torque MITSUBISHI MONTERO 2000 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 958 of 1839

Page 1001 of 1839

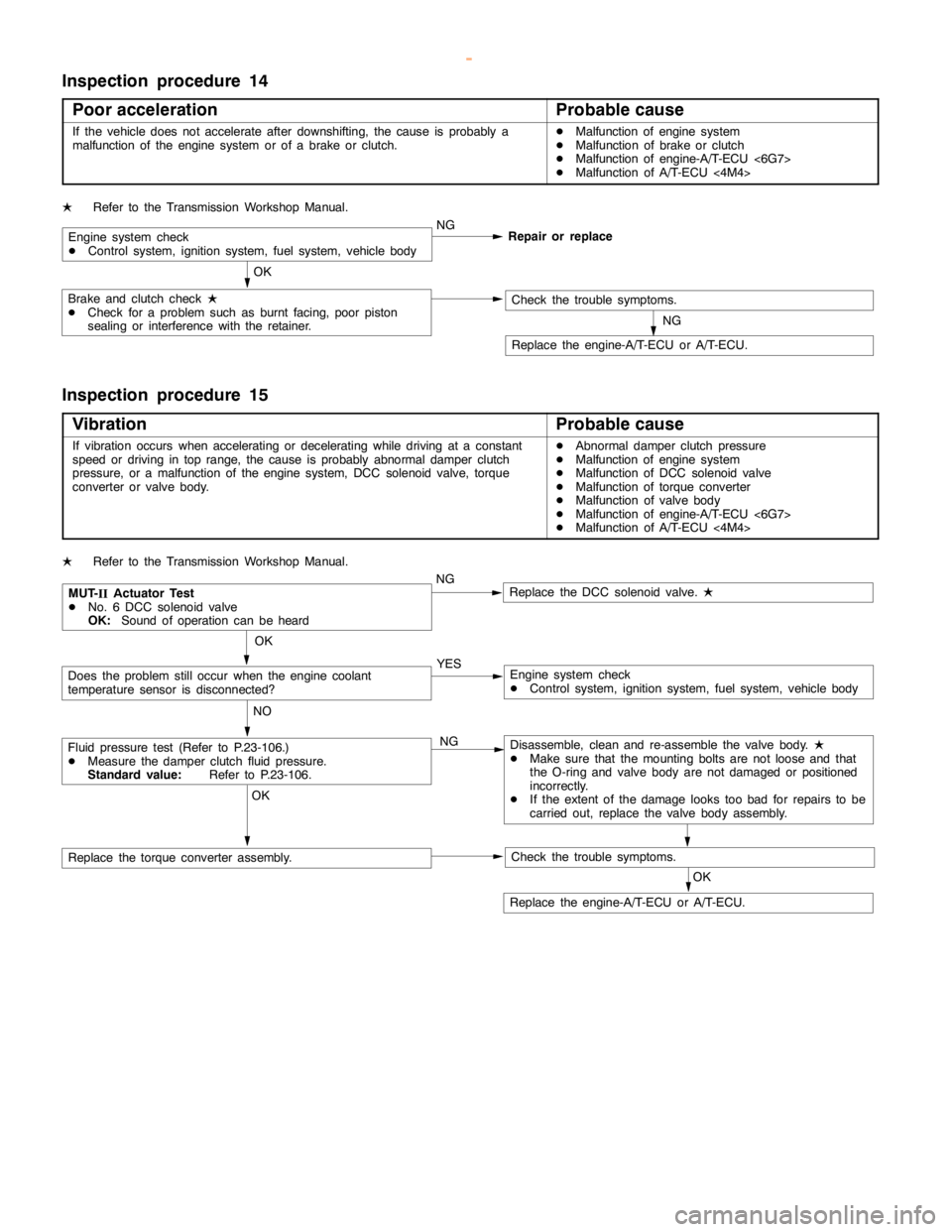

AUTOMATIC TRANSMISSION -On-vehicle Service23-100

Specified lubricant:

Hypoid gear oil SAE 75W-90 or 75W-85W

conforming to API GL-4

Oil level: 2.8 L

4. Install the oil filler plug, and tighten it to the specified

torque.

Tightening torque: 32±

2N×

m

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1009 of 1839

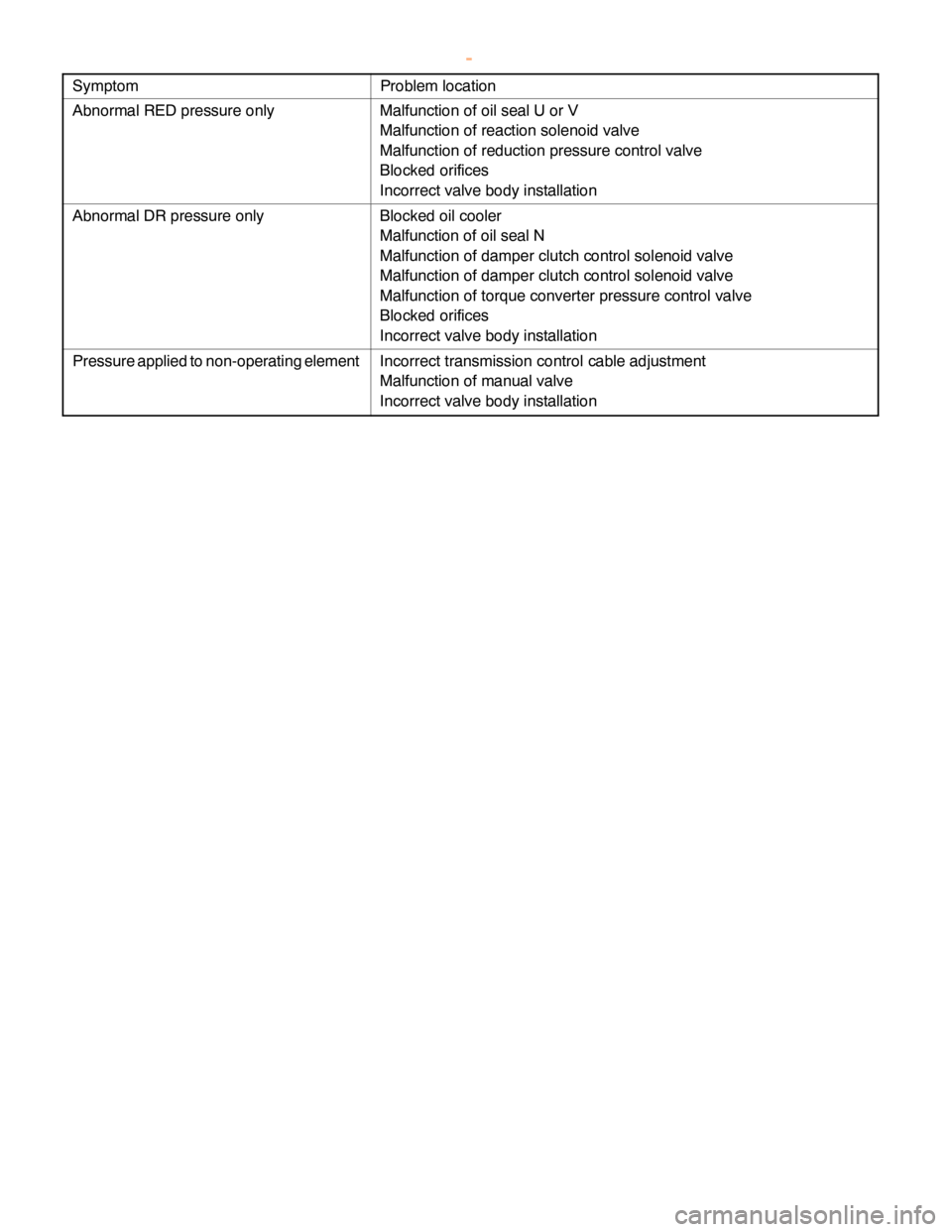

AUTOMATIC TRANSMISSION -On-vehicle Service23-108

Symptom Problem location

Abnormal RED pressure onlyMalfunction of oil seal U or V

Malfunction of reaction solenoid valve

Malfunction of reduction pressure control valve

Blocked orifices

Incorrect valve body installation

Abnormal DR pressure onlyBlocked oil cooler

Malfunction of oil seal N

Malfunction of damper clutch control solenoid valve

Malfunction of damper clutch control solenoid valve

Malfunction of torque converter pressure control valve

Blocked orifices

Incorrect valve body installation

Pressure applied to non-operating elementIncorrect transmission control cable adjustment

Malfunction of manual valve

Incorrect valve body installation

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1053 of 1839

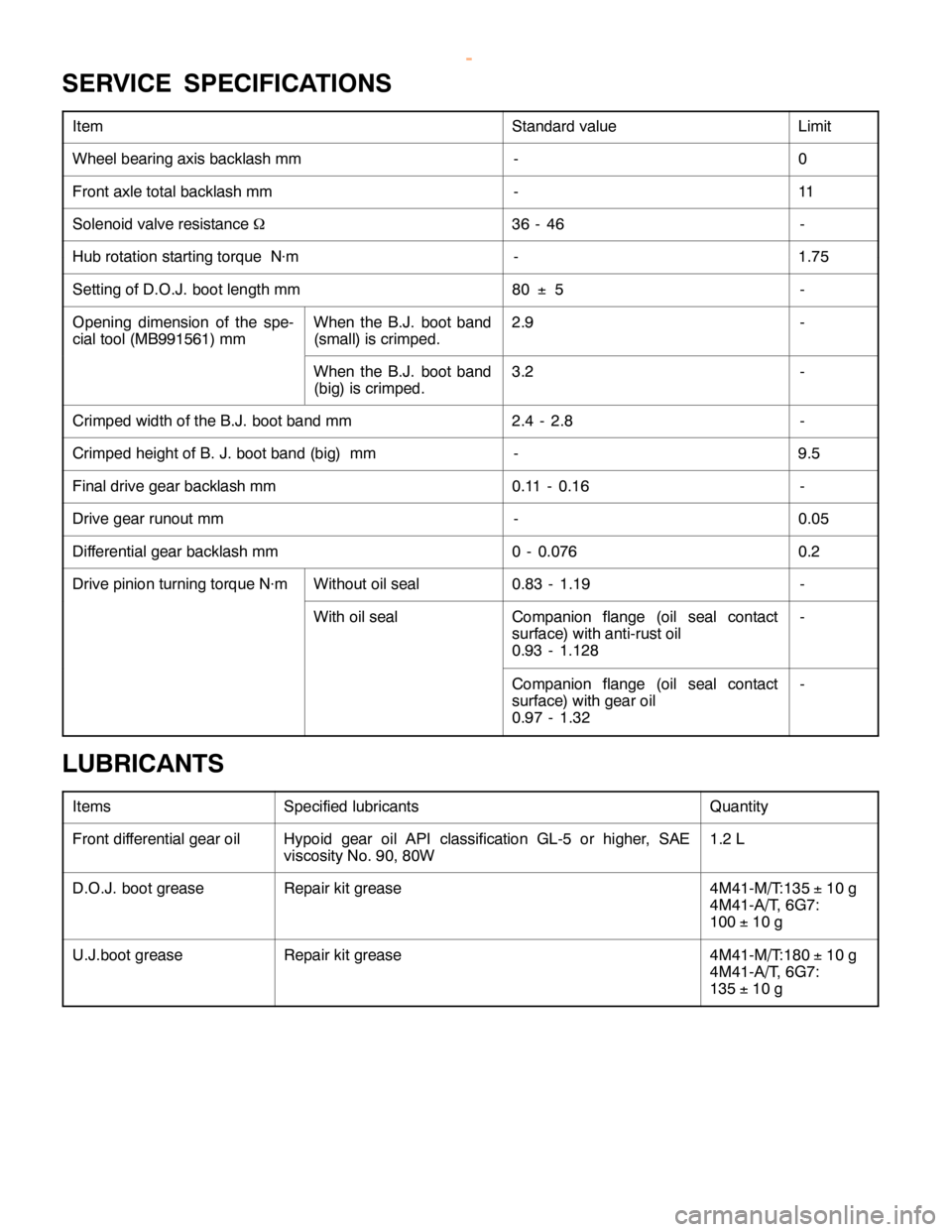

FRONT AXLE -Service Specifications/Lubricants26-4

SERVICE SPECIFICATIONS

ItemStandard valueLimit

Wheel bearing axis backlash mm-0

Front axle total backlash mm-11

Solenoid valve resistanceW36 - 46-

Hub rotation starting torque N×m-1.75

Setting of D.O.J. boot length mm80±5-

Opening dimension of the spe-

cial tool (MB991561) mmWhen the B.J. boot band

(small) is crimped.2.9-

When the B.J. boot band

(big) is crimped.3.2-

Crimped width of the B.J. boot band mm2.4 - 2.8-

Crimped height of B. J. boot band (big) mm-9.5

Final drive gear backlash mm0.11 - 0.16-

Drive gear runout mm-0.05

Differential gear backlash mm0 - 0.0760.2

Drive pinion turning torque N×mWithout oil seal0.83 - 1.19-

With oil sealCompanion flange (oil seal contact

surface) with anti-rust oil

0.93 - 1.128-

Companion flange (oil seal contact

surface) with gear oil

0.97 - 1.32-

LUBRICANTS

ItemsSpecified lubricantsQuantity

Front differential gear oilHypoid gear oil API classification GL-5 or higher, SAE

viscosity No. 90, 80W1.2 L

D.O.J. boot greaseRepair kit grease4M41-M/T:135±10 g

4M41-A/T, 6G7:

100±10 g

U.J.boot greaseRepair kit grease4M41-M/T:180±10 g

4M41-A/T, 6G7:

135±10 g

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1104 of 1839

REAR AXLE -General Information27-2

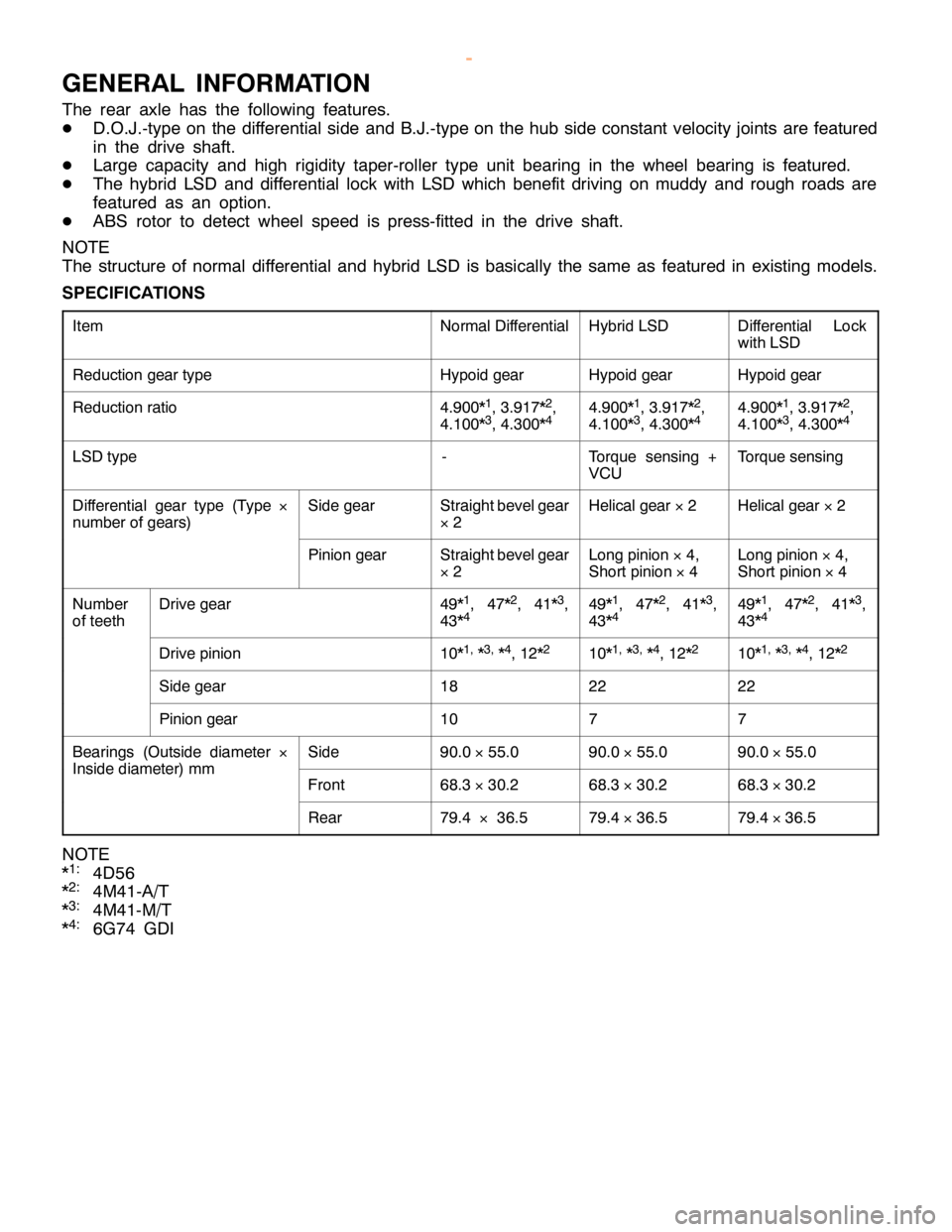

GENERAL INFORMATION

The rear axle has the following features.

DD.O.J.-type on the differential side and B.J.-type on the hub side constant velocity joints are featured

in the drive shaft.

DLarge capacity and high rigidity taper-roller type unit bearing in the wheel bearing is featured.

DThe hybrid LSD and differential lock with LSD which benefit driving on muddy and rough roads are

featured as an option.

DABS rotor to detect wheel speed is press-fitted in the drive shaft.

NOTE

The structure of normal differential and hybrid LSD is basically the same as featured in existing models.

SPECIFICATIONS

ItemNormal DifferentialHybrid LSDDifferential Lock

with LSD

Reduction gear typeHypoid gearHypoid gearHypoid gear

Reduction ratio4.900*1, 3.917*2,

4.100*3, 4.300*44.900*1, 3.917*2,

4.100*3, 4.300*44.900*1, 3.917*2,

4.100*3, 4.300*4

LSD type-Torque sensing +

VCUTorque sensing

Differential gear type (Type´

number of gears)Side gearStraight bevel gear

´2Helical gear´2Helical gear´2

Pinion gearStraight bevel gear

´2Long pinion´4,

Short pinion´4Long pinion´4,

Short pinion´4

Number

of teethDrive gear49*1, 47*2, 41*3,

43*449*1, 47*2, 41*3,

43*449*1, 47*2, 41*3,

43*4

Drive pinion10*1,*3,*4, 12*210*1,*3,*4, 12*210*1,*3,*4, 12*2

Side gear182222

Pinion gear1077

Bearings (Outside diameter´Side90.0´55.090.0´55.090.0´55.0

Inside diameter) mm

Front68.3´30.268.3´30.268.3´30.2

Rear79.4´36.579.4´36.579.4´36.5

NOTE

*1:4D56

*2:4M41-A/T

*3:4M41-M/T

*4:6G74 GDI

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

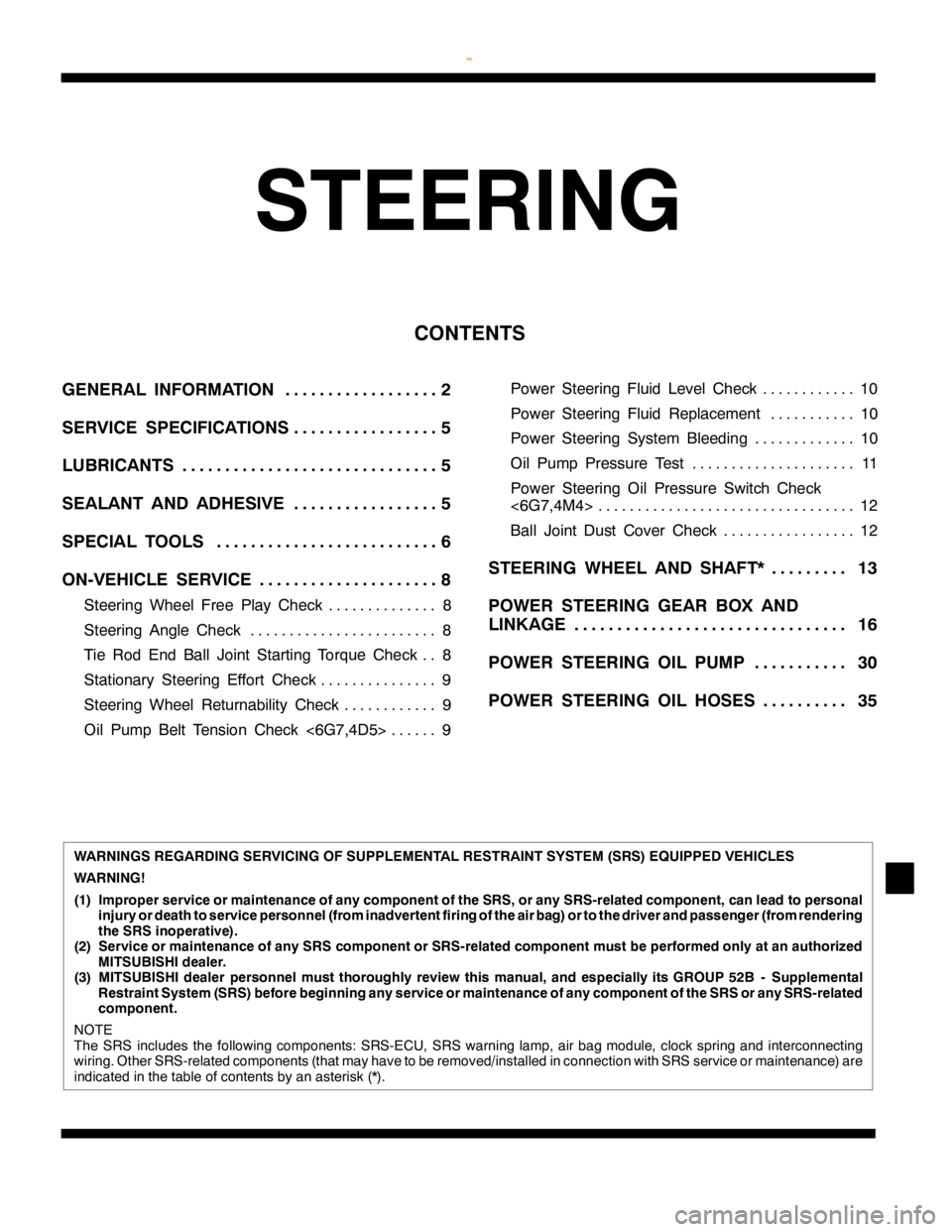

Page 1310 of 1839

37A-1

STEERING

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 5.................

LUBRICANTS 5..............................

SEALANT AND ADHESIVE 5.................

SPECIAL TOOLS 6..........................

ON-VEHICLE SERVICE 8.....................

Steering Wheel Free Play Check 8..............

Steering Angle Check 8........................

Tie Rod End Ball Joint Starting Torque Check 8..

Stationary Steering Effort Check 9...............

Steering Wheel Returnability Check 9............

Oil Pump Belt Tension Check <6G7,4D5> 9......Power Steering Fluid Level Check 10............

Power Steering Fluid Replacement 10...........

Power Steering System Bleeding 10.............

Oil Pump Pressure Test 11.....................

Power Steering Oil Pressure Switch Check

<6G7,4M4> 12.................................

Ball Joint Dust Cover Check 12.................

STEERING WHEEL AND SHAFT* 13.........

POWER STEERING GEAR BOX AND

LINKAGE 16................................

POWER STEERING OIL PUMP 30...........

POWER STEERING OIL HOSES 35..........

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING!

(1) Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to personal

injury or death to service personnel (from inadvertent firing of the air bag) or to the driver and passenger (from rendering

the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an authorized

MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any SRS-related

component.

NOTE

The SRS includes the following components: SRS-ECU, SRS warning lamp, air bag module, clock spring and interconnecting

wiring. Other SRS-related components (that mayhave to be removed/installed in connectionwith SRS service or maintenance) are

indicated in the table of contents by an asterisk(*).

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1314 of 1839

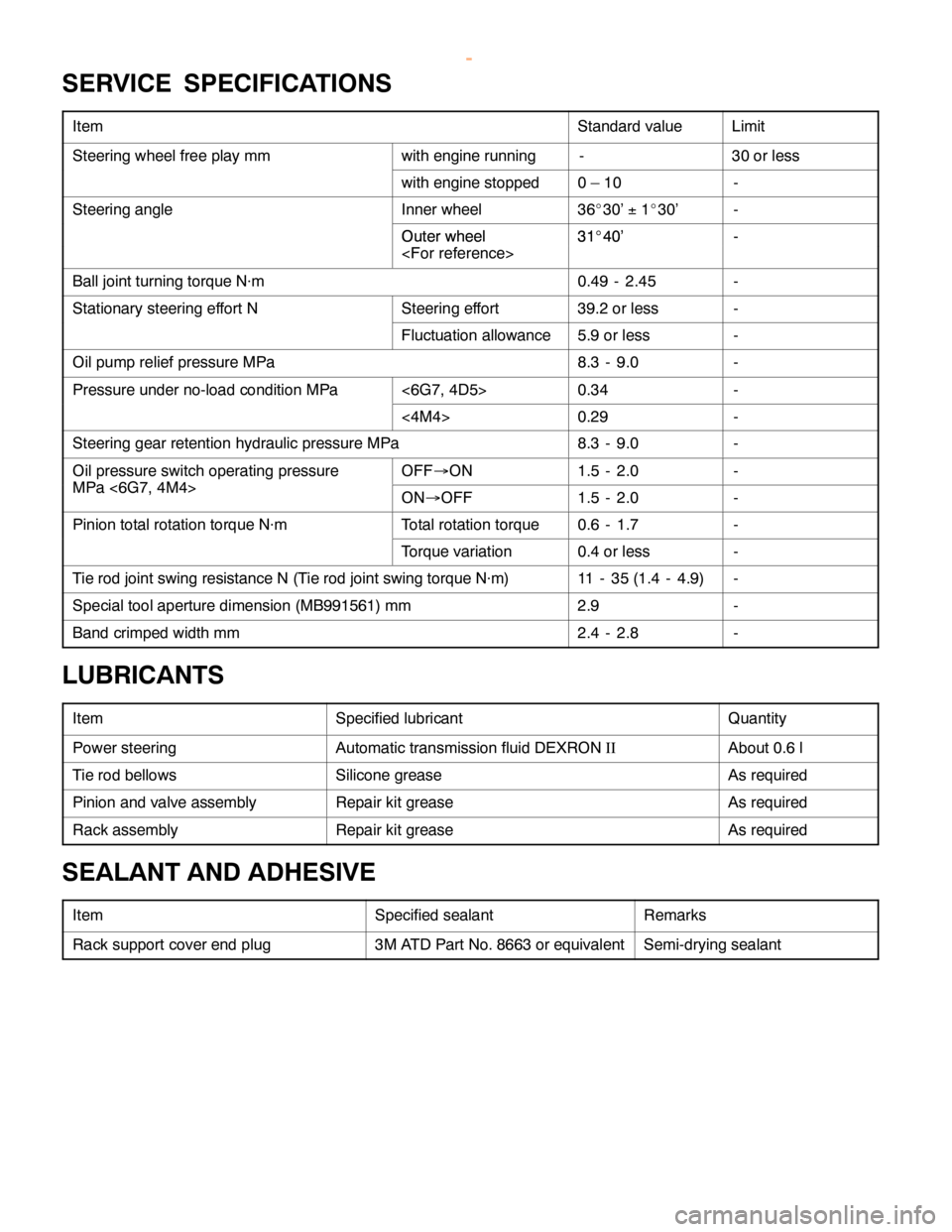

STEERING -Service Specifications/Lubricants/Sealant and Adhesive37A-5

SERVICE SPECIFICATIONS

ItemStandard valueLimit

Steering wheel free play mmwith engine running-30 or less

with engine stopped0–10-

Steering angleInner wheel36_30’±1_30’-

Outer wheel31_40’-Outer wheel

Ball joint turning torque N×m0.49 - 2.45-

Stationary steering effort NSteering effort39.2 or less-

Fluctuation allowance5.9 or less-

Oil pump relief pressure MPa8.3 - 9.0-

Pressure under no-load condition MPa<6G7, 4D5>0.34-

<4M4>0.29-

Steering gear retention hydraulic pressure MPa8.3 - 9.0-

Oil pressure switch operating pressureOFF®ON1.5 - 2.0-

MPa <6G7, 4M4>ON®OFF1.5 - 2.0-

Pinion total rotation torque N×mTotal rotation torque0.6 - 1.7-

Torque variation0.4 or less-

Tie rod joint swing resistance N (Tie rod joint swing torque N×m)11 - 35 (1.4 - 4.9)-

Special tool aperture dimension (MB991561) mm2.9-

Band crimped width mm2.4 - 2.8-

LUBRICANTS

ItemSpecified lubricantQuantity

Power steeringAutomatic transmission fluid DEXRONIIAbout 0.6 l

Tie rod bellowsSilicone greaseAs required

Pinion and valve assemblyRepair kit greaseAs required

Rack assemblyRepair kit greaseAs required

SEALANT AND ADHESIVE

ItemSpecified sealantRemarks

Rack support cover end plug3M ATD Part No. 8663 or equivalentSemi-drying sealant

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1763 of 1839

HEATER, AIR CONDITIONER AND VENTILATION - On-vehicle Service55A-17

REFRIGERANT LEAK REPAIR

LOST CHARGE

If the system has lost all charge due to a leak:

1. Evacuate the system. (See procedure.)

2. Charge the system with approximately one

pound of refrigerant.

3. Check for leaks.

4. Discharge the system.

5. Repair leaks.

6. Replace receiver drier.

Caution

Replacement filter-drier units must be

sealed while in storage. The drier used in

these units will saturate water quickly upon

exposure to the atmosphere. When

installing a drier, have all tools and supplies

ready for quick reassembly to avoid keeping

the system open any longer than necessary.

7. Evacuate and charge system.

LOW CHARGE

If the system has not lost all of its refrigerant charge;

locate and repair all leaks. If it is necessary to

increase the system pressure to find the leak

(because of an especially low charge) add

refrigerant. If it is possible to repair the leak without

discharging the refrigerant system, use the

procedure for correcting low refrigerant level.HANDLING TUBING AND FITTINGS

Kinks in the refrigerant tubing or sharp bends in

the refrigerant hose lines will greatly reduce the

capacity of the entire system. High pressures are

produced in the system when it is operating.

Extreme care must be exercised to make sure that

all connections are pressure tight. Dirt and moisture

can enter the system when it is opened for repair

or replacement of lines or components. The

following precautions must be observed. The

system must be completely discharged before

opening any fitting of connection in the refrigeration

system. Open fittings with caution even after the

system has been discharged. If any pressure is

noticed as a fitting is loosened, allow trapped

pressure to bleed off very slowly.

Never attempt to rebend formed lines to fit. Use

the correct line for the installation you are servicing.

A good rule for the flexible hose lines is keep the

radius of all bends at least 10 times the diameter

of the hose.

Sharper bends will reduce the flow of refrigerant.

The flexible hose lines should be routed so that

they are at least 80 mm from the exhaust manifold.

It is good practice to inspect all flexible hose lines

at least once a year to make sure they are in good

condition and properly routed.

Unified plumbing connections with O-rings, these

O-rings are not reusable.

COMPRESSOR NOISE

You must first know the conditions when the noise

occurs. These conditions are: weather, vehicle

speed, in gear or neutral, engine temperature or

any other special conditions.

Noises that develop during A/C operation can often

be misleading. For example: what sounds like a

failed front bearing or connecting rod, may be

caused by loose bolts, nuts, mounting brackets,

or a loose clutch assembly. Verify accessory drive

belt tension (power steering or alternator).

Improper accessory drive belt tension can cause

a misleading noise when the compressor is

engaged and little or no noise when the compressor

is disengaged.

Drive belts are speed-sensitive. That is, at different

engine speeds, and depending upon belt tension,

belts can develop unusual noises that are often

mistaken for mechanical problems within the

compressor.ADJUSTMENT

1. Select a quiet area for testing. Duplicate

conditions as much as possible. Switch

compressor on and off several times to clearly

identify compressor noise. To duplicate high

ambient conditions (high head pressure),

restrict air flow through condenser. Install

manifold gauge set to make sure discharge

pressure doesn’t exceed 2,070 kPa.

2. Tighten all compressor mounting bolts, clutch

mounting bolt, and compressor drive belt.

Check to assure clutch coil is tight (no rotation

or wobble).

3. Check refrigerant hoses for rubbing or

interference that can cause unusual noises.

4. Check refrigerant charge. (See “Charging

System”.)

5. Recheck compressor noise as in Step 1.

6. If noise still exists, loosen compressor mounting

bolts and retorque. Repeat Step 1.

7. If noise continues, replace compressor and

repeat Step 1.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk