clock LINCOLN MKZ HYBRID 2016 Owners Manual

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2016, Model line: MKZ HYBRID, Model: LINCOLN MKZ HYBRID 2016Pages: 543, PDF Size: 5.04 MB

Page 35 of 543

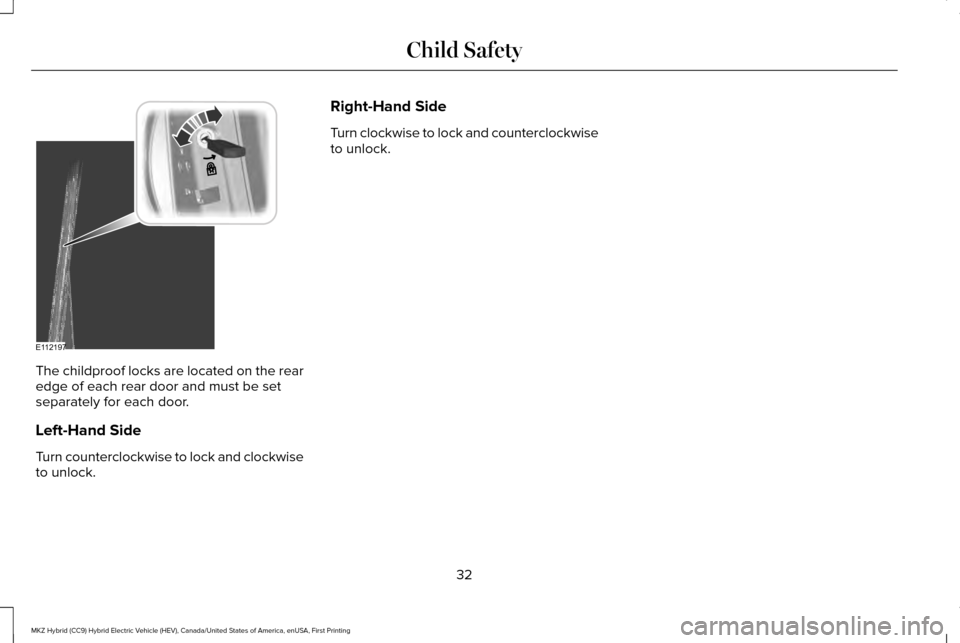

The childproof locks are located on the rear

edge of each rear door and must be set

separately for each door.

Left-Hand Side

Turn counterclockwise to lock and clockwise

to unlock. Right-Hand Side

Turn clockwise to lock and counterclockwise

to unlock.

32

MKZ Hybrid (CC9) Hybrid Electric Vehicle (HEV), Canada/United States of America, enUSA, First Printing Child SafetyE112197

Page 58 of 543

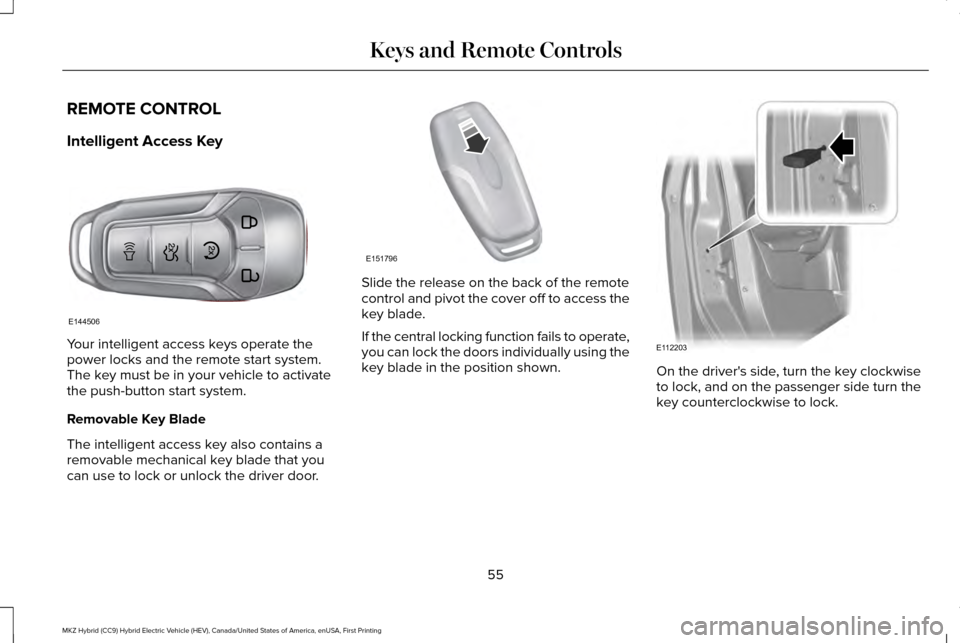

REMOTE CONTROL

Intelligent Access Key

Your intelligent access keys operate the

power locks and the remote start system.

The key must be in your vehicle to activate

the push-button start system.

Removable Key Blade

The intelligent access key also contains a

removable mechanical key blade that you

can use to lock or unlock the driver door. Slide the release on the back of the remote

control and pivot the cover off to access the

key blade.

If the central locking function fails to operate,

you can lock the doors individually using the

key blade in the position shown.

On the driver's side, turn the key clockwise

to lock, and on the passenger side turn the

key counterclockwise to lock.

55

MKZ Hybrid (CC9) Hybrid Electric Vehicle (HEV), Canada/United States of America, enUSA, First Printing Keys and Remote ControlsE144506 E151796 E112203

Page 301 of 543

When a low voltage battery replacement is

necessary, see an authorized dealer to

replace the low voltage battery with a Ford

recommended replacement low voltage

battery that matches the electrical

requirements of the vehicle

To ensure proper operation of the battery

management system (BMS), do not allow a

technician to connect any electrical device

ground connection directly to the low voltage

battery negative post. A connection at the

low voltage battery negative post can cause

inaccurate measurements of the battery

condition and potential incorrect system

operation.

Note:

If a person adds electrical or electronic

accessories or components to the vehicle,

the accessories or components may

adversely affect the low voltage battery

performance and durability and may also

affect the performance of other electrical

systems in the vehicle.

For longer, trouble-free operation, keep the

top of the battery clean and dry. Also, make

certain the battery cables are always tightly

fastened to the battery terminals. If you see any corrosion on the battery or

terminals, remove the cables from the

terminals and clean with a wire brush. You

can neutralize the acid with a solution of

baking soda and water.

When a battery replacement is required, the

battery should only be replaced with a Ford

recommended replacement battery that

matches the electrical requirements of the

vehicle.

Because your vehicle

’s engine is

electronically-controlled by a computer,

some engine control settings are maintained

by power from the low voltage battery. Some

engine computer settings, like the idle trim

and fuel trim strategy, optimize the

driveability and performance of the engine.

Some other computer settings, like the clock

and radio station presets, are also maintained

in memory by power from the low voltage

battery. When a technician disconnects and

connects the low voltage battery, these

settings are erased. Note:

Until you switch the ignition to the on

position, you will receive a message in your

information display stating that your vehicle

is not in park.

Complete the following procedure in order

to restore the settings:

1. With the vehicle at a complete stop, set the parking brake.

2. Shift the transmission into P.

3. Turn off all accessories.

4. Step on the brake pedal and start the vehicle.

5. Run the engine until it reaches normal operating temperature. While the engine

is warming up, complete the following:

Reset the clock. See Audio System

(page 358). Reset the power windows

bounce-back feature. See Windows and

Mirrors (page 95). Reset the radio station

presets.

See Audio System (page 358).

6. Allow the engine to idle for at least one minute. If the engine turns off, step on

the accelerator to start the engine.

298

MKZ Hybrid (CC9) Hybrid Electric Vehicle (HEV), Canada/United States of America, enUSA, First Printing Maintenance

Page 304 of 543

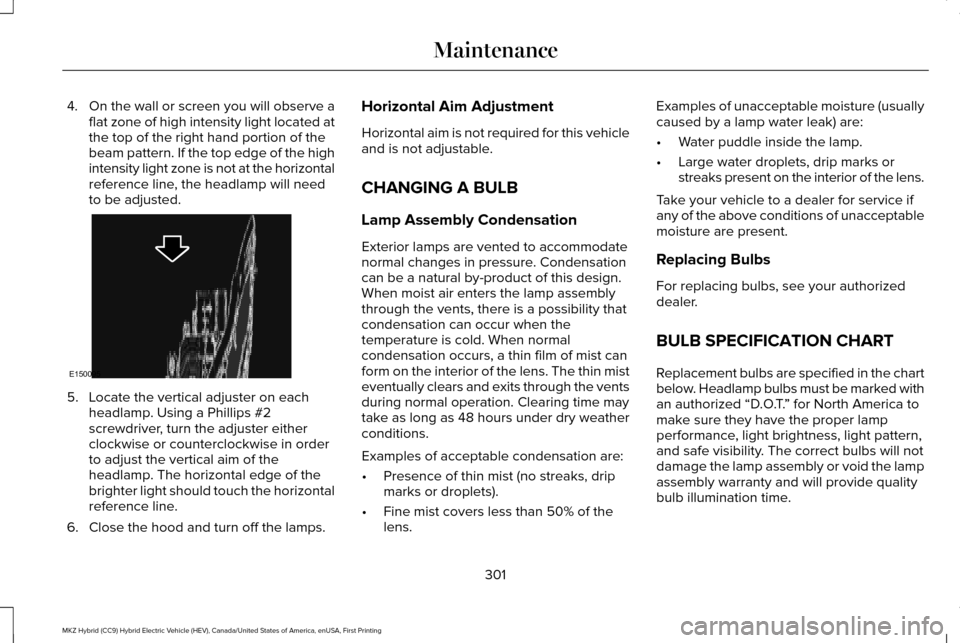

4.

On the wall or screen you will observe a

flat zone of high intensity light located at

the top of the right hand portion of the

beam pattern. If the top edge of the high

intensity light zone is not at the horizontal

reference line, the headlamp will need

to be adjusted. 5. Locate the vertical adjuster on each

headlamp. Using a Phillips #2

screwdriver, turn the adjuster either

clockwise or counterclockwise in order

to adjust the vertical aim of the

headlamp. The horizontal edge of the

brighter light should touch the horizontal

reference line.

6. Close the hood and turn off the lamps. Horizontal Aim Adjustment

Horizontal aim is not required for this vehicle

and is not adjustable.

CHANGING A BULB

Lamp Assembly Condensation

Exterior lamps are vented to accommodate

normal changes in pressure. Condensation

can be a natural by-product of this design.

When moist air enters the lamp assembly

through the vents, there is a possibility that

condensation can occur when the

temperature is cold. When normal

condensation occurs, a thin film of mist can

form on the interior of the lens. The thin mist

eventually clears and exits through the vents

during normal operation. Clearing time may

take as long as 48 hours under dry weather

conditions.

Examples of acceptable condensation are:

•

Presence of thin mist (no streaks, drip

marks or droplets).

• Fine mist covers less than 50% of the

lens. Examples of unacceptable moisture (usually

caused by a lamp water leak) are:

•

Water puddle inside the lamp.

• Large water droplets, drip marks or

streaks present on the interior of the lens.

Take your vehicle to a dealer for service if

any of the above conditions of unacceptable

moisture are present.

Replacing Bulbs

For replacing bulbs, see your authorized

dealer.

BULB SPECIFICATION CHART

Replacement bulbs are specified in the chart

below. Headlamp bulbs must be marked with

an authorized “D.O.T. ” for North America to

make sure they have the proper lamp

performance, light brightness, light pattern,

and safe visibility. The correct bulbs will not

damage the lamp assembly or void the lamp

assembly warranty and will provide quality

bulb illumination time.

301

MKZ Hybrid (CC9) Hybrid Electric Vehicle (HEV), Canada/United States of America, enUSA, First Printing MaintenanceE150095

Page 319 of 543

What to do when a Tire Is Punctured

A tire puncture within the tire tread area can

be repaired in two stages with the kit.

•

In the first stage, the tire will be reinflated

with a sealing compound and air. After

the tire has been reinflated, you will need

to drive the vehicle a short distance 4 mi

(6 km) to distribute the sealant in the tire.

• In the second stage, you will need to

check the tire pressure and adjust, if

necessary, to the vehicle tire inflation

pressure.

First Stage: Reinflating the Tire with

Sealing Compound and Air WARNINGS

Do not stand directly over the kit while

inflating the tire. If you notice any

unusual bulges or deformations in the tire

sidewall during inflation, stop and call

roadside assistance. If the tire does not inflate to the

recommended tire pressure within 15

minutes, stop and call roadside assistance. Preparation: Park the vehicle in a safe, level

and secure area, away from moving traffic.

Turn the hazard lights on. Apply the parking

brake and turn the engine off. Inspect the

flat tire for visible damage.

Sealant compound contains latex. To avoid

any allergic reactions, use the non-latex

gloves located in the accessory box on the

underside of the kit housing.

Do not remove any foreign object that has

pierced the tire. If a puncture is located in

the tire sidewall, stop and call roadside

assistance.

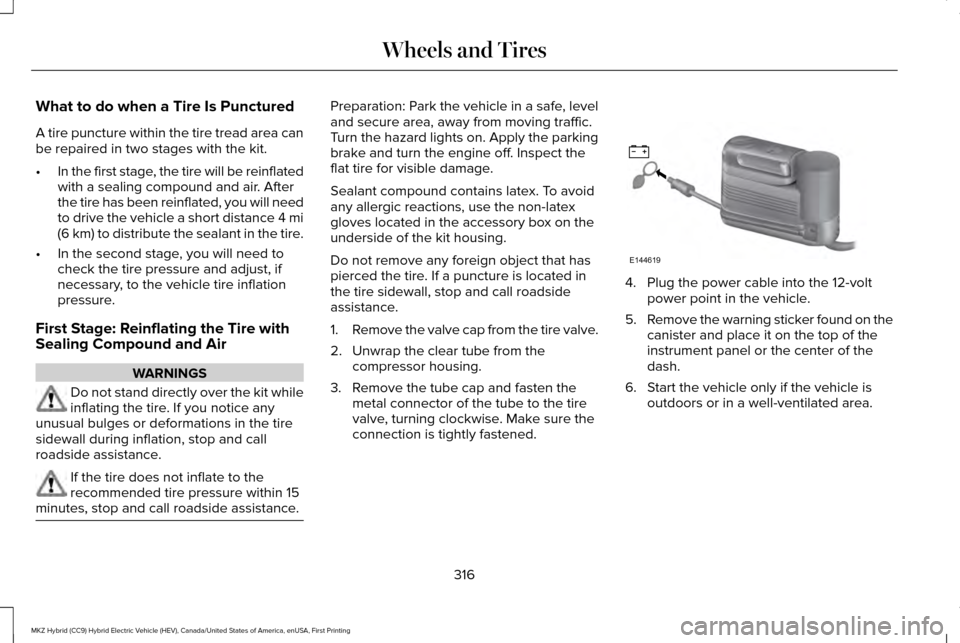

1.

Remove the valve cap from the tire valve.

2. Unwrap the clear tube from the compressor housing.

3. Remove the tube cap and fasten the metal connector of the tube to the tire

valve, turning clockwise. Make sure the

connection is tightly fastened. 4. Plug the power cable into the 12-volt

power point in the vehicle.

5. Remove the warning sticker found on the

canister and place it on the top of the

instrument panel or the center of the

dash.

6. Start the vehicle only if the vehicle is outdoors or in a well-ventilated area.

316

MKZ Hybrid (CC9) Hybrid Electric Vehicle (HEV), Canada/United States of America, enUSA, First Printing Wheels and TiresE144619

Page 320 of 543

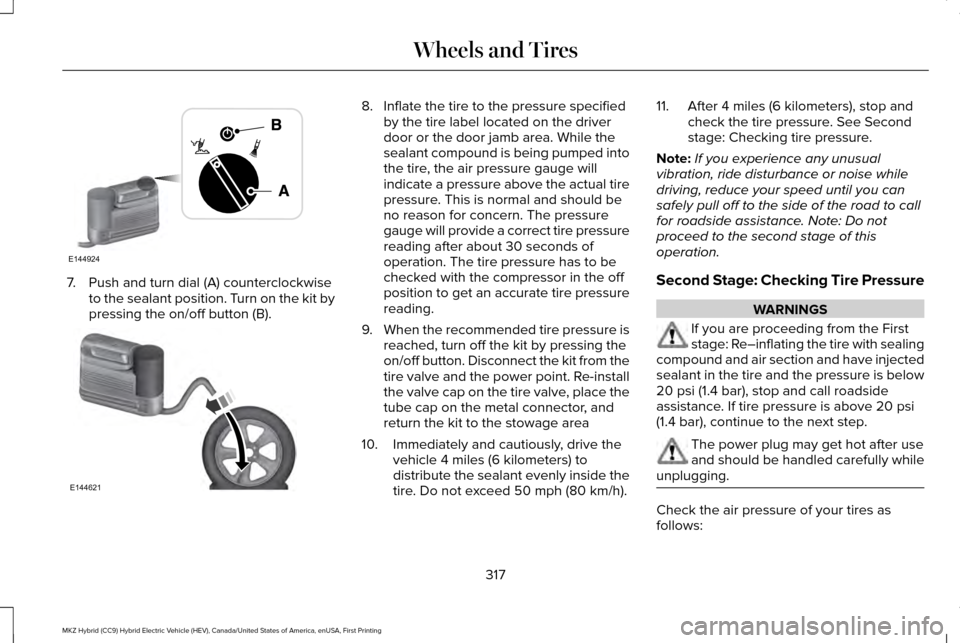

7. Push and turn dial (A) counterclockwise

to the sealant position. Turn on the kit by

pressing the on/off button (B). 8. Inflate the tire to the pressure specified

by the tire label located on the driver

door or the door jamb area. While the

sealant compound is being pumped into

the tire, the air pressure gauge will

indicate a pressure above the actual tire

pressure. This is normal and should be

no reason for concern. The pressure

gauge will provide a correct tire pressure

reading after about 30 seconds of

operation. The tire pressure has to be

checked with the compressor in the off

position to get an accurate tire pressure

reading.

9. When the recommended tire pressure is

reached, turn off the kit by pressing the

on/off button. Disconnect the kit from the

tire valve and the power point. Re-install

the valve cap on the tire valve, place the

tube cap on the metal connector, and

return the kit to the stowage area

10. Immediately and cautiously, drive the vehicle 4 miles (6 kilometers) to

distribute the sealant evenly inside the

tire. Do not exceed 50 mph (80 km/h). 11. After 4 miles (6 kilometers), stop and

check the tire pressure. See Second

stage: Checking tire pressure.

Note: If you experience any unusual

vibration, ride disturbance or noise while

driving, reduce your speed until you can

safely pull off to the side of the road to call

for roadside assistance. Note: Do not

proceed to the second stage of this

operation.

Second Stage: Checking Tire Pressure WARNINGS

If you are proceeding from the First

stage: Re–inflating the tire with sealing

compound and air section and have injected

sealant in the tire and the pressure is below

20 psi (1.4 bar), stop and call roadside

assistance. If tire pressure is above 20 psi

(1.4 bar), continue to the next step. The power plug may get hot after use

and should be handled carefully while

unplugging. Check the air pressure of your tires as

follows:

317

MKZ Hybrid (CC9) Hybrid Electric Vehicle (HEV), Canada/United States of America, enUSA, First Printing Wheels and TiresE144924 E144621

Page 321 of 543

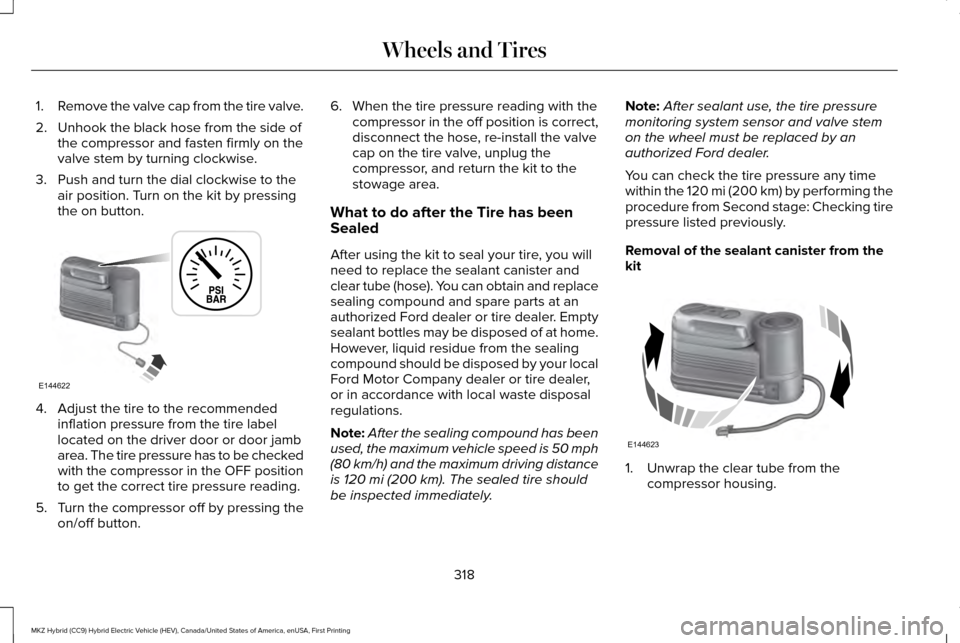

1.

Remove the valve cap from the tire valve.

2. Unhook the black hose from the side of the compressor and fasten firmly on the

valve stem by turning clockwise.

3. Push and turn the dial clockwise to the air position. Turn on the kit by pressing

the on button. 4. Adjust the tire to the recommended

inflation pressure from the tire label

located on the driver door or door jamb

area. The tire pressure has to be checked

with the compressor in the OFF position

to get the correct tire pressure reading.

5. Turn the compressor off by pressing the on/off button. 6. When the tire pressure reading with the

compressor in the off position is correct,

disconnect the hose, re-install the valve

cap on the tire valve, unplug the

compressor, and return the kit to the

stowage area.

What to do after the Tire has been

Sealed

After using the kit to seal your tire, you will

need to replace the sealant canister and

clear tube (hose). You can obtain and replace

sealing compound and spare parts at an

authorized Ford dealer or tire dealer. Empty

sealant bottles may be disposed of at home.

However, liquid residue from the sealing

compound should be disposed by your local

Ford Motor Company dealer or tire dealer,

or in accordance with local waste disposal

regulations.

Note: After the sealing compound has been

used, the maximum vehicle speed is 50 mph

(80 km/h) and the maximum driving distance

is 120 mi (200 km). The sealed tire should

be inspected immediately. Note:

After sealant use, the tire pressure

monitoring system sensor and valve stem

on the wheel must be replaced by an

authorized Ford dealer.

You can check the tire pressure any time

within the

120 mi (200 km) by performing the

procedure from Second stage: Checking tire

pressure listed previously.

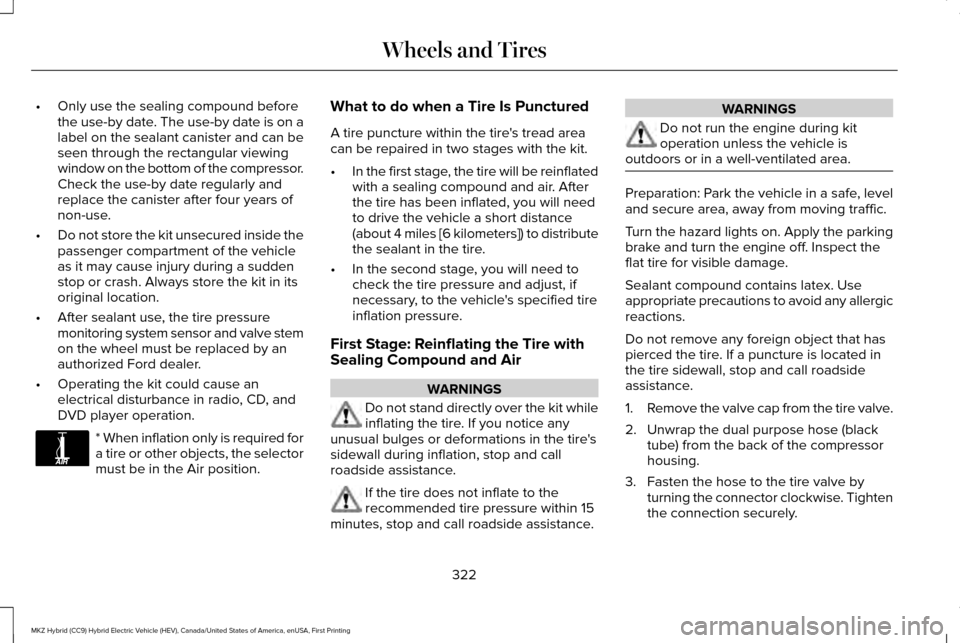

Removal of the sealant canister from the

kit 1. Unwrap the clear tube from the

compressor housing.

318

MKZ Hybrid (CC9) Hybrid Electric Vehicle (HEV), Canada/United States of America, enUSA, First Printing Wheels and TiresE144622 E144623

Page 325 of 543

•

Only use the sealing compound before

the use-by date. The use-by date is on a

label on the sealant canister and can be

seen through the rectangular viewing

window on the bottom of the compressor.

Check the use-by date regularly and

replace the canister after four years of

non-use.

• Do not store the kit unsecured inside the

passenger compartment of the vehicle

as it may cause injury during a sudden

stop or crash. Always store the kit in its

original location.

• After sealant use, the tire pressure

monitoring system sensor and valve stem

on the wheel must be replaced by an

authorized Ford dealer.

• Operating the kit could cause an

electrical disturbance in radio, CD, and

DVD player operation. * When inflation only is required for

a tire or other objects, the selector

must be in the Air position. What to do when a Tire Is Punctured

A tire puncture within the tire's tread area

can be repaired in two stages with the kit.

•

In the first stage, the tire will be reinflated

with a sealing compound and air. After

the tire has been inflated, you will need

to drive the vehicle a short distance

(about 4 miles [6 kilometers]) to distribute

the sealant in the tire.

• In the second stage, you will need to

check the tire pressure and adjust, if

necessary, to the vehicle's specified tire

inflation pressure.

First Stage: Reinflating the Tire with

Sealing Compound and Air WARNINGS

Do not stand directly over the kit while

inflating the tire. If you notice any

unusual bulges or deformations in the tire's

sidewall during inflation, stop and call

roadside assistance. If the tire does not inflate to the

recommended tire pressure within 15

minutes, stop and call roadside assistance. WARNINGS

Do not run the engine during kit

operation unless the vehicle is

outdoors or in a well-ventilated area. Preparation: Park the vehicle in a safe, level

and secure area, away from moving traffic.

Turn the hazard lights on. Apply the parking

brake and turn the engine off. Inspect the

flat tire for visible damage.

Sealant compound contains latex. Use

appropriate precautions to avoid any allergic

reactions.

Do not remove any foreign object that has

pierced the tire. If a puncture is located in

the tire sidewall, stop and call roadside

assistance.

1.

Remove the valve cap from the tire valve.

2. Unwrap the dual purpose hose (black tube) from the back of the compressor

housing.

3. Fasten the hose to the tire valve by turning the connector clockwise. Tighten

the connection securely.

322

MKZ Hybrid (CC9) Hybrid Electric Vehicle (HEV), Canada/United States of America, enUSA, First Printing Wheels and TiresE175978

Page 326 of 543

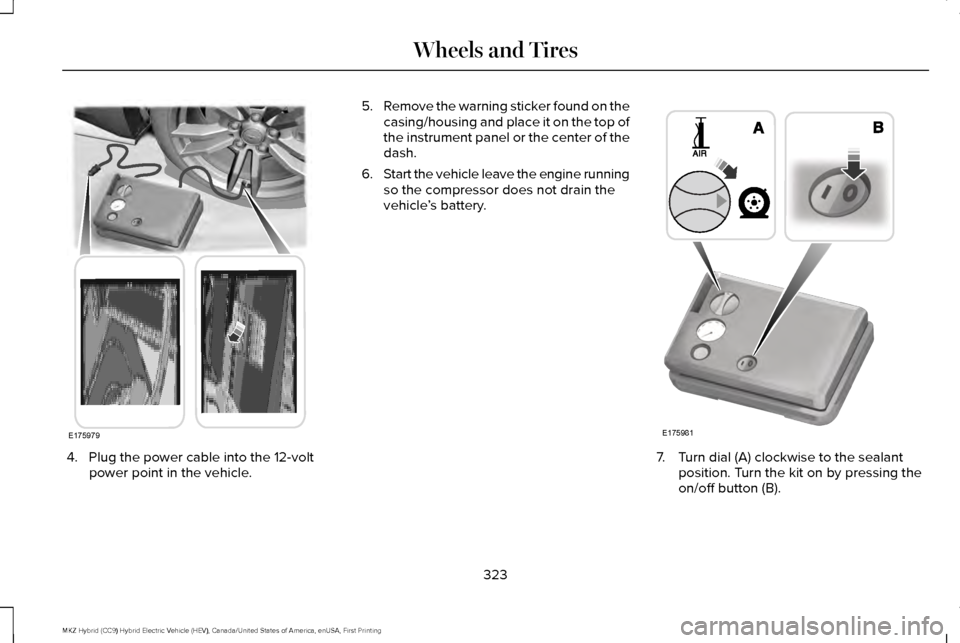

4. Plug the power cable into the 12-volt

power point in the vehicle. 5.

Remove the warning sticker found on the

casing/housing and place it on the top of

the instrument panel or the center of the

dash.

6. Start the vehicle leave the engine running

so the compressor does not drain the

vehicle ’s battery. 7. Turn dial (A) clockwise to the sealant

position. Turn the kit on by pressing the

on/off button (B).

323

MKZ Hybrid (CC9) Hybrid Electric Vehicle (HEV), Canada/United States of America, enUSA, First Printing Wheels and TiresE175979 E175981

Page 328 of 543

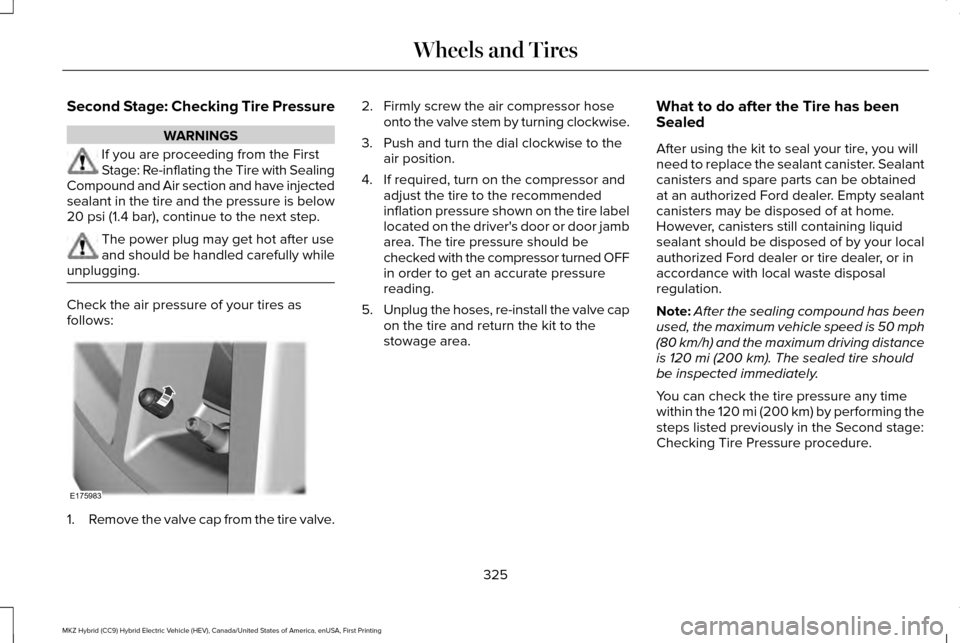

Second Stage: Checking Tire Pressure

WARNINGS

If you are proceeding from the First

Stage: Re-inflating the Tire with Sealing

Compound and Air section and have injected

sealant in the tire and the pressure is below

20 psi (1.4 bar), continue to the next step. The power plug may get hot after use

and should be handled carefully while

unplugging. Check the air pressure of your tires as

follows:

1.

Remove the valve cap from the tire valve. 2. Firmly screw the air compressor hose

onto the valve stem by turning clockwise.

3. Push and turn the dial clockwise to the air position.

4. If required, turn on the compressor and adjust the tire to the recommended

inflation pressure shown on the tire label

located on the driver's door or door jamb

area. The tire pressure should be

checked with the compressor turned OFF

in order to get an accurate pressure

reading.

5. Unplug the hoses, re-install the valve cap

on the tire and return the kit to the

stowage area. What to do after the Tire has been

Sealed

After using the kit to seal your tire, you will

need to replace the sealant canister. Sealant

canisters and spare parts can be obtained

at an authorized Ford dealer. Empty sealant

canisters may be disposed of at home.

However, canisters still containing liquid

sealant should be disposed of by your local

authorized Ford dealer or tire dealer, or in

accordance with local waste disposal

regulation.

Note:

After the sealing compound has been

used, the maximum vehicle speed is 50 mph

(80 km/h) and the maximum driving distance

is

120 mi (200 km). The sealed tire should

be inspected immediately.

You can check the tire pressure any time

within the

120 mi (200 km) by performing the

steps listed previously in the Second stage:

Checking Tire Pressure procedure.

325

MKZ Hybrid (CC9) Hybrid Electric Vehicle (HEV), Canada/United States of America, enUSA, First Printing Wheels and TiresE175983