brake NISSAN 300ZX 1984 Z31 Automatic Transmission User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1984, Model line: 300ZX, Model: NISSAN 300ZX 1984 Z31Pages: 99, PDF Size: 3.09 MB

Page 55 of 99

![NISSAN 300ZX 1984 Z31 Automatic Transmission User Guide ASSEMBLY ~

Total

end play

Totql end play = [B - 0 1 mm (0.004 in)] - C

Specified total end play:

0 25 - 0.50 mm

(0.0098 - 0.0197 in)

Total end play can be adjusted with bearing race

Avail NISSAN 300ZX 1984 Z31 Automatic Transmission User Guide ASSEMBLY ~

Total

end play

Totql end play = [B - 0 1 mm (0.004 in)] - C

Specified total end play:

0 25 - 0.50 mm

(0.0098 - 0.0197 in)

Total end play can be adjusted with bearing race

Avail](/img/5/563/w960_563-54.png)

ASSEMBLY ~

Total

end play

Totql end play = [B - 0 1 mm (0.004 in)] - C

Specified total end play:

0 25 - 0.50 mm

(0.0098 - 0.0197 in)

Total end play can be adjusted with bearing race

Available oil pump cover bearing race

Thickness rnm (in)

1 2 (0 0471

1

4 (0055)

16 (0.0631

18 (0071)

20

(0 079)

22

(00871

Pan number

31556-X0100 31556-XOlO1

31 556-X0102

31 556-XO103

31 556-XO104

31 556-XO105

17 Install brake band, band strut, and band servo.

Lubricate servo O-rings before installing

SAT066

18 Install and torque the retainer bolts. Loosen

piston stem.

,GG91060000

19 Finger tighten brake band servo piston stem

enough to prevent brake band and

strut from

falling out

Do not adjust brake band at this time.

SAT068

20 Apply vaseline to bearing race and thrust

washer, then mount them

on drum support

e- Bearing race

SA1573

AT-55

Page 58 of 99

ASSEMBLY

15 (0 059)

17 (0 067)

19 (0 075)

2 1 (0 083)

2.3 (0 091)

25 (0098)

2 7 (0 106)

Available 0 D thrust washer

3 1528-XO106

31 528-XO105

31528-X0100

31 528-X0101

31 528-XO102

31528-XO103

31 528-XO104

Thickness mm (in) I Part number

Thickness mm (in) Part number

1 2 (0.047)

14 (0 055)

16 (0063)

18

(0071)

20 (0079)

22 (0087)

31556-X0100

3 1556-X0101

31556-X0102

31 556-XO103

31 556.X0104

31 556-XOlO5

26. Adjust 2nd brake band. Tighten piston stem to

the specified value Back off two full turns and

secure with lock nut

SAT580

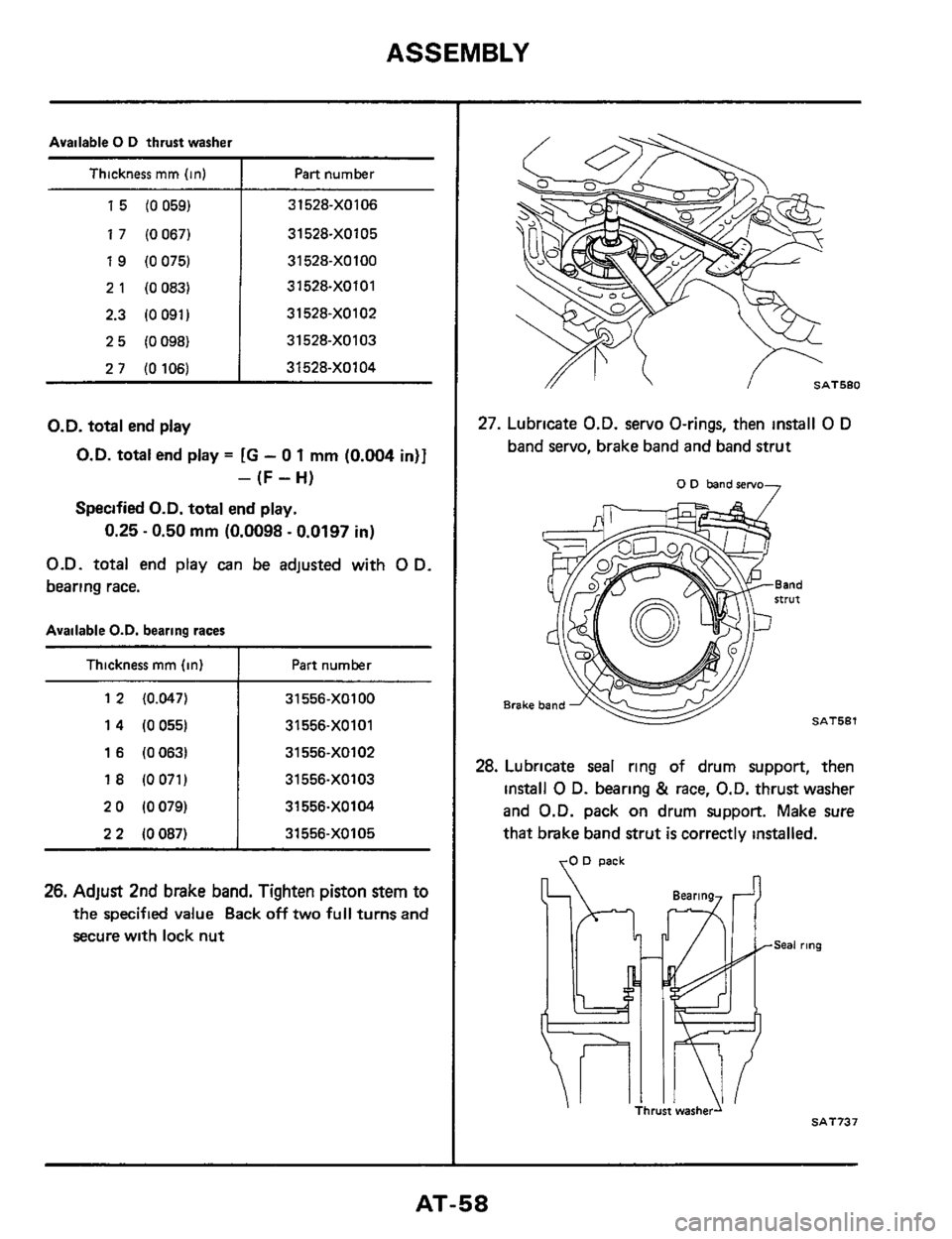

27. Lubricate O.D. servo O-rings, then install 0 D

band servo, brake band and band strut

7 0 D band %NO

SAT581

28. Lubricate seal ring of drum support, then

install

0 D. bearing & race, O.D. thrust washer

and

O.D. pack on drum support. Make sure

that brake band strut

is correctly installed.

70 D pack

AT-58

Page 60 of 99

ASSEMBLY

Air check point

Governor feed (From

valve) Forward clutch Control

LOW & reverse

brake

SAT586

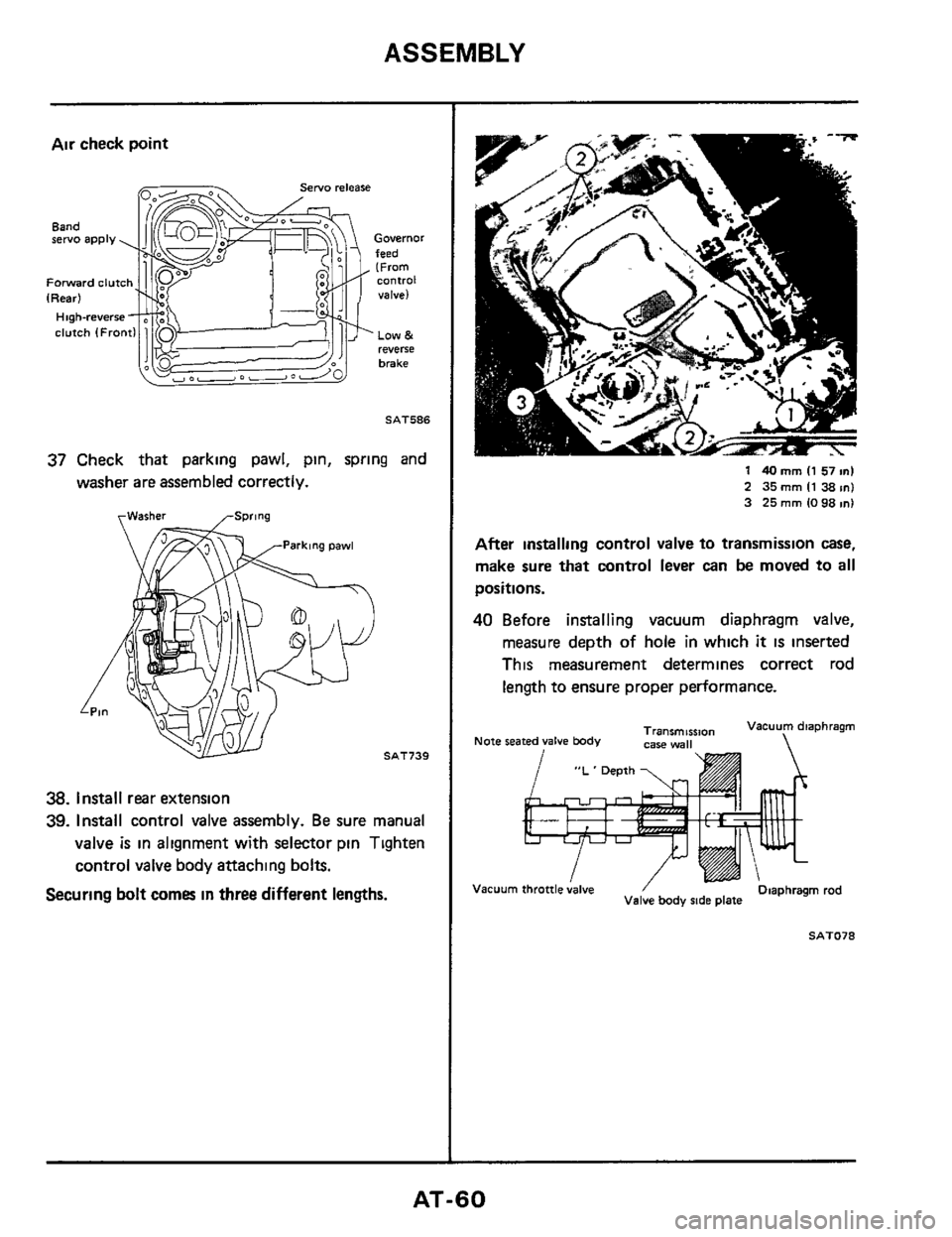

37 Check that parking pawl, pin, spring and

washer are assembled correctly.

rWasher

SAT739

38. Install rear extension

39. Install control valve assembly. Be sure manual

valve

is in alignment with selector pin Tighten

control valve

body attaching bolts.

Securing bolt comes in three different lengths.

1 40 mm I1 57 ml

2 35 mm I1 38 m) 3 25 mm IO 98 1n1

After installing control valve to transmission case,

make sure that control lever can be moved to all

positions.

40 Before installing vacuum diaphragm valve,

measure depth of hole in which

it is inserted

This measurement determines correct rod

length to ensure proper performance.

"L ' Depth

Vacuum Diaphragm rod , throttle;alve / Valve body ride plate

AT-60

Page 63 of 99

TROUBLE-SHOOTING AND DIAGNOSES

Preliminary Checks

(Prior to Road Testing)

FLUID LEAKAGE

To detect a fluid leak

1) Raise vehicle

2) Clean area suspected of leaking

3) Start engine, apply foot brake, place control

lever in drive, and wait a few minutes

4) Stop engine

5) Check for fresh leakage

FLUID CONDITION

Examine the AT F and note its color, texture,

and odor

1) Dark of Black Fluid

With a burned odor

- Worn friction material

2) Milky Pink Fluid Water Contamination

- Road water entering through filler

tube or breather

3) Varnished Fluid, light to dark brown and

tacky Oxidation

- Over or Underfilling

- Overheating

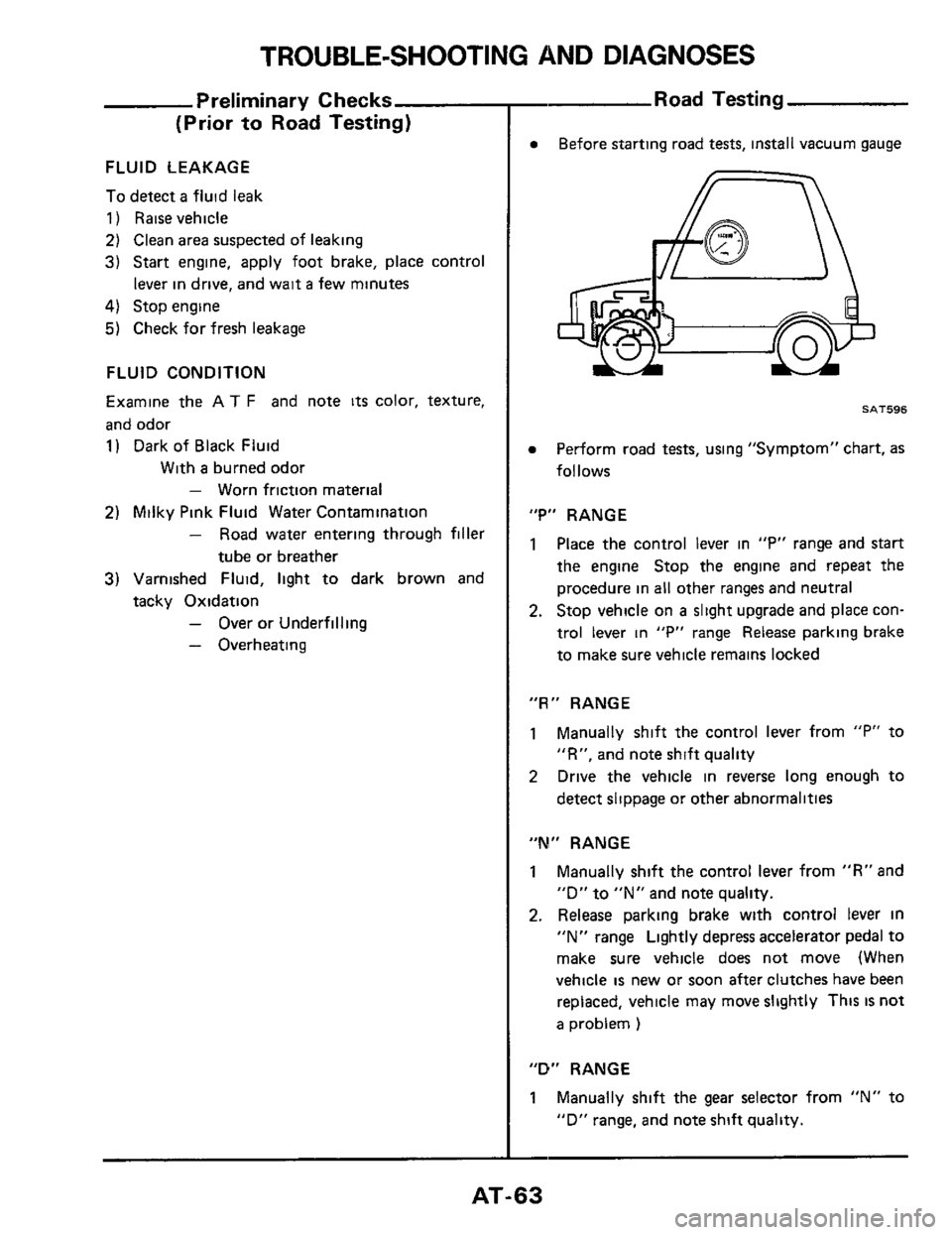

- Road Testing

Before starting road tests, install vacuum gauge

SAT596

Perform road tests, using "Symptom" chart, as

follows

"P" RANGE

1 Place the control lever in "P" range and start

the engine Stop the engine and repeat the

procedure in all other ranges and neutral

2. Stop vehicle on a slight upgrade and place con-

trol lever

in "P" range Release parking brake

to make sure vehicle remains locked

"R" RANGE

1 Manually shift the control lever from "P" to

"R", and note shift quality

2 Drive the vehicle in reverse long enough to

detect slippage or other abnormalities

"M" RANGE

1 Manually shift the control lever from "R" and

"D"

to "N" and note quality.

2. Release parking brake with control lever in

"N" range Lightly depress accelerator pedal to

make sure vehicle does not move (When

vehicle

is new or soon after clutches have been

replaced, vehicle may move slightly This

IS not

a problem )

"D" RANGE

1 Manually shift the gear selector from "N" to

"D" range, and note shift quality.

-

AT-63

Page 64 of 99

TROUBLE-SHOOTING AND DIAGNOSES

Road Test

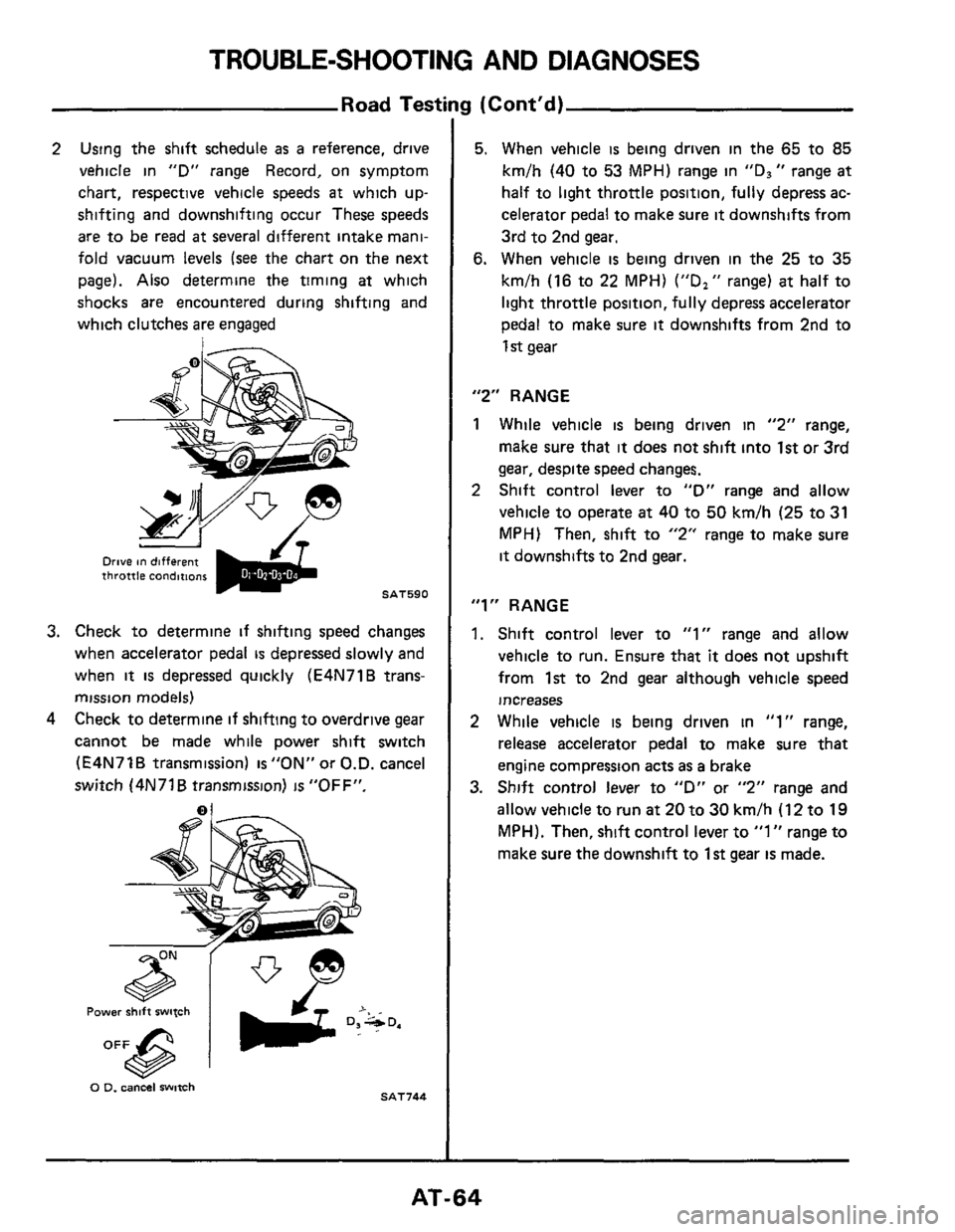

2 Using the shift schedule as a reference, drive

vehicle in

"D" range Record, on symptom

chart, respective vehicle speeds

at which up-

shifting and downshifting occur These speeds

are to be read at several different intake mani-

fold vacuum levels

(see the chart on the next

page). Also determine the timing

at which

shocks are encountered during shifting and

which clutches

are engaged

Drive on different throttle condirtom

SAT590

3. Check to determine if shifting speed changes

when accelerator pedal

is depressed slowly and

when

it is depressed quickly (E4N71B trans-

mission models)

4 Check to determine if shifting to overdrive gear

cannot be made while power shift switch

(E4N71B transmission) is"0N" or

O.D. cancel

switch (4N71

B transmission) is "OFF".

0 0. cancel witch SAT744

3 (Cont'd)

5. When vehicle is being driven in the 65 to 85

km/h (40 to 53 MPH) range in "Ds" range at

half to light throttle position, fully depress ac-

celerator pedal to make sure

it downshifts from

3rd to 2nd

gear.

6. When vehicle is being driven in the 25 to 35

km/h (16 to 22 MPH) ("D," range) at half to

light throttle position, fully depress accelerator

pedal to make sure

it downshifts from 2nd to

1 st gear

"2" RANGE

1 While vehicle is being driven in "2" range,

make sure that

it does not shift into 1st or 3rd

gear, despite speed changes.

2 Shift control lever to "D" range and allow

vehicle to operate

at 40 to 50 km/h (25 to 31

MPH) Then, shift to "2" range to make sure

it downshifts to 2nd gear.

"1" RANGE

1. Shift control lever to "1" range and allow

vehicle to run. Ensure

that it does not upshift

from 1st to 2nd gear although vehicle speed

increases

2 While vehicle is being driven in "1" range,

release accelerator pedal

to make sure that

engine compression acts

as a brake

3. Shift control lever to "D" or "2" range and

allow vehicle to run

at 20 to 30 km/h (12 to 19

MPH). Then, shift control lever to "1" range to

make sure the downshift to 1st gear is made.

AT-64

Page 76 of 99

TROUBLE-SHOOTING AND DIAGNOSES

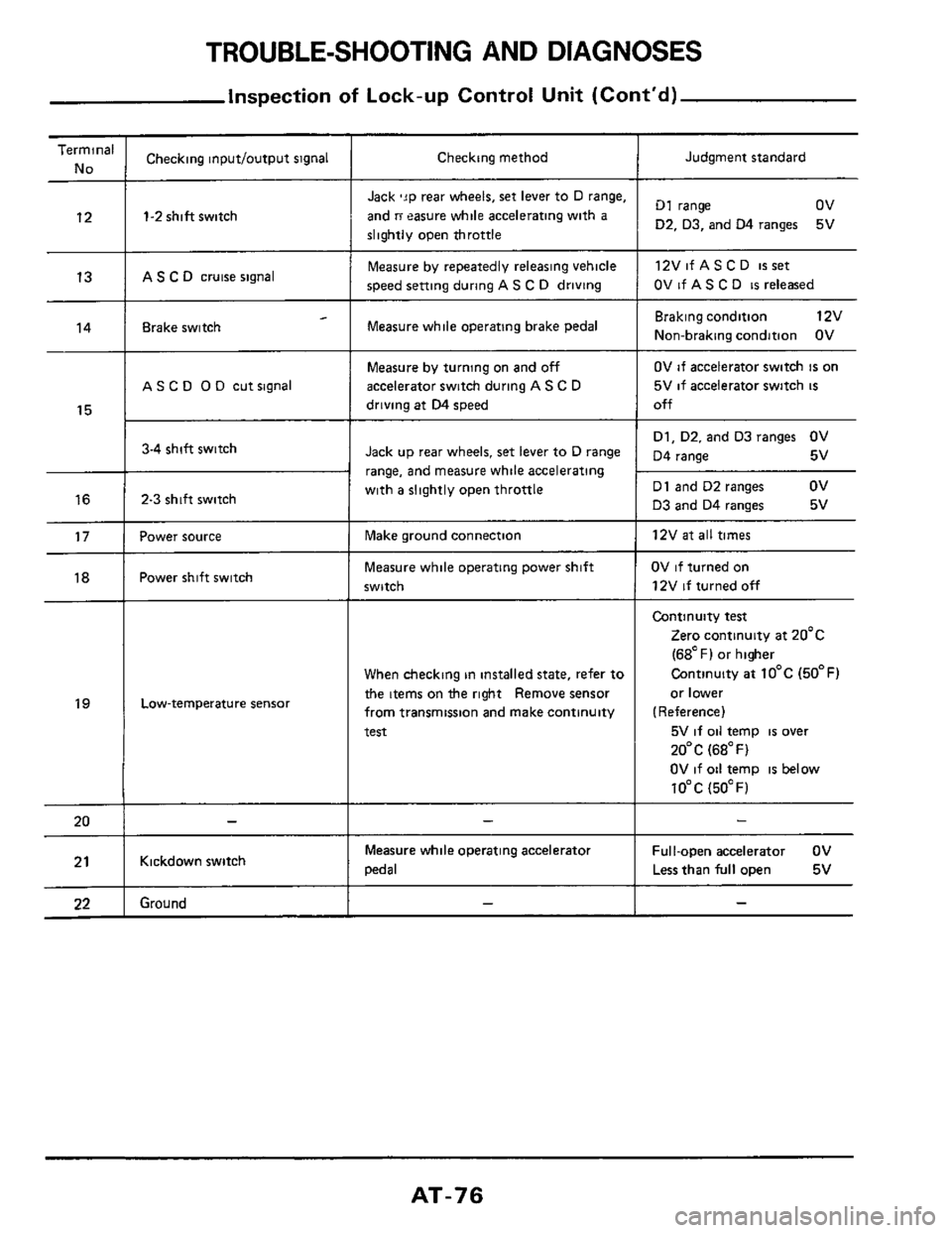

Inspection of Lock-up Control Unit (Cont'd)

Terminal

No

12

13

14

15

16

17

18

19

20

21

22

___

Checking inputloutput signal

1-2 shift switch

AS C D cruise signal

- Brake switch

A S C 0 0 D cut signal

3-4 shift switch

2-3 shift switch

Power source

Power shift switch

Low-temperature sensor

Kickdown switch

Ground

Checking method

Jack 'JP rear wheels, set lever to D range,

and

ri easure while accelerating with a

slightly open throttle

Measure by repeatedly releasing vehicle

speed setting during

AS C D driving

Measure while operating brake pedal

Measure by turning on and off

accelerator switch during A S C D

driving at D4 speed

Jack up rear wheels, set lever to D range

range,

and measure while accelerating

with

a slightly open throttle

Make ground connection

Measure while operating power shift

switch

When checking in installed state, refer to

the items on the right Remove sensor

from transmission and make continuity

test

Measure while operating acceleratoi

pedal

Judgment standard

D1 range ov

D2. D3, and 04 ranges

12VifASCD

isset

OV if AS C D is released

5V

Braking condition 12v

Non-braking condition OV

OV if accelerator switch is on

5V

if accelerator switch is

off

D1, D2. and D3 ranges OV

D4 range 5v

D1 and D2 ranges

ov

D3 and D4 ranges 5v

12V

at all times

OV if turned on

12V

if turned off

Continuity test

Zero continuity at 20'c

(68OF) or higher

Continuity

at 10°C (50°F)

or lower

(Reference)

5V

if oil temp is over

20°C (68°F)

OV if oil temp

is below

10°C (5OOF)

Ful I-open accelerator OV

Less than

full open 5v

AT-76

Page 80 of 99

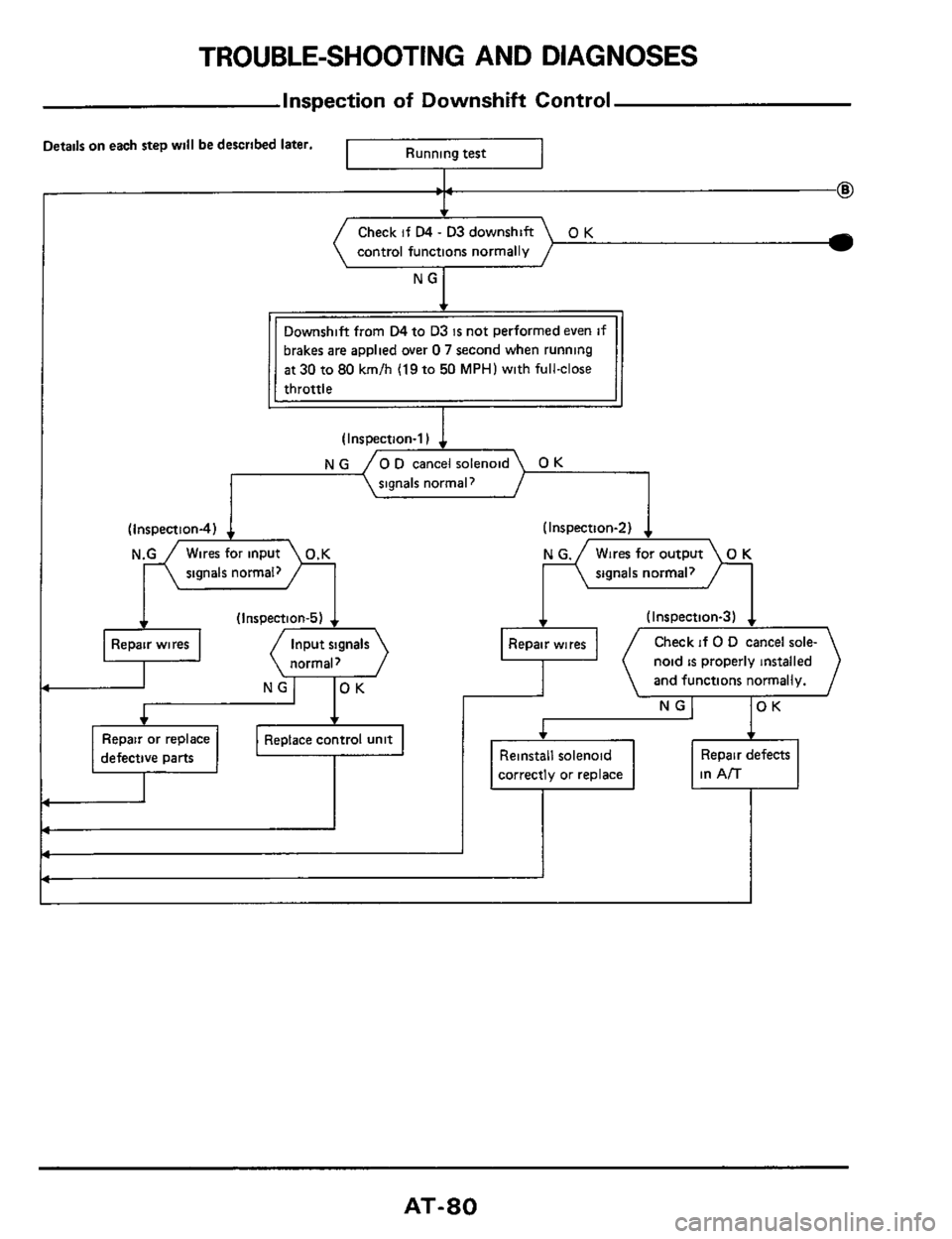

TROUBLE-SHOOTING AND DIAGNOSES

Inspection of Downshift Control

Details on each step will be described later.

I Running test

Check if D4 - D3 downshift

control functions normally 0 K

brakes are applied over 0 7 second when running

at 30 to 80 kmlh (19 to 50 MPH) with full-close

throttle

(Inspection-1) 1.

N G 0 D cancel solenoid 0 K

signals normal7

(Inspection-4)

P I

signals normal?

(~nspection-3) 4

Repair wires Check if 0 D cancel sole-

noid

is properly installed

and functions normally.

NG OK

Repair defects

AT-80

Page 81 of 99

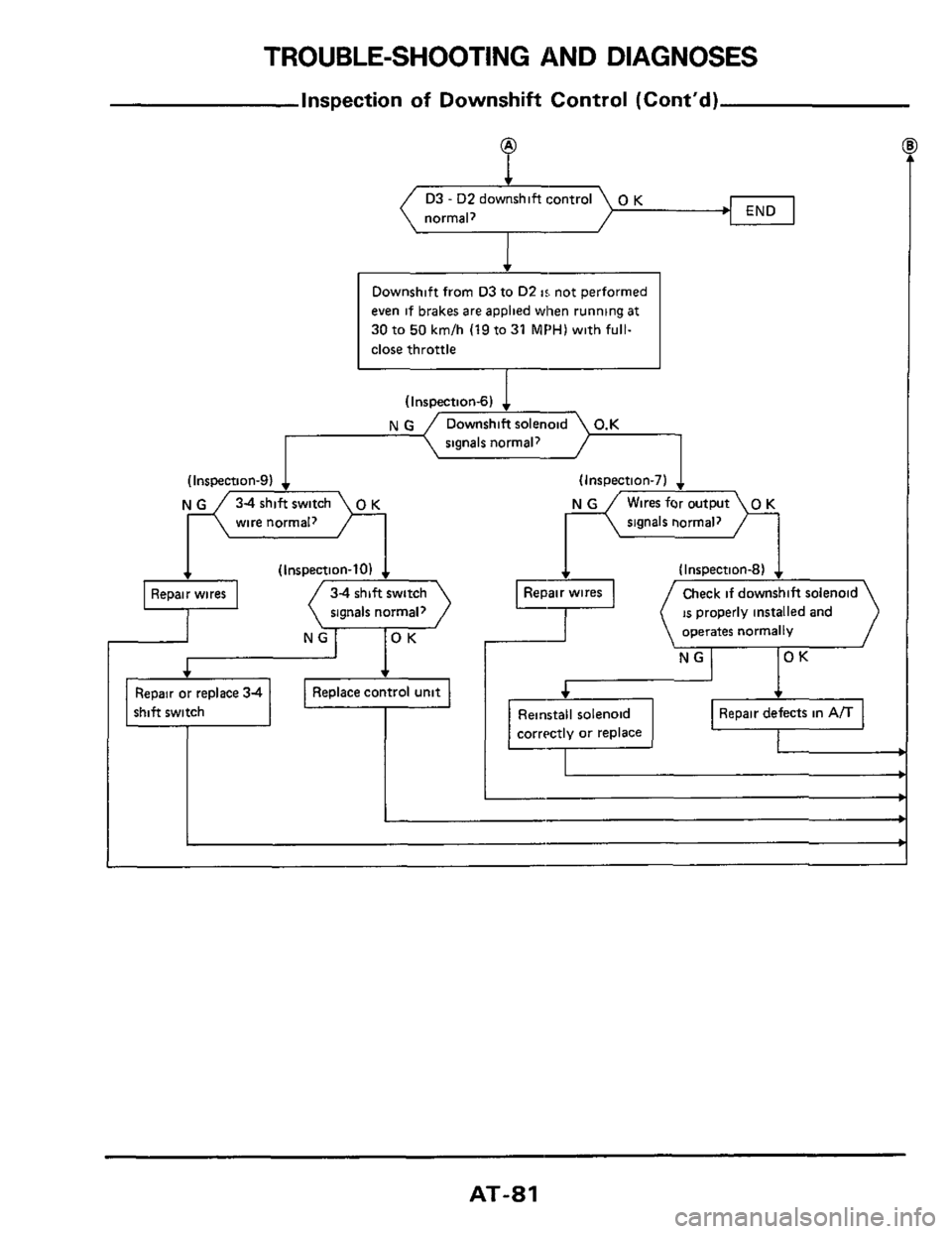

TROUBLE-SHOOTING AND DIAGNOSES

Inspection of Downshift Control (Cont‘d)

D3 - D2 downshift control

normal, 0 K END

Downshift from D3 to D2 is, not performed

even

if brakes are applied when running at

30 to 50 km/h (19 to 31 MPH) with full-

close throttle

(Inspection-6) 1

, NG(-G*

signals normal?

(Inspection-9) 4

N G 34 shift switch

wire normal?

1 Inspection-10)

signals normal7

~~nspection-7) 1

signals normal)

‘1

Repair or replace 34

shift switch

Check if downshift solenoid

IS properly installed and

operates normally

corrrctly or replace

AT-81

Page 82 of 99

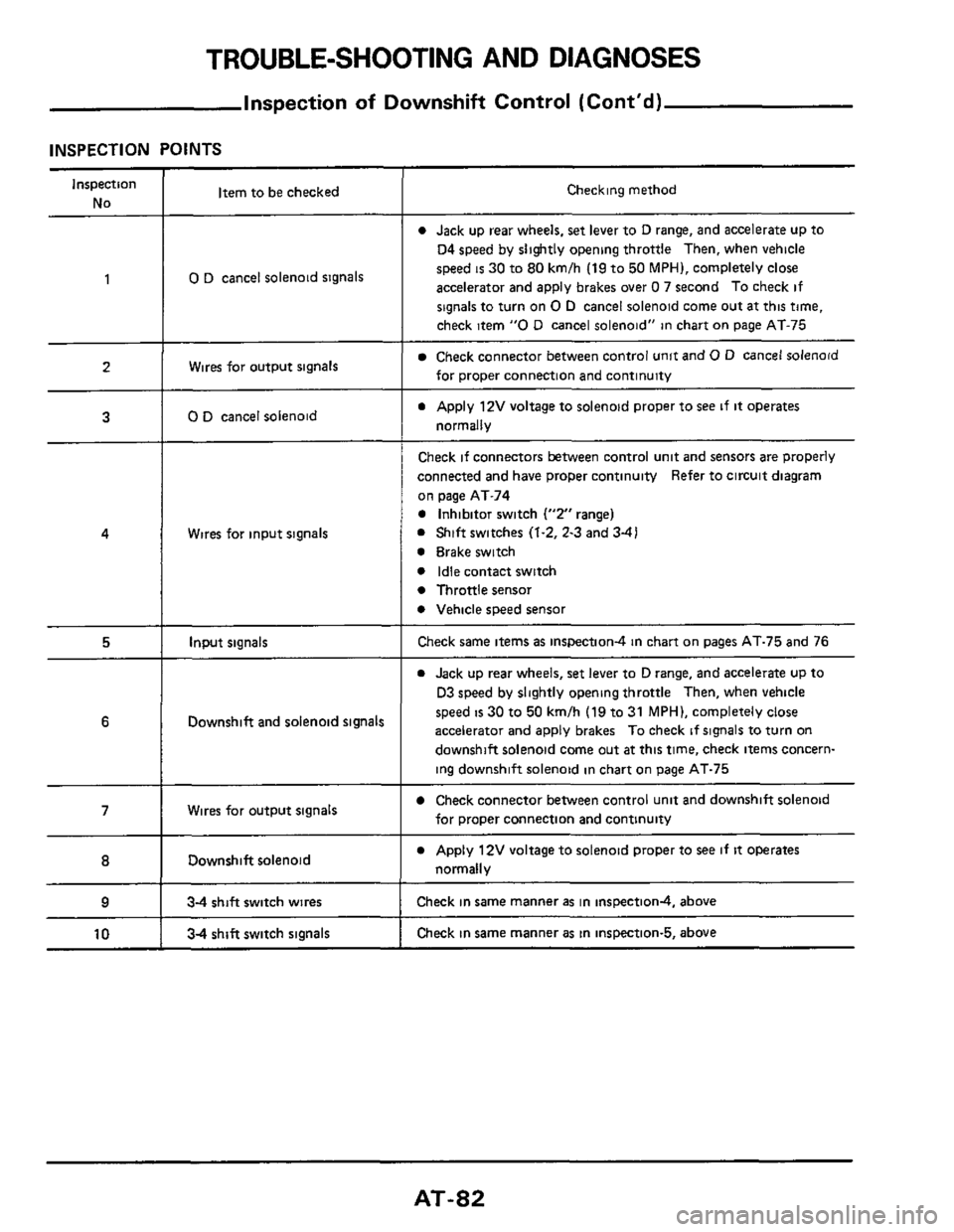

TROUBLE-SHOOTING AND DIAGNOSES

Inspection of Downshift Control (Cont'd)

INSPECTION POINTS

Inspection

No Item to be checked Checking method

0 Jack up rear wheels, set lever to D range, and accelerate up to

04 speed by slightly opening throttle Then, when vehicle

speed

is 30 to 80 kmlh (19 to 50 MPH), completely close

accelerator and apply brakes over

0 7 second To check if

signals to turn on

0 D cancel solenoid come out at this time,

check item

"0 D cancel solenoid" in chart on page AT-75

1 0 D cancel solenoid signals

Wires for output signals Check connector between control unit and 0 D cancel solenoid

for proper connection and continuity

a Apply 12V voltage to solenoid proper to see if it operates

normally

2

3 0 D cancel solenoid

Wires for input signals

Check if connectors between control unit and sensors are properly

connected and have proper continuity Refer to circuit diagram

on page AT-74

0 Inhibitor switch ("2" range)

0 Shift switches (1.2, 2-3 and 3-41

0 Brake switch

0 Idle contact switch

0 Throttle sensor

0 Vehicle speed sensor

4

5 Input signals Check same items as inspection4 in chart on pages AT-75 and 76

0 Jack up rear wheels, set lever to D range, and accelerate up to

D3 speed by slightly opening throttle Then, when vehicle

speed

is 30 to 50 kmlh (19 to 31 MPH), completely close

accelerator and apply brakes To check

if signals to turn on

downshift solenoid come out

at this time, check items concern-

ing downshift solenoid in chart on page AT-75

6 Downshift and solenoid signals

Check connector between control unit and downshift solenoid

for proper connection and continuity 7 Wires for output signals

Downshift solenoid

___ ~~ ~~~

0 Apply 12V voltage to solenoid proper to see if it operates

normally 8

9 34 shift switch wires Check in same manner as in inspectiond, above

Check in same manner

as in inspection-5, above 10 34 shift switch signals

AT-82

Page 88 of 99

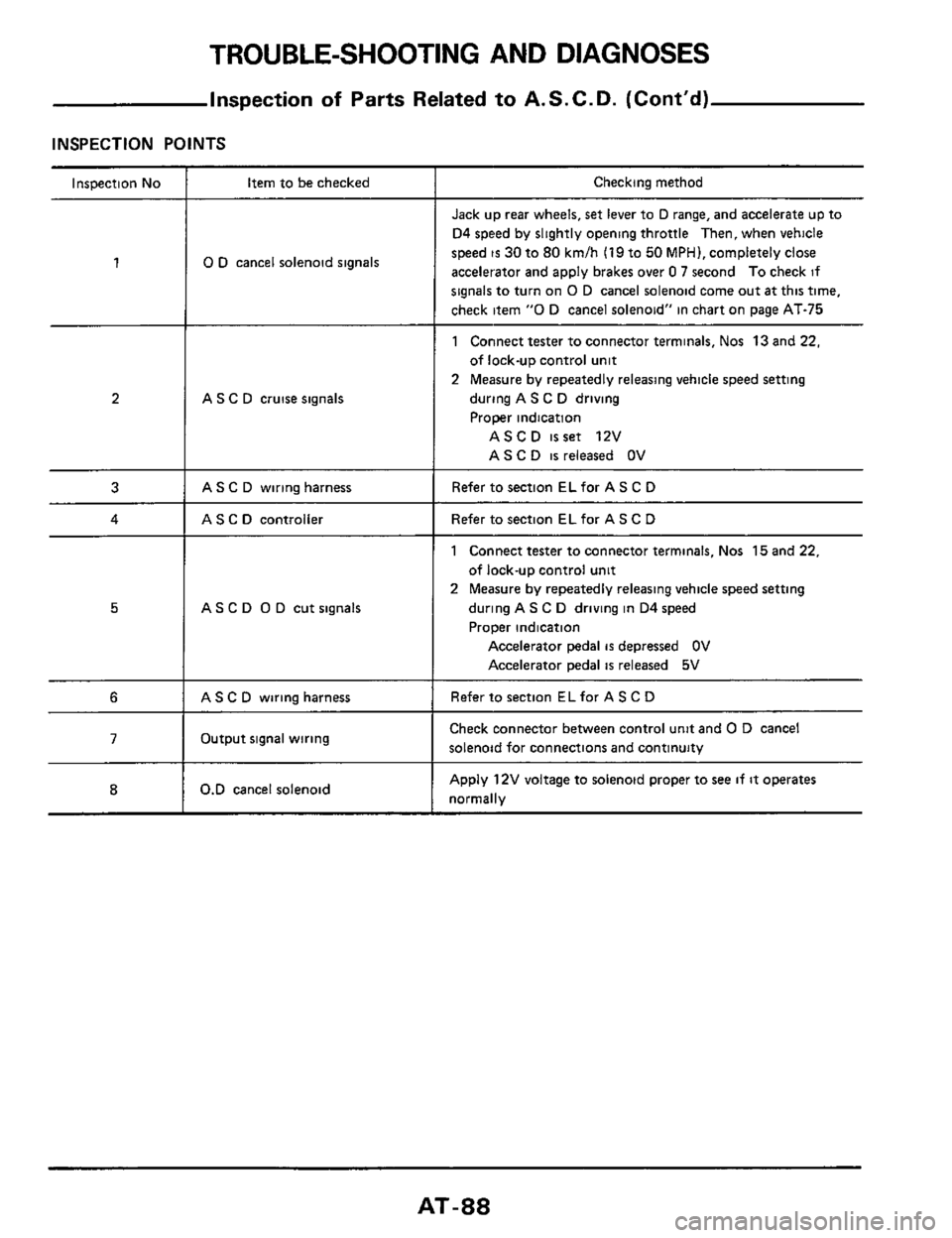

TROUBLE-SHOOTING AND DIAGNOSES

Inspection of Parts Related to A. S. C. D. (Cont’d)

INSPECTION POINTS

Inspection No

1

2

3

4

5

6

7

8

Item to be checked

0 D cancel solenoid signals

A S C D cruise signals

AS C D wiring harness

AS C D controller

AS C D 0 D cut signals

AS C D wiring harness

Output signal wiring

0.D cancel solenoid

Checking method

Jack up rear wheels, set lever to D range, and accelerate up to

D4 speed by slightly opening throttle

Then, when vehicle

speed

is 30 to 80 kmlh (19 to 50 MPH), completely close

accelerator and apply brakes over

0 7 second To check if

signals to turn on 0 D cancel solenoid come out at this time,

check item

“0 D cancel solenoid” in chart on page AT-75

1 Connect tester to connector terminals, Nos 13 and 22,

of lock-up control unit

2 Measure by repeatedly releasing vehicle speed setting

during A S C D driving

Proper indication

ASCD isset 12V

AS C

D is released OV

Refer to section EL for A S C D

Refer to section EL for AS C D

1 Connect tester to connector terminals, Nos 15 and 22,

of lock-up control

unit

2 Measure by repeatedly releasing vehicle speed setting

during AS C

D driving in D4 speed

Proper indication

Accelerator pedal is depressed OV

Accelerator pedal

is released 5V

Refer to section ELfor A S C D

Check connector between control unit and 0 D cancel

solenoid for connections and continuity

Apply 12V voltage to solenoid proper to see if it operates

normally

AT-88