Ignition switch NISSAN ALMERA N16 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 3093 of 3189

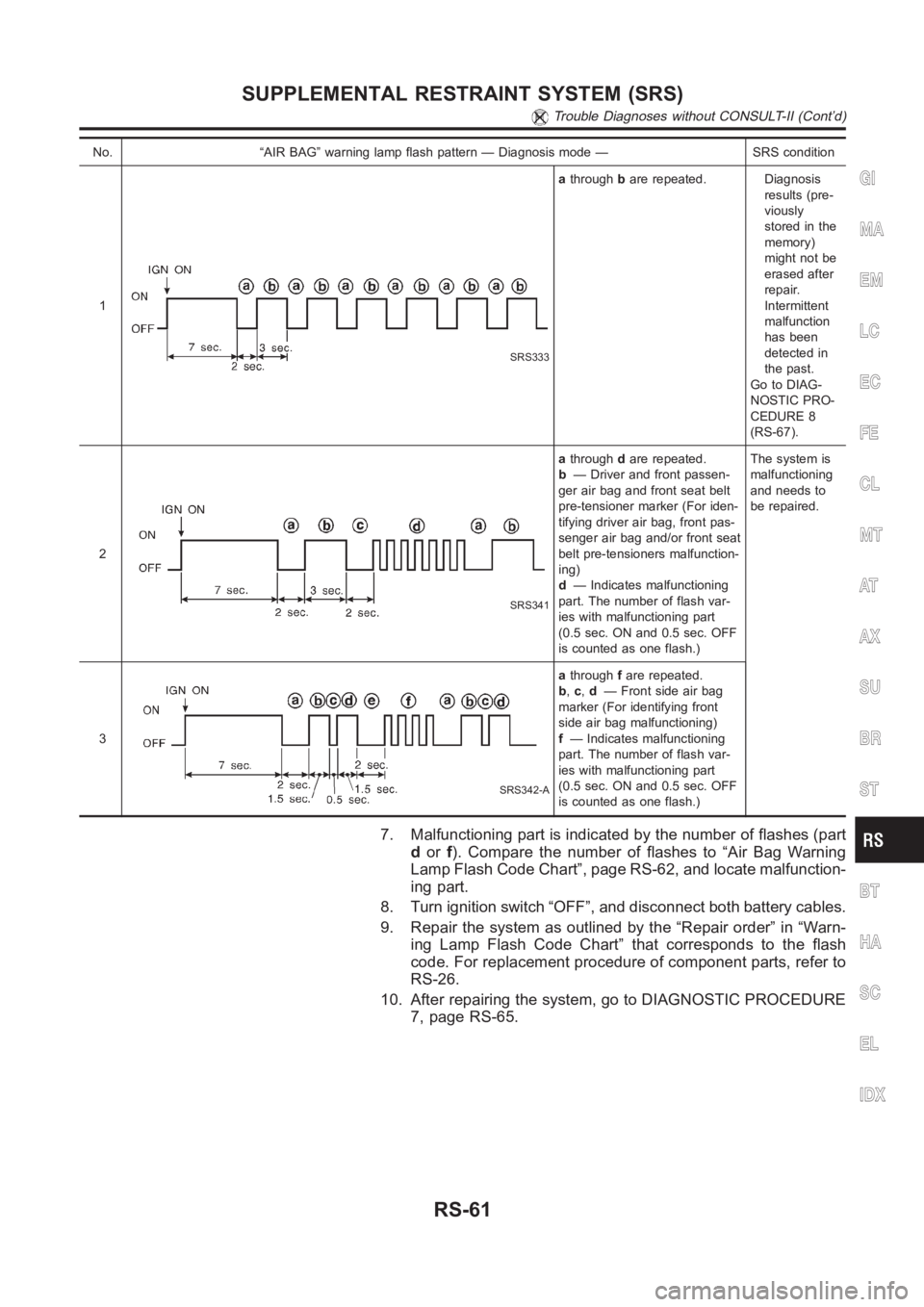

No. “AIR BAG” warning lamp flash pattern — Diagnosis mode — SRS condition

1

SRS333

athroughbare repeated. Diagnosis

results (pre-

viously

stored in the

memory)

might not be

erased after

repair.

Intermittent

malfunction

has been

detected in

the past.

Go to DIAG-

NOSTIC PRO-

CEDURE 8

(RS-67).

2

SRS341

athroughdare repeated.

b— Driver and front passen-

ger air bag and front seat belt

pre-tensioner marker (For iden-

tifying driver air bag, front pas-

senger air bag and/or front seat

belt pre-tensioners malfunction-

ing)

d— Indicates malfunctioning

part. The number of flash var-

ies with malfunctioning part

(0.5 sec. ON and 0.5 sec. OFF

is counted as one flash.)The system is

malfunctioning

and needs to

be repaired.

3

SRS342-A

athroughfare repeated.

b,c,d— Front side air bag

marker (For identifying front

side air bag malfunctioning)

f— Indicates malfunctioning

part. The number of flash var-

ies with malfunctioning part

(0.5 sec. ON and 0.5 sec. OFF

is counted as one flash.)

7. Malfunctioning part is indicated by the number of flashes (part

dorf). Compare the number of flashes to “Air Bag Warning

Lamp Flash Code Chart”, page RS-62, and locate malfunction-

ing part.

8. Turn ignition switch “OFF”, and disconnect both battery cables.

9. Repair the system as outlined by the “Repair order” in “Warn-

ing Lamp Flash Code Chart” that corresponds to the flash

code. For replacement procedure of component parts, refer to

RS-26.

10. After repairing the system, go to DIAGNOSTIC PROCEDURE

7, page RS-65.

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

BT

HA

SC

EL

IDX

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses without CONSULT-II (Cont’d)

RS-61

Page 3097 of 3189

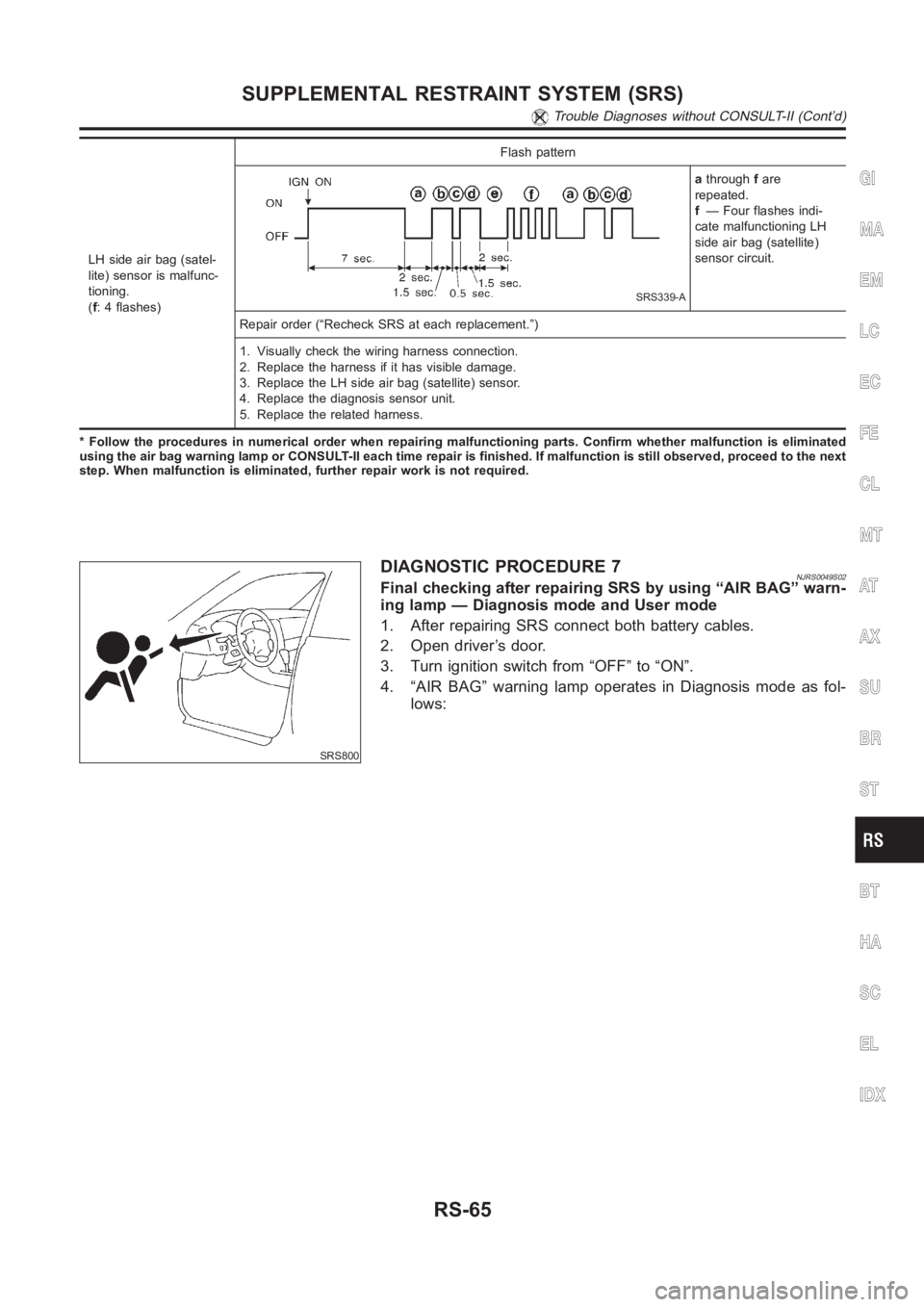

LH side air bag (satel-

lite) sensor is malfunc-

tioning.

(f: 4 flashes)Flash pattern

SRS339-A

athroughfare

repeated.

f— Four flashes indi-

cate malfunctioning LH

side air bag (satellite)

sensor circuit.

Repair order (“Recheck SRS at each replacement.”)

1. Visually check the wiring harness connection.

2. Replace the harness if it has visible damage.

3. Replace the LH side air bag (satellite) sensor.

4. Replace the diagnosis sensor unit.

5. Replace the related harness.

* Follow the procedures in numerical order when repairing malfunctioningparts. Confirm whether malfunction is eliminated

using the air bag warning lamp or CONSULT-II each time repair is finished. If malfunction is still observed, proceed to the next

step. When malfunction is eliminated, further repair work is not required.

SRS800

DIAGNOSTIC PROCEDURE 7NJRS0049S02Final checking after repairing SRS by using “AIR BAG” warn-

ing lamp — Diagnosis mode and User mode

1. After repairing SRS connect both battery cables.

2. Open driver’s door.

3. Turn ignition switch from “OFF” to “ON”.

4. “AIR BAG” warning lamp operates in Diagnosis mode as fol-

lows:

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

BT

HA

SC

EL

IDX

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses without CONSULT-II (Cont’d)

RS-65

Page 3098 of 3189

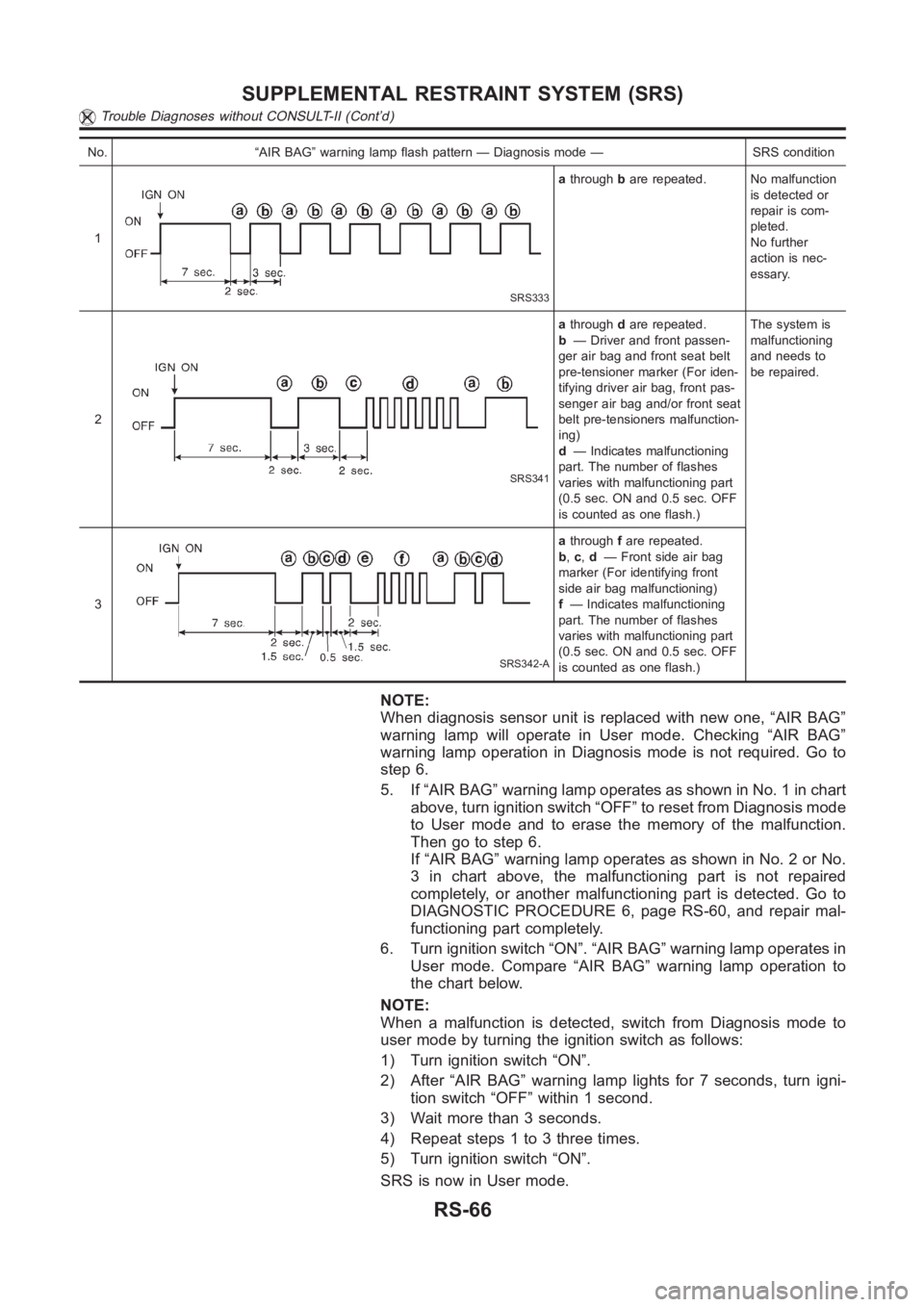

No. “AIR BAG” warning lamp flash pattern — Diagnosis mode — SRS condition

1

SRS333

athroughbare repeated. No malfunction

is detected or

repair is com-

pleted.

No further

action is nec-

essary.

2

SRS341

athroughdare repeated.

b— Driver and front passen-

ger air bag and front seat belt

pre-tensioner marker (For iden-

tifying driver air bag, front pas-

senger air bag and/or front seat

belt pre-tensioners malfunction-

ing)

d— Indicates malfunctioning

part. The number of flashes

varies with malfunctioning part

(0.5 sec. ON and 0.5 sec. OFF

is counted as one flash.)The system is

malfunctioning

and needs to

be repaired.

3

SRS342-A

athroughfare repeated.

b,c,d— Front side air bag

marker (For identifying front

side air bag malfunctioning)

f— Indicates malfunctioning

part. The number of flashes

varies with malfunctioning part

(0.5 sec. ON and 0.5 sec. OFF

is counted as one flash.)

NOTE:

When diagnosis sensor unit is replaced with new one, “AIR BAG”

warning lamp will operate in User mode. Checking “AIR BAG”

warning lamp operation in Diagnosis mode is not required. Go to

step 6.

5. If “AIR BAG” warning lamp operates as shown in No. 1 in chart

above, turn ignition switch “OFF” to reset from Diagnosis mode

to User mode and to erase the memory of the malfunction.

Then go to step 6.

If “AIR BAG” warning lamp operates as shown in No. 2 or No.

3 in chart above, the malfunctioning part is not repaired

completely, or another malfunctioning part is detected. Go to

DIAGNOSTIC PROCEDURE 6, page RS-60, and repair mal-

functioning part completely.

6. Turn ignition switch “ON”. “AIR BAG” warning lamp operates in

User mode. Compare “AIR BAG” warning lamp operation to

the chart below.

NOTE:

When a malfunction is detected, switch from Diagnosis mode to

user mode by turning the ignition switch as follows:

1) Turn ignition switch “ON”.

2) After “AIR BAG” warning lamp lights for 7 seconds, turn igni-

tion switch “OFF” within 1 second.

3) Wait more than 3 seconds.

4) Repeat steps 1 to 3 three times.

5) Turn ignition switch “ON”.

SRS is now in User mode.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses without CONSULT-II (Cont’d)

RS-66

Page 3100 of 3189

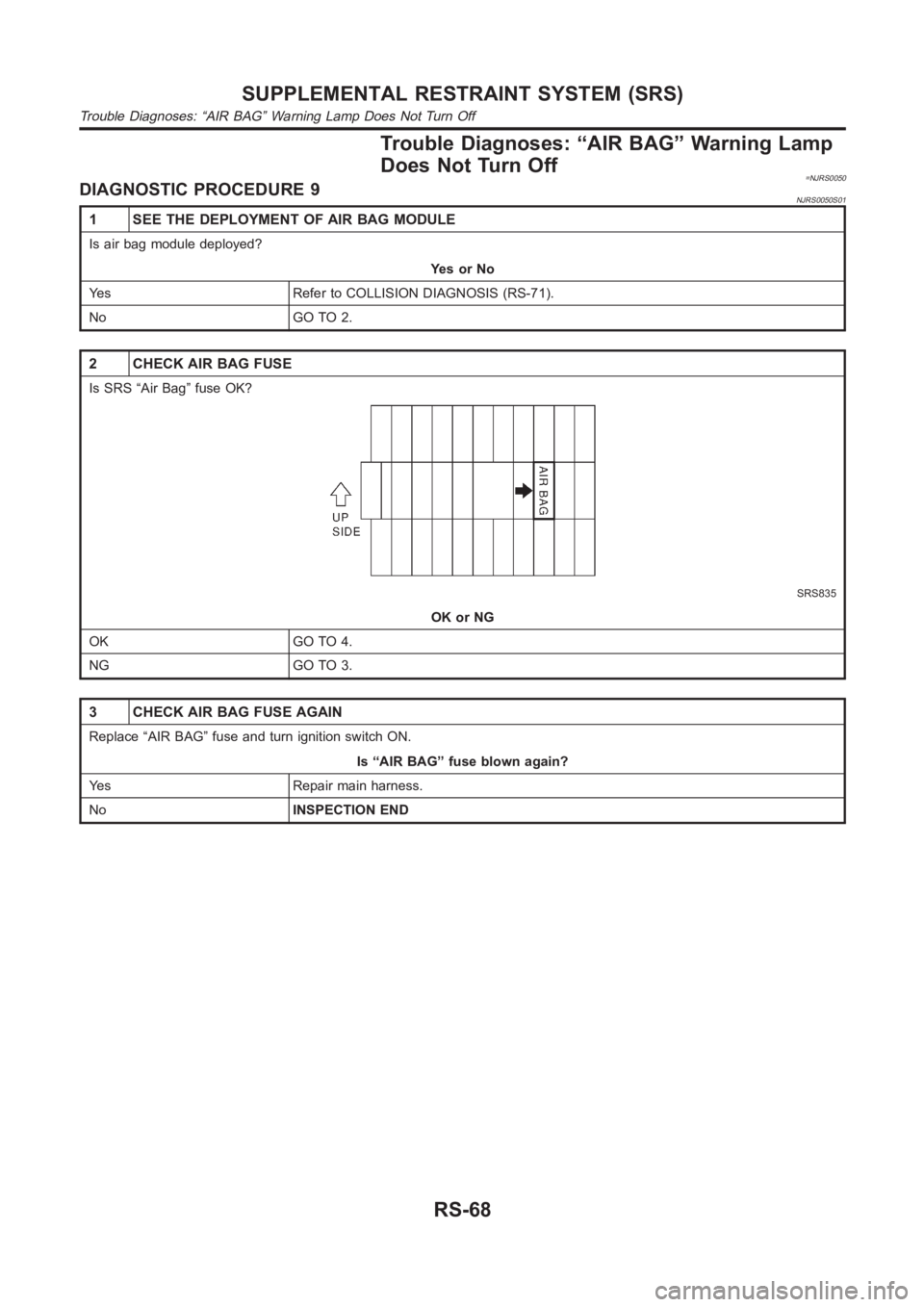

Trouble Diagnoses: “AIR BAG” Warning Lamp

Does Not Turn Off

=NJRS0050DIAGNOSTIC PROCEDURE 9NJRS0050S01

1 SEE THE DEPLOYMENT OF AIR BAG MODULE

Is air bag module deployed?

YesorNo

Yes Refer to COLLISION DIAGNOSIS (RS-71).

No GO TO 2.

2 CHECK AIR BAG FUSE

Is SRS “Air Bag” fuse OK?

SRS835

OK or NG

OK GO TO 4.

NG GO TO 3.

3 CHECK AIR BAG FUSE AGAIN

Replace “AIR BAG” fuse and turn ignition switch ON.

Is “AIR BAG” fuse blown again?

Yes Repair main harness.

NoINSPECTION END

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses: “AIR BAG” Warning Lamp Does Not Turn Off

RS-68

Page 3102 of 3189

Trouble Diagnoses: “AIR BAG” Warning Lamp

Does Not Turn On

=NJRS0051DIAGNOSTIC PROCEDURE 10NJRS0051S01

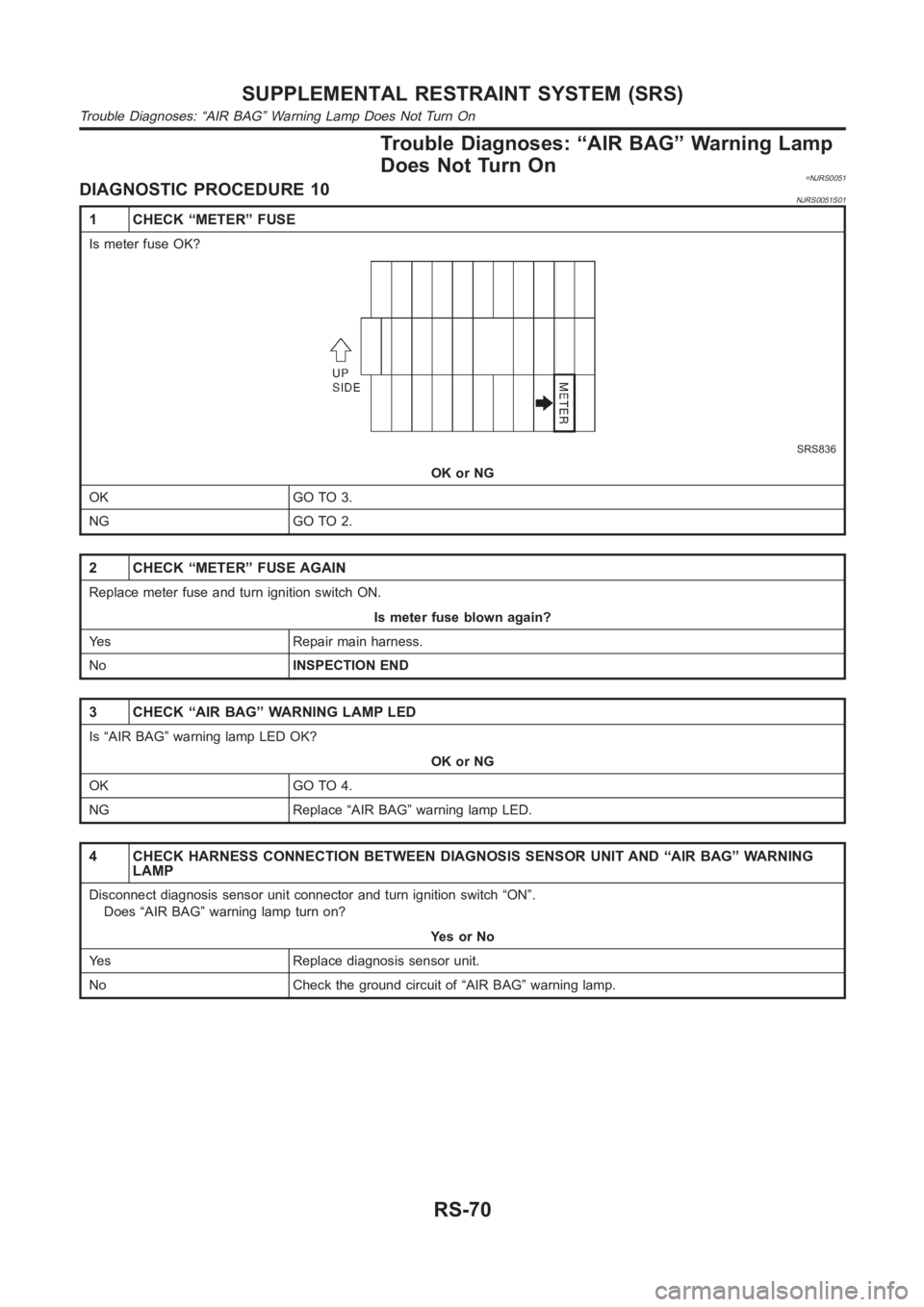

1 CHECK “METER” FUSE

Is meter fuse OK?

SRS836

OK or NG

OK GO TO 3.

NG GO TO 2.

2 CHECK “METER” FUSE AGAIN

Replace meter fuse and turn ignition switch ON.

Is meter fuse blown again?

Yes Repair main harness.

NoINSPECTION END

3 CHECK “AIR BAG” WARNING LAMP LED

Is “AIR BAG” warning lamp LED OK?

OK or NG

OK GO TO 4.

NG Replace “AIR BAG” warning lamp LED.

4 CHECK HARNESS CONNECTION BETWEEN DIAGNOSIS SENSOR UNIT AND “AIR BAG” WARNING

LAMP

Disconnect diagnosis sensor unit connector and turn ignition switch “ON”.

Does “AIR BAG” warning lamp turn on?

YesorNo

Yes Replace diagnosis sensor unit.

No Check the ground circuit of “AIR BAG” warning lamp.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses: “AIR BAG” Warning Lamp Does Not Turn On

RS-70

Page 3119 of 3189

System DescriptionNJSC0004M/T MODELSNJSC0004S01Power is supplied at all times

through 40A fusible link (letterB, located in the fuse and fusible link box)

to ignition switch terminal 1.

With the ignition switch in START position, power is supplied

from ignition switch terminal 5

to smart entrance control unit terminal 58

from smart entrance control unit terminal 59

to starter motor harness connector terminal 1.

The starter motor plunger closes and provides a closed circuit between thebattery and starter motor. The

starter motor is grounded to the engine block. With power and ground supplied, cranking occurs and the engine

starts.

A/T MODELSNJSC0004S02Power is supplied at all times

through 40A fusible link (letterB, located in the fuse and fusible link box)

to ignition switch terminal 1.

With the ignition switch in the START position, power is supplied

from ignition switch terminal 5

to park/neutral position relay terminal 5.

With the ignition switch ON or START position, power is supplied

through 10A fuse [No. 20, located in the fuse block (J/B)]

to park/neutral position (PNP) relay terminal 1.

With the selector lever in the P or N position, ground is supplied

to park/neutral position relay terminal 2 through the park/neutral position switch

to smart entrance control unit terminal 59

from smart entrance control unit terminal 58

from body grounds, F9 and F10.

Then park/neutral position relay is energized and power is supplied

from park/neutral position relay terminal 3

to starter motor harness connector terminal 1.

The starter motor plunger closes and provides a closed circuit between thebattery and starter motor. The

starter motor is grounded to the engine block. With power and ground supplied, cranking occurs and the engine

starts.

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

EL

IDX

STARTING SYSTEM

System Description

SC-13

Page 3133 of 3189

System DescriptionNJSC0009The alternator provides DC voltage to operate the vehicle’s electrical system and to keep the battery charged.

The voltage output is controlled by the IC regulator.

Power is supplied at all times to alternator terminal 4 (S) through:

10A fuse (No. 39, located in the fuse and fusible link box).

Terminal B supplies power to charge the battery and operate the vehicle’s electrical system. Output voltage

is controlled by the IC regulator at terminal 4 (S) detecting the input voltage. The charging circuit is protected

by the 100A fusible link.

The alternator is grounded to the engine block.

With the ignition switch in the ON or START position, power is supplied

through 10A fuse [No. 30, located in the fuse block (J/B)]

to combination meter terminal 30

Ground is supplied to terminal 18 of the combination meter through terminal 3 (L) of the alternator. With power

and ground supplied, the charge warning lamp will illuminate. When the alternator is providing sufficient volt-

age with the engine running, the ground is opened and the charge warning lamp will go off.

If the charge warning lamp illuminates with the engine running, a fault is indicated.GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

EL

IDX

CHARGING SYSTEM

System Description

SC-27

Page 3178 of 3189

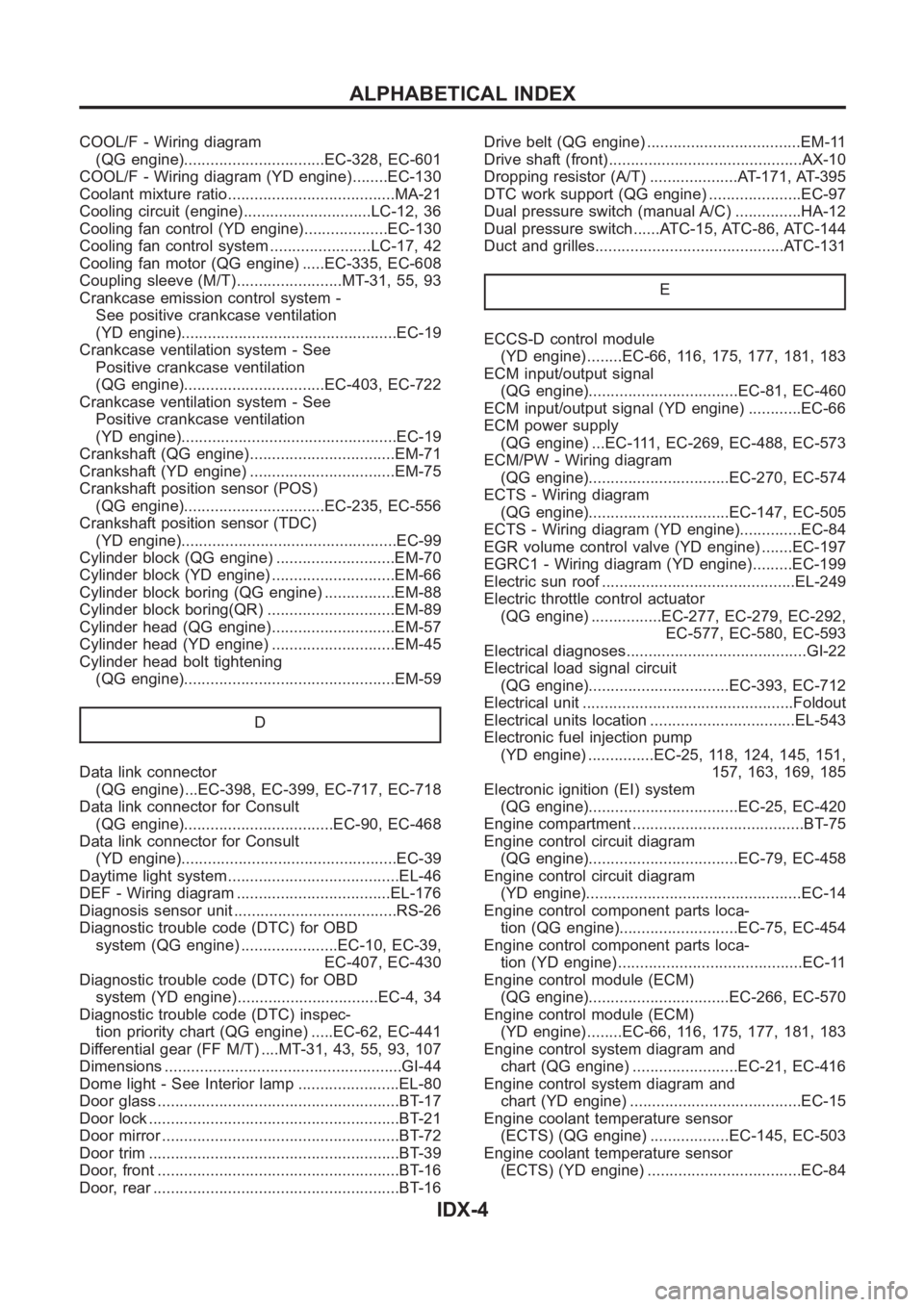

COOL/F - Wiring diagram

(QG engine)................................EC-328, EC-601

COOL/F - Wiring diagram (YD engine) ........EC-130

Coolant mixture ratio......................................MA-21

Cooling circuit (engine).............................LC-12, 36

Cooling fan control (YD engine)...................EC-130

Cooling fan control system .......................LC-17, 42

Cooling fan motor (QG engine) .....EC-335, EC-608

Coupling sleeve (M/T)........................MT-31, 55, 93

Crankcase emission control system -

See positive crankcase ventilation

(YD engine).................................................EC-19

Crankcase ventilation system - See

Positive crankcase ventilation

(QG engine)................................EC-403, EC-722

Crankcase ventilation system - See

Positive crankcase ventilation

(YD engine).................................................EC-19

Crankshaft (QG engine).................................EM-71

Crankshaft (YD engine) .................................EM-75

Crankshaft position sensor (POS)

(QG engine)................................EC-235, EC-556

Crankshaft position sensor (TDC)

(YD engine).................................................EC-99

Cylinder block (QG engine) ...........................EM-70

Cylinder block (YD engine) ............................EM-66

Cylinder block boring (QG engine) ................EM-88

Cylinder block boring(QR) .............................EM-89

Cylinder head (QG engine)............................EM-57

Cylinder head (YD engine) ............................EM-45

Cylinder head bolt tightening

(QG engine)................................................EM-59

D

Data link connector

(QG engine) ...EC-398, EC-399, EC-717, EC-718

Data link connector for Consult

(QG engine)..................................EC-90, EC-468

Data link connector for Consult

(YD engine).................................................EC-39

Daytime light system.......................................EL-46

DEF - Wiring diagram ...................................EL-176

Diagnosis sensor unit .....................................RS-26

Diagnostic trouble code (DTC) for OBD

system (QG engine) ......................EC-10, EC-39,

EC-407, EC-430

Diagnostic trouble code (DTC) for OBD

system (YD engine) ................................EC-4, 34

Diagnostic trouble code (DTC) inspec-

tion priority chart (QG engine) .....EC-62, EC-441

Differential gear (FF M/T) ....MT-31, 43, 55, 93, 107

Dimensions <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011[.GI-44

Dome light - See Interior lamp .......................EL-80

Door glass <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011[.BT-17

Door lock <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011001100110011[..BT-21

Door mirror <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011[.BT-72

Door trim <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011001100110011[..BT-39

Door, front <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011[..BT-16

Door, rear <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011[..BT-16Drive belt (QG engine) ...................................EM-11

Drive shaft (front)............................................AX-10

Dropping resistor (A/T) ....................AT-171, AT-395

DTC work support (QG engine) .....................EC-97

Dual pressure switch (manual A/C) ...............HA-12

Dual pressure switch ......ATC-15, ATC-86, ATC-144

Duct and grilles...........................................ATC-131

E

ECCS-D control module

(YD engine) ........EC-66, 116, 175, 177, 181, 183

ECM input/output signal

(QG engine)..................................EC-81, EC-460

ECM input/output signal (YD engine) ............EC-66

ECM power supply

(QG engine) ...EC-111, EC-269, EC-488, EC-573

ECM/PW - Wiring diagram

(QG engine)................................EC-270, EC-574

ECTS - Wiring diagram

(QG engine)................................EC-147, EC-505

ECTS - Wiring diagram (YD engine)..............EC-84

EGR volume control valve (YD engine) .......EC-197

EGRC1 - Wiring diagram (YD engine) .........EC-199

Electric sun roof ............................................EL-249

Electric throttle control actuator

(QG engine) ................EC-277, EC-279, EC-292,

EC-577, EC-580, EC-593

Electrical diagnoses.........................................GI-22

Electrical load signal circuit

(QG engine)................................EC-393, EC-712

Electrical unit ................................................Foldout

Electrical units location .................................EL-543

Electronic fuel injection pump

(YD engine) ...............EC-25, 118, 124, 145, 151,

157, 163, 169, 185

Electronic ignition (EI) system

(QG engine)..................................EC-25, EC-420

Engine compartment .......................................BT-75

Engine control circuit diagram

(QG engine)..................................EC-79, EC-458

Engine control circuit diagram

(YD engine).................................................EC-14

Engine control component parts loca-

tion (QG engine)...........................EC-75, EC-454

Engine control component parts loca-

tion (YD engine) ..........................................EC-11

Engine control module (ECM)

(QG engine)................................EC-266, EC-570

Engine control module (ECM)

(YD engine) ........EC-66, 116, 175, 177, 181, 183

Engine control system diagram and

chart (QG engine) ........................EC-21, EC-416

Engine control system diagram and

chart (YD engine) .......................................EC-15

Engine coolant temperature sensor

(ECTS) (QG engine) ..................EC-145, EC-503

Engine coolant temperature sensor

(ECTS) (YD engine) ...................................EC-84

ALPHABETICAL INDEX

IDX-4