transmission fluid LEXUS LS430 2003 Factory Owner's Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 2742 of 4500

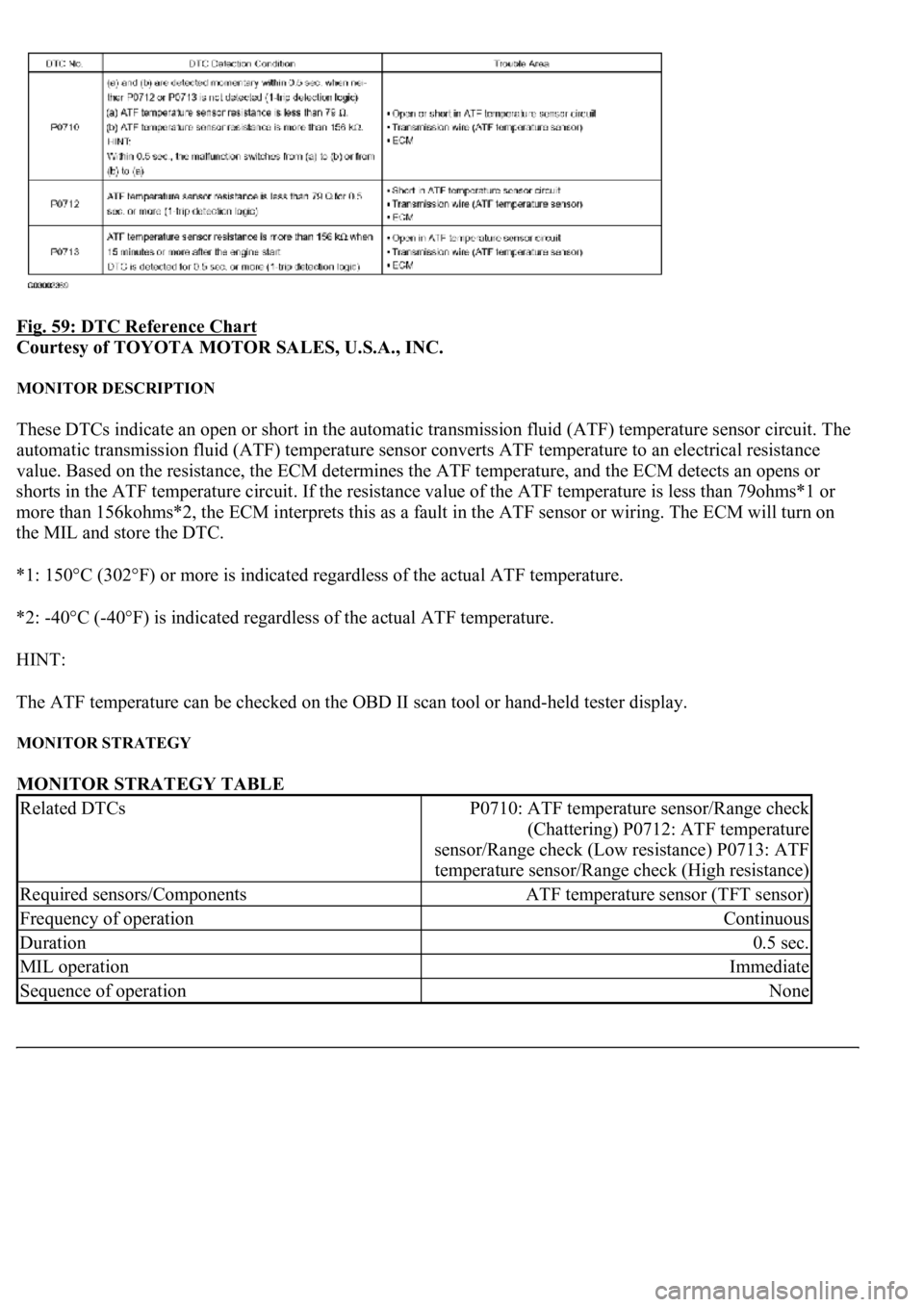

Fig. 59: DTC Reference Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

MONITOR DESCRIPTION

These DTCs indicate an open or short in the automatic transmission fluid (ATF) temperature sensor circuit. The

automatic transmission fluid (ATF) temperature sensor converts ATF temperature to an electrical resistance

value. Based on the resistance, the ECM determines the ATF temperature, and the ECM detects an opens or

shorts in the ATF temperature circuit. If the resistance value of the ATF temperature is less than 79ohms*1 or

more than 156kohms*2, the ECM interprets this as a fault in the ATF sensor or wiring. The ECM will turn on

the MIL and store the DTC.

*1: 150°C (302°F) or more is indicated regardless of the actual ATF temperature.

*2: -40°C (-40°F) is indicated regardless of the actual ATF temperature.

HINT:

The ATF temperature can be checked on the OBD II scan tool or hand-held tester display.

MONITOR STRATEGY

MONITOR STRATEGY TABLE

Related DTCsP0710: ATF temperature sensor/Range check

(Chattering) P0712: ATF temperature

sensor/Range check (Low resistance) P0713: ATF

temperature sensor/Range check (High resistance)

Required sensors/ComponentsATF temperature sensor (TFT sensor)

Frequency of operationContinuous

Duration0.5 sec.

MIL operationImmediate

Sequence of operationNone

Page 2743 of 4500

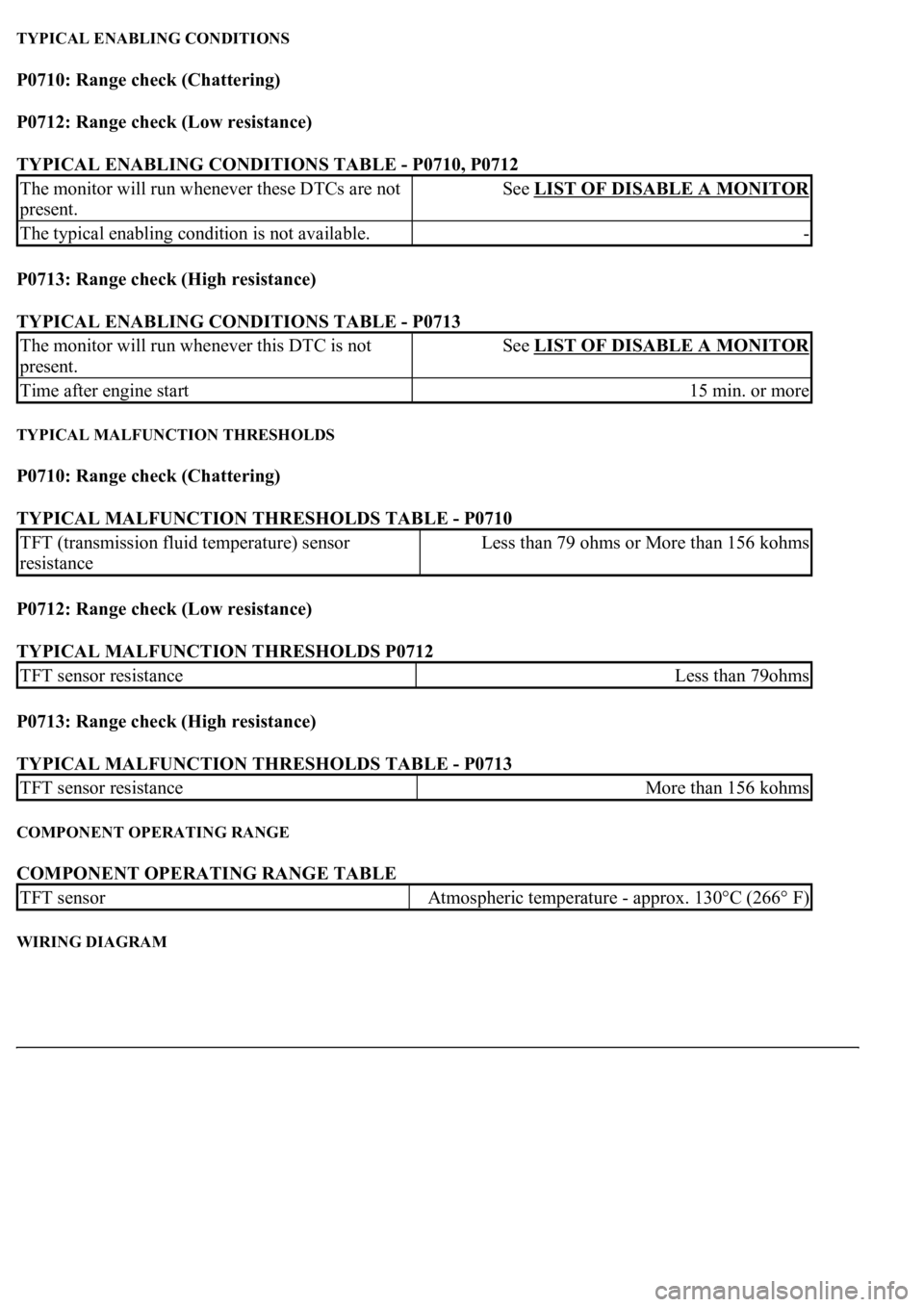

TYPICAL ENABLING CONDITIONS

P0710: Range check (Chattering)

P0712: Range check (Low resistance)

TYPICAL ENABLING CONDITIONS TABLE - P0710, P0712

P0713: Range check (High resistance)

TYPICAL ENABLING CONDITIONS TABLE - P0713

TYPICAL MALFUNCTION THRESHOLDS

P0710: Range check (Chattering)

TYPICAL MALFUNCTION THRESHOLDS TABLE - P0710

P0712: Range check (Low resistance)

TYPICAL MALFUNCTION THRESHOLDS P0712

P0713: Range check (High resistance)

TYPICAL MALFUNCTION THRESHOLDS TABLE - P0713

COMPONENT OPERATING RANGE

COMPONENT OPERATING RANGE TABLE

WIRING DIAGRAM

The monitor will run whenever these DTCs are not

present.See LIST OF DISABLE A MONITOR

The typical enabling condition is not available.-

The monitor will run whenever this DTC is not

present.See LIST OF DISABLE A MONITOR

Time after engine start15 min. or more

TFT (transmission fluid temperature) sensor

resistanceLess than 79 ohms or More than 156 kohms

TFT sensor resistanceLess than 79ohms

TFT sensor resistanceMore than 156 kohms

TFT sensorAtmospheric temperature - approx. 130°C (266° F)

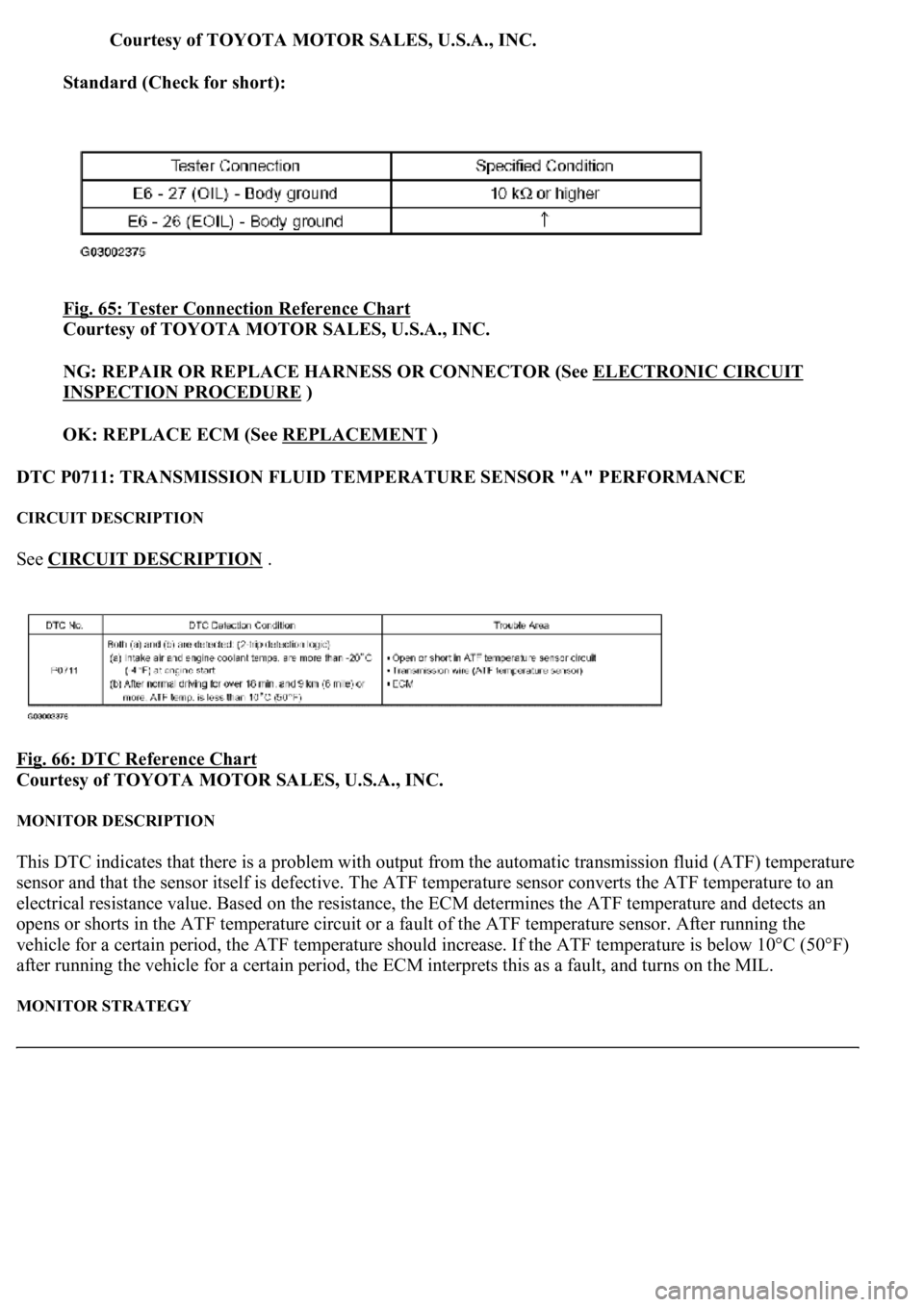

Page 2748 of 4500

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Standard (Check for short):

Fig. 65: Tester Connection Reference Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG: REPAIR OR REPLACE HARNESS OR CONNECTOR (See ELECTRONIC CIRCUIT

INSPECTION PROCEDURE )

OK: REPLACE ECM (See REPLACEMENT

)

DTC P0711: TRANSMISSION FLUID TEMPERATURE SENSOR "A" PERFORMANCE

CIRCUIT DESCRIPTION

See CIRCUIT DESCRIPTION .

Fig. 66: DTC Reference Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

MONITOR DESCRIPTION

This DTC indicates that there is a problem with output from the automatic transmission fluid (ATF) temperature

sensor and that the sensor itself is defective. The ATF temperature sensor converts the ATF temperature to an

electrical resistance value. Based on the resistance, the ECM determines the ATF temperature and detects an

opens or shorts in the ATF temperature circuit or a fault of the ATF temperature sensor. After running the

vehicle for a certain period, the ATF temperature should increase. If the ATF temperature is below 10°C (50°F)

after running the vehicle for a certain period, the ECM interprets this as a fault, and turns on the MIL.

MONITOR STRATEGY

Page 2749 of 4500

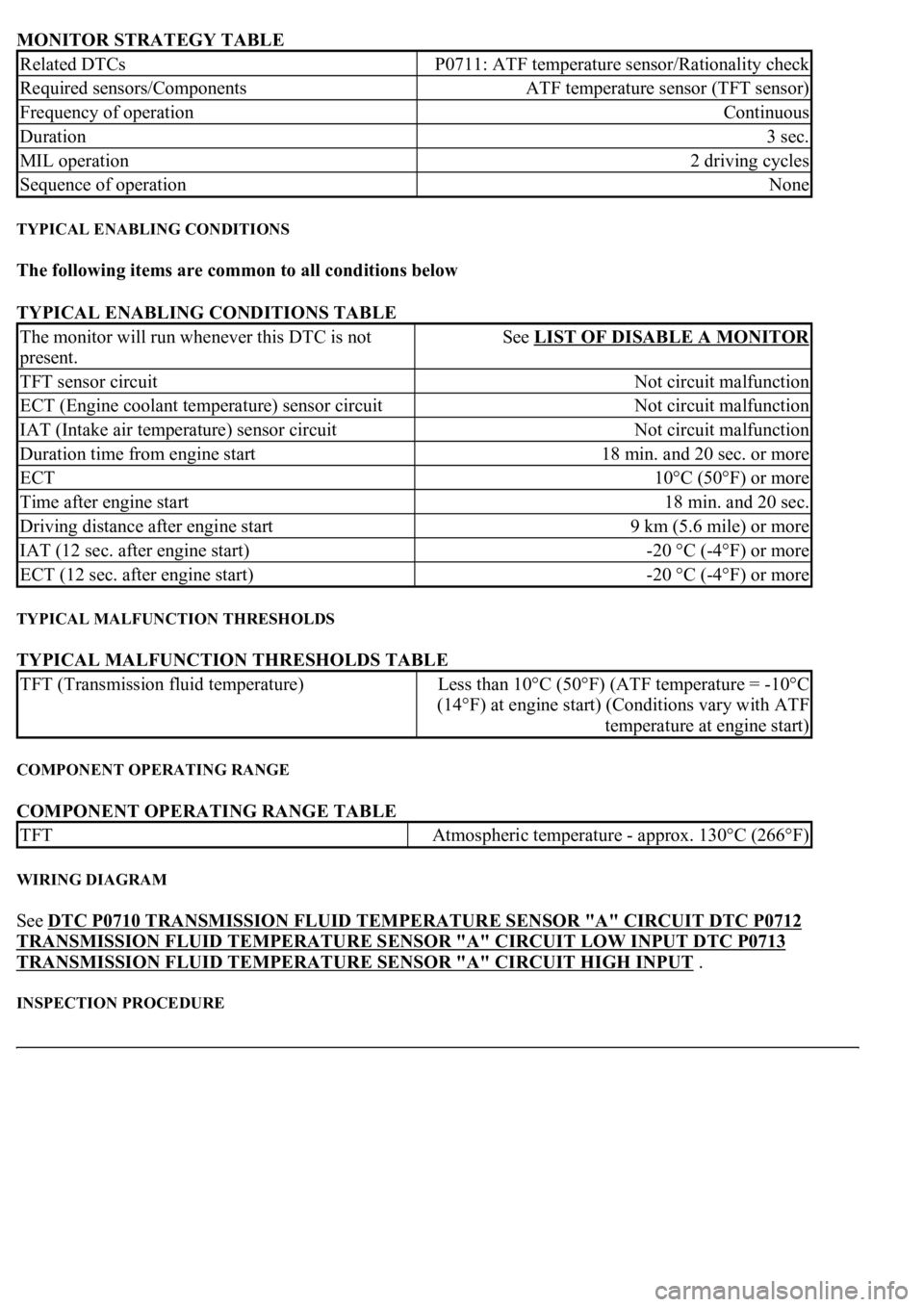

MONITOR STRATEGY TABLE

TYPICAL ENABLING CONDITIONS

The following items are common to all conditions below

TYPICAL ENABLING CONDITIONS TABLE

TYPICAL MALFUNCTION THRESHOLDS

TYPICAL MALFUNCTION THRESHOLDS TABLE

COMPONENT OPERATING RANGE

COMPONENT OPERATING RANGE TABLE

WIRING DIAGRAM

See DTC P0710 TRANSMISSION FLUID TEMPERATURE SENSOR "A" CIRCUIT DTC P0712

TRANSMISSION FLUID TEMPERATURE SENSOR "A" CIRCUIT LOW INPUT DTC P0713

TRANSMISSION FLUID TEMPERATURE SENSOR "A" CIRCUIT HIGH INPUT .

INSPECTION PROCEDURE

Related DTCsP0711: ATF temperature sensor/Rationality check

Required sensors/ComponentsATF temperature sensor (TFT sensor)

Frequency of operationContinuous

Duration3 sec.

MIL operation2 driving cycles

Sequence of operationNone

The monitor will run whenever this DTC is not

present.See LIST OF DISABLE A MONITOR

TFT sensor circuitNot circuit malfunction

ECT (Engine coolant temperature) sensor circuitNot circuit malfunction

IAT (Intake air temperature) sensor circuitNot circuit malfunction

Duration time from engine start18 min. and 20 sec. or more

ECT10°C (50°F) or more

Time after engine start18 min. and 20 sec.

Driving distance after engine start9 km (5.6 mile) or more

IAT (12 sec. after engine start)-20 °C (-4°F) or more

ECT (12 sec. after engine start)-20 °C (-4°F) or more

TFT (Transmission fluid temperature)Less than 10°C (50°F) (ATF temperature = -10°C

(14°F) at engine start) (Conditions vary with ATF

temperature at engine start)

TFTAtmospheric temperature - approx. 130°C (266°F)

Page 2751 of 4500

It is not necessary to inspect the circuit when P0711 is set.

1.CHECK OTHER DTCS OUTPUT (IN ADDITION TO DTC P0711)

a. Connect the hand-held tester to the DLC3.

b. Turn the ignition switch to the ON position and push the hand-held tester main switch ON.

c. Select the item "DIAGNOSIS/ENHANCED OBD II/DTC INFO/CURRENT CODES".

d. Read the DTCs using the hand-held tester.

Result:

DTC OUTPUT RESULT TABLE

HINT:

If any other codes besides "P0711" are output, perform troubleshooting for those DTCs first.

B: GO TO RELEVANT DTC CHART (See DIAGNOSTIC TROUBLE CODE CHART

)

A: Go to next step

2.CHECK TRANSMISSION FLUID LEVEL (See ADJUSTMENT

- AUTOMATIC

TRANSMISSION FLUID )

OK:

Automatic transmission fluid level is correct.

NG: ADD FLUID

OK: REPLACE TRANSMISSION WIRE (See step 5 on REPLACEMENT

)

DTC P0717: TURBINE SPEED SENSOR CIRCUIT NO SIGNAL

CIRCUIT DESCRIPTION

This sensor detects the rotation speed of the turbine which shows the input revolution of transmission. By

comparing the input turbine speed signal (NT) with the counter gear speed sensor signal (SP2), the ECM detects

the shift timing of the gears and appropriately controls the engine torque and hydraulic pressure according to

various conditions. Thus, providin

g smooth gear shift.

Display (DTC output)Proceed to

Only "P0711" is outputA

"P0711" and other DTCsB

Page 3313 of 4500

13.DRAIN AUTOMATIC TRANSMISSION FLUID

14.REMOVE RADIATOR ASSY (See REPLACEMENT

)

15.DISCONNECT FUEL PIPE SUB-ASSY NO.2 (See REPLACEMENT

)

16.REMOVE FAN AND GENERATOR V BELT (See REPLACEMENT

)

17.DISCONNECT ENGINE WIRE

a. Disconnect the engine wire from the ECM box.

b. Remove the nut, and disconnect the generator wire from the generator.

c. Disconnect the wire for generator wire from the wire clamp on generator.

d. Remove the bolt, and disconnect the ground cable from the stay on the generator.

e. Remove the 2 bolts, and disconnect the PS oil hose from the No. 1 oil pan.

f. Remove the bolt, and disconnect the ground strap from the body.

18.DISCONNECT AIR HOSE NO.5

19.DISCONNECT FUEL VAPOR FEED HOSE NO.2

20.DISCONNECT HEATER WATER INLET HOSE A

21.DISCONNECT HEATER WATER OUTLET HOSE A (FROM HEATER UNIT)

22.DISCONNECT VANE PUMP OIL RESERVOIR ASSY

23.DISCONNECT VANE PUMP ASSY

a. Disconnect the 2 PS air hoses.

b. Remove the 2 screws and RH engine under cover.

c. Disconnect the PS oil pressure switch connector.

d. Remove the 2 bolts and nut, and disconnect the pump from the engine.

e. Support the pump securely.

24.DISCONNECT COOLER COMPRESSOR ASSY

a. Disconnect the compressor connector.

b. Disconnect the wire clamp from the wire bracket on the compressor.

c. Remove the bolt, nut and stay.

d. Remove the bolt, and disconnect the wire bracket from the compressor.

e. Remove the bolt, and disconnect the compressor from the engine.

f. Support the cooler compressor securely.

25.REMOVE FRONT FLOOR BRACE CENTER

a. Remove the 4 bolts and brace center.

26.REMOVE EXHAUST PIPE ASSY (See REPLACEMENT

)

27.REMOVE W/ CATALYST CONVERTER ASSY

28.REMOVE FRONT FLOOR HEAT INSULATOR NO.1

29.REMOVE PARKING BRAKE CABLE HEAT INSULATOR

30.REMOVE PROPELLER W/ CENTER BEARING SHAFT ASSY (See OVERHAUL

)

31.REMOVE FLOOR SHIFT GEAR SHIFTING ROD SUB-ASSY

32.REMOVE STEERING SLIDING W/ SHAFT YOKE SUB-ASSY

Page 3361 of 4500

140.INSTALL ENGINE UNDER COVER NO.2

141.INSTALL ENGINE UNDER COVER NO.1

142.INSTALL FRONT WHEEL

143.INSTALL AIR CLEANER ASSY

144.INSTALL INTAKE AIR CONNECTOR PIPE

145.INSTALL AIR CLEANER INLET NO.1

146.INSTALL V-BANK COVER

147.INSTALL HOOD SUB-ASSY (See ADJUSTMENT

and OVERHAUL )

148.CONNECT BATTERY NEGATIVE TERMINAL

149.ADD AUTOMATIC TRANSMISSION FLUID

150.ADD ENGINE COOLANT (See REPLACEMENT

)

151.ADD ENGINE OIL (See ON

-VEHICLE INSPECTION )

152.ADD POWER STEERING FLUID

153.BLEED POWER STEERING FLUID

154.INSPECT AUTOMATIC TRANSMISSION FLUID (See ADJUSTMENT

)

155.INSPECT ENGINE OIL LEAKS

156.CHECK FOR ENGINE COOLANT LEAKS

157.INSPECT FOR FUEL LEAKS

158.CHECK FOR EXHAUST GAS LEAKS

159.INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

160.INSPECT IGNITION TIMING

161.INSPECT ENGINE IDLE SPEED

162.INSPECT CO/HC

163.ADJUST ENGINE (See INSPECTION

)

164.CHECK ABS SPEED SENSOR SIGNAL (See TEST MODE PROCEDURE

)

OVERHAUL

1.REMOVE SPARK PLUG

2.REMOVE OIL FILLER CAP SUB-ASSY

3.REMOVE CYLINDER HEAD COVER SUB-ASSY LH

a. Remove the 9 bolts, 9 seal washers, cylinder head cover and gasket.

4.REMOVE CYLINDER HEAD COVER SUB-ASSY

a. Remove the 9 bolts, 9 seal washers, c

ylinder head cover and gasket.