torque NISSAN 300ZX 1984 Z31 Steering System Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1984, Model line: 300ZX, Model: NISSAN 300ZX 1984 Z31Pages: 20, PDF Size: 0.7 MB

Page 11 of 20

POWER STEERING GEAR AND LINKAGE

1701.

I601

I501

Disassembly and

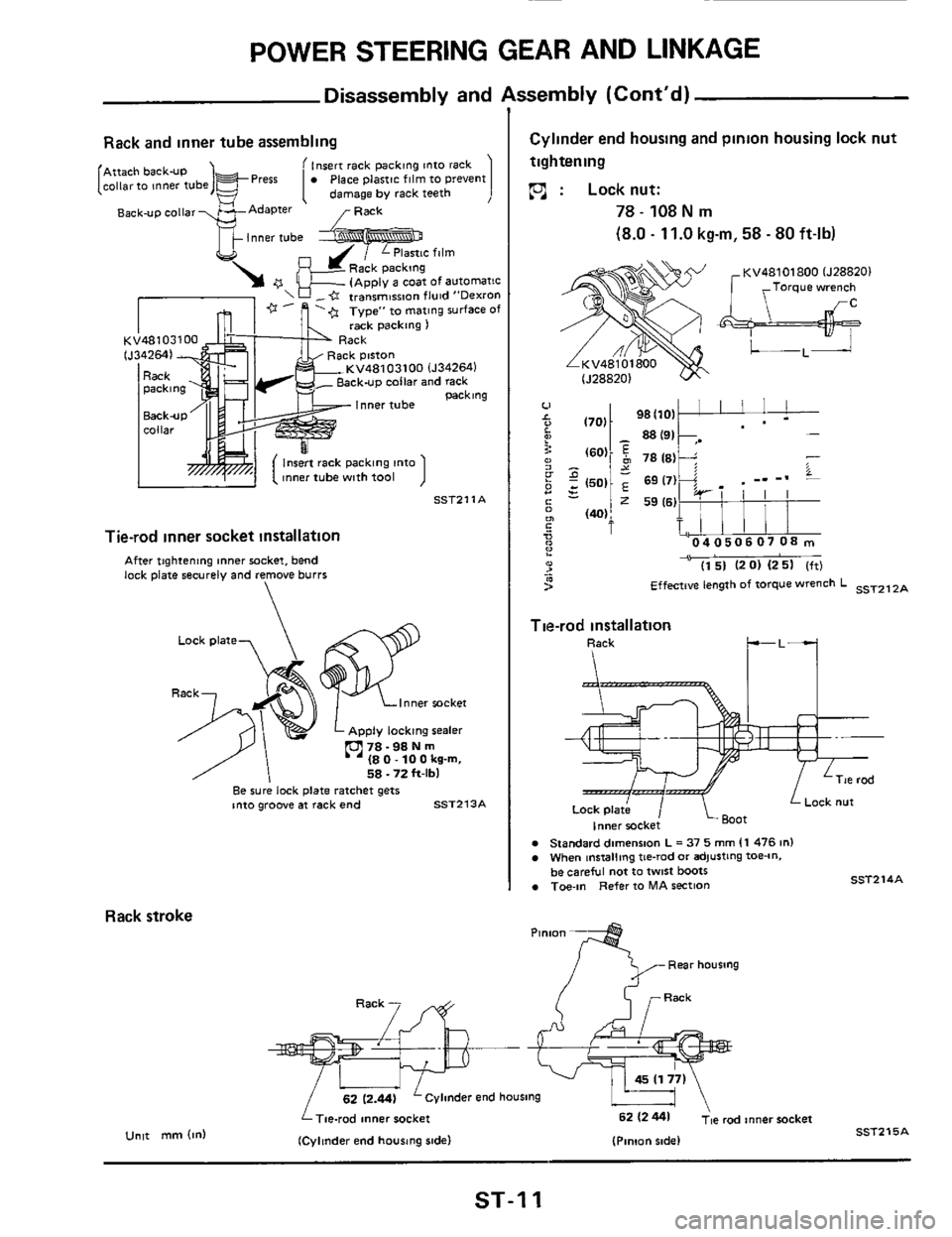

Rack and inner tube assembling

-

1

Insert rack packing into rack

damage by rack teeth Attach back-up

oat of automatic 80" fluid "Dexion * 1 - n '6 Type" to matlng surface of rack packing 1 ack

k pnrton

KV48103100 lJ342641

ackup collar and rack

1

Insert rack packing into mer tube with tool

SST211A

Tie-rod inner socket installation

After tightening inner socket, bend

lock plate securely and remove burrs

7 Lock plate

Inner socket

Apply locking sealer

78-98Nm ' I8 0 - 10 0 kern. 58.72 h-lbl / I Be sure lock plate ratchet gets into groove at rack end SST213A

Rack stroke

sembly (Cont'd)

Cylinder end housing and pinion housing lock nut

tightening

n : Locknut:

78 - 108 N m

(8.0 - 11.0 kg-m, 58 - 80 ft-lb)

Torque wrench

lJ288201 vc'

98 I101

88 I91

-

04050607 08 m

4' I1 51 I2 01 (2 51 Iff1

Effective length of torque wrench L ssT212A

Tie-rod installation

Lack nut Lock plate

Inner socket

Standard dimension L = 31 5 mm I1 476 In1 When installing tie-rod or adiustmg toe-,".

be careful not to twist boots Toe-," Refer to MA section

Pl"l.3"

Rear housing

I?-

- 62 lz.441 'Cylmder end housing /

SST'214A

iTie-rad inner socket

ICylmder

end hourlng sidel SSTZlBA IPinion sidel

ST-I 1

Page 12 of 20

POWER STEERING GEAR AND LINKAGE

Inspection and Adjustment

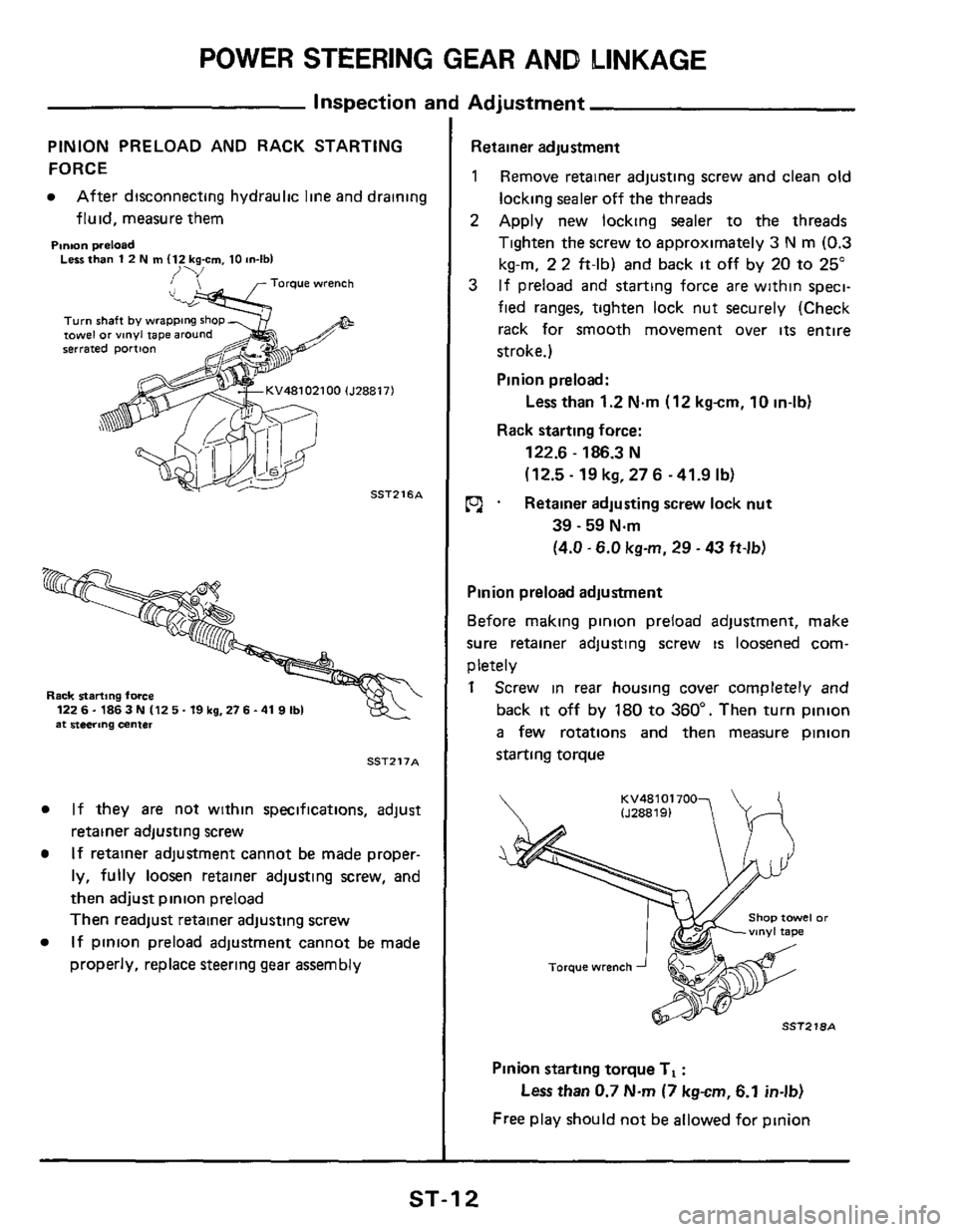

PINION PRELOAD AND RACK STARTING

FORCE

After disconnecting hydraulic line and draining

fluid, measure them

Pmon preload Less than 1 2 N m I12 kg-cm, 10 In-lbl

Turn shaft by wrappi towel or wnvl tape ar serrated portion

102100 (J288171

SST216A

Rack starting force 122 6.1863 N I12 5- 19 kg.276 -41 9 Ibl at Steernng Ce"t.3,

SST217A

If they are not within specifications, adjust

retainer adjusting screw

If retainer adjustment cannot be made proper-

ly, fully loosen retainer adjusting screw, and

then adjust pinion preload

Then readjust retainer adjusting screw

If pinion preload adjustment cannot be made

properly, replace steering gear assembly

Retainer adjustment

1

2

3

R

Remove retainer adjusting screw and clean old

locking

sealer off the threads

Apply new locking sealer to the threads

Tighten

the screw to approximately 3 N rn (0.3

kg-m, 2 2 h-lb) and back it off by 20 to 25"

If preload and starting force are within speci-

fied ranges, tighten lock nut securely (Check

rack for smooth movement over

its entire

stroke.)

Pinion preload:

Less than 1.2 Nm 112 kgcm, 10 in-lb)

Rack starting force:

122.6

- 186.3 N

(12.5-19kg,276 -41.9lb)

. Retainer adjusting screw lock nut

39 - 59 Nm

(4.0 - 6.0 kgm, 29 - 43 ft-lb)

Pinion preload adjustment

Before making pinion preload adjustment, make

sure retainer adjusting screw

is loosened com-

pletely

1 Screw in rear housing cover completely and

back it off by 180 to 360". Then turn pinion

a few rotations and then measure pinion

starting torque

KV48101700

I or

SST218A

Pinion starting torque T, :

Free play should not be allowed for pinion

Less than 0.7 Nm (7 kg-cm, 6.1 in-lb)

ST-1 2

Page 13 of 20

POWER STEERING GEAR AND LINKAGE

inspection and Ac

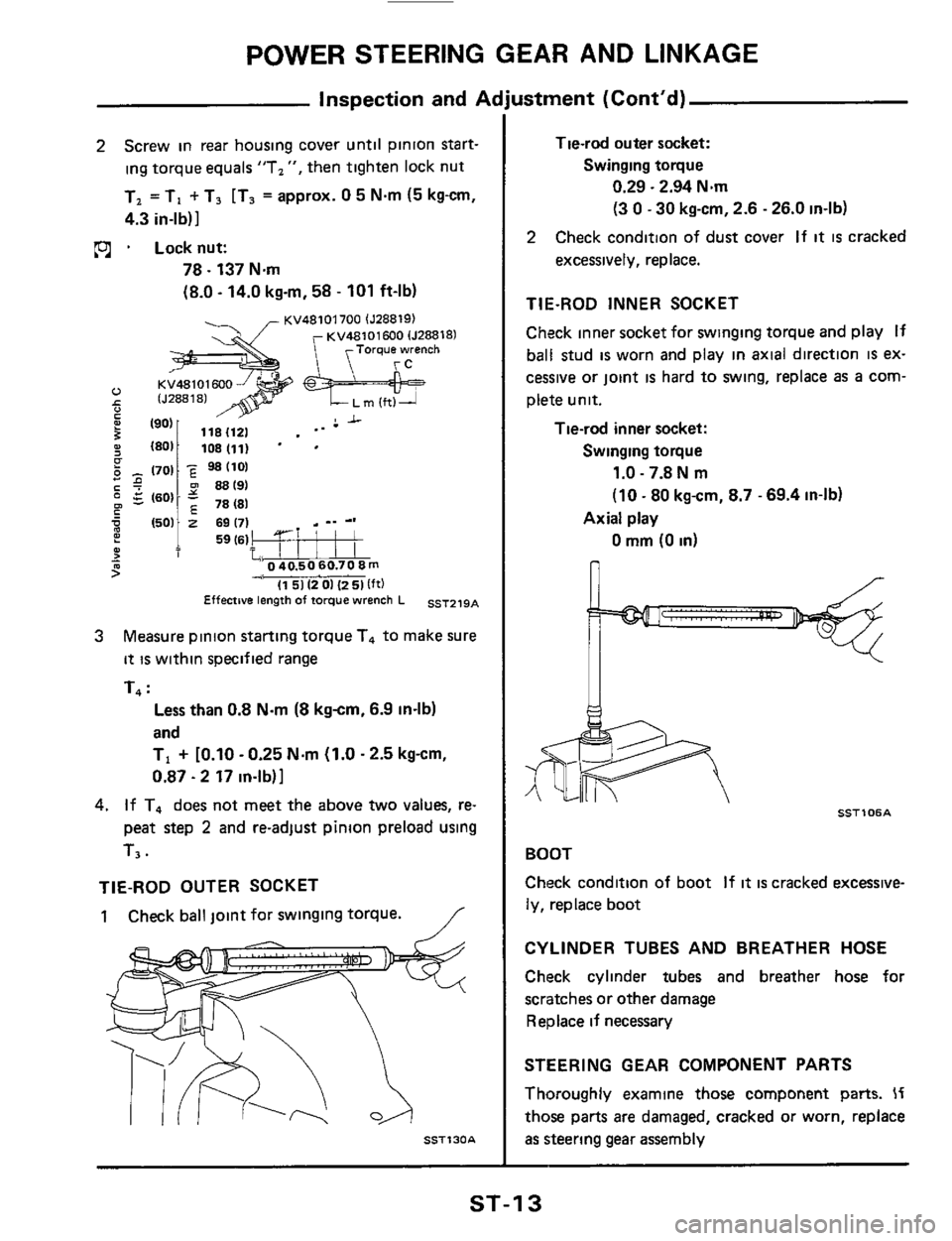

2 Screw in rear housing cover until pinion start-

ing torque equals "T,

", then tighten lock nut

T, =TI

+ T3 [T3 = approx. 0 5 N.m (5 kg-cm,

4.3 in-lb)]

pj . Locknut:

78.137 Nm

(8.0 - 14.0 kgrn, 58 - 101 ft-lb)

KV48101700 lJ288191 KV48101690 lJ28818)

1501 2 69 171 _. -.

? 1 59(61!* T %40.50 60.70 8 m - 9

5 4, I1 51 12 01 (2 51 lft)

Effective length of torque wrench L SST219A

Measure pinion starting torque T4 to make sure

it is within specified range

T4

:

3

Less than 0.8 N.m (8 kgcm, 6.9 in-lb)

and

TI

+ [0.10 - 0.25 Nm (1.0.2.5 kg-cm,

0.87.2 17 in-lb)]

4. If T, does not meet the above two values, re-

peat step

2 and re-adjust pinion preload using

T3.

TIE-ROD OUTER SOCKET

1 Check ball joint for swinging torque. /

SST130A

ustment (Cont'd)

Tie-rod outer socket:

Swinging toque

0.29.2.94 Nm

(3

0 - 30 kg-cm, 2.6 - 26.0 in-lb)

2 Check condition of dust cover If it is cracked

excessively, replace.

TIE-ROD INNER SOCKET

Check inner socket for swinging torque and play If

ball stud

is worn and play in axial direction IS ex-

cessive or joint

is hard to swing, replace as a com-

plete unit.

Tie-rod inner socket:

Swinging toque

1.0 - 7.8 N m

(10 - 80 kg-cm, 8.7 - 69.4 in-lb)

0 mm (0 in)

Axial play

n

it- * SSTl 06A

BOOT

Check condition of boot

If it is cracked excessive-

ly, replace boot

CYLINDER TUBES AND BREATHER HOSE

Check cylinder tubes and breather hose for

scratches or other damage

Replace if necessary

STEERING GEAR COMPONENT PARTS

Thoroughly examine those component parts.

If

those parts are damaged, cracked or worn, replace

as steering gear assembly

ST-1 3

Page 18 of 20

SERVICE DATA AND SPECIFICATIONS (S.D.S.)

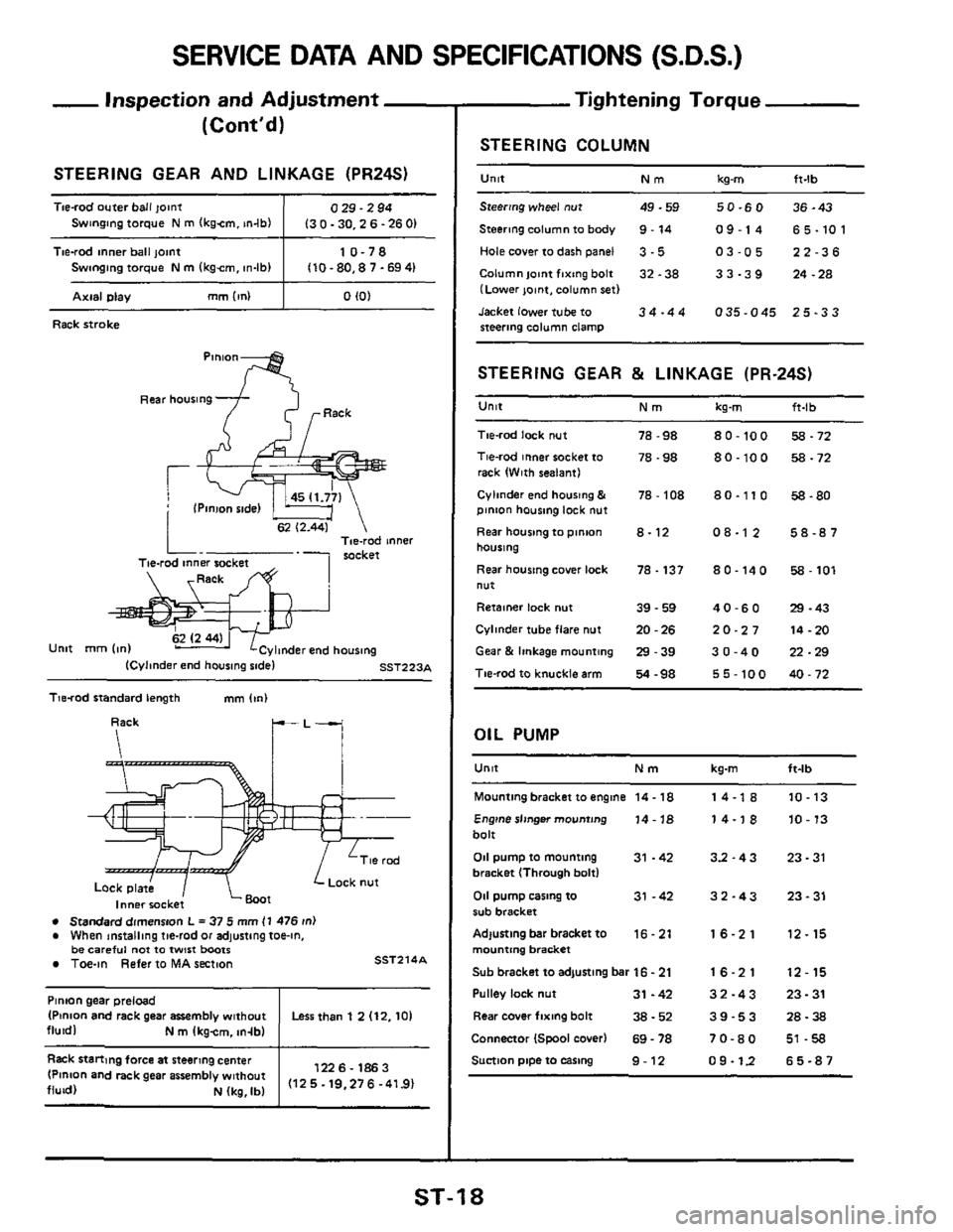

Tie-rod outer ball joint

Swinging torque N m (kgim. m4b)

- Inspection and Adjustment

(Cont'd)

0 29.2 94

I3 0.30,2 6.26

01 ~~~

Pinion gear

preload

(Ptnlon and rack gear assembly without

fluid1 N m Ikgcm, tn-lbl

Tie-rod inner ball joint 10-78 Swinging torque N m (kgem, in-lb) 110 - 80.8 7 .69 41

__~ ~

Less than 1 2 (12.10)

Axial Dlay mm (in) I 0 IO)

Rack stroke

Pinion

I' ? Pack

Rear housing

Tne-rod innel rocket Tie-rod inner socket

& .l

Unit mm Ion) linder end housina - ICyImder end hourmg sadel SST223A

Tie-rod standard length mm (In)

Inner rocket

8 Standard dimensnn L = 37 5 mm I1 476 ln) e When installing tie-rod or adjusting toe-in, be careful not Io twist boots Toe-in Refer to MA seCtion SST214A

1226- 1863

(12 5.19.276 -41.9) Rack stanmg force at steering center (Pinion and rack gear assembly without

fluid) N (kg. Ib)

Tightening Torque

STEERING COLUMN ~~~~

U"lt Nm kg-m ft-lb

Steering wheel nut 49-59 50-60 36-43

Steering column to

body 9 - 14 09-14 65-101

Hole cover to dash panel 3 .5 03-05 22-36

Columnlaintfixingbolt 32-38 33-39 24.28 (Lower joint, column set)

Jacket lower tube to

34-44 035-045 25-33 steering column clamp

STEERING GEAR & LINKAGE (PR-24s)

Unit Nm kg-m ft-lb

Tie-rod lock nut

Tie-rod inner socket to

rack (With sealant)

Cylinder end housmg

& pinion housmg lock nut

Rear housmg to pman

housing

Rear housing

cover lack

nut

Retainer lock nut

Cylinder tube flare nut

Gear & linkage mounting

Tie-rod

to knuckle arm

78 -98

78 -98

78 - 108

8-12

78.137

39 - 59

20

- 26

29-39

54 -98

80-100

80.100

80.110

08-1 2

80-140

40-60

20-27

30-40

55-100

58.72

58-72

58-80

58-87

Ea - 101

29 -43

14-20

22-29

40 - 72

OIL PUMP

U"lt Nm kg-m ft-lb

Mounting bracket to engine 14. 18

Engine sllnger mounting 14 - 18 bolt

011 pump to mounting 31 .42 bracket (Through bolt)

011 pump casing to 31 -42 rub bracket

Adlusting bar bracket

to 16.21 mounting bracket

Sub bracket to adjusting bar

16 - 21

Pulley lock nut 31 -42

Rear cover fixing bolt 38 - 52

Connector (Spool cover) 69 - 78

Suction piDe to easing 9-12

14-1 8

14-18

33-43

32-43

16-21

16-21

32-43

39-53

70-80

09-12

10-13

10

- 13

23 - 31

23 - 31

12-15

12-15

23.31

28-38

51

-58

65-87

ST-1 8

Page 19 of 20

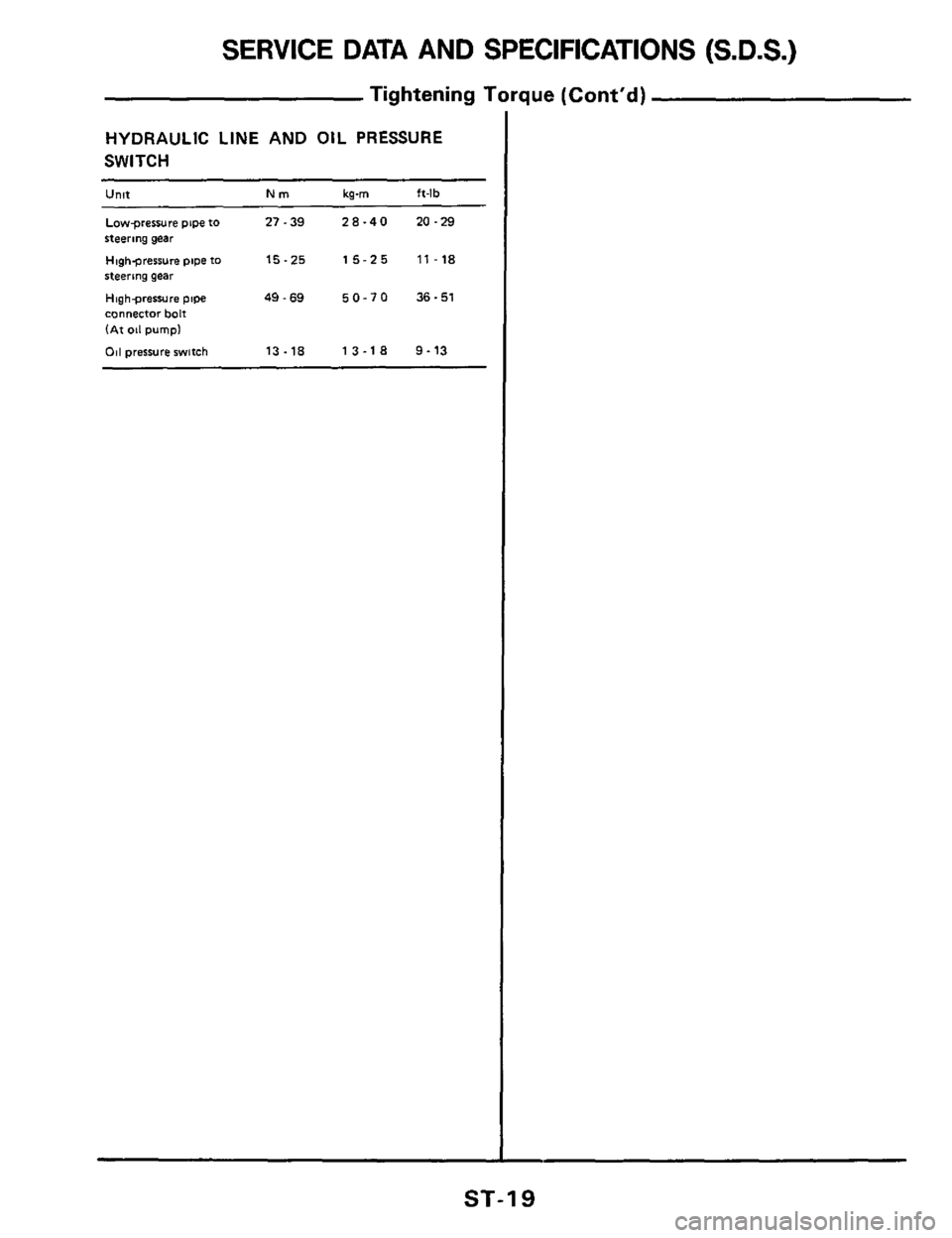

SERVICE DATA AND SPECIFICATIONS (S.D.S.)

Tightening Torque (Cont'd)

HYDRAULIC LINE AND OIL PRESSURE

SWITCH

U"lt Nm kg-m ft-lb

Lowpressure pipe to 27-39 28-40 20-29

Steering gear

Highpressure pipe to

15-25 15-25 11-18

steering gear

H ig hprerw re pipe 49 - 69 50-70 36-51

connector bolt

(At

011 pump1

011 pressure switch 13.18 13-18 9-13

ST-19