MITSUBISHI SPYDER 1990 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1771 of 2103

PARKING BRAKES, parking Brake Brake>

Shoe

Paint

Shoe-to-anchor spring (rear)

Forward

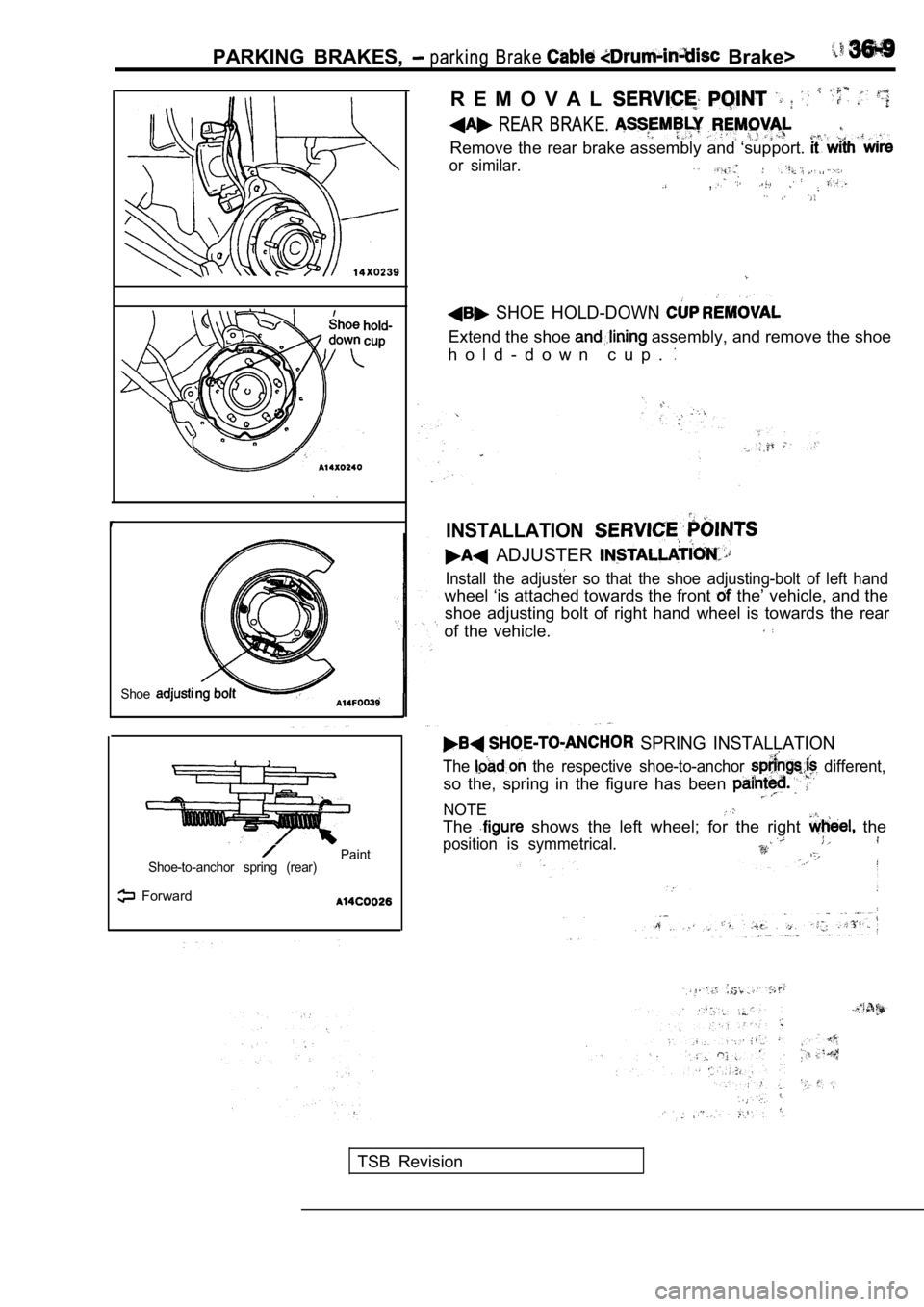

R E M O V A L

REAR BRAKE.

Remove the rear brake assembly and ‘support.

or similar.

,

SHOE HOLD-DOWN

Extend the shoe assembly, and remove the shoe

h o l d - d o w n c u p .

INSTALLATION

ADJUSTER

Install the adjuster so that the shoe adjusting-bol t of left hand

wheel ‘is attached towards the front the’ vehicle, and the

shoe adjusting bolt of right hand wheel is towards the rear

of the vehicle.

SPRING INSTALLATION

The the respective shoe-to-anchor different,

so the, spring in the figure has been

NOTE

The shows the left wheel; for the right the

position is symmetrical.

TSB Revision

Page 1772 of 2103

R E M O V A L A N D

Post-installation Operation ,

Parking Brake Lever Stroke Adjustment

(Refer to

54-65

36-43

grease .

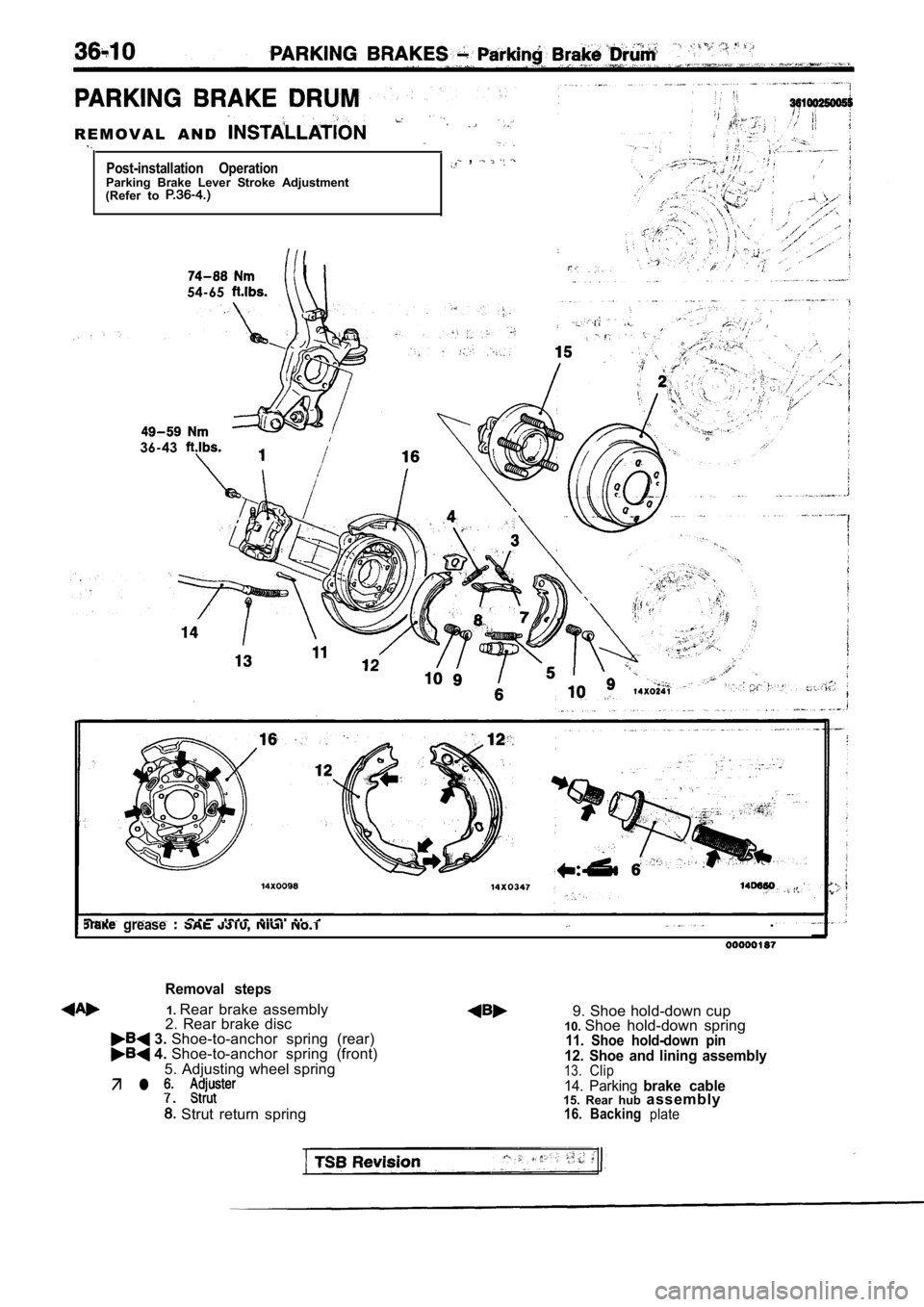

Removal steps

1. Rear brake assembly2. Rear brake disc 9. Shoe hold-down cup

10. Shoe hold-down spring 3. Shoe-to-anchor spring (rear) 4. Shoe-to-anchor spring (front)11. Shoe hold-down pin

5. Adjusting wheel spring12. Shoe and lining assembly13.Clip

Page 1773 of 2103

PARKING BRAKES

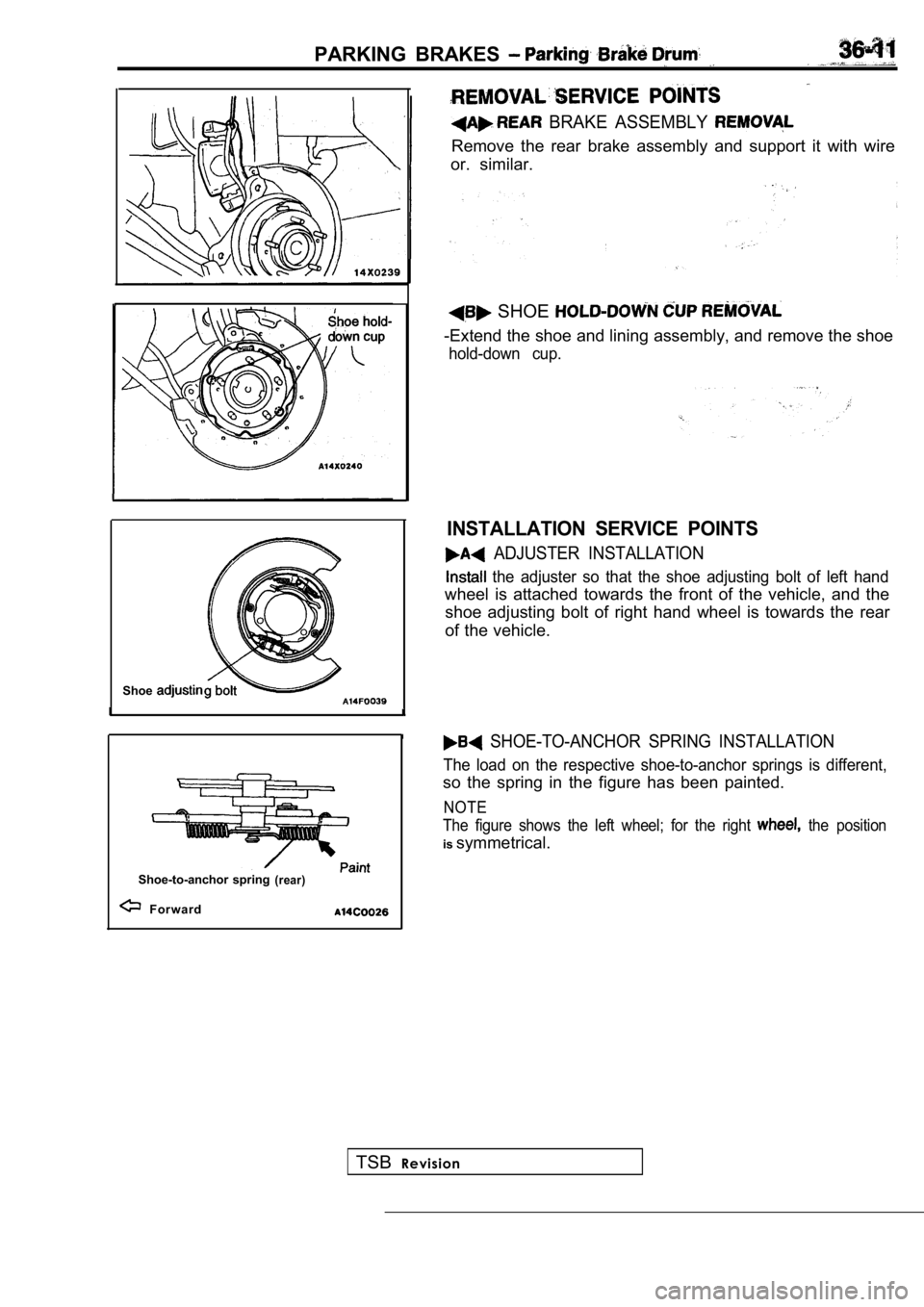

BRAKE ASSEMBLY

Remove the rear brake assembly and support it with wire

or. similar.

Shoe

Shoe-to-anchor spring(rear)

Forward

SHOE

-Extend the shoe and lining assembly, and remove th e shoe

hold-down cup.

INSTALLATION SERVICE POINTS

ADJUSTER INSTALLATION

the adjuster so that the shoe adjusting bolt of left hand

wheel is attached towards the front of the vehicle, and the

shoe adjusting bolt of right hand wheel is towards the rear

of the vehicle.

SHOE-TO-ANCHOR SPRING INSTALLATION

The load on the respective shoe-to-anchor springs i s different,

so the spring in the figure has been painted.

NOTE

The figure shows the left wheel; for the right

the position

is symmetrical.

TSB Revision

Page 1774 of 2103

PARKING BRAKES Parking Drum

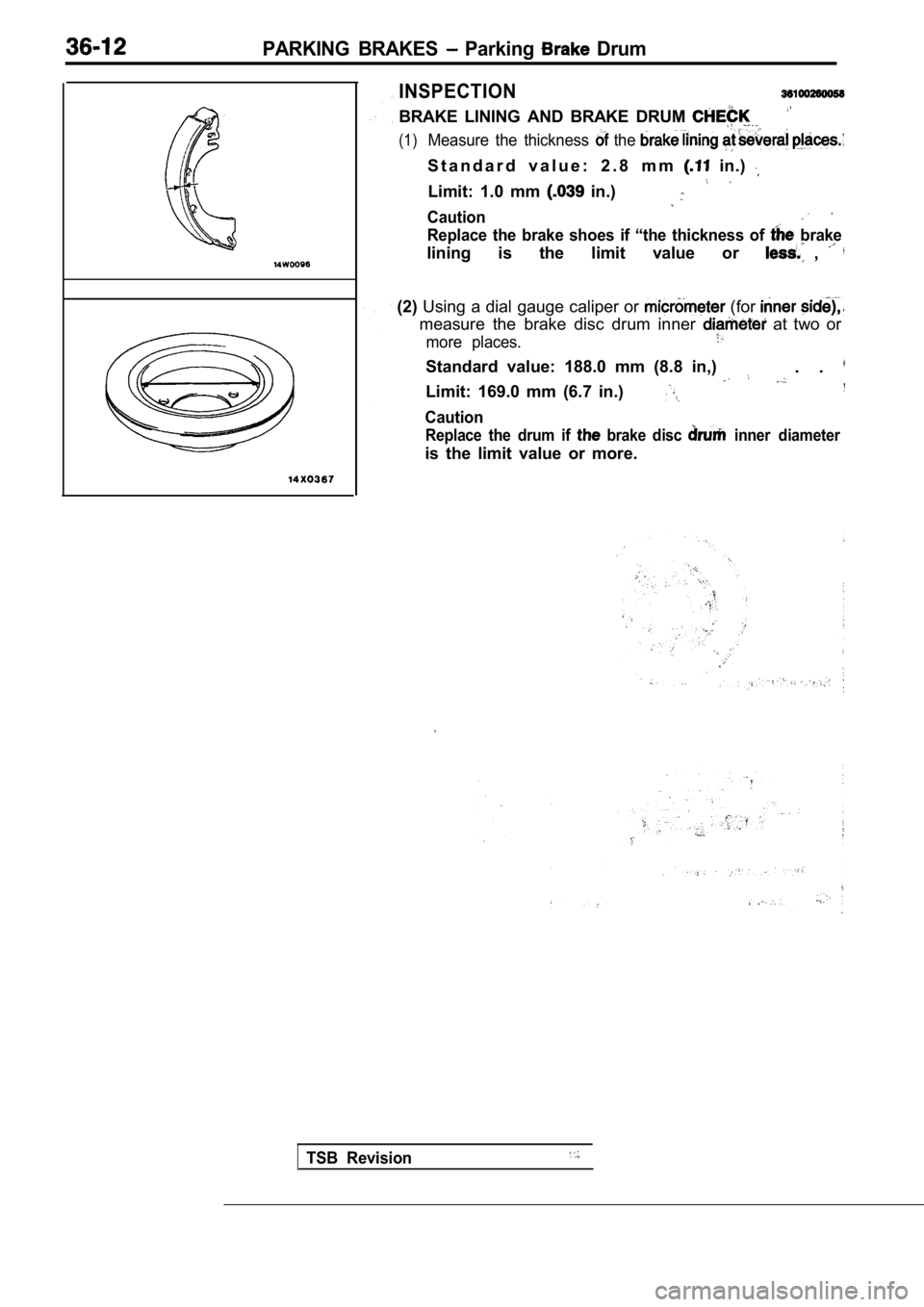

INSPECTION

BRAKE LINING AND BRAKE DRUM

(1)Measure the thickness the

S t a n d a r d v a l u e : 2 . 8 m m in.)

Limit: 1.0 mm in.)

Caution

Replace the brake shoes if “the thickness of brake

lining is the limit value or ,

(2)Using a dial gauge caliper or (for

measure the brake disc drum inner at two or

more places.

Standard value: 188.0 mm (8.8 in,). .

Limit: 169.0 mm (6.7 in.)

Caution

Replace the drum if brake disc inner diameter

is the limit value or more.

TSB Revision

Page 1775 of 2103

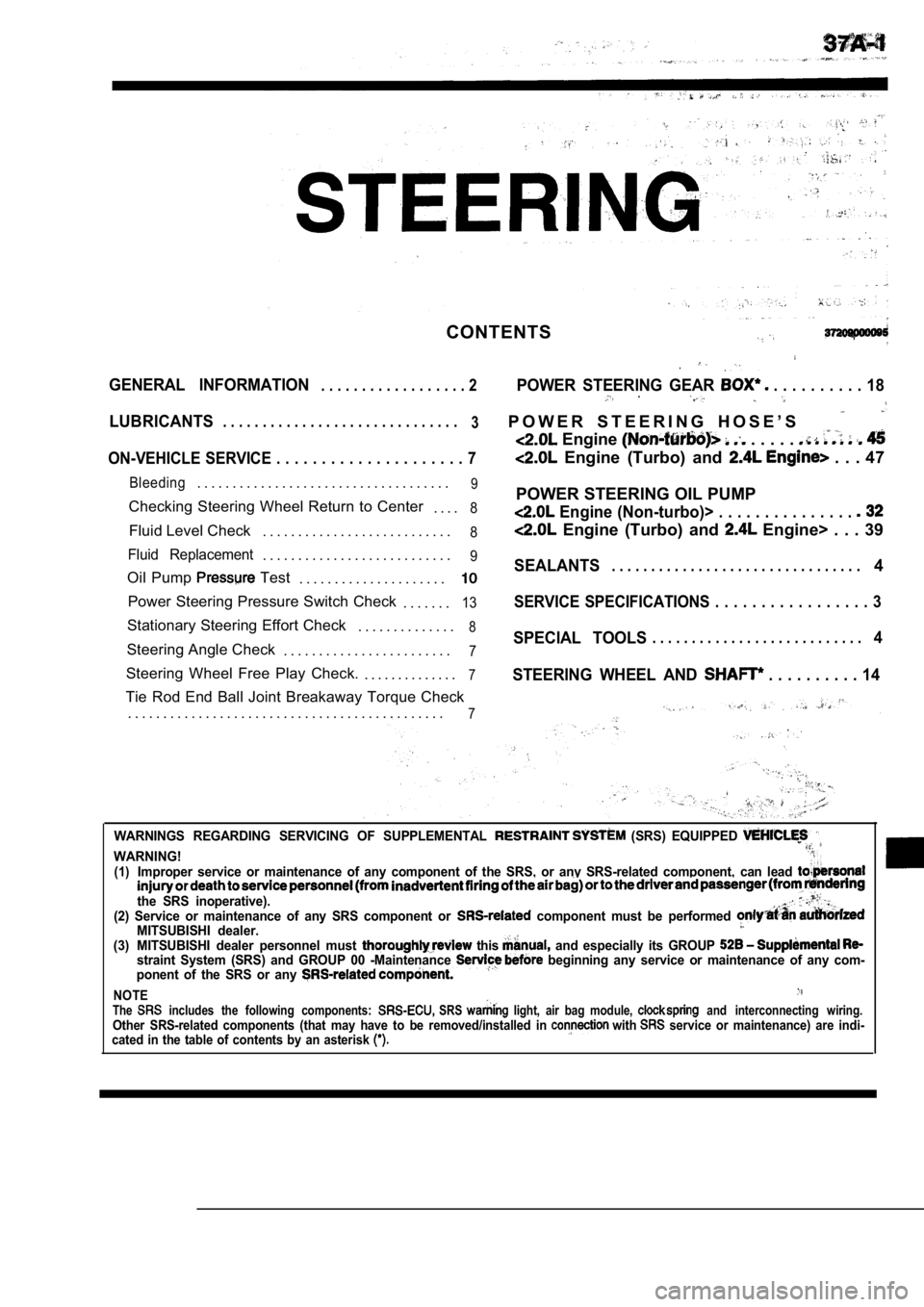

CONTENTS

GENERAL INFORMATION. . . . . . . . . . . . . . . . . . 2POWER STEERING GEAR . . . . . . . . . . 18

LUBRICANTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3P O W E R S T E E R I N G H O S E ’ S

Engine . . . . .

ON-VEHICLE SERVICE . . . . . . . . . . . . . . . . . . . . . 7 Engine (Turbo) and . . . 47

Bleeding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Checking Steering Wheel Return to Center

. . . .8

Fluid Level Check. . . . . . . . . . . . . . . . . . . . . . . . . . .8

Fluid Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . .9

Oil Pump Test

. . . . . . . . . . . . . . . . . . . . .

Power Steering Pressure Switch Check

. . . . . . .13

Stationary Steering Effort Check. . . . . . . . . . . . . .8

Steering Angle Check. . . . . . . . . . . . . . . . . . . . . . . .7

Steering Wheel Free Play Check. . . . . . . . . . . . . . .7

Tie Rod End Ball Joint Breakaway Torque Check

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7

POWER STEERING OIL PUMP

Engine (Non-turbo)> . . . . . . . . . . . . . . .

Engine (Turbo) and Engine> . . . 39

SEALANTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

SERVICE SPECIFICATIONS . . . . . . . . . . . . . . . . . 3

SPECIAL TOOLS. . . . . . . . . . . . . . . . . . . . . . . . . . .4

STEERING WHEEL AND

. . . . . . . . . . 14

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL (SRS) EQUIPPED

WARNING!(1)Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead

the SRS inoperative).(2) Service or maintenance of any SRS component or component must be performed MITSUBISHI dealer.(3) MITSUBISHI dealer personnel must this and especially its GROUP straint System (SRS) and GROUP 00 -Maintenance beginning any service or maintenance of any com-

ponent of the SRS or any

NOTEThe includes the following components: SRS light, air bag module, and interconnecting wiring.Other SRS-related components (that may have to be r emoved/installed in with service or maintenance) are indi-

cated in the table of contents by an asterisk

Page 1776 of 2103

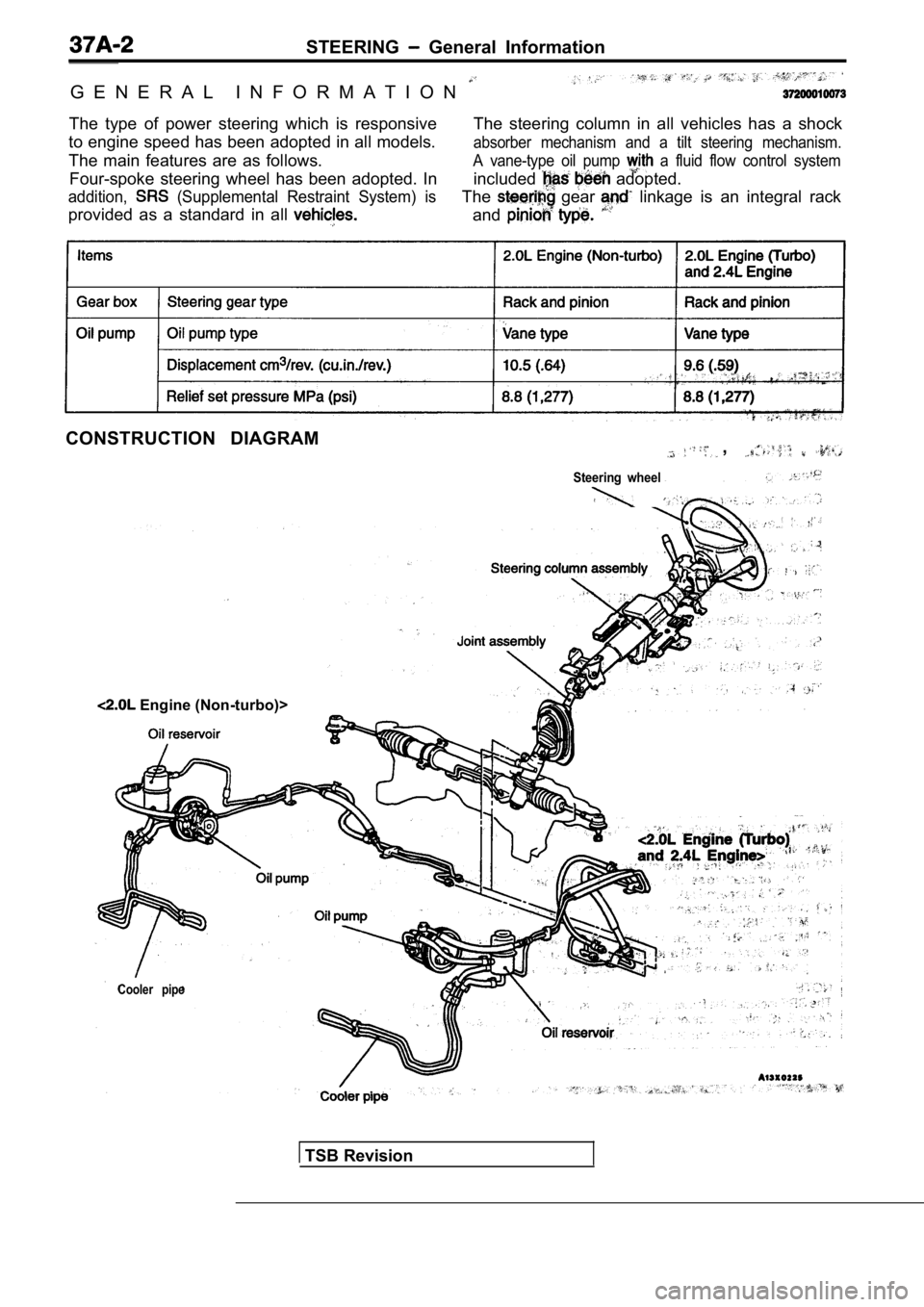

STEERING General Information

G E N E R A L I N F O R M A T I O N

The type of power steering which is responsive

to engine speed has been adopted in all models.

The main features are as follows. The steering column in all vehicles has a shock

absorber mechanism and a tilt steering mechanism.

Four-spoke steering wheel has been adopted. In

A vane-type oil pump a fluid flow control system

addition, (Supplemental Restraint System) is

included adopted.

provided as a standard in all

The gear linkage is an integral rack

and

CONSTRUCTION DIAGRAM,

Steering wheel

Cooler pipe

Engine (Non-turbo)>

TSB Revision

Page 1777 of 2103

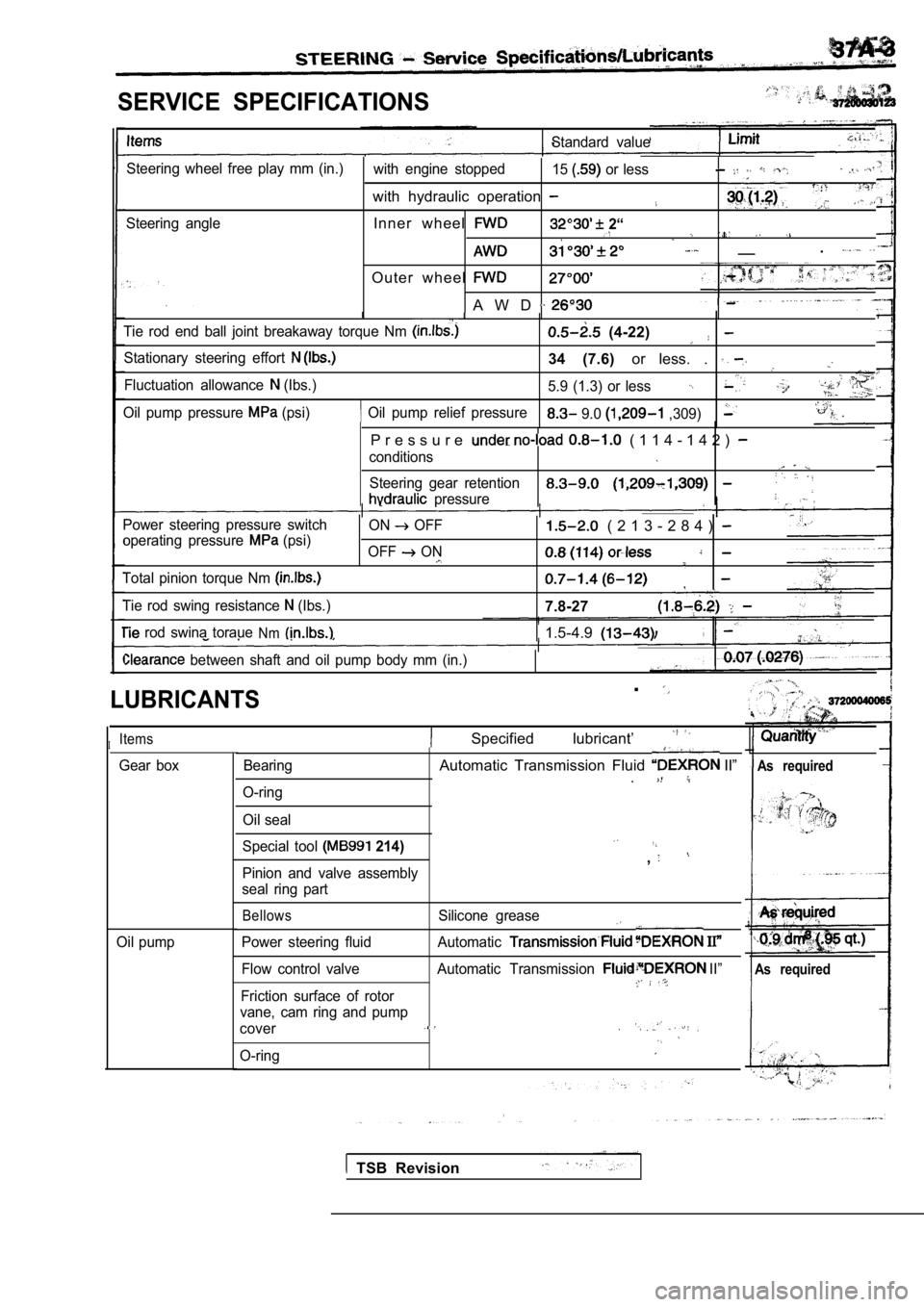

SERVICE SPECIFICATIONS

Standard value

Steering wheel free play mm (in.) with engine stopped15

or less,

with hydraulic operation

Steering angleInner wheel 2“

__

.

O u t e r w h e e l

A W D

Tie rod end ball joint breakaway torque Nm (4-22)

Stationary steering effort 34 (7.6) or less. .

Fluctuation allowance (Ibs.)

5.9 (1.3) or less

Oil pump relief pressureOil pump pressure (psi) 9.0 ,309)

P r e s s u r e ( 1 1 4 - 1 4 2 )

conditions

Steering gear retention

pressure

Power steering pressure switch

operating pressure

(psi)

Total pinion torque Nm

Tie rod swing resistance (Ibs.) ON

OFF

OFF

ON

( 2 1 3 - 2 8 4 )

7.8-27

rod swina toraueNm1.5-4.9

between shaft and oil pump body mm (in.)

LUBRICANTS

IItems

Bearing

O-ring

Oil seal

.

Specified lubricant’

Gear boxAutomatic Transmission Fluid II”

.As required

Oil pump Special tool

214)

Pinion and valve assembly

seal ring part

,

BellowsSilicone grease

Power steering fluid Automatic

Flow control valve Automatic Transmission II”

Friction surface of rotor

vane, cam ring and pump

cover.

O-ring

As required

TSB Revision

Page 1778 of 2103

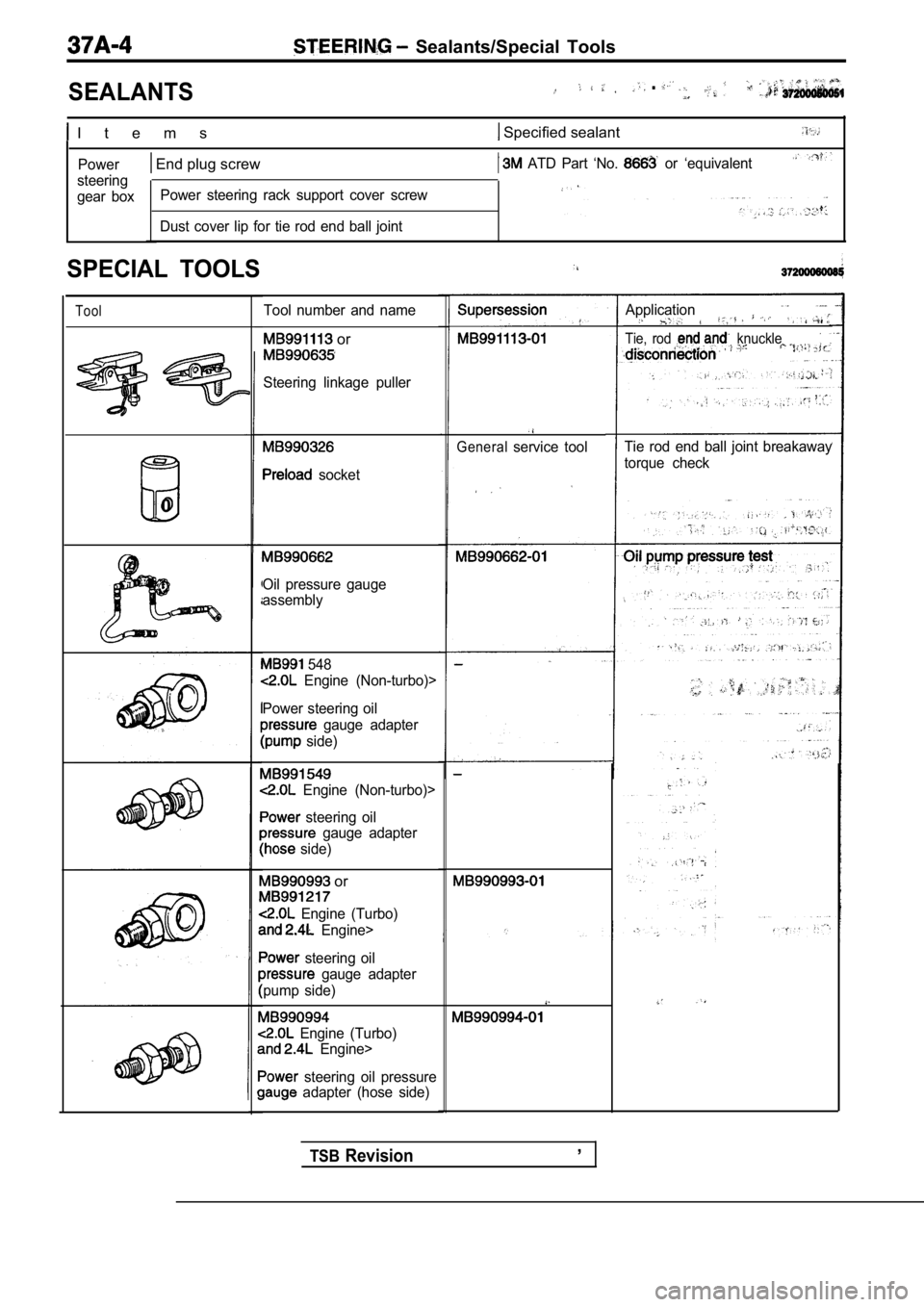

SEALANTS

Sealants/Special Tools

.

I t e m s Specified sealant

Power

steering

gear box End plug screw ATD Part ‘No. or ‘equivalent

Power steering rack support cover screw

Dust cover lip for tie rod end ball joint

SPECIAL TOOLS

Tool

0

Tool number and name

or

Steering linkage puller

socket

Oil pressure gauge

assembly

548

Engine (Non-turbo)>

Power steering oil

gauge adapter

side)

Engine (Non-turbo)>

steering oil

gauge adapter

side)

or

Engine (Turbo)

Engine>

steering oil

gauge adapter

pump side)

Engine (Turbo)

Engine>

steering oil pressure adapter (hose side)

Generalservice tool

TSBRevision,

Application

Tie, rod knuckle

Tie rod end ball joint breakaway

torque check

Page 1779 of 2103

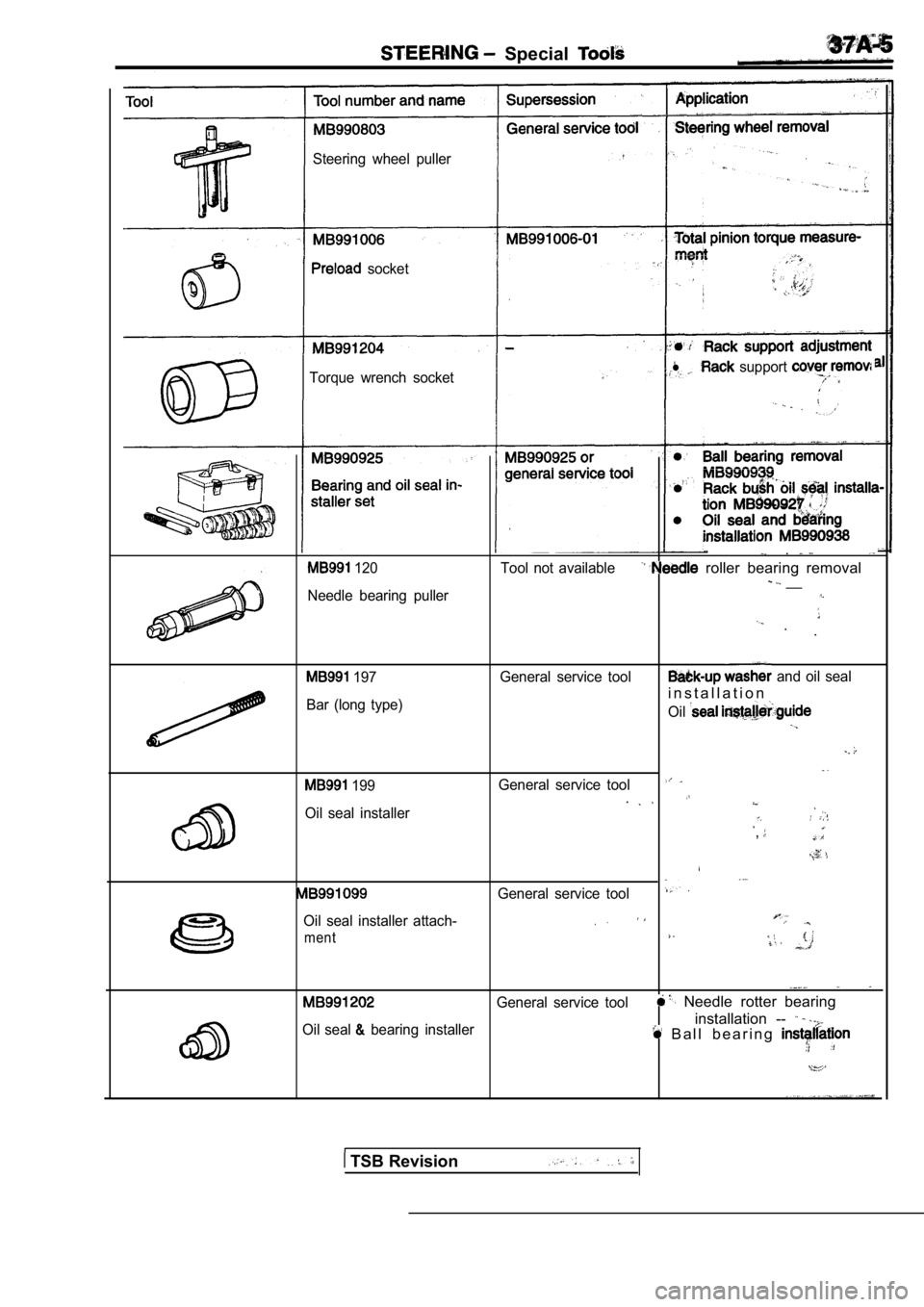

Special

Steering wheel puller

socket

Torque wrench socket

l support

120

Needle bearing puller

.

Tool not available roller bearing removal __

. .

197

Bar (long type) General service tool and oil seal

i n s t a l l a t i o n

Oil

199

Oil seal installerGeneral service tool

,

General service tool

Oil seal installer attach-

ment

General service tool Needle rotter bearing

Oil seal bearing installerinstallation -- B a l l b e a r i n g

TSB Revision

Page 1780 of 2103

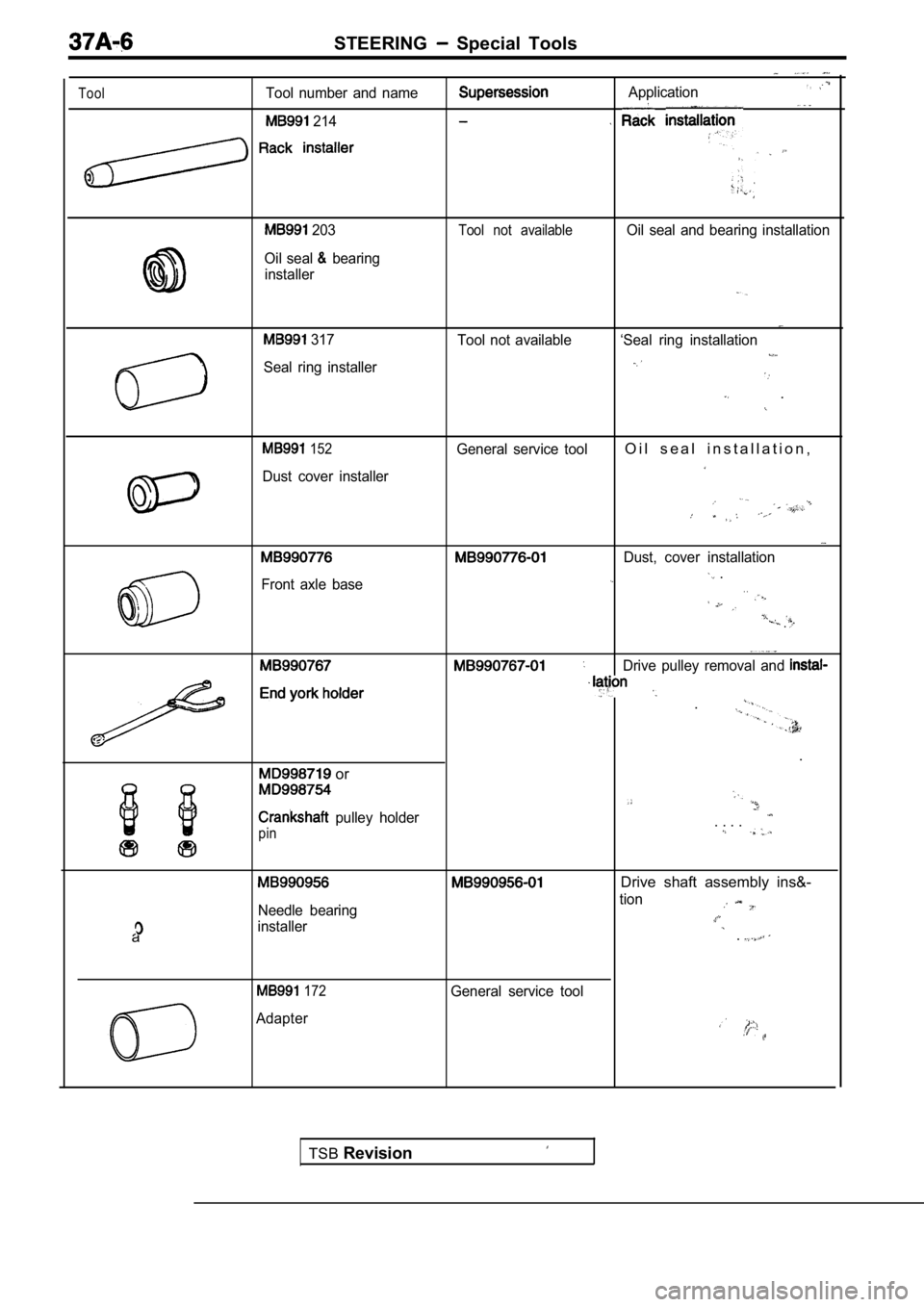

STEERING Special Tools

ToolTool number and name

214

203

Oil seal bearing

installer

Application

.

Tool not availableOil seal and bearing installation

317 Tool not available ‘Seal ring installation

Seal ring installer

.

152General service toolO i l s e a l i n s t a l l a t i o n ,

Dust cover installer

Dust, cover installation

Front axle base .. .

.

Drive pulley removal and

.

.

or

pulley holder. . . .pin

a

Needle bearing

installer

Drive shaft assembly ins&-

tion

.

172

Adapter General service tool

TSB

Revision