display MITSUBISHI MONTERO 2000 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 271 of 1839

GDI -Troubleshooting

OK

Check the harness wire between the

crankanglesensor and the

engine-ECU, and repair if necessary.

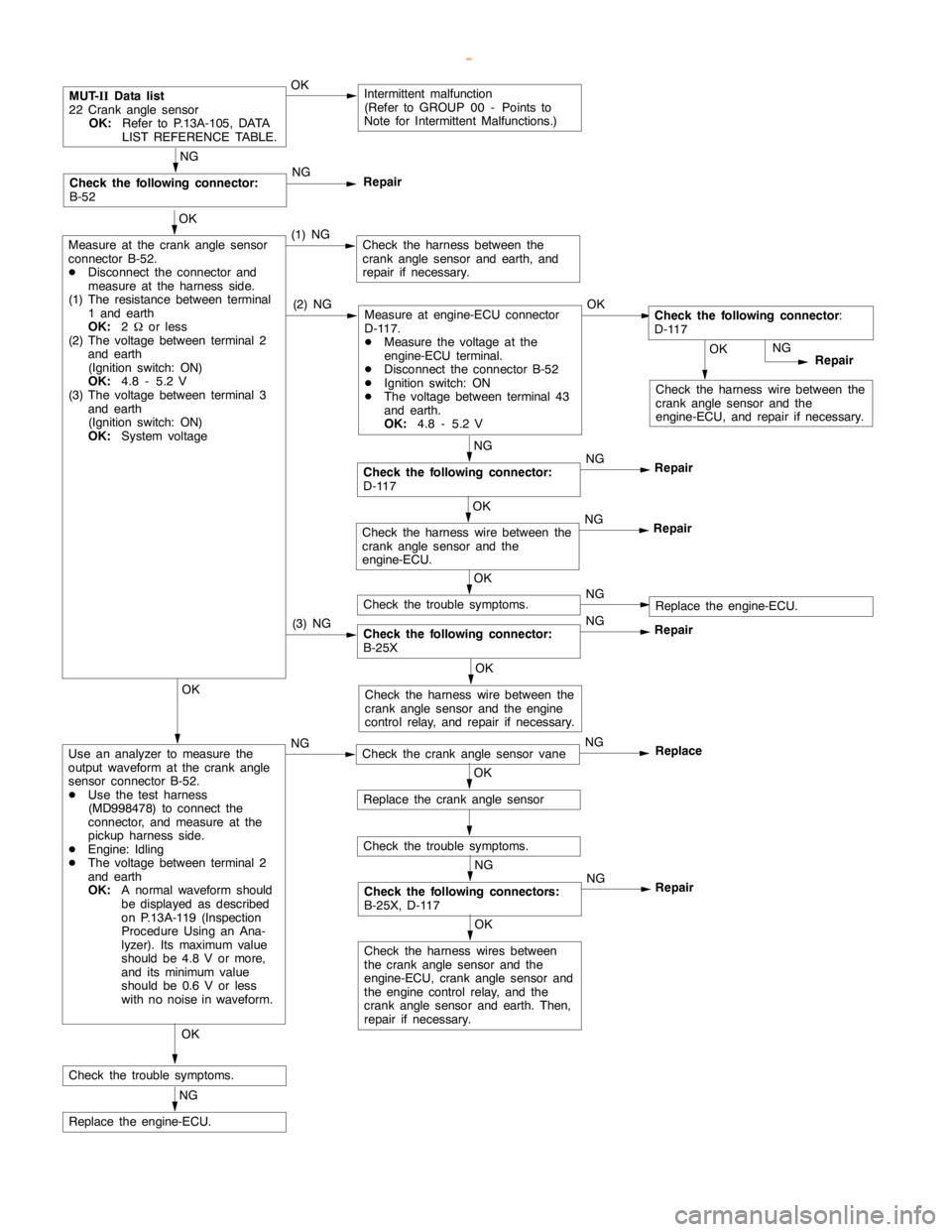

MUT-

IIData list

22 Crankanglesensor

OK:

Refer to P.13A-105, DATA

LIST REFERENCE TABLE.OKIntermittent malfunction

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)

OK

Measure at the crankanglesensor

connector B-52.

DDisconnect the connector and

measure at the harness side.

(1) The resistance between terminal

1 and earth

OK:

2Wor less

(2) The voltage between terminal 2

and earth

(Ignition switch: ON)

OK:

4.8 - 5.2 V

(3) The voltage between terminal 3

and earth

(Ignition switch: ON)

OK:

System voltage(1) NGCheck the harness between the

crankanglesensor and earth, and

repair if necessary.

NG

Repair

NG

Check the following connector:

D-117NG

Repair

NG

Check the following connector:

B-52NG

Repair

(2) NGMeasure at engine-ECU connector

D-117.

DMeasure the voltage at the

engine-ECU terminal.

DDisconnect the connector B-52

DIgnition switch: ON

DThe voltage between terminal 43

and earth.

OK:

4.8 - 5.2 VOKCheck the following connector

:

D-117

Check the following connector:

B-25XNG

Repair

OK

Check the harness wire between the

crankanglesensor and the

engine-ECU.NG

Repair

OK

Check the trouble symptoms.NGReplace the engine-ECU.

(3) NG

OK

Check the harness wire between the

crankanglesensor and theengine

control relay, and repair if necessary.OK

Use an analyzer to measure the

output waveform at the crankangle

sensor connector B-52.

DUse the test harness

(MD998478) to connect the

connector, and measure at the

pickup harness side.

DEngine: Idling

DThe voltage between terminal 2

and earth

OK:

A normal waveform should

be displayed as described

on P.13A-119 (Inspection

Procedure Using an Ana-

lyzer). Its maximum value

should be 4.8 V or more,

and its minimumvalue

should be 0.6 V or less

with no noise in waveform.NGCheck the crankanglesensor vaneNG

Replace

OK

Replace the crankanglesensor

Check the trouble symptoms.

NG

Check the following connectors:

B-25X, D-117NG

Repair

OK

Check the harness wires between

the crankanglesensor and the

engine-ECU, crankanglesensor and

the engine controlrelay, and the

crankanglesensor and earth. Then,

repair if necessary.

OK

Check the trouble symptoms.

NG

Replace the engine-ECU.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 273 of 1839

GDI -Troubleshooting

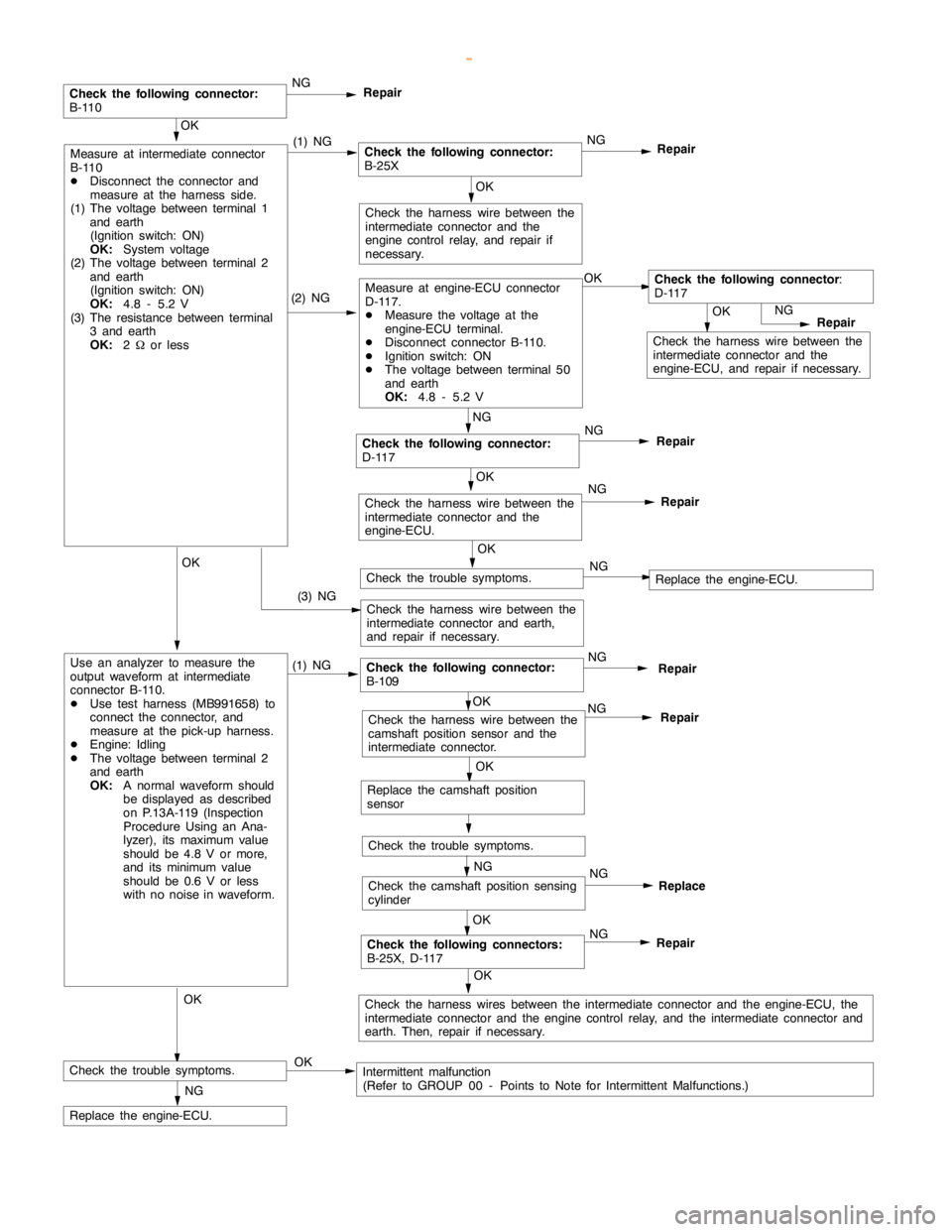

OK

Check the harness wire between the

intermediate connector and the

engine-ECU, and repair if necessary.NG

Repair

NG

NG

Repair

NG

Repair

(2) NGMeasure at engine-ECU connector

D-117.

DMeasure the voltage at the

engine-ECU terminal.

DDisconnect connector B-110.

DIgnition switch: ON

DThe voltage between terminal 50

and earth

OK:

4.8 - 5.2 VOKCheck the following connector

:

D-117

Check the harness wire between the

intermediate connector and earth,

and repair if necessary.

OK

Check the harness wire between the

intermediate connector and the

engine controlrelay, and repair if

necessary.

(3) NG

OK

Measure at intermediate connector

B-110

DDisconnect the connector and

measure at the harness side.

(1) The voltage between terminal 1

and earth

(Ignition switch: ON)

OK:

System voltage

(2) The voltage between terminal 2

and earth

(Ignition switch: ON)

OK:

4.8 - 5.2 V

(3) The resistance between terminal

3 and earth

OK:

2Wor less(1) NGCheck the following connector:

B-25XNG

Repair

OK

Replace the camshaft position

sensor

Check the trouble symptoms.

OK

NG

Repair

OK

Check the harness wires between the intermediate connector and the engine-ECU, the

intermediate connector and theengine controlrelay, and the intermediate connector and

earth. Then, repair if necessary.

NG

Replace the engine-ECU.

OK

Check the harness wire between the

intermediate connector and the

engine-ECU.NG

Repair

OK

Use an analyzer to measure the

output waveform at intermediate

connector B-110.

DUse test harness (MB991658) to

connect the connector, and

measure at the pick-up harness.

DEngine: Idling

DThe voltage between terminal 2

and earth

OK:

A normal waveform should

be displayed as described

on P.13A-119 (Inspection

Procedure Using an Ana-

lyzer), its maximum value

should be 4.8 V or more,

and its minimumvalue

should be 0.6 V or less

with no noise in waveform.(1) NGCheck the following connector:

B-109NG

Repair

OK

Check the harness wire between the

camshaft position sensor and the

intermediate connector.NG

Repair

NG

Check the camshaft position sensing

cylinderNG

OK

Check the trouble symptoms.Intermittent malfunction

(Refer to GROUP 00 - Points to Note for Intermittent Malfunctions.)

OK

Check the trouble symptoms.NGReplace the engine-ECU.

Replace

OK

Check the following connector:

B-110

Check the following connector:

D-117

Check the following connectors:

B-25X, D-117

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 277 of 1839

GDI -Troubleshooting

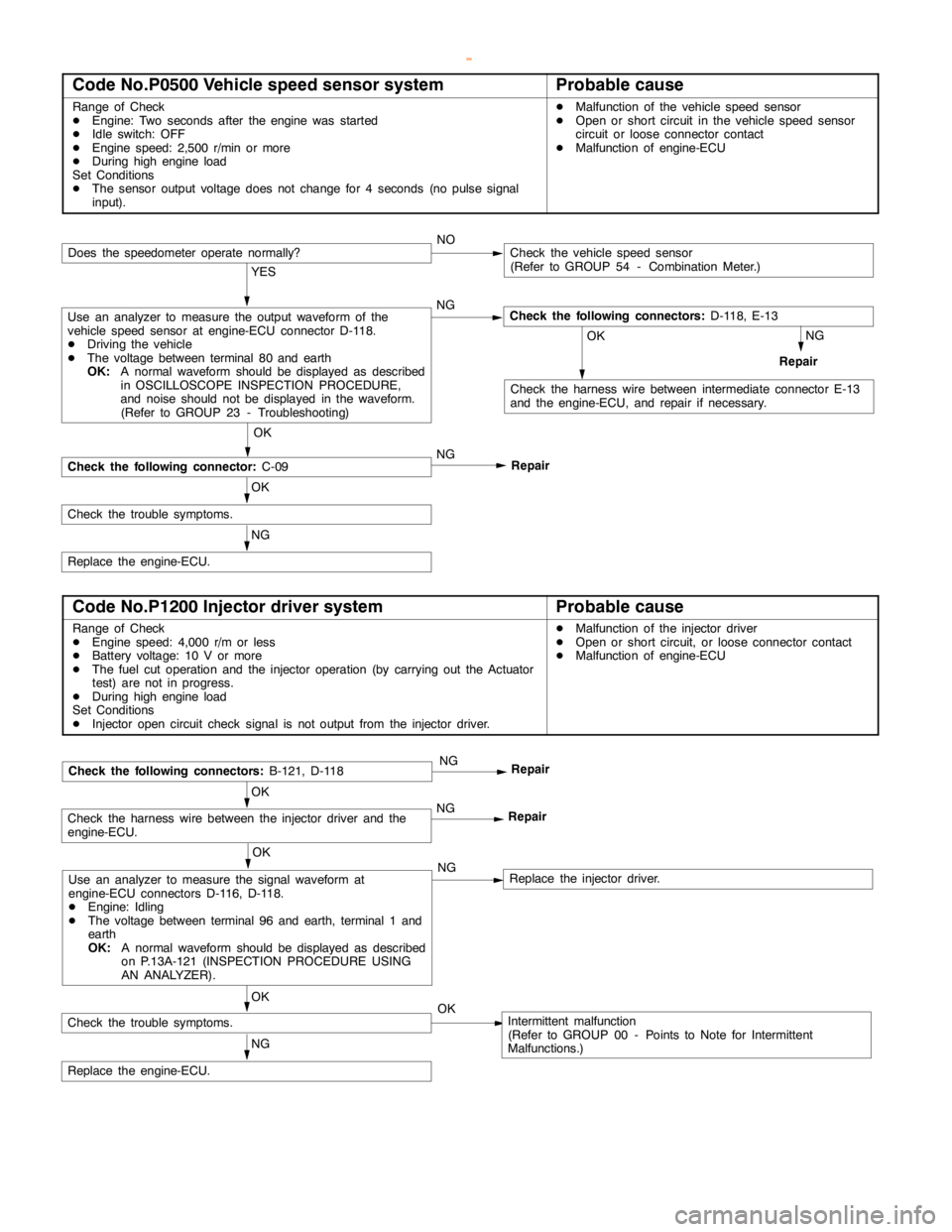

Code No.P0500 Vehicle speed sensor systemProbable cause

Range of Check

DEngine: Two seconds after theengine wasstarted

DIdle switch: OFF

DEngine speed: 2,500 r/min or more

DDuring high engine load

Set Conditions

DThe sensor output voltage does not change for 4 seconds (no pulse signal

input).DMalfunction of the vehicle speed sensor

DOpen or short circuit in the vehicle speed sensor

circuit or loose connector contact

DMalfunction of engine-ECU

NOCheck the vehicle speed sensor

(Refer to GROUP 54 - Combination Meter.)

YES

Use an analyzer to measure the output waveform of the

vehicle speed sensor at engine-ECU connector D-118.

DDriving the vehicle

DThe voltage between terminal 80 and earth

OK:

A normal waveform should be displayed as described

in OSCILLOSCOPE INSPECTION PROCEDURE,

and noise should not be displayed in the waveform.

(Refer to GROUP 23 - Troubleshooting)NGCheck the following connectors:

D-118, E-13

NG

Repair

OK

Check the harness wire between intermediate connector E-13

and the engine-ECU, and repair if necessary.

OK

Check the following connector:

C-09NG

Repair

OK

Check the trouble symptoms.

NG

Replace the engine-ECU.

Does the speedometer operate normally?

Code No.P1200 Injector driver systemProbable cause

Range of Check

DEngine speed: 4,000 r/m or less

DBattery voltage: 10 V or more

DThe fuel cut operation and the injector operation (by carrying out the Actuator

test) are not in progress.

DDuring high engine load

Set Conditions

DInjector opencircuit check signal is not output from the injector driver.DMalfunction of the injector driver

DOpen or short circuit, or loose connector contact

DMalfunction of engine-ECU

OK

Use an analyzer to measure the signal waveform at

engine-ECU connectors D-116, D-118.

DEngine: Idling

DThe voltage between terminal 96 and earth, terminal 1 and

earth

OK:

A normal waveform should be displayed as described

on P.13A-121 (INSPECTIONPROCEDURE USING

AN ANALYZER).NGReplace the injector driver.

OK

Check the harness wire between the injector driver and the

engine-ECU.NG

Repair

NG

Replace the engine-ECU.

Check the following connectors:

B-121, D-118NG

Repair

OK

Check the trouble symptoms.OKIntermittent malfunction

(Refer to GROUP 00 - Points to Note for Intermittent

Malfunctions.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 285 of 1839

GDI -Troubleshooting

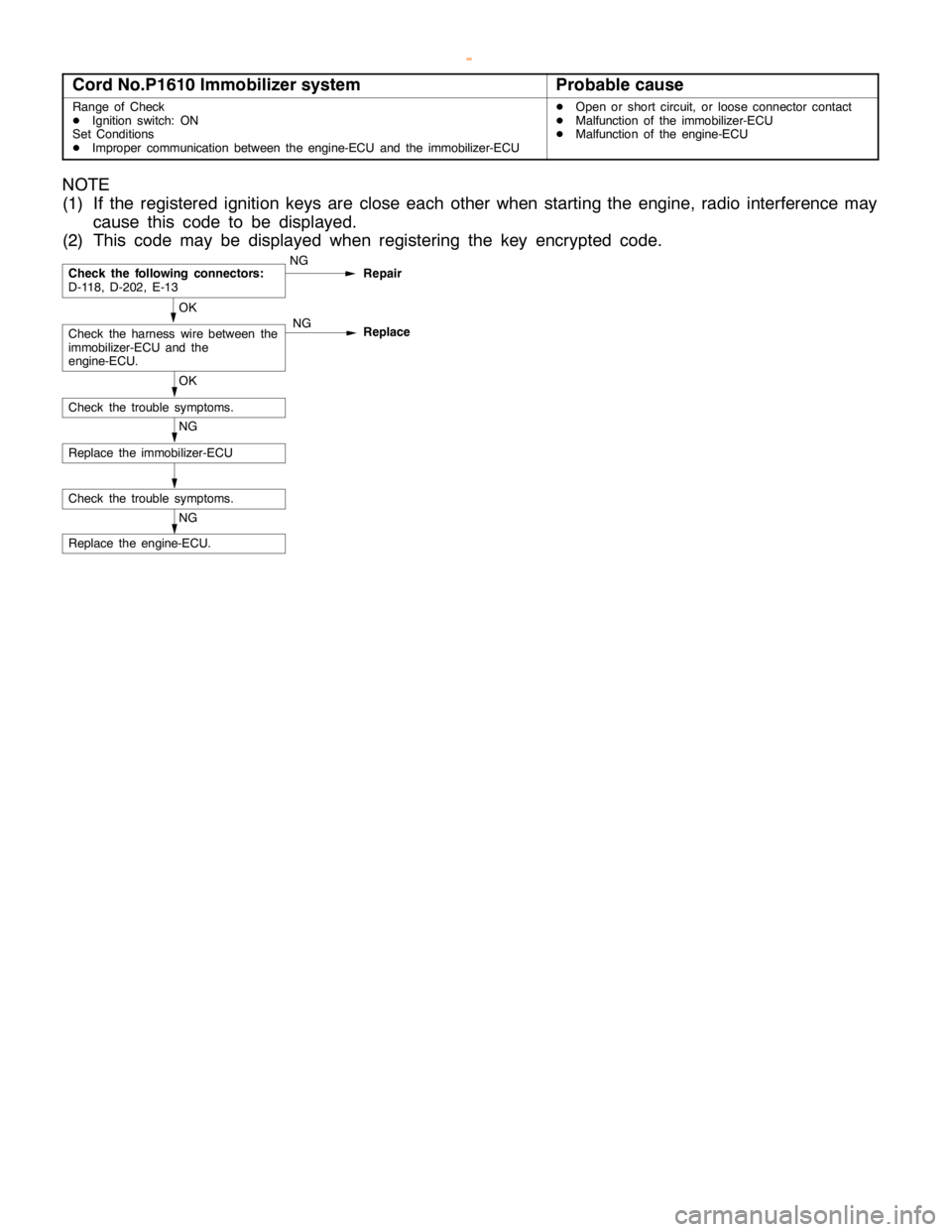

Cord No.P1610 Immobilizer systemProbable cause

Range of Check

DIgnition switch: ON

Set Conditions

DImproper communication between the engine-ECU and the immobilizer-ECUDOpen or short circuit, or loose connector contact

DMalfunction of the immobilizer-ECU

DMalfunction of the engine-ECU

NOTE

(1) If the registered ignition keys are close each other when starting the engine, radio interference may

cause this code to be displayed.

(2) This code may be displayed when registering the key encrypted code.

NG

Replace the engine-ECU.

Check the trouble symptoms.

NG

Replace the immobilizer-ECU

OK

Check the trouble symptoms.

OK

Check the harness wire between the

immobilizer-ECU and the

engine-ECU.NG

Replace

Check the following connectors:

D-118, D-202, E-13NG

Repair

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 289 of 1839

GDI -Troubleshooting

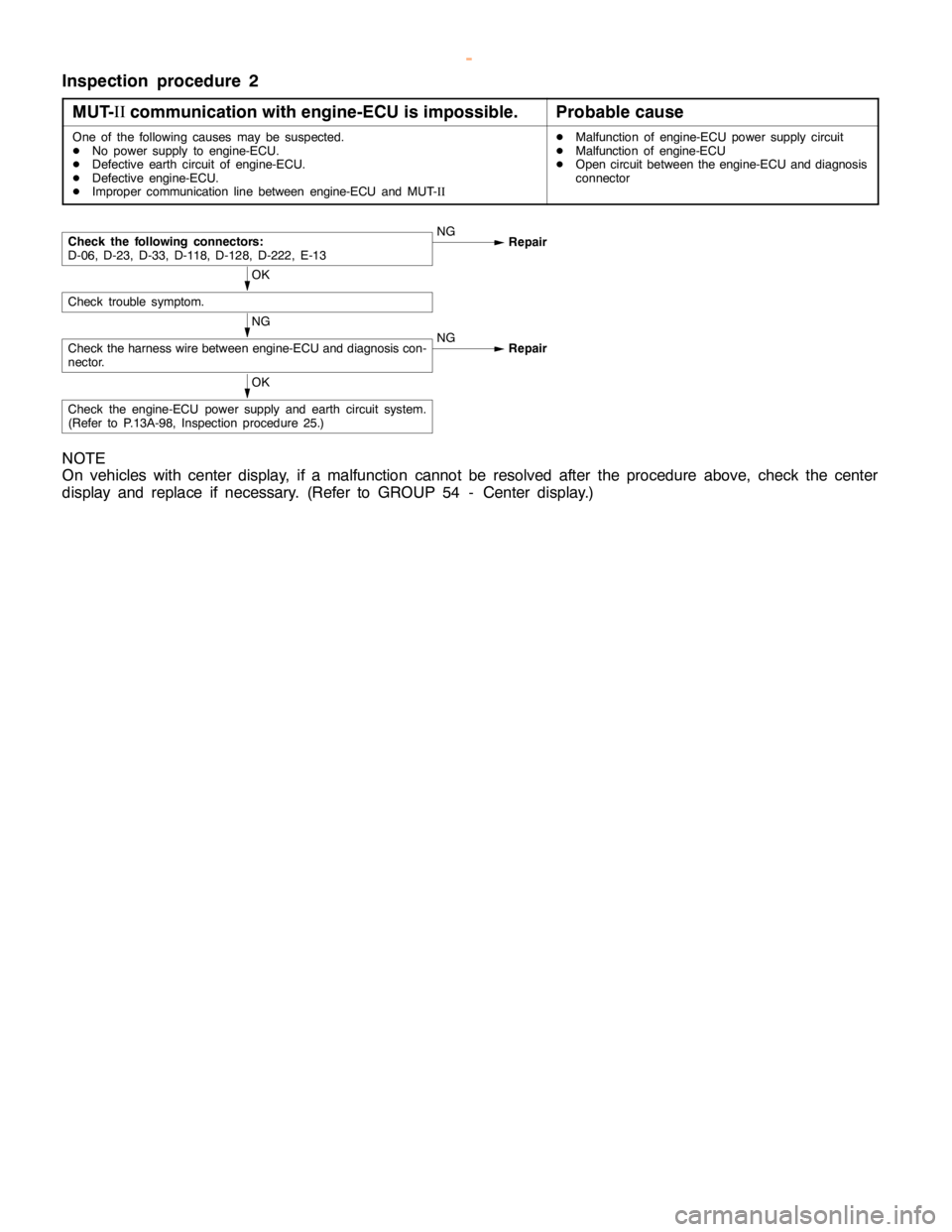

Inspection procedure 2

MUT-II

communication with engine-ECU is impossible.

Probable cause

One of the following causes may be suspected.

DNo power supply to engine-ECU.

DDefective earth circuit of engine-ECU.

DDefective engine-ECU.

DImproper communication line between engine-ECU and MUT-IIDMalfunction of engine-ECU power supply circuit

DMalfunction of engine-ECU

DOpen circuit between the engine-ECU and diagnosis

connector

NG

Check the harness wire between engine-ECU and diagnosis con-

nector.NG

Repair

OK

Check trouble symptom.

Check the following connectors:

D-06, D-23, D-33, D-118, D-128, D-222, E-13NG

Repair

OK

Check the engine-ECU power supply and earth circuit system.

(Refer to P.13A-98, Inspection procedure 25.)

NOTE

On vehicles with center display, if a malfunction cannot be resolved after the procedure above, check the center

display and replace if necessary. (Refer to GROUP 54 - Center display.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 290 of 1839

GDI -Troubleshooting

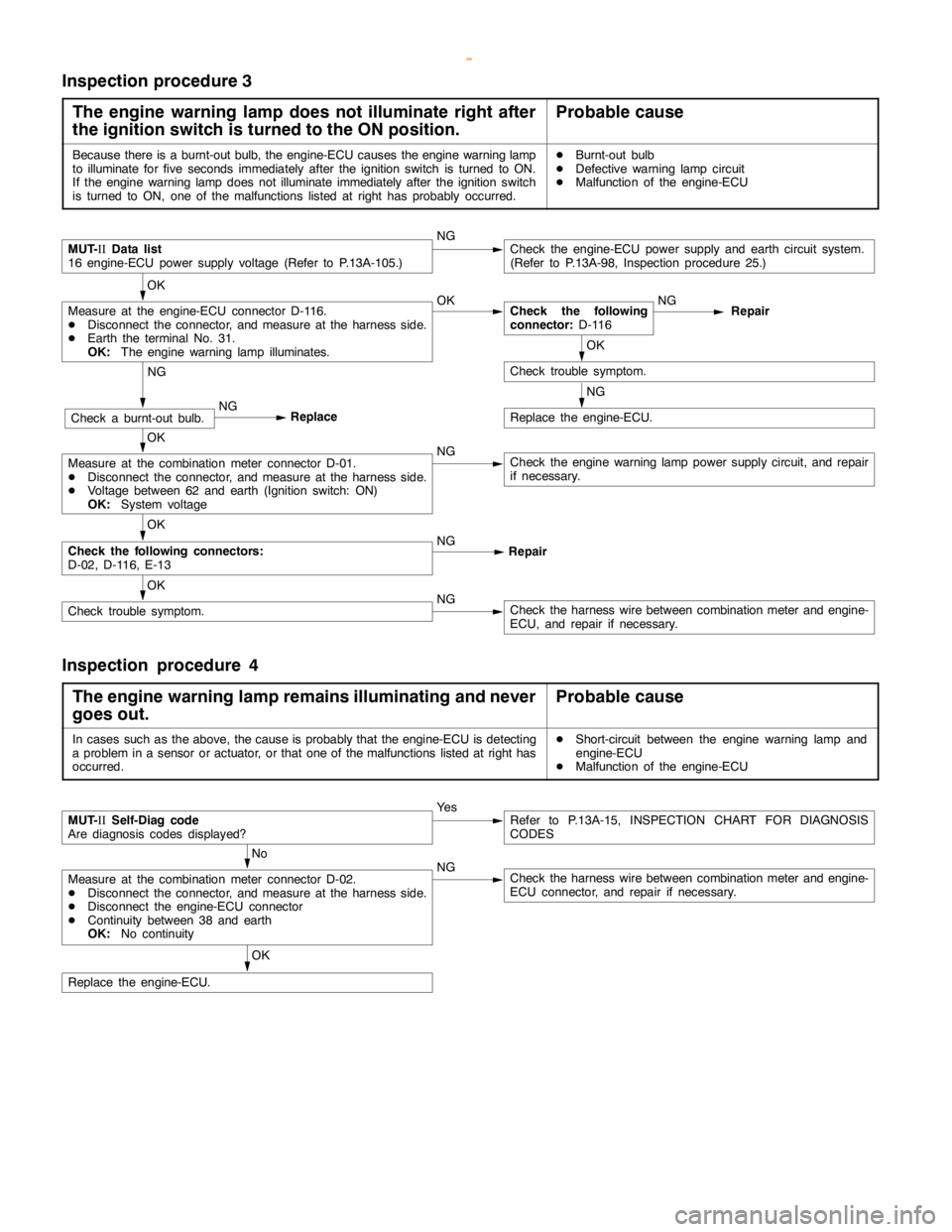

Inspection procedure 3

The engine warning lamp does not illuminate right after

the ignition switch is turned to the ON position.

Probable cause

Because there is a burnt-out bulb, the engine-ECU causes theengine warning lamp

to illuminate forfive seconds immediately after the ignition switch is turned to ON.

If the engine warning lampdoes notilluminate immediately after the ignitionswitch

is turned to ON, one of the malfunctions listed at right has probably occurred.DBurnt-out bulb

DDefective warninglampcircuit

DMalfunction of the engine-ECU

MUT-

IIData list

16 engine-ECU power supply voltage (Refer to P.13A-105.)NGCheck the engine-ECU power supply and earth circuit system.

(Refer to P.13A-98, Inspection procedure 25.)

OK

Measure at the engine-ECU connector D-116.

DDisconnect the connector, and measure at the harness side.

DEarth the terminal No. 31.

OK:

The engine warning lamp illuminates.OKCheck the following

connector:

D-116NG

Repair

OK

Check trouble symptom.

NG

Replace the engine-ECU.

NG

Check a burnt-out bulb.NG

Replace

OK

Measure at the combination meter connector D-01.

DDisconnect the connector, and measure at the harness side.

DVoltage between 62 and earth (Ignition switch: ON)

OK:

System voltageNGCheck theengine warning lamppower supply circuit, and repair

if necessary.

OK

Check the following connectors:

D-02, D-116, E-13NG

Repair

OK

Check trouble symptom.NGCheck the harness wire between combination meter and engine-

ECU, and repair if necessary.

Inspection procedure 4

The engine warning lamp remains illuminating and never

goes out.

Probable cause

In cases such as the above, the cause is probably that the engine-ECU is detecting

a problem in a sensor or actuator, or that one of the malfunctions listed at right has

occurred.DShort-circuit between the engine warning lamp and

engine-ECU

DMalfunction of the engine-ECU

MUT-

IISelf-Diag code

Are diagnosis codes displayed?Ye sRefer to P.13A-15, INSPECTION CHART FOR DIAGNOSIS

CODES

No

Measure at the combination meter connector D-02.

DDisconnect the connector, and measure at the harness side.

DDisconnect the engine-ECU connector

DContinuity between 38 and earth

OK:

No continuityNGCheck the harness wire between combination meter and engine-

ECU connector, and repair if necessary.

OK

Replace the engine-ECU.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 291 of 1839

GDI -Troubleshooting

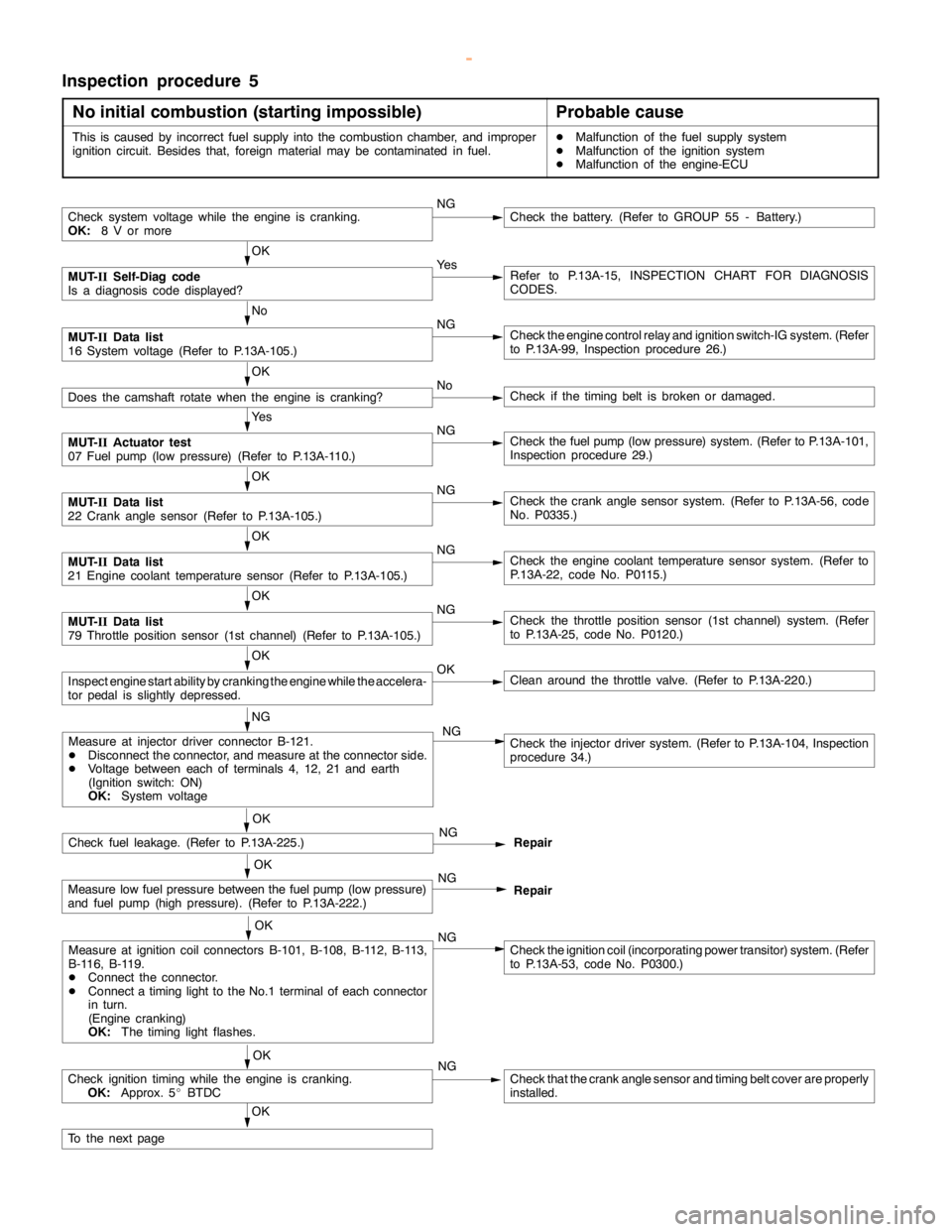

Inspection procedure 5

No initial combustion (starting impossible)

Probable cause

This is caused by incorrect fuel supply into the combustion chamber, and improper

ignition circuit. Besides that, foreign material may be contaminated in fuel.DMalfunction of the fuel supply system

DMalfunction of the ignition system

DMalfunction of the engine-ECU

Check system voltage while theengine iscranking.

OK:

8 V or moreNGCheck the battery. (Refer to GROUP 55 - Battery.)

OK

MUT-

IISelf-Diag code

Is a diagnosis code displayed?Ye sRefer to P.13A-15, INSPECTION CHART FOR DIAGNOSIS

CODES.

No

MUT-

IIData list

16 System voltage (Refer to P.13A-105.)NGCheck theengine controlrelay and ignition switch-IG system. (Refer

to P.13A-99, Inspection procedure 26.)

OK

Does the camshaft rotate when theengine is cranking?NoCheck if thetiming belt isbroken ordamaged.

Ye s

MUT-

IIActuator test

07 Fuel pump(low pressure) (Refer to P.13A-110.)NGCheck the fuelpump(low pressure) system. (Refer to P.13A-101,

Inspection procedure 29.)

OK

MUT-

IIData list

22 Crankanglesensor (Refer to P.13A-105.)NGCheck the crankanglesensor system. (Refer to P.13A-56, code

No. P0335.)

OK

MUT-

IIData list

21 Engine coolant temperature sensor (Refer to P.13A-105.)NGCheck theengine coolant temperaturesensor system. (Refer to

P.13A-22, code No. P0115.)

OK

MUT-

IIData list

79 Throttle position sensor (1st channel) (Refer to P.13A-105.)NGCheck the throttle position sensor (1st channel) system. (Refer

to P.13A-25, code No. P0120.)

OK

Inspectenginestart ability by cranking theengine while theaccelera-

tor pedal isslightly depressed.OKClean around the throttle valve. (Refer to P.13A-220.)

NG

Check fuel leakage. (Refer to P.13A-225.)NG

Repair

OK

Measure low fuel pressure between the fuelpump(low pressure)

and fuel pump (highpressure). (Refer to P.13A-222.)NG

Repair

OK

Measure at ignition coil connectors B-101, B-108, B-112, B-113,

B-116, B-119.

DConnect the connector.

DConnect atiming light to theNo.1 terminal of each connector

in turn.

(Engine cranking)

OK:

The timing lightflashes.NGCheck the ignition coil (incorporating power transitor) system. (Refer

to P.13A-53, code No. P0300.)

OK

Check ignitiontiming while the engine iscranking.

OK:

Approx. 5_BTDCNGCheck that the crankanglesensor andtiming beltcover are properly

installed.

OK

To the nextpage

Measure at injector driver connector B-121.

DDisconnect the connector, and measure at the connector side.

DVoltage between each of terminals 4, 12, 21 and earth

(Ignition switch: ON)

OK:

System voltageCheck the injector driver system. (Refer to P.13A-104, Inspection

procedure 34.) NG

OK

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 293 of 1839

GDI -Troubleshooting

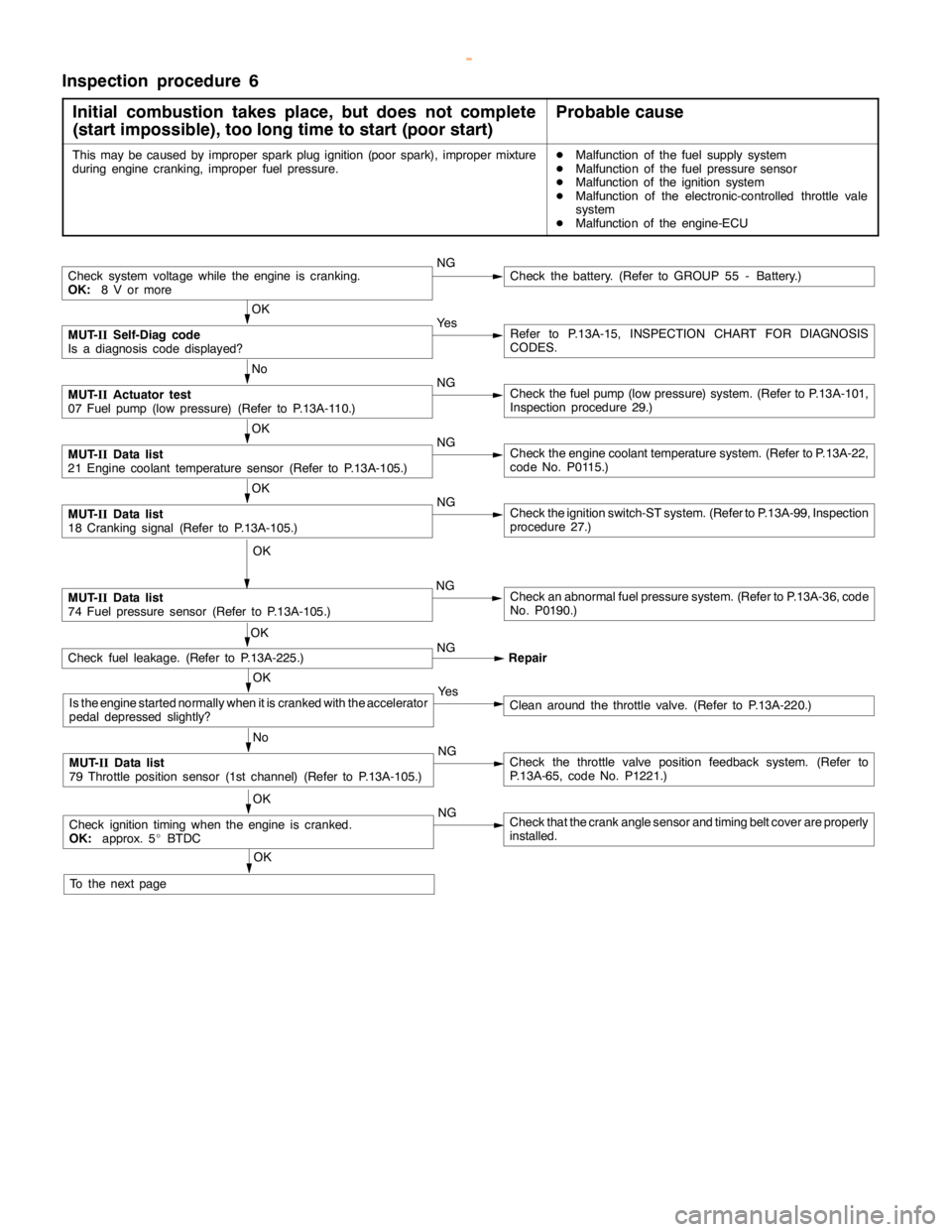

Inspection procedure 6

Initial combustion takes place, but does not complete

(start impossible), too long time to start (poor start)

Probable cause

This may be caused by improper sparkplug ignition (poorspark), improper mixture

during enginecranking, improper fuel pressure.DMalfunction of the fuel supply system

DMalfunction of the fuel pressure sensor

DMalfunction of the ignition system

DMalfunction of the electronic-controlled throttle vale

system

DMalfunction of the engine-ECU

Check system voltage while theengine iscranking.

OK:

8 V or moreNGCheck the battery. (Refer to GROUP 55 - Battery.)

OK

MUT-

IISelf-Diag code

Is a diagnosis code displayed?Ye sRefer to P.13A-15, INSPECTION CHART FOR DIAGNOSIS

CODES.

No

MUT-

IIActuator test

07 Fuel pump(low pressure) (Refer to P.13A-110.)NGCheck the fuelpump(low pressure) system. (Refer to P.13A-101,

Inspection procedure 29.)

OK

MUT-

IIData list

21 Engine coolant temperature sensor (Refer to P.13A-105.)NGCheck theengine coolant temperaturesystem. (Refer to P.13A-22,

code No. P0115.)

OK

MUT-

IIData list

18 Cranking signal (Refer to P.13A-105.)NGCheck the ignition switch-ST system. (Refer to P.13A-99, Inspection

procedure 27.)

OK

MUT-

IIData list

74 Fuel pressure sensor (Refer to P.13A-105.)NGCheck an abnormal fuel pressure system. (Refer to P.13A-36, code

No. P0190.)

Check fuel leakage. (Refer to P.13A-225.)NG

Repair

OK

Is the enginestarted normally when it is cranked with the accelerator

pedal depressed slightly?Ye sClean around the throttle valve. (Refer to P.13A-220.)

No

MUT-

IIData list

79 Throttle position sensor (1st channel) (Refer to P.13A-105.)NGCheck the throttle valve position feedback system. (Refer to

P.13A-65, code No. P1221.)

OK

Check ignitiontimingwhen theengine iscranked.

OK:

approx. 5_BTDCNGCheck that the crankanglesensor andtiming beltcover are properly

installed.

OK

To the nextpageOK

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 295 of 1839

GDI -Troubleshooting

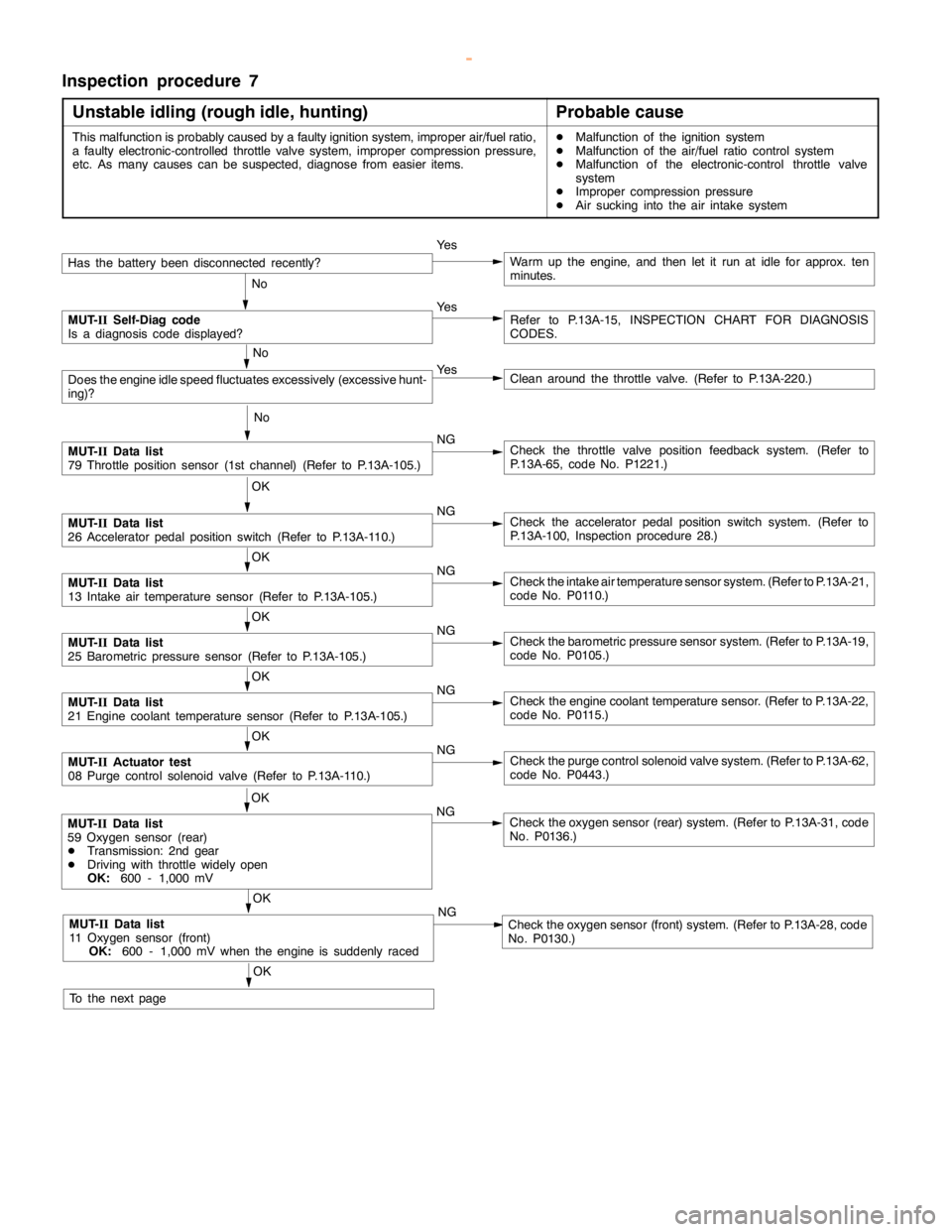

Inspection procedure 7

Unstable idling (rough idle, hunting)

Probable cause

This malfunction is probably caused by a faulty ignition system, improper air/fuel ratio,

a faulty electronic-controlled throttle valve system, improper compression pressure,

etc. As many causes can be suspected, diagnose from easier items.DMalfunction of the ignition system

DMalfunction of the air/fuel ratio control system

DMalfunction of the electronic-control throttle valve

system

DImproper compression pressure

DAir sucking into the air intake system

Has the batterybeen disconnectedrecently?Ye sWarm up the engine, and then let it run at idle for approx. ten

minutes.

No

MUT-

IISelf-Diag code

Is a diagnosis code displayed?Ye sRefer to P.13A-15, INSPECTION CHART FOR DIAGNOSIS

CODES.

No

Does theengine idlespeed fluctuates excessively (excessivehunt-

ing)?Ye sClean around the throttle valve. (Refer to P.13A-220.)

No

MUT-

IIData list

79 Throttle position sensor (1st channel) (Refer to P.13A-105.)NGCheck the throttle valve position feedback system. (Refer to

P.13A-65, code No. P1221.)

OK

MUT-

IIData list

26 Acceleratorpedal positionswitch (Refer to P.13A-110.)NGCheck the acceleratorpedal positionswitch system. (Refer to

P.13A-100, Inspection procedure 28.)

OK

MUT-

IIData list

13 Intake air temperature sensor (Refer to P.13A-105.)NGCheck the intake air temperature sensor system. (Refer to P.13A-21,

code No. P0110.)

OK

MUT-

IIData list

25 Barometric pressure sensor (Refer to P.13A-105.)NGCheck the barometric pressure sensor system. (Refer to P.13A-19,

code No. P0105.)

OK

MUT-

IIData list

21 Engine coolant temperature sensor (Refer to P.13A-105.)NGCheck theengine coolant temperaturesensor. (Refer to P.13A-22,

code No. P0115.)

OK

MUT-

IIActuator test

08 Purge control solenoid valve (Refer to P.13A-110.)NGCheck the purge control solenoid valve system. (Refer to P.13A-62,

code No. P0443.)

OK

MUT-

IIData list

11 Oxygen sensor (front)

OK:

600 - 1,000 mV when theengine is suddenlyracedNGCheck the oxygen sensor (front) system. (Refer to P.13A-28, code

No. P0130.)

OK

MUT-

IIData list

59 Oxygen sensor (rear)

DTransmission: 2nd gear

DDriving with throttle widelyopen

OK:

600 - 1,000 mVNGCheck the oxygen sensor (rear) system. (Refer to P.13A-31, code

No. P0136.)

OK

To the nextpage

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 297 of 1839

GDI -Troubleshooting

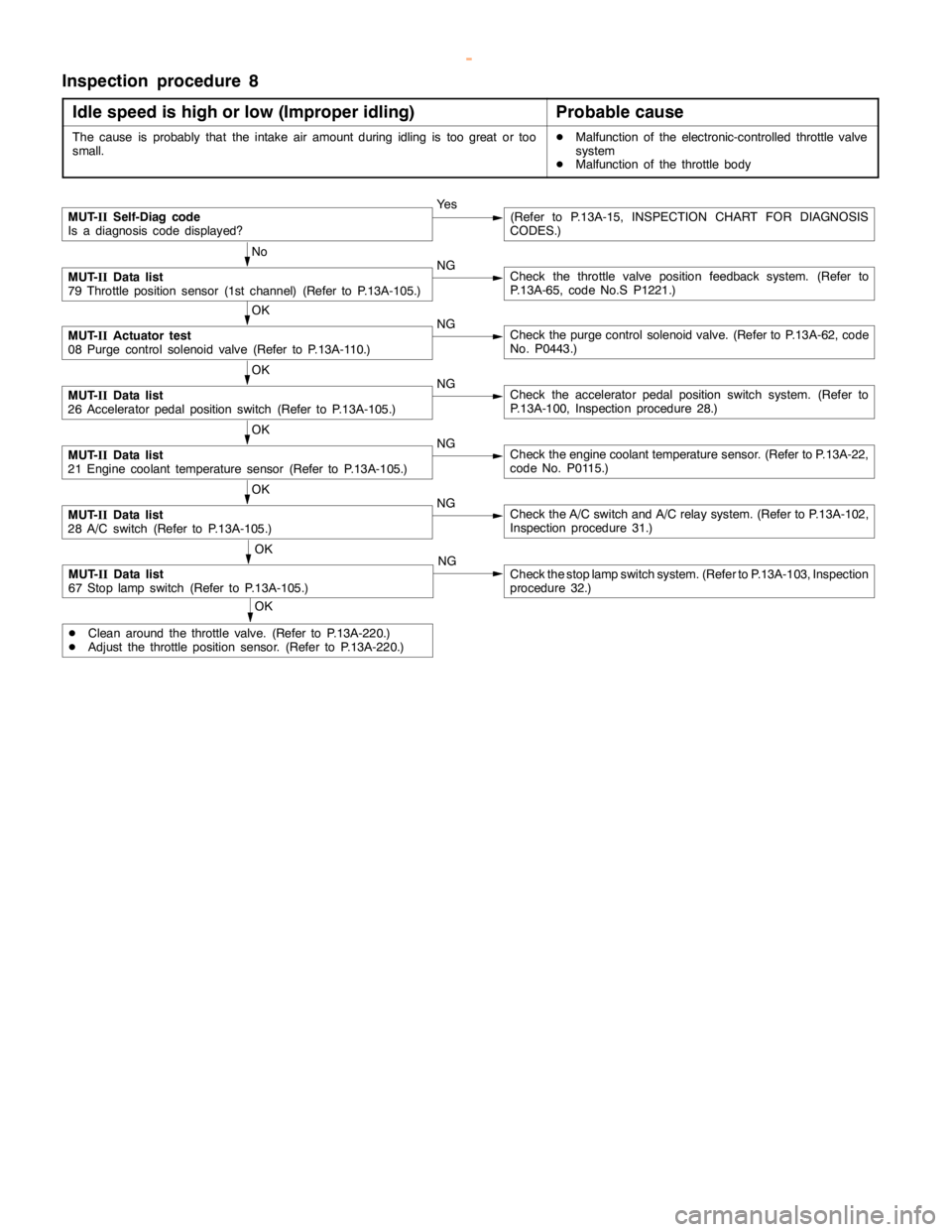

Inspection procedure 8

Idle speed is high or low (Improper idling)

Probable cause

The cause is probably that the intake airamount during idling is too great or too

small.DMalfunction of the electronic-controlled throttle valve

system

DMalfunction of the throttle body

MUT-

IISelf-Diag code

Is a diagnosis code displayed?Ye s(Refer to P.13A-15, INSPECTION CHART FOR DIAGNOSIS

CODES.)

No

MUT-

IIData list

79 Throttle position sensor (1st channel) (Refer to P.13A-105.)NGCheck the throttle valve position feedback system. (Refer to

P.13A-65, code No.S P1221.)

OK

MUT-

IIActuator test

08 Purge control solenoid valve (Refer to P.13A-110.)NGCheck the purge control solenoid valve. (Refer to P.13A-62, code

No. P0443.)

OK

MUT-

IIData list

26 Acceleratorpedal positionswitch (Refer to P.13A-105.)NGCheck the acceleratorpedal positionswitch system. (Refer to

P.13A-100, Inspection procedure 28.)

OK

MUT-

IIData list

21 Engine coolant temperature sensor (Refer to P.13A-105.)NGCheck theengine coolant temperaturesensor. (Refer to P.13A-22,

code No. P0115.)

OK

MUT-

IIData list

28 A/C switch (Refer to P.13A-105.)NGCheck the A/C switch and A/C relay system. (Refer to P.13A-102,

Inspection procedure 31.)

OK

MUT-

IIData list

67 Stoplampswitch (Refer to P.13A-105.)NGCheck the stoplampswitch system. (Refer to P.13A-103, Inspection

procedure 32.)

OK

DClean around the throttle valve. (Refer to P.13A-220.)

DAdjust the throttle position sensor. (Refer to P.13A-220.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk