flat tire MERCEDES-BENZ SPRINTER 2019 MY19 with no MMS Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2019, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2019Pages: 322, PDF Size: 5.91 MB

Page 40 of 322

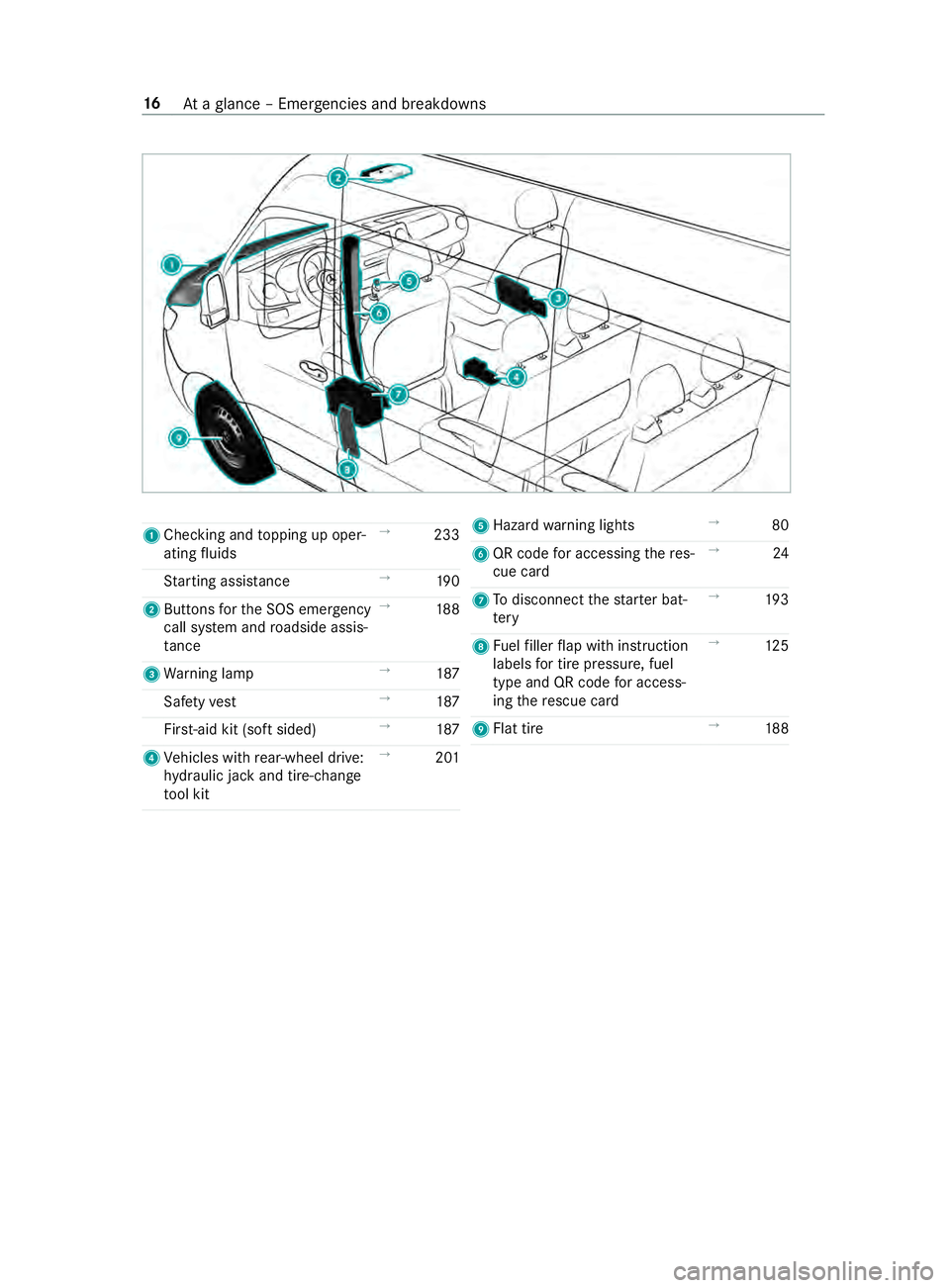

1

Checkin gand topping up oper‐

ating fluids →

233

St artin gassis tance →

19 0

2 Buttons fort he SOS emergency

call sy stem and roadside assis‐

ta nce →

188

3 Warning lamp →

187

Saf etyv est →

187

Fir st-ai dk it (so ftsided) →

187

4 Vehicles wit hrear-wheel drive:

hy draulic jac kand tire-change

to ol kit →

201 5

Hazar dwarning lights →

80

6 QR code fora ccessing ther es‐

cue card →

24

7 Todisconnect thes tarter bat‐

te ry →

19 3

8 Fuelfiller flap wit hinstruction

labels fort irep ressu re,fuel

type and QR code fora ccess‐

ing ther escue card →

12 5

9 Flattire →

188 16

Atag lanc e–Emer gencie sand breakdowns

Page 206 of 322

wa

sher and thea ssociated spr aycould cause

considerable damag etothevehicle.

To avo id damag etoyourvehicle, obser vethef ol‐

lowing when using apowerwa sher:

R maintain aminimum dis tance of 11.8 in

(30 cm) tothev ehicle when using 25° flat-

spr aynozzle sand di rtgrinder sor27.6in

(70 cm) whe nusing round-spra ynozzle sand

obse rvet he information in thee quipment

manufacturer's operating instructions.

R do no tdirect then ozzle of thep owerwa sher

directl yatsensitiv eparts suc hastires, slits,

electrical components, batteries, light bulbs

and ventilation slits.

R maintai naminimum di stanc eof1 9.7 in

(50 cm) forar ear vie wcamera. Wa

shing thev ehicle byhand Obser

vethel egal requirements, fore xamp le in

man ycountries washing byhand is only allo wed

at speciall ydesignated wash ba ys.Int his case,

mak esuret hat aspeciall ydesignated wash ba yis

used forw ashing byhand. #

Use amild cleaning agent, e.g. car shampoo. #

Washthev ehicle wit hlukew armw ater and a

sof tcar sponge. When doing so, do not

ex pose thev ehicle todirect sunlight. #

Carefully spr aythev ehicle wit hwater and dry

of fw ithal eather clo th.Bec arefulnot to

point thew ater je tdirectl ytow ards thea ir

inle tgrilles. The blo wershould be switched

of fw hiled oing so. #

Do no tlet thec leaning agent dr yonthe paint‐

wo rk.

At theo nse tofw inter,remo veall traces of road

salt deposits carefull yand as soon as possible. Note

sonc areofp aint and matte finish *

NO

TEPaint wo rkdamag eand cor rosion

due toinadequat ecare Fa

ilur etop romp tly and thoroughly remo ve

dir tfromb irdd roppings or other residue

could result in paintwor kdamag eand cor ro‐

sion at alater date. #

Cleand irto ffpaint and matt efinish

th oroughly and as soon as possible. 18 2

Maintenance and care

Page 212 of 322

Tr

iggering an automatic emer gency call Re

quirements:

R The ignition is switched on.

R The star terb atter yhas suf ficient charge.

If re stra int sy stems suc hasairbags or Emer gency

Te nsioning Device shave been activated af teran

accident, eCall ma yautomatically initia tean

emer gency call.

The eme rgency call has been made:

R Avoice connection is made totheM ercedes-

Benz emer gency cal lcenter.

R Am essa gewitha cciden tdataist ransmitted

to theM ercedes-Benz emer gency cal lcenter.

The Mercedes-Benz emergency cal lcenter

can transmit thev ehicle position dat atoone

of thee mer gency cal lcenters.

The SOS button in theo verhead cont rolp anel

fl ashes until thee mer gency cal lisfinished.

It is no tpossible toimmediately end an auto‐

matic emer gency call.

If no connection can be mad etothe emer gency

service seithe r,ac orresponding message

appears inthem edia displa y.

If no connection can be made tothee mer gency

services: #

Dialthe local emergency num berony our

mobile phone.

If an emer gency cal lhas been initia ted:

R Remain in thev ehicle if ther oad and traf fic

conditions permit youtodosou ntilavoice

connection is es tablished wit hthe emergency

call cen ters ervice pr ovider.

R Based on thec all, theo perator decides

whe ther it is necessar ytocallr escue teams

and/or thep olice tothea ccident site.

R If no vehicle occupant answers, an ambu‐

lance is sent tothev ehicle immediately. Tr

iggering amanual emer gency call #

Using theS OS but tonint heove rhead con‐

trol panel: presstheS OS button at leas tone

secon dlong.

The emer gency cal lhas been made:

R Avoice connection is made totheM ercedes-

Benz emer gency cal lcenter.

R Am essa gewitha cciden tdataist ransmitted

to theM ercedes-Benz emer gency cal lcenter. The Mercedes-Benz emergency cal

lcenter

can transmit thev ehicle position dat atoone

of thee mer gency cal lcenters.

R Remain in thev ehicle if ther oad and traf fic

conditions permit youtodosou ntilavoice

connection is es tablished wit hthe emergency

call cen ters ervice pr ovider. Tr

ansmitted data with thee mer gency call Dat

atransmitte dbythe eCall includes but is not

limited to:

R Vehicle's GPS position data

R GPS position dat aontheroute(af ewhun‐

dred me ters befor ethe incident)

R Direction of tra vel

R Vehicle identification number

R Vehicle driv etype

R Estimated number of people in thev ehicle

R Whe ther Mercedes PR Oconnect is available

or not

R Whe ther thee mer gency cal lwas initia ted

manually or automatically

R Time of thea ccident

Dat atransmit tedisv ehicle information. Fora ny

qu estions about thec ollection, use and sharing

of thee Call sy stem data, please contact MBU‐

SA 's Cus tomer Assis tance Center at 800-FOR-

MERC.

Fo rC anada, please contact MBC’ sCustomer

Assis tance Center at 1-800-387-0 100.

Cust omer requests forc ove redi nformation

should be submitted via thes ame channels.

Fo ra ccident clarificatio npurposes ,the following

measures can be take nu ptoa nhour af tert he

emer gency cal lhas been initia ted:

R The cur rent vehicle position can be de ter‐

mined

R Avoice connection tothev ehicle occupants

can be es tablished Flat tire

Note

sonf lat tires &

WARNING Risk of an accident whe ndriv‐

ing wi thaflat tire

Af lat tir egreatly impair sdriving characteris‐

tics, as well as steering and braking. 18 8

Breakdown assis tance

Page 213 of 322

#

Do no tdrive with aflat tire. #

Remo vethef lat tir eand ins tallthe

spar ewheel or consult aqualified spe‐

cialis tworks hop. In

thee vent of aflat tir eyou ha vethef ollowing

possibilities depending on your vehicle's equip‐

ment:

R Vehicles with Mercede sPRO connec t:in

th ee vent of aflat tire, youc an call Roadside

Assis tance via theR oadside Assis tance call

button in theo verhead cont rolp anel

(/ page164).

R Allvehicles: chang ethe wheel

(/ page221). Batte

ry Note

sont he12Vb attery &

WARNING Risk of an accident du eto

wo rkcar ried out incor rectl yont he bat‐

te ry

Wo rkcar ried out incor rectly on theb attery

can, fore xamp le, lead toas hor tcircuit .This

can lead tofunction restrictions in saf ety-re l‐

ev ant sy stems, fore xamp lethel ighting sys‐

te m, ABS (anti-loc kbraking sy stem) or ESP ®

(Elect ronic Stabilit yProgram). The ope rating

saf etyofy ourvehicle ma yberestricted.

Yo uc oul dlose control of thev ehicle in the

fo llowing situations:

R when braking

R inthee vent of ab rupt steering maneuvers

and/or when thev ehicle's speed is not

adap tedtot heroad conditions #

Inthee vent of ashortcircui tora simi‐

la ri ncident, contact aqualified special‐

is tw orks hop immediately. #

Do no tcontinue driving. #

Alwaysh ave workon theb atter ycarried

out at aqualified specialis tworks hop. R

Further information on ABS (/ page137)

R Further information on ESP ®

(/ page138)

Mercedes-Benz recommends that youh ave the

12 Vb atter yreplaced at aqualified specialist

wo rkshop, e.g. at an authorized Mercedes-Benz

Center. Should

youw ant toreplace theb atter yyourself,

obser vethef ollowing information:

R Alwaysr eplace adefectiv ebatter ywithab at‐

te ry whic hfulfills thev ehicle's specific

re qu irements.

R Use de tach able parts suc hasthevent hose,

elbo wfittin gort erminal co verfromt he bat‐

te ry to be replaced.

R Mak esuret hat thev ent hose is alw aysc on‐

nected toits original openin gonthe battery

side.

Ins tallth ee xisting or newly supplied stop

plugs.

Otherwise, gases or batter yacid could

escape.

R Mak esuret hat thed etachable parts ar econ‐

nec tedint he same wayasb efore.

Fo rs afet yr easons, Mercedes-Benz recommends

th at youo nlyu se bat teries that ha vebeen tested

and appr ovedfor your vehicle byMercedes-Benz.

These batteries pr ovide inc reased impact pr otec‐

tion topreve ntvehicle occupants from suf fering

aci db urns should theb atter ybed amaged in an

accident. &

WARNING Risk ofexplosion due toelec‐

tros tatic charge

Electros tatic charge can cause spa rksw hich

ma yignit ethe highly flammable gasm ixture

in theb atter y. #

Todischar geanye lectrostatic charge

th at ma yhave built up, touc ht he me tal

ve hicle body befor ehandling theb at‐

te ry. The highly

flammable gasm ixtur eisc reated while

th eb atter yisc harging and when jump-s tarting. &

WARNING Danger of chemical burns

from theb atter yacid

Batter yacid is caustic. #

Avoid contact wit hthe skin, eyes or

clo thing. #

Do no tlean overthe batter y. #

Do no tinhal ebattery gases. #

Keep children away from theb atter y. #

Immedia tely rinse batter yacido ffthor‐

oughly wit hplenty of clean waterand

seek medica lattention immediately. Breakdown assi

stance 18 9

Page 230 of 322

Fr

ont axle tir epressures on vehicles with all-wheel/rear wheel driv eand single tires

Max. front axle load 4101 lbs (1860 kg) Ti

re s/disc wheel Vehicl eload Max. front axle load

4101 lbs (1860 kg)

LT 24 5/75R1 6120/1 16QF ullyladen 320k Pa(3.2b ar/46 psi) Fr

ont axle tir epressures on vehicles with rear wheel driv eand single tires

Max. front axle load 4409 lbs (2000 kg) Ti

re s/disc wheel Vehicl eload Max. front axle load

4409 lbs (2000 kg)

LT 24 5/75R1 6120/1 16QF ullyladen

360k Pa(3.6b ar/52 psi) 1) 1)

Only valid forv ehicles wit halong wheelbase

17 1in( 4350 mm) and apermissible gross weight

of ove r7716l bs (3. 5t).

Re ar axle tir epressures on vehicles with all-wheel/rear wheel driv eand single tires

Max. rear axle load 535 7lbs (2430 kg) Ti

re s/disc wheel Vehicl eload Max.rear axle load

535 7lbs (2430 kg)

LT 24 5/75R1 6120/1 16QF ullyladen 480k Pa(4.8b ar/70 psi)

LT 24 5/75R1 6120/1 16 Q

Partiall yladen 2)

420 kPa(4.2b ar/6 1psi)2) 2)

It is onl ypermissible touse this reduced tire

pressur eifitcan be guaranteed byweighing the

ve hicle that ther ear axle load of 4960 lbs (2250

kg)w ill no tbee xceeded. In case of doubt,

inflat eto4 80 kPa(4.8 bar/70 psi).

Fr ont axle tir epressures on vehicles with all-wheel/rear wheel driv eand twin tires

Max. front axle load 4079 lbs (1850 kg)Ti

re s/disc wheel Vehicl eload Max. front axle load

4079 lbs (1850kg)

LT 21 5/85R1 6115/112 QF ullyladen 380k Pa(3.8b ar/55 psi) Max. front axl

eload 4409 lbs (2000 kg) Ti

re s/disc wheel Vehicl eload Max. front axle load

4409 lbs (2000 kg)

LT 21 5/85R1 6115/112 QF ullyladen 420k Pa(4.2b ar/ 61psi) 206

Wheels and tires

Page 232 of 322

Re

ar axle tir epressures on vehicles with rear wheel driv eand Super Single tires

Max. rear axle load 7055 lbs (3200 kg)Ti

re s/disc wheel Vehicl eload Max.rear axle load

7055 lbs (3200 kg)

225/75R16C 121/120R (122L) Fullyl aden

690 kPa(6.9b ar/100 psi) 3)

285/65R16C 131R Fully laden 460 kPa(4.6b ar/6 7psi) Max

.rear axl eload 7716 lbs (3500 kg) Ti

re s/disc wheel Vehicl eload Max.rear axle load

77 16 lbs (3500 kg)

225/75R16C 121/120R (122L) Fullyl aden

690 kPa(6.9b ar/100 psi) 3)

285/65R16C 131R Fully laden 520 kPa(5.2b ar/7 5psi) 3)

Va lid touse foras horttime as aspar ew heel

on ther ear axle foram aximu mdista nce of

62 miles (100 km) and amaximum speed of

34 mph(55 km/h).

Be sur etoalso obse rvet he following fur ther rela‐

te ds ubjects:

R Notesont irep ressur e(/pag e204)

R Tire and Loadin gInforma tionp lacard

(/ page210)

R Maximum tirep ressure (/ page 215) Ti

re pressur emonitor Fu

nction of tir epressur emonitor on single

tires &

DANG ER Risk of acciden tdue toincor‐

re ct tir epressure

Ever ytire, including thes par e(if pr ovided),

should be checkedw hen cold at leas toncea

mont hand inflated tothep ressur erecom‐

mended bythev ehicle manufacturer (see Tire

and Loadin gInforma tionp lacar dont he B-pil‐

lar on thed rive r’ss ide or thet irep ressure

label on thei nside of thef uel filler flap of your

ve hicle). If your vehicle has tires of adiffe re nt

size than thes ize indicated on theT irea nd

Loading In form atio nplacar dort he tirepres‐

sur etable, youn eedtod etermine thep roper

tir ep ressur efor those tires.

As an added saf etyf eature, your vehicle has

been equipped wit hatirep ressur emonitor‐ ing sy

stem (TPMS) that illuminates alow tire

pressur eindicator lam pwhen one or mor eof

yo ur tires ar esignificantl yunde rinfla ted.

Ac cordingly ,ifthe lo wtirep ressur eindicator

lam plights up, yous houl dstopa nd check

yo ur tires as soon as possible, and inflate

th em tothep roper pressure. Driving on asig‐

nificantly underinflated tir ecauses thet ireto

ove rheat and can lead totiref ailure. Underin‐

fl atio nalso inc reases fuel consum ption and

re duces tir etread life, and ma yaffect the

ve hicle's handling and braking ability .Please

no te that theT PMS is no tasubstitut efor

proper tir emaintenance, and it is thed rive r's

re sponsibility tomaintain cor rect tir epres‐

sure, even if underinflation has no treached

th el eve ltot rigger illumination of theT PMS

lo wt irep ressur eindicator lamp.

Yo ur vehicle has also been equipped wit ha

TPMS malfunction indicator toindicat ewhen

th es ystem is no toperating properly .The

TPMS malfunction indicator is combined with

th el ow tirep ressur eindicator lamp. When

th es ystem de tects am alfunction, thei ndica‐

to rlamp willf lashfora pproxima tely am inute

and then remain continuously illumina ted.

This sequence will continue upon subsequent

ve hicle start-ups as lon gasthe malfunction

ex ists.

When them alfunction indicator is illuminated,

th es ystem ma ynotbe able todetect or sig‐

nal lo wtirep ressu reas intended. TPMS mal‐

function smayoccur forav ariety of reasons,

includin gthe ins tallation of incompatible 208

Wheels and tires

Page 238 of 322

tire's ability

tocome toas tandstill on awetpave‐

ment under controlle dconditions on aspecified

U. S. go vernment test sur face mad efroma sphalt

and concr ete.

Te mp eratur egrade &

WARNING Risk of accident from tire

ove rheating and tir efailure

The temp eratur egrade fort his tir eisestab‐

lished forat iret hat is properly inflated and

no to verloaded. Excessiv espeed, underinfla‐

tion, or excessiv eloading, either separatel yor

in combination, can cause excessiv eheat

build-up and possible tir efailure. #

Obser vether ecommended tir epres‐

sures and regular lych eckt he tir epres‐

sur eofa ll tires including thes pare

wheel. #

Adjus tthe tir epressur easn ecessar y. The

temp eratur egrades ar eA(highes tgrade), B

and C. These relat etoat ire'sresis tance toheat

and its ability torelease heat on aspecified test

wheel in laborator ytests under cont rolled condi‐

tions. Sus tained high temp eratures can cause the

material of thet iretod egenerat eand reduce tire

life. In addition, excessivel yhigh temp eratures

can lead tosudden tir efailure. Grade Crefer sto

ap erform anc ewhicha ll passenger vehicle tires

mus texhibit, accordin gtotheU.S. Depa rtment

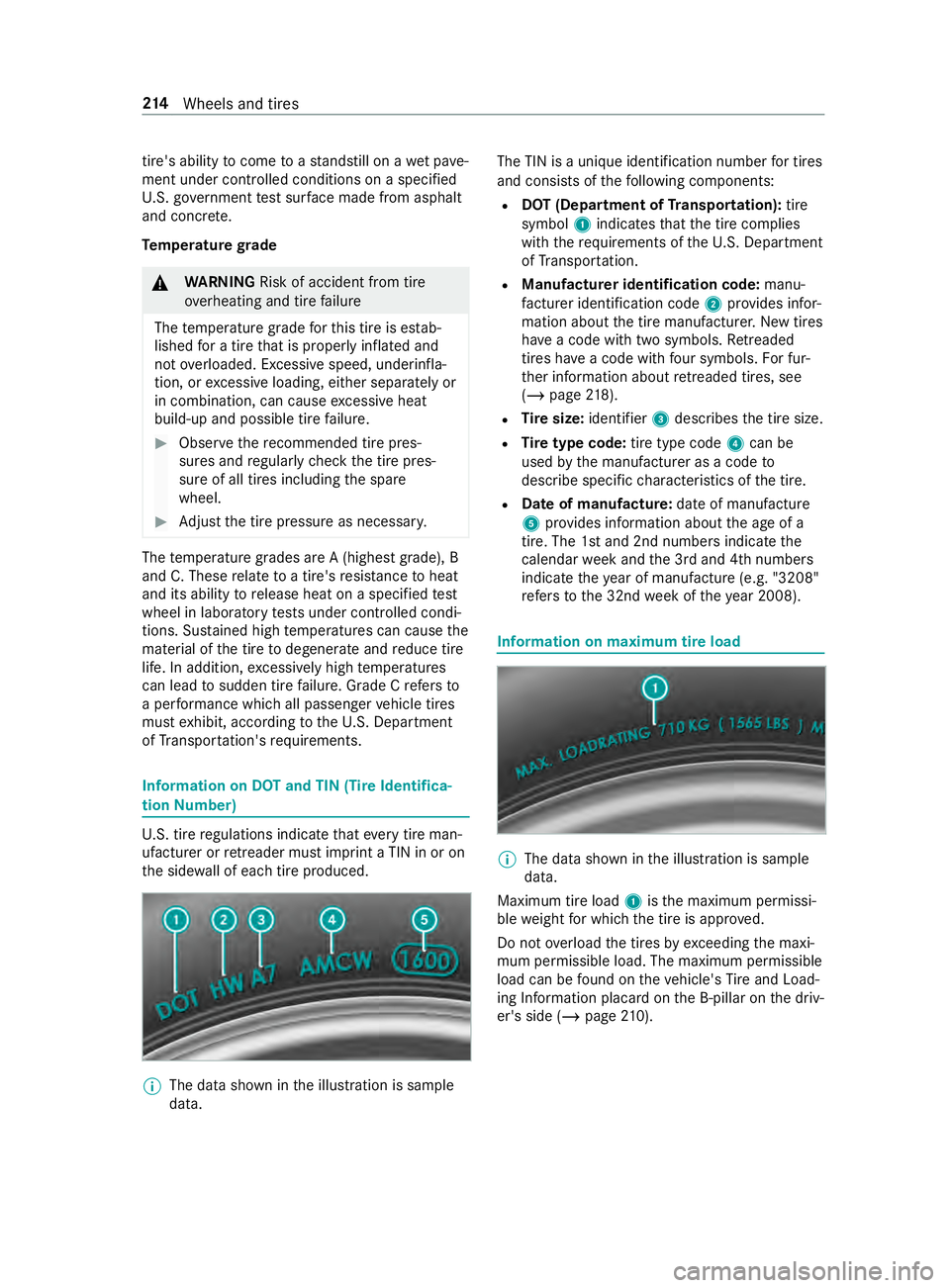

of Transpor tation's requ irements. Information on DO

Tand TIN (Tir eIdentifica‐

tion Number) U.

S. tir eregulations indicat ethat everyt irem an‐

ufacturer or retreade rmustimp rint aT IN in or on

th es ide wall of eac htirep roduced. %

The dat

ashown in thei llustration is sample

data. The TIN is

aunique identification number fort ires

and consists of thef ollowing components:

R DOT(Department of Transportation): tire

symbol 1indicates that thet irec omplies

wit hthe requ irements of theU .S. Depa rtment

of Transpor tation.

R Manufacturer identi fication code: manu‐

fa cturer identification code 2prov ides infor‐

matio nabout thet irem anufacturer .New tires

ha ve ac odew itht wo symbols. Retreaded

tires ha veac odew ithf our symbols.F or fur‐

th er information about retreade dtires, see

(/ page 218).

R Tire size: identifier 3describes thet ires ize.

R Tire type code: tiret ypec ode 4can be

used bythem anufacturer as acode to

describe specific characteristic softhe tire.

R Dat eofm anufactu re:date of manufacture

5 prov ides informatio nabout thea geof a

tire. The 1s tand 2nd number sindicat ethe

calendar week and the3 rdand 4t hnumbers

indicat ethe year of manufactur e(e.g. "3208"

re fers to the3 2ndw eek of they ear 2008). Information on maximum tir

eload %

The dat

ashown in thei llustration is sample

data.

Maximum tir eload 1isthem aximum permissi‐

ble weight forw hichthe tir eisa pprove d.

Do no toverload thet ires by ex ceeding them axi‐

mum permissible load. The maximum permissible

load can be found on thev ehicle's Tire and Load‐

ing In form atio nplacar dont he B-pillar on thed riv‐

er's side (/ page210). 214

Wheels and tires

Page 243 of 322

Befor

epurch asing and using non-appr oved

accesso ries, visit aqualified specialis tworks hop

and inquir eabout:

R Suitability

R Legal stipulations

R Factor yrecommendations

Obser vethef ollowing points when selecting,

ins talling and replacing tires:

R Use onl ytires and wheels of thes ame type,

design (winter tires, all-season tire) and

make.

R Onlyins tall wheels of thes ame size and tread

design on one axle (lef tand right).

It is onl ypermissible toins tallad iffe re nt

wheel size tothis in thee vent of aflat tir ein

order todriv etot he specialis tworks hop.

R Onlyins tall tires of thec orrect size ont othe

wheels.

R Ve

hicles with atirep ressur emonitoring

sy stem: all ins talled wheels mus tbeequip‐

ped wit hfunctioning sensor sfor thet irep res‐

sur em onitoring sy stem.

R Attemp eratures belo w50°F(10°C), use

winter tires or all-season tir emarke dM +Sfor

all wheels.

Wi nter tires bearing the004D snowflak esym‐

bol in addition totheM +S marking pr ovide

th eb estp ossible grip in wintr yroad condi‐

tions.

R Only use tires wit hthe same tread.

R Obser vethem aximum permissible speed for

th ei nstalled tires.

If th is is belo wthe vehicle's maximum speed,

th is mus tbeindicated in an appropriat elabel

in thed rive r's field of vision.

R Break in ne wtires at moderat espeeds fort he

fi rs t60m iles (100 km).

R Replace thet ires af ters ixyearsatt he latest,

re ga rdless of wear.

Fo rm orei nformation on wheels and tires, con‐

ta ct aq ualified specialis tworks hop.

% Ve

hicles with twin tires:

Fo rv ehicles wit htwin tires wit haGVW of

11 ,030 lbs or 12,125 lbs, onl yuse tires with

th ed imension LT215/85 R1 6which have

been appr ovedfor this vehicle bythem anu‐

fa cturer .Itisn otpermissibl etouse tires with

dif fere nt dimensions; doing so ma ylea dtoa ge

neral ope rating pe rmit being rende red

in va lid.

% Ve

hicles with single tires:

Fo rv ehicles wit hsingle tires wit haGVW less

th an or equal to9480 lbs, onl yuse tires with

th ed imension LT245/7 5R16whi chhave

been appr ovedfor this vehicle bythem anu‐

fa cturer .Itisn otpermissibl etouse tires with

dif fere nt dimensions; doing so ma ylea dtoa

ge neral ope rating pe rmit being rende red

in va lid.

% Ve

hicles with Super Single tires:

Fo rv ehicles wit hsingle tires wit haGVW of

11 ,030 lbs, onl yuse tires wit hthe dimen‐

sions 225/7 5R16C( FA)and 285/65 R16C

(RA) whic hhaveb een appr ovedfor this vehi‐

cle bythem anufacturer .Itisnotpermissible

to use tires wit hdiffe re nt dimensions; doing

so ma ylea dtoa general ope rating pe rmit

being rende redi nva lid.

Be sur etoalso obse rvet he following fur ther rela‐

te ds ubjects:

R Notesont irep ressur e(/pag e204)

R Tire and Loadin gInforma tionp lacard

(/ page210)

R Tire size designation, load-beari ng capacity,

speed rating and load ind ex (/pag e215 )

R Tire pressur etable

R Notesont he emergency spar ewheel

(/ page225) Note

sonr otating wheels &

WARNING Risk of inju rythro ugh dif fer‐

ent whee lsizes

Inter changing thef ront and rear wheels if the

wheels or tires ha vediffere nt dimensions may

se verely impair thed riving characteristics.

The wheel brakes or wheel suspension com‐

ponent smayalso be damaged. #

Rotate front and rear wheels onl yifthe

wheels and tires ar eofthe same dimen‐

sions. On

vehicles that ha vethes ame size front and

re ar wheels ,rotatet he wheels according tothe

inter vals in thet irem anufacturer's warrant ybook

in your vehicle documents. If this is no tavailable,

ro tate thet ires every3,000 (5,000) to

6,000 mile s(10 ,000 km) ,depending on the Wheels and tires

219

Page 246 of 322

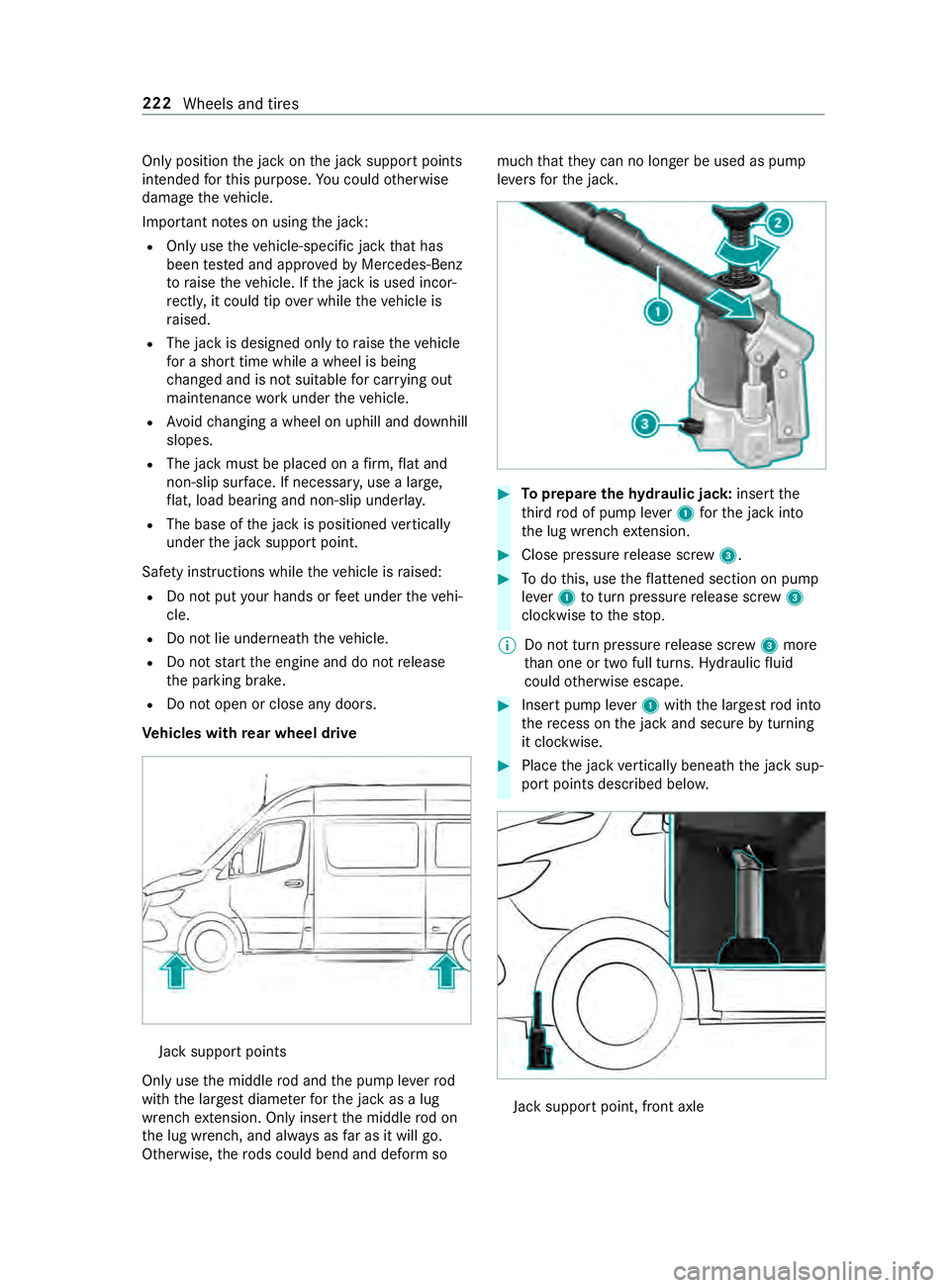

Only position

thej ackont he jac ksuppor tpoints

intended fort his purpose. Youc oul do therwise

damag ethe vehicle.

Impor tant no tesonu singthej ack:

R Onlyusethev ehicle-speci ficj ackt hat has

been tested and appr ovedbyM ercedes-Benz

to raise thev ehicle. If thej ackisu sed incor‐

re ctly ,itc ould tip over while thev ehicle is

ra ised.

R The jac kisdesigned onl ytoraisethev ehicle

fo ras horttime whil eawheelisb eing

ch anged and is no tsuitable forc arrying out

maintenance workunde rthe vehicle.

R Avoid changing awheel on uphill and downhill

slopes.

R The jac kmustbep lacedonaf irm,flat and

non-slip sur face. If necessar y,use alarge,

fl at, load bearing and non-slip unde rlay.

R The base of thej ackisp ositioned vertically

under thej acks uppor tpoint.

Saf etyi nstruction swhile thev ehicle is raised:

R Do no tputyour hands or feet unde rthe vehi‐

cle.

R Do no tlie underneat hthe vehicle.

R Do no tstart thee ngine and do no trelease

th ep arking brake.

R Do no topen or close an ydoors.

Ve hicles with rear wheel drive Jack

suppor tpoints

Only use them iddle roda nd thep um pleve rrod

wit hthe larges tdiame terf or thej ackasa lug

wrenc hextension. Only inse rtthem iddle rodon

th el ug wrench, and alw aysasf ar as it will go.

Otherwise, ther ods could bend and defor msomuc

hthat they can no longer be use daspump

le ve rs fort he jac k. #

Toprepar ethe hydrauli cjack: insertthe

th irdr od of pum plever 1fort he jac kinto

th el ug wrenc hextension. #

Close pressur erelease scr ew3. #

Todo this, use thef lattened sectio nonpump

le ver 1totur np ressur erelease scr ew3

clockwise tothes top.

% Do no

tturnp ressur erelease scr ew3 more

th an one or tw ofull turns .Hydraulic fluid

coul dotherwise escape. #

Inser tpum plever 1withthe larges trod into

th er eces sont he jac kand secur ebyturning

it clo ckwise. #

Place thej ackv erticall ybeneat hthe jac ksup‐

por tpoints described belo w. Jac

ksuppor tpoint, front axle 222

Wheels and tires

Page 252 of 322

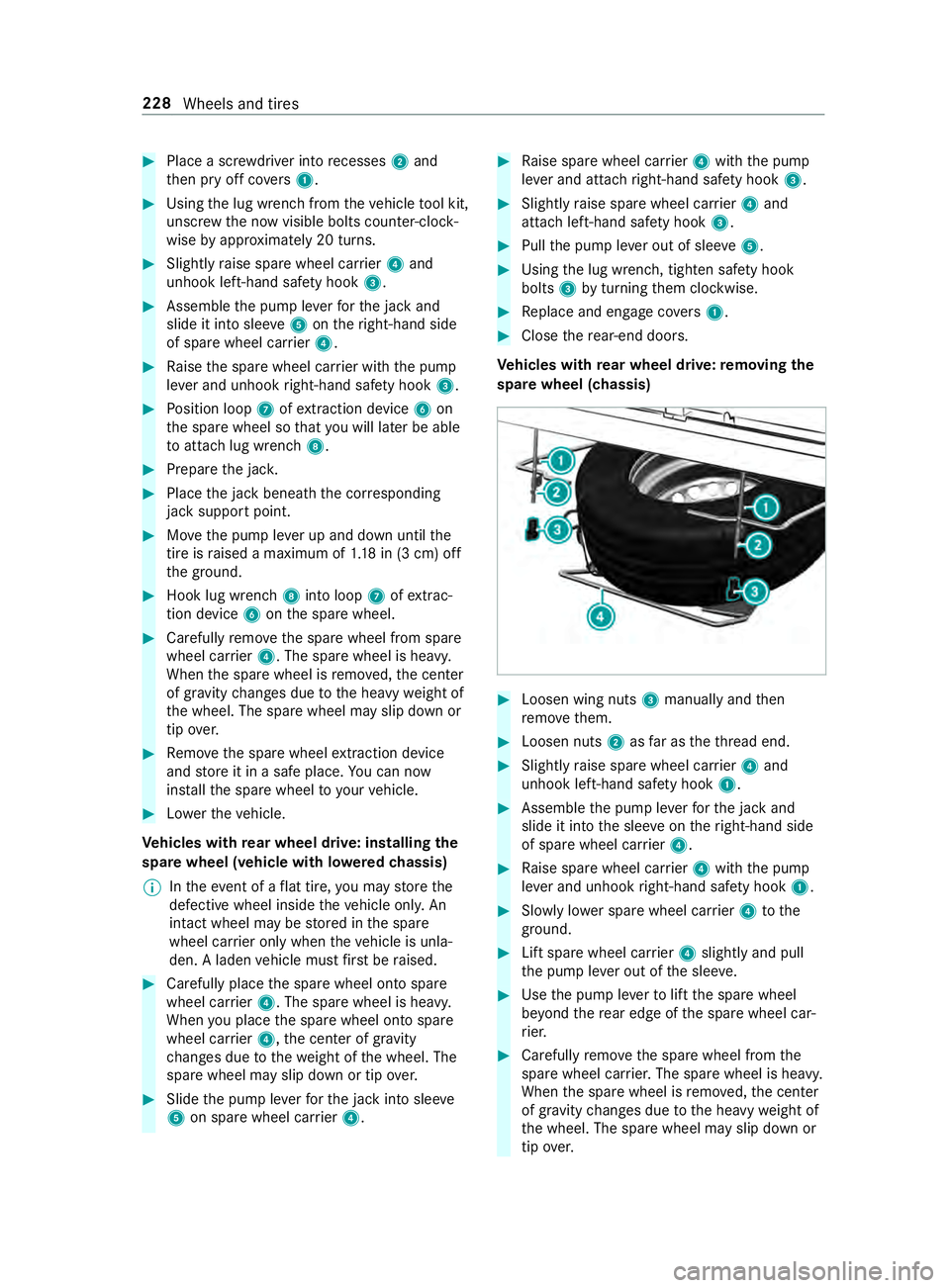

#

Place ascrew driver int orecesses 2and

th en pr yoffco vers 1 . #

Using thel ug wrenc hfromt hevehicle tool kit,

unscr ewthen ow visible bolts counter-clock‐

wise byappr oximatel y20turns. #

Slightly raise spar ewheel car rier 4 and

unhook left-hand saf etyh ook 3. #

Assemble thep um pleve rfor thej acka nd

slide it int osleeve5 onther ight-ha ndside

of spar ewheel car rier 4. #

Raise thes par ew heel car rier wit hthe pump

le ve ra nd unhook right-han dsafet yh ook 3. #

Position loop 7ofextraction device 6on

th es par ew heel so that youw ill later be able

to attac hlug wrench 8. #

Prepar ethe jac k. #

Place thej ackb eneat hthe cor responding

jac ksuppor tpoint. #

Movethep um pleve rupa nd down until the

tir eisr aised amaximum of 1.18 in (3 cm) off

th eg round. #

Hook lug wrench 8intoloop 7ofextrac‐

tio nd evice 6 onthes par ew heel. #

Carefully remo vethes par ew heel from spare

wheel car rier 4.T he spar ewheel is heavy.

When thes par ew heel is remo ved, thec enter

of gr avity changes due totheh eavy weight of

th ew heel. The spar ewheel ma yslip down or

tip ove r. #

Remo vethes par ew heel extraction device

and stor eitinas afep lace. Youc an now

ins tallth es par ew heel to yo urvehicle. #

Lowe rthe vehicle.

Ve hicles with rear wheel drive: installin gthe

spar ewheel (vehicle with lo weredc hassis)

% In

thee vent of aflat tire, youm aystor et he

defectiv ewheel inside thev ehicle only .An

intact wheel ma ybestore dint he spare

wheel car rier onl ywhen thev ehicle is unla‐

den. Aladen vehicle mus tfirst be raised. #

Carefull yplace thes par ew heel ont ospare

wheel car rier 4.T he spar ewheel is heavy.

When youp lacethe spar ewheel ont ospare

wheel car rier 4,t he center of gravity

ch anges due tothew eight of thew heel. The

spar ewheel ma yslip down or tip over. #

Slide thep um pleve rfor thej acki ntos leeve

5 on spar ewheel car rier 4. #

Raise spar ewheel car rier 4 withthe pump

le ve ra nd attac hright-ha ndsafetyh ook 3. #

Slight lyraise spar ewheel car rier 4 and

attac hleft-hand saf etyh ook 3. #

Pull thep um pleve rout of slee ve5 . #

Using thel ug wrench, tighten saf etyh ook

bolts 3byturning them clockwise. #

Replace and engag ecovers 1. #

Close ther ear-end doors.

Ve hicles with rear wheel drive: removing the

spar ewheel (chassis) #

Loosen wing nuts 3manually and then

re mo vethem. #

Loosen nuts 2asfarast hethre ad end. #

Slightly raise spar ewheel car rier 4 and

unhook left-hand saf etyh ook 1. #

Assemble thep um pleve rfor thej acka nd

slide it int othe slee veon ther ight-ha ndside

of spar ewheel car rier 4. #

Raise spar ewheel car rier 4 withthe pump

le ve ra nd unhook right-han dsafet yh ook 1. #

Slowl ylow er spar ewhee lcarrier 4 tothe

ground. #

Lift spar ewheel car rier 4 slightl yand pull

th ep um pleve rout of thes lee ve. #

Use thep um pleve rtol iftt he spar ewheel

be yond ther ear edg eofthe spar ewheel car‐

ri er. #

Carefully remo vethes par ew heel from the

spar ewheel car rier .T he spar ewheel is heavy.

When thes par ew heel is remo ved, thec enter

of gr avity changes due totheh eavy weight of

th ew heel. The spar ewheel ma yslip down or

tip ove r. 228

Wheels and tires