oil type NISSAN 300ZX 1984 Z31 Automatic Transmission Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1984, Model line: 300ZX, Model: NISSAN 300ZX 1984 Z31Pages: 99, PDF Size: 3.09 MB

Page 22 of 99

DISASSEMBLY

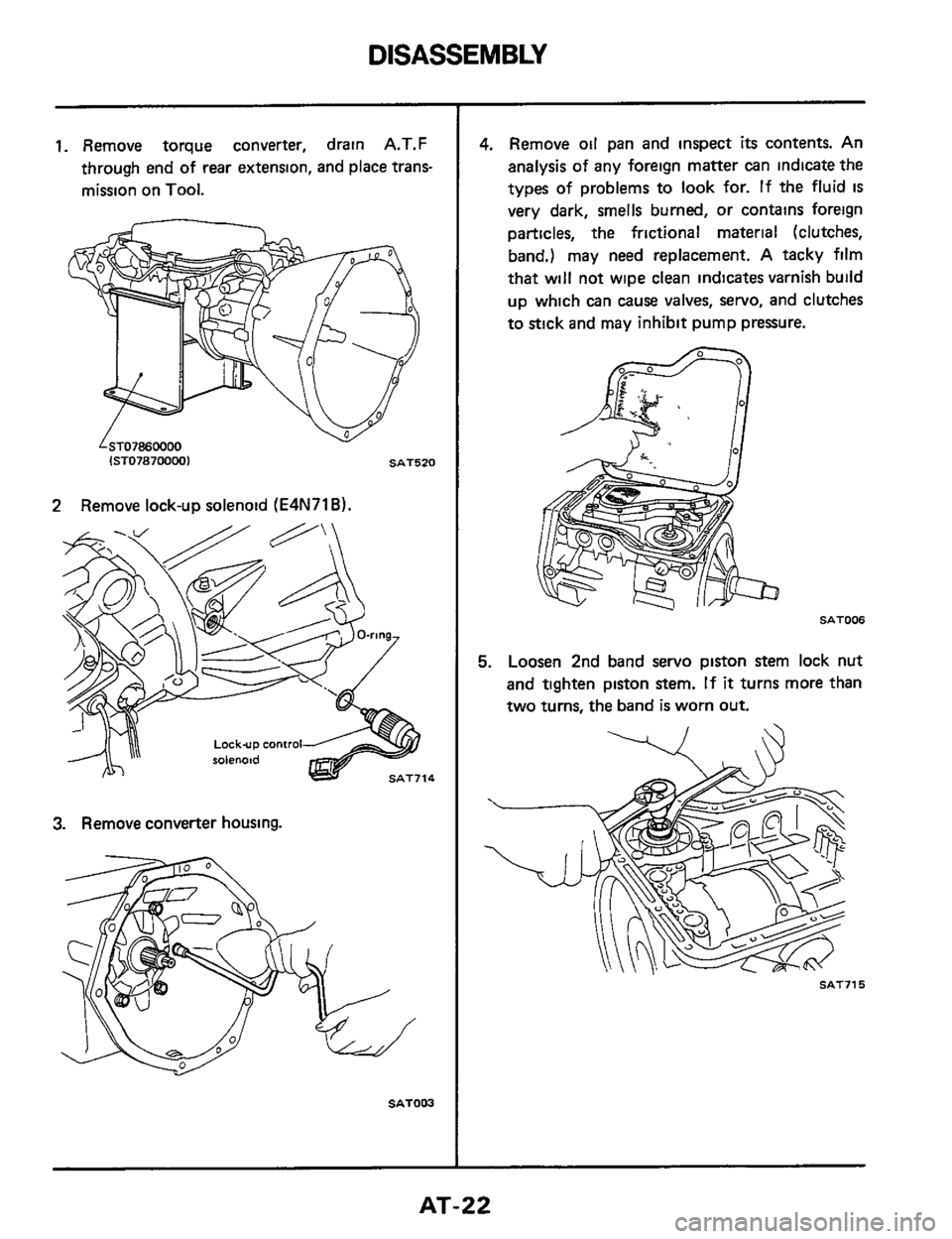

1. Remove torque converter, drain A.T.F

through end of

rear extension, and place trans-

mission on

Tool.

v

SAT520

2 Remove lock-up solenoid (E4N71B).

3. Remove converter housing.

SATOW

4. Remove oil pan and inspect its contents. An

analysis of any foreign matter can indicate the

types of problems to look for. If the fluid

IS

very dark, smells burned, or contains foreign

particles, the frictional material (clutches,

band.) may need replacement. A tacky film

that will not wipe clean indicates varnish bulld

up which can cause valves, servo, and clutches

to stick and may inhibit pump pressure.

SAT006

5. Loosen 2nd band servo piston stem lock nut

and tighten piston stem.

If it turns more than

two turns, the band

is worn out.

SAT71 5

AT-22

Page 36 of 99

REPAIR FOR COMPONENT PARTS

Control Valve Body (Cont'd)

DISASSEMBLY

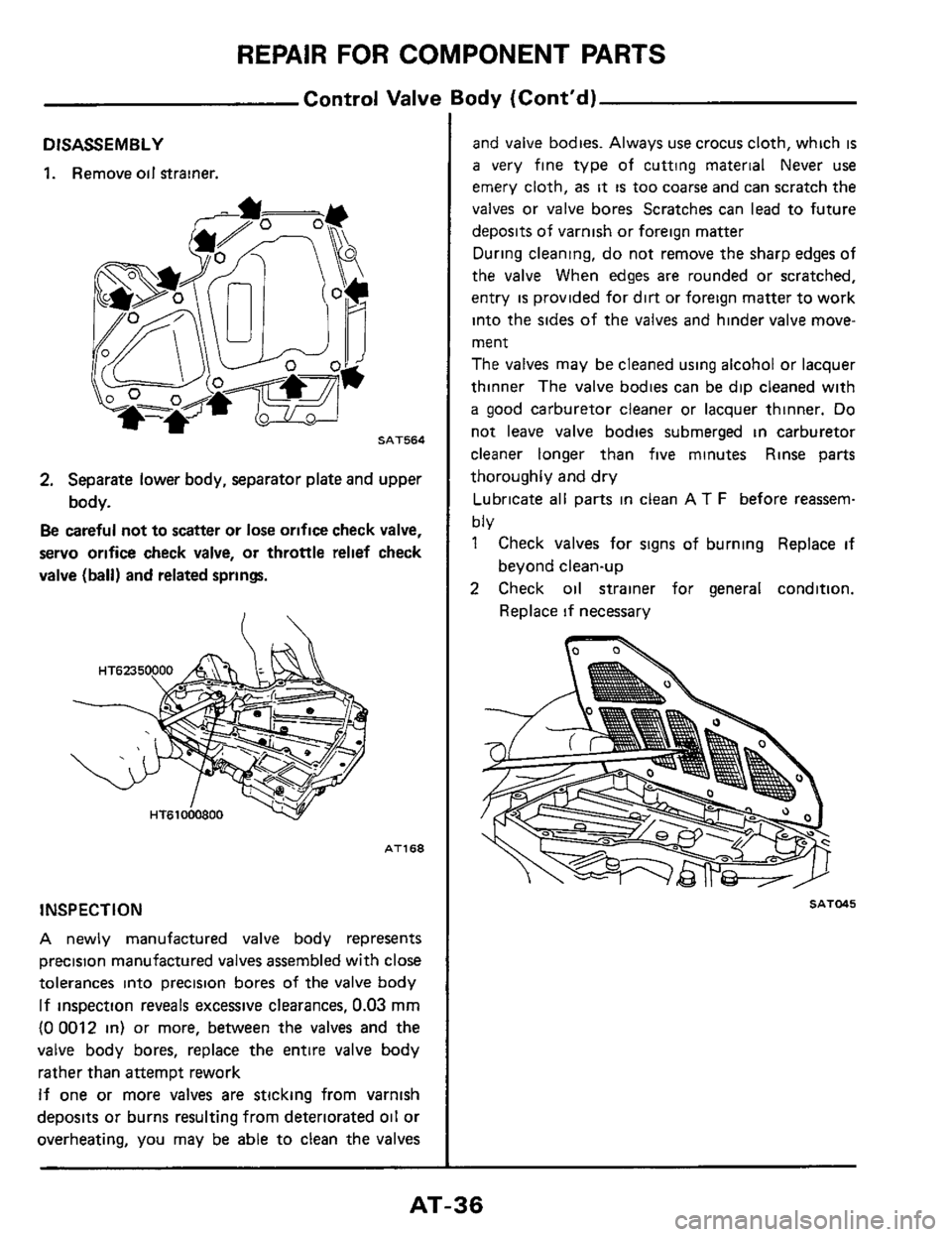

1. Remove oil Strainer.

SAT564

2. Separate lower body, separator plate and upper

body.

Be careful not to scatter or lose orifice check valve,

servo orifice check valve, or throttle relief check

valve (ball)

and related spring.

AT168

INSPECTION

A newly manufactured valve body represents

precision manufactured valves assembled with close

tolerances into precision bores of the valve body

If inspection reveals excessive clearances, 0.03 mm

(0 0012 in) or more, between the valves and the

valve body bores, replace the entire valve body

rather than attempt rework

If one or more valves are sticking from varnish

deposits or burns resulting from deteriorated oil or

overheating, you may be able to clean the valves

and valve bodies. Always use crocus cloth, which is

a very fine type of cutting material Never use

emery cloth,

as it is too coarse and can scratch the

valves or valve bores Scratches can lead to future

deposits of varnish or foreign matter

During cleaning, do not remove the sharp edges of

the valve When

edges are rounded or scratched,

entry

is provided for dirt or foreign matter to work

into the sides

of the valves and hinder valve move-

ment

The valves may be cleaned using alcohol or lacquer

thinner The valve bodies can be dip cleaned with

a good carburetor cleaner or lacquer thinner. Do

not leave valve bodies submerged in carburetor

cleaner longer than five minutes Rinse parts

thoroughly

and dry

Lubricate

all parts in clean AT F before reassem-

bly

1 Check valves for signs of burning Replace if

2 Check oil strainer for general condition.

beyond clean-up

Replace

if necessary

SATMS

AT-36

Page 95 of 99

SERVICE DATA AND SPECIFICATIONS (S.D.S.)

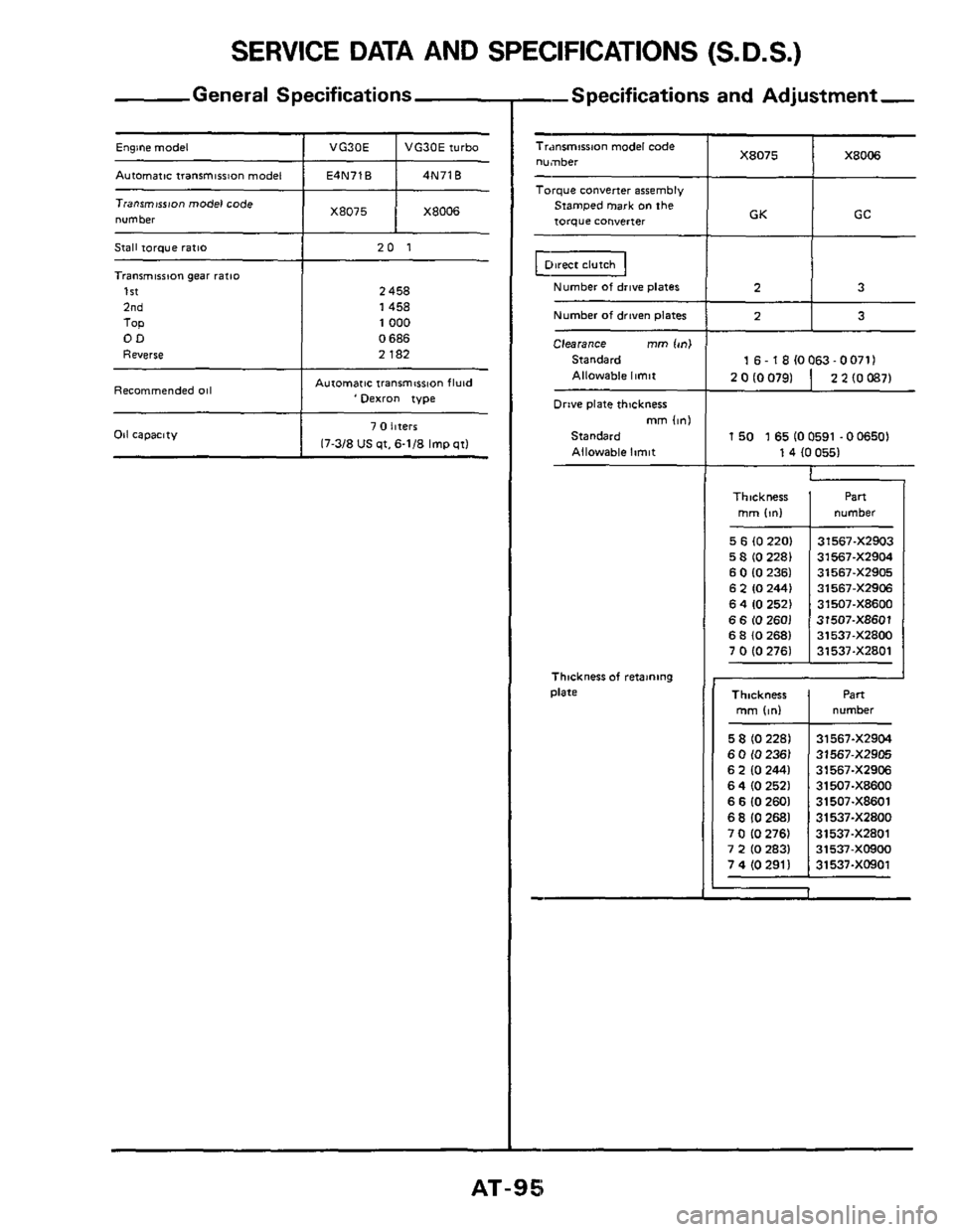

General Specifications

X8075 Engine model ~ I VG30E t VG30Eiurbo X8006 -

Autamatictranrmirrion model I E4N71B I 4N71B ~~

Stall torque ratlo

Transmission gear ratio

1st

2nd

TOP OD

Reverse

Recommended 011

1 X8075 1 X8006 Tianrmwon model code

number ~

20 1

2 458

1458

1000

0 686

2 182

Aurornar~c lranmwon fluid 'oexro" type

2 0 IO 0791

Oil capacity

2 2 (0 0871

7 0 hferr

17-3/8 US qt, 6-1/8 Imp qtl

5 6 (0 220)

5 8 (0 2281

6 0 (0 2361 6 2 IO 2441

6 4 10 2521

6 6 10 2601 6 8 (0 2681

7 0 (0 2761

--Specifications and Adjustment,

31567-XZ903

31567-XZ904

31567-XZ905

31567-XZ906

31507-X86W

31507-X8601

31537-XZ800

31537-XZ801

Tr.msmirrmn model code number

Torque converter assembly

Srarnped mark on the

torque COnYerter

Number of drive plates

Number of driven plates

Clearance rnm Ion1

Standard Allowable limit

Drive plate thickness mm (in1

Standard

Allowable limit

Thlcknesr of retamng

Dlate

1 GC GK

1 50 1 65 (0 0591 .O 06501

1 4 (0 0551

Thickness I numbel Part

mrn Iml

Thickness number

AT-95