MERCEDES-BENZ G-CLASS SUV 2018 Owners Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2018, Model line: G-CLASS SUV, Model: MERCEDES-BENZ G-CLASS SUV 2018Pages: 549, PDF Size: 10.22 MB

Page 421 of 549

Fo

r more information on wheels and tyres, con‐

ta ct a qualified specialist workshop.

Be sure toalso obse rveth efo llowing fur ther

re lated subjects:

R Notes on tyre pressure (/ page 409)

R Tyre pressure table (/ page410)

R Notes on the emer gency spa rewheel

(/ page 424) Note

s on inter changing wheels &

WARNING Risk of inju rythro ugh dif fer‐

ent wheel sizes

Inter changing the front and rear wheels if the

wheels or tyres ha vediffere nt dimensions

may se verely impair the driving characteris‐

tics.

The disk brakes or wheel suspension compo‐

nents may also be damaged. #

Rotate front and rear wheels on lyifthe

wheels and tyres are of the same

dimensions. Inter

changing the front and rear wheels if the

wheels or tyres ha vediffere nt dimensions can

re nder thege neral operating pe rmit in valid.

The wear pat tern s on the front and rear wheels

dif fer:

R Front wheels wear more on the shoulder of

th e tyre

R Rear wheels wear more in the cent reofthe

tyre

On vehicles with the same front and rear wheel

size, you can inter change the wheels every

5,000 to10,000 km, depending on thewe ar.

Ensure the direction of rotation is maintained for

th e wheels.

It is imperative toobser vethe instructions and

saf ety no tes on "Changing a wheel" when doing

so Preparing theve hicle for a wheel

ch ange( /page 419). Note

s onstoring wheels When

storing wheels, obser vethefo llowing

no tes:

R Afterre moving wheels, store them in a cool,

dry and preferably dark place.

R Protect the tyres from conta ct withoil,

grease or fuel. Ve

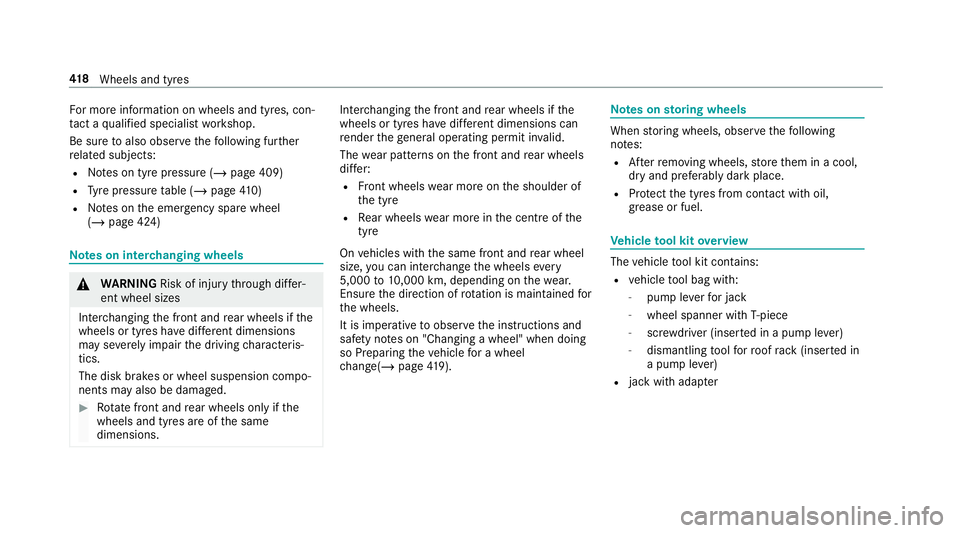

hicle tool kit overview The

vehicle tool kit contains:

R vehicle tool bag with:

- pump le verfo r jack

- wheel spanner with T-piece

- screwdriver (inser ted in a pump le ver)

- dismantling tool forro of rack (inser ted in

a pump le ver)

R jack with adapter 41 8

Wheels and tyres

Page 422 of 549

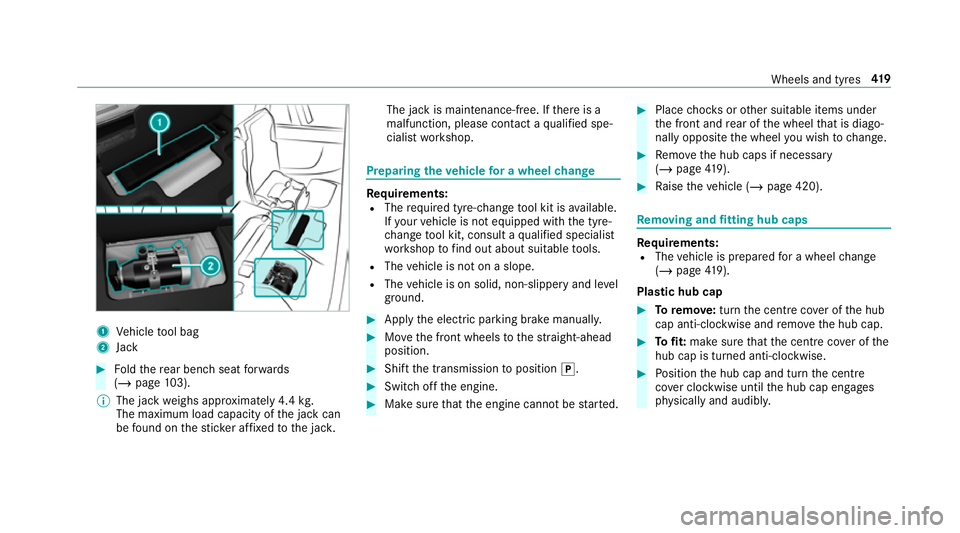

1

Vehicle tool bag

2 Jack #

Foldthere ar ben chseat forw ards

(/ page 103).

% The jack weighs appr oximately 4.4 kg.

The maximum load capacity of the jack can

be found on thest icke r af fixe dto the jac k. The jack is maintenance-free. If

there is a

malfunction, please conta ct aqualified spe‐

cialist workshop. Preparing

theve hicle for a wheel change Re

quirements:

R The requ ired tyre-change tool kit is available.

If yo ur vehicle is not equipped with the tyre-

ch ange tool kit, consult a qualified specialist

wo rkshop tofind out about suitable tools.

R The vehicle is not on a slope.

R The vehicle is on solid, non-slippery and le vel

ground. #

Apply the electric parking brake manually. #

Movethe front wheels tothest ra ight-ahead

position. #

Shift the transmission toposition j. #

Switch off the engine. #

Make sure that the engine cann otbe star ted. #

Place choc ks orother suitable items under

th e front and rear of the wheel that is diago‐

nally opposite the wheel you wish tochange. #

Remo vethe hub caps if necessary

(/ page 419). #

Raise theve hicle (/ page 420). Re

moving and fitting hub caps Re

quirements:

R The vehicle is prepared for a wheel change

(/ page 419).

Plas tic hub cap #

Toremo ve:turn the cent recover of the hub

cap anti-clockwise and remo vethe hub cap. #

Tofit: make sure that the cent recover of the

hub cap is turned anti-clockwise. #

Position the hub cap and turn the cent re

co ver clockwise until the hub cap engages

ph ysically and audibly. Wheels and tyres

419

Page 423 of 549

Ra

ising theve hicle when changing a wheel Re

quirements:

R There are no persons in theve hicle.

R The vehicle has been prepared for a wheel

ch ange (/ page419).

R The hub caps havebeen remo ved

( / page 419).

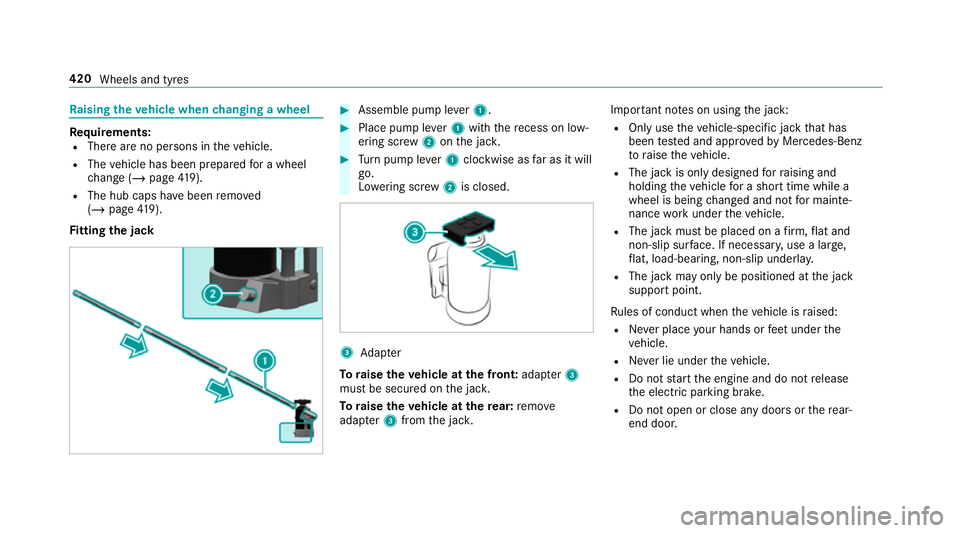

Fi tting the jack #

Assemble pu mpleve r1. #

Place pump le ver1 with there cess on low‐

ering scr ew2 onthe jac k. #

Turn pump le ver1 clockwise as far as it will

go.

Lo we ring scr ew2 is closed. 3

Adapter

To raise theve hicle at the front: adapter3

must be secured on the jac k.

To raise theve hicle at there ar: remo ve

adap ter3 from the jac k. Impor

tant no tes on using the jack:

R Only use theve hicle-specific jack that has

been tested and appr ovedby Mercedes-Benz

to raise theve hicle.

R The jack is only designed forra ising and

holding theve hicle for a short time while a

wheel is being changed and not for mainte‐

nance workunder theve hicle.

R The jack must be placed on a firm ,fl at and

non-slip sur face. If necessar y,use a lar ge,

fl at, load-bearing, non-slip unde rlay.

R The jack may only be positioned at the jack

support point.

Ru les of conduct when theve hicle is raised:

R Never place your hands or feet under the

ve hicle.

R Never lie under theve hicle.

R Do not start the engine and do not release

th e electric parking brake.

R Do not open or close any doors or there ar-

end door. 420

Wheels and tyres

Page 424 of 549

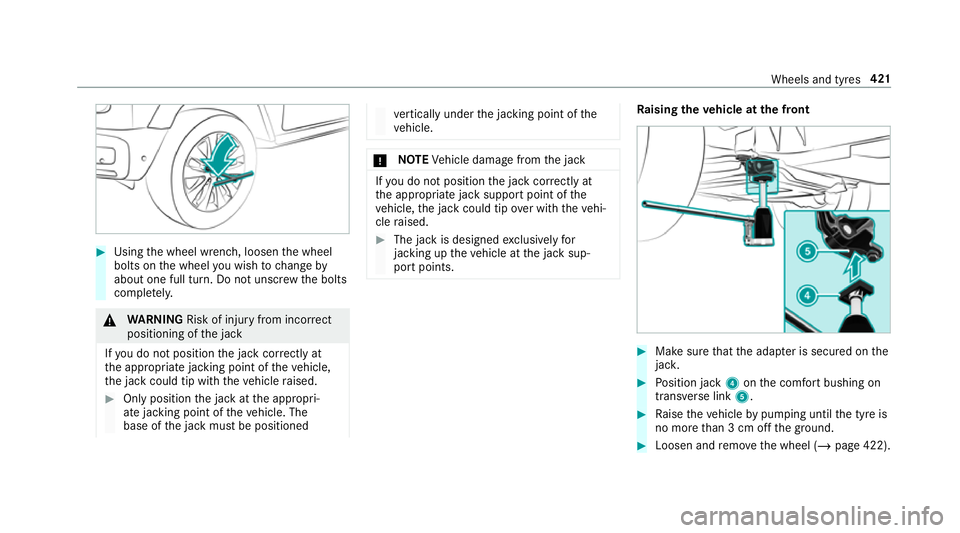

#

Using the wheel wrench, loosen the wheel

bolts on the wheel you wish tochange by

about one full turn. Do not unscr ewthe bolts

comple tely. &

WARNING Risk of inju ryfrom incor rect

positioning of the jack

If yo u do not position the jack cor rectly at

th e appropriate jacking point of theve hicle,

th e jack could tip with theve hicle raised. #

Only position the jack at the appropri‐

ate jacking point of theve hicle. The

base of the jack must be positioned ve

rtically under the jacking point of the

ve hicle. *

NO

TEVehicle damage from the jack If

yo u do not position the jack cor rectly at

th e appropriate jack support point of the

ve hicle, the jack could tip over with theve hi‐

cle raised. #

The jack is designed exclusively for

jacking up theve hicle at the jack sup‐

port points. Ra

ising theve hicle at the front #

Make sure that the adap ter is secured on the

jac k. #

Position jack 4onthe comfort bushing on

transverse link 5. #

Raise theve hicle bypumping until the tyre is

no more than 3 cm off the ground. #

Loosen and remo vethe wheel (/ page 422). Wheels and tyres

421

Page 425 of 549

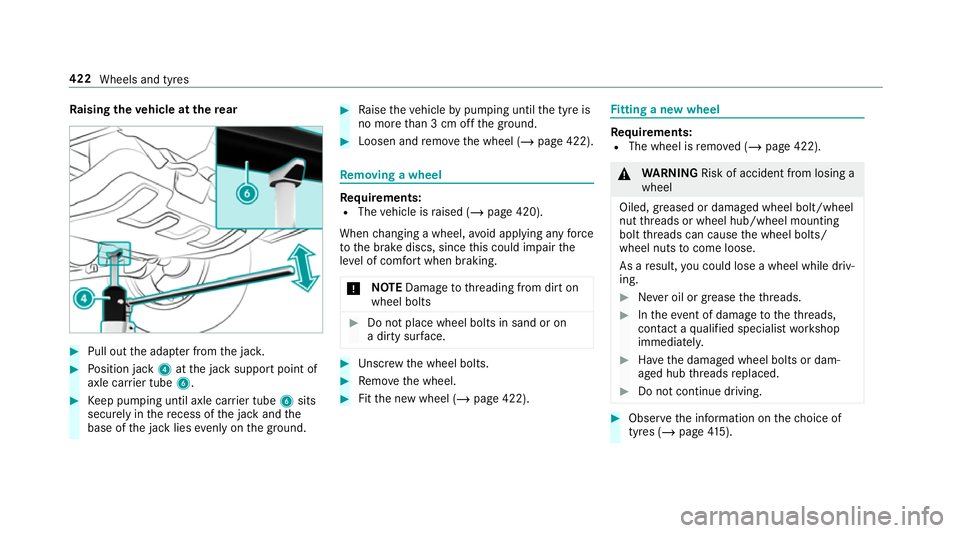

Ra

ising theve hicle at there ar #

Pull out the adap ter from the jac k. #

Position jack 4atthe jack support point of

axle car rier tube 6. #

Keep pumping until axle car rier tube 6sits

securely in there cess of the jack and the

base of the jack lies evenly on the ground. #

Raise theve hicle bypumping until the tyre is

no more than 3 cm off the ground. #

Loosen and remo vethe wheel (/ page 422). Re

moving a wheel Re

quirements:

R The vehicle is raised (/ page 420).

When changing a wheel, avoid applying any force

to the brake discs, since this could impair the

le ve l of com fort when braking.

* NO

TEDama getothre ading from dirt on

wheel bolts #

Do not place wheel bolts in sand or on

a dirty sur face. #

Unscr ew the wheel bolts. #

Remo vethe wheel. #

Fitthe new wheel (/ page 422). Fi

tting a new wheel Re

quirements:

R The wheel is remo ved (/ page 422). &

WARNING Risk of accident from losing a

wheel

Oiled, greased or damaged wheel bolt/wheel

nut thre ads or wheel hub/wheel mounting

bolt thre ads can cause the wheel bolts/

wheel nuts tocome loose.

As a result, you could lose a wheel while driv‐

ing. #

Never oil or grease theth re ads. #

Intheeve nt of dama getotheth re ads,

con tact a qualified specialist workshop

immediatel y. #

Have the damaged wheel bolts or dam‐

aged hub thre ads replaced. #

Do not continue driving. #

Obser vethe information on thech oice of

tyres (/ page415). 422

Wheels and tyres

Page 426 of 549

Fo

r tyres with a specified direction of rotat ion,

an ar rowonthe side wall of the tyre indicates

th e cor rect di rection of rotation. Obse rvethe

direction of rotation when fitting. #

Place the wheel tobe fitted on the wheel hub

and push it on. &

WARNING Risk of inju ryfrom tightening

wheel bolts and nuts

If yo u tighten the wheel bolts or wheel nuts

when theve hicle is raised, the jack could tip. #

Only tighten wheel bolts or wheel nuts

when theve hicle is on the ground. #

For saf etyre asons, on lyuse wheel bolts

which ha vebeen appr ovedby Mercedes-

Benz and forth e wheel in question. #

Tighten the wheel bolts evenly in a diagonal

pattern in the order indicated until they are

fi nger-tight. #

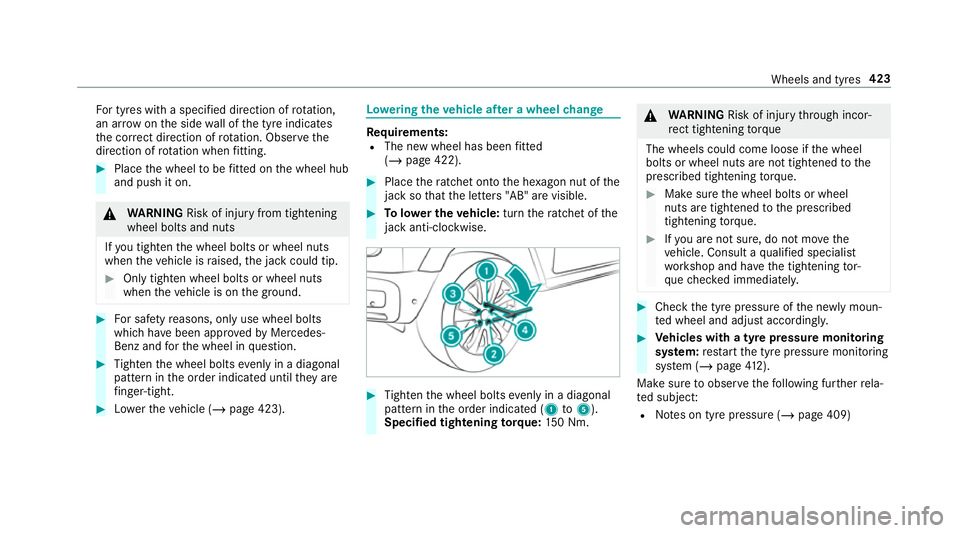

Lowe rth eve hicle (/ page 423). Lo

weri ngtheve hicle af ter a wheel change Re

quirements:

R The new wheel has been fitted

(/ page 422). #

Place thera tchet onto the he xagon nut of the

jack so that the letters "AB" are visible. #

Tolowe r the vehicle: turnthera tchet of the

jack anti-clo ckwise. #

Tighten the wheel bolts evenly in a diagonal

pattern in the order indicated (1 to5 ).

Specified tightening torq ue: 150 Nm. &

WARNING Risk of inju rythro ugh incor‐

re ct tigh tening torque

The wheels could come loose if the wheel

bolts or wheel nuts are not tightened tothe

prescribed tightening torque. #

Makesure the wheel bolts or wheel

nuts are tightened tothe prescribed

tightening torque. #

Ifyo u are not sure, do not mo vethe

ve hicle. Consult a qualified specialist

wo rkshop and ha vethe tightening tor‐

qu ech ecked immediately. #

Check the tyre pressure of the newly moun‐

te d wheel and adjust according ly. #

Vehicles with a tyre pressure monitoring

sy stem: restart the tyre pressure monitoring

sy stem (/ page412).

Ma kesure toobser vethefo llowing fur ther rela‐

te d subjec t:

R Notes on tyre pressure (/ page 409) Wheels and tyres

423

Page 427 of 549

Emer

gency spare wheel Note

s onthe emer gency spare wheel &

WARNING Risk of accident caused by

incor rect wheel and tyre dimensions

The wheel or tyre size and the tyre type of

th e emer gency spa rewheel or spare wheel

and the wheel tobe replaced may dif fer.

Mounting an emer gency spa rewheel/spare

wheel may se verely impair the driving char‐

acteristics.

To preve nt hazardous situations: #

Adapt your driving style according lyand

drive carefull y. #

Neverfit more than one emer gency

spa rewheel or spare wheel that dif fers

in size. #

Only use an emer gency spa rewheel or

spare wheel of a dif fere nt size brie fly. #

Do not switch off ESP ®

. #

Have the emer gency spa rewheel or

spare wheel of a dif fere nt size replaced

at the nearest qualified specialist work‐ shop. The new wheel must ha

vethe

cor rect dimensions. Check

the tyre pressure of the emer gency spa re

wheel fitted. Co rrect the pressure as necessar y.

The maximum permissible speed with an emer‐

ge ncy spa rewheel fitted is 80 km/h.

Do not fit th e emer gency spa rewheel with sn ow

ch ains.

Re place the emer gency spa rewheel af ter six

ye ars at the latest, rega rdless of wear.

Be sure toalso obse rveth efo llowing fur ther

re lated subjects:

R Notes on tyre pressure (/ page 409)

R Tyre pressure table (/ page410) 424

Wheels and tyres

Page 428 of 549

Note

s ontech nical data

Mercedes-AMG vehicles: be sure toobser ve

th e no tes in the Supplement. Otherwise, you

may failto recognise dangers.

The tech nical da tawa s de term ined in accord‐

ance with EU Directives. The data stated on ly

applies tovehicles with standard equipment. Yo u

can obtain fur ther information from a Mercedes-

Benz Service Centre.

Only for ce rtain countries: you can find vehi‐

cle-specific vehicle data in the EC-Certificate of

Conformity (CERTIFIC ATE OF CONFORMITY).

These documents are deli vered with your vehi‐

cle. On-board electronics

Note

s on tampering with the engine elec‐

tronics *

NO

TEPremature wearthro ugh improper

main tenance Improper maintenance may cause

vehicle

components towe ar more quickly and the

ve hicle's operating permit may be in valida‐

te d. #

Alw ays ha vewo rkon the engine elec‐

tronics and related components car ried

out at a qualified specialist workshop. Tw

o-w ayradios Note

s onfitting two-w ayradios &

WARNING Risk of accident due to

improper workon two-w ayradios

The elect romagnetic radiation from two-w ay

ra dios can inter fere with the on-board elec‐ tronics if RF transmit

ters are manipulated or

re trofitted inco rrectly.

This could jeopardise the operating saf ety of

th eve hicle. #

You should ha veall workon electrical

and electronic components car ried out

at a qualified specialist workshop. &

WARNING Risk of accident from incor‐

re ct ope ration of two-w ayradios

If yo u operate two- wayra dios inco rrectly in

th eve hicle, the electromagnetic radiation

could inter fere with the on-board electronics,

e.g.:

R ifth e two-w ayradio is not connec tedto

an exterior aerial

R ifth eex terior aerial is not cor rectly

mounted or is not of low reflection

This could jeopardise the operating saf ety of

th eve hicle. #

Have the lo w-reflection exterior aerial

fi tted at a qualified specialist workshop. Te

ch nical da ta425

Page 429 of 549

#

When operating two-w ayradios in the

ve hicle, alw ays connect them tothe

lo w- reflection exterior aerial. *

NO

TEInva lidation of the operating per‐

mit due tofailure tocomply wi th the

instructions for ins tallation and use The operating permit may be in

validated if

th e instructions for ins tallation and use of

two-w ayradios are not obser ved. #

Only use appr oved frequency bands. #

Obser vethe maximum permissible out‐

put po wer in these frequency bands. #

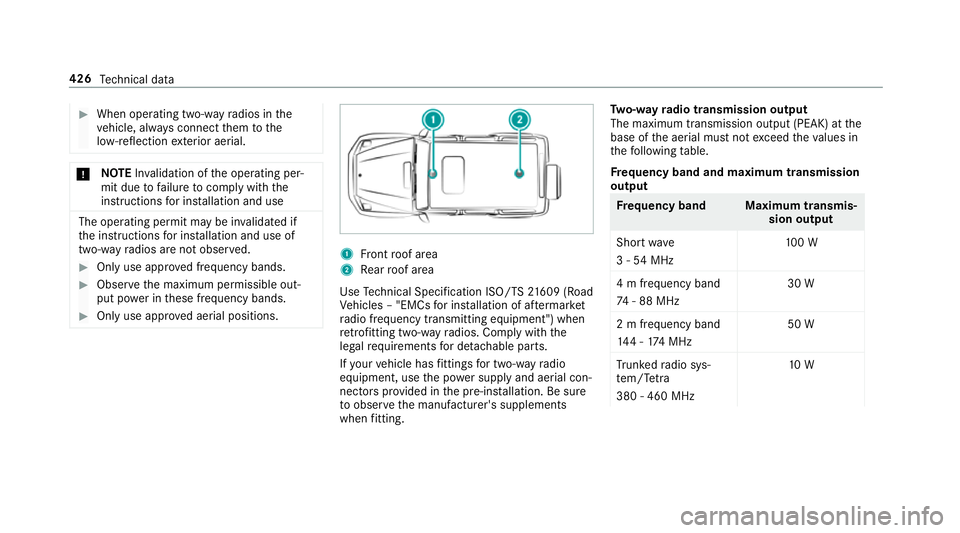

Only use appr oved aerial positions. 1

Front roof area

2 Rear roof area

Use Tech nical Specification ISO/TS 21609 (Road

Ve hicles – "EMCs for ins tallation of af term arket

ra dio frequency transmitting equipment") when

re trofitting two-w ayradios. Comply with the

legal requirements for de tach able parts.

If yo ur vehicle has fittings for two-w ayradio

equipment, use the po wer supp lyand aerial con‐

nec tors prov ided in the pre-ins tallation. Be sure

to obser vethe manufacturer's supplements

when fitting. Tw

o-w ayradio transmission output

The maximum transmission output (PEAK) at the

base of the aerial must not exceed theva lues in

th efo llowing table.

Fr equency band and maximum transmission

output Fr

equency band Maximum transmis‐

sion output

Sho rtwa ve

3 - 54 MHz 10

0 W

4 m frequency band

74 - 88 MHz 30 W

2 m frequency band

14 4 - 174 MHz 50 W

Tr unked radio sys‐

te m/T etra

380 - 460 MHz 10 W426

Tech nical da ta

Page 430 of 549

Fr

equency band Maximum transmis‐

sion output

70 cm frequency

band

420 - 450 MHz 35 W

Tw o-w ayradio

(2G/3G/4G) 10 WThe

following devices can be used in theve hicle

without restrictions:

R two-w ayradios with a maximum transmission

output of up to100 mW

R two-w ayradios with transmit ter frequencies

in the 380 - 410 MHz frequency band and a

maximum transmission output of up to2 W

(trunked radio sy stem/T etra)

R mobile phones (2G/3G/4G)

There are no restrictions when positioning the

aerial on the outside of theve hicle forth efo llow‐

ing frequency bands:

R Trunked radio sy stem/T etra

R 70 cm frequency band R

2G/3G/4G Ve

hicle identification plate, VIN and engine

number

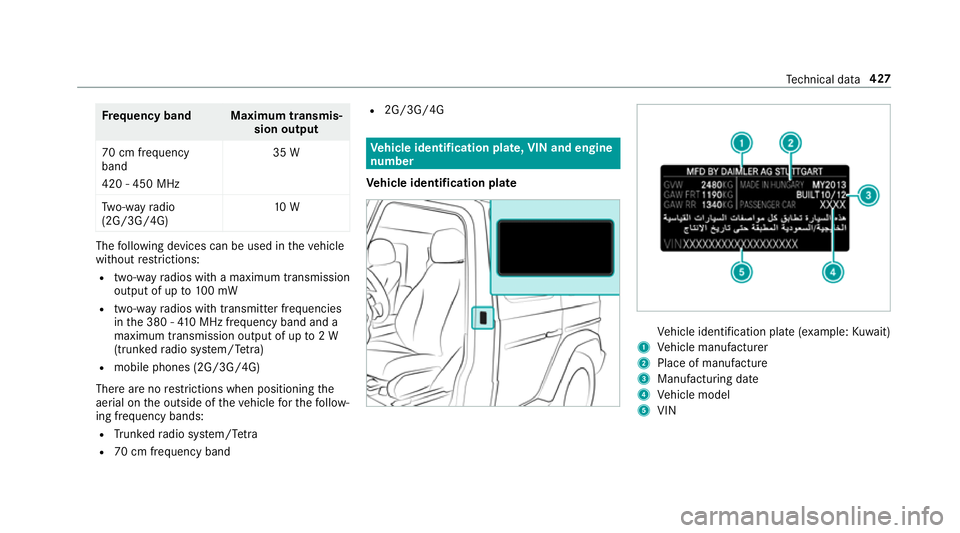

Ve hicle identification plate Ve

hicle identification plate (e xample:Kuwa it)

1 Vehicle manufacturer

2 Place of manufacture

3 Manufacturing date

4 Vehicle model

5 VIN Te

ch nical da ta427