wiring MITSUBISHI LANCER 2006 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 21 of 800

TROUBLESHOOTING

ENGINE COOLING14-7

•The engine-ECU

controls the cooling fan motor drive control

unit to activate the cooling fan motor (L.H.) and

the cooling fan motor (R.H.) <4G1 (Vehicles with

A/C)> or A/C condenser fan motor <4G6>.

TECHNICAL DESCRIPTION

•The cause could be a malfunction of the cooling

fan motor drive control unit power supply or earth

circuit.

•If the communication line wiring harness between

the cooling fan motor drive control unit and the

engine-ECU

short-circuited to earth, the cooling fan motor

(L.H.) and the cooling fan motor (R.H.) <4G1

(Vehicles with A/C)> or the A/C condenser fan

motor <4G6> will not rotate.

•The cause could also be a malfunction of the

cooling fan motor (L.H.).

•The cause could also be a malfunction of imput

signal from the A/C switch, the water temperature

sensor unit and the vehicle speed sensor

or the output shaft speed sensor to the

engine-ECU

•The cause could also be a malfunction of the

cooling fan motor drive control unit or the

engine-ECU

TROUBLESHOOTING HINTS

•Malfunction of fusible link (2)

•Malfunction of fan control relay

•Malfunction of cooling fan motor (L.H.)

•Malfunction of cooling fan motor drive control unit

•Malfunction of engine-ECU

engine-A/T-ECU

•Damaged wiring harness or connector

DIAGNOSIS

STEP 1. Check the cooling fan motor (L.H.).

Refer to P.14-24.

Q: Is the cooling fan motor (L.H.) in good condition?

YES : Go to Step 2 .

NO : Replace the cooling fan motor (L.H.) (Refer

to

P.14-33) <4G1> (Refer to P.14-35)

<4G6>. Then go to Step 24 .

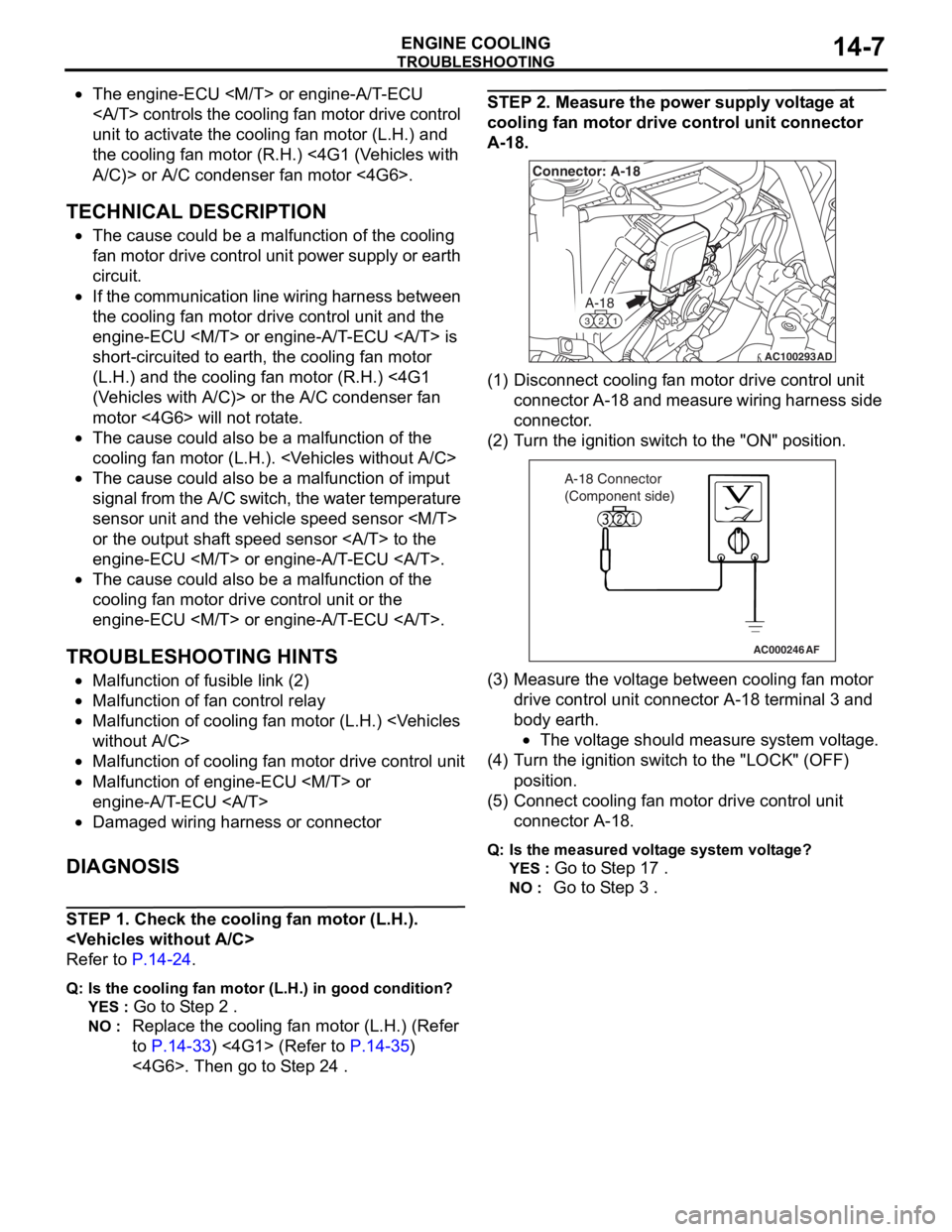

STEP 2. Measure the power supply voltage at

cooling fan motor drive control unit connector

A-18.

AC100293

A-18

321

Connector: A-18

AD

(1)D isconn ect cooling f an motor drive contro l unit

conne ctor A-18 a nd measure wirin g har ness side

connector .

(2)T urn t he ig nition switch t o the "ON" positio n.

AC000246AF

A-18 Connector

(Component side)

(3)M easu r e the volt age between cooling fan motor

drive control unit con nect o r A-18 te rmin al 3 a nd

bod y ea rth.

•The voltage shou ld measu r e syste m volt age.

(4)T urn t he ig nition switch t o the "L OCK" (OF F )

position.

(5)C onne ct cooling fa n mot o r drive control unit

connector A-18.

Q:Is t h e mea s ure d volt a g e sy ste m v o lt ag e?

YES : Go to S t ep 1 7 .

NO : Go to S t ep 3 .

Page 26 of 800

TROUBLESHOOTING

ENGINE COOLING14-12

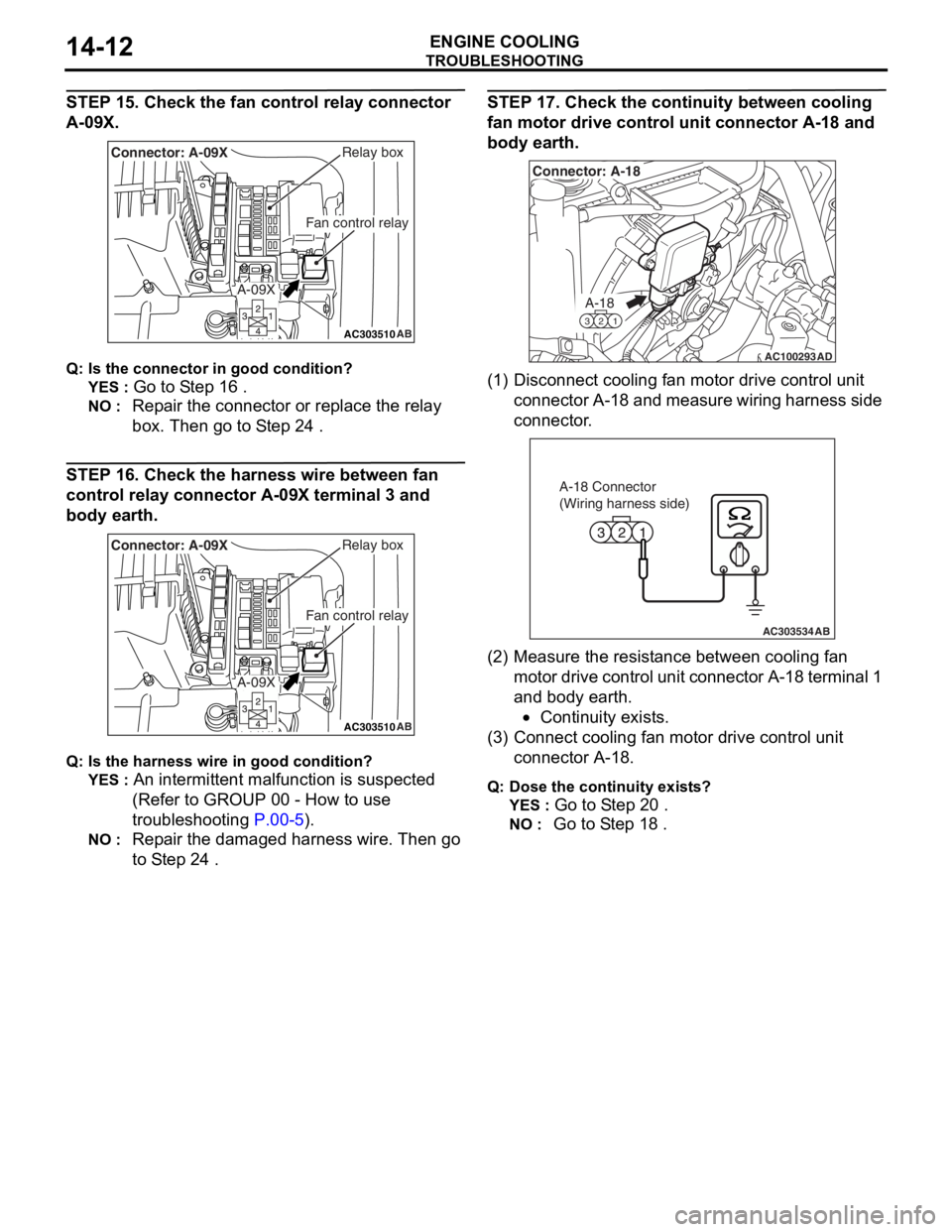

STEP 15. Check the fan control relay connector

A-09X.

AC303510AB

Fan control relay

Relay boxConnector: A-09X

A-09X

Q:Is t h e con n ec tor in goo d c ondit i o n ?

YES : Go to S t ep 16 .

NO : Repa ir the con nect o r or rep l ace the re lay

box. Then

go to S t ep 24

.

STEP 16 . Check th e harness wire b e twee n fan

control relay

connect or A-09 X terminal 3 and

body ea

rth.

AC303510AB

Fan control relay

Relay boxConnector: A-09X

A-09X

Q:Is t h e har n es s wire in good c ondition ?

YES : An intermittent malf unction is suspe c ted

(Refer to GROUP 00 - How to use

troub lesh ooting

P.00-5).

NO : Repa ir the dama ged harness wire. Then go

to S

t ep 2 4

.

STEP 1 7 . Check t he contin uity between cooling

fan motor drive

control un it connec tor A-1 8 and

body ea

rth.

AC100293

A-18

321

Connector: A-18

AD

(1)D isconn ect cooling f an motor drive contro l unit

conne ctor A-18 a nd measure wirin g har ness side

connector .

AC303534AB

A-18 Connector

(Wiring harness side)

(2)M easu r e the re sist ance between cooling fan

mot o r d r ive cont rol unit conn ecto r A-1 8 te rmina l 1

and body earth .

•Continu i ty exist s .

(3)C onne ct cooling fa n mot o r drive control unit

connector A-18.

Q:Dos e the cont inuity e x ist s ?

YES : Go to S t ep 2 0 .

NO : Go to S t ep 18 .

Page 30 of 800

TROUBLESHOOTING

ENGINE COOLING14-16

INSPECTION PROCEDURE 2: Cooling Fan (L.H.) and Cooling Fan (R.H.) <4G1 (Vehicles with A/C)> or

A/C Condenser Fan <4G6> do not Change Speed or Stop

COOLING FAN (L.H.) AND COOLING FAN

(R.H.) OR A/C CONDENSER FAN DRIVE

CIRCUIT

Refer to P.14-6.

CIRCUIT OPERATION

Refer to P.14-6.

TECHNICAL DESCRIPTION

•If the communication line wiring harness between

the cooling fan motor drive control unit and the

engine-ECU

is open, the cooling fan motor (L.H.) and

the cooling fan motor (R.H.) <4G1 (Vehicles with

A/C)>, or the A/C condenser fan motor <4G6>

rotate to prevent the engine from overheating.

•If the system voltage is continuously supplied to

the cooling fan motor drive control unit by a fan

motor relay malfunction and a short circuit on the

cooling fan motor drive control unit power supply

wiring harness, the cooling fan motor (L.H.) and

the cooling fan motor (R.H.) <4G1 (Vehicles with

A/C)>, or the A/C condenser fan motor <4G6>

rotate.

•The cause could also be a malfunction of the

cooling fan motor (L.H.).

•The cause could also be a malfunction of input

signal from the A/C switch, the water temperature

sensor unit and the vehicle speed sensor

or the output shaft speed sensor to the

engine-ECU

•The cause could also be a malfunction of the

cooling fan motor drive control unit or the

engine-ECU

TROUBLESHOOTING HINTS

•Malfunction of fan control relay

•Malfunction of cooling fan motor (L.H.)

•Malfunction of cooling fan motor drive control unit

•Malfunction of engine-ECU

engine-A/T-ECU

•Damaged wiring harness or connector

DIAGNOSIS

STEP 1. Check the fan control relay.

Refer to P.14-23.

Q: Is the fan control relay in good condition?

YES : Go to Step 2 .

NO : Replace the fan control relay. Then go to

Step 8

.

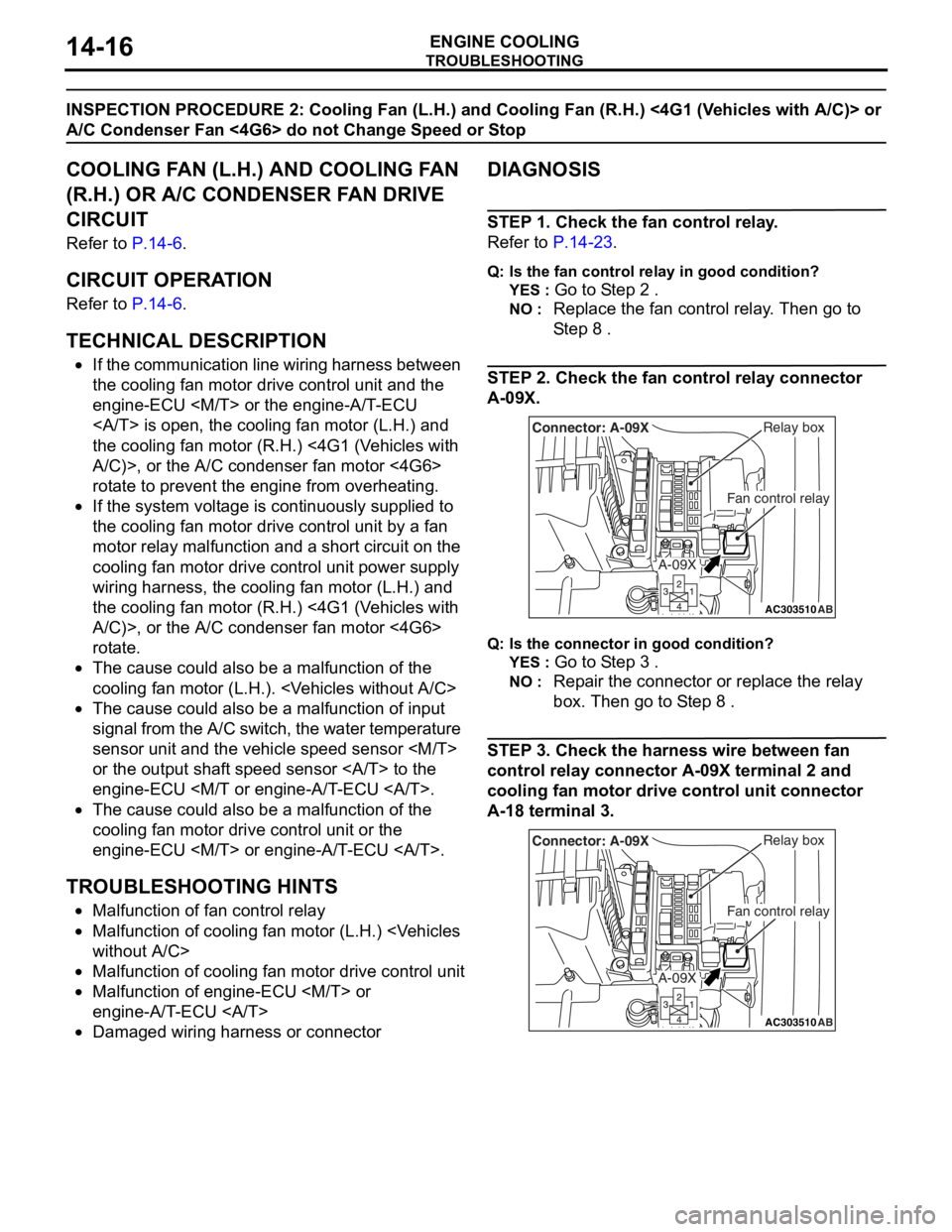

STEP 2. Check the fan control relay connector

A-09X.

AC303510AB

Fan control relay

Relay boxConnector: A-09X

A-09X

Q:Is t h e con n ec tor in goo d c ond it io n?

YES : Go to S t ep 3 .

NO : Repa ir th e con nect o r or rep l ace the re lay

box. Then

go to S t ep 8

.

STEP 3 . Check the harness wire be twee n fan

control relay

connec tor A-0 9 X terminal 2 and

cooling f

an motor drive control uni t connec tor

A-1

8 terminal 3.

AC303510AB

Fan control relay

Relay boxConnector: A-09X

A-09X

Page 39 of 800

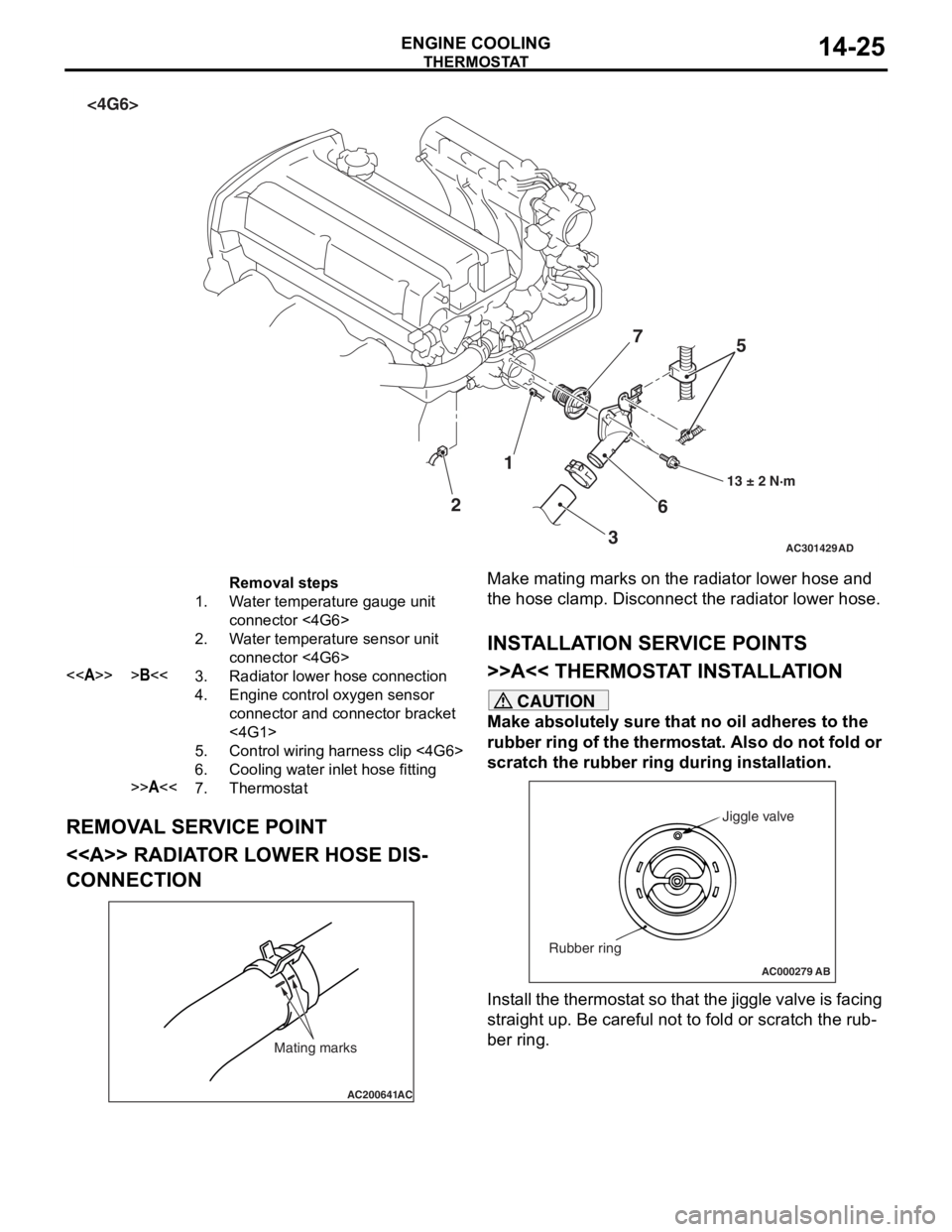

AC301429

1

2 36

7

13 ± 2 N·m

AD

5

<4G6>

Removal steps

1.Water temperature gauge unit

connector <4G6>

2.Water temperature sensor unit

connector <4G6>

<>>B<<3.Radiator lower hose connection

4.Engine control oxygen sensor

connector and connector bracket

<4G1>

5.Control wiring harness clip <4G6>

6.Cooling water inlet hose fitting

>>A<<7.Thermostat

THERMOST

A T

ENGINE COOLING14-25

REMOV A L SER V ICE POINT

<> RADIAT OR LOW E R HOSE DIS-

CONNECTION

AC200641AC

Mating marks

Make mating marks on the rad i ator lower ho se an d

the hose clamp. Disconn

ect t he radiator lower hose.

INSTALLA T ION SER VICE POINTS

>>A<< THERMOSTA T INST ALLA TION

CAUTION

Make absolutely sure that no oil adheres to the

rubber ring of the thermostat. Also do not fold or

scratch the rubber ring during installation.

AC000279

Jiggle valve

Rubber ring

AB

Install the thermostat so that the jiggle valve is facing

straight up. Be careful not to fold or scratch the rub

-

ber ring.

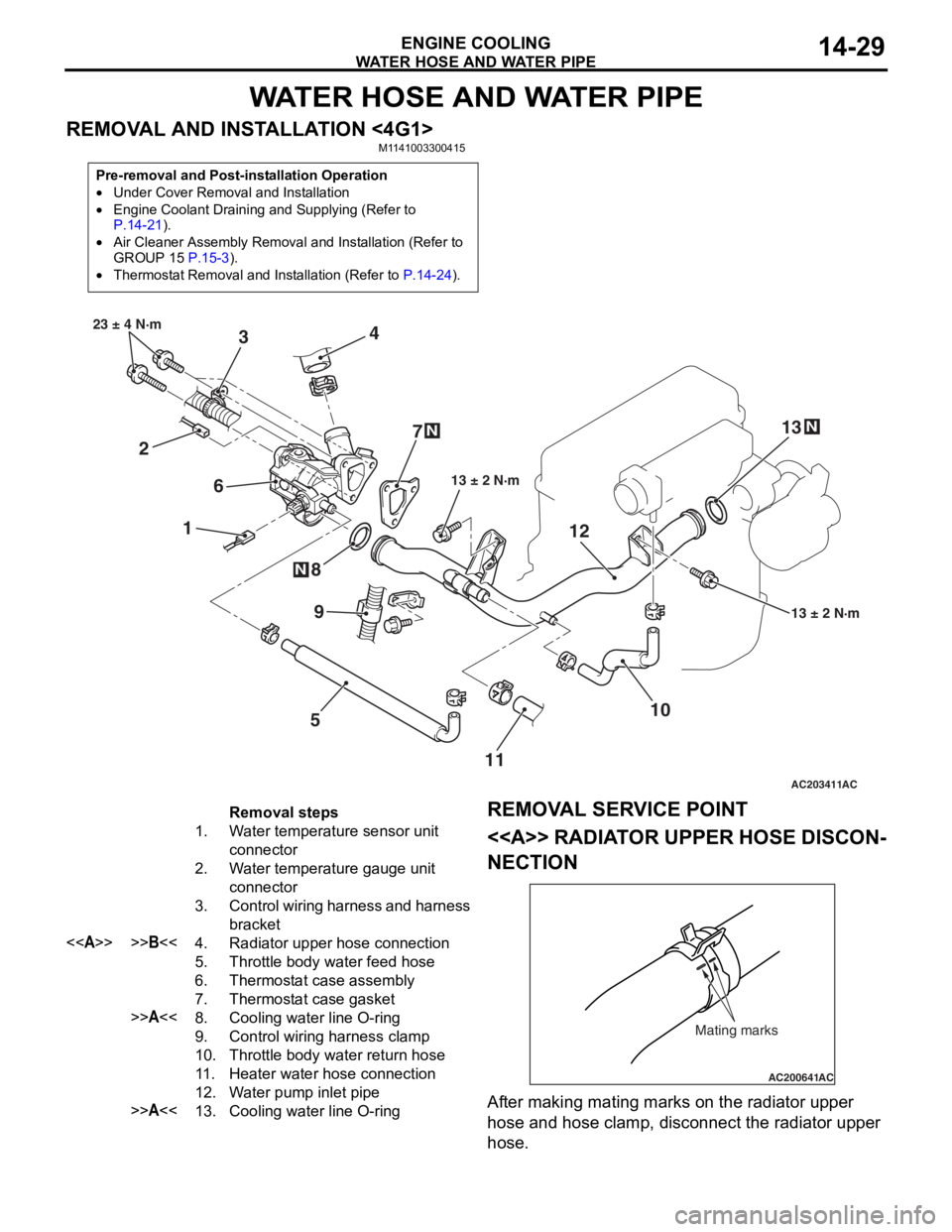

Page 43 of 800

WATER HOSE AND WATER PIPE

ENGINE COOLING14-29

WATER HOSE AND WATER PIPE

REMOVAL AND INSTALLATION <4G1>M1141003300415

Pre-removal and Post-installation Operation

•Under Cover Removal and Installation

•Engine Coolant Draining and Supplying (Refer to P.14-21).

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15 P.15-3).

•Thermostat Removal and Installation (Refer to P.14-24).

AC203411

1

2 3

4

5

6

7

8

10

9

13 ± 2 N·m

23 ± 4 N·m

13 ± 2 N·m

N

N

AC

1112

13

N

Removal steps

1.Water temperature sensor unit

connector

2.Water temperature gauge unit

connector

3.Control wiring harness and harness

bracket

<>>>B<<4.Radiator upper hose connection

5.Throttle body water feed hose

6.Thermostat case assembly

7.Thermostat case gasket

>>A<<8.Cooling water line O-ring

9.Control wiring harness clamp

10.Throttle body water return hose

11 .Heater water hose connection

12.Water pump inlet pipe

>>A<<13.Cooling water line O-ring

REMOV

A L SER VICE POINT

<> RADIAT OR UPPER HOSE DISCON-

NECTION

AC200641AC

Mating marks

After making matin g ma rks on the radia t or upp er

hose

and h o se clamp, disconnect the radia t or upp er

hose

.

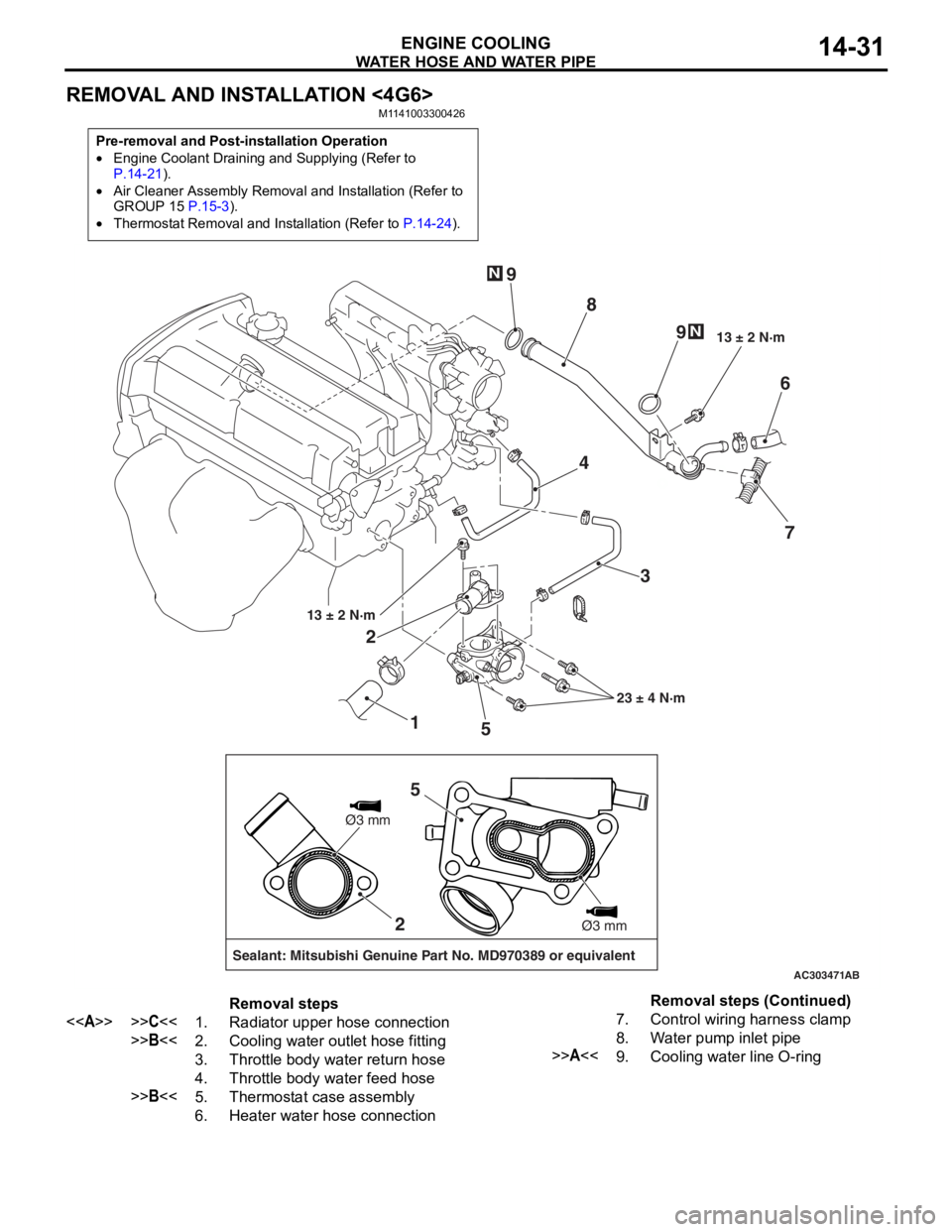

Page 45 of 800

WATER HOSE AND WATER PIPE

ENGINE COOLING14-31

REMOVAL AND INSTALLATION <4G6>

M1141003300426

Pre-removal and Post-installation Operation

•Engine Coolant Draining and Supplying (Refer to P.14-21).

•Air Cleaner Assembly Removal and Installation (Refer to

GROUP 15 P.15-3).

•Thermostat Removal and Installation (Refer to P.14-24).

AC303471

1

2

3

4

5 6

7

8

9

9

13 ± 2 N·m

23 ± 4 N·m

13 ± 2 N·m

N

N

AB

2

Sealant: Mitsubishi Genuine Part No. MD970389 or equivalent

Ø3 mm

Ø3 mm

5

Removal steps

<>>>C<<1.Radiator upper hose connection

>>B<<2.Cooling water outlet hose fitting

3.Throttle body water return hose

4.Throttle body water feed hose

>>B<<5.Thermostat case assembly

6.Heater water hose connection

7.Control wiring harness clamp

8.Water pump inlet pipe

>>A<<9.Cooling water line O-ring

Removal steps (Continued)

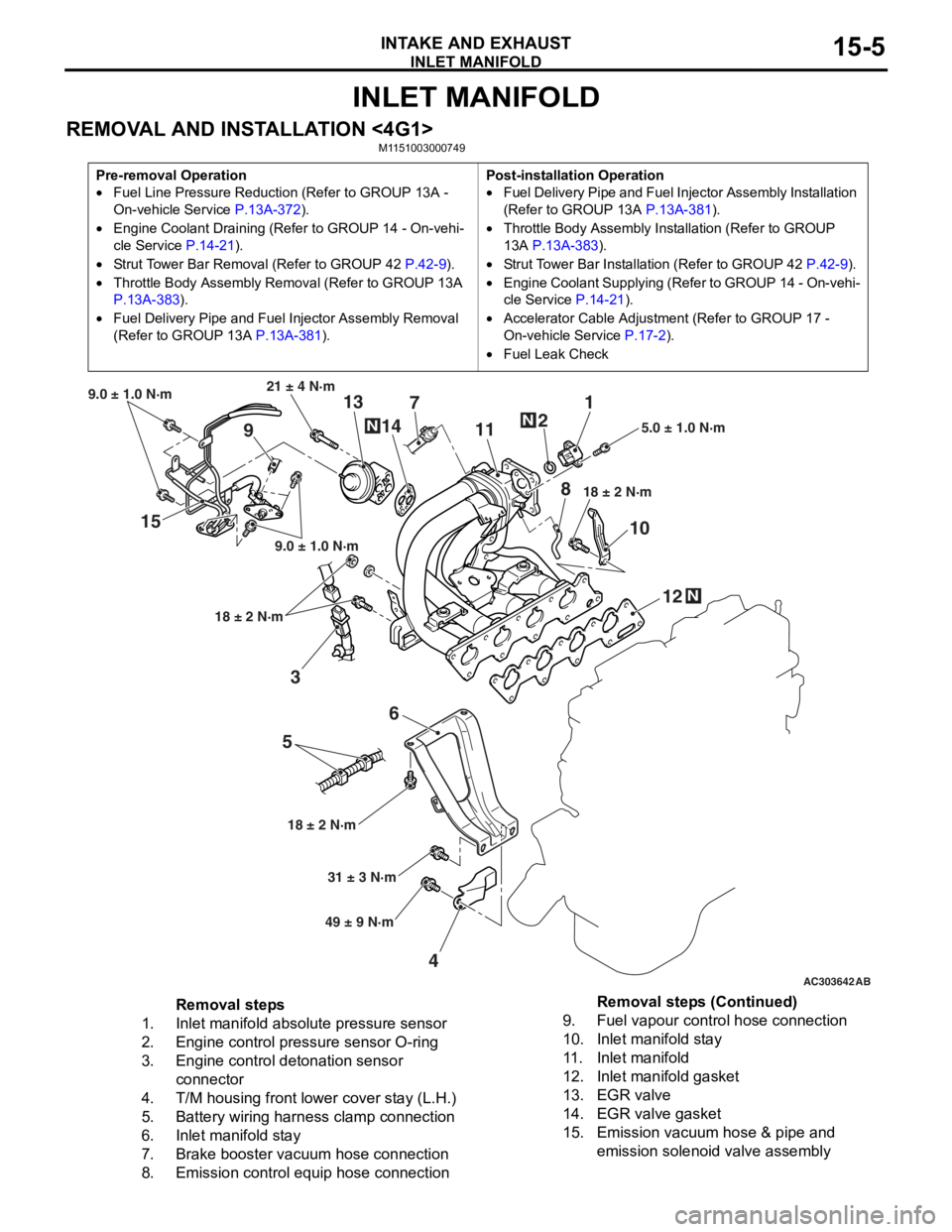

Page 55 of 800

INLET MANIFOLD

INTAKE AND EXHAUST15-5

INLET MANIFOLD

REMOVAL AND INSTALLATION <4G1>M1151003000749

Pre-removal Operation

•Fuel Line Pressure Reduction (Refer to GROUP 13A -

On-vehicle Service

P.13A-372).

•Engine Coolant Draining (Refer to GROUP 14 - On-vehi-

cle Service P.14-21).

•Strut Tower Bar Removal (Refer to GROUP 42 P.42-9).

•Throttle Body Assembly Re moval (Refer to GROUP 13A

P.13A-383).

•Fuel Delivery Pipe and Fuel Injector Assembly Removal

(Refer to GROUP 13A

P.13A-381).

Post-installation Operation

•Fuel Delivery Pipe and Fuel Injector Assembly Installation

(Refer to GROUP 13A

P.13A-381).

•Throttle Body Assembly Inst allation (Refer to GROUP

13A

P.13A-383).

•Strut Tower Bar Installati on (Refer to GROUP 42 P.42-9).

•Engine Coolant Supplying (Refer to GROUP 14 - On-vehi-

cle Service P.14-21).

•Accelerator Cable Adjustment (Refer to GROUP 17 -

On-vehicle Service

P.17-2).

•Fuel Leak Check

AC303642AB

15

36

5

4 12

10

7

1

2

11

9 13

14

21 ± 4 N·m

9.0 ± 1.0 N·m

9.0 ± 1.0 N·m

18 ± 2 N·m

18 ± 2 N·m 18 ± 2 N·m

5.0 ± 1.0 N·m

31 ± 3 N·m

49 ± 9 N·m

N

N

N

8

Removal steps

1.Inlet manifold absolute pressure sensor

2.Engine control pressure sensor O-ring

3.Engine control detonation sensor

connector

4.T/M housing front lower cover stay (L.H.)

5.Battery wiring harness clamp connection

6.Inlet manifold stay

7.Brake booster vacuum hose connection

8.Emission control equip hose connection

9.Fuel vapour control hose connection

10.Inlet manifold stay

11 .Inlet manifold

12.Inlet manifold gasket

13.EGR valve

14.EGR valve gasket

15.Emission vacuum hose & pipe and

emission solenoid valve assembly

Removal steps (Continued)

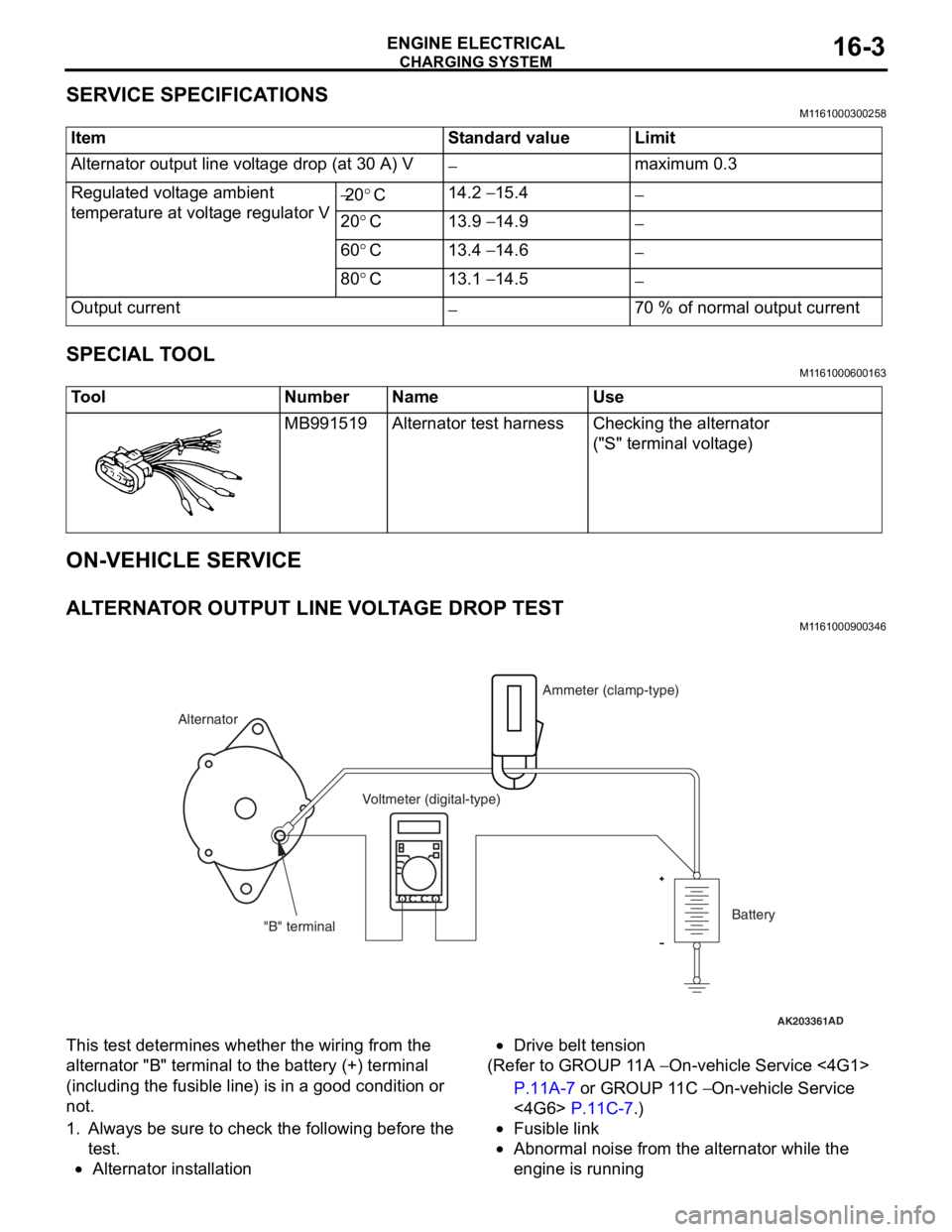

Page 65 of 800

CHARGING SYSTEM

ENGINE ELECTRICAL16-3

SERVICE SPECIFICATIONS

M1161000300258

ItemStandard valueLimit

Alternator output line voltage drop (at 30 A) V−maximum 0.3

Regulated voltage ambient

temperature at voltage regulator V−20°C14.2 − 15.4−

20°C13.9 − 14.9−

60°C13.4 − 14.6−

80°C13.1 − 14.5−

Output current−70 % of normal output current

SPECIAL TOOLM1161000600163

ToolNumberNameUse

MB991519Alterna t or test harn e ssChec king th e alt e rnator

("S" te rminal volt age )

ON-VEHICLE SERV ICE

ALTERNA T O R OUTPUT LINE VOL T AGE DROP TEST

M1161 0009 0034 6

AK203361AD

Alternator Ammeter (clamp-type)

Voltmeter (digital-type)

"B" terminal Battery

This test

determine s whethe r the wiring fro m th e

altern

ator "B" termina l to t he batt e ry (+) terminal

(including the

fusible line ) is in a good condition or

not.

1.Always b e su re to check the following b e fore th e

te st.

•Alternator inst allatio n

•Drive belt tension

(Ref er to GROUP 1 1 A − On-veh icle Service <4G1>

P.11A-7 or GROUP 1 1 C − On-vehicle Service

<4G6> P.11C-7.)

•Fusible link

•Abnormal noise from the altern ator while the

eng

ine is ru nning

Page 66 of 800

CHARGING SYSTEM

ENGINE ELECTRICAL16-4

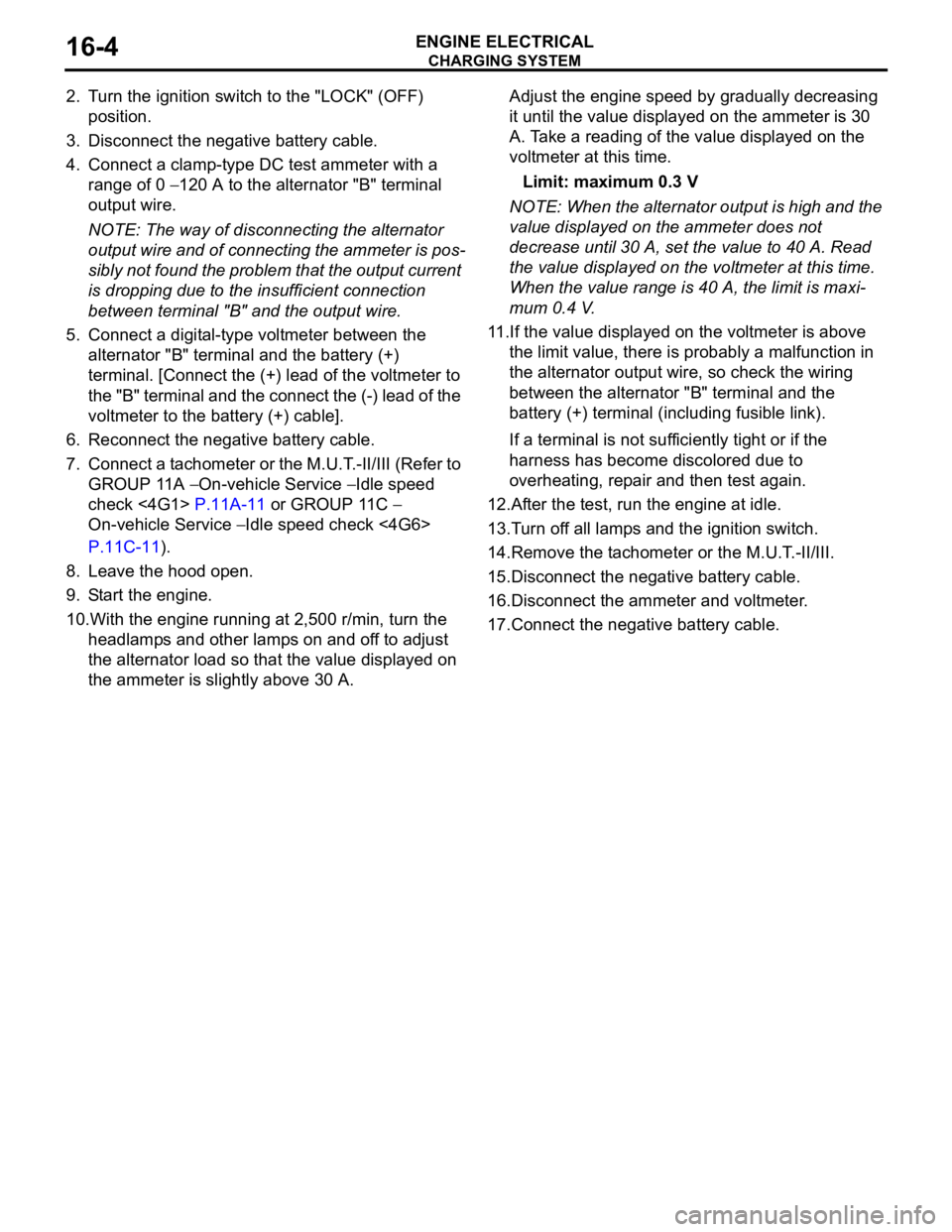

2. Turn the ignition switch to the "LOCK" (OFF)

position.

3. Disconnect the negative battery cable.

4. Connect a clamp-type DC test ammeter with a

range of 0

− 120 A to the alternator "B" terminal

output wire.

NOTE: The way of disconnecting the alternator

output wire and of connecting the ammeter is pos

-

sibly not found the problem that the output current

is dropping due to the insufficient connection

between terminal "B" and the output wire.

5. Connect a digital-type voltmeter between the

alternator "B" terminal and the battery (+)

terminal. [Connect the (+) lead of the voltmeter to

the "B" terminal and the connect the (-) lead of the

voltmeter to the battery (+) cable].

6. Reconnect the negative battery cable.

7. Connect a tachometer or the M.U.T.-II/III (Refer to

GROUP 11A

− On-vehicle Service − Idle speed

check <4G1>

P.11A-11 or GROUP 11C −

On-vehicle Service − Idle speed check <4G6>

P.11C-11).

8. Leave the hood open.

9. Start the engine.

10.With the engine running at 2,500 r/min, turn the

headlamps and other lamps on and off to adjust

the alternator load so that the value displayed on

the ammeter is slightly above 30 A.

Adjust the engine speed by gradually decreasing

it until the value displayed on the ammeter is 30

A. Take a reading of the value displayed on the

voltmeter at this time.

Limit: maximum 0.3 V

NOTE: When the alternator output is high and the

value displayed on the ammeter does not

decrease until 30 A, set the value to 40 A. Read

the value displayed on the voltmeter at this time.

When the value range is 40 A, the limit is maxi

-

mum 0.4 V.

11.If the value displayed on the voltmeter is above

the limit value, there is probably a malfunction in

the alternator output wire, so check the wiring

between the alternator "B" terminal and the

battery (+) terminal (including fusible link).

If a terminal is not sufficiently tight or if the

harness has become discolored due to

overheating, repair and then test again.

12.After the test, run the engine at idle.

13.Turn off all lamps and the ignition switch.

14.Remove the tachometer or the M.U.T.-II/III.

15.Disconnect the negative battery cable.

16.Disconnect the ammeter and voltmeter.

17.Connect the negative battery cable.

Page 76 of 800

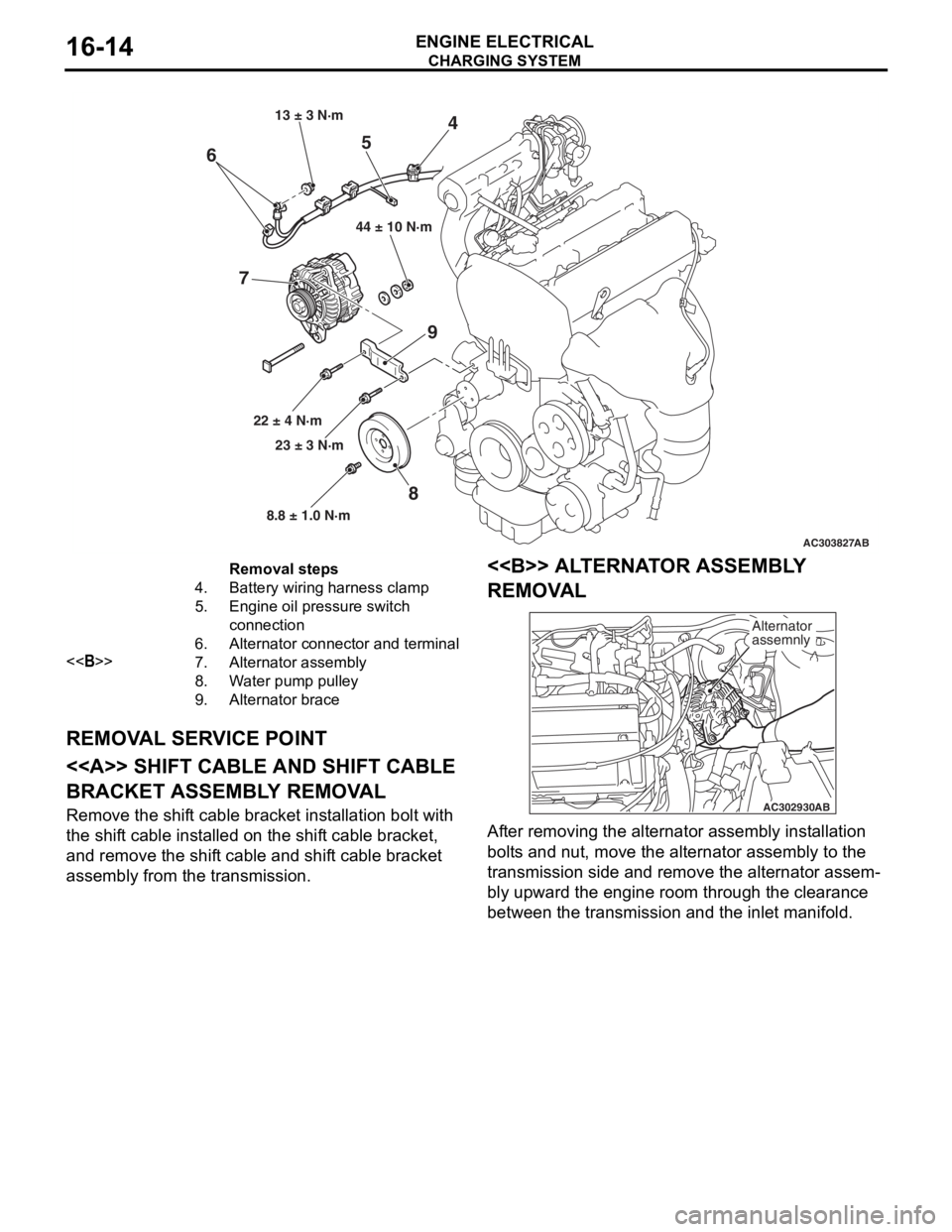

AC303827

65

84

9

7

22 ± 4 N·m

23 ± 3 N·m

8.8 ± 1.0 N·m 44 ± 10 N·m

AB

13 ± 3 N·m

Removal steps

4.Battery wiring harness clamp

5.Engine oil pressure switch

connection

6.Alternator connector and terminal

<>7.Alternator assembly

8.Water pump pulley

9.Alternator brace

CHARGING SYSTEM

ENGINE ELECTRICAL16-14

REMOV

A L SER V ICE POINT

<> SHIFT CABLE AND SHIFT CABLE

BRACKET ASSEMBL

Y REMOV A L

Remove the shift cable bracket inst allation bolt with

the shif

t ca ble inst alled o n the shif t cable bracket,

and remove

the shif t cable and shif t cable bracket

assembly fro

m the transmission.

<> ALTERNA T O R ASSEMBL Y

REMOV

A L

AC302930 AB

Alternator

assemnly

Af

ter re moving the alternato r assembly inst allation

bolt

s a nd nu t, move the alte rnator a sse mbly to the

transmission side an

d remove the alternato r assem

-

bly upward the engine roo m thr ough th e clearan ce

between t

he tran smission and the inlet ma nifold.