engine LEXUS SC400 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 1814 of 4087

41. INSTALL TIMING BELT REAR PLATESInstall the rear plate with the two bolts. Install the two rear

plates.

Torque: 7.8 N Vm (80 kgf Vcm, 69 in. Vlbf)

42. INSTALL WATER INLET AND INLET HOUSING

(a) Remove any old packing (FIPG) material.w Using a razor blade and gasket scraper, remove all

the old packing (FIPG) materials from the gasket

surfaces and sealing groove.

w Thoroughly clean all components to remove all the

loose materials.

w Using a non±residue solvent, clean both sealing

surfaces.

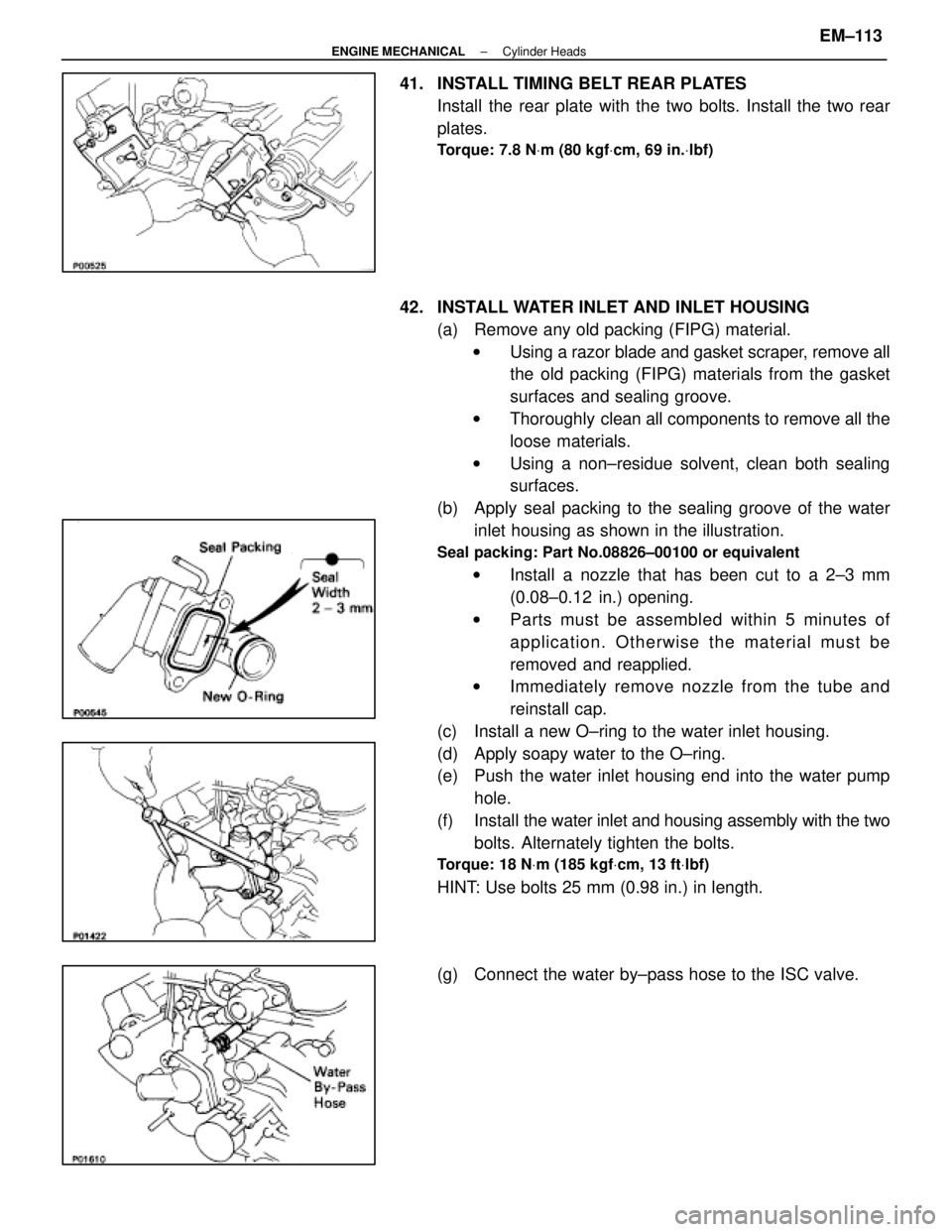

(b) Apply seal packing to the sealing groove of the water inlet housing as shown in the illustration.

Seal packing: Part No.08826±00100 or equivalent

w Install a nozzle that has been cut to a 2±3 mm

(0.08±0.12 in.) opening.

w Parts must be assembled within 5 minutes of

application. Otherwise the material must be

removed and reapplied.

w Immediately remove nozzle from the tube and

reinstall cap.

(c) Install a new O±ring to the water inlet housing.

(d) Apply soapy water to the O±ring.

(e) Push the water inlet housing end into the water pump hole.

(f) Install the water inlet and housing assembly with the two

bolts. Alternately tighten the bolts.

Torque: 18 N Vm (185 kgf Vcm, 13 ft Vlbf)

HINT: Use bolts 25 mm (0.98 in.) in length.

(g) Connect the water by±pass hose to the ISC valve.

±

ENGINE MECHANICAL Cylinder HeadsEM±113

WhereEverybodyKnowsYourName

Page 1815 of 4087

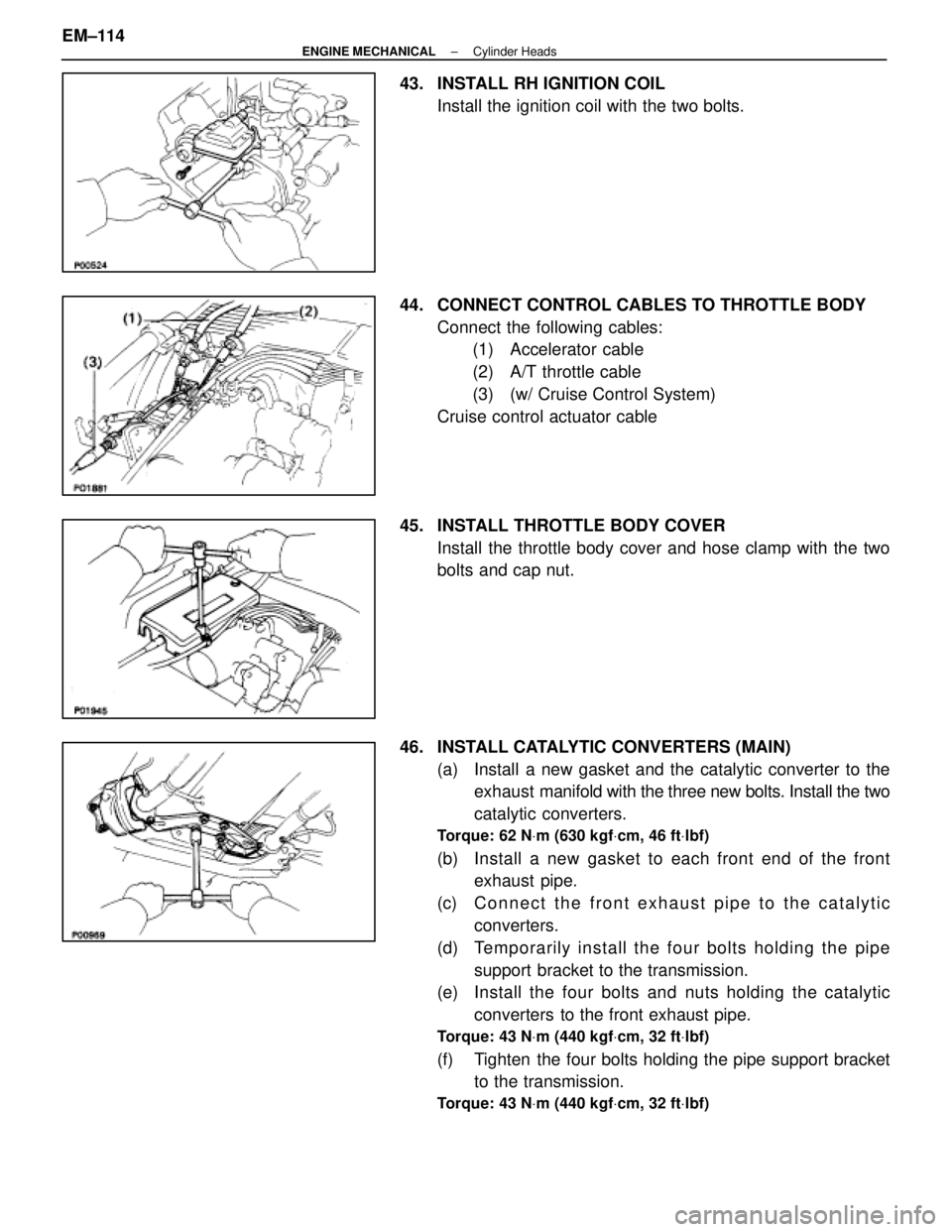

43. INSTALL RH IGNITION COILInstall the ignition coil with the two bolts.

44. CONNECT CONTROL CABLES TO THROTTLE BODY Connect the following cables:(1) Accelerator cable

(2) A/T throttle cable

(3) (w/ Cruise Control System)

Cruise control actuator cable

45. INSTALL THROTTLE BODY COVER Install the throttle body cover and hose clamp with the two

bolts and cap nut.

46. INSTALL CATALYTIC CONVERTERS (MAIN) (a) Install a new gasket and the catalytic converter to theexhaust manifold with the three new bolts. Install the two

catalytic converters.

Torque: 62 N Vm (630 kgf Vcm, 46 ft Vlbf)

(b) Install a new gasket to each front end of the front

exhaust pipe.

(c) C onnect the front exhaust pipe to the catalytic

converters.

(d) Te mp o ra rily in sta ll th e fo u r bo lts ho ld in g th e pip e support bracket to the transmission.

(e) Install the four bolts and nuts holding the catalytic

converters to the front exhaust pipe.

Torque: 43 N Vm (440 kgf Vcm, 32 ft Vlbf)

(f) Tighten the four bolts holding the pipe support bracket

to the transmission.

Torque: 43 N Vm (440 kgf Vcm, 32 ft Vlbf)

EM±114±

ENGINE MECHANICAL Cylinder Heads

WhereEverybodyKnowsYourName

Page 1816 of 4087

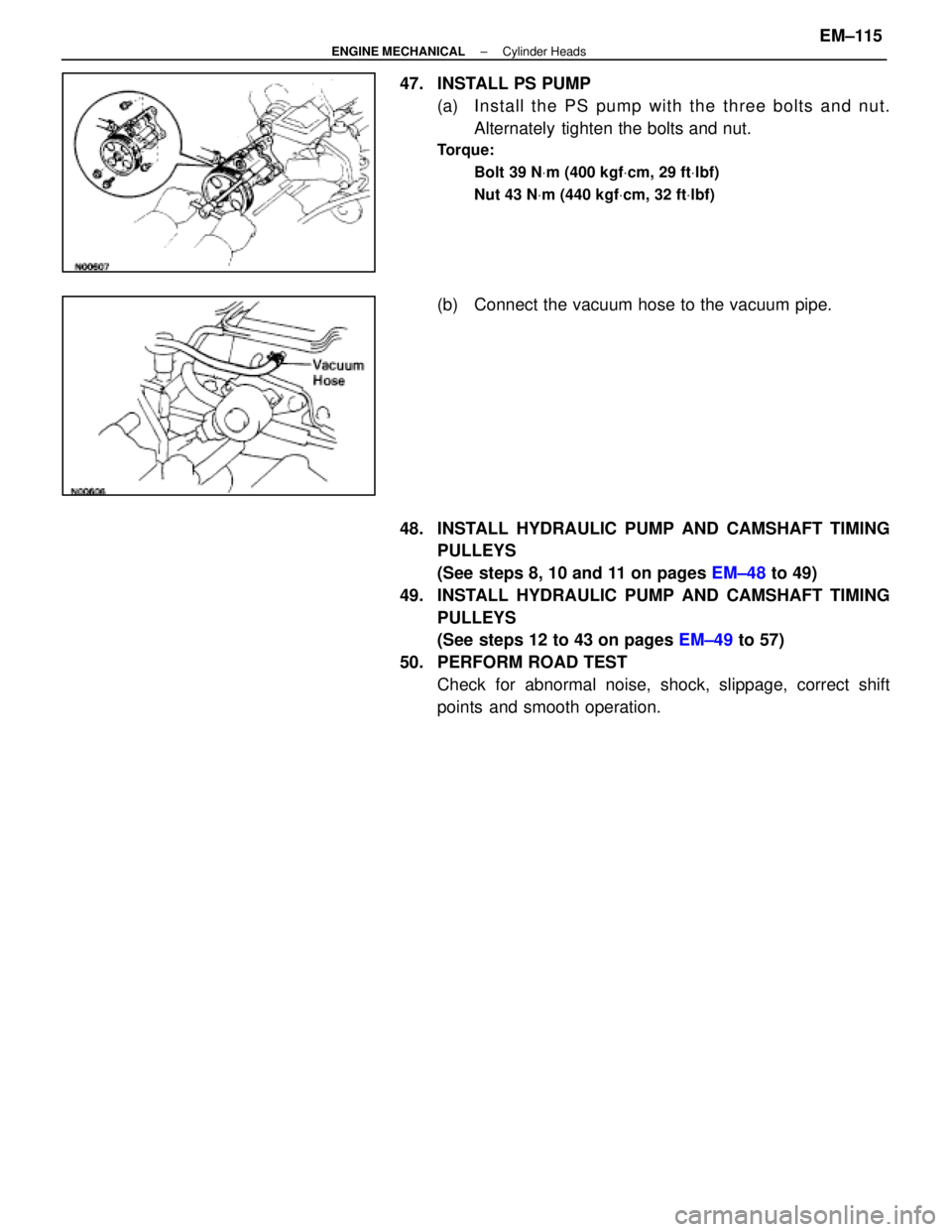

47. INSTALL PS PUMP(a) In sta ll th e PS pu mp with th e th re e bo lts an d nu t.Alternately tighten the bolts and nut.

Torque:

Bolt 39 N Vm (400 kgf Vcm, 29 ft Vlbf)

Nut 43 N Vm (440 kgf Vcm, 32 ft Vlbf)

(b) Connect the vacuum hose to the vacuum pipe.

48. INSTALL HYDRAULIC PUMP AND CAMSHAFT TIMING PULLEYS

(See steps 8, 10 and 11 on pages EM±48 to 49)

49. INSTALL HYDRAULIC PUMP AND CAMSHAFT TIMING PULLEYS

(See steps 12 to 43 on pages EM±49 to 57)

50. PERFORM ROAD TEST Check for abnormal noise, shock, slippage, correct shift

points and smooth operation.

±

ENGINE MECHANICAL Cylinder HeadsEM±115

WhereEverybodyKnowsYourName

Page 1817 of 4087

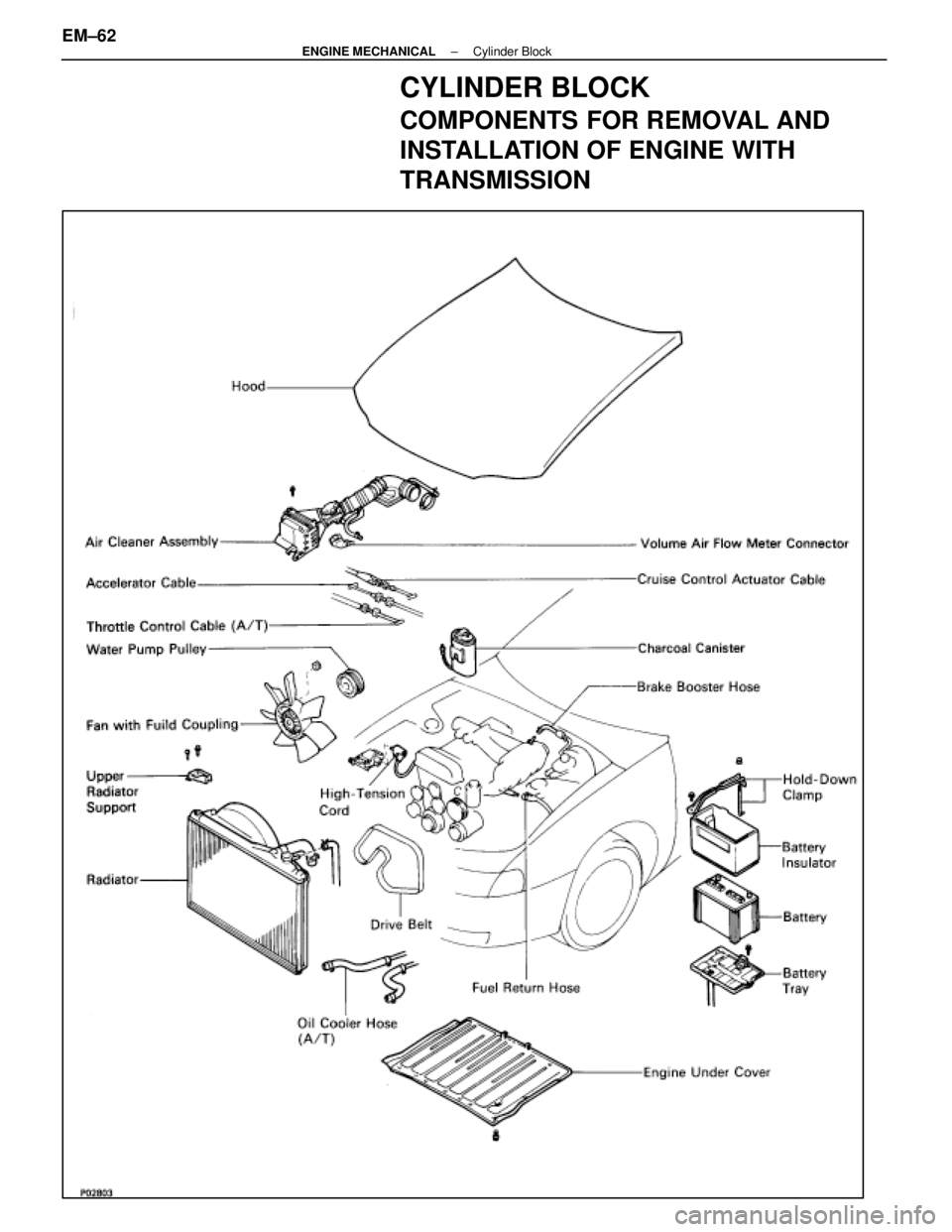

CYLINDER BLOCK

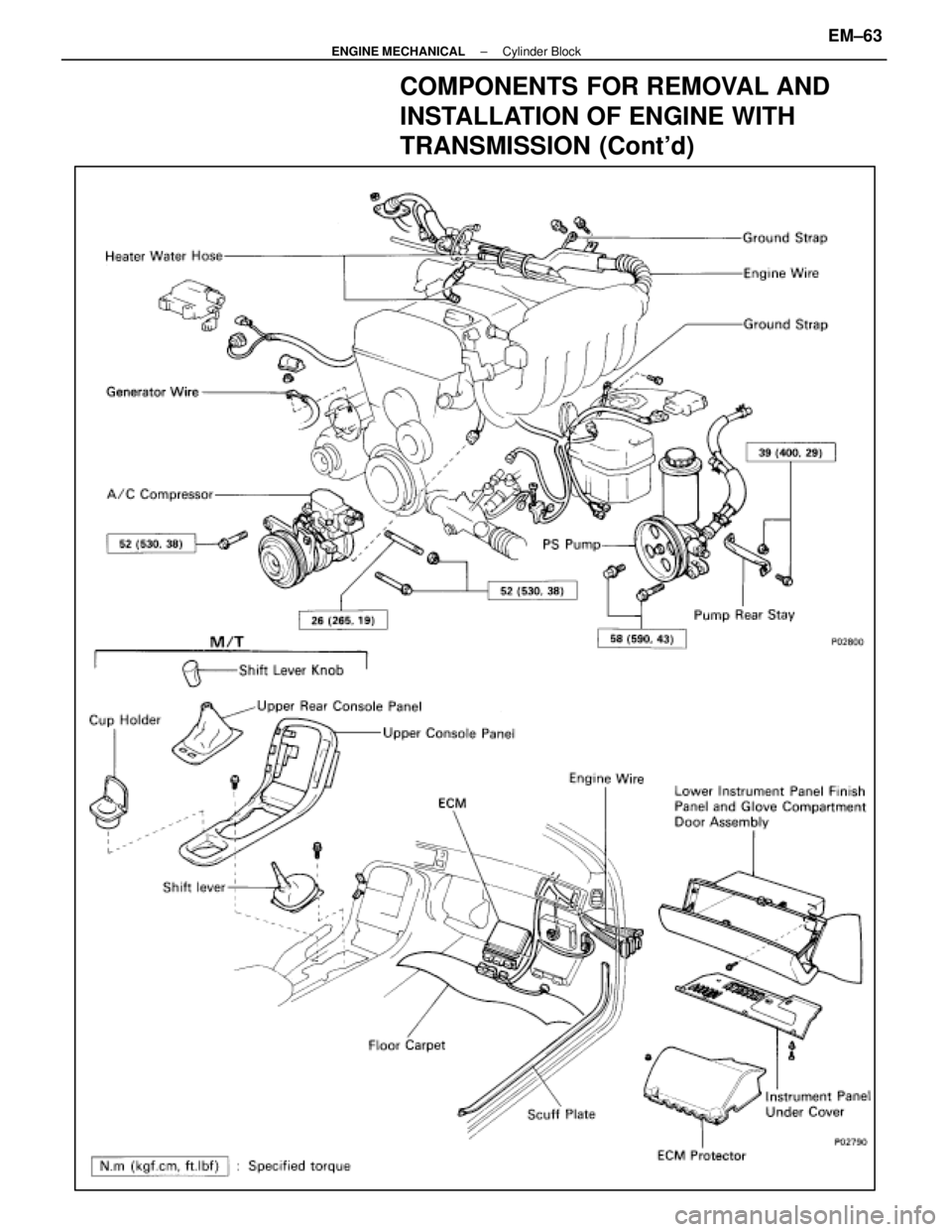

COMPONENTS FOR REMOVAL AND

INSTALLATION OF ENGINE WITH

TRANSMISSION

EM±62±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 1818 of 4087

COMPONENTS FOR REMOVAL AND

INSTALLATION OF ENGINE WITH

TRANSMISSION (Cont'd)

±

ENGINE MECHANICAL Cylinder BlockEM±63

WhereEverybodyKnowsYourName

Page 1819 of 4087

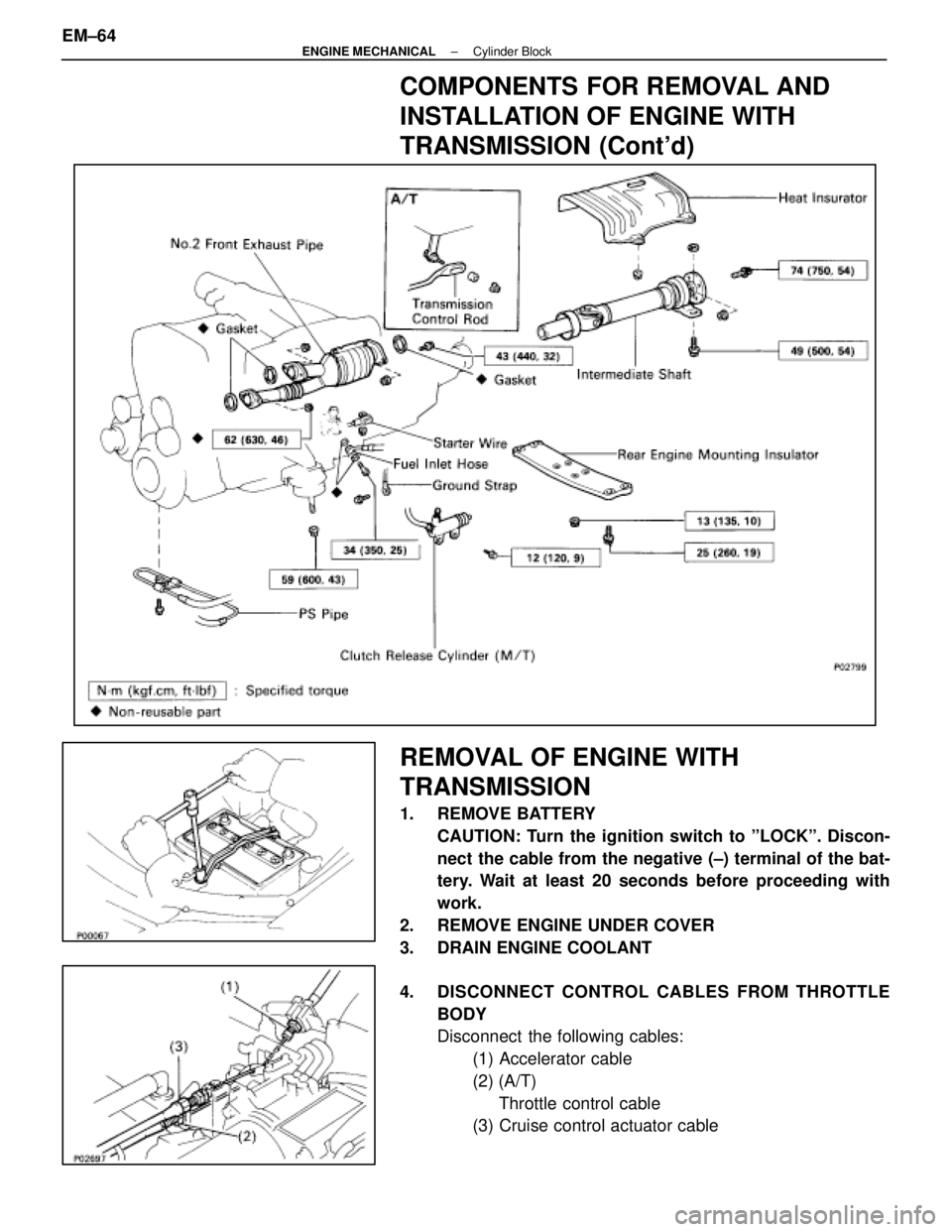

COMPONENTS FOR REMOVAL AND

INSTALLATION OF ENGINE WITH

TRANSMISSION (Cont'd)

REMOVAL OF ENGINE WITH

TRANSMISSION

1. REMOVE BATTERYCAUTION: Turn the ignition switch to ºLOCKº. Discon-

nect the cable from the negative (±) terminal of the bat-

tery. Wait at least 20 seconds before proceeding with

work.

2. REMOVE ENGINE UNDER COVER

3. DRAIN ENGINE COOLANT

4. DISCONNECT CONTROL CABLES FROM THROTTLE BODY

Disconnect the following cables:(1) Accelerator cable

(2) (A/T)Throttle control cable

(3) Cruise control actuator cable

EM±64

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 1820 of 4087

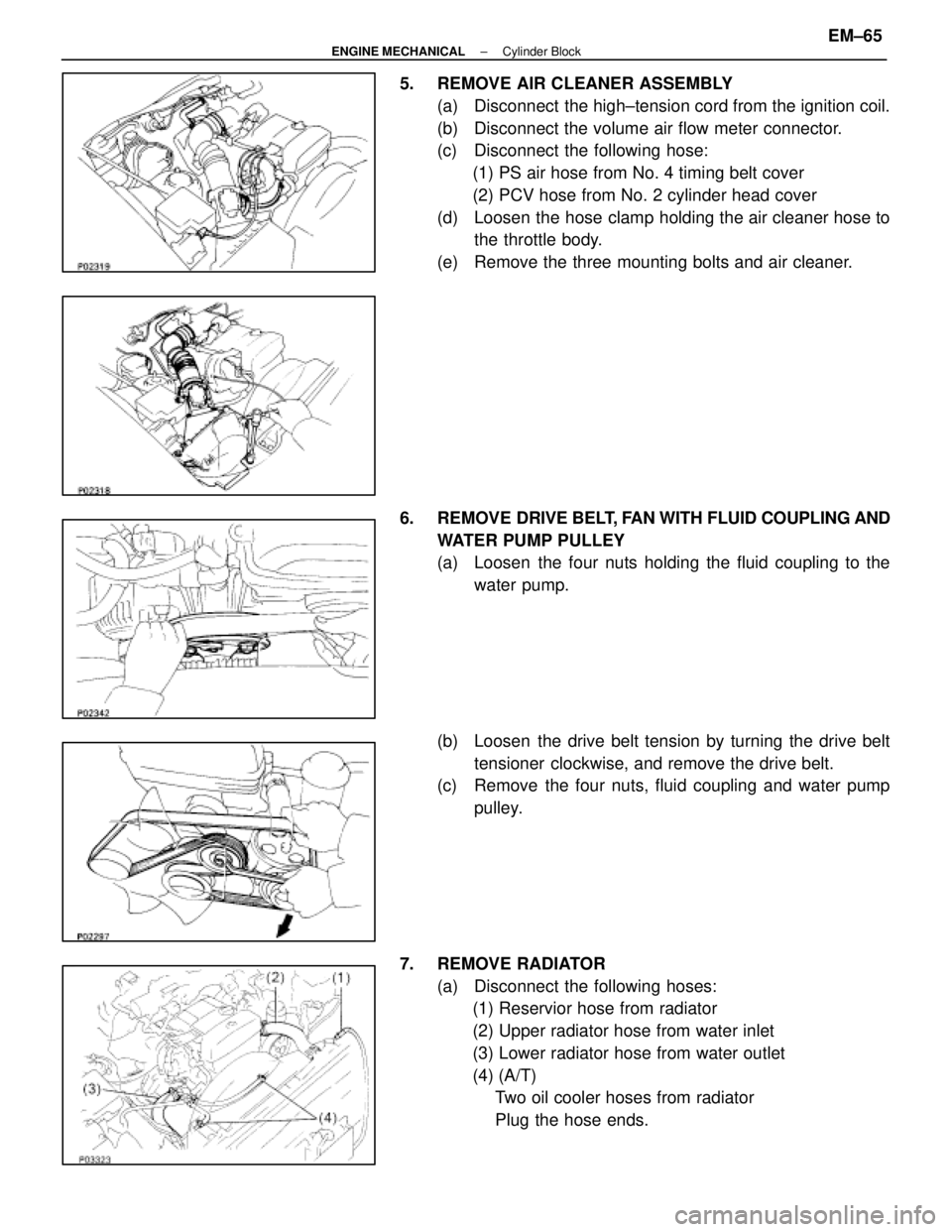

5. REMOVE AIR CLEANER ASSEMBLY(a) Disconnect the high±tension cord from the ignition coil.

(b) Disconnect the volume air flow meter connector.

(c) Disconnect the following hose:(1) PS air hose from No. 4 timing belt cover

(2) PCV hose from No. 2 cylinder head cover

(d) Loosen the hose clamp holding the air cleaner hose to the throttle body.

(e) Remove the three mounting bolts and air cleaner.

6. REMOVE DRIVE BELT, FAN WITH FLUID COUPLING AND

WATER PUMP PULLEY

(a) Loosen the four nuts holding the fluid coupling to the water pump.

(b) Loosen the drive belt tension by turning the drive belt tensioner clockwise, and remove the drive belt.

(c) Remove the four nuts, fluid coupling and water pump

pulley.

7. REMOVE RADIATOR (a) Disconnect the following hoses:(1) Reservior hose from radiator

(2) Upper radiator hose from water inlet

(3) Lower radiator hose from water outlet

(4) (A/T)Two oil cooler hoses from radiator

Plug the hose ends.

±

ENGINE MECHANICAL Cylinder BlockEM±65

WhereEverybodyKnowsYourName

Page 1821 of 4087

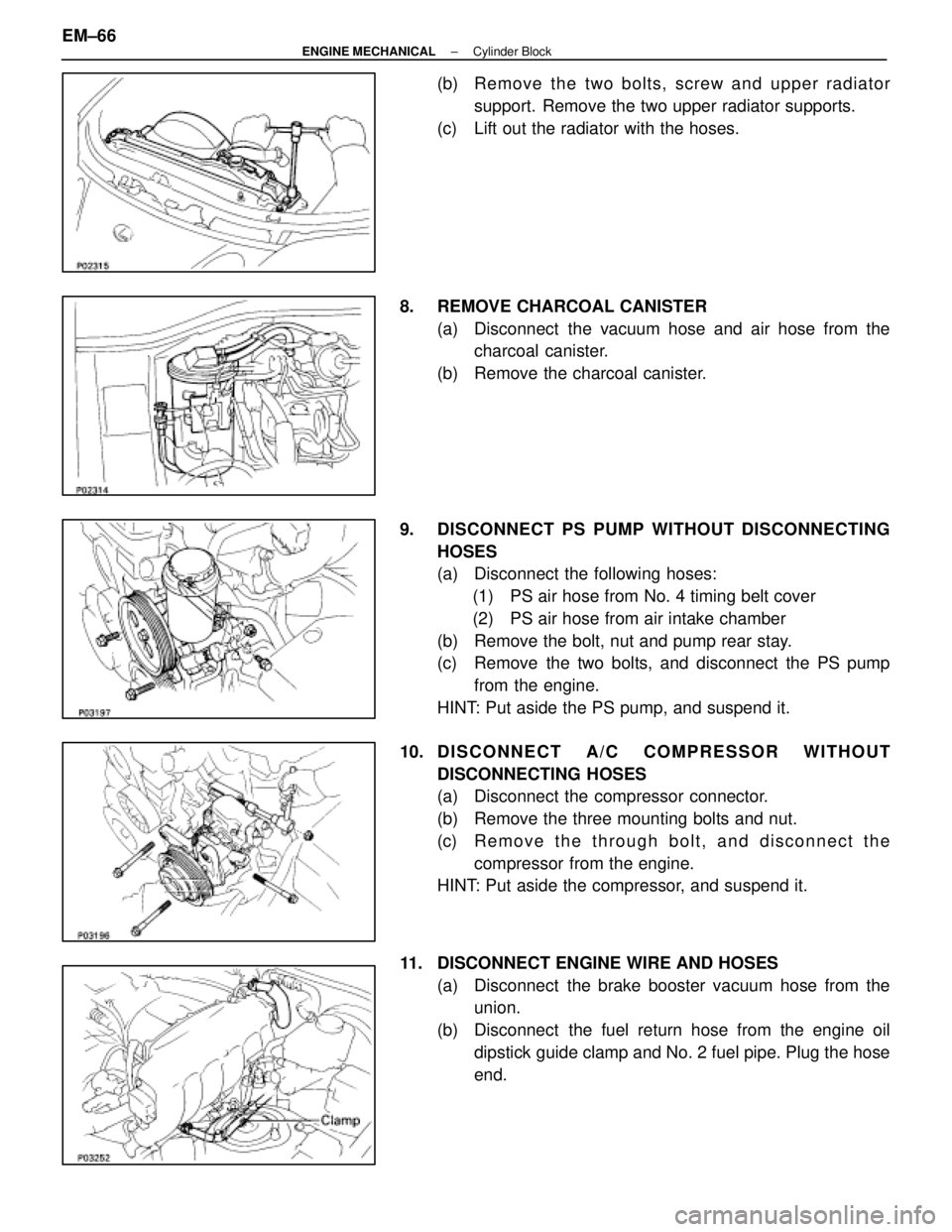

(b) Remove the two bolts, screw and upper radiatorsupport. Remove the two upper radiator supports.

(c) Lift out the radiator with the hoses.

8. REMOVE CHARCOAL CANISTER (a) Disconnect the vacuum hose and air hose from thecharcoal canister.

(b) Remove the charcoal canister.

9. DISCONNECT PS PUMP WITHOUT DISCONNECTING HOSES

(a) Disconnect the following hoses:(1) PS air hose from No. 4 timing belt cover

(2) PS air hose from air intake chamber

(b) Remove the bolt, nut and pump rear stay.

(c) Remove the two bolts, and disconnect the PS pump from the engine.

HINT: Put aside the PS pump, and suspend it.

10. D I S C O N N E C T A / C C O M P R ESSOR WITHOUT

DISCONNECTING HOSES

(a) Disconnect the compressor connector.

(b) Remove the three mounting bolts and nut.

(c) R e m o v e t h e t h r ough bolt, and disconnect the

compressor from the engine.

HINT: Put aside the compressor, and suspend it.

11. DISCONNECT ENGINE WIRE AND HOSES (a) Disconnect the brake booster vacuum hose from theunion.

(b) Disconnect the fuel return hose from the engine oil dipstick guide clamp and No. 2 fuel pipe. Plug the hose

end.

EM±66

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 1822 of 4087

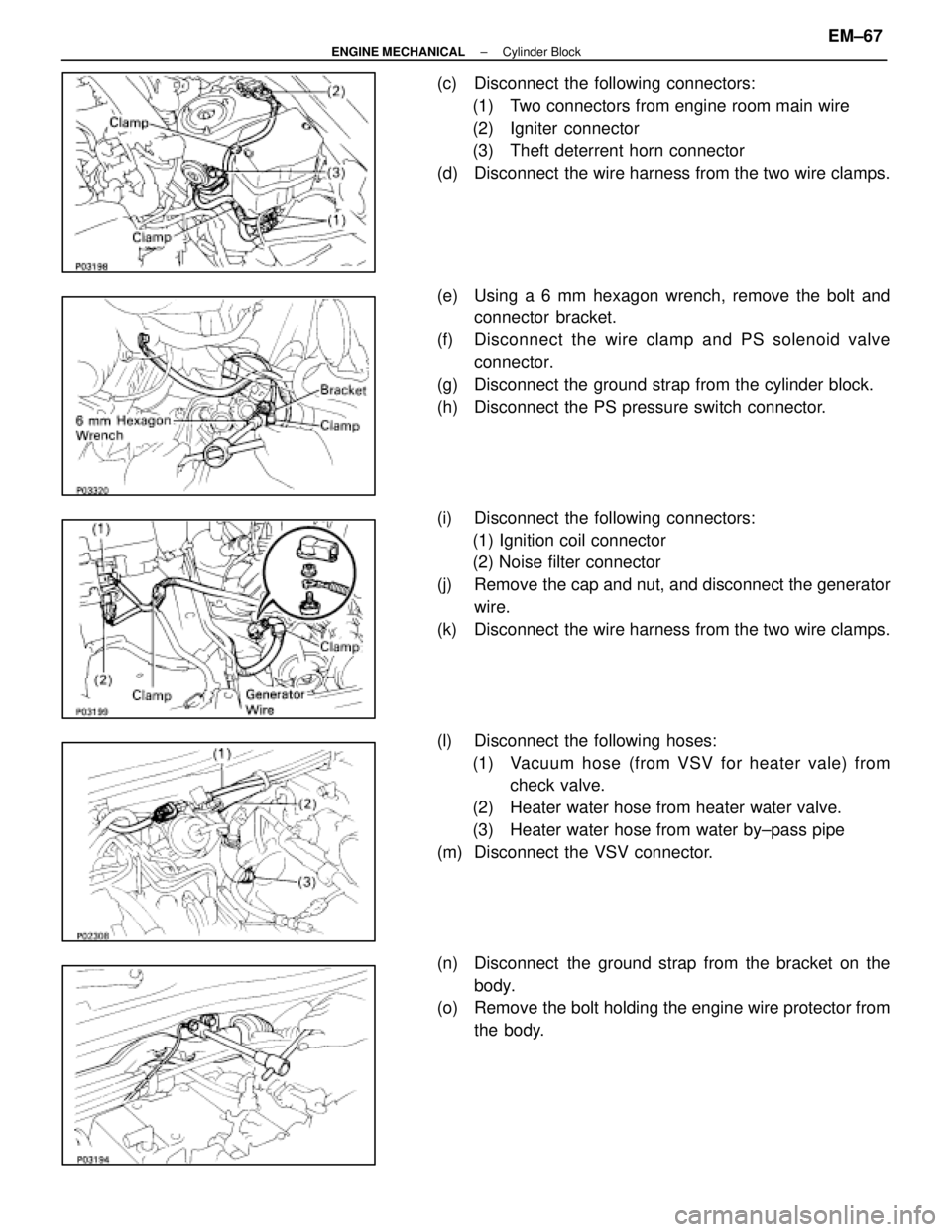

(c) Disconnect the following connectors:(1) Two connectors from engine room main wire

(2) Igniter connector

(3) Theft deterrent horn connector

(d) Disconnect the wire harness from the two wire clamps.

(e) Using a 6 mm hexagon wrench, remove the bolt and connector bracket.

(f) Disc onnect the wire clamp and PS solenoid valve

connector.

(g) Disconnect the ground strap from the cylinder block.

(h) Disconnect the PS pressure switch connector.

(i) Disconnect the following connectors: (1) Ignition coil connector

(2) Noise filter connector

(j) Remove the cap and nut, and disconnect the generator wire.

(k) Disconnect the wire harness from the two wire clamps.

(l) Disconnect the following hoses: (1) Vacuum hose (from VSV for heater vale) from check valve.

(2) Heater water hose from heater water valve.

(3) Heater water hose from water by±pass pipe

(m) Disconnect the VSV connector.

(n) Disconnect the ground strap from the bracket on the body.

(o) Remove the bolt holding the engine wire protector from

the body.

±

ENGINE MECHANICAL Cylinder BlockEM±67

WhereEverybodyKnowsYourName

Page 1823 of 4087

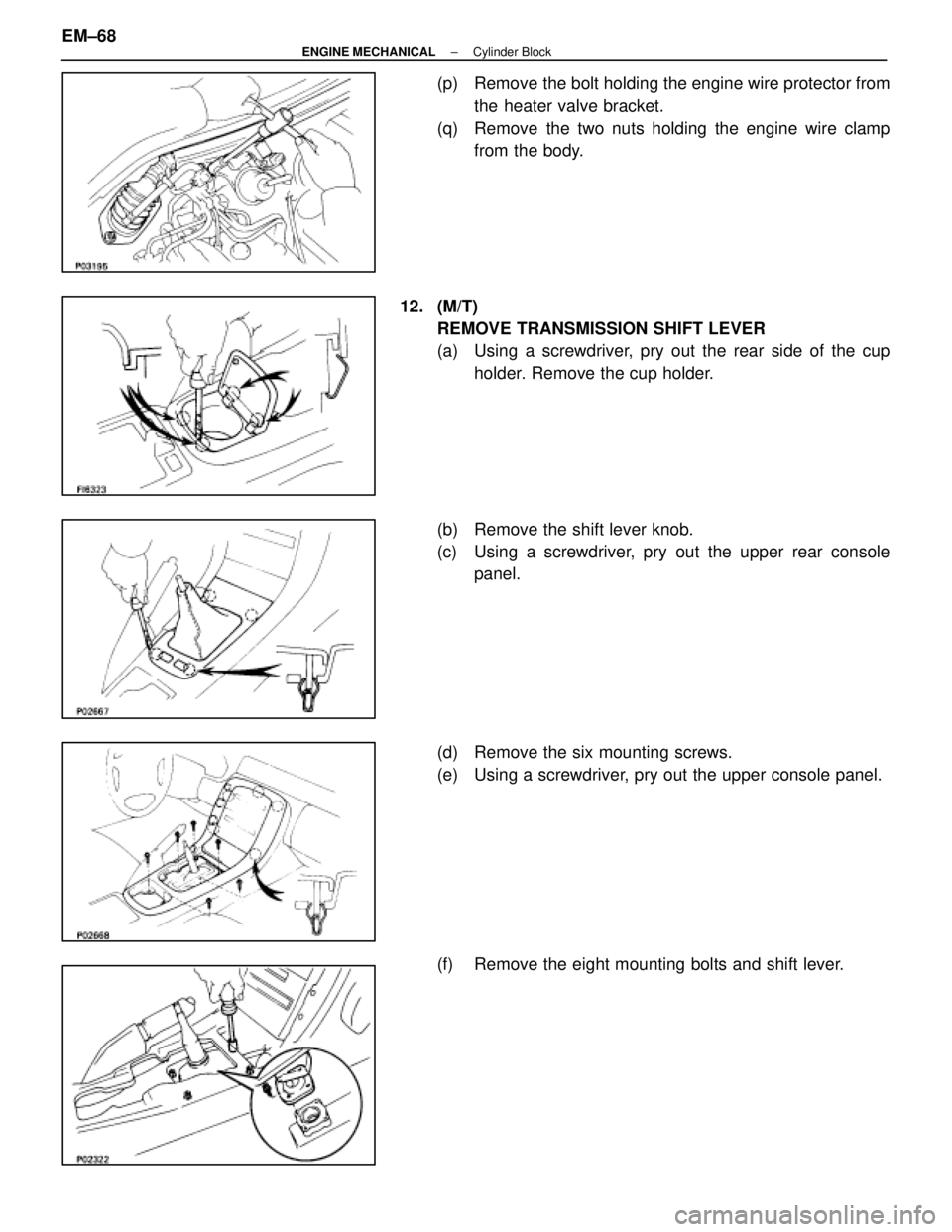

(p) Remove the bolt holding the engine wire protector fromthe heater valve bracket.

(q) Remove the two nuts holding the engine wire clamp from the body.

12. (M/T) REMOVE TRANSMISSION SHIFT LEVER

(a) Using a screwdriver, pry out the rear side of the cupholder. Remove the cup holder.

(b) Remove the shift lever knob.

(c) Using a screwdriver, pry out the upper rear console panel.

(d) Remove the six mounting screws.

(e) Using a screwdriver, pry out the upper console panel.

(f) Remove the eight mounting bolts and shift lever.

EM±68

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName