Meter NISSAN ALMERA N16 2001 Electronic Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 82 of 2493

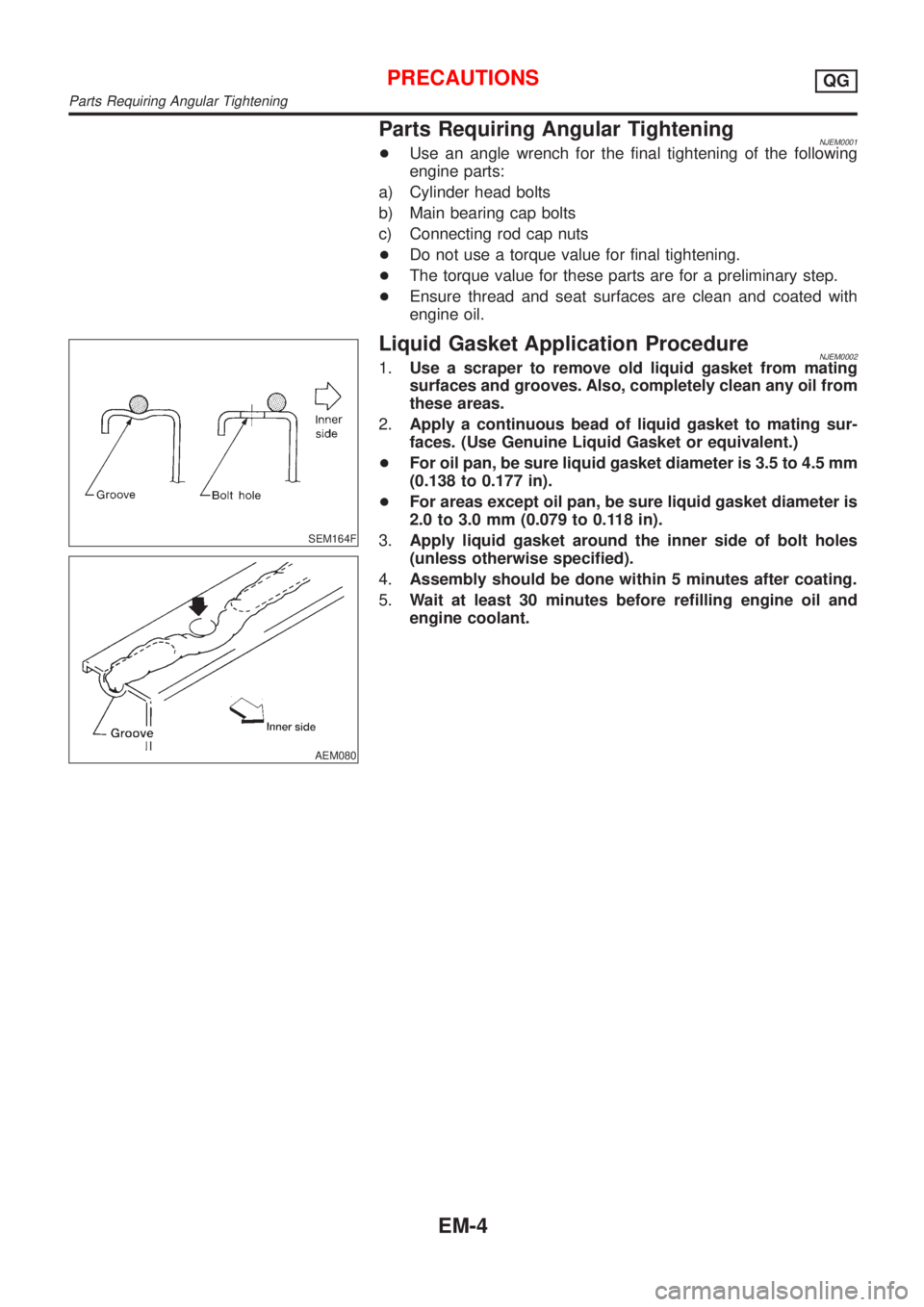

Parts Requiring Angular TighteningNJEM0001+Use an angle wrench for the final tightening of the following

engine parts:

a) Cylinder head bolts

b) Main bearing cap bolts

c) Connecting rod cap nuts

+Do not use a torque value for final tightening.

+The torque value for these parts are for a preliminary step.

+Ensure thread and seat surfaces are clean and coated with

engine oil.

SEM164F

AEM080

Liquid Gasket Application ProcedureNJEM00021.Use a scraper to remove old liquid gasket from mating

surfaces and grooves. Also, completely clean any oil from

these areas.

2.Apply a continuous bead of liquid gasket to mating sur-

faces. (Use Genuine Liquid Gasket or equivalent.)

+For oil pan, be sure liquid gasket diameter is 3.5 to 4.5 mm

(0.138 to 0.177 in).

+For areas except oil pan, be sure liquid gasket diameter is

2.0 to 3.0 mm (0.079 to 0.118 in).

3.Apply liquid gasket around the inner side of bolt holes

(unless otherwise specified).

4.Assembly should be done within 5 minutes after coating.

5.Wait at least 30 minutes before refilling engine oil and

engine coolant.

PRECAUTIONSQG

Parts Requiring Angular Tightening

EM-4

Page 99 of 2493

SEM259G

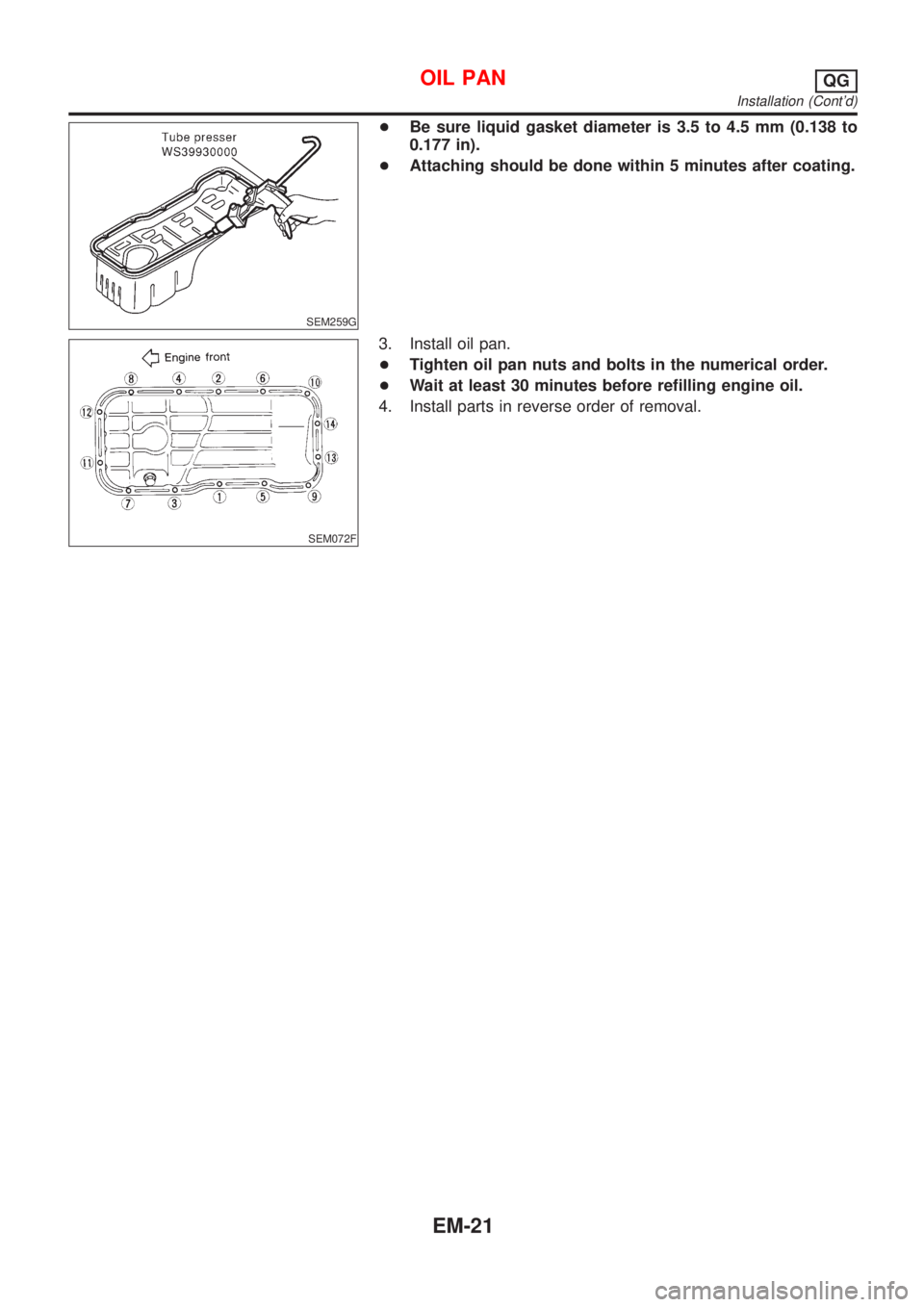

+Be sure liquid gasket diameter is 3.5 to 4.5 mm (0.138 to

0.177 in).

+Attaching should be done within 5 minutes after coating.

SEM072F

3. Install oil pan.

+Tighten oil pan nuts and bolts in the numerical order.

+Wait at least 30 minutes before refilling engine oil.

4. Install parts in reverse order of removal.

OIL PANQG

Installation (Cont'd)

EM-21

Page 115 of 2493

SEM154D

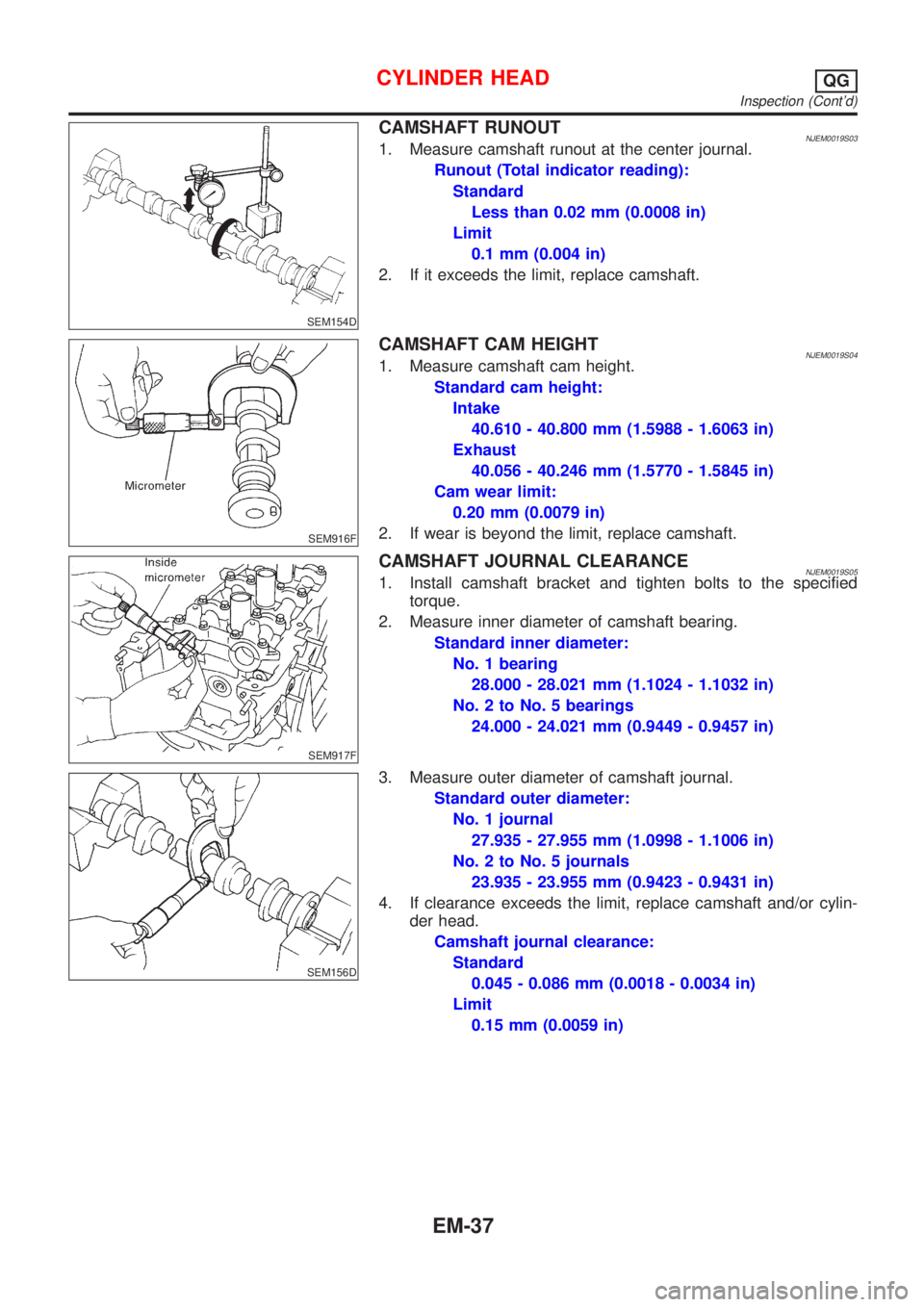

CAMSHAFT RUNOUTNJEM0019S031. Measure camshaft runout at the center journal.

Runout (Total indicator reading):

Standard

Less than 0.02 mm (0.0008 in)

Limit

0.1 mm (0.004 in)

2. If it exceeds the limit, replace camshaft.

SEM916F

CAMSHAFT CAM HEIGHTNJEM0019S041. Measure camshaft cam height.

Standard cam height:

Intake

40.610 - 40.800 mm (1.5988 - 1.6063 in)

Exhaust

40.056 - 40.246 mm (1.5770 - 1.5845 in)

Cam wear limit:

0.20 mm (0.0079 in)

2. If wear is beyond the limit, replace camshaft.

SEM917F

CAMSHAFT JOURNAL CLEARANCENJEM0019S051. Install camshaft bracket and tighten bolts to the specified

torque.

2. Measure inner diameter of camshaft bearing.

Standard inner diameter:

No. 1 bearing

28.000 - 28.021 mm (1.1024 - 1.1032 in)

No. 2 to No. 5 bearings

24.000 - 24.021 mm (0.9449 - 0.9457 in)

SEM156D

3. Measure outer diameter of camshaft journal.

Standard outer diameter:

No. 1 journal

27.935 - 27.955 mm (1.0998 - 1.1006 in)

No. 2 to No. 5 journals

23.935 - 23.955 mm (0.9423 - 0.9431 in)

4. If clearance exceeds the limit, replace camshaft and/or cylin-

der head.

Camshaft journal clearance:

Standard

0.045 - 0.086 mm (0.0018 - 0.0034 in)

Limit

0.15 mm (0.0059 in)

CYLINDER HEADQG

Inspection (Cont'd)

EM-37

Page 116 of 2493

SEM918F

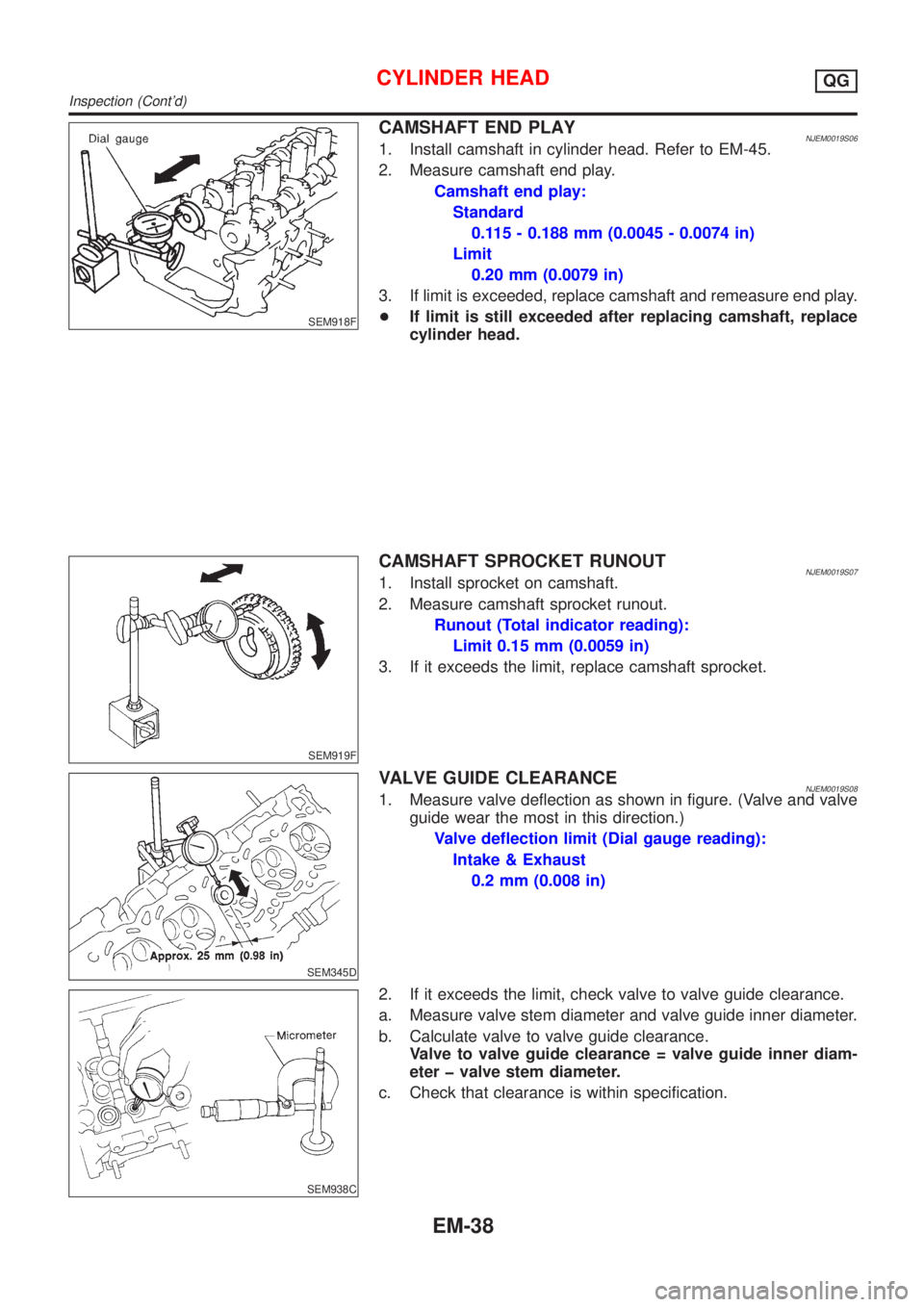

CAMSHAFT END PLAYNJEM0019S061. Install camshaft in cylinder head. Refer to EM-45.

2. Measure camshaft end play.

Camshaft end play:

Standard

0.115 - 0.188 mm (0.0045 - 0.0074 in)

Limit

0.20 mm (0.0079 in)

3. If limit is exceeded, replace camshaft and remeasure end play.

+If limit is still exceeded after replacing camshaft, replace

cylinder head.

SEM919F

CAMSHAFT SPROCKET RUNOUTNJEM0019S071. Install sprocket on camshaft.

2. Measure camshaft sprocket runout.

Runout (Total indicator reading):

Limit 0.15 mm (0.0059 in)

3. If it exceeds the limit, replace camshaft sprocket.

SEM345D

VALVE GUIDE CLEARANCENJEM0019S081. Measure valve deflection as shown in figure. (Valve and valve

guide wear the most in this direction.)

Valve deflection limit (Dial gauge reading):

Intake & Exhaust

0.2 mm (0.008 in)

SEM938C

2. If it exceeds the limit, check valve to valve guide clearance.

a. Measure valve stem diameter and valve guide inner diameter.

b. Calculate valve to valve guide clearance.

Valve to valve guide clearance = valve guide inner diam-

eter þ valve stem diameter.

c. Check that clearance is within specification.

CYLINDER HEADQG

Inspection (Cont'd)

EM-38

Page 117 of 2493

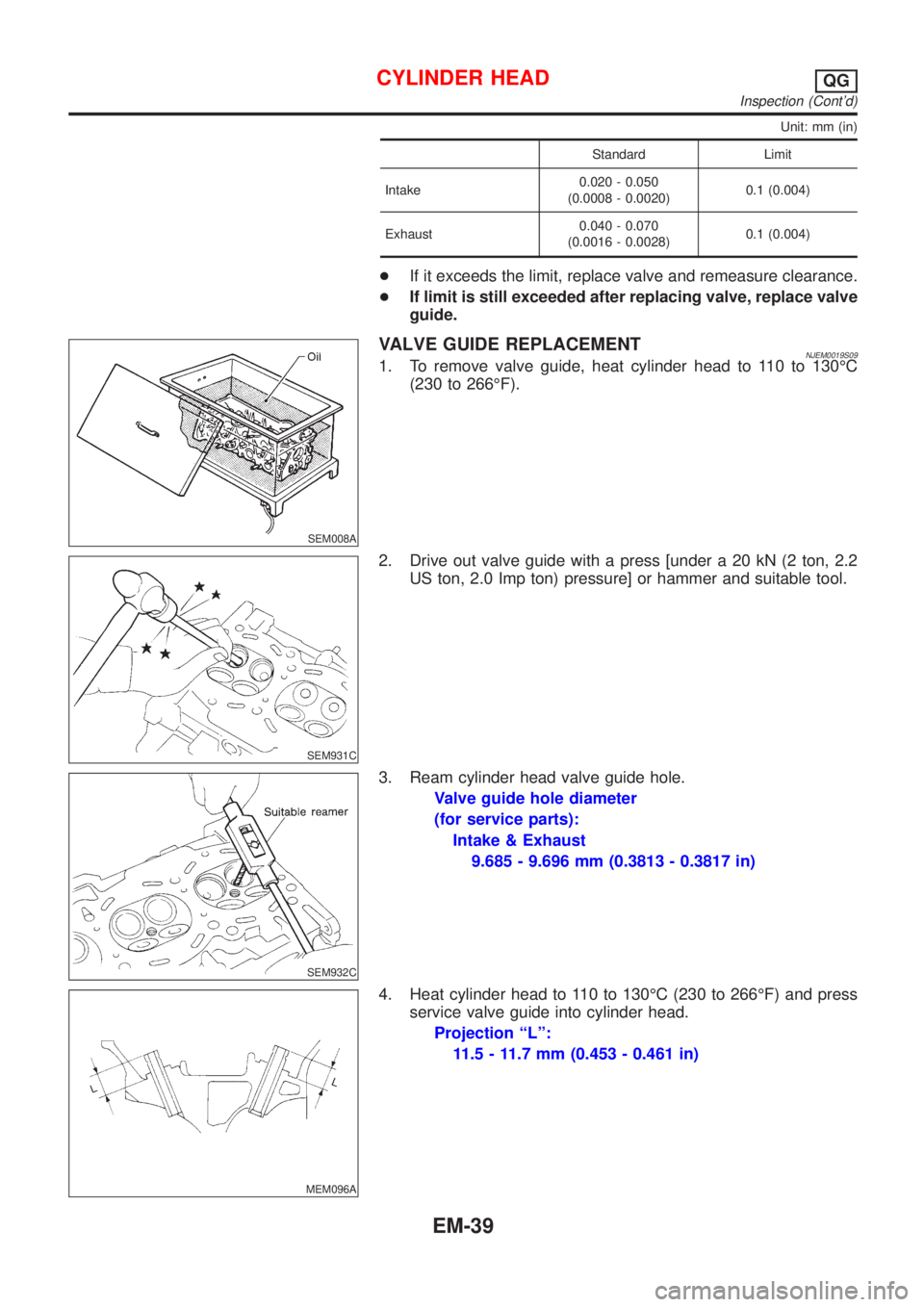

Unit: mm (in)

Standard Limit

Intake0.020 - 0.050

(0.0008 - 0.0020)0.1 (0.004)

Exhaust0.040 - 0.070

(0.0016 - 0.0028)0.1 (0.004)

+If it exceeds the limit, replace valve and remeasure clearance.

+If limit is still exceeded after replacing valve, replace valve

guide.

SEM008A

VALVE GUIDE REPLACEMENTNJEM0019S091. To remove valve guide, heat cylinder head to 110 to 130ÉC

(230 to 266ÉF).

SEM931C

2. Drive out valve guide with a press [under a 20 kN (2 ton, 2.2

US ton, 2.0 Imp ton) pressure] or hammer and suitable tool.

SEM932C

3. Ream cylinder head valve guide hole.

Valve guide hole diameter

(for service parts):

Intake & Exhaust

9.685 - 9.696 mm (0.3813 - 0.3817 in)

MEM096A

4. Heat cylinder head to 110 to 130ÉC (230 to 266ÉF) and press

service valve guide into cylinder head.

Projection ªLº:

11.5 - 11.7 mm (0.453 - 0.461 in)

CYLINDER HEADQG

Inspection (Cont'd)

EM-39

Page 120 of 2493

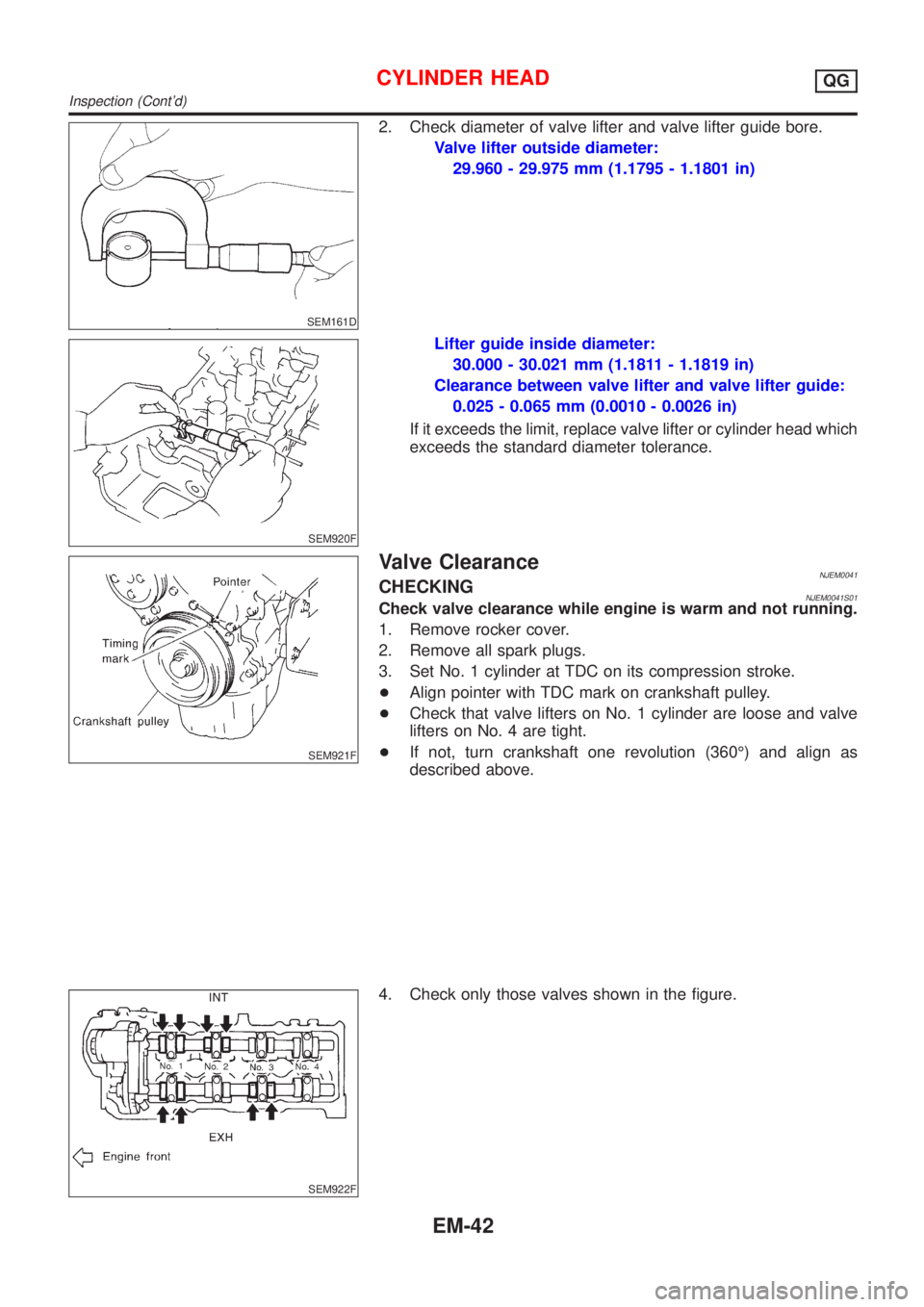

SEM161D

2. Check diameter of valve lifter and valve lifter guide bore.

Valve lifter outside diameter:

29.960 - 29.975 mm (1.1795 - 1.1801 in)

SEM920F

Lifter guide inside diameter:

30.000 - 30.021 mm (1.1811 - 1.1819 in)

Clearance between valve lifter and valve lifter guide:

0.025 - 0.065 mm (0.0010 - 0.0026 in)

If it exceeds the limit, replace valve lifter or cylinder head which

exceeds the standard diameter tolerance.

SEM921F

Valve ClearanceNJEM0041CHECKINGNJEM0041S01Check valve clearance while engine is warm and not running.

1. Remove rocker cover.

2. Remove all spark plugs.

3. Set No. 1 cylinder at TDC on its compression stroke.

+Align pointer with TDC mark on crankshaft pulley.

+Check that valve lifters on No. 1 cylinder are loose and valve

lifters on No. 4 are tight.

+If not, turn crankshaft one revolution (360É) and align as

described above.

SEM922F

4. Check only those valves shown in the figure.

CYLINDER HEADQG

Inspection (Cont'd)

EM-42

Page 122 of 2493

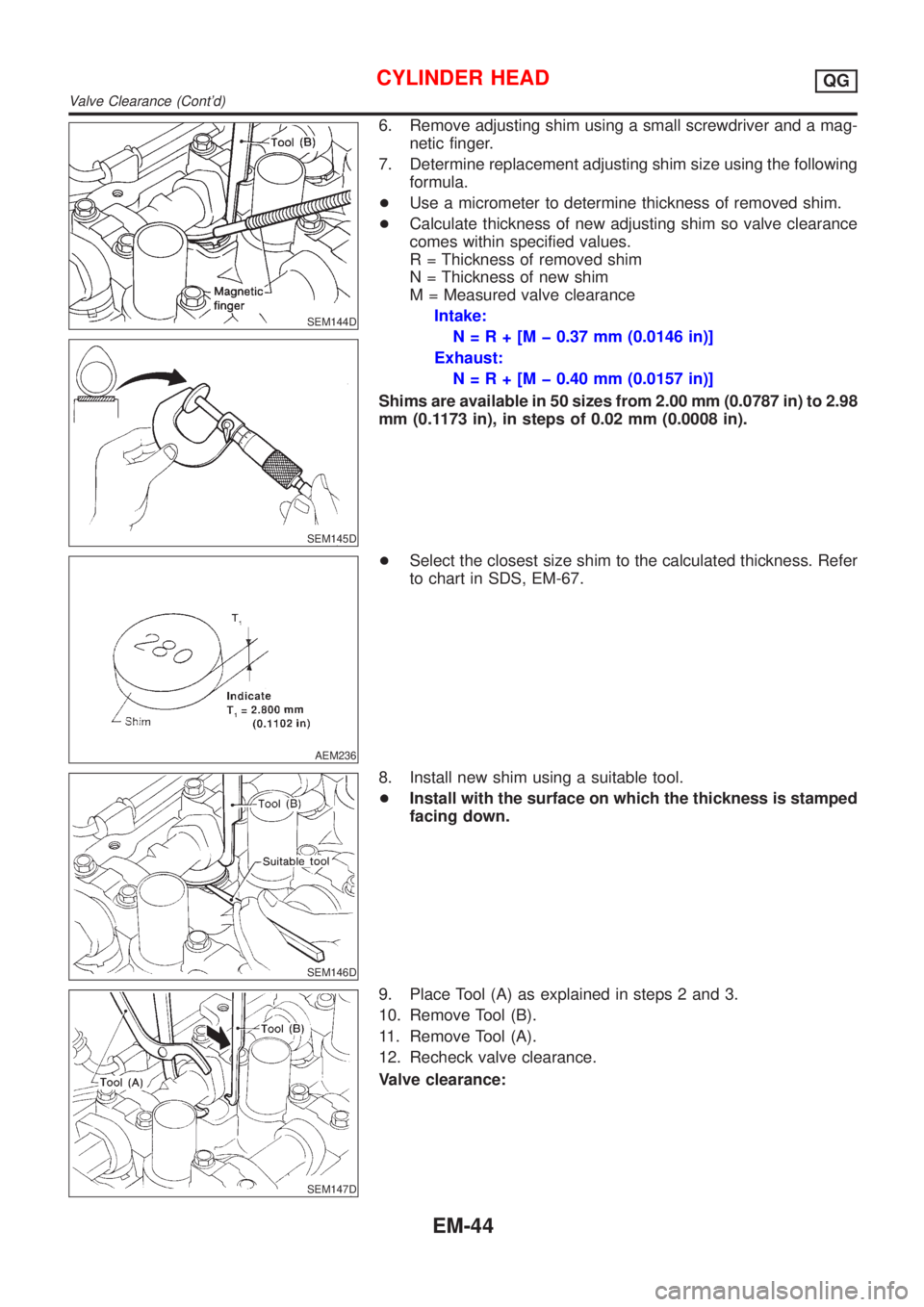

SEM144D

SEM145D

6. Remove adjusting shim using a small screwdriver and a mag-

netic finger.

7. Determine replacement adjusting shim size using the following

formula.

+Use a micrometer to determine thickness of removed shim.

+Calculate thickness of new adjusting shim so valve clearance

comes within specified values.

R = Thickness of removed shim

N = Thickness of new shim

M = Measured valve clearance

Intake:

N=R+[Mþ0.37 mm (0.0146 in)]

Exhaust:

N=R+[Mþ0.40 mm (0.0157 in)]

Shims are available in 50 sizes from 2.00 mm (0.0787 in) to 2.98

mm (0.1173 in), in steps of 0.02 mm (0.0008 in).

AEM236

+Select the closest size shim to the calculated thickness. Refer

to chart in SDS, EM-67.

SEM146D

8. Install new shim using a suitable tool.

+Install with the surface on which the thickness is stamped

facing down.

SEM147D

9. Place Tool (A) as explained in steps 2 and 3.

10. Remove Tool (B).

11. Remove Tool (A).

12. Recheck valve clearance.

Valve clearance:

CYLINDER HEADQG

Valve Clearance (Cont'd)

EM-44

Page 132 of 2493

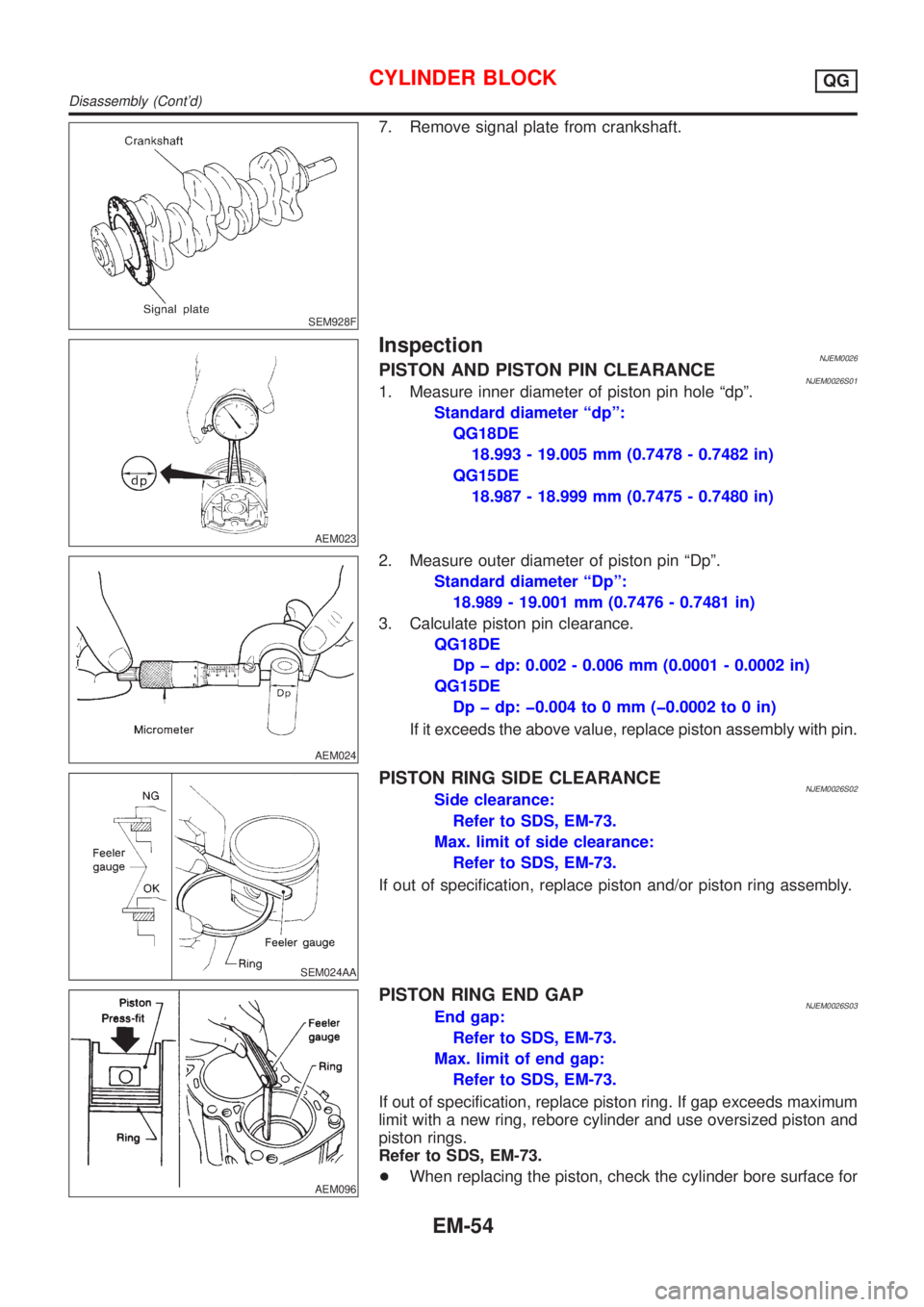

SEM928F

7. Remove signal plate from crankshaft.

AEM023

InspectionNJEM0026PISTON AND PISTON PIN CLEARANCENJEM0026S011. Measure inner diameter of piston pin hole ªdpº.

Standard diameter ªdpº:

QG18DE

18.993 - 19.005 mm (0.7478 - 0.7482 in)

QG15DE

18.987 - 18.999 mm (0.7475 - 0.7480 in)

AEM024

2. Measure outer diameter of piston pin ªDpº.

Standard diameter ªDpº:

18.989 - 19.001 mm (0.7476 - 0.7481 in)

3. Calculate piston pin clearance.

QG18DE

Dp þ dp: 0.002 - 0.006 mm (0.0001 - 0.0002 in)

QG15DE

Dp þ dp: þ0.004 to 0 mm (þ0.0002 to 0 in)

If it exceeds the above value, replace piston assembly with pin.

SEM024AA

PISTON RING SIDE CLEARANCENJEM0026S02Side clearance:

Refer to SDS, EM-73.

Max. limit of side clearance:

Refer to SDS, EM-73.

If out of specification, replace piston and/or piston ring assembly.

AEM096

PISTON RING END GAPNJEM0026S03End gap:

Refer to SDS, EM-73.

Max. limit of end gap:

Refer to SDS, EM-73.

If out of specification, replace piston ring. If gap exceeds maximum

limit with a new ring, rebore cylinder and use oversized piston and

piston rings.

Refer to SDS, EM-73.

+When replacing the piston, check the cylinder bore surface for

CYLINDER BLOCKQG

Disassembly (Cont'd)

EM-54

Page 134 of 2493

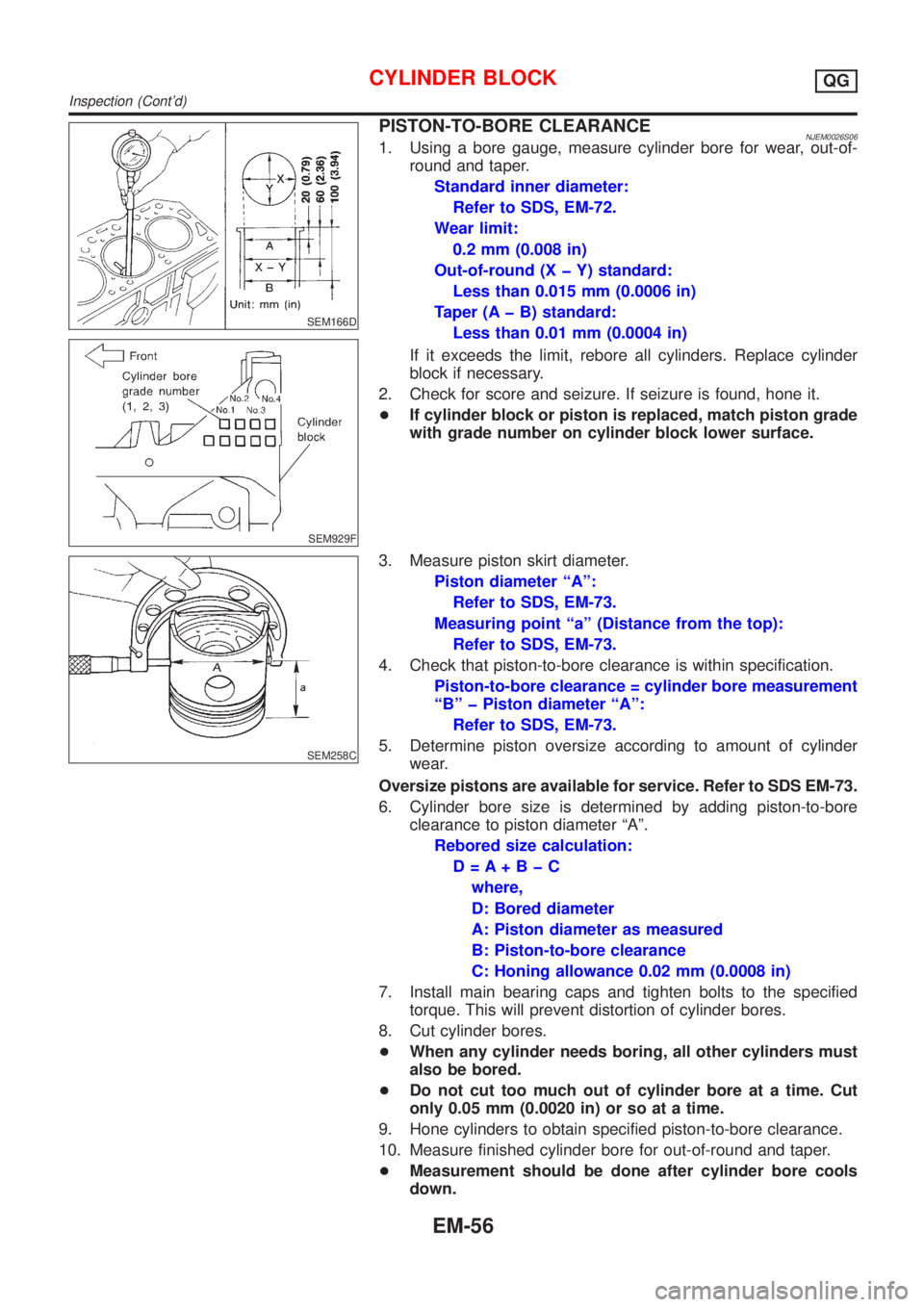

SEM166D

SEM929F

PISTON-TO-BORE CLEARANCENJEM0026S061. Using a bore gauge, measure cylinder bore for wear, out-of-

round and taper.

Standard inner diameter:

Refer to SDS, EM-72.

Wear limit:

0.2 mm (0.008 in)

Out-of-round (X þ Y) standard:

Less than 0.015 mm (0.0006 in)

Taper (A þ B) standard:

Less than 0.01 mm (0.0004 in)

If it exceeds the limit, rebore all cylinders. Replace cylinder

block if necessary.

2. Check for score and seizure. If seizure is found, hone it.

+If cylinder block or piston is replaced, match piston grade

with grade number on cylinder block lower surface.

SEM258C

3. Measure piston skirt diameter.

Piston diameter ªAº:

Refer to SDS, EM-73.

Measuring point ªaº (Distance from the top):

Refer to SDS, EM-73.

4. Check that piston-to-bore clearance is within specification.

Piston-to-bore clearance = cylinder bore measurement

ªBº þ Piston diameter ªAº:

Refer to SDS, EM-73.

5. Determine piston oversize according to amount of cylinder

wear.

Oversize pistons are available for service. Refer to SDS EM-73.

6. Cylinder bore size is determined by adding piston-to-bore

clearance to piston diameter ªAº.

Rebored size calculation:

D=A+BþC

where,

D: Bored diameter

A: Piston diameter as measured

B: Piston-to-bore clearance

C: Honing allowance 0.02 mm (0.0008 in)

7. Install main bearing caps and tighten bolts to the specified

torque. This will prevent distortion of cylinder bores.

8. Cut cylinder bores.

+When any cylinder needs boring, all other cylinders must

also be bored.

+Do not cut too much out of cylinder bore at a time. Cut

only 0.05 mm (0.0020 in) or so at a time.

9. Hone cylinders to obtain specified piston-to-bore clearance.

10. Measure finished cylinder bore for out-of-round and taper.

+Measurement should be done after cylinder bore cools

down.

CYLINDER BLOCKQG

Inspection (Cont'd)

EM-56

Page 135 of 2493

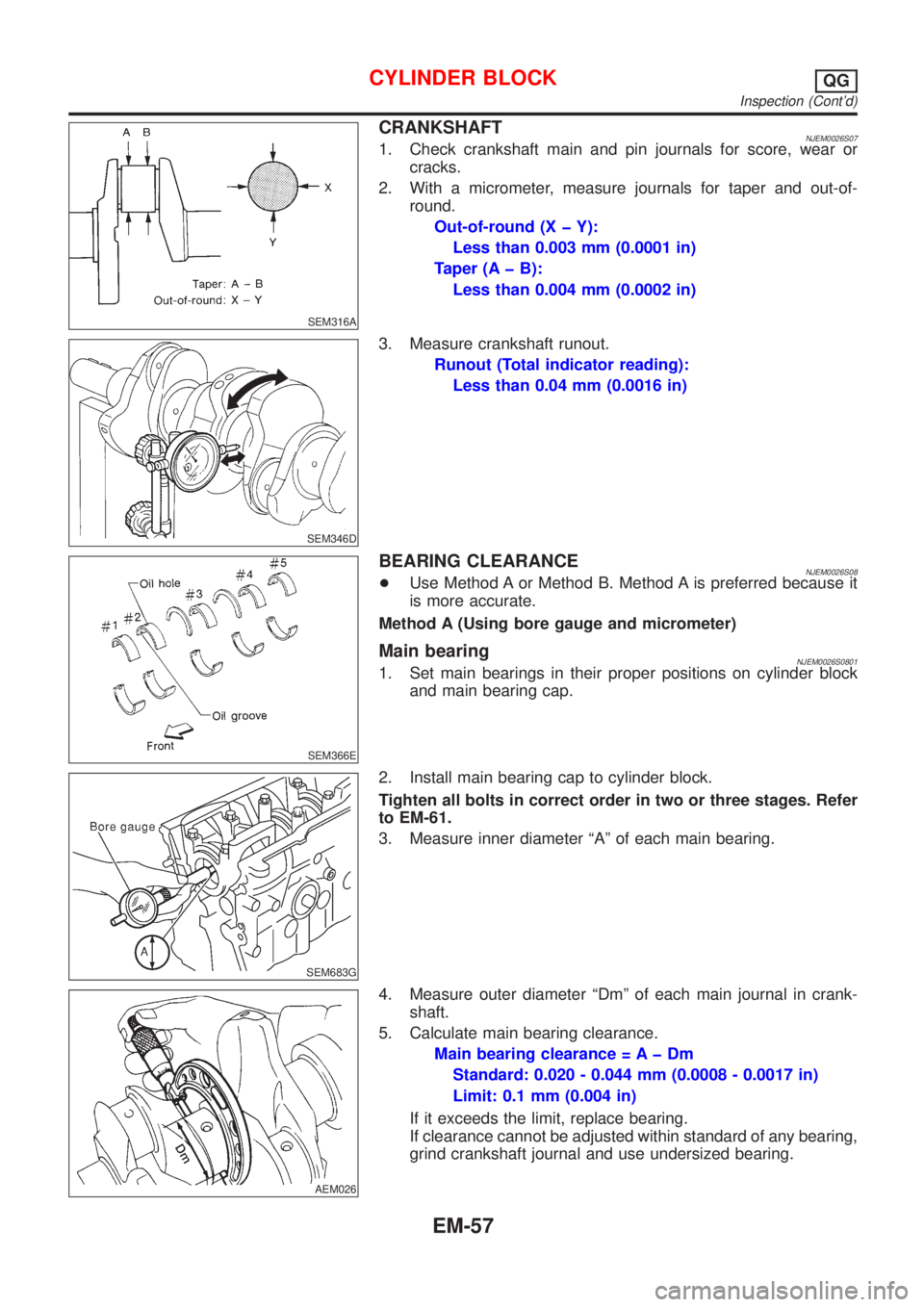

SEM316A

CRANKSHAFTNJEM0026S071. Check crankshaft main and pin journals for score, wear or

cracks.

2. With a micrometer, measure journals for taper and out-of-

round.

Out-of-round (X þ Y):

Less than 0.003 mm (0.0001 in)

Taper (A þ B):

Less than 0.004 mm (0.0002 in)

SEM346D

3. Measure crankshaft runout.

Runout (Total indicator reading):

Less than 0.04 mm (0.0016 in)

SEM366E

BEARING CLEARANCENJEM0026S08+Use Method A or Method B. Method A is preferred because it

is more accurate.

Method A (Using bore gauge and micrometer)

Main bearingNJEM0026S08011. Set main bearings in their proper positions on cylinder block

and main bearing cap.

SEM683G

2. Install main bearing cap to cylinder block.

Tighten all bolts in correct order in two or three stages. Refer

to EM-61.

3. Measure inner diameter ªAº of each main bearing.

AEM026

4. Measure outer diameter ªDmº of each main journal in crank-

shaft.

5. Calculate main bearing clearance.

Main bearing clearance = A þ Dm

Standard: 0.020 - 0.044 mm (0.0008 - 0.0017 in)

Limit: 0.1 mm (0.004 in)

If it exceeds the limit, replace bearing.

If clearance cannot be adjusted within standard of any bearing,

grind crankshaft journal and use undersized bearing.

CYLINDER BLOCKQG

Inspection (Cont'd)

EM-57