wheel alignment MITSUBISHI ECLIPSE 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 613 of 1216

Special Tools/Troubleshooting/REAR SUSPENSION

SPECIAL TOOLN17DA.A

ToolNumberName1 Use1

L-451 4

Spring compressorRemoval and installation of the coil spring

bodyTROUBLESHOOTINGNI’IEA-A

Symptom

Squeaks or other

abnormal noiseProbable cause

Loose rear suspension installation bolts and nuts

Malfunction of shock absorber

Worn bushings

Remedy

Retighten

Replace

Poor rideExcessive tire inflation pressure

Malfunction of shock absorberWeak or broken springs

Adjust the pressure

Replace

Body tiltingWeak or deteriorated bushings

Weak or broken springs

Replace

SERVICE ADJUSTMENT PROCEDURES

REAR WHEEL ALIGNMENT INSPECTIONN17FAAC

The rear suspension assembly must be free of worn, loosen or

damaged parts prior to measurement of rear wheel alignment.

Standard value:

Toe-in (Left-right difference)

Of3 mm (Of.118 in.)

Camber-45’ + 30’

NOTEThe rear wheel alignment is set at the factory and cannot be

adjusted.If toe-in or camber is not within the standard value, replace

bent or damaged parts.

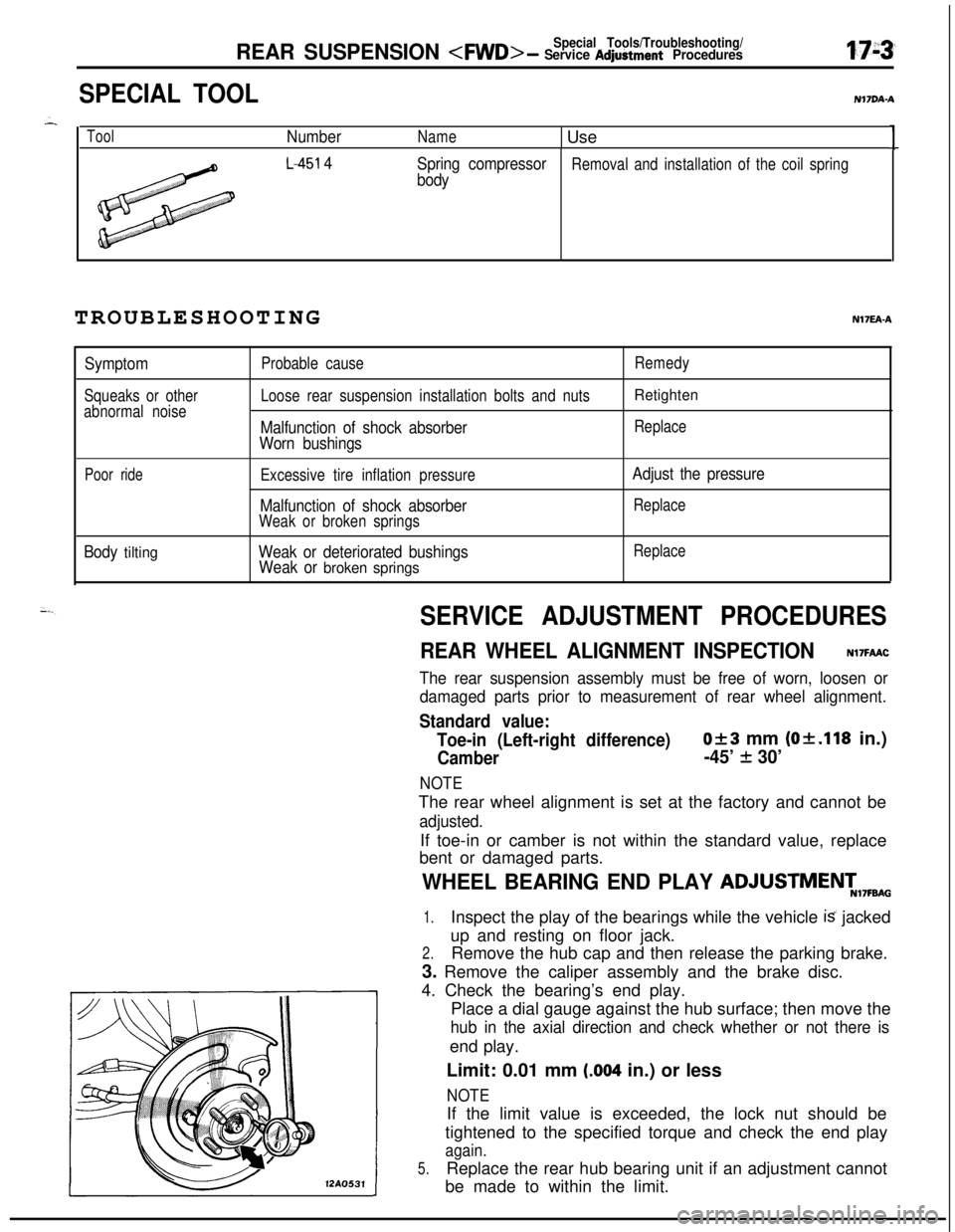

WHEEL BEARING END PLAY ADJUSTMENT,7FBA0

1.Inspect the play of the bearings while the vehicle is jacked

up and resting on floor jack.

2.Remove the hub cap and then release the parking brake.

3. Remove the caliper assembly and the brake disc.

4. Check the bearing’s end play.

Place a dial gauge against the hub surface; then move the

hub in the axial direction and check whether or not there isend play.

Limit: 0.01 mm

(.004 in.) or less

NOTE12AO531If the limit value is exceeded, the lock nut should be

tightened to the specified torque and check the end play

again.

5.Replace the rear hub bearing unit if an adjustment cannot

be made to within the limit.

Page 630 of 1216

17-20REAR SUSPENSION

12R0556-- Upper arm

(L.H.)

12A0081

SERVICE ADJUSTMENT PROCEDURES

REAR WHEEL ALIGNMENT INSPECTIONN17FDAB is.Measure the wheel alignment with the vehicle parked on level

--’

ground.The rear suspension and wheels should be inspected for

wear’or damage and repaired prior to measurement of wheel,

alignment.

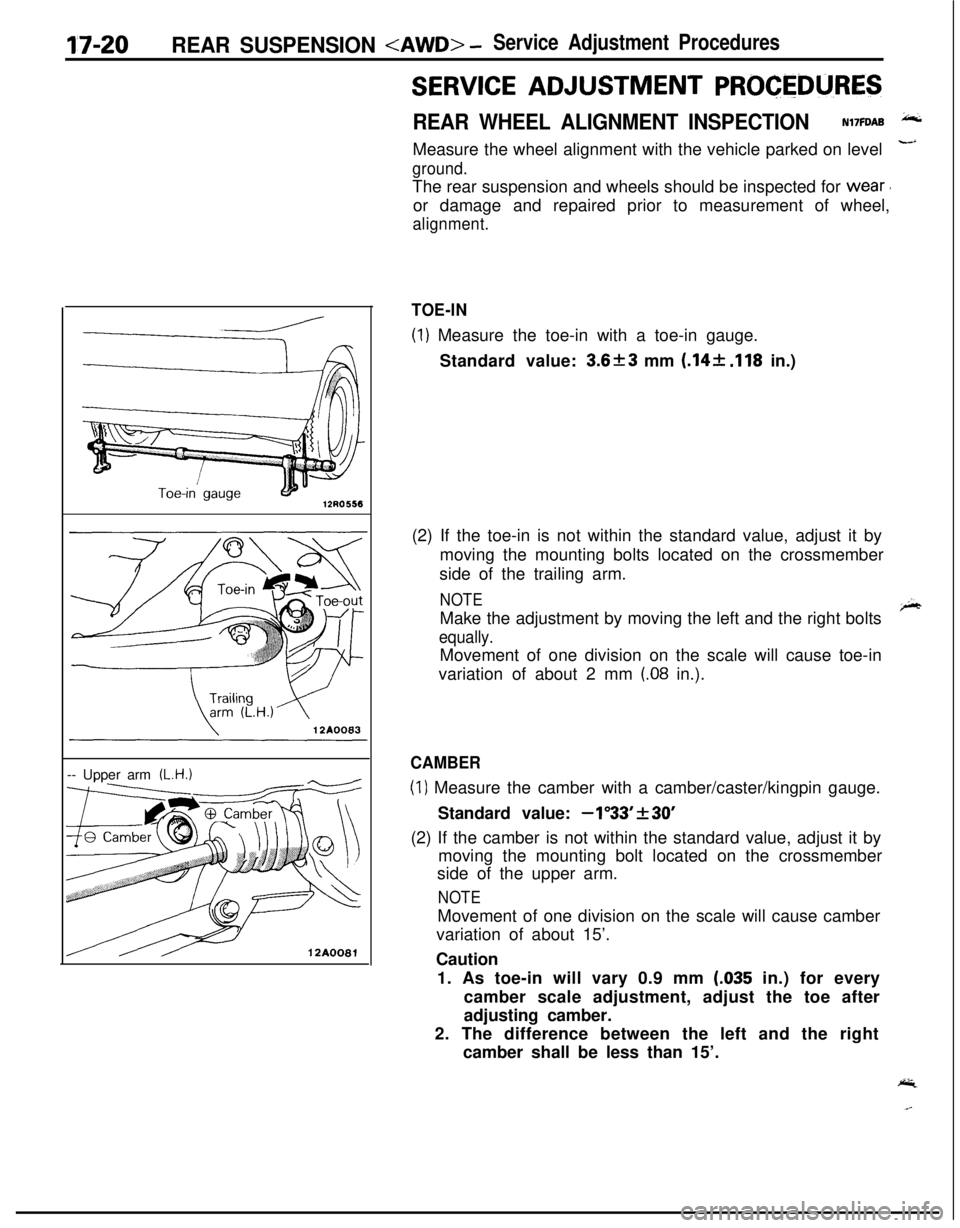

TOE-IN

(1) Measure the toe-in with a toe-in gauge.

Standard value:

3.6f3 mm (.14+ .I18 in.)

(2) If the toe-in is not within the standard value, adjust it by

moving the mounting bolts located on the crossmember

side of the trailing arm.

NOTEMake the adjustment by moving the left and the right bolts

r;hr

equally.Movement of one division on the scale will cause toe-in

variation of about 2 mm

(.08 in.).

CAMBER

(1) Measure the camber with a camber/caster/kingpin gauge.

Standard value:

-1”33’f30’(2) If the camber is not within the standard value, adjust it by

moving the mounting bolt located on the crossmember

side of the upper arm.

NOTEMovement of one division on the scale will cause camber

variation of about 15’.

Caution

1. As toe-in will vary 0.9 mm

(.035 in.) for every

camber scale adjustment, adjust the toe after

adjusting camber.

2. The difference between the left and the right

camber shall be less than 15’.

Page 631 of 1216

REAR SUSPENSION

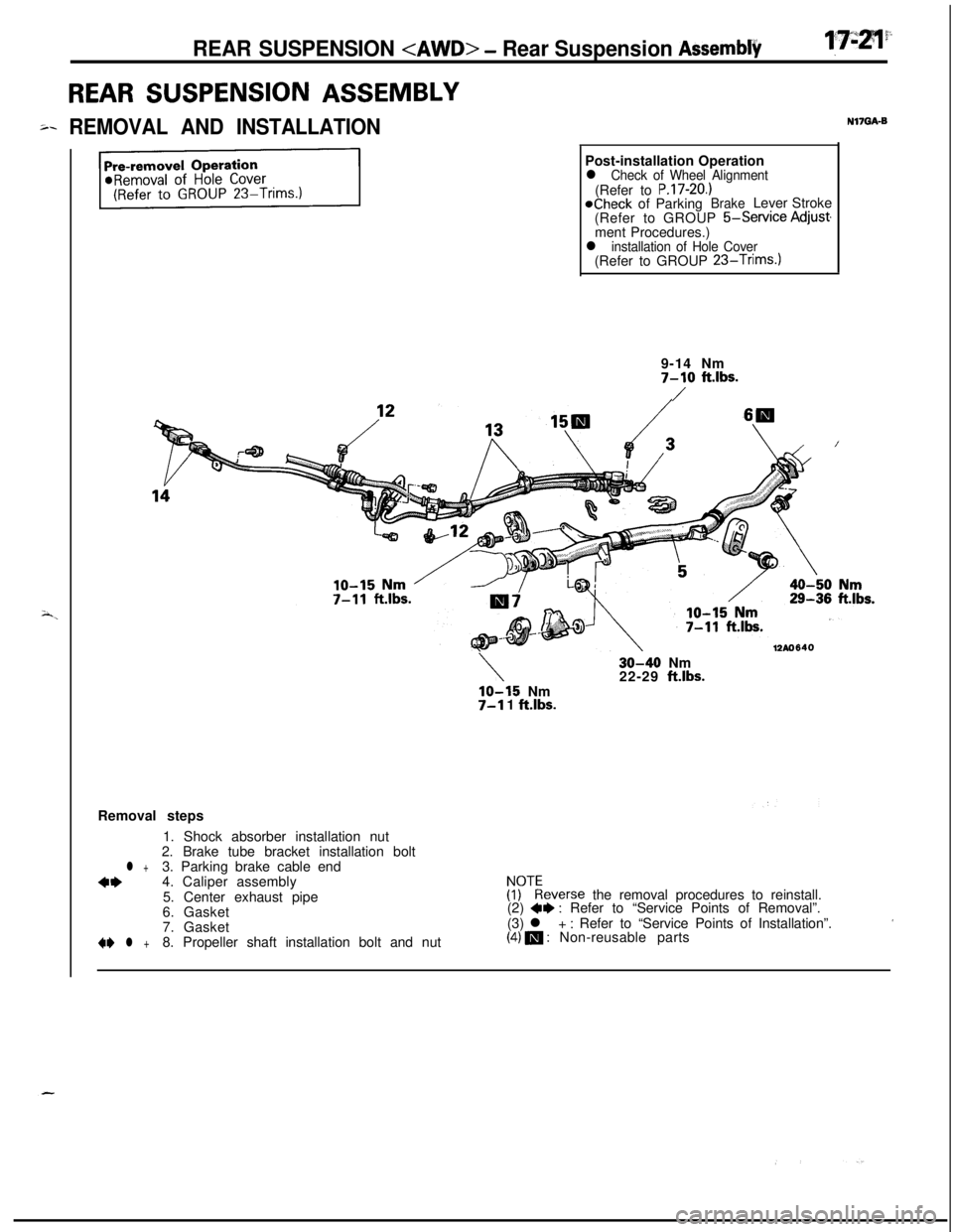

REAR SUSPENSION ASSEMBLY

5.REMOVAL AND INSTALLATIONN17GA-BPost-installation Operation

l Check of Wheel Alignment(Refer to P.17-20.)@Check of ParkingBrakeLever Stroke

(Refer to GROUP 5-Service Adjust

ment Procedures.)

l installation of Hole Cover(Refer to GROUP 23-Trims.)9-14 Nm

7-10 ft.lbs.

/

12AO640

\lo-15 Nm7-l 1 ft.lbs.

30-40 Nm

22-29 ft.lbs.

Removal steps

1. Shock absorber installation nut

2. Brake tube bracket installation bolt

l +3. Parking brake cable end

**4. Caliper assembly

5. Center exhaust pipe!rEeverse the removal procedures to reinstall.

6. Gasket(2) 4e: Refer to “Service Points of Removal”.

7. Gasket(3) l + : Refer to “Service Points of Installation”.’+I)

l +8. Propeller shaft installation bolt and nut(4) m : Non-reusable parts

Page 638 of 1216

17-28REAR SUSPENSION

TRAILING ARMr

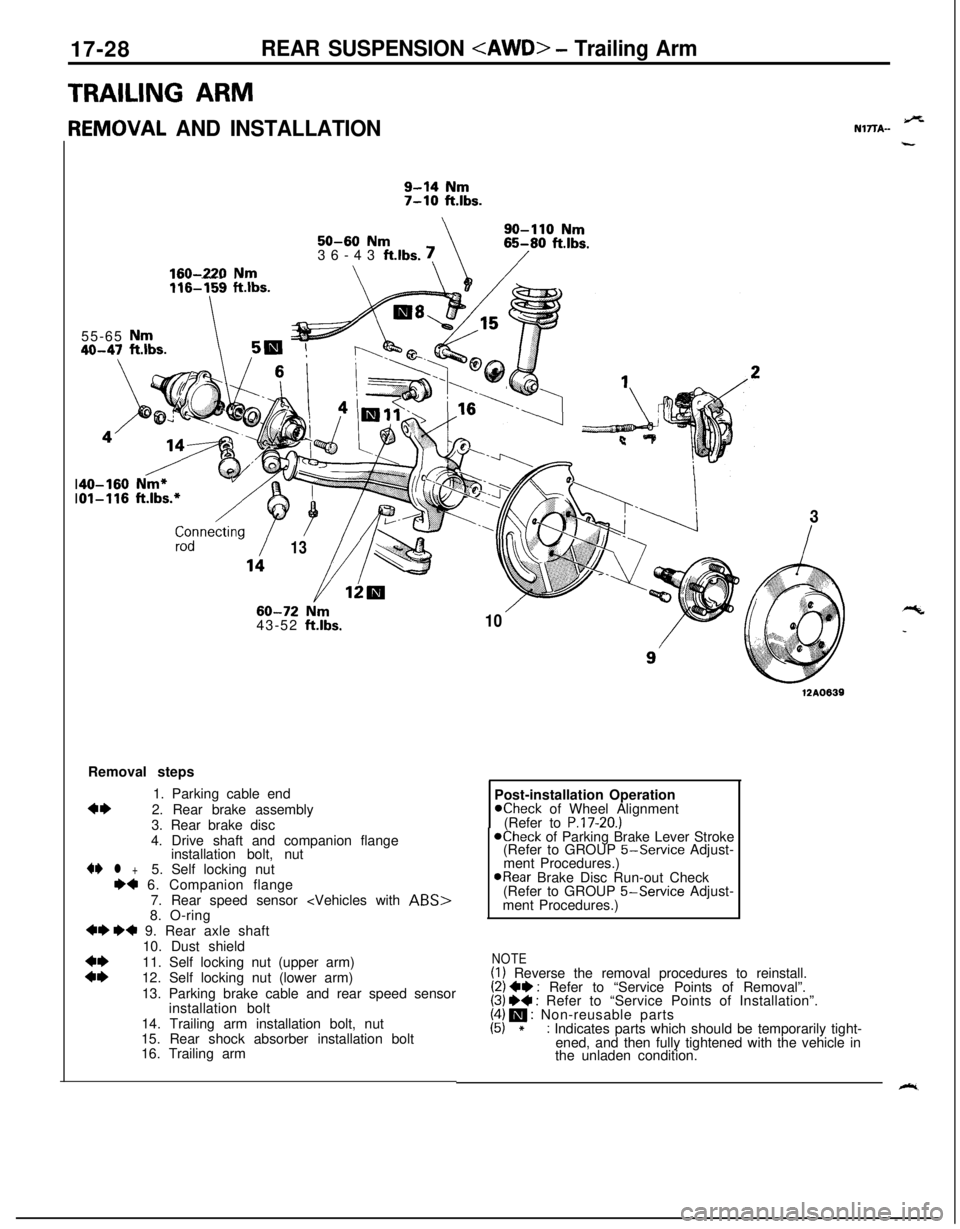

{EMOVAL AND INSTALLATION

9-14 Nm7-10 ft.lbs.

\SO-110

Nm50-60 Nm36-43 ft.lbs. !65-80 ftlbs.

/160-220 Nm\\\ /zdnnecting

/

/

13

_-_ --- .~~~~116-159 ftlbs.55-65

Nm40-47 ft.lbs.5m

60-72 Nrn43-52 ft.lbs.

/-\

103Removal steps

1. Parking cable end

4*2. Rear brake assembly

3. Rear brake disc

4. Drive shaft and companion flange

installation bolt, nut4I)

l +5. Self locking nut++ 6. Companion flange

7. Rear speed sensor

+I) ++ 9. Rear axle shaft

10. Dust shield

::11. Self locking nut (upper arm)

12. Self locking nut (lower arm)

13. Parking brake cable and rear speed sensor

installation bolt

14. Trailing arm installation bolt, nut

15. Rear shock absorber installation bolt

16. Trailing arm

12A0639Post-installation Operation

Kheck of Wheel Alignment

(Refer to P.17-20.)@Check of Parking Brake Lever Stroke

(Refer to GROUP 5-Service Adjust-

ment Procedures.)

@Rear Brake Disc Run-out Check

(Refer to GROUP 5-Service Adjust-

ment Procedures.)

NOTE(I) Reverse the removal procedures to reinstall.(2) ++ : Refer to “Service Points of Removal”.(3) W : Refer to “Service Points of Installation”.(4) m : Non-reusable parts(5) *: Indicates parts which should be temporarily tight-

ened, and then fully tightened with the vehicle in

the unladen condition.

9%NlTTA-

“c

_

k.

Page 668 of 1216

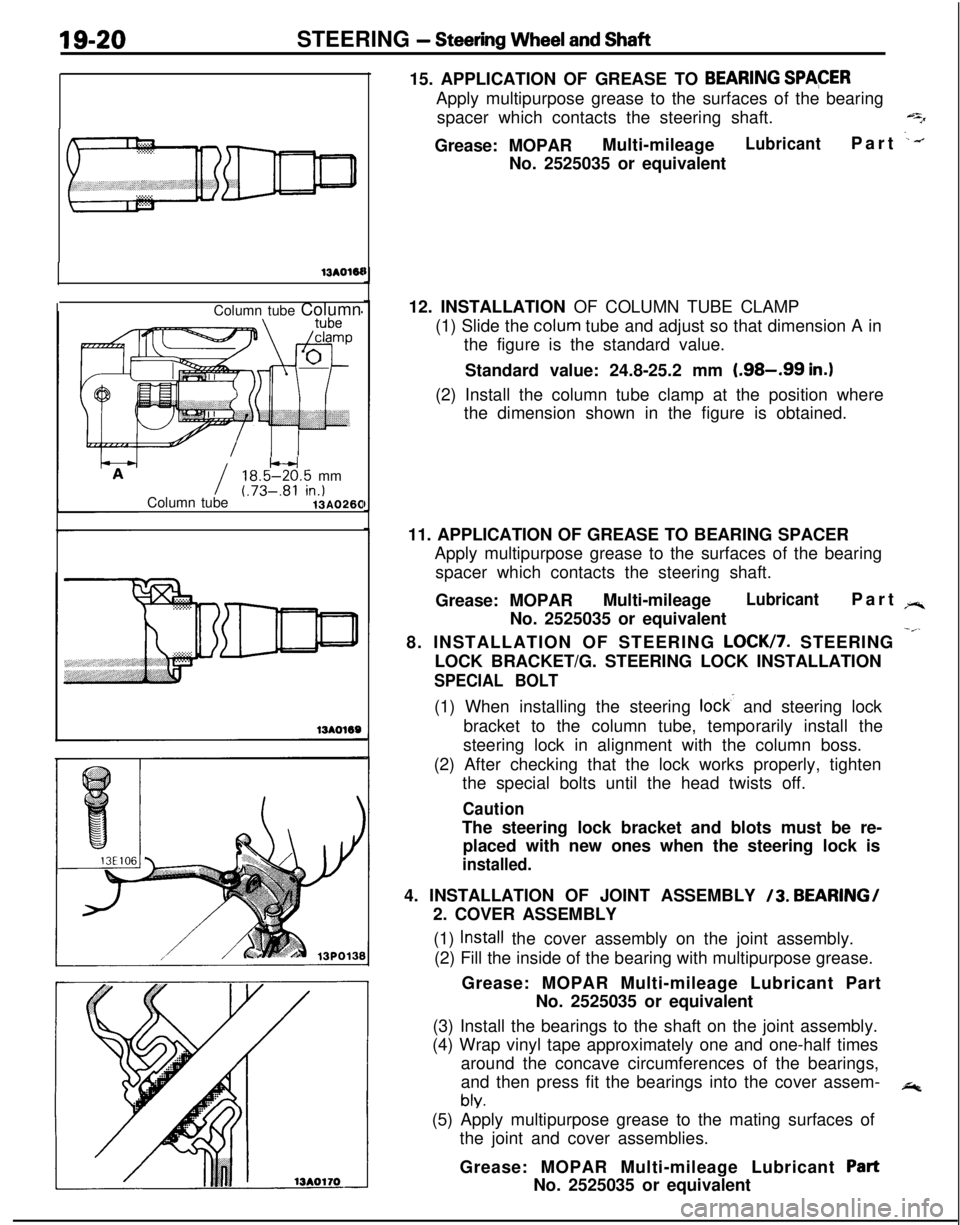

19-20STEERING - Steering Wheel and Shaft

13AOWColumn tube Column

I18.5W.5 mm

Column tube(.73-.81 in.)13AO26015. APPLICATION OF GREASE TO

BEARING SPACERApply multipurpose grease to the surfaces of the bearing

spacer which contacts the steering shaft.

qGrease: MOPARMulti-mileage

LubricantPart .--.No. 2525035 or equivalent

12. INSTALLATION OF COLUMN TUBE CLAMP

(1) Slide the colum tube and adjust so that dimension A in

the figure is the standard value.

Standard value: 24.8-25.2 mm

(.98-.99 in.)(2) Install the column tube clamp at the position where

the dimension shown in the figure is obtained.

11. APPLICATION OF GREASE TO BEARING SPACER

Apply multipurpose grease to the surfaces of the bearing

spacer which contacts the steering shaft.

Grease: MOPARMulti-mileage

LubricantPart rr.No. 2525035 or equivalent

8. INSTALLATION OF STEERING

LOCK/7. STEERING -”LOCK BRACKET/G. STEERING LOCK INSTALLATION

SPECIAL BOLT(1) When installing the steering

lock- and steering lock

bracket to the column tube, temporarily install the

steering lock in alignment with the column boss.

(2) After checking that the lock works properly, tighten

the special bolts until the head twists off.

CautionThe steering lock bracket and blots must be re-

placed with new ones when the steering lock is

installed.4. INSTALLATION OF JOINT ASSEMBLY

/3. BEARING/

2. COVER ASSEMBLY

(1)

Install the cover assembly on the joint assembly.

(2) Fill the inside of the bearing with multipurpose grease.

Grease: MOPAR Multi-mileage Lubricant Part

No. 2525035 or equivalent

(3) Install the bearings to the shaft on the joint assembly.

(4) Wrap vinyl tape approximately one and one-half times

around the concave circumferences of the bearings,

and then press fit the bearings into the cover assem-

*

bly.(5) Apply multipurpose grease to the mating surfaces of

the joint and cover assemblies.

Grease: MOPAR Multi-mileage Lubricant

PartNo. 2525035 or equivalent

Page 676 of 1216

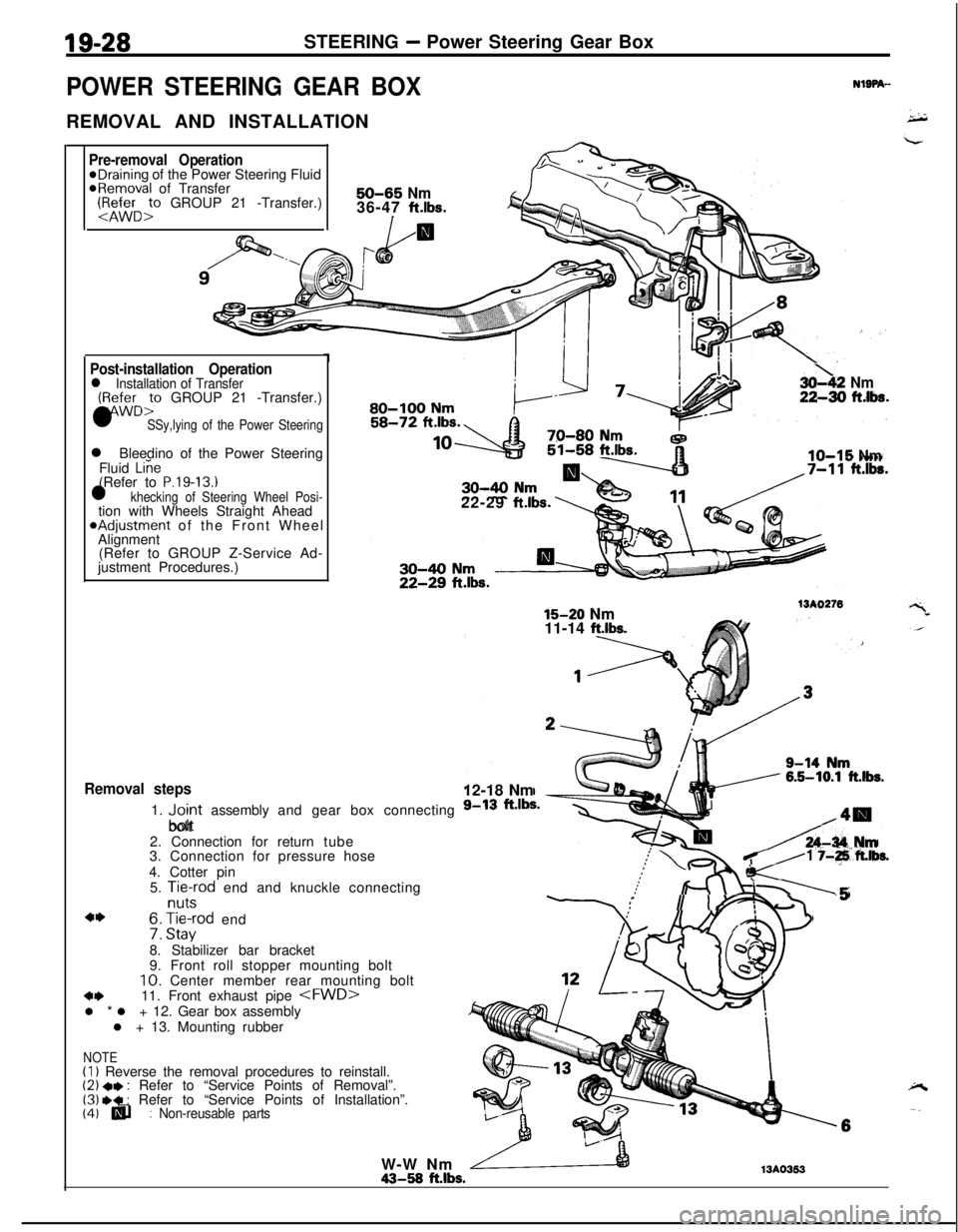

19-28STEERING - Power Steering Gear Box

POWER STEERING GEAR BOXREMOVAL AND INSTALLATION

-

NlSPA--

Pre-removal Operation@Draining of the Power Steering Fluid@Removal of Transfer:1&&r:, GROUP 21 -Transfer.)50-65 Nm36-47 ft.lbs.

I/a

Post-installation Operationl Installation of Transfer(:zD:” GROUP 21 -Transfer.)

l SSy,lying of the Power Steeringl Bleedino of the Power Steering

Fluid

Liie(Refer to P.19-13.1l khecking of Steering Wheel Posi-tion with Wheels Straight Ahead*Adjustment of the Front Wheel

Alignment

(Refer to GROUP Z-Service Ad-

justment Procedures.)

Removal steps1.

“,;;rt assembly and gear box connecting

bolt

2. Connection for return tube

3. Connection for pressure hose

4. Cotter pin

5.

Aft-cd end and knuckle connecting

4I)f3: H,“a:od end

8. Stabilizer bar bracket

9. Front roll stopper mounting bolt10. Center member rear mounting bolt

4411. Front exhaust pipe

l + 13. Mounting rubber

(I) Reverse the removal procedures to reinstall.(2) +e : Refer to “Service Points of Removal”.(3) .* : Refer to “Service Points of Installation”.(4) q : Non-reusable parts(4) lli

3oh2 Nm22-30 ftlba.^a-aa I.au-IUU NrnI

IO-15 Nm22-29

ft.lbs.

15-20 Nm15-20 Nm

11-14 ft.lbs.

13A027612-18 Nm

A-34 IUm

K-

1 j-+ft.lbs.

:II I-.5

/ .2!

i!!1

NOTEW-W Nm43-58

ft.lbs.13A0353

Page 1041 of 1216

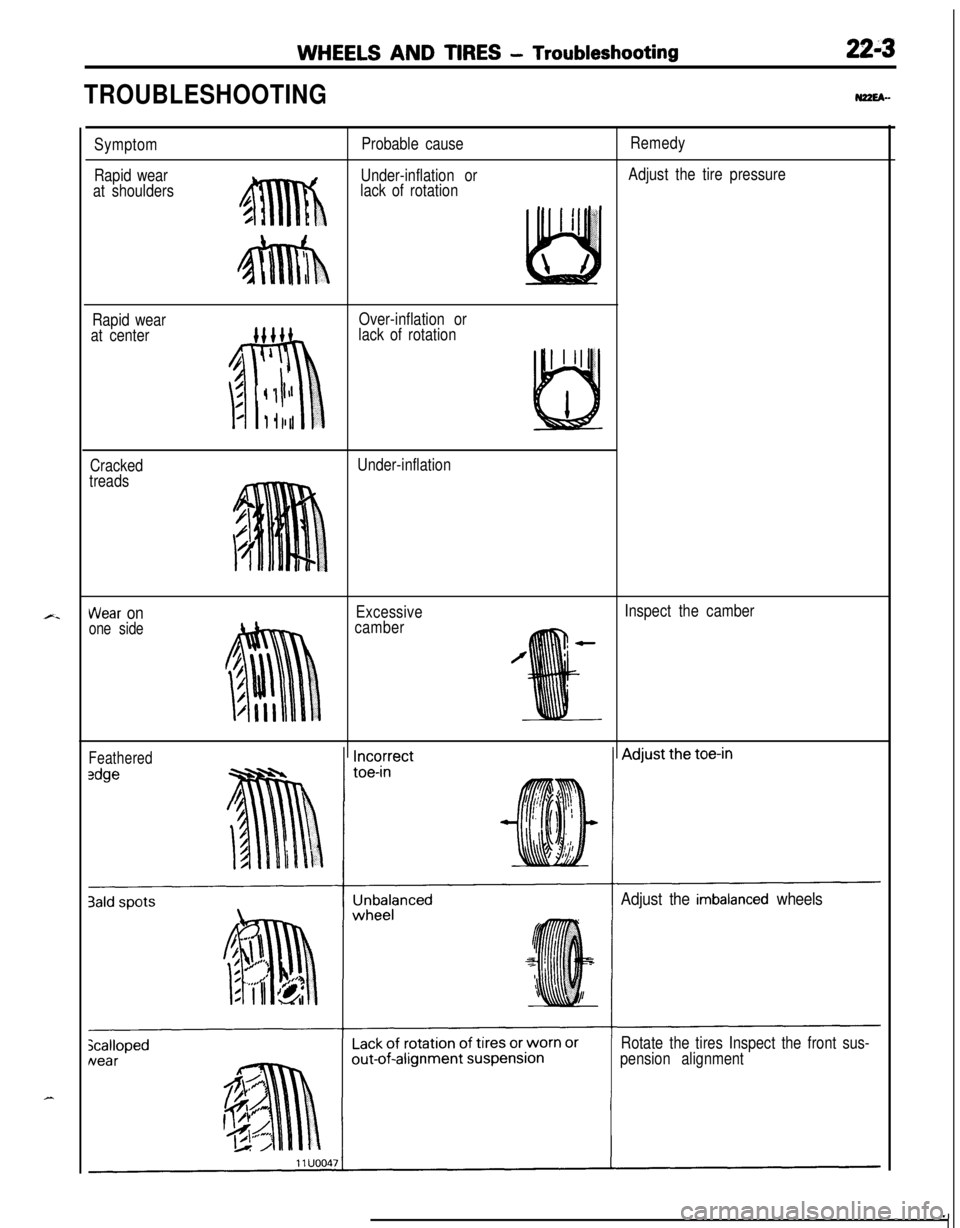

WHEELS AND TIRES - Troubleshooting22-3

TROUBLESHOOTINGN22EA-

Symptom

Rapid wear

at shouldersProbable cause

Under-inflation or

lack of rotationRemedy

Adjust the tire pressure

Rapid wear

at centerOver-inflation or

lack of rotation

Cracked

treadsUnder-inflation

Wear onone side

Excessive

camberInspect the camber

Feathered

Adjust the imbalanced wheels

Rotate the tires Inspect the front sus-

pension alignment