roof MERCEDES-BENZ ML320 1997 Complete Owner's Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 719 of 4133

252

Battery

Te ch n ica l

data

Instruments

and controls Operation Driving

Instrument

cluster display Practical hints

Car care Index

Therefore, we strongly recommend that you have the

battery charge checked frequently, and corrected if

necessary, especially if you use the vehicle less than

approximately 200 miles (300 km) per month,

mostly for short distance trips, or if it is not used for

long periods of time.

Only charge a battery with a battery charger after the

battery has been disconnected from the vehicle’s

electrical circuit.

Always disconnect the battery negative lead first and

connect last.

When removing and connecting the battery, always

make sure that all electrical consumers are off and the

key is in steering lock position 0. The battery must

always be securely installed when the vehicle is in

operation. During removal and installation always

protect the disconnected battery positive (+) terminal

with the cover attached to the battery.

While the engine is running the battery terminal clamps

must not be loosened or detached, otherwise the

generator and other electronic components would be

damaged. Note:

After reconnecting the battery also set the clock in

instrument cluster (see page 80), set date in trip

computer (see page 83), resynchronize the sliding / pop-

up roof (see page 272), the Skyview Top (see page 273)

and the electronic stability program (ESP) (see

page 206).

Battery recycling

Batteries contain material that can harm the

environment with improper disposal.

Large 12 Volt storage batteries contain lead.

Recycling of batteries is the preferred method of

disposal.

Many states require sellers of batteries to accept old

batteries for recycling.

Page 739 of 4133

272

Emergency operation of sliding/pop-up roof

Te ch n ica l

data

Instruments

and controls Operation Driving

Instrument

cluster display Practical hints

Car care Index

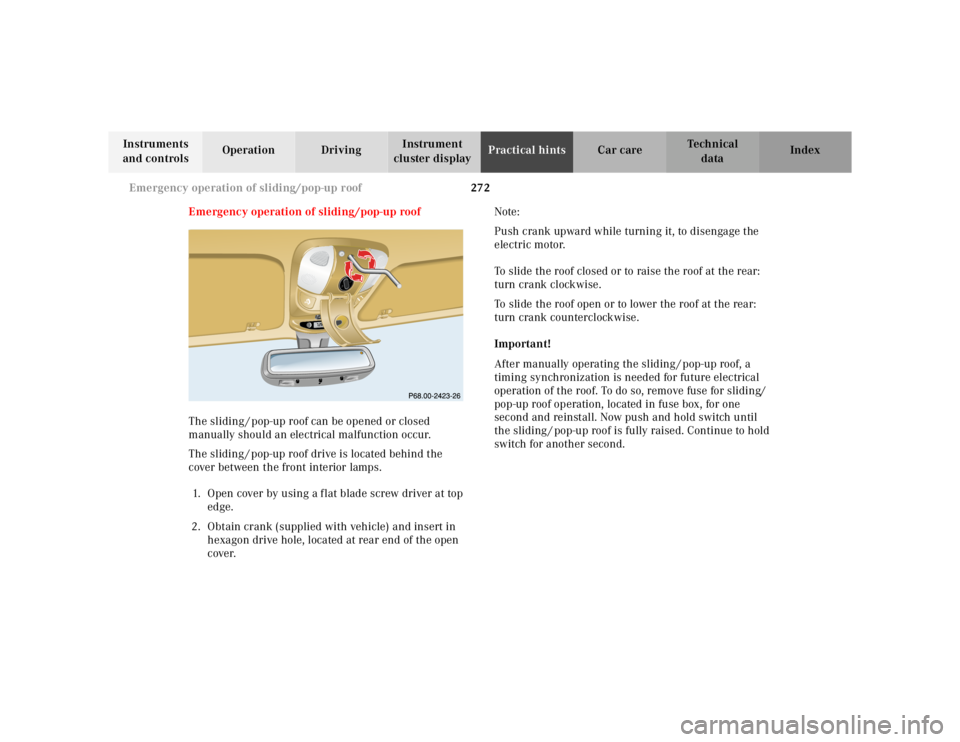

Emergency operation of sliding/pop-up roof

The sliding / pop-up roof can be opened or closed

manually should an electrical malfunction occur.

The sliding / pop-up roof drive is located behind the

cover between the front interior lamps.

1. Open cover by using a f lat blade screw driver at top edge.

2. Obtain crank (supplied with vehicle) and insert in hexagon drive hole, located at rear end of the open

cover. Note:

Push crank upward while turning it, to disengage the

electric motor.

To slide the roof closed or to raise the roof at the rear:

turn crank clockwise.

To slide the roof open or to lower the roof at the rear:

turn crank counterclockwise.

Important!

After manually operating the sliding / pop-up roof, a

timing synchronization is needed for future electrical

operation of the roof. To do so, remove fuse for sliding/

pop-up roof operation, located in fuse box, for one

second and reinstall. Now push and hold switch until

the sliding / pop-up roof is fully raised. Continue to hold

switch for another second.

R ESETM O

DEM OD

E

Page 743 of 4133

276

Roof rack

Te ch n ica l

data

Instruments

and controls Operation Driving

Instrument

cluster display Practical hints

Car care Index

Roof rack

Use only those roof racks approved by Mercedes-Benz.

Follow manufacturer’s installation instructions. They

mount to the roof rails and do not require additional

supports (e.g. suction cups or legs). Such supports may

lead to marring of the paint or denting the roof. For

further information inquire at your Mercedes-Benz

Light Truck Center.

Take into consideration that when the roof rack is

loaded, the handling characteristics are different from

those when operating the vehicles without the roof rack

loaded.

Page 745 of 4133

278

Cleaning and care of the vehicle

Te ch n ica l

data

Instruments

and controls Operation Driving

Instrument

cluster display Practical hints

Car care Index

Cleaning and care of the vehicle

In operation, your vehicle is subjected to varying

external inf luences which, if gone unchecked, can

attack the paintwork as well as the underbody and

cause lasting damage.

Such damage is caused not only by extreme and varying

climatic conditions, but also by air polution, road salt,

tar, gravel and stone chipping. Grease and oil, fuel,

coolant, brake fluid, bird droppings, insects, tree resins

etc. should be removed immediately to avoid paint

damage. Frequent washing reduces and / or eliminates

the aggressiveness and potency of the above adverse

influences. More frequent washings are necessary to deal with

unfavorable conditions; for example, near the ocean, in

industrial areas (smoke, exhaust emissions), or during

winter operation.

You should check your vehicle from time to time for

stone chipping or other damage. Any damage should be

repaired as soon as possible to prevent the start of

corrosion.

In doing so, do not neglect the underside of the vehicle.

A prerequisite for a thorough check is a washing of the

underbody followed by a thorough inspection. Damaged

areas need to be reundercoated.

Your vehicle has been treated at the factory with a wax-

base ru stproof ing in th e body cavities w hich will la st for

the lifetime of the vehicle. Post-production treatment is

neither necessary nor recommended by Mercedes-Benz

because of the possibility of incompatibility between

materials used in the production process and others

applied later.

We have selected car-care products and compiled

recommendations which are specially matched to our

vehicles and which always reflect the latest technology.

You can obtain Mercedes-Benz approved car-care

products at your authorized Mercedes-Benz Light Truck

Center.

Wa r n i n g !

Many cleaning products can be hazardous. Some

are poisonous, others are flammable. Always follow

the instructions on the particular container.

Always open your vehicle’s doors or windows when

cleaning the inside.Never use fluids or solvents that are not designed

for cleaning your vehicle.

Page 757 of 4133

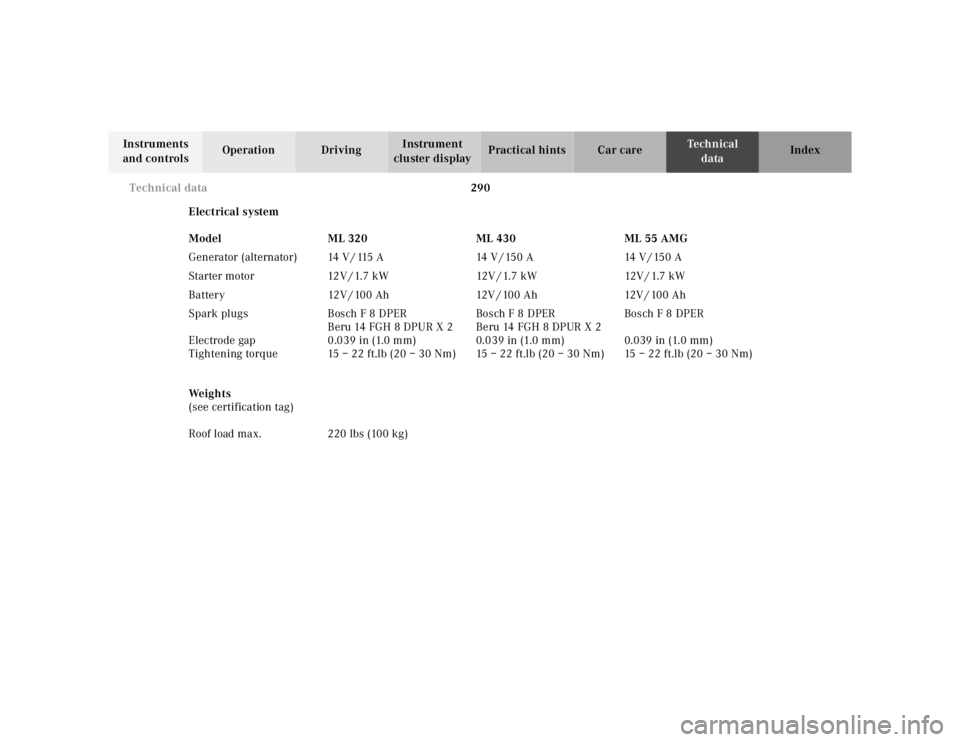

290

Technical data

Te ch n ica l

data

Instruments

and controls Operation Driving

Instrument

cluster display Practical hints Car care Index

Electrical system

We i g h t s

(see certification tag)

Model ML 320 ML 430 ML 55 AMG

Generator (alternator) 14 V / 115 A 14 V / 150 A 14 V / 150 A

S t a r te r m o to r 12 V / 1. 7 k W 12V / 1. 7 k W 12V / 1.7 k W

Battery 12V / 100 Ah 12V / 100 Ah 12V / 100 Ah

Spark plugs

Electrode gap

Tightening torque Bosch F 8 DPER

Beru 14 FGH 8 DPUR X 2

0.039 in (1.0 mm)

15–22ft.lb (20–30Nm) Bosch F 8 DPER

Beru 14 FGH 8 DPUR X 2

0.039 in (1.0 mm)

15–22ft.lb (20–30Nm) Bosch F 8 DPER

0.039 in (1.0 mm)

15–22ft.lb (20–30Nm)

Roof load max. 220 lbs (100 kg)

Page 773 of 4133

306

Index

Te ch n ica l

data

Instruments

and controls Operation Driving

Instrument

cluster display Practical hints Car care

Index

Parking lamp ...................................................... 90, 264

Replacing bulbs .........................................................260

Side marker lamp ......................................................264

Standing lamp .................................................... 90, 264

Taillamp assemblies .................................................265

Turn signal lamp ................................................ 90, 264

Turn signal lamp, side .............................................266

Layout of poly-V-belt ......................................................286

Liftgate ............................................................................... 34 Unlocking ..................................................................... 28

Lighter ..............................................................................119

Limp home mode (Automatic transmission) ............. 172

Loading instructions ..................................................... 136

Lockable storage compartment .....................................116

Locking and unlocking the vehicle ............................... 27

Low engine coolant level warning ..............................224

Low engine oil level warning .......................................224

LOW RANGE Indicator lamp ........................................................... 221

LOW RANGE mode ........................................................209 LOW RANGE – 4-ETS+ .............................................204

LOW RANGE – ABS ..................................................202

LOW RANGE – ESP ...................................................208

MMaintenance ...................................................................147

Malfunction and indicator lamps in the instrument cluster ......................................................................... 218

Manual locking/unlocking the doors ...........................29

Manual operation of Skyview Top .............................. 273

Manual operation of sliding/pop-up roof .................. 272

Manual seat, front ............................................................39

MCS, radio and telephone ............................................146

Mechanical keys ............................................................... 29

Memory .............................................................................42 Recalling ....................................................................... 42

Storing ........................................................................... 42

Mirror, exterior, adjusting ..............................................73

Mirror, exterior, rear view ..............................................73

Mirror, inside, rear view ................................................. 71

Mirrors, vanity ................................................................ 113

Page 775 of 4133

308

Index

Te ch n ica l

data

Instruments

and controls Operation Driving

Instrument

cluster display Practical hints Car care

Index

Remote control ................................................................. 24 Battery replacement .................................................270

Changing batteries ...................................................270

Operation ..................................................................... 26

Synchronizing remote control ................................ 271

Removable cargo floor plates ....................................... 129

Replacement keys ............................................................ 25

Replacing bulbs ..............................................................260

Replacing wiper blade insert .......................................275

Reporting safety defects ................................................. 16

Reserve key ................................................................ 24, 25

Roadside assistance ......................................................... 10

Roadside assistance call See Tele Aid ............................................................... 148

Roof rack ......................................................................... 276

SSafety guidelines for the seat belt, emergency tensioning retractor and airbag ................................ 63

Screwdriver .....................................................................237

Seat belt warning lamp .................................................223

Seat belts ........................................................................... 46 Fastening ...................................................................... 48

Seat belt nonusage warning system ........................ 47 Unfastening .................................................................. 50

Warning lamp ........................................................... 223

Seat belts and integrated restraint system .................. 46

Seat bench ....................................................................... 120

Seats, folding (Third row seats) ................................... 126

Seats, front ........................................................................37 Heated seats .................................................................44

Manual seats ................................................................39

Power seats .................................................................. 40

Service indicator

See Flexible service system (FSS) ............................ 87

Side marker lamp .......................................................... 264

Skyview Top ....................................................................109 Emergency operation .............................................. 273

Sliding/pop-up roof ........................................................107 Emergency operation .............................................. 272

Express opening ........................................................108

Synchronizing .......................................................... 272

Snow chains ....................................................................179

SOS-call See Tele Aid ...............................................................148

Space-saver tire

Air pump ................................................................... 239

Spare parts service ....................................................... 284

Spare wheel ................................................................... 242 Space-saver tire ........................................................ 243

Page 783 of 4133

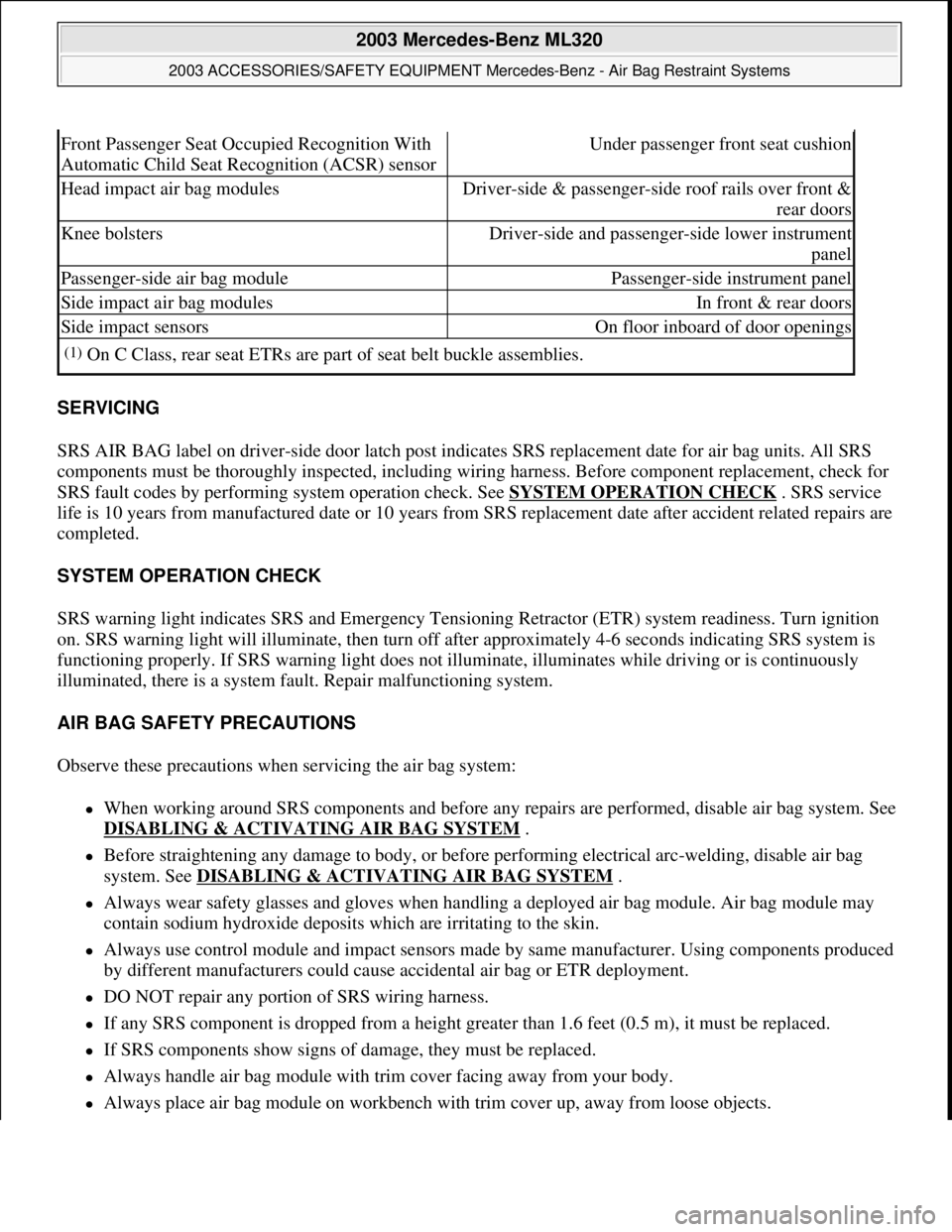

SERVICING

SRS AIR BAG label on driver-side door latch post indicates SRS replacement date for air bag units. All SRS

components must be thoroughly inspected, including wiring harness. Before component replacement, check for

SRS fault codes by performing system operation check. See SYSTEM OPERATION CHECK

. SRS service

life is 10 years from manufactured date or 10 years from SRS replacement date after accident related repairs are

completed.

SYSTEM OPERATION CHECK

SRS warning light indicates SRS and Emergency Tensioning Retractor (ETR) system readiness. Turn ignition

on. SRS warning light will illuminate, then turn off after approximately 4-6 seconds indicating SRS system is

functioning properly. If SRS warning light does not illuminate, illuminates while driving or is continuously

illuminated, there is a system fault. Repair malfunctioning system.

AIR BAG SAFETY PRECAUTIONS

Observe these precautions when servicing the air bag system:

When working around SRS components and before any repairs are performed, disable air bag system. See

DISABLING & ACTIVATING AIR BAG SYSTEM

.

Before straightening any damage to body, or before performing electrical arc-welding, disable air bag

system. See DISABLING & ACTIVATING AIR BAG SYSTEM

.

Always wear safety glasses and gloves when handling a deployed air bag module. Air bag module may

contain sodium hydroxide deposits which are irritating to the skin.

Always use control module and impact sensors made by same manufacturer. Using components produced

by different manufacturers could cause accidental air bag or ETR deployment.

DO NOT repair any portion of SRS wiring harness.

If any SRS component is dropped from a height greater than 1.6 feet (0.5 m), it must be replaced.

If SRS components show signs of damage, they must be replaced.

Always handle air bag module with trim cover facing away from your body.

Always place air bag module on workbench with trim cover up, away from loose objects.

Front Passenger Seat Occupied Recognition With

Automatic Child Seat Recognition (ACSR) sensorUnder passenger front seat cushion

Head impact air bag modulesDriver-side & passenger-side roof rails over front &

rear doors

Knee bolstersDriver-side and passenger-side lower instrument

panel

Passenger-side air bag modulePassenger-side instrument panel

Side impact air bag modulesIn front & rear doors

Side impact sensorsOn floor inboard of door openings

(1)On C Class, rear seat ETRs are part of seat belt buckle assemblies.

2003 Mercedes-Benz ML320

2003 ACCESSORIES/SAFETY EQUIPMENT Mercedes-Benz - Air Bag Restraint Systems

me

Saturday, October 02, 2010 3:32:07 PMPage 2 © 2006 Mitchell Repair Information Company, LLC.

Page 786 of 4133

2004 ACCESSORIES/SAF ETY EQUIPMENT

Mercedes-Benz - Air Bag Restraint Systems

DESCRIPTION & OPERATION

The main components of Supplemental Restraint System (SRS) are dual-stage driver-side and passenger-side

air bag modules, side impact air bag modules, head impact air bag modules , SRS control module, side impact

sensors, AIR BAG warning light, driv er-side and passenger-side Emergency Tensioning Retractors (ETR). See

COMPONENT LOCATIONS

.

COMPONENT LOCATIONS

COMPONENT LOCATIONS

SERVICING

SRS AIR BAG label on driver-side door latch post indicates SRS replacement date for air bag units. All SRS

components must be thoroughly inspected, including wiring harness. Before component replacement, check for

SRS fault codes by performing system operation check. See SYSTEM OPERATION CHECK

. SRS service

life is 10 years from manufactured da te or 10 years from SRS replacement date after accident related repairs are

completed.

SYSTEM OPERATION CHECK

AIR BAG warning light indicates SRS and Emergency Te nsioning Retractor (ETR) system readiness. Turn

ignition on. AIR BAG warning light will illuminate, then turn off after 4-20 seconds indicating SRS system is

functioning properly. If AIR BAG warn ing light does not illuminate, illuminates while driving or is

continuously illuminated, ther e is a system fault. Repair malfunctioning system.

AIR BAG SAFETY PRECAUTIONS

WARNING:

Accidental air bag deployment is pos sible. Personal injury may result.

Read and follow all WARNINGS and AIR BAG SAFETY PRECAUTIONS

before working on ai r bag system or related components.

ComponentLocation

AIR BAG warning lightInstrument Panel Cluster

ClockspringUnder steering wheel

Driver-side air bag moduleOn steering wheel

Emergency Tensioning Retractor (ETR)Driver-side & passenger-si de lower B- & C-pillars

Head impact air bag modulesDriver-side & passenger-side roof rails

Passenger-side air bag modulePassenger-side instrument panel

Side impact air bag modulesIn front & rear doors

Side impact sensorsOn floor near driver-side & passenger-side B-pillars

2004 Mercedes-Benz ML350

2004 ACCESSORIES/SAFETY EQUIPMENT Merce des-Benz - Air Bag Restraint Systems

2004 Mercedes-Benz ML350

2004 ACCESSORIES/SAFETY EQUIPMENT Mercedes-Benz - Air Bag Restraint Systems

me

Saturday, October 02, 2010 3:40:40 PMPage 1 © 2006 Mitchell Repair Information Company, LLC.

me

Saturday, October 02, 2010 3:40:43 PMPage 1 © 2006 Mitchell Repair Information Company, LLC.

Page 792 of 4133

Removal & Installation (Front)

1. Before proceeding, see AIR BAG SAFETY PRECAUTIONS . Disable air bag system. See

DISABLING & ACTIVATI NG AIR BAG SYSTEM

.

2. Move appropriate front seat full y forward. Remove lower trim panel from outer edge of seat cushion

frame. Remove bolt from seat belt end fitting. Remove end fitting from seat cushion. Remove B-pillar

trim panel. Remove bolt from be lt height adjuster. Disconnect ET R electrical connector. Remove ETR

bolts. Remove ETR.

3. To install, reverse removal procedur e. Tighten ETR, seat belt end fitting and belt height adjuster bolts to

specification. See TORQUE SPECIFICATIONS

. Activate air bag system . Read diagnostic codes and

erase memory. See DIAGNOSTICS

.

Removal & Installation (Outer Rear)

1. Before proceeding, see AIR BAG SAFETY PRECAUTIONS . Disable air bag system. See

DISABLING & ACTIVATI NG AIR BAG SYSTEM

.

2. Remove appropriate C-pillar trim panel. Remove bolt from upper seat belt guide bracket. Disconnect

ETR connector. Remove bolts from ETR. Remove ETR.

3. To install, reverse removal proc edure. Tighten ETR bolts and upper seat belt guide bracket bolt to

specification. See TORQUE SPECIFICATIONS

. Activate air bag system Read diagnostic codes and

erase memory. See DIAGNOSTICS

.

HEAD IMPACT AIR BAG MODULE (OUTER REAR)

Removal & Installation

1. Before proceeding, see AIR BAG SAFETY PRECAUTIONS . Disable air bag system. See

DISABLING & ACTIVATI NG AIR BAG SYSTEM

.

2. Remove headliner. See HEADLINER

. Disconnect appropriate head im pact air bag module electrical

connector. Remove screws from rear bracket. Rem ove screws from front and center brackets. Using

Wedge (115-589-03-59-00), remove head impact air ba g module from bracket. Remove head impact air

bag module.

3. To install, reverse removal proce dure. Activate air bag system. Read diagnostic codes and erase memory.

See DIAGNOSTICS

.

HEADLINER

Removal & Installation

1. Before proceeding, see AIR BAG SAFETY PRECAUTIONS . Remove edge trim from sliding/pop-up

roof. Remove front door seals from A- and B-pillars.

2. Remove A-pillar trim panels. Remove front fold ing handle. Remove sun visors and mounting clips.

Remove upper B-pillar trim panels . Remove cargo net holding point c overs. Remove load compartment

handles.

3. Remove coat hooks. Remove C-pill ar trim panels. Remove upper screws from D-pillar trim panels.

Detach rear headliner at roof. Lower headliner until it is supported on front seats. Lower front seat backs

rearward until sufficient ac cess to head impact air ba

g modules is available.

2004 Mercedes-Benz ML350

2004 ACCESSORIES/SAFETY EQUIPMENT Merce des-Benz - Air Bag Restraint Systems

me

Saturday, October 02, 2010 3:40:40 PMPage 7 © 2006 Mitchell Repair Information Company, LLC.