion of t he rot ary control i s ignored. The i ns t rument clus ter mess age cent er will di spl ay a mes s age'SY STEM FAULT SPECIAL PROGRAMS NOT AVAILABLE' when t he fault occurs , if t he fault i s pres ent and the driver att emptst o s el ect a s pecial program (if t he cont rol module is able to do thi s) or at t he next i gni ti on mode 2 (on) cycle.

The Terrai n Res pons e rotary cont rol and t he cont rol module are an i nt egral unit . If a fault occurs in eit her component , thewhole uni t wil l requi re replacement. ENSURE T HAT T HE FAULT IS WIT H T HE T ERRAIN RESPONSE CO NT ROL MO DULEAND NOT IN A SUB-SYST EM MODULE BEFO RE REPLACING T HE MODULE.

If a CAN faul t exi s ts and prevent s Terrai n Res pons e s yst em operat ion, all of t he Terrai n Res pons e rotary cont rol icon LED'swil l be il lumi nat ed and rot ati on of the rot ary cont rol i s ignored.

If the i nst rument clus ter does not receive a Terrain Res ponse s ys t em CAN mess age from the Terrain Res ponse cont rolmodule, t he mes sage 'SY STEM FAULT SPECIAL PROGRAMS NO T AVAILABLE' wi ll be dis played when t he faul t occurs and willbe repeat ed at every ignit ion mode 2 (on) cycl e.

User Error

The fol lowing incorrect us age of t he s yst em may be mi si nterpreted as a s ys t em fault :

Engi ne not running - Program changes and driver advi s ory mes s ages are only avail abl e wi th the engine runni ngSpeci al program change att empted wi th DSC or ABS acti ve (t his i ncl udes ABS cycling which is operat ional when HDCis bei ng used on s lippery or l oose surfaces)Speci al program change att empted wi th overheat condi ti on pres ent on the act ive on-demand coupling.

Page 308 of 3229

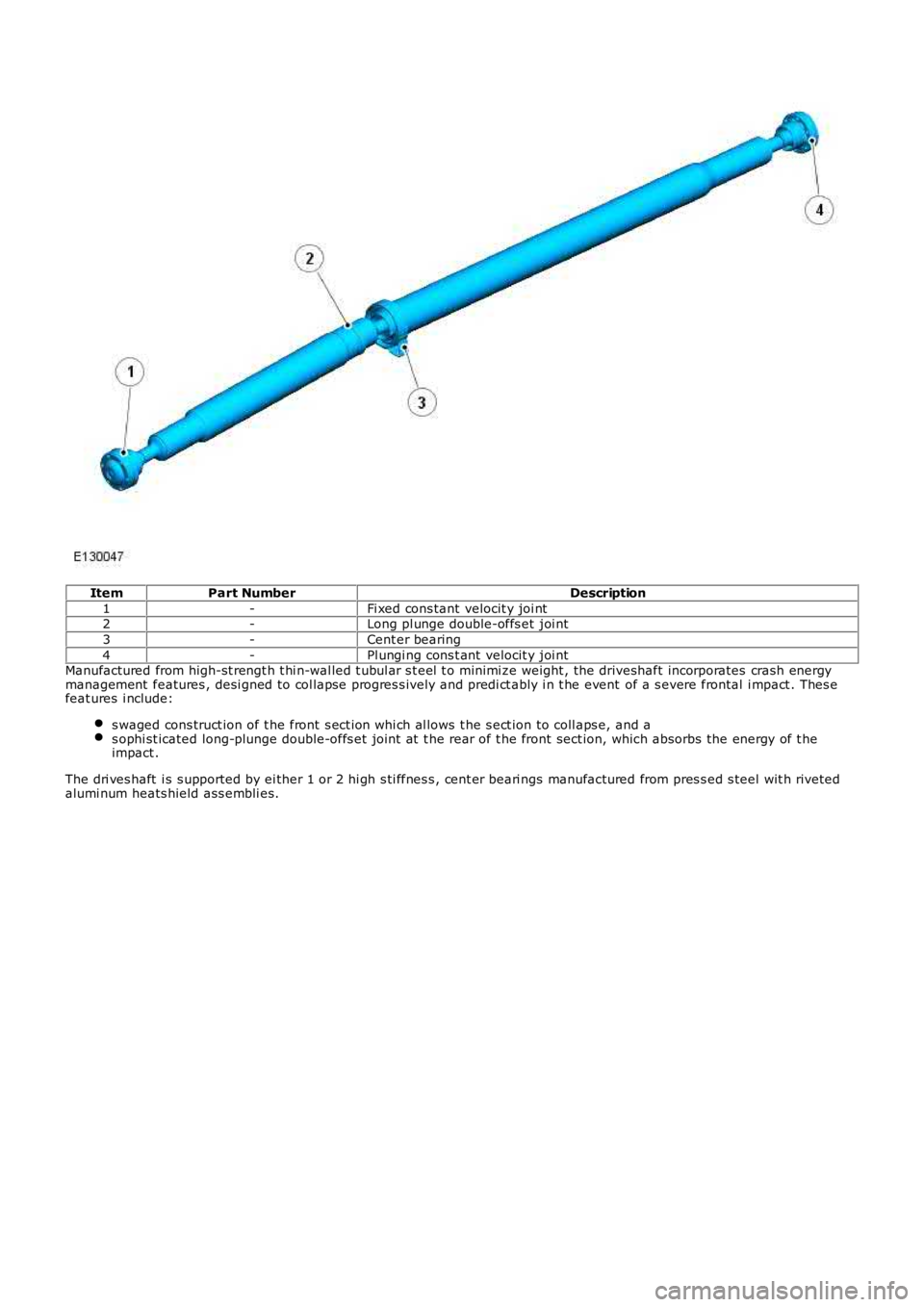

ItemPart NumberDescription

1-Fi xed cons tant velocit y joi nt2-Long pl unge double-offs et joi nt

3-Cent er bearing

4-Pl ungi ng cons t ant velocit y joi ntManufactured from high-st rengt h t hi n-wal led t ubul ar s t eel t o minimi ze weight , the driveshaft incorporates crash energymanagement features , desi gned to col lapse progres s ively and predi ct ably i n t he event of a s evere frontal i mpact . Thes efeat ures i nclude:

s waged cons truct ion of t he front s ect ion whi ch al lows t he s ect ion to coll aps e, and as ophi st icated long-plunge double-offs et joi nt at t he rear of t he front sect ion, which absorbs the energy of t heimpact .

The dri ves haft i s s upported by ei ther 1 or 2 hi gh s ti ffnes s , cent er beari ngs manufactured from pres s ed s teel wit h rivetedalumi num heats hield ass embli es.

Page 357 of 3229

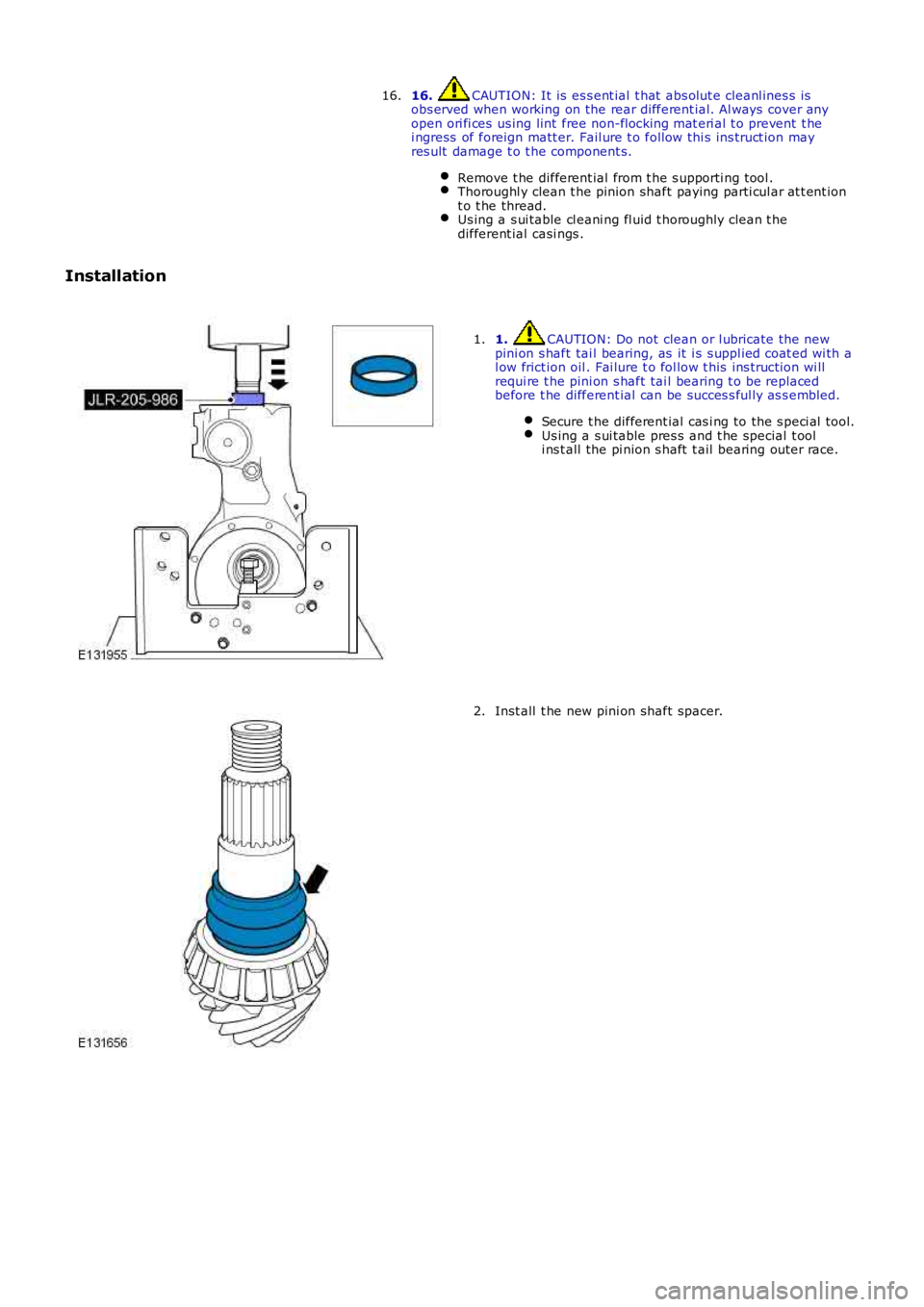

16. CAUTION: It is es s ent ial t hat abs olut e cleanl ines s isobs erved when working on the rear different ial. Al ways cover anyopen ori fi ces us ing lint free non-flocking mat eri al t o prevent t hei ngress of foreign matt er. Fail ure t o follow thi s ins truct ion mayres ult damage t o t he component s.

Remove t he different ial from t he s upporti ng tool .Thoroughl y clean t he pinion shaft paying parti cul ar at t ent iont o t he thread.Us ing a s ui table cl eani ng fl uid t horoughly clean t hedifferent ial casi ngs .

16.

Installation

1. CAUTION: Do not clean or l ubricate the newpini on s haft tai l bearing, as it i s s uppl ied coat ed wi th al ow frict ion oil . Fai lure t o fol low t his ins truct ion wi llrequi re t he pini on s haft tai l bearing t o be repl acedbefore t he different ial can be succes s ful ly as s embled.

Secure t he different ial cas i ng to the s peci al tool.Us ing a s ui table pres s and t he special t ooli ns t all the pi nion s haft t ail bearing out er race.

1.

Inst all t he new pini on shaft spacer.2.

Page 375 of 3229

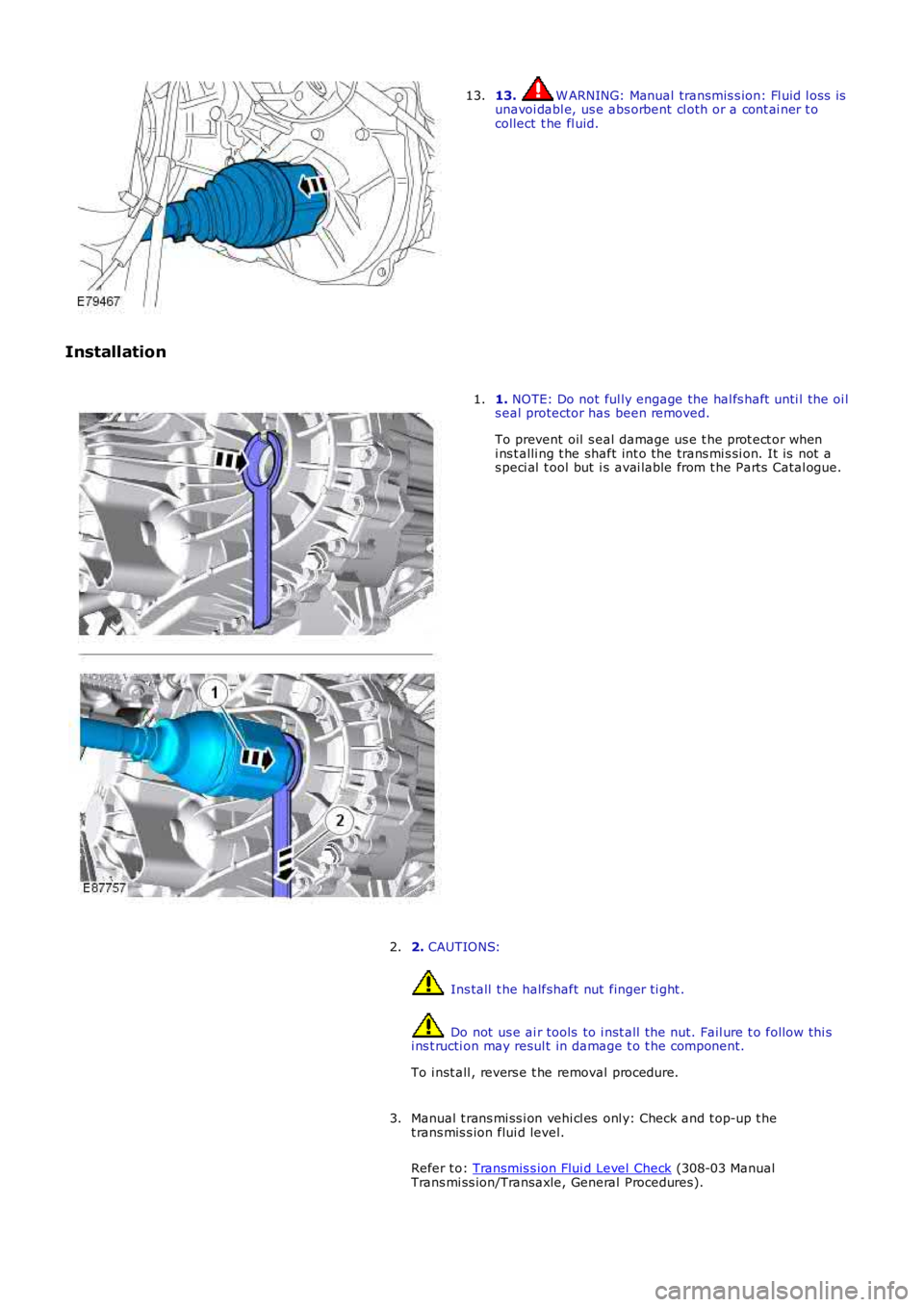

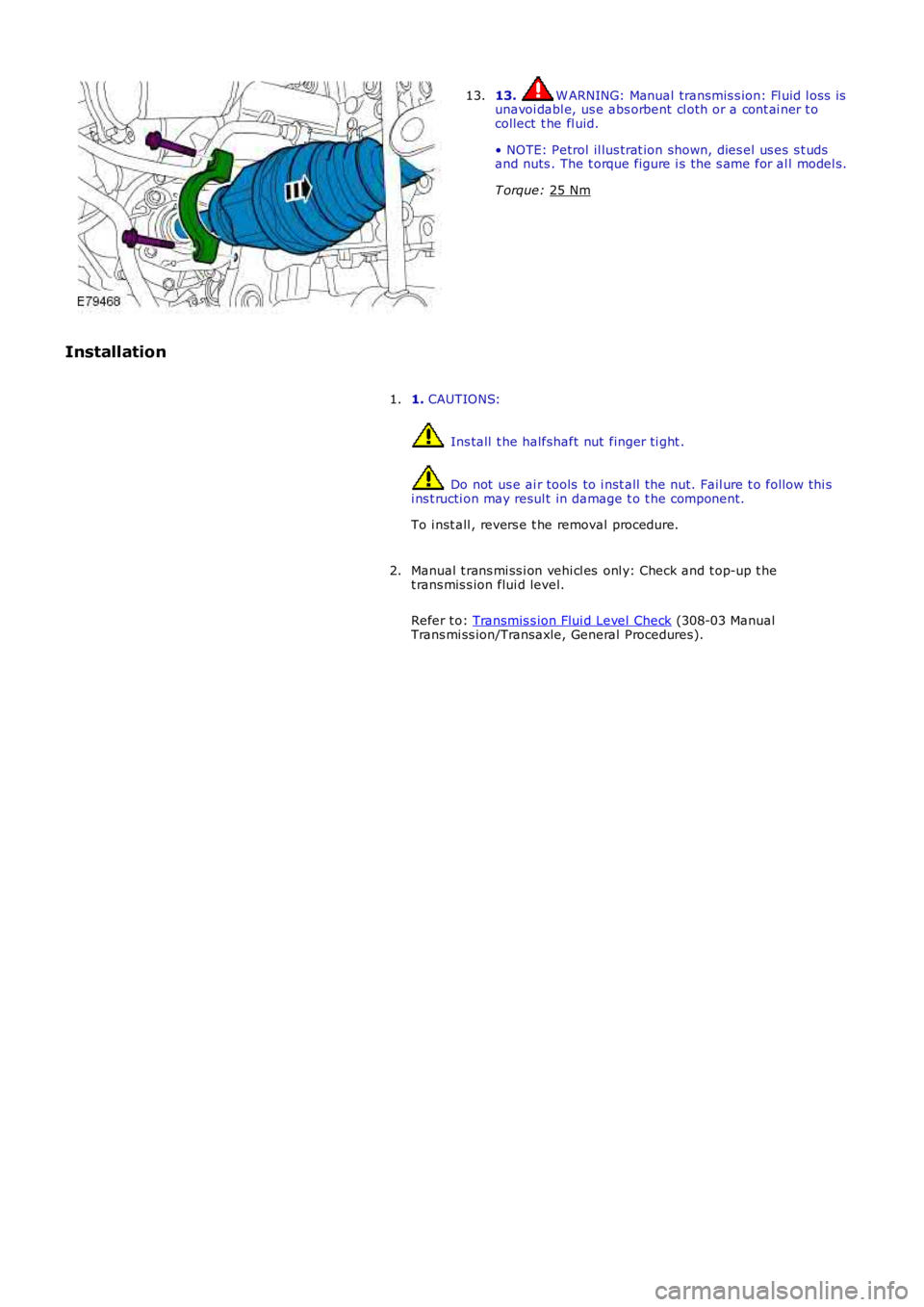

13. W ARNING: Manual transmis s ion: Fl uid l oss isunavoi dabl e, us e abs orbent cl oth or a cont ai ner t ocollect t he fl uid.

13.

Installation

1. NOTE: Do not ful ly engage the hal fs haft unti l the oi ls eal protector has been removed.

To prevent oil s eal damage us e t he prot ect or wheni ns t alli ng t he shaft int o the trans mi s si on. It is not as peci al t ool but i s avai lable from t he Part s Catal ogue.

1.

2. CAUTIONS:

Ins tall t he halfshaft nut finger ti ght .

Do not us e ai r tools to i nst all t he nut. Fail ure t o follow thi si ns t ructi on may resul t in damage t o t he component.

To i nst all , revers e t he removal procedure.

2.

Manual t rans mi ss i on vehi cl es onl y: Check and t op-up t het rans mis s ion flui d level.

Refer t o: Transmis s ion Flui d Level Check (308-03 ManualTrans mi ss ion/Transaxle, General Procedures).

3.

Page 379 of 3229

13. W ARNING: Manual transmis s ion: Fl uid l oss is

unavoi dabl e, us e abs orbent cl oth or a cont ai ner t o

collect t he fl uid.

• NOTE: Petrol il lus trat ion shown, dies el us es s t uds

and nuts . The t orque figure i s t he s ame for al l model s.

T orque: 25 Nm 13.

Installation 1. CAUTIONS: Ins tall t he halfshaft nut finger ti ght .

Do not us e ai r tools to i nst all t he nut. Fail ure t o follow thi s

i ns t ructi on may resul t in damage t o t he component.

To i nst all , revers e t he removal procedure.

1.

Manual t rans mi ss i on vehi cl es onl y: Check and t op-up t he

t rans mis s ion flui d level.

Refer t o: Transmis s ion Flui d Level Check (308-03 Manual

Trans mi ss ion/Transaxle, General Procedures).

2.

Page 407 of 3229

Publi s hed: 11-May-2011

Brake System - General Information - Brake System

Des cript ion and Operat ion

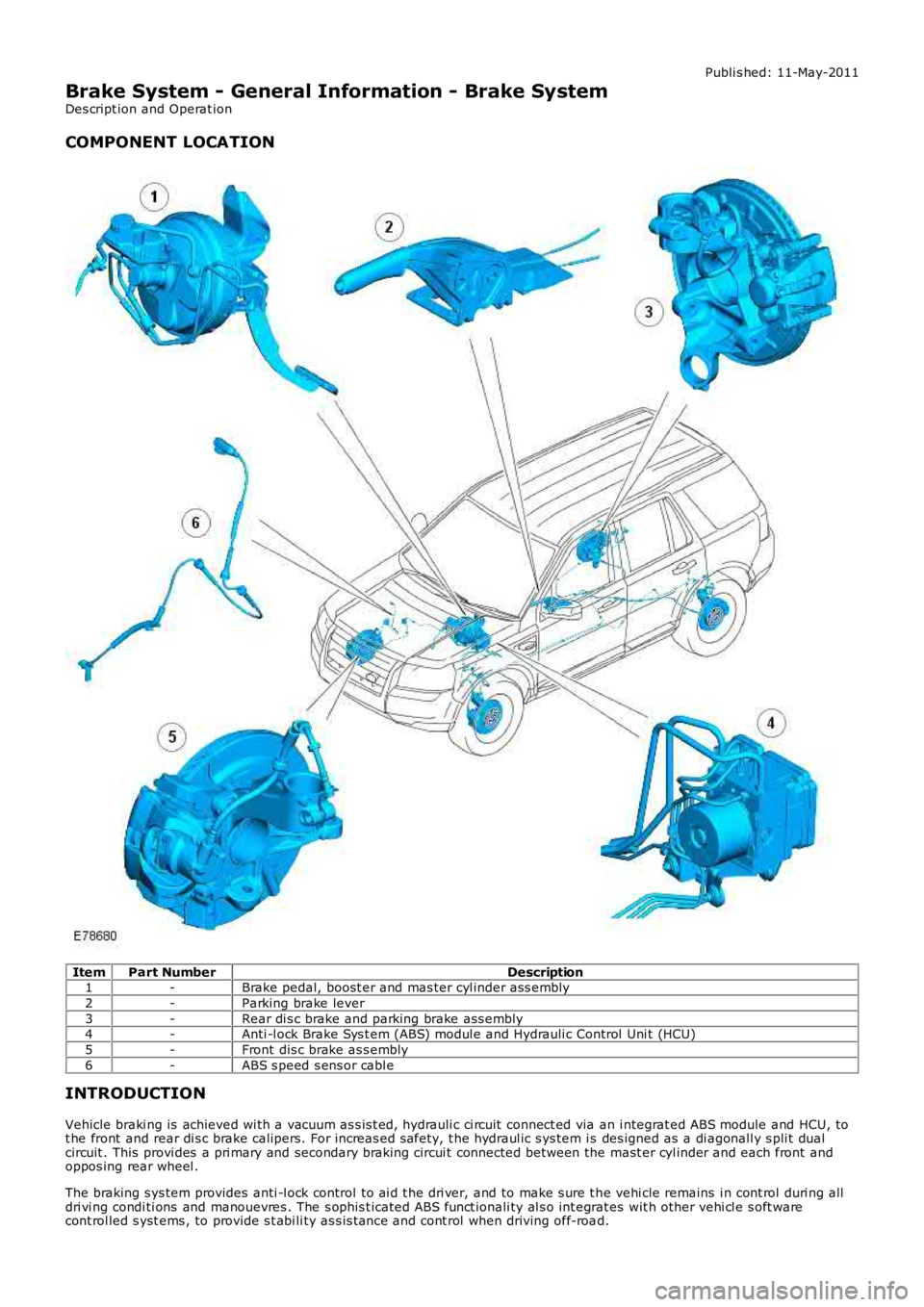

COMPONENT LOCATION

ItemPart NumberDescription1-Brake pedal, boost er and mas ter cyl inder ass embly

2-Parking brake lever

3-Rear di s c brake and parking brake ass embly4-Anti -l ock Brake Sys t em (ABS) modul e and Hydrauli c Control Uni t (HCU)

5-Front dis c brake as s embly

6-ABS s peed s ens or cabl e

INTRODUCTION

Vehicle braki ng is achieved wi th a vacuum as s is t ed, hydrauli c ci rcuit connect ed via an i ntegrat ed ABS module and HCU, tot he front and rear di s c brake calipers. For increas ed s afety, t he hydraul ic s ys tem is des igned as a di agonall y s pli t dualcircuit . This provi des a pri mary and secondary braking circui t connected bet ween the mast er cyl inder and each front andoppos ing rear wheel .

The braking s ys tem provides anti -l ock control to ai d t he dri ver, and to make s ure t he vehi cle remains i n cont rol duri ng alldri vi ng condi ti ons and manouevres . The s ophis t icated ABS funct ionali ty al s o int egrates wit h other vehi cl e s oft warecont rol led s yst ems , to provide s t abi li ty as s is tance and cont rol when driving off-road.

Page 408 of 3229

The parking brake is a manual ly appli ed cabl e s ys t em t hat operates brake s hoes, housed wit hin the i nner diamet er of eachrear brake di sc.

FRONT AND REAR DISC BRAKES

The 3.2L i 6 vehicle i s ins t al led wit h vent il ated front and rear brake di scs . The 2.2L TD4 vehicle is i nst all ed wit h venti latedfront and sol id rear brake dis cs. Bot h t he i6 and TD4 vehicl es feature s ingle pi s ton, s lidi ng cal ipers on all brake dis cs . Foraddi ti onal i nformat ion, refer to:

Front Dis c Brake (206-03 Front Di sc Brake, Des cri pt ion and Operati on),Rear Di sc Brake (206-04 Rear Di s c Brake, Des cri pti on and Operati on).

PARKING BRAKE

The parking brake is a manual ly appli ed, cable operat ed s yst em. The RH and LH rear brake dis cs form the parki ng brakedrums , and provide the l ocat ion for the parki ng brake s hoes and components .For addit ional informat ion, refer t o: Parking Brake (206-05 Parki ng Brake and Act uat ion, Descripti on and Operat ion).

HYDRAULIC BRAKE ACTUATION

Hydrauli c brake act uati on cons is t s of the brake pedal , mast er cyl inder, HCU, and t he connect ing hydraul ic pipes and hos es.

The t andem brake mas ter cylinder wit h reservoi r is at tached to, and operat ed by t he brake boos t er. The brake mas t ercyl inder is a tandem des ign t hat suppli es pres s ure t o 2 i ndependent (pri mary and secondary) hydraul ic circui ts .For addit ional informat ion, refer t o: Hydraulic Brake Actuati on (206-06 Hydraulic Brake Act uati on, Des cri pt ion andOperat ion).

BRAKE BOOSTER

The brake boost er is vacuum operat ed and provides power as s is t ance t o t he brake hydrauli c s ys t em. The boos t er i s oft andem des ign that incorporat es 2 s eparate diaphragms . On both the gas oline and di esel models , t he vacuum required forboos t er operat ion is produced by an engine driven, vacuum pump.For addit ional informat ion, refer t o: Brake Boos ter (206-07 Power Brake Act uati on, Des cript ion and Operat ion).

ANTI-LOCK CONTROL

The anti -l ock control sys tem feat ures a Cont inental Teves Mk25E1 ABS module wit h i ntegral 4 channel HCU. The ABSmodule and HCU provide brake sys tem monit ori ng, and acti ve brake funct ions t o cont rol t he vehi cl e s tabil it y and t racti on.The ABS module al s o provides s peci fi c functi ons to as s is t t he vehi cl e duri ng off-road drivi ng.

The anti -l ock control sys tem provides t he fol lowing funct ions :

Anti -l ock Brake Sys t em (ABS)Corner Brake Control (CBC)Dynamic St abi li ty Cont rol (DSC)Electroni c Brake Force Di s tributi on (EBD)Electroni c Tracti on Control (ETC)Emergency Brake As s is t (EBA)Engi ne Drag-Torque Control (EDC)Hil l Descent Cont rol (HDC) wit h gradi ent release cont rolRoll Stabi lit y Control (RSC)Terrai n Res pons e™ sys tem int egrati on.

For addit ional informat ion, refer t o: Anti -Lock Cont rol - St abi li ty As s is t (206-09C Anti -Lock Cont rol - St abi lit y As s is t,Des cript ion and Operat ion).

Page 416 of 3229

brake boos ter.

5. Operate the engine for a minimum of 10 s econds at a fast i dle. Stop the engine and al low t he vehicle t o s t andfor 10 mi nut es. Then, appl y the brake pedal wi th approxi mately 89 N (20lb) of force. The pedal feel (brakeappli cat ion) s houl d be t he s ame as t hat not ed wit h t he engine runni ng. If the brake pedal feel s hard (no poweras s is t), ins t al l a new valve and t hen repeat t he tes t. If t he brake pedal s t ill feels hard, i ns t all a new brakeboos ter. If t he brake pedal movement feel s s pongy, bleed t he brake s ys t em.REFER t o: Brake Syst em Bl eedi ng (206-00 Brake Syst em - General Informati on, General Procedures ) /Brake Sys t em Pres s ure Bl eedi ng (206-00 Brake Syst em - General Informati on, General Procedures ).

5.

Brake Master Cylinder

Us ual ly, t he fi rs t and s tronges t indicat or of anything wrong i n t he brake s ys t em i s a feeling through t he brake pedal. Indiagnosi ng the condit ion of t he brake mas t er cyli nder, check pedal feel as evidence of a brake concern. Check for brakewarni ng lamp ill uminat ion and t he brake fluid level i n t he brake mas t er cyli nder reservoi r.

Normal Condit ions

The fol lowing condit ions are cons idered normal and are not i ndi cat ions t hat t he brake mast er cyl inder i s i n need of repair.

Modern brake sys tems are des igned t o produce a pedal effort that is not as hard as in the pas t . Compl aint s of lightpedal effort s s houl d be compared t o t he pedal efforts of another vehi cl e of t he s ame model and year.The fl uid l evel wi ll fal l wit h brake pad wear.

Abnormal Condi ti ons

Changes i n t he brake pedal feel or brake pedal travel are indicators t hat s omet hi ng coul d be wrong in the brake sys tem.The diagnost ic procedure and techni ques us e brake pedal feel , warning i ndi cat or il lumi nat ion and l ow brake flui d level asindicat ors t o diagnosi ng brake s yst em concerns . The foll owing condi ti ons are consi dered abnormal and indi cat e t hat t hebrake mas t er cyli nder i s in need of repai r:

• NOTE: Pri or to carrying out any diagnosi s , ens ure the brake sys tem warni ng indicator i s functi onal .

Brake pedal goes down fast . This could be caus ed by an external or int ernal leak.Brake pedal goes down s l owl y. Thi s coul d be caused by an int ernal or external l eak.Brake pedal is l ow or feels spongy. Thi s condit ion may be caus ed by no fl ui d i n the brake mas ter cylinder, reservoi rcap vent holes cl ogged or air i n t he hydraul ic s ys tem.Brake pedal effort is excess ive. This may be caus ed by a bi nd or obs t ructi on in the pedal/li nkage, a faul tynon-ret urn val ve, boost er or ins ufficient boos t er vacuum.Rear brakes lock up during light pedal force. Thi s may be caus ed by damaged brake pads , a parti ally appl ied parkingbrake, a damaged ABS s ens or or bearing fail ure.Brake pedal effort errat ic. This condit ion could be caus ed by the brake boos t er or incorrectl y ins tal led brake pads .Brake warning i ndi cat or is on. This may be caus ed by low fl uid l evel or fl oat as s embly damaged.

Non Pressure Leaks

Any reduced fl uid volume in t he brake mast er cyl inder res ervoi r may be caused by two types of none pres sure externalleaks .

Type 1: An ext ernal leak may occur at the brake mast er cyl inder res ervoir cap because of incorrect posi ti oning of t hegasket and cap. Repos it ion cap and gasket .

Type 2: An ext ernal leak may occur at the brake mast er cyl inder res ervoir mounti ng seal s. Repair s uch a l eak by ins tall ingnew s eals and make s ure that t he brake mas t er cyli nder reservoi r ret ai ning bolt i s correct ly i nst all ed.

Page 421 of 3229

Publi s hed: 11-May-2011

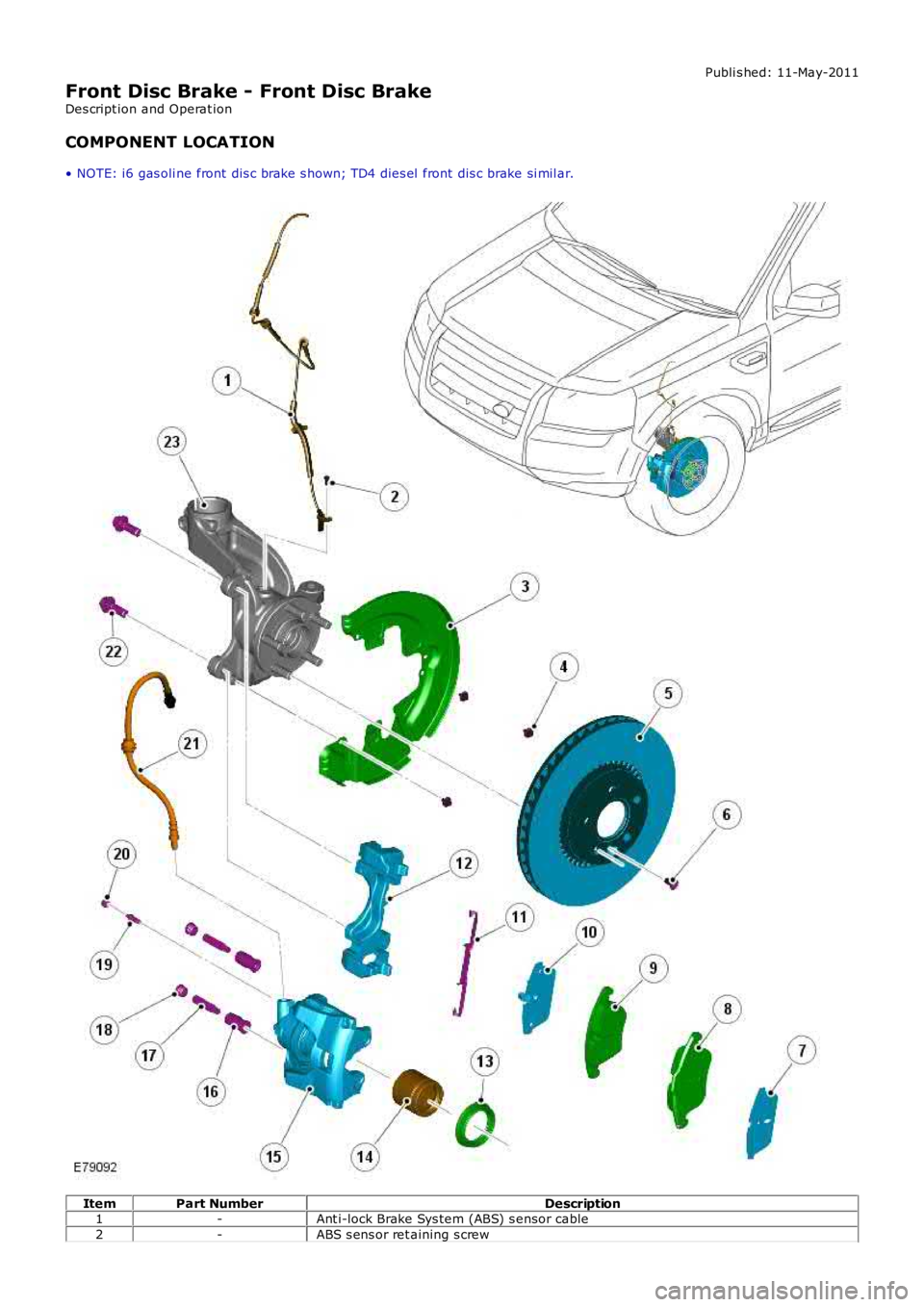

Front Disc Brake - Front Disc Brake

Des cript ion and Operat ion

COMPONENT LOCATION

• NOTE: i6 gas oli ne front dis c brake s hown; TD4 dies el front dis c brake si mil ar.

ItemPart NumberDescription1-Ant i-lock Brake Sys tem (ABS) s ensor cable

2-ABS s ens or ret aining s crew

Page 434 of 3229

Publi s hed: 11-May-2011

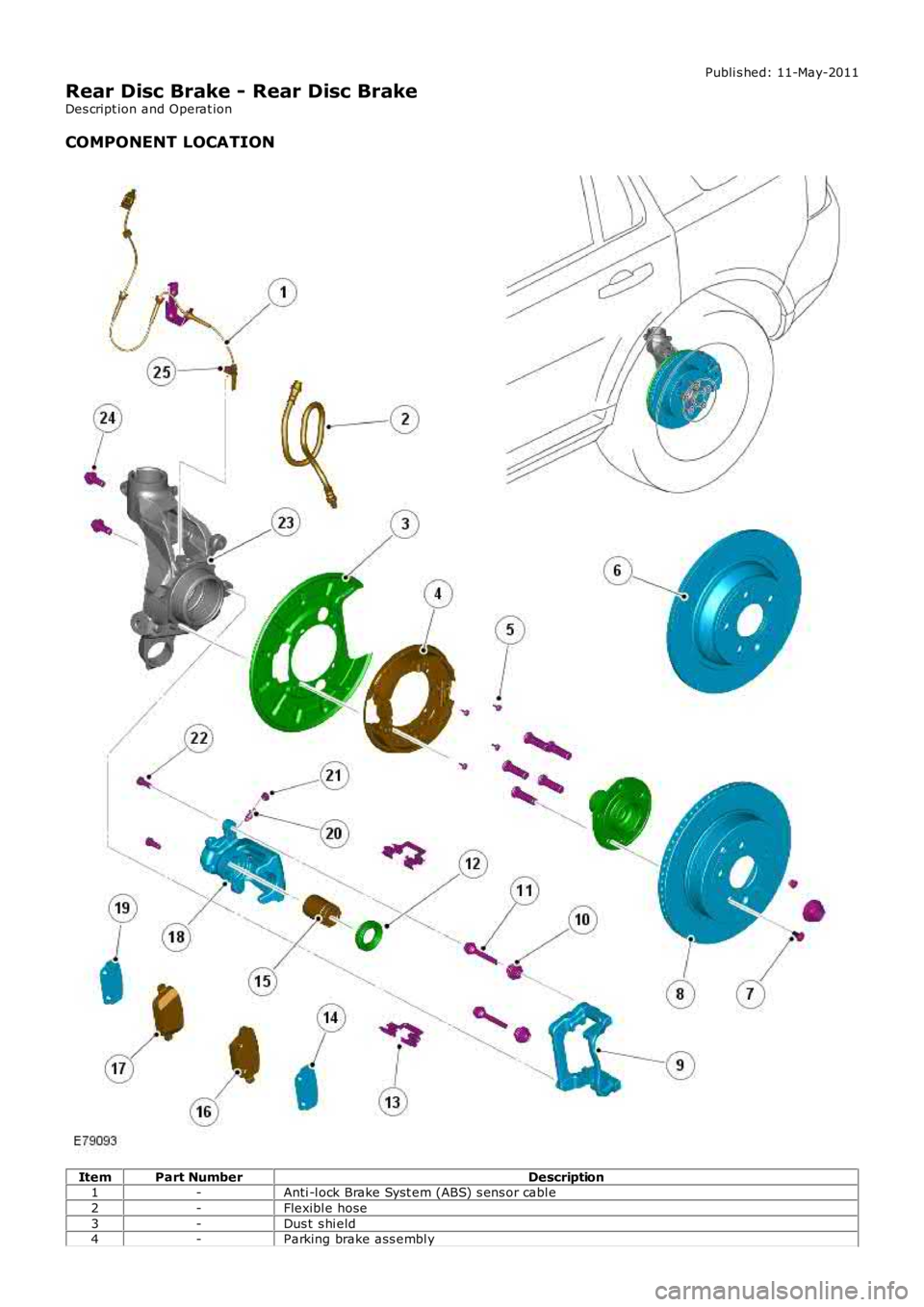

Rear Disc Brake - Rear Disc Brake

Des cript ion and Operat ion

COMPONENT LOCATION Item

Part Number Description

1 -Anti -l ock Brake Syst em (ABS) s ens or cabl e

2 -Flexibl e hose

3 -Dus t s hi eld

4 -Parking brake ass embl y