turn signal NISSAN ALMERA TINO 2001 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 169 of 3051

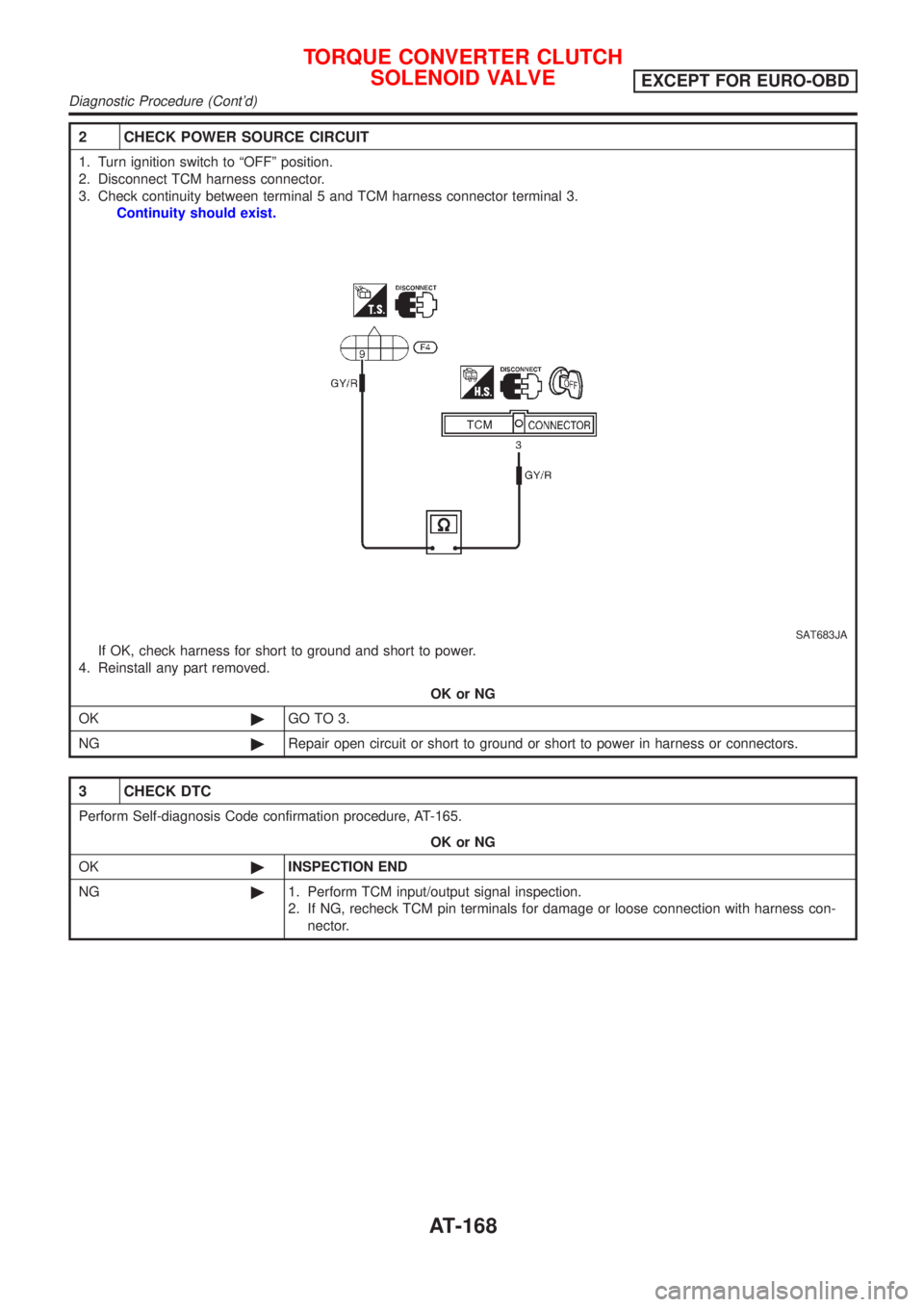

2 CHECK POWER SOURCE CIRCUIT

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check continuity between terminal 5 and TCM harness connector terminal 3.

Continuity should exist.

SAT683JA

If OK, check harness for short to ground and short to power.

4. Reinstall any part removed.

OK or NG

OK©GO TO 3.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

3 CHECK DTC

Perform Self-diagnosis Code confirmation procedure, AT-165.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

TORQUE CONVERTER CLUTCH

SOLENOID VALVE

EXCEPT FOR EURO-OBD

Diagnostic Procedure (Cont'd)

AT-168

Page 175 of 3051

Diagnostic ProcedureNLAT0283

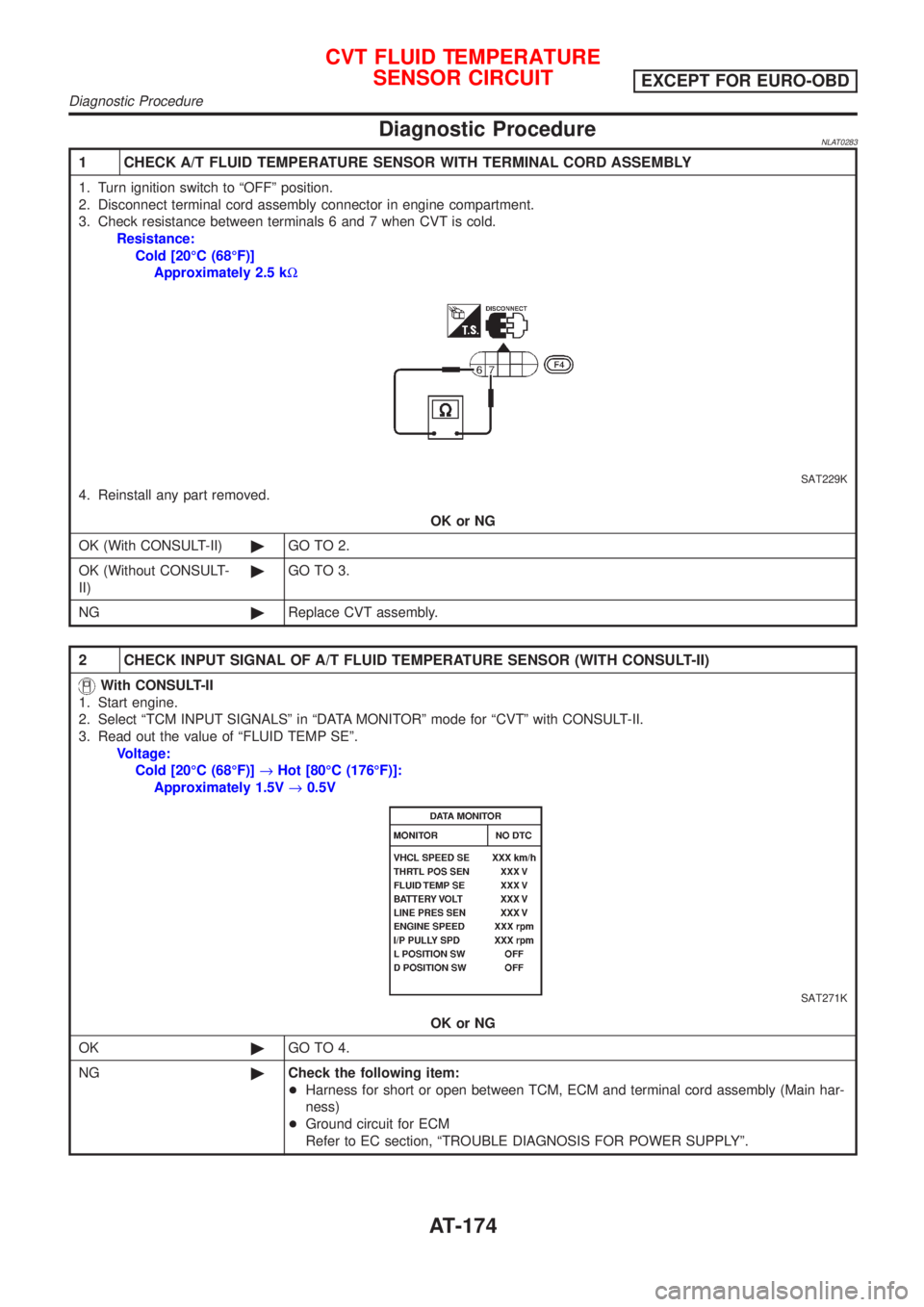

1 CHECK A/T FLUID TEMPERATURE SENSOR WITH TERMINAL CORD ASSEMBLY

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector in engine compartment.

3. Check resistance between terminals 6 and 7 when CVT is cold.

Resistance:

Cold [20ÉC (68ÉF)]

Approximately 2.5 kW

SAT229K

4. Reinstall any part removed.

OK or NG

OK (With CONSULT-II)©GO TO 2.

OK (Without CONSULT-

II)©GO TO 3.

NG©Replace CVT assembly.

2 CHECK INPUT SIGNAL OF A/T FLUID TEMPERATURE SENSOR (WITH CONSULT-II)

With CONSULT-II

1. Start engine.

2. Select ªTCM INPUT SIGNALSº in ªDATA MONITORº mode for ªCVTº with CONSULT-II.

3. Read out the value of ªFLUID TEMP SEº.

Voltage:

Cold [20ÉC (68ÉF)]®Hot [80ÉC (176ÉF)]:

Approximately 1.5V®0.5V

SAT271K

OK or NG

OK©GO TO 4.

NG©Check the following item:

+Harness for short or open between TCM, ECM and terminal cord assembly (Main har-

ness)

+Ground circuit for ECM

Refer to EC section, ªTROUBLE DIAGNOSIS FOR POWER SUPPLYº.

CVT FLUID TEMPERATURE

SENSOR CIRCUIT

EXCEPT FOR EURO-OBD

Diagnostic Procedure

AT-174

Page 176 of 3051

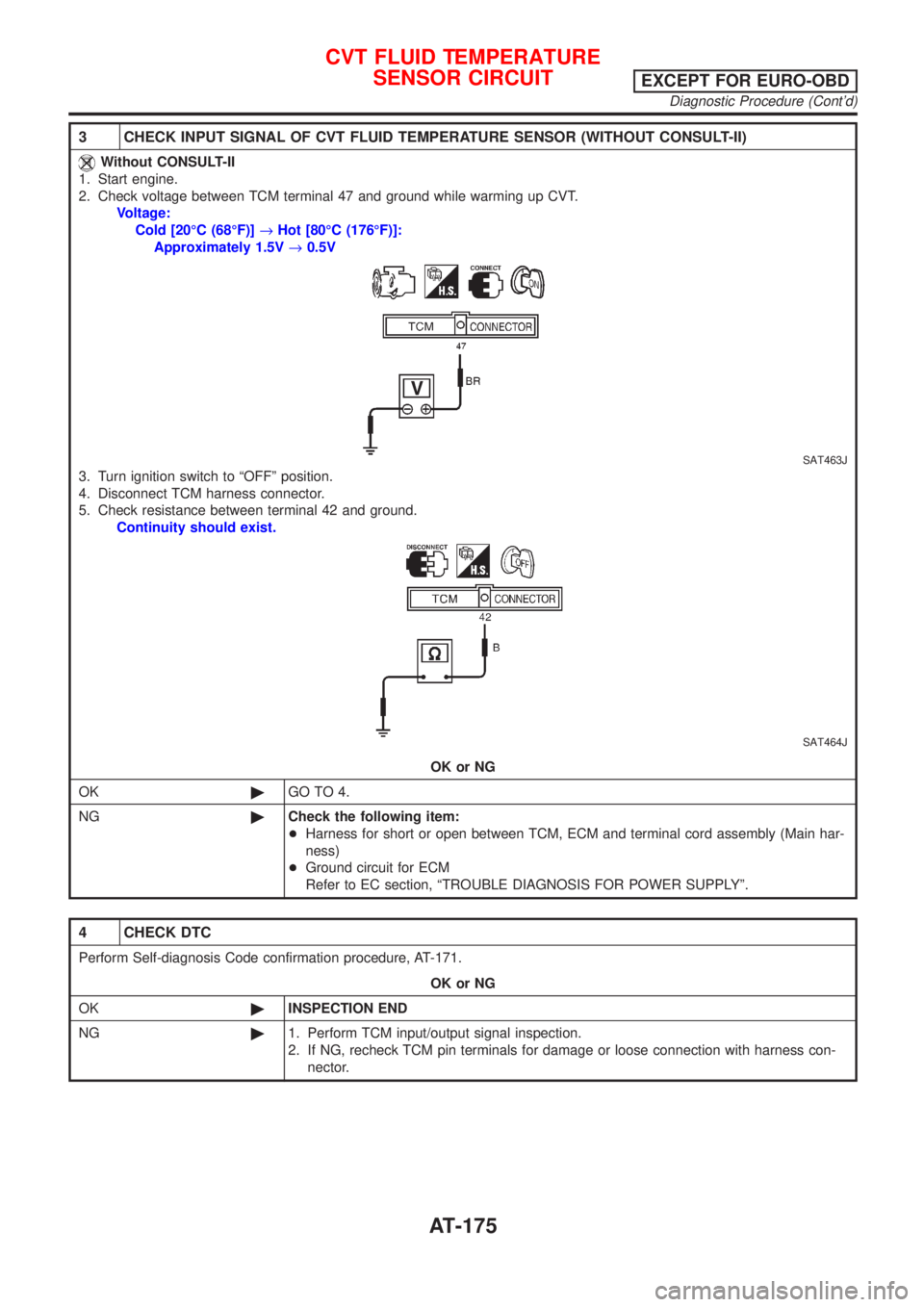

3 CHECK INPUT SIGNAL OF CVT FLUID TEMPERATURE SENSOR (WITHOUT CONSULT-II)

Without CONSULT-II

1. Start engine.

2. Check voltage between TCM terminal 47 and ground while warming up CVT.

Voltage:

Cold [20ÉC (68ÉF)]®Hot [80ÉC (176ÉF)]:

Approximately 1.5V®0.5V

SAT463J

3. Turn ignition switch to ªOFFº position.

4. Disconnect TCM harness connector.

5. Check resistance between terminal 42 and ground.

Continuity should exist.

SAT464J

OK or NG

OK©GO TO 4.

NG©Check the following item:

+Harness for short or open between TCM, ECM and terminal cord assembly (Main har-

ness)

+Ground circuit for ECM

Refer to EC section, ªTROUBLE DIAGNOSIS FOR POWER SUPPLYº.

4 CHECK DTC

Perform Self-diagnosis Code confirmation procedure, AT-171.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

CVT FLUID TEMPERATURE

SENSOR CIRCUIT

EXCEPT FOR EURO-OBD

Diagnostic Procedure (Cont'd)

AT-175

Page 181 of 3051

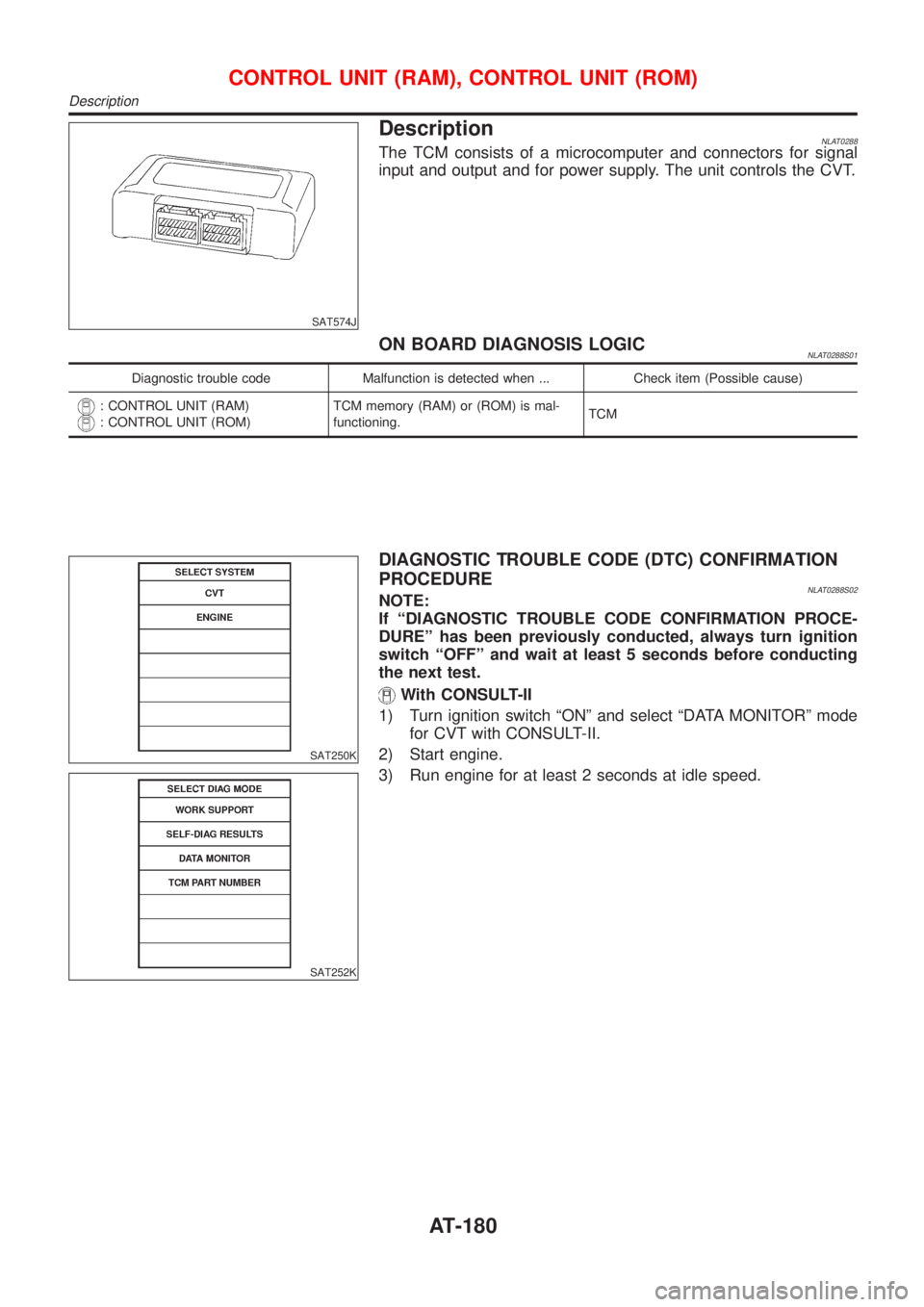

SAT574J

DescriptionNLAT0288The TCM consists of a microcomputer and connectors for signal

input and output and for power supply. The unit controls the CVT.

ON BOARD DIAGNOSIS LOGICNLAT0288S01

Diagnostic trouble code Malfunction is detected when ... Check item (Possible cause)

: CONTROL UNIT (RAM)

: CONTROL UNIT (ROM)TCM memory (RAM) or (ROM) is mal-

functioning.TCM

SAT250K

SAT252K

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NLAT0288S02NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

for CVT with CONSULT-II.

2) Start engine.

3) Run engine for at least 2 seconds at idle speed.

CONTROL UNIT (RAM), CONTROL UNIT (ROM)

Description

AT-180

Page 183 of 3051

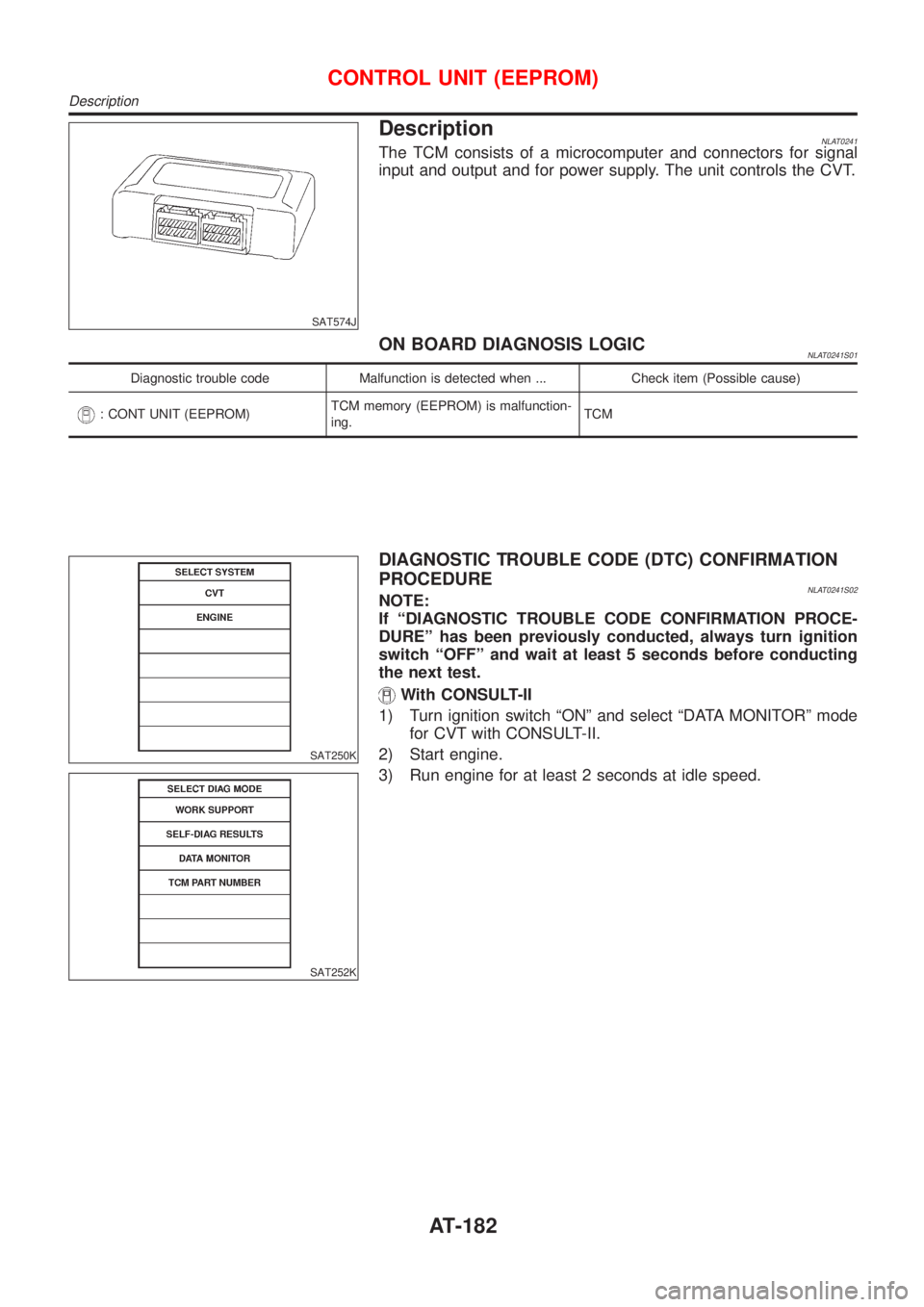

SAT574J

DescriptionNLAT0241The TCM consists of a microcomputer and connectors for signal

input and output and for power supply. The unit controls the CVT.

ON BOARD DIAGNOSIS LOGICNLAT0241S01

Diagnostic trouble code Malfunction is detected when ... Check item (Possible cause)

: CONT UNIT (EEPROM)TCM memory (EEPROM) is malfunction-

ing.TCM

SAT250K

SAT252K

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NLAT0241S02NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

for CVT with CONSULT-II.

2) Start engine.

3) Run engine for at least 2 seconds at idle speed.

CONTROL UNIT (EEPROM)

Description

AT-182

Page 185 of 3051

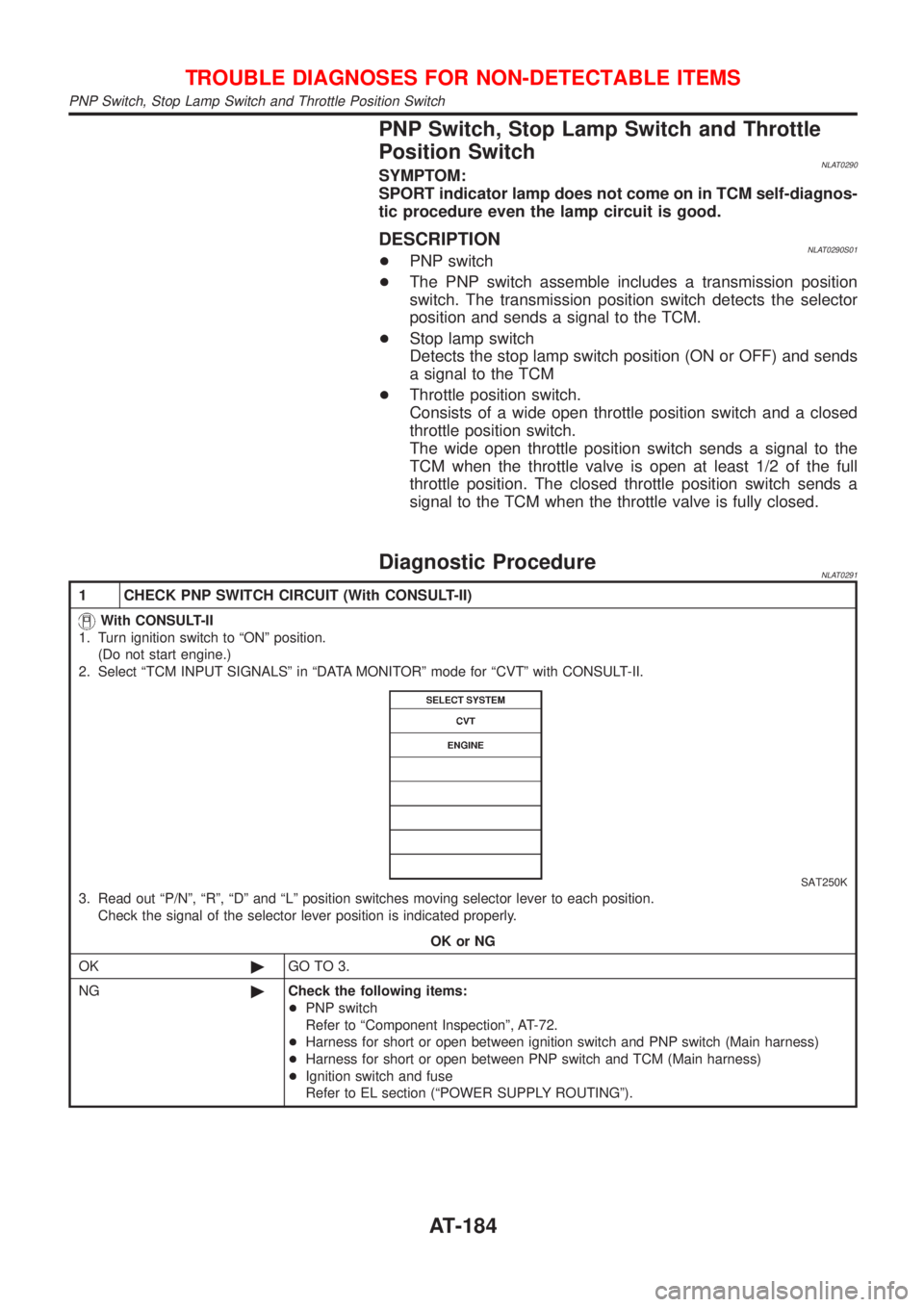

PNP Switch, Stop Lamp Switch and Throttle

Position Switch

NLAT0290SYMPTOM:

SPORT indicator lamp does not come on in TCM self-diagnos-

tic procedure even the lamp circuit is good.

DESCRIPTIONNLAT0290S01+PNP switch

+The PNP switch assemble includes a transmission position

switch. The transmission position switch detects the selector

position and sends a signal to the TCM.

+Stop lamp switch

Detects the stop lamp switch position (ON or OFF) and sends

a signal to the TCM

+Throttle position switch.

Consists of a wide open throttle position switch and a closed

throttle position switch.

The wide open throttle position switch sends a signal to the

TCM when the throttle valve is open at least 1/2 of the full

throttle position. The closed throttle position switch sends a

signal to the TCM when the throttle valve is fully closed.

Diagnostic ProcedureNLAT0291

1 CHECK PNP SWITCH CIRCUIT (With CONSULT-II)

With CONSULT-II

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Select ªTCM INPUT SIGNALSº in ªDATA MONITORº mode for ªCVTº with CONSULT-II.

SAT250K

3. Read out ªP/Nº, ªRº, ªDº and ªLº position switches moving selector lever to each position.

Check the signal of the selector lever position is indicated properly.

OK or NG

OK©GO TO 3.

NG©Check the following items:

+PNP switch

Refer to ªComponent Inspectionº, AT-72.

+Harness for short or open between ignition switch and PNP switch (Main harness)

+Harness for short or open between PNP switch and TCM (Main harness)

+Ignition switch and fuse

Refer to EL section (ªPOWER SUPPLY ROUTINGº).

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

PNP Switch, Stop Lamp Switch and Throttle Position Switch

AT-184

Page 186 of 3051

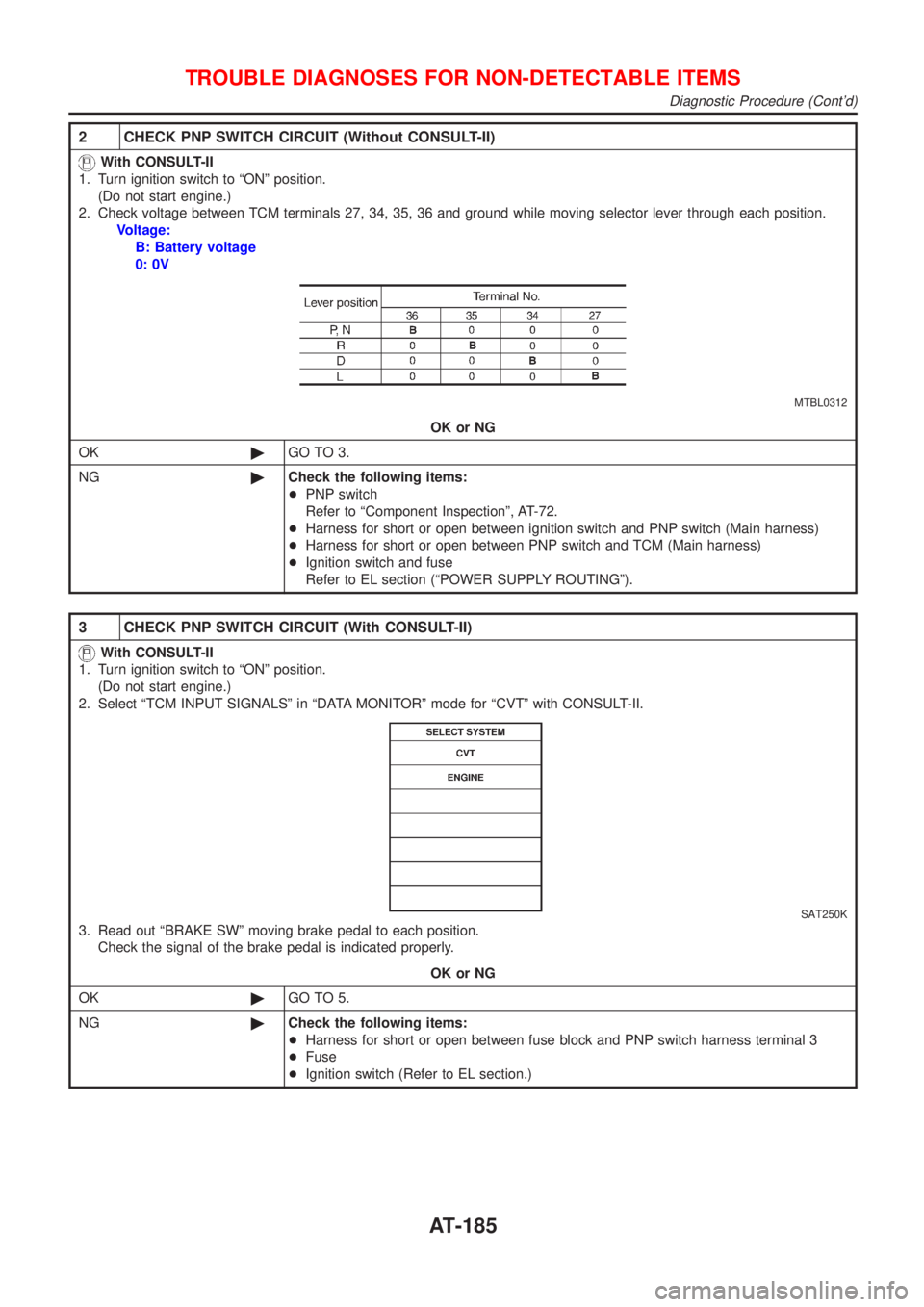

2 CHECK PNP SWITCH CIRCUIT (Without CONSULT-II)

With CONSULT-II

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between TCM terminals 27, 34, 35, 36 and ground while moving selector lever through each position.

Voltage:

B: Battery voltage

0: 0V

MTBL0312

OK or NG

OK©GO TO 3.

NG©Check the following items:

+PNP switch

Refer to ªComponent Inspectionº, AT-72.

+Harness for short or open between ignition switch and PNP switch (Main harness)

+Harness for short or open between PNP switch and TCM (Main harness)

+Ignition switch and fuse

Refer to EL section (ªPOWER SUPPLY ROUTINGº).

3 CHECK PNP SWITCH CIRCUIT (With CONSULT-II)

With CONSULT-II

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Select ªTCM INPUT SIGNALSº in ªDATA MONITORº mode for ªCVTº with CONSULT-II.

SAT250K

3. Read out ªBRAKE SWº moving brake pedal to each position.

Check the signal of the brake pedal is indicated properly.

OK or NG

OK©GO TO 5.

NG©Check the following items:

+Harness for short or open between fuse block and PNP switch harness terminal 3

+Fuse

+Ignition switch (Refer to EL section.)

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Diagnostic Procedure (Cont'd)

AT-185

Page 187 of 3051

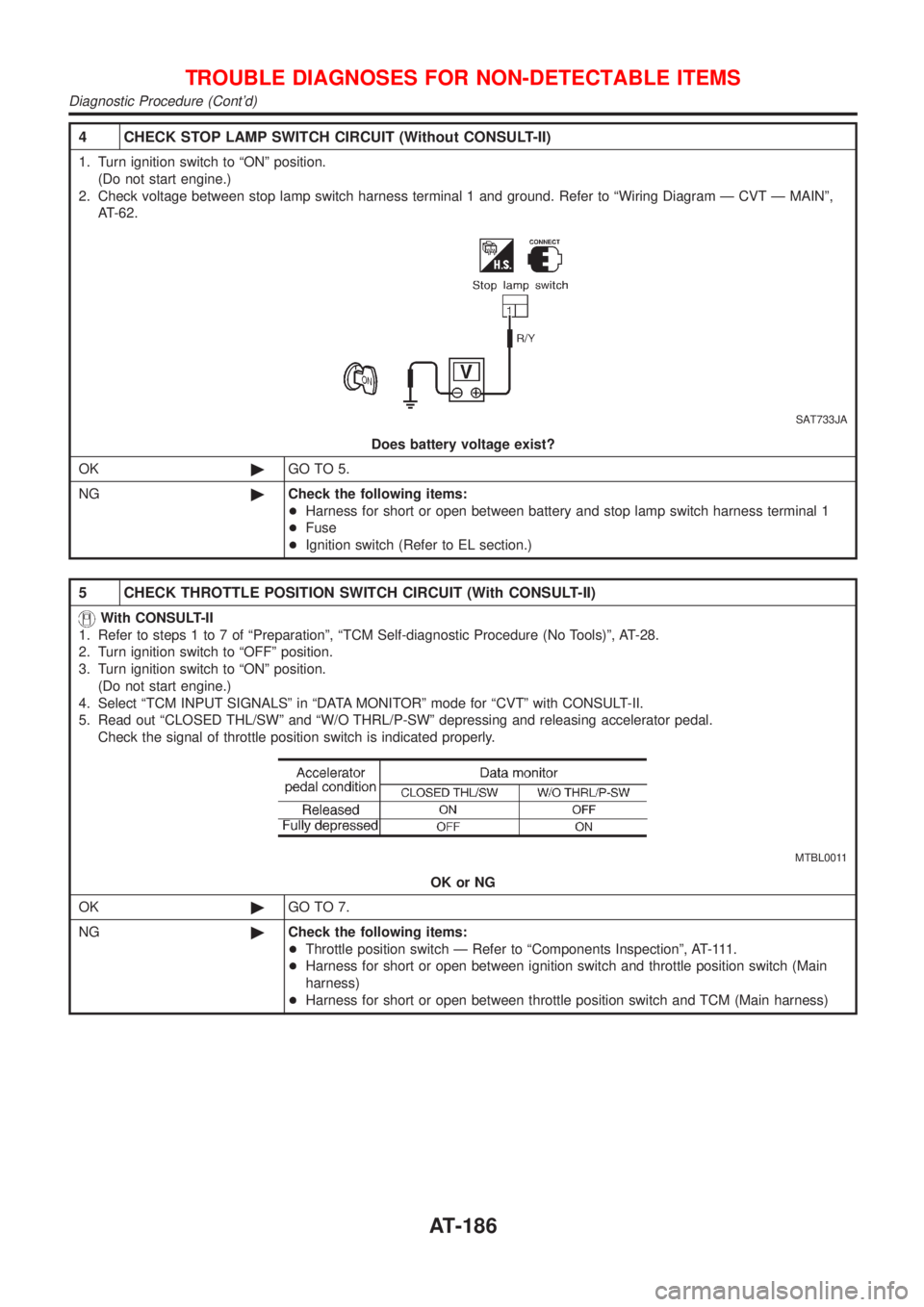

4 CHECK STOP LAMP SWITCH CIRCUIT (Without CONSULT-II)

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between stop lamp switch harness terminal 1 and ground. Refer to ªWiring Diagram Ð CVT Ð MAINº,

AT-62.

SAT733JA

Does battery voltage exist?

OK©GO TO 5.

NG©Check the following items:

+Harness for short or open between battery and stop lamp switch harness terminal 1

+Fuse

+Ignition switch (Refer to EL section.)

5 CHECK THROTTLE POSITION SWITCH CIRCUIT (With CONSULT-II)

With CONSULT-II

1. Refer to steps 1 to 7 of ªPreparationº, ªTCM Self-diagnostic Procedure (No Tools)º, AT-28.

2. Turn ignition switch to ªOFFº position.

3. Turn ignition switch to ªONº position.

(Do not start engine.)

4. Select ªTCM INPUT SIGNALSº in ªDATA MONITORº mode for ªCVTº with CONSULT-II.

5. Read out ªCLOSED THL/SWº and ªW/O THRL/P-SWº depressing and releasing accelerator pedal.

Check the signal of throttle position switch is indicated properly.

MTBL0011

OK or NG

OK©GO TO 7.

NG©Check the following items:

+Throttle position switch Ð Refer to ªComponents Inspectionº, AT-111.

+Harness for short or open between ignition switch and throttle position switch (Main

harness)

+Harness for short or open between throttle position switch and TCM (Main harness)

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Diagnostic Procedure (Cont'd)

AT-186

Page 188 of 3051

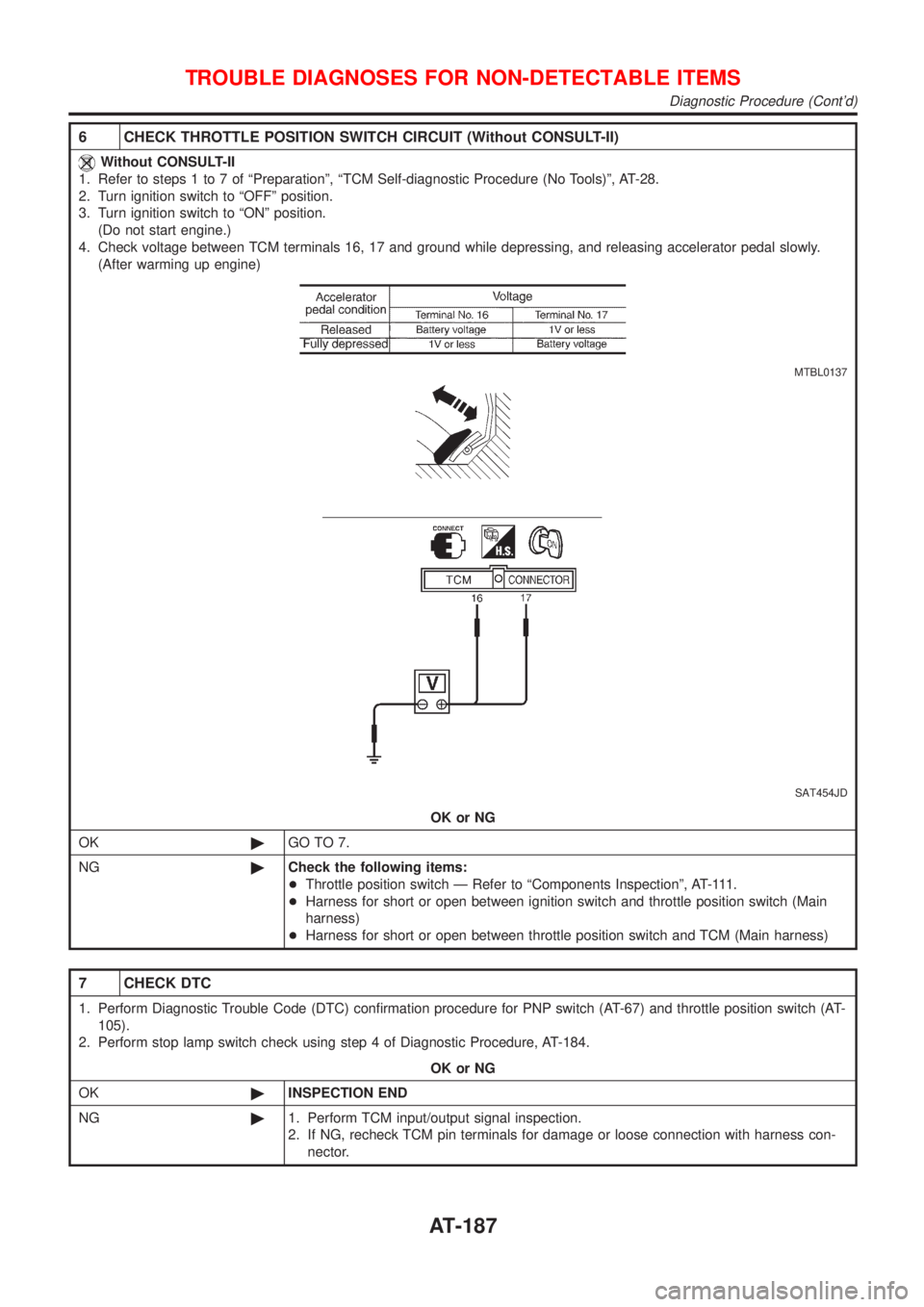

6 CHECK THROTTLE POSITION SWITCH CIRCUIT (Without CONSULT-II)

Without CONSULT-II

1. Refer to steps 1 to 7 of ªPreparationº, ªTCM Self-diagnostic Procedure (No Tools)º, AT-28.

2. Turn ignition switch to ªOFFº position.

3. Turn ignition switch to ªONº position.

(Do not start engine.)

4. Check voltage between TCM terminals 16, 17 and ground while depressing, and releasing accelerator pedal slowly.

(After warming up engine)

MTBL0137

SAT454JD

OK or NG

OK©GO TO 7.

NG©Check the following items:

+Throttle position switch Ð Refer to ªComponents Inspectionº, AT-111.

+Harness for short or open between ignition switch and throttle position switch (Main

harness)

+Harness for short or open between throttle position switch and TCM (Main harness)

7 CHECK DTC

1. Perform Diagnostic Trouble Code (DTC) confirmation procedure for PNP switch (AT-67) and throttle position switch (AT-

105).

2. Perform stop lamp switch check using step 4 of Diagnostic Procedure, AT-184.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Diagnostic Procedure (Cont'd)

AT-187

Page 200 of 3051

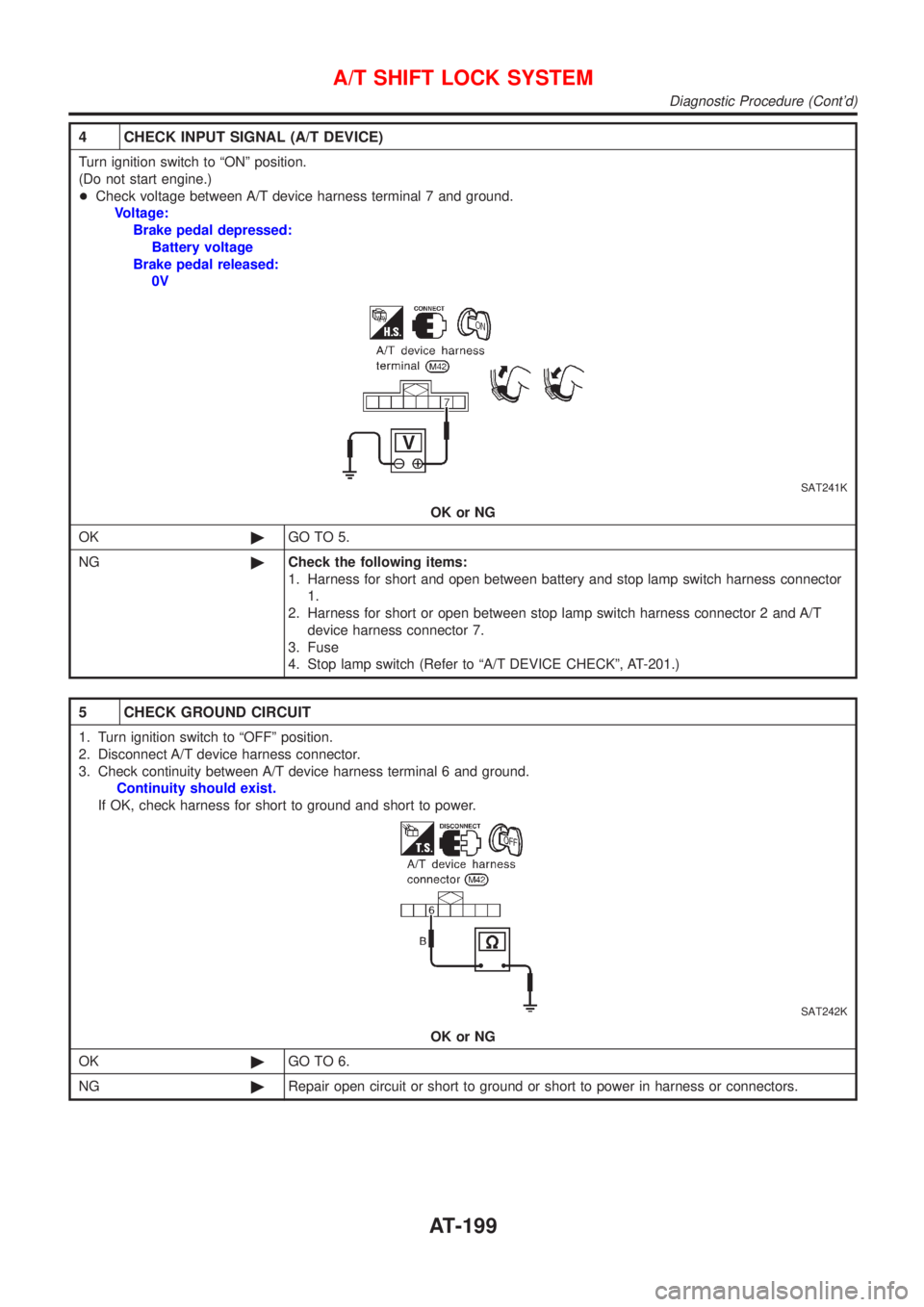

4 CHECK INPUT SIGNAL (A/T DEVICE)

Turn ignition switch to ªONº position.

(Do not start engine.)

+Check voltage between A/T device harness terminal 7 and ground.

Voltage:

Brake pedal depressed:

Battery voltage

Brake pedal released:

0V

SAT241K

OK or NG

OK©GO TO 5.

NG©Check the following items:

1. Harness for short and open between battery and stop lamp switch harness connector

1.

2. Harness for short or open between stop lamp switch harness connector 2 and A/T

device harness connector 7.

3. Fuse

4. Stop lamp switch (Refer to ªA/T DEVICE CHECKº, AT-201.)

5 CHECK GROUND CIRCUIT

1. Turn ignition switch to ªOFFº position.

2. Disconnect A/T device harness connector.

3. Check continuity between A/T device harness terminal 6 and ground.

Continuity should exist.

If OK, check harness for short to ground and short to power.

SAT242K

OK or NG

OK©GO TO 6.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure (Cont'd)

AT-199