lock MINI Hardtop 2 Door 2007 Owner's Guide

[x] Cancel search | Manufacturer: MINI, Model Year: 2007, Model line: Hardtop 2 Door, Model: MINI Hardtop 2 Door 2007Pages: 148, PDF Size: 2.43 MB

Page 96 of 148

Under the bonnet

94

Under the bonnet

Do not work on the car unless you possess

the necessary technical knowledge. If you

are not familiar with the regulations to be

observed, have the necessary work on your

vehicle carried out only by a MINI Dealer or a

workshop that has specially trained personnel

working in accordance with the specifications of

the MINI manufacturer. If this work is not carried

out properly, there is a danger of subsequent

damage and related safety hazards.<

Bonnet

Releasing

Pull the lever.

Do not clean the windshield and head-

lamps if the bonnet is unlocked as this

may damage the headlamp washer system

*.<

Opening

To avoid damage, make sure that the

wiper arms are against the windshield

before you open the bonnet.<

Press the release handle and open the bonnet.

Closing

Close the bonnet from a height of approx. 16 in/

40 cm with momentum. It must be clearly heard

to engage.

If you notice any signs while driving your

vehicle that the bonnet is not completely

closed, stop at once and close it securely.

Make sure that the closing path of the bonnet is

clear, otherwise injuries may result.<

Page 98 of 148

Under the bonnet

96

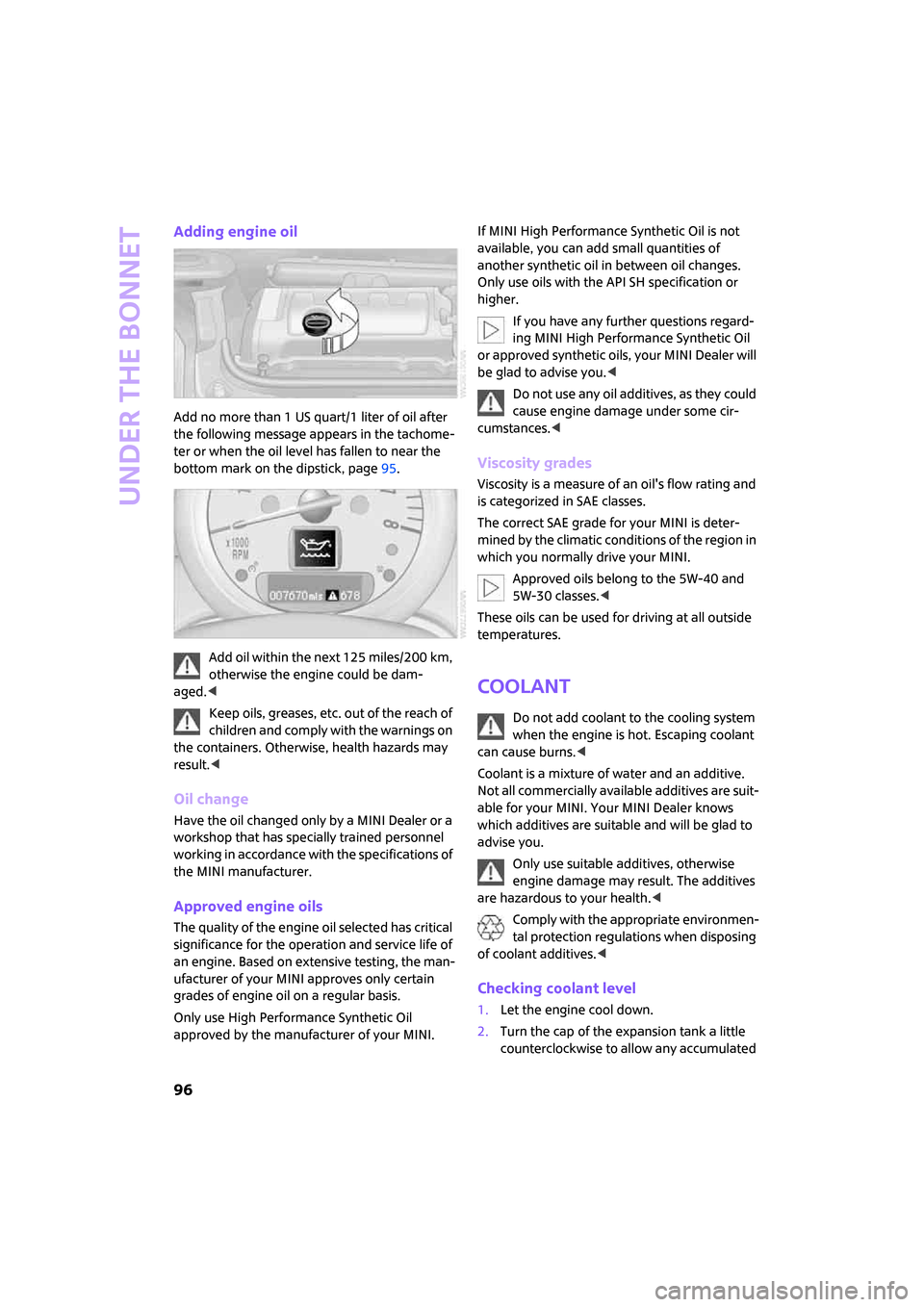

Adding engine oil

Add no more than 1 US quart/1 liter of oil after

the following message appears in the tachome-

ter or when the oil level has fallen to near the

bottom mark on the dipstick, page95.

Add oil within the next 125 miles/200 km,

otherwise the engine could be dam-

aged.<

Keep oils, greases, etc. out of the reach of

children and comply with the warnings on

the containers. Otherwise, health hazards may

result.<

Oil change

Have the oil changed only by a MINI Dealer or a

workshop that has specially trained personnel

working in accordance with the specifications of

the MINI manufacturer.

Approved engine oils

The quality of the engine oil selected has critical

significance for the operation and service life of

an engine. Based on extensive testing, the man-

ufacturer of your MINI approves only certain

grades of engine oil on a regular basis.

Only use High Performance Synthetic Oil

approved by the manufacturer of your MINI.If MINI High Performance Synthetic Oil is not

available, you can add small quantities of

another synthetic oil in between oil changes.

Only use oils with the API SH specification or

higher.

If you have any further questions regard-

ing MINI High Performance Synthetic Oil

or approved synthetic oils, your MINI Dealer will

be glad to advise you.<

Do not use any oil additives, as they could

cause engine damage under some cir-

cumstances.<

Viscosity grades

Viscosity is a measure of an oil's flow rating and

is categorized in SAE classes.

The correct SAE grade for your MINI is deter-

mined by the climatic conditions of the region in

which you normally drive your MINI.

Approved oils belong to the 5W-40 and

5W-30 classes.<

These oils can be used for driving at all outside

temperatures.

Coolant

Do not add coolant to the cooling system

when the engine is hot. Escaping coolant

can cause burns.<

Coolant is a mixture of water and an additive.

Not all commercially available additives are suit-

able for your MINI. Your MINI Dealer knows

which additives are suitable and will be glad to

advise you.

Only use suitable additives, otherwise

engine damage may result. The additives

are hazardous to your health.<

Comply with the appropriate environmen-

tal protection regulations when disposing

of coolant additives.<

Checking coolant level

1.Let the engine cool down.

2.Turn the cap of the expansion tank a little

counterclockwise to allow any accumulated

Page 106 of 148

Replacing components

104

3.Fold the retaining clip to the side, arrow3.

4.Remove the bulb.

5.Insert the new bulb with the tab facing up,

arrow4.

6.Fold back and lock the retaining clip.

7.Reattach the cover.

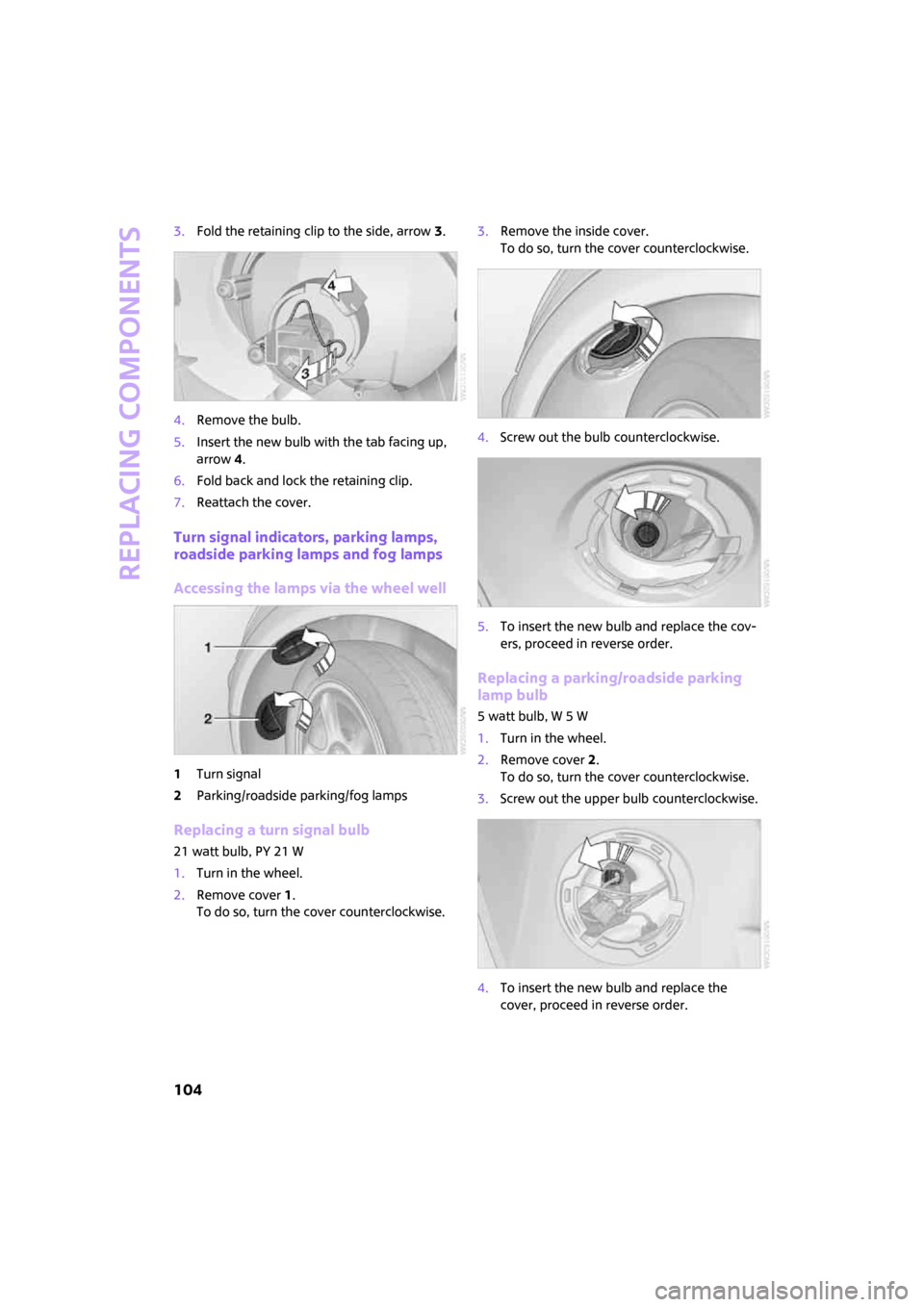

Turn signal indicators, parking lamps,

roadside parking lamps and fog lamps

Accessing the lamps via the wheel well

1Turn signal

2Parking/roadside parking/fog lamps

Replacing a turn signal bulb

21 watt bulb, PY 21 W

1.Turn in the wheel.

2.Remove cover 1.

To do so, turn the cover counterclockwise.3.Remove the inside cover.

To do so, turn the cover counterclockwise.

4.Screw out the bulb counterclockwise.

5.To insert the new bulb and replace the cov-

ers, proceed in reverse order.

Replacing a parking/roadside parking

lamp bulb

5 watt bulb, W 5 W

1.Turn in the wheel.

2.Remove cover 2.

To do so, turn the cover counterclockwise.

3.Screw out the upper bulb counterclockwise.

4.To insert the new bulb and replace the

cover, proceed in reverse order.

Page 107 of 148

ReferenceAt a glance Controls Driving tips Mobility

105

Replacing a fog lamp bulb

H8 bulb, 35 watts

1.Turn in the wheel.

2.Remove cover 2.

To do so, turn the cover counterclockwise.

3.Screw out the lower bulb counterclockwise.

4.To insert the new bulb and replace the

cover, proceed in reverse order.

Side turn signal indicators

5 watt bulb, W 5 W

1.Push the lamp with the ventilation grate for-

ward and remove.

2.Screw out the bulb holder counterclockwise.

3.Pull out and replace the bulb.

4.To insert the new bulb and replace the

cover, proceed in reverse order.

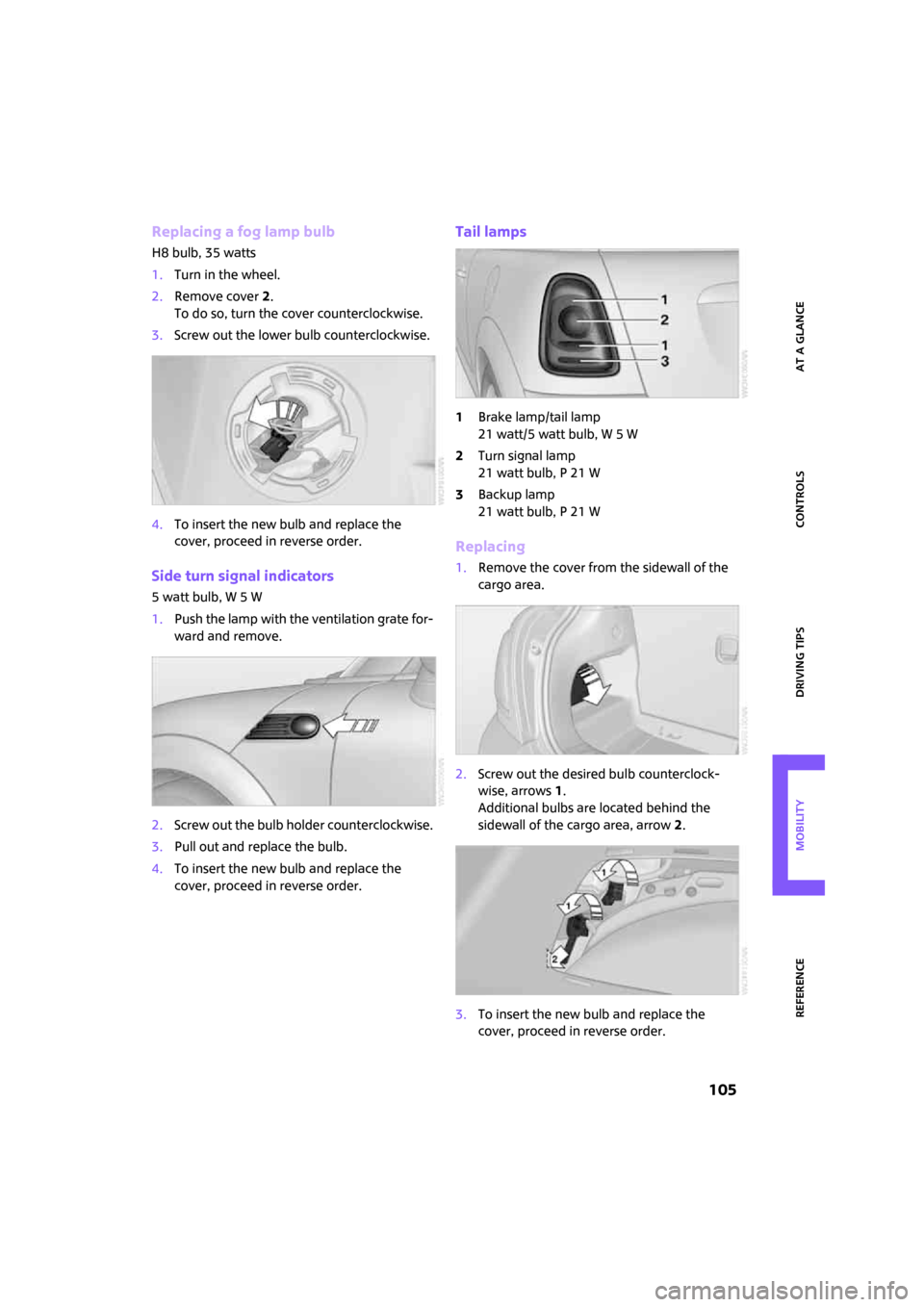

Tail lamps

1Brake lamp/tail lamp

21 watt/5 watt bulb, W 5 W

2Turn signal lamp

21 watt bulb, P 21 W

3Backup lamp

21 watt bulb, P 21 W

Replacing

1.Remove the cover from the sidewall of the

cargo area.

2.Screw out the desired bulb counterclock-

wise, arrows1.

Additional bulbs are located behind the

sidewall of the cargo area, arrow 2.

3.To insert the new bulb and replace the

cover, proceed in reverse order.

Page 108 of 148

Replacing components

106

Rear fog lamp*

2 watt bulb, P 21 W

Access to the lamp via the back or underside of

the bumper.

The illustration shows the fog lamp in the

bumper of the MINI Cooper.

1.Screw out the bulb holder counterclockwise.

2.Screw out and replace the bulb.

3.To insert the new bulb and bulb holder, pro-

ceed in reverse order.

License plate lamps

5 watt bulb, C 5 W

1.Using a screwdriver, push the lamp to the

left in the tab of the lamp housing, arrow1.

2.Remove the lamp, arrow 2.

3.Replace the bulb.

4.Insert the lamp.

Center brake lamp

This lamp uses LED technology for operation. In

the event of a malfunction, contact your MINI

Dealer or a workshop that has specially trained

personnel working in accordance with the spec-

ifications of your MINI manufacturer.

Repairing a flat tire

Safety measures in the event of a break-

down:

Park the vehicle as far as possible from moving

traffic and switch on the hazard warning flash-

ers.

Turn the steering wheel until the front wheels

are in the straight-ahead position and engage

the steering wheel lock. Engage the parking

brake and shift into 1st or reverse gear or place

the selector lever in position P.

All passengers should be outside the vehicle and

in a safe place, e.g. behind a guardrail.

Erect a warning triangle or warning flasher at the

appropriate distance if necessary. Comply with

all safety guidelines and regulations.<

In the event of a flat tire, different procedures

should be followed depending on the equip-

ment included in your vehicle:

>MINI Mobility System, refer to the following

section

>Run-Flat Tires, page92

>Tire change with space-saver spare tire,

page108

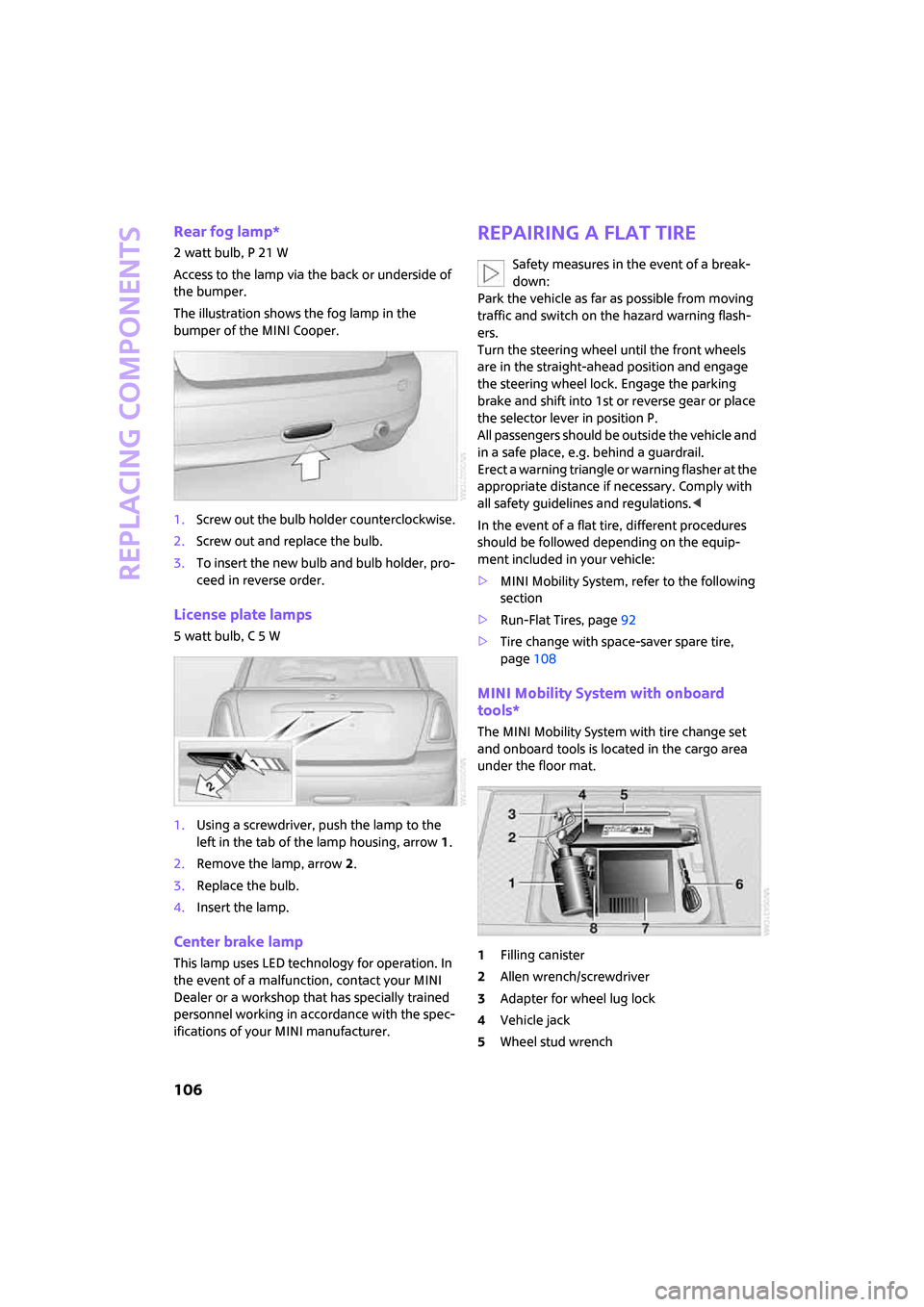

MINI Mobility System with onboard

tools*

The MINI Mobility System with tire change set

and onboard tools is located in the cargo area

under the floor mat.

1Filling canister

2Allen wrench/screwdriver

3Adapter for wheel lug lock

4Vehicle jack

5Wheel stud wrench

Page 110 of 148

Replacing components

108

Distributing liquid sealant

Immediately drive for approx. 10 minutes, so

that the liquid sealant is uniformly distributed.

Do not exceed a speed of 35 mph/

60 km/h.

If possible, do not drive at a speed lower than

12 mph/20 km/h.<

Checking tire inflation pressure

1.After driving for approx. 10 minutes, pull

over at a suitable location.

2.Screw the hose with manometer back onto

the tire valve.

3.Check the tire inflation pressure.

The tire inflation pressure must be at

least 18.9 psi/1.3 bar. If it is not, do not

continue driving.<

If at least 18.9 psi/1.3 bar are displayed:

1.Switch on the compressor. Correct the tire

inflation pressure to the specified value,

page86.

2.Replace the tire as soon as possible.

Driving on

Do not exceed the permitted maximum

speed of 50 mph/80 km/h; doing so may

result in an accident.<

Replace the defective tire as soon as possible

and have the new wheel/tire assembly bal-

anced.

Have the MINI Mobility System refilled.

Tire change set

When changing a tire, always observe the safety

measures and the procedure for changing tires

described below.

In case of a flat tire the tire change set is

not needed due to the availability of the

MINI Mobility System.<

Changing wheels

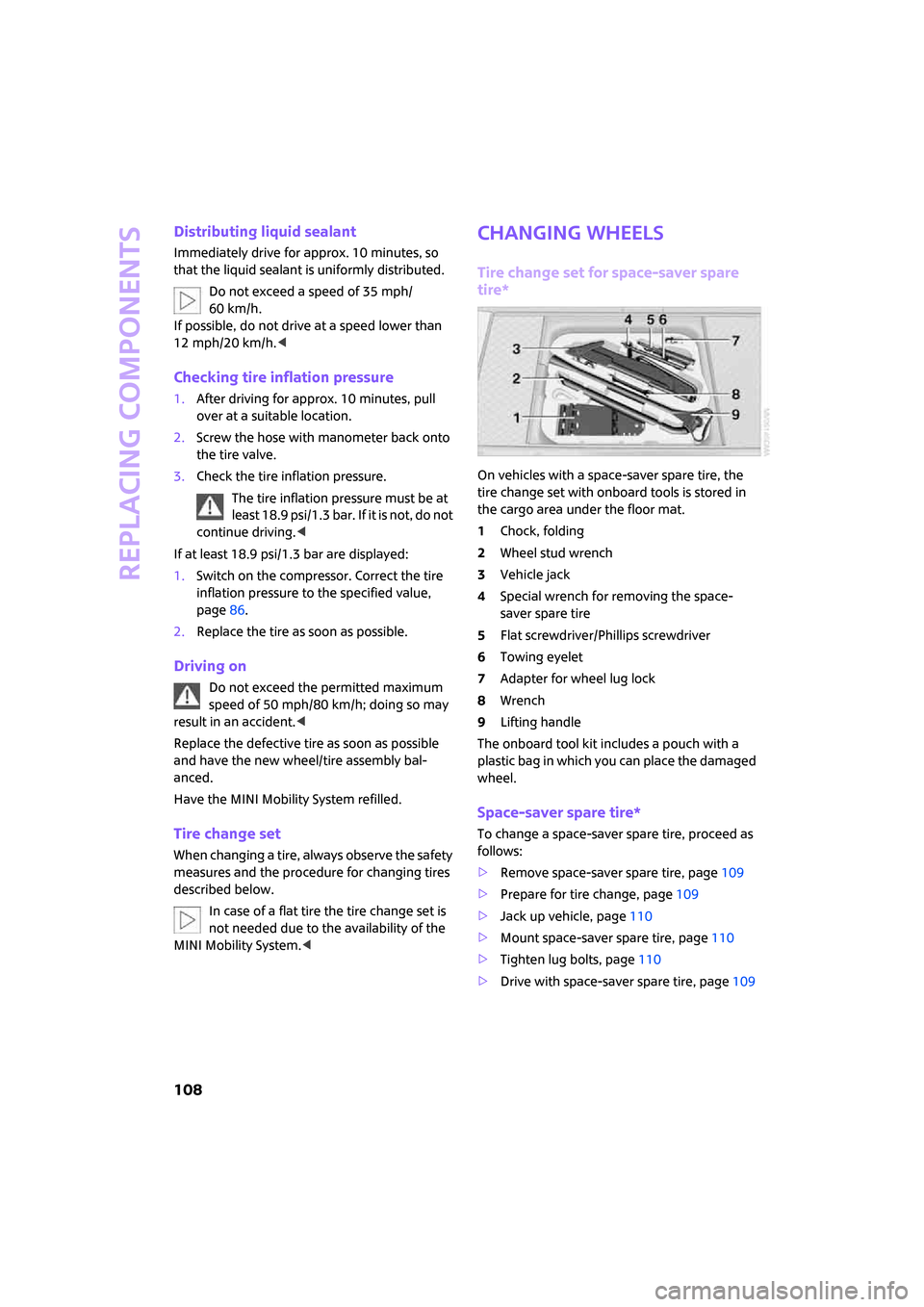

Tire change set for space-saver spare

tire*

On vehicles with a space-saver spare tire, the

tire change set with onboard tools is stored in

the cargo area under the floor mat.

1Chock, folding

2Wheel stud wrench

3Vehicle jack

4Special wrench for removing the space-

saver spare tire

5Flat screwdriver/Phillips screwdriver

6Towing eyelet

7Adapter for wheel lug lock

8Wrench

9Lifting handle

The onboard tool kit includes a pouch with a

plastic bag in which you can place the damaged

wheel.

Space-saver spare tire*

To change a space-saver spare tire, proceed as

follows:

>Remove space-saver spare tire, page109

>Prepare for tire change, page109

>Jack up vehicle, page110

>Mount space-saver spare tire, page110

>Tighten lug bolts, page110

>Drive with space-saver spare tire, page109

Page 112 of 148

Replacing components

110

Only change the tire when parked on a surface

that is level, firm and not slippery.

The vehicle or the jack could slip sideways on

soft or slippery support surfaces, such as snow,

ice, flagstones, etc.

Do not use a wooden block or similar object as a

support base for the jack, as this would prevent

it from extending to its full support height and

reduce its load-carrying capacity.

Do not lie under the vehicle or start the engine

when the vehicle is supported by the jack; other-

wise there is a risk of fatal injury.<

1.Place the foldable chock

* behind the front

wheel on the other side of the vehicle or in

front of the wheel if the vehicle is on an

incline. If the wheel is changed on a surface

with a more severe slope, take additional

precautions to secure the vehicle from roll-

ing.

2.Uncover the lug bolts if necessary.

If the wheel is equipped with a hub cover,

pry it off using the screwdriver from the tire

change kit.

3.Loosen the lug bolts by a half turn.

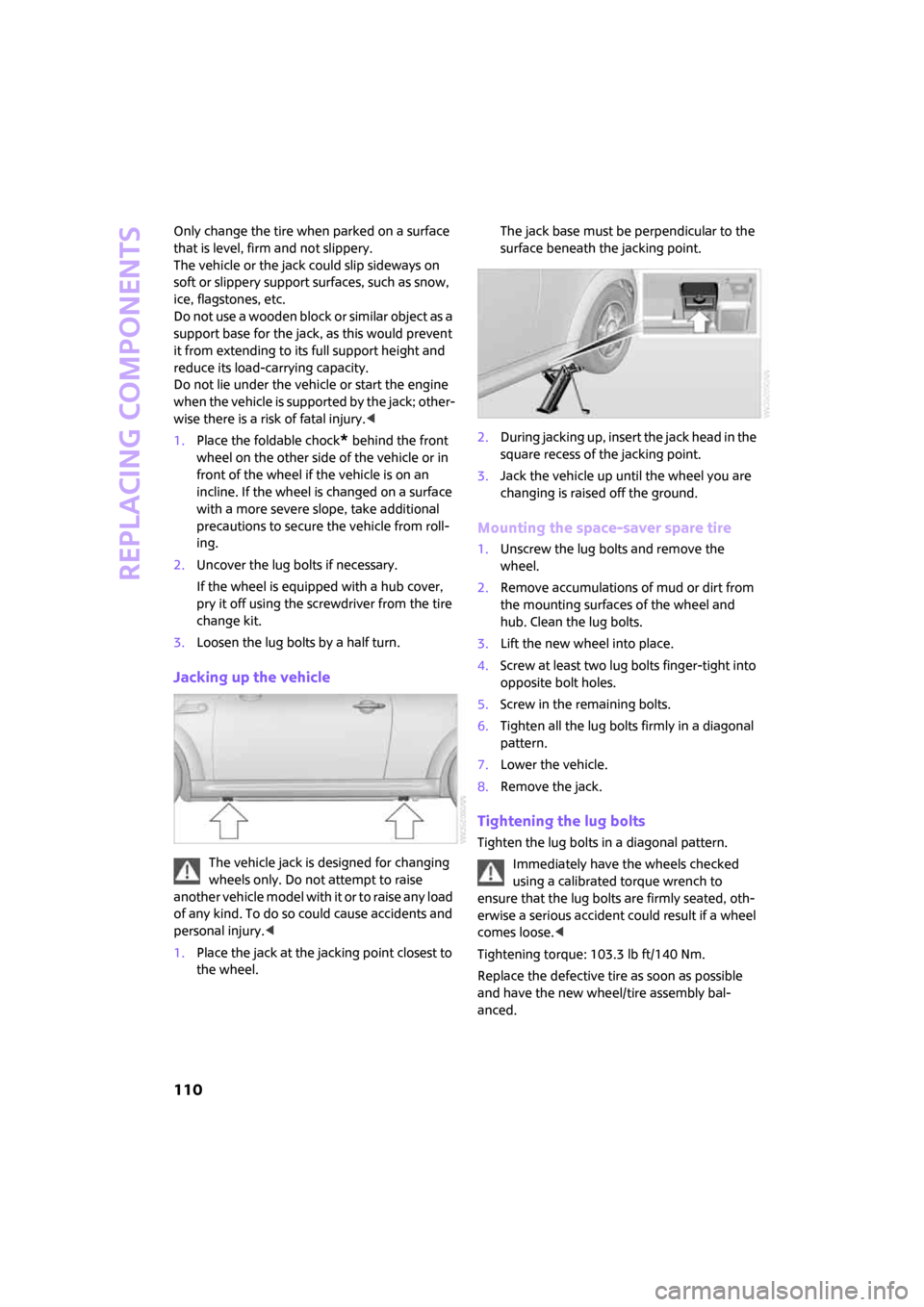

Jacking up the vehicle

The vehicle jack is designed for changing

wheels only. Do not attempt to raise

another vehicle model with it or to raise any load

of any kind. To do so could cause accidents and

personal injury.<

1.Place the jack at the jacking point closest to

the wheel.The jack base must be perpendicular to the

surface beneath the jacking point.

2.During jacking up, insert the jack head in the

square recess of the jacking point.

3.Jack the vehicle up until the wheel you are

changing is raised off the ground.

Mounting the space-saver spare tire

1.Unscrew the lug bolts and remove the

wheel.

2.Remove accumulations of mud or dirt from

the mounting surfaces of the wheel and

hub. Clean the lug bolts.

3.Lift the new wheel into place.

4.Screw at least two lug bolts finger-tight into

opposite bolt holes.

5.Screw in the remaining bolts.

6.Tighten all the lug bolts firmly in a diagonal

pattern.

7.Lower the vehicle.

8.Remove the jack.

Tightening the lug bolts

Tighten the lug bolts in a diagonal pattern.

Immediately have the wheels checked

using a calibrated torque wrench to

ensure that the lug bolts are firmly seated, oth-

erwise a serious accident could result if a wheel

comes loose.<

Tightening torque: 103.3 lb ft/140 Nm.

Replace the defective tire as soon as possible

and have the new wheel/tire assembly bal-

anced.

Page 114 of 148

Giving and receiving assistance

112

Giving and receiving assistance

Roadside Assistance

The Roadside Assistance service is there to assist

you around the clock in the event of a break-

down, including on weekends and public holi-

days.

The phone numbers of the Roadside Assistance

in your home country can be found in the Con-

tact brochure.

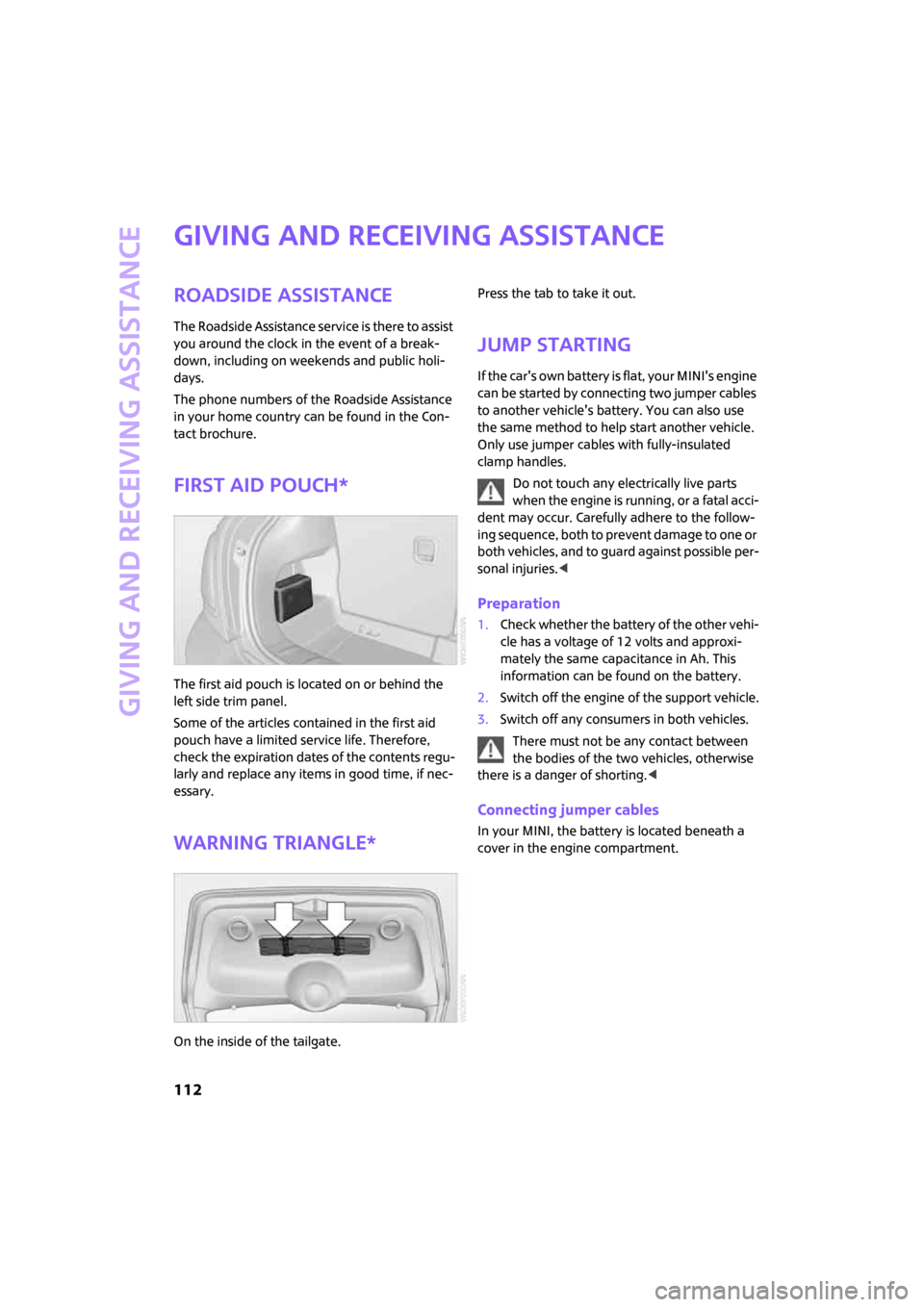

First aid pouch*

The first aid pouch is located on or behind the

left side trim panel.

Some of the articles contained in the first aid

pouch have a limited service life. Therefore,

check the expiration dates of the contents regu-

larly and replace any items in good time, if nec-

essary.

Warning triangle*

On the inside of the tailgate.Press the tab to take it out.

Jump starting

If the car's own battery is flat, your MINI's engine

can be started by connecting two jumper cables

to another vehicle's battery. You can also use

the same method to help start another vehicle.

Only use jumper cables with fully-insulated

clamp handles.

Do not touch any electrically live parts

when the engine is running, or a fatal acci-

dent may occur. Carefully adhere to the follow-

ing sequence, both to prevent damage to one or

both vehicles, and to guard against possible per-

sonal injuries.<

Preparation

1.Check whether the battery of the other vehi-

cle has a voltage of 12 volts and approxi-

mately the same capacitance in Ah. This

information can be found on the battery.

2.Switch off the engine of the support vehicle.

3.Switch off any consumers in both vehicles.

There must not be any contact between

the bodies of the two vehicles, otherwise

there is a danger of shorting.<

Connecting jumper cables

In your MINI, the battery is located beneath a

cover in the engine compartment.

Page 116 of 148

Giving and receiving assistance

114

Front

Rear

Being towed

Check that the car is radio-ready and that

the electric steering wheel lock is not

engaged, otherwise the car would not be steer-

able. If the electrical system fails, do not attempt

to tow-start or tow away the car. The electric

steering wheel lock cannot be disengaged and

the car is not steerable. Jump starting, refer to

page112.<

There is no power assist while the engine is off.

Thus, braking and steering will require increased

effort.

Switch on the hazard warning flashers, depend-

ing on local regulations.

Manual transmission

Gearshift lever in idle position.

Automatic transmission

Tow vehicles with automatic transmission

only with a tow truck or with the front

wheels lifted; otherwise the transmission can be

damaged.<

Towing with a tow bar

The towing vehicle must not be lighter

than the towed vehicle, otherwise it may

be impossible to maintain control.<

The tow fittings used should be on the same side

on both vehicles. Should it prove impossible to

avoid mounting the tow bar at an angle, please

observe the following:

>Clearance and maneuvering capability will

be sharply limited during cornering.

>The tow bar will generate lateral forces if it is

attached offset.

Attach the tow bar to the tow fittings only,

as attaching it to other parts of the vehicle

could result in damage.<

Towing with a tow rope

When starting off in the towing vehicle, make

sure that the tow rope is taut.

To avoid jerking and the associated

stresses on vehicle components when

towing, always use nylon ropes or nylon straps.

Attach the tow rope to the tow fittings only, as

attaching it to other parts of the vehicle could

result in damage.<

Towing with a tow truck

Have the MINI transported with a tow truck with

a so-called lift bar or on a flat bed.

Do not lift the vehicle by a tow fitting or

body and chassis parts, otherwise damage

may result.<

Tow-starting

Avoid tow-starting the vehicle whenever possi-

ble; instead, jump-start the engine, page112.

Page 117 of 148

ReferenceAt a glance Controls Driving tips Mobility

115

Vehicles with a catalytic converter should only

be tow-started when the engine is cold, vehicles

with an automatic transmission cannot be tow-

started at all.

If the electrical system fails, do not tow or

tow-start the vehicle, as it would be

impossible to release the electric steering-wheel

lock and the vehicle could not be steered.<

1.Switch on hazard warning flashers, comply

with local regulations.

2.Switch on the ignition, page35.

3.Shift into 3rd gear.

4.Have the vehicle tow-started with the clutch

completely depressed and then slowly

release the clutch. After the engine starts,

immediately depress the clutch completely

again.

5.Stop at a suitable location, remove the tow

bar or rope and switch off the hazard warn-

ing flashers.

6.Have the vehicle checked.