Meter NISSAN ALMERA N16 2001 Electronic Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 222 of 2493

AEM023

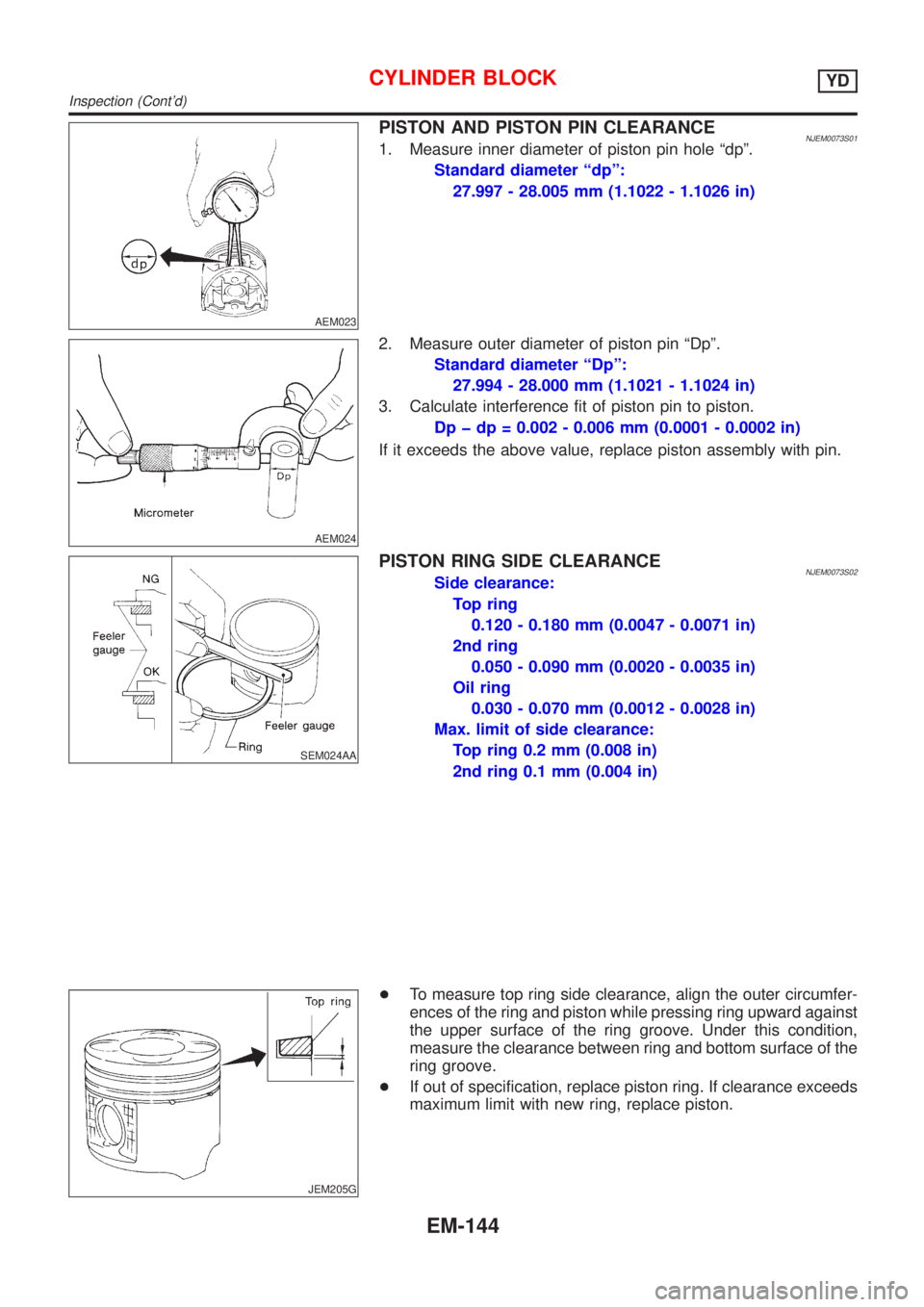

PISTON AND PISTON PIN CLEARANCENJEM0073S011. Measure inner diameter of piston pin hole ªdpº.

Standard diameter ªdpº:

27.997 - 28.005 mm (1.1022 - 1.1026 in)

AEM024

2. Measure outer diameter of piston pin ªDpº.

Standard diameter ªDpº:

27.994 - 28.000 mm (1.1021 - 1.1024 in)

3. Calculate interference fit of piston pin to piston.

Dp þ dp = 0.002 - 0.006 mm (0.0001 - 0.0002 in)

If it exceeds the above value, replace piston assembly with pin.

SEM024AA

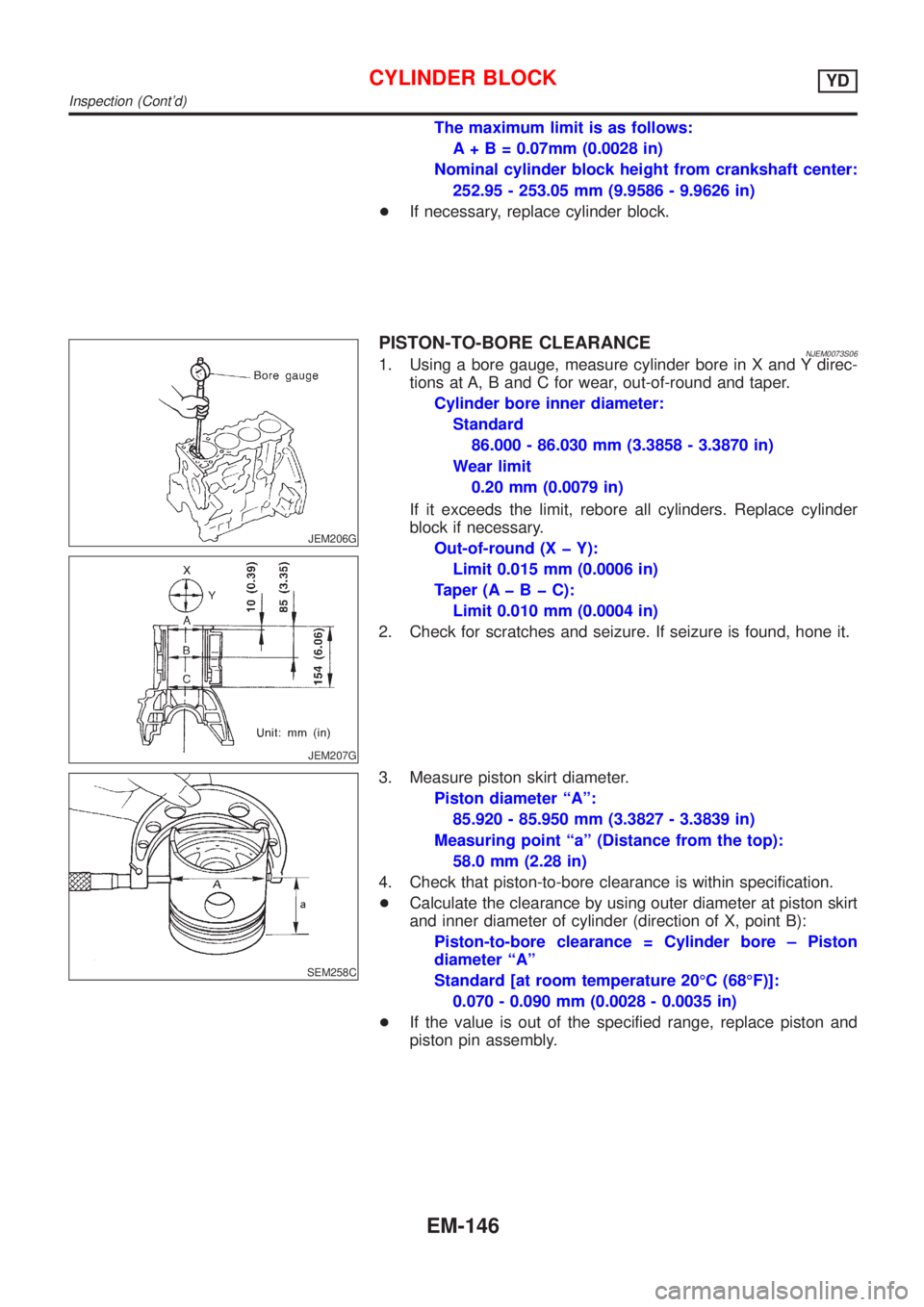

PISTON RING SIDE CLEARANCENJEM0073S02Side clearance:

Top ring

0.120 - 0.180 mm (0.0047 - 0.0071 in)

2nd ring

0.050 - 0.090 mm (0.0020 - 0.0035 in)

Oil ring

0.030 - 0.070 mm (0.0012 - 0.0028 in)

Max. limit of side clearance:

Top ring 0.2 mm (0.008 in)

2nd ring 0.1 mm (0.004 in)

JEM205G

+To measure top ring side clearance, align the outer circumfer-

ences of the ring and piston while pressing ring upward against

the upper surface of the ring groove. Under this condition,

measure the clearance between ring and bottom surface of the

ring groove.

+If out of specification, replace piston ring. If clearance exceeds

maximum limit with new ring, replace piston.

CYLINDER BLOCKYD

Inspection (Cont'd)

EM-144

Page 224 of 2493

The maximum limit is as follows:

A + B = 0.07mm (0.0028 in)

Nominal cylinder block height from crankshaft center:

252.95 - 253.05 mm (9.9586 - 9.9626 in)

+If necessary, replace cylinder block.

JEM206G

JEM207G

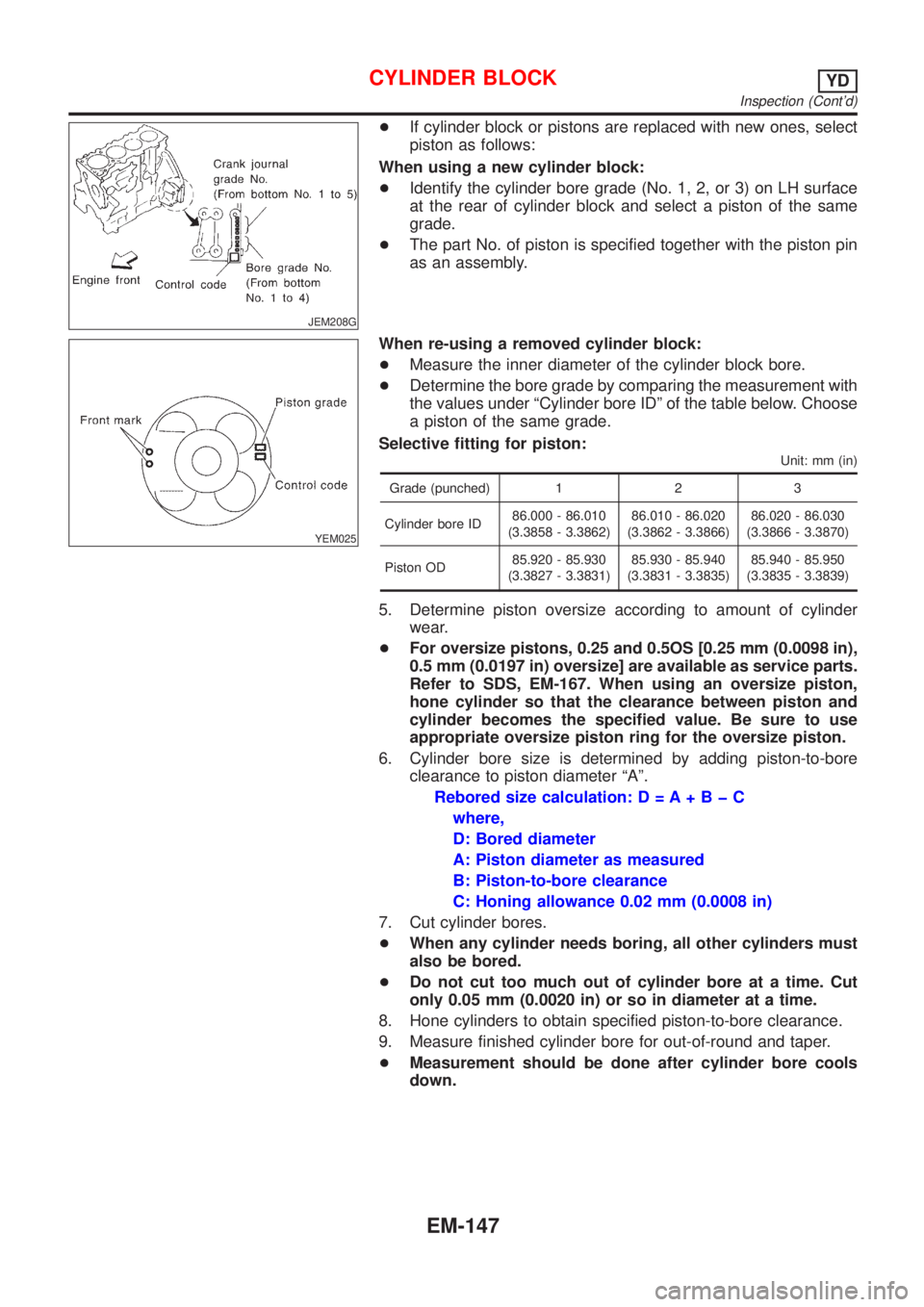

PISTON-TO-BORE CLEARANCENJEM0073S061. Using a bore gauge, measure cylinder bore in X and Y direc-

tions at A, B and C for wear, out-of-round and taper.

Cylinder bore inner diameter:

Standard

86.000 - 86.030 mm (3.3858 - 3.3870 in)

Wear limit

0.20 mm (0.0079 in)

If it exceeds the limit, rebore all cylinders. Replace cylinder

block if necessary.

Out-of-round (X þ Y):

Limit 0.015 mm (0.0006 in)

Taper (AþBþC):

Limit 0.010 mm (0.0004 in)

2. Check for scratches and seizure. If seizure is found, hone it.

SEM258C

3. Measure piston skirt diameter.

Piston diameter ªAº:

85.920 - 85.950 mm (3.3827 - 3.3839 in)

Measuring point ªaº (Distance from the top):

58.0 mm (2.28 in)

4. Check that piston-to-bore clearance is within specification.

+Calculate the clearance by using outer diameter at piston skirt

and inner diameter of cylinder (direction of X, point B):

Piston-to-bore clearance = Cylinder bore ± Piston

diameter ªAº

Standard [at room temperature 20ÉC (68ÉF)]:

0.070 - 0.090 mm (0.0028 - 0.0035 in)

+If the value is out of the specified range, replace piston and

piston pin assembly.

CYLINDER BLOCKYD

Inspection (Cont'd)

EM-146

Page 225 of 2493

JEM208G

+If cylinder block or pistons are replaced with new ones, select

piston as follows:

When using a new cylinder block:

+Identify the cylinder bore grade (No. 1, 2, or 3) on LH surface

at the rear of cylinder block and select a piston of the same

grade.

+The part No. of piston is specified together with the piston pin

as an assembly.

YEM025

When re-using a removed cylinder block:

+Measure the inner diameter of the cylinder block bore.

+Determine the bore grade by comparing the measurement with

the values under ªCylinder bore IDº of the table below. Choose

a piston of the same grade.

Selective fitting for piston:

Unit: mm (in)

Grade (punched) 1 2 3

Cylinder bore ID86.000 - 86.010

(3.3858 - 3.3862)86.010 - 86.020

(3.3862 - 3.3866)86.020 - 86.030

(3.3866 - 3.3870)

Piston OD85.920 - 85.930

(3.3827 - 3.3831)85.930 - 85.940

(3.3831 - 3.3835)85.940 - 85.950

(3.3835 - 3.3839)

5. Determine piston oversize according to amount of cylinder

wear.

+For oversize pistons, 0.25 and 0.5OS [0.25 mm (0.0098 in),

0.5 mm (0.0197 in) oversize] are available as service parts.

Refer to SDS, EM-167. When using an oversize piston,

hone cylinder so that the clearance between piston and

cylinder becomes the specified value. Be sure to use

appropriate oversize piston ring for the oversize piston.

6. Cylinder bore size is determined by adding piston-to-bore

clearance to piston diameter ªAº.

Rebored size calculation: D = A+BþC

where,

D: Bored diameter

A: Piston diameter as measured

B: Piston-to-bore clearance

C: Honing allowance 0.02 mm (0.0008 in)

7. Cut cylinder bores.

+When any cylinder needs boring, all other cylinders must

also be bored.

+Do not cut too much out of cylinder bore at a time. Cut

only 0.05 mm (0.0020 in) or so in diameter at a time.

8. Hone cylinders to obtain specified piston-to-bore clearance.

9. Measure finished cylinder bore for out-of-round and taper.

+Measurement should be done after cylinder bore cools

down.

CYLINDER BLOCKYD

Inspection (Cont'd)

EM-147

Page 226 of 2493

SEM316A

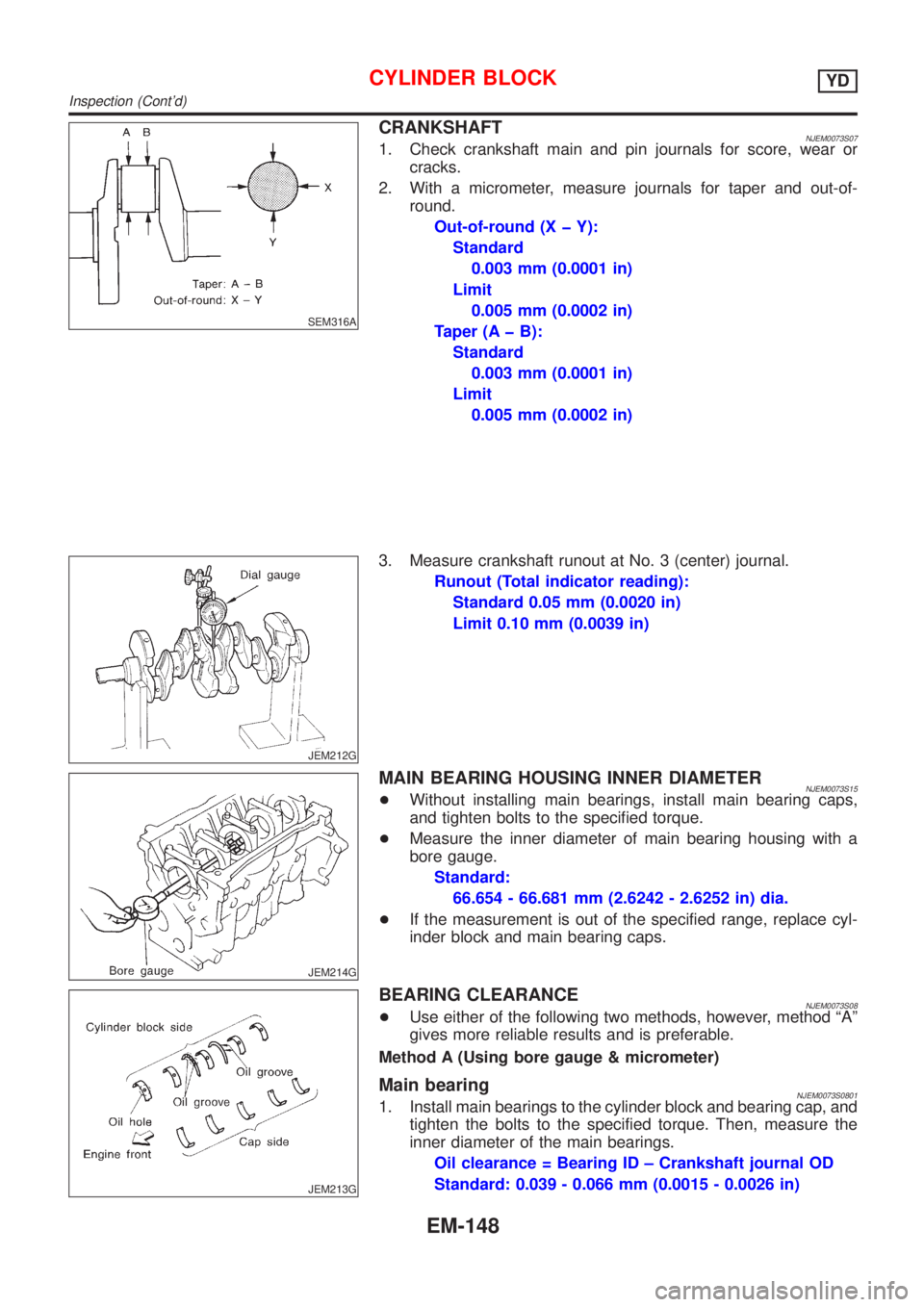

CRANKSHAFTNJEM0073S071. Check crankshaft main and pin journals for score, wear or

cracks.

2. With a micrometer, measure journals for taper and out-of-

round.

Out-of-round (X þ Y):

Standard

0.003 mm (0.0001 in)

Limit

0.005 mm (0.0002 in)

Taper (A þ B):

Standard

0.003 mm (0.0001 in)

Limit

0.005 mm (0.0002 in)

JEM212G

3. Measure crankshaft runout at No. 3 (center) journal.

Runout (Total indicator reading):

Standard 0.05 mm (0.0020 in)

Limit 0.10 mm (0.0039 in)

JEM214G

MAIN BEARING HOUSING INNER DIAMETERNJEM0073S15+Without installing main bearings, install main bearing caps,

and tighten bolts to the specified torque.

+Measure the inner diameter of main bearing housing with a

bore gauge.

Standard:

66.654 - 66.681 mm (2.6242 - 2.6252 in) dia.

+If the measurement is out of the specified range, replace cyl-

inder block and main bearing caps.

JEM213G

BEARING CLEARANCENJEM0073S08+Use either of the following two methods, however, method ªAº

gives more reliable results and is preferable.

Method A (Using bore gauge & micrometer)

Main bearingNJEM0073S08011. Install main bearings to the cylinder block and bearing cap, and

tighten the bolts to the specified torque. Then, measure the

inner diameter of the main bearings.

Oil clearance = Bearing ID ± Crankshaft journal OD

Standard: 0.039 - 0.066 mm (0.0015 - 0.0026 in)

CYLINDER BLOCKYD

Inspection (Cont'd)

EM-148

Page 227 of 2493

2. If the value is out of the specified range, select main bearings

to obtain the specified oil clearance, based on the measure-

ments of the main bearing housing inner diameter and crank-

shaft journal outer diameter.

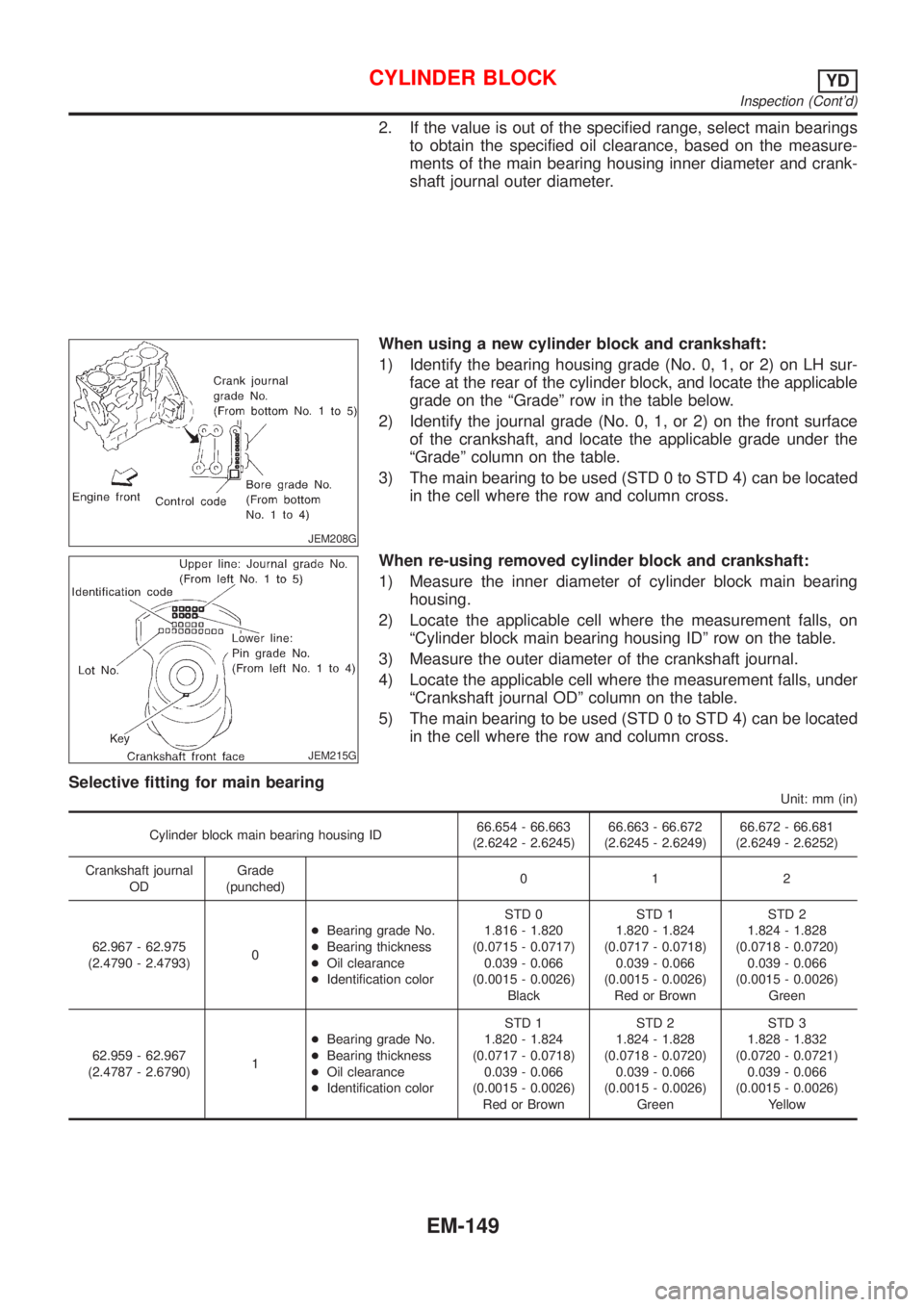

JEM208G

When using a new cylinder block and crankshaft:

1) Identify the bearing housing grade (No. 0, 1, or 2) on LH sur-

face at the rear of the cylinder block, and locate the applicable

grade on the ªGradeº row in the table below.

2) Identify the journal grade (No. 0, 1, or 2) on the front surface

of the crankshaft, and locate the applicable grade under the

ªGradeº column on the table.

3) The main bearing to be used (STD 0 to STD 4) can be located

in the cell where the row and column cross.

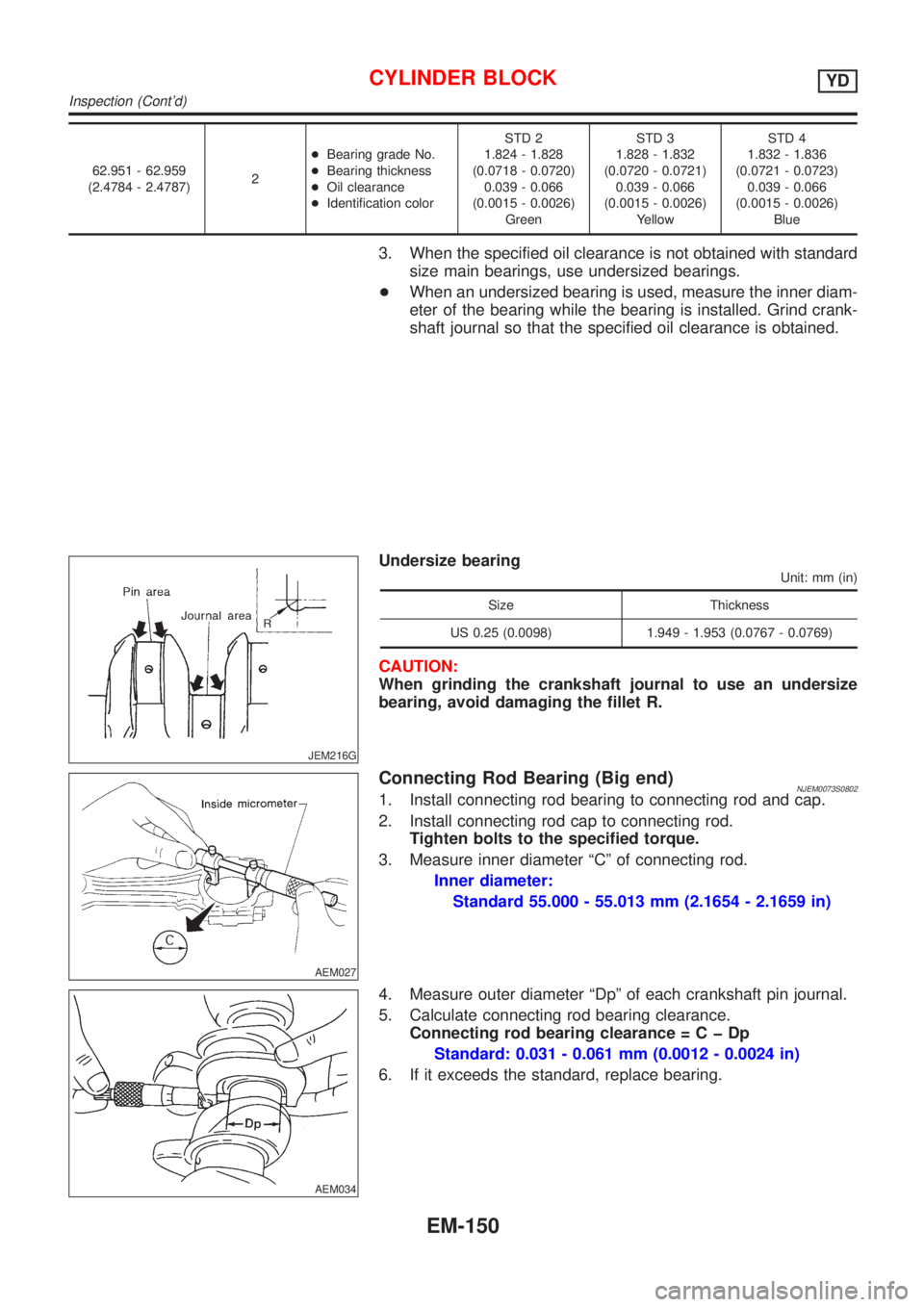

JEM215G

When re-using removed cylinder block and crankshaft:

1) Measure the inner diameter of cylinder block main bearing

housing.

2) Locate the applicable cell where the measurement falls, on

ªCylinder block main bearing housing IDº row on the table.

3) Measure the outer diameter of the crankshaft journal.

4) Locate the applicable cell where the measurement falls, under

ªCrankshaft journal ODº column on the table.

5) The main bearing to be used (STD 0 to STD 4) can be located

in the cell where the row and column cross.

Selective fitting for main bearing

Unit: mm (in)

Cylinder block main bearing housing ID66.654 - 66.663

(2.6242 - 2.6245)66.663 - 66.672

(2.6245 - 2.6249)66.672 - 66.681

(2.6249 - 2.6252)

Crankshaft journal

ODGrade

(punched)012

62.967 - 62.975

(2.4790 - 2.4793)0+Bearing grade No.

+Bearing thickness

+Oil clearance

+Identification colorSTD 0

1.816 - 1.820

(0.0715 - 0.0717)

0.039 - 0.066

(0.0015 - 0.0026)

BlackSTD 1

1.820 - 1.824

(0.0717 - 0.0718)

0.039 - 0.066

(0.0015 - 0.0026)

Red or BrownSTD 2

1.824 - 1.828

(0.0718 - 0.0720)

0.039 - 0.066

(0.0015 - 0.0026)

Green

62.959 - 62.967

(2.4787 - 2.6790)1+Bearing grade No.

+Bearing thickness

+Oil clearance

+Identification colorSTD 1

1.820 - 1.824

(0.0717 - 0.0718)

0.039 - 0.066

(0.0015 - 0.0026)

Red or BrownSTD 2

1.824 - 1.828

(0.0718 - 0.0720)

0.039 - 0.066

(0.0015 - 0.0026)

GreenSTD 3

1.828 - 1.832

(0.0720 - 0.0721)

0.039 - 0.066

(0.0015 - 0.0026)

Yellow

CYLINDER BLOCKYD

Inspection (Cont'd)

EM-149

Page 228 of 2493

62.951 - 62.959

(2.4784 - 2.4787)2+Bearing grade No.

+Bearing thickness

+Oil clearance

+Identification colorSTD 2

1.824 - 1.828

(0.0718 - 0.0720)

0.039 - 0.066

(0.0015 - 0.0026)

GreenSTD 3

1.828 - 1.832

(0.0720 - 0.0721)

0.039 - 0.066

(0.0015 - 0.0026)

YellowSTD 4

1.832 - 1.836

(0.0721 - 0.0723)

0.039 - 0.066

(0.0015 - 0.0026)

Blue

3. When the specified oil clearance is not obtained with standard

size main bearings, use undersized bearings.

+When an undersized bearing is used, measure the inner diam-

eter of the bearing while the bearing is installed. Grind crank-

shaft journal so that the specified oil clearance is obtained.

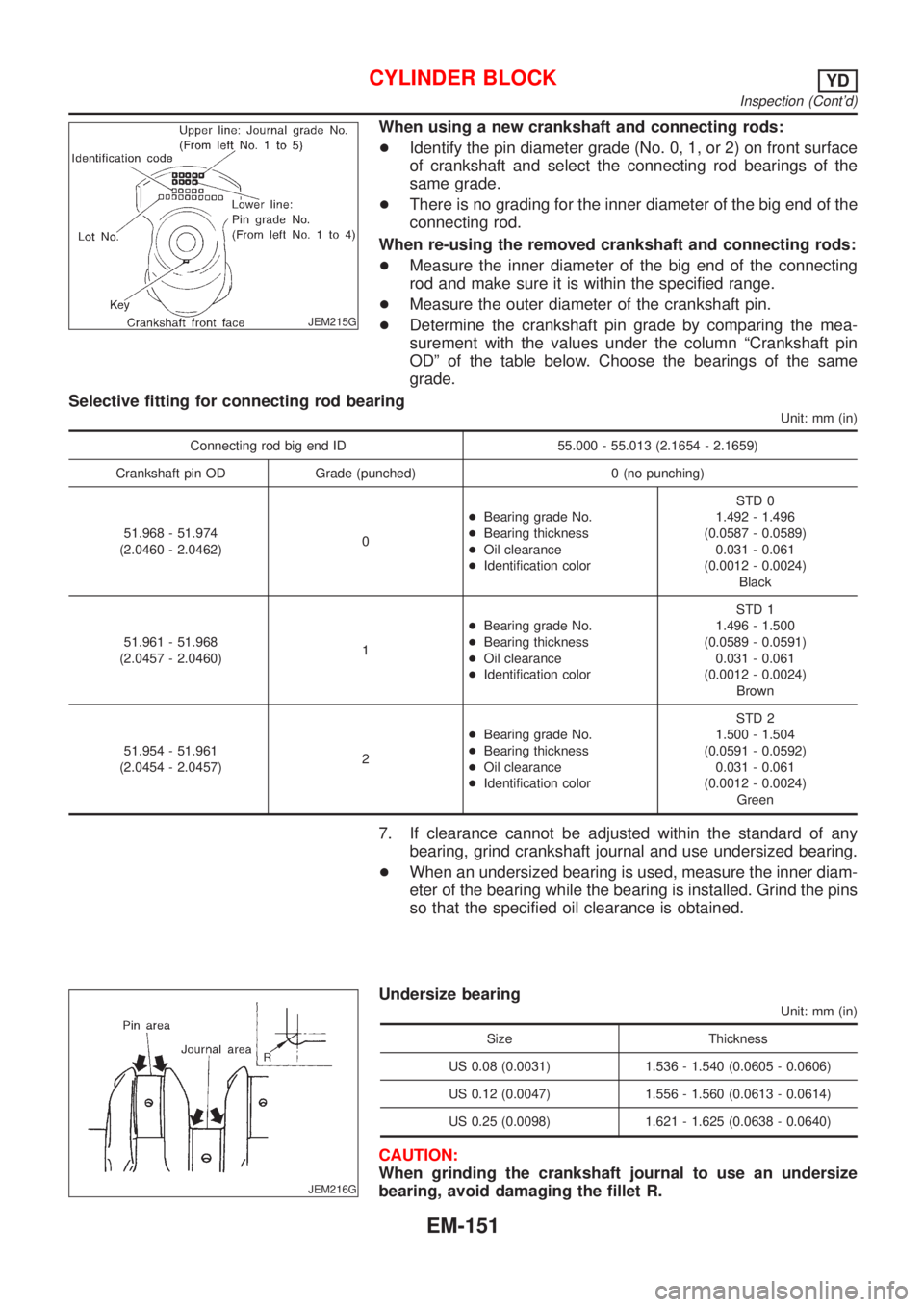

JEM216G

Undersize bearing

Unit: mm (in)

Size Thickness

US 0.25 (0.0098) 1.949 - 1.953 (0.0767 - 0.0769)

CAUTION:

When grinding the crankshaft journal to use an undersize

bearing, avoid damaging the fillet R.

AEM027

Connecting Rod Bearing (Big end)NJEM0073S08021. Install connecting rod bearing to connecting rod and cap.

2. Install connecting rod cap to connecting rod.

Tighten bolts to the specified torque.

3. Measure inner diameter ªCº of connecting rod.

Inner diameter:

Standard 55.000 - 55.013 mm (2.1654 - 2.1659 in)

AEM034

4. Measure outer diameter ªDpº of each crankshaft pin journal.

5. Calculate connecting rod bearing clearance.

Connecting rod bearing clearance=CþDp

Standard: 0.031 - 0.061 mm (0.0012 - 0.0024 in)

6. If it exceeds the standard, replace bearing.

CYLINDER BLOCKYD

Inspection (Cont'd)

EM-150

Page 229 of 2493

JEM215G

When using a new crankshaft and connecting rods:

+Identify the pin diameter grade (No. 0, 1, or 2) on front surface

of crankshaft and select the connecting rod bearings of the

same grade.

+There is no grading for the inner diameter of the big end of the

connecting rod.

When re-using the removed crankshaft and connecting rods:

+Measure the inner diameter of the big end of the connecting

rod and make sure it is within the specified range.

+Measure the outer diameter of the crankshaft pin.

+Determine the crankshaft pin grade by comparing the mea-

surement with the values under the column ªCrankshaft pin

ODº of the table below. Choose the bearings of the same

grade.

Selective fitting for connecting rod bearing

Unit: mm (in)

Connecting rod big end ID 55.000 - 55.013 (2.1654 - 2.1659)

Crankshaft pin OD Grade (punched) 0 (no punching)

51.968 - 51.974

(2.0460 - 2.0462)0+Bearing grade No.

+Bearing thickness

+Oil clearance

+Identification colorSTD 0

1.492 - 1.496

(0.0587 - 0.0589)

0.031 - 0.061

(0.0012 - 0.0024)

Black

51.961 - 51.968

(2.0457 - 2.0460)1+Bearing grade No.

+Bearing thickness

+Oil clearance

+Identification colorSTD 1

1.496 - 1.500

(0.0589 - 0.0591)

0.031 - 0.061

(0.0012 - 0.0024)

Brown

51.954 - 51.961

(2.0454 - 2.0457)2+Bearing grade No.

+Bearing thickness

+Oil clearance

+Identification colorSTD 2

1.500 - 1.504

(0.0591 - 0.0592)

0.031 - 0.061

(0.0012 - 0.0024)

Green

7. If clearance cannot be adjusted within the standard of any

bearing, grind crankshaft journal and use undersized bearing.

+When an undersized bearing is used, measure the inner diam-

eter of the bearing while the bearing is installed. Grind the pins

so that the specified oil clearance is obtained.

JEM216G

Undersize bearing

Unit: mm (in)

Size Thickness

US 0.08 (0.0031) 1.536 - 1.540 (0.0605 - 0.0606)

US 0.12 (0.0047) 1.556 - 1.560 (0.0613 - 0.0614)

US 0.25 (0.0098) 1.621 - 1.625 (0.0638 - 0.0640)

CAUTION:

When grinding the crankshaft journal to use an undersize

bearing, avoid damaging the fillet R.

CYLINDER BLOCKYD

Inspection (Cont'd)

EM-151

Page 230 of 2493

Standard dimension R:

1.5 - 1.7 mm (0.0591 - 0.0669 in)

EM142

Method B (Using plastigage)

CAUTION:

+Do not turn crankshaft or connecting rod while plastigage

is being inserted.

+When bearing clearance exceeds the specified limit,

ensure that the proper bearing has been installed. If incor-

rect bearing clearance exists, use a thicker or undersized

main bearing to ensure specified clearance.

SEM502G

MAIN BEARING CRUSH HEIGHTNJEM0073S16+When the bearing cap is removed after being tightened to the

specified torque with main bearings installed, the tip end of

bearing must protrude.

Standard: There must be crush height.

+If the standard is not met, replace main bearings.

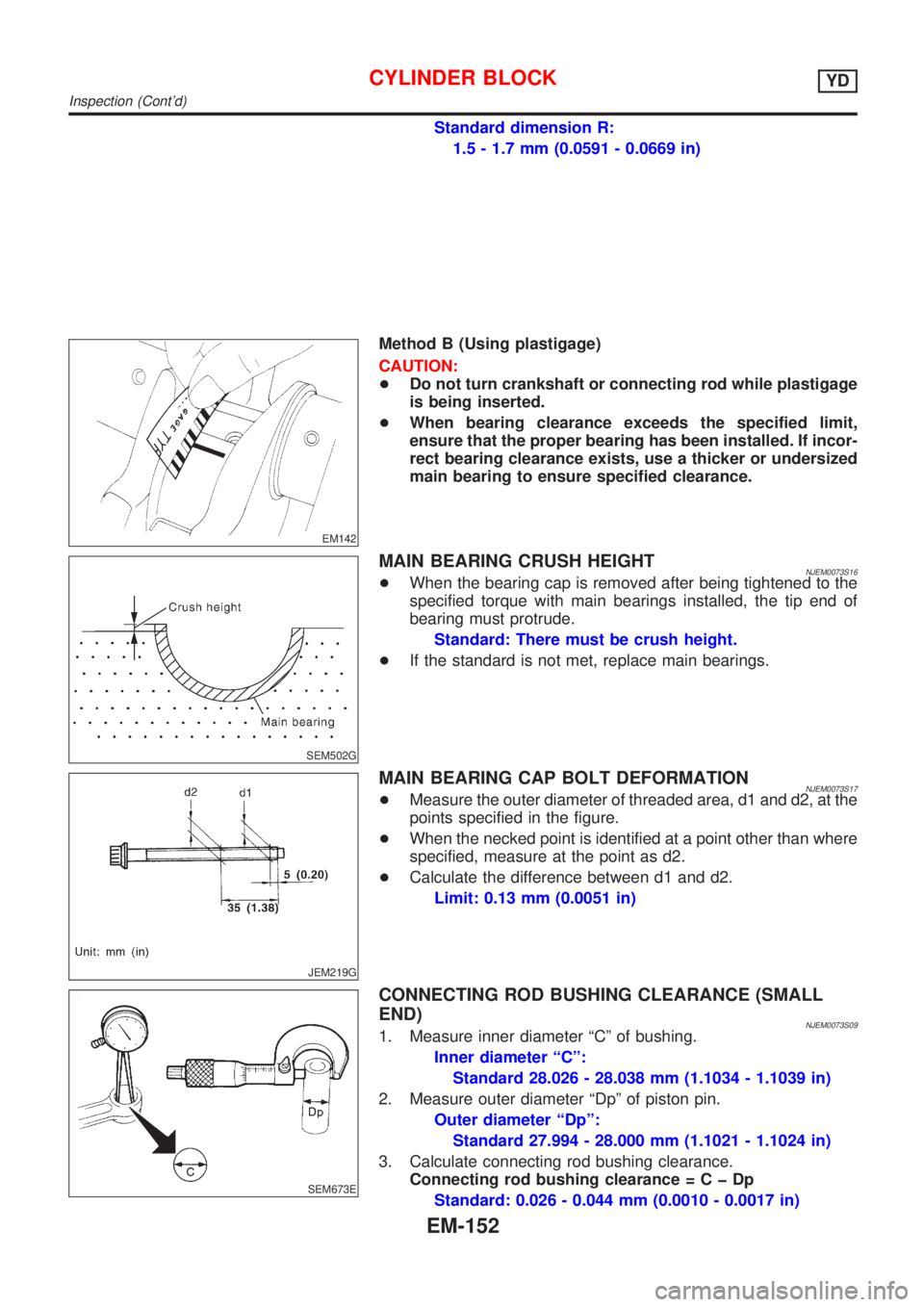

JEM219G

MAIN BEARING CAP BOLT DEFORMATIONNJEM0073S17+Measure the outer diameter of threaded area, d1 and d2, at the

points specified in the figure.

+When the necked point is identified at a point other than where

specified, measure at the point as d2.

+Calculate the difference between d1 and d2.

Limit: 0.13 mm (0.0051 in)

SEM673E

CONNECTING ROD BUSHING CLEARANCE (SMALL

END)

NJEM0073S091. Measure inner diameter ªCº of bushing.

Inner diameter ªCº:

Standard 28.026 - 28.038 mm (1.1034 - 1.1039 in)

2. Measure outer diameter ªDpº of piston pin.

Outer diameter ªDpº:

Standard 27.994 - 28.000 mm (1.1021 - 1.1024 in)

3. Calculate connecting rod bushing clearance.

Connecting rod bushing clearance=CþDp

Standard: 0.026 - 0.044 mm (0.0010 - 0.0017 in)

CYLINDER BLOCKYD

Inspection (Cont'd)

EM-152

Page 233 of 2493

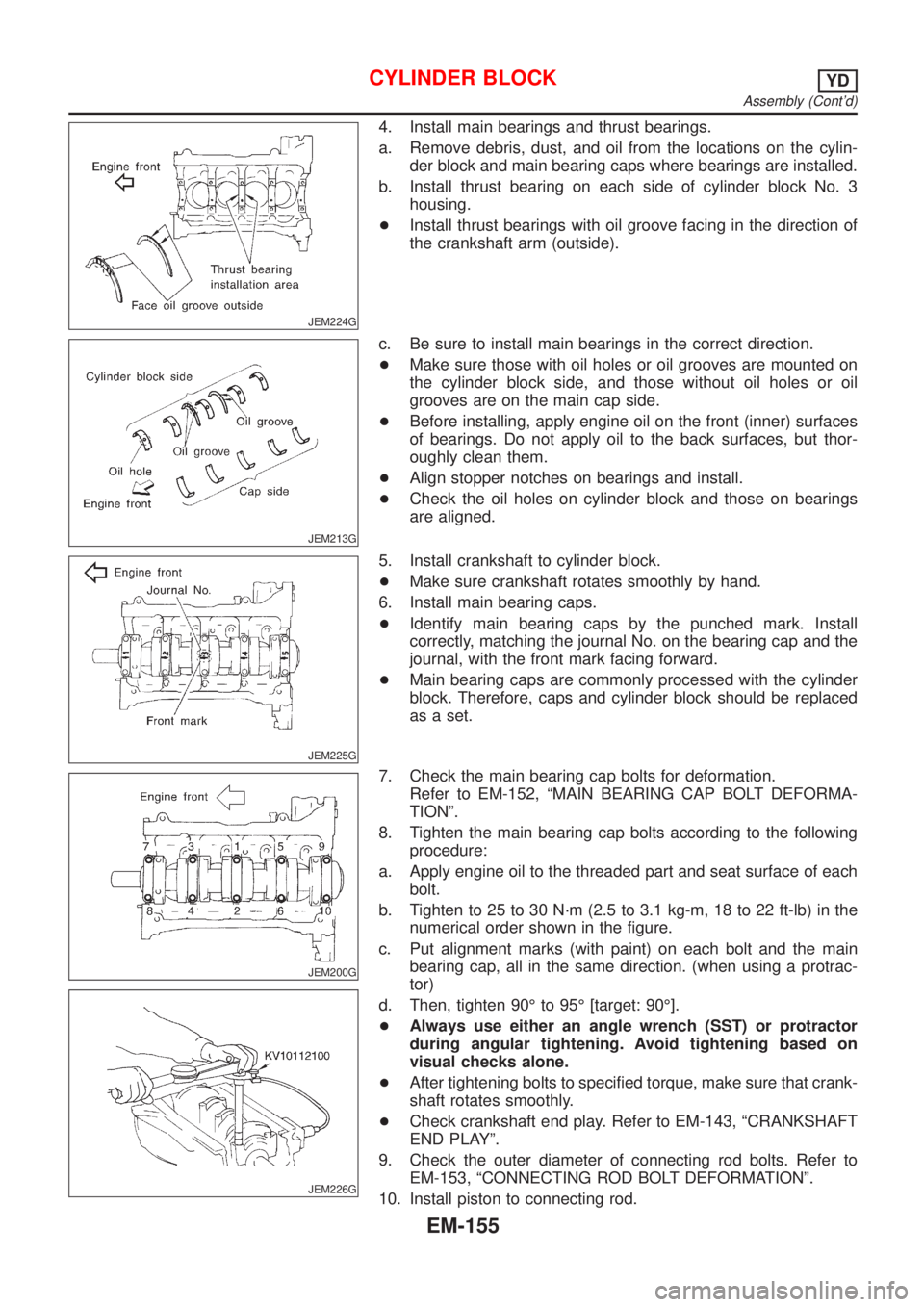

JEM224G

4. Install main bearings and thrust bearings.

a. Remove debris, dust, and oil from the locations on the cylin-

der block and main bearing caps where bearings are installed.

b. Install thrust bearing on each side of cylinder block No. 3

housing.

+Install thrust bearings with oil groove facing in the direction of

the crankshaft arm (outside).

JEM213G

c. Be sure to install main bearings in the correct direction.

+Make sure those with oil holes or oil grooves are mounted on

the cylinder block side, and those without oil holes or oil

grooves are on the main cap side.

+Before installing, apply engine oil on the front (inner) surfaces

of bearings. Do not apply oil to the back surfaces, but thor-

oughly clean them.

+Align stopper notches on bearings and install.

+Check the oil holes on cylinder block and those on bearings

are aligned.

JEM225G

5. Install crankshaft to cylinder block.

+Make sure crankshaft rotates smoothly by hand.

6. Install main bearing caps.

+Identify main bearing caps by the punched mark. Install

correctly, matching the journal No. on the bearing cap and the

journal, with the front mark facing forward.

+Main bearing caps are commonly processed with the cylinder

block. Therefore, caps and cylinder block should be replaced

as a set.

JEM200G

JEM226G

7. Check the main bearing cap bolts for deformation.

Refer to EM-152, ªMAIN BEARING CAP BOLT DEFORMA-

TIONº.

8. Tighten the main bearing cap bolts according to the following

procedure:

a. Apply engine oil to the threaded part and seat surface of each

bolt.

b. Tighten to 25 to 30 N´m (2.5 to 3.1 kg-m, 18 to 22 ft-lb) in the

numerical order shown in the figure.

c. Put alignment marks (with paint) on each bolt and the main

bearing cap, all in the same direction. (when using a protrac-

tor)

d. Then, tighten 90É to 95É [target: 90É].

+Always use either an angle wrench (SST) or protractor

during angular tightening. Avoid tightening based on

visual checks alone.

+After tightening bolts to specified torque, make sure that crank-

shaft rotates smoothly.

+Check crankshaft end play. Refer to EM-143, ªCRANKSHAFT

END PLAYº.

9. Check the outer diameter of connecting rod bolts. Refer to

EM-153, ªCONNECTING ROD BOLT DEFORMATIONº.

10. Install piston to connecting rod.

CYLINDER BLOCKYD

Assembly (Cont'd)

EM-155

Page 238 of 2493

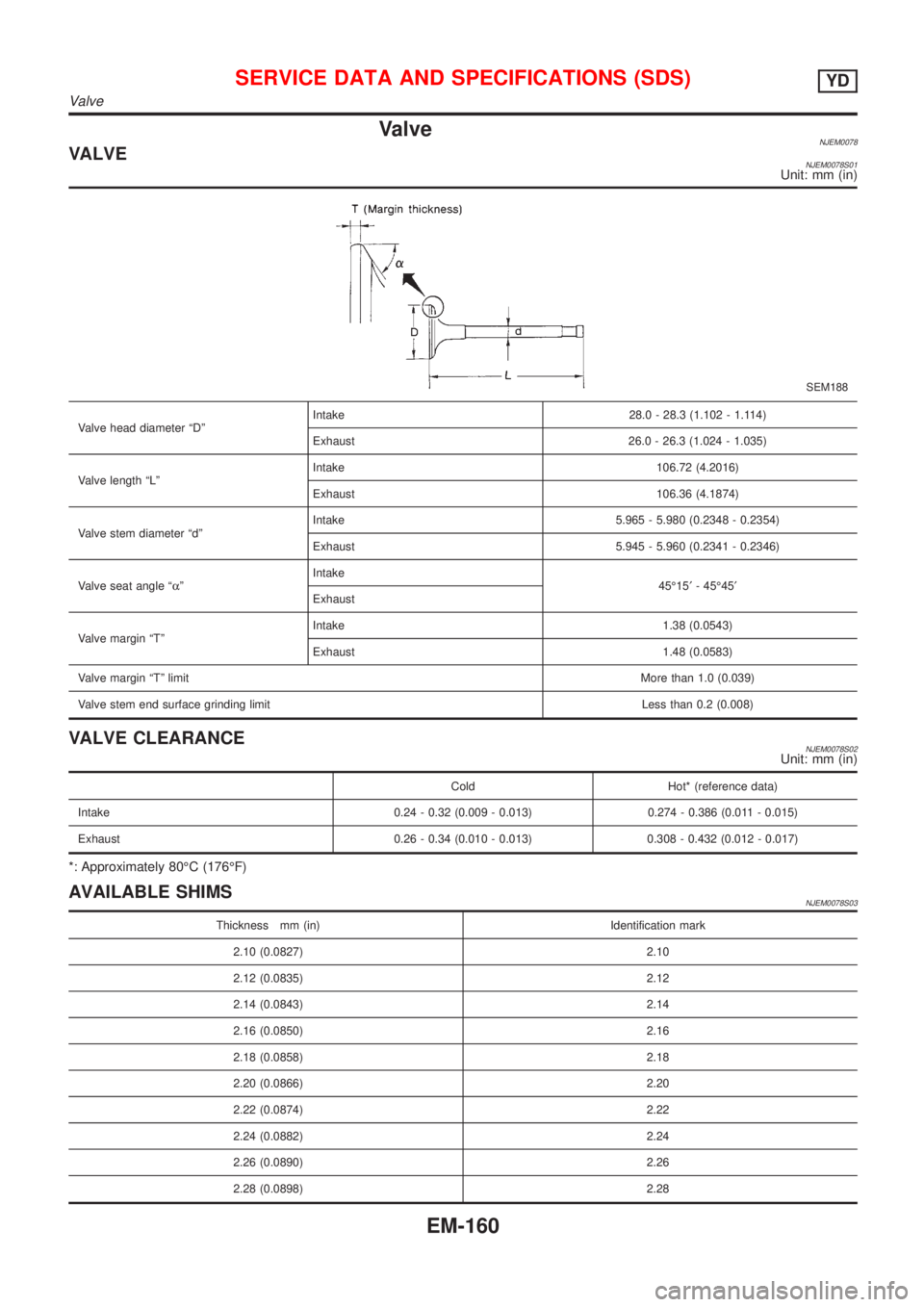

ValveNJEM0078VALVENJEM0078S01Unit: mm (in)

SEM188

Valve head diameter ªDºIntake 28.0 - 28.3 (1.102 - 1.114)

Exhaust 26.0 - 26.3 (1.024 - 1.035)

Valve length ªLºIntake 106.72 (4.2016)

Exhaust 106.36 (4.1874)

Valve stem diameter ªdºIntake 5.965 - 5.980 (0.2348 - 0.2354)

Exhaust 5.945 - 5.960 (0.2341 - 0.2346)

Valve seat angle ªaºIntake

45É15¢- 45É45¢

Exhaust

Valve margin ªTºIntake 1.38 (0.0543)

Exhaust 1.48 (0.0583)

Valve margin ªTº limitMore than 1.0 (0.039)

Valve stem end surface grinding limit Less than 0.2 (0.008)

VALVE CLEARANCENJEM0078S02Unit: mm (in)

Cold Hot* (reference data)

Intake 0.24 - 0.32 (0.009 - 0.013) 0.274 - 0.386 (0.011 - 0.015)

Exhaust 0.26 - 0.34 (0.010 - 0.013) 0.308 - 0.432 (0.012 - 0.017)

*: Approximately 80ÉC (176ÉF)

AVAILABLE SHIMSNJEM0078S03

Thickness mm (in) Identification mark

2.10 (0.0827) 2.10

2.12 (0.0835) 2.12

2.14 (0.0843) 2.14

2.16 (0.0850) 2.16

2.18 (0.0858) 2.18

2.20 (0.0866) 2.20

2.22 (0.0874) 2.22

2.24 (0.0882) 2.24

2.26 (0.0890) 2.26

2.28 (0.0898) 2.28

SERVICE DATA AND SPECIFICATIONS (SDS)YD

Valve

EM-160