charging NISSAN NAVARA 2005 Repair User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 351 of 3171

PREPARATION

ATC-17

C

D

E

F

G

H

I

K

L

MA

B

AT C

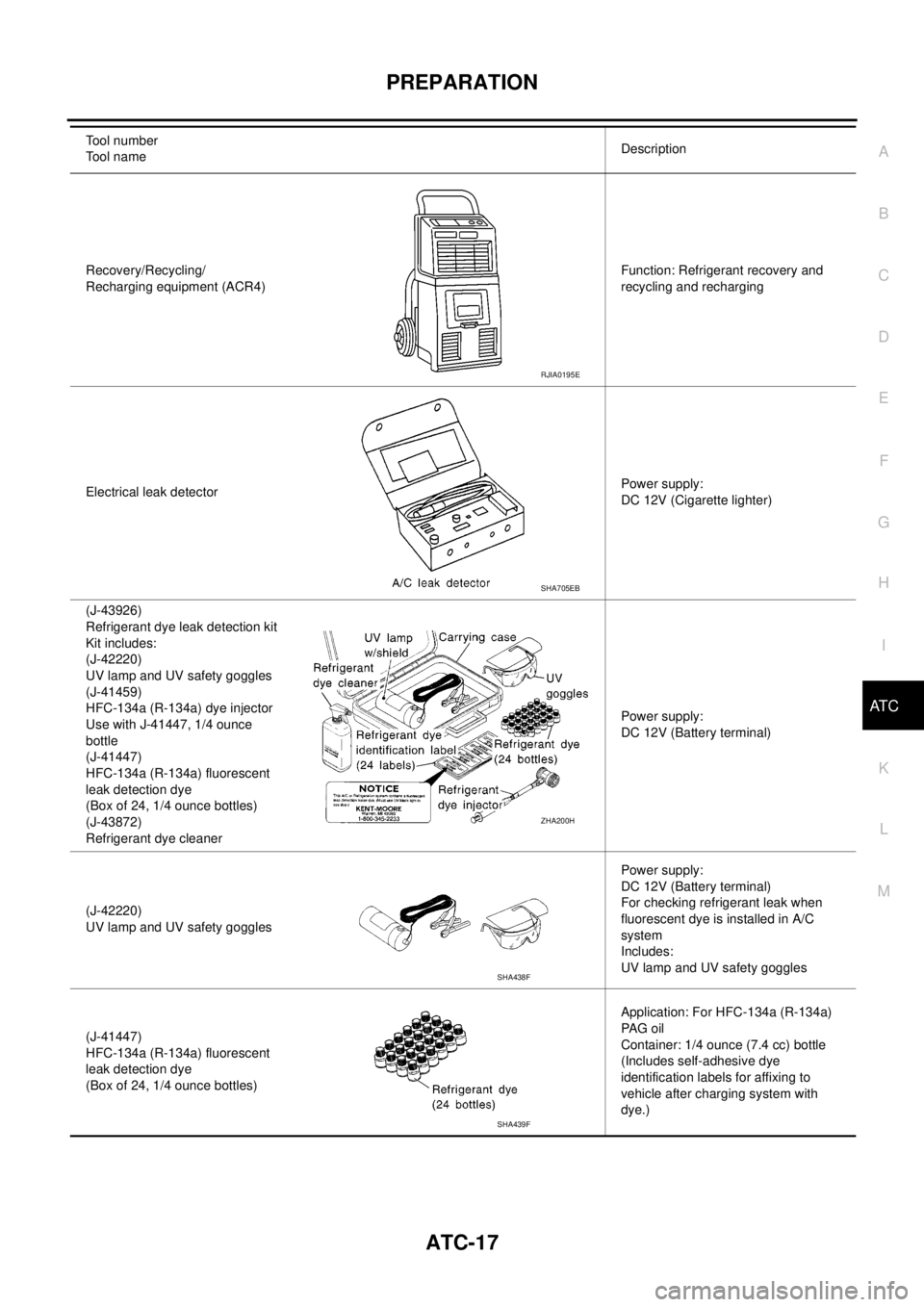

Recovery/Recycling/

Recharging equipment (ACR4)Function: Refrigerant recovery and

recycling and recharging

Electrical leak detectorPower supply:

DC 12V (Cigarette lighter)

(J-43926)

Refrigerant dye leak detection kit

Kit includes:

(J-42220)

UV lamp and UV safety goggles

(J-41459)

HFC-134a (R-134a) dye injector

Use with J-41447, 1/4 ounce

bottle

(J-41447)

HFC-134a (R-134a) fluorescent

leak detection dye

(Box of 24, 1/4 ounce bottles)

(J-43872)

Refrigerant dye cleanerPower supply:

DC 12V (Battery terminal)

(J-42220)

UV lamp and UV safety gogglesPower supply:

DC 12V (Battery terminal)

For checking refrigerant leak when

fluorescent dye is installed in A/C

system

Includes:

UV lamp and UV safety goggles

(J-41447)

HFC-134a (R-134a) fluorescent

leak detection dye

(Box of 24, 1/4 ounce bottles)Application: For HFC-134a (R-134a)

PA G o i l

Container: 1/4 ounce (7.4 cc) bottle

(Includes self-adhesive dye

identification labels for affixing to

vehicle after charging system with

dye.) Tool number

Tool nameDescription

RJIA0195E

SHA705EB

ZHA200H

SHA438F

SHA439F

Page 359 of 3171

LUBRICANT

ATC-25

C

D

E

F

G

H

I

K

L

MA

B

AT C

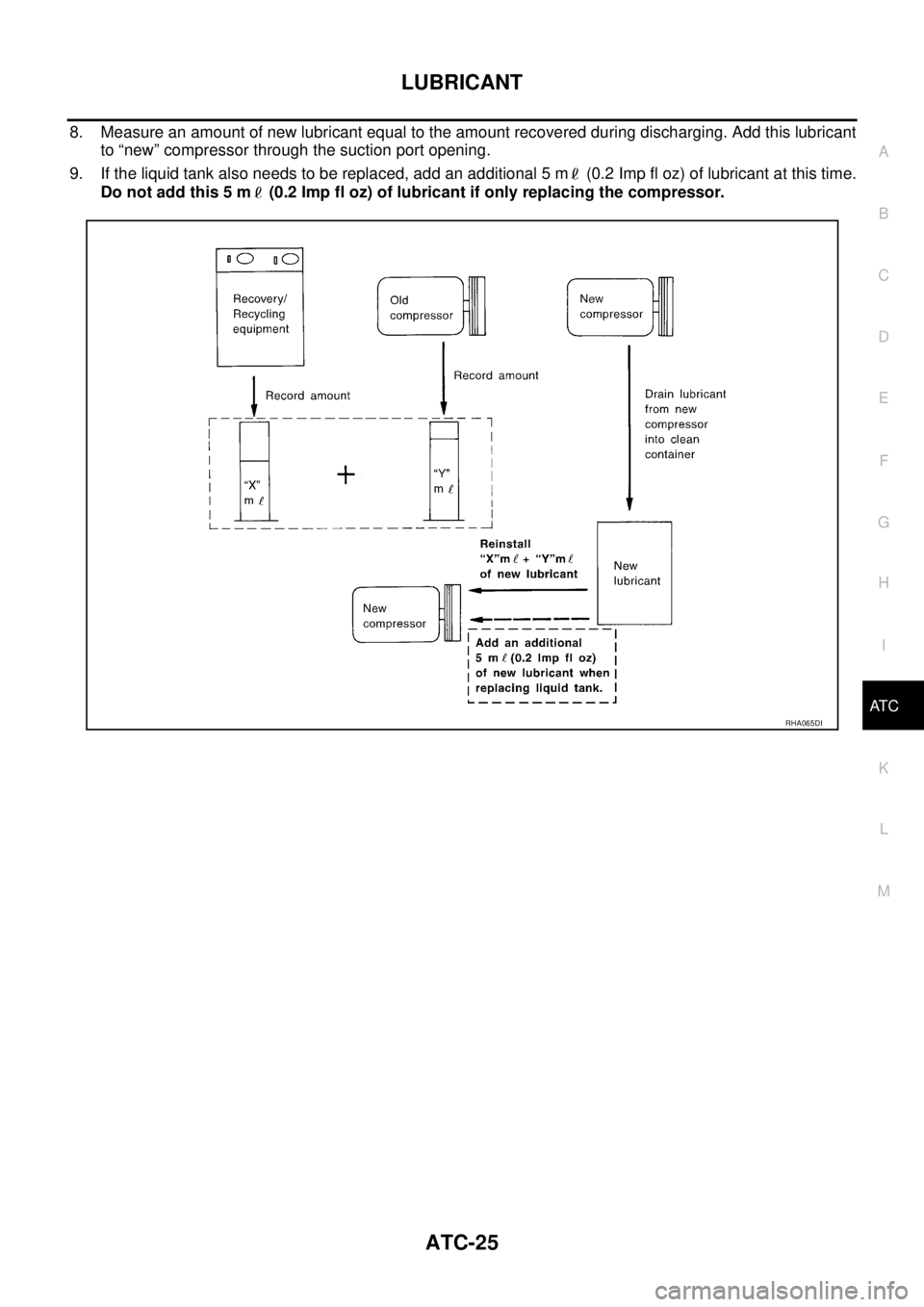

8. Measure an amount of new lubricant equal to the amount recovered during discharging. Add this lubricant

to “new” compressor through the suction port opening.

9. If the liquid tank also needs to be replaced, add an additional 5 m (0.2 Imp fl oz) of lubricant at this time.

Do not add this 5 m (0.2 Imp fl oz) of lubricant if only replacing the compressor.

RHA065DI

Page 460 of 3171

ATC-126

HEATER & COOLING UNIT ASSEMBLY

Removal and Installation

EJS006C9

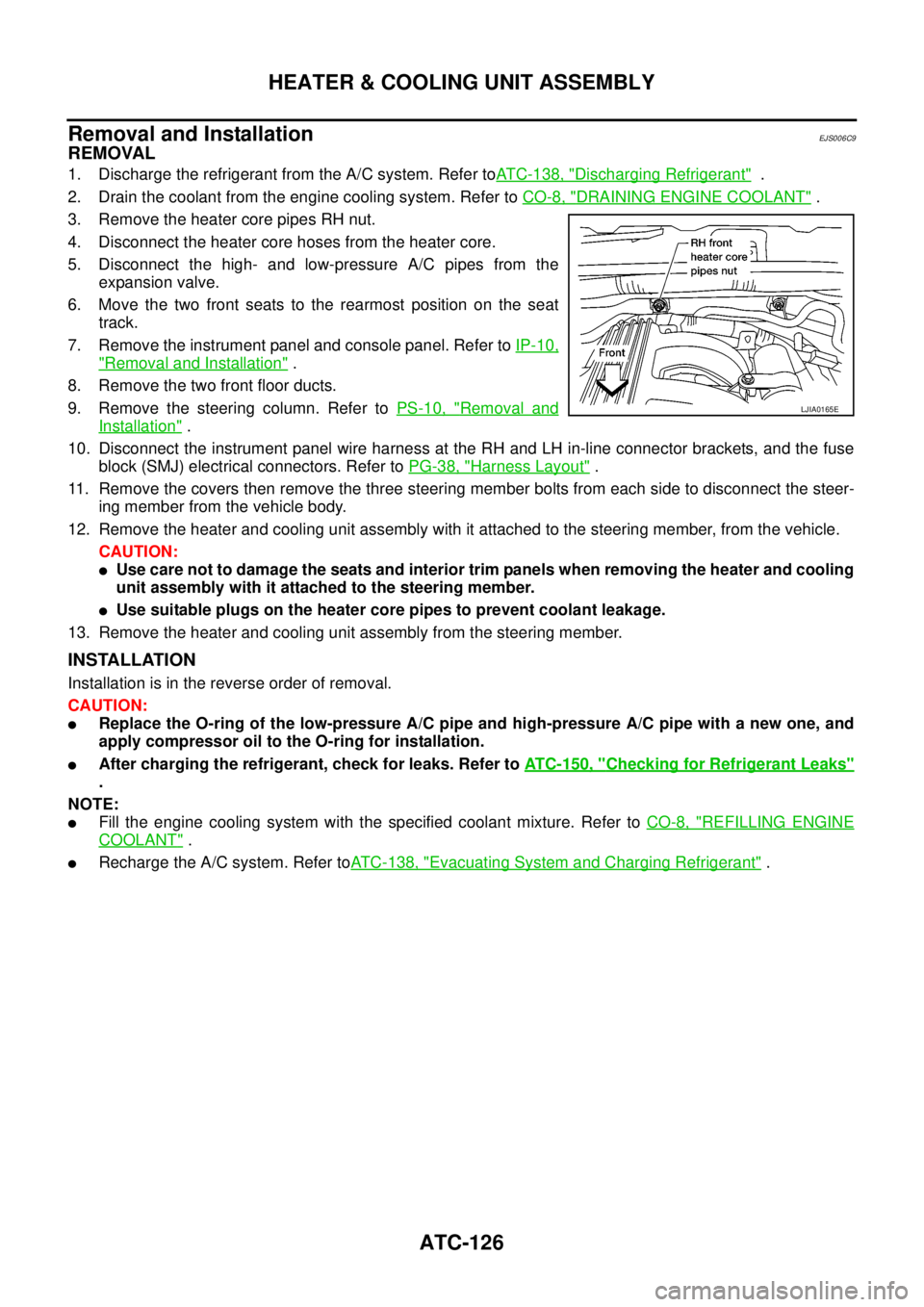

REMOVAL

1. Discharge the refrigerant from the A/C system. Refer toATC-138, "Discharging Refrigerant".

2. Drain the coolant from the engine cooling system. Refer toCO-8, "

DRAINING ENGINE COOLANT".

3. Remove the heater core pipes RH nut.

4. Disconnect the heater core hoses from the heater core.

5. Disconnect the high- and low-pressure A/C pipes from the

expansion valve.

6. Move the two front seats to the rearmost position on the seat

track.

7. Remove the instrument panel and console panel. Refer toIP-10,

"Removal and Installation".

8. Remove the two front floor ducts.

9. Remove the steering column. Refer toPS-10, "

Removal and

Installation".

10. Disconnect the instrument panel wire harness at the RH and LH in-line connector brackets, and the fuse

block (SMJ) electrical connectors. Refer toPG-38, "

Harness Layout".

11. Remove the covers then remove the three steering member bolts from each side to disconnect the steer-

ing member from the vehicle body.

12. Remove the heater and cooling unit assembly with it attached to the steering member, from the vehicle.

CAUTION:

lUse care not to damage the seats and interior trim panels when removing the heater and cooling

unit assembly with it attached to the steering member.

lUse suitable plugs on the heater core pipes to prevent coolant leakage.

13. Remove the heater and cooling unit assembly from the steering member.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

lReplace the O-ring of the low-pressure A/C pipe and high-pressure A/C pipe with a new one, and

apply compressor oil to the O-ring for installation.

lAfter charging the refrigerant, check for leaks. Refer toATC-150, "Checking for Refrigerant Leaks"

.

NOTE:

lFill the engine cooling system with the specified coolant mixture. Refer toCO-8, "REFILLING ENGINE

COOLANT".

lRecharge the A/C system. Refer toATC-138, "Evacuating System and Charging Refrigerant".

LJIA0165E

Page 472 of 3171

ATC-138

REFRIGERANT LINES

REFRIGERANT LINES

PFP:92600

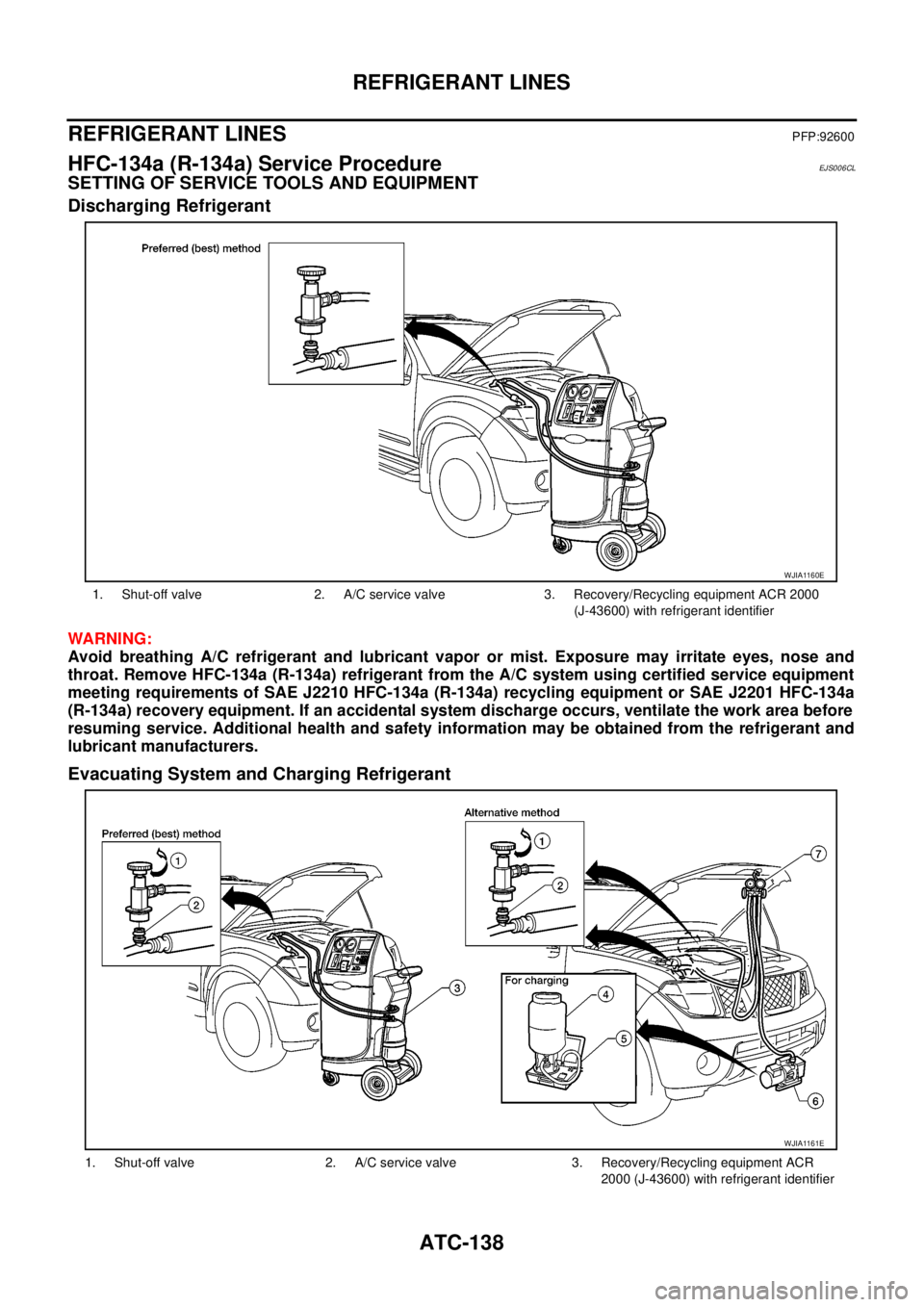

HFC-134a (R-134a) Service ProcedureEJS006CL

SETTING OF SERVICE TOOLS AND EQUIPMENT

Discharging Refrigerant

WARNING:

Avoid breathing A/C refrigerant and lubricant vapor or mist. Exposure may irritate eyes, nose and

throat. Remove HFC-134a (R-134a) refrigerant from the A/C system using certified service equipment

meeting requirements of SAE J2210 HFC-134a (R-134a) recycling equipment or SAE J2201 HFC-134a

(R-134a) recovery equipment. If an accidental system discharge occurs, ventilate the work area before

resuming service. Additional health and safety information may be obtained from the refrigerant and

lubricant manufacturers.

Evacuating System and Charging Refrigerant

1. Shut-off valve 2. A/C service valve 3. Recovery/Recycling equipment ACR 2000

(J-43600) with refrigerant identifier

WJIA1160E

1. Shut-off valve 2. A/C service valve 3. Recovery/Recycling equipment ACR

2000 (J-43600) with refrigerant identifier

WJIA1161E

Page 476 of 3171

ATC-142

REFRIGERANT LINES

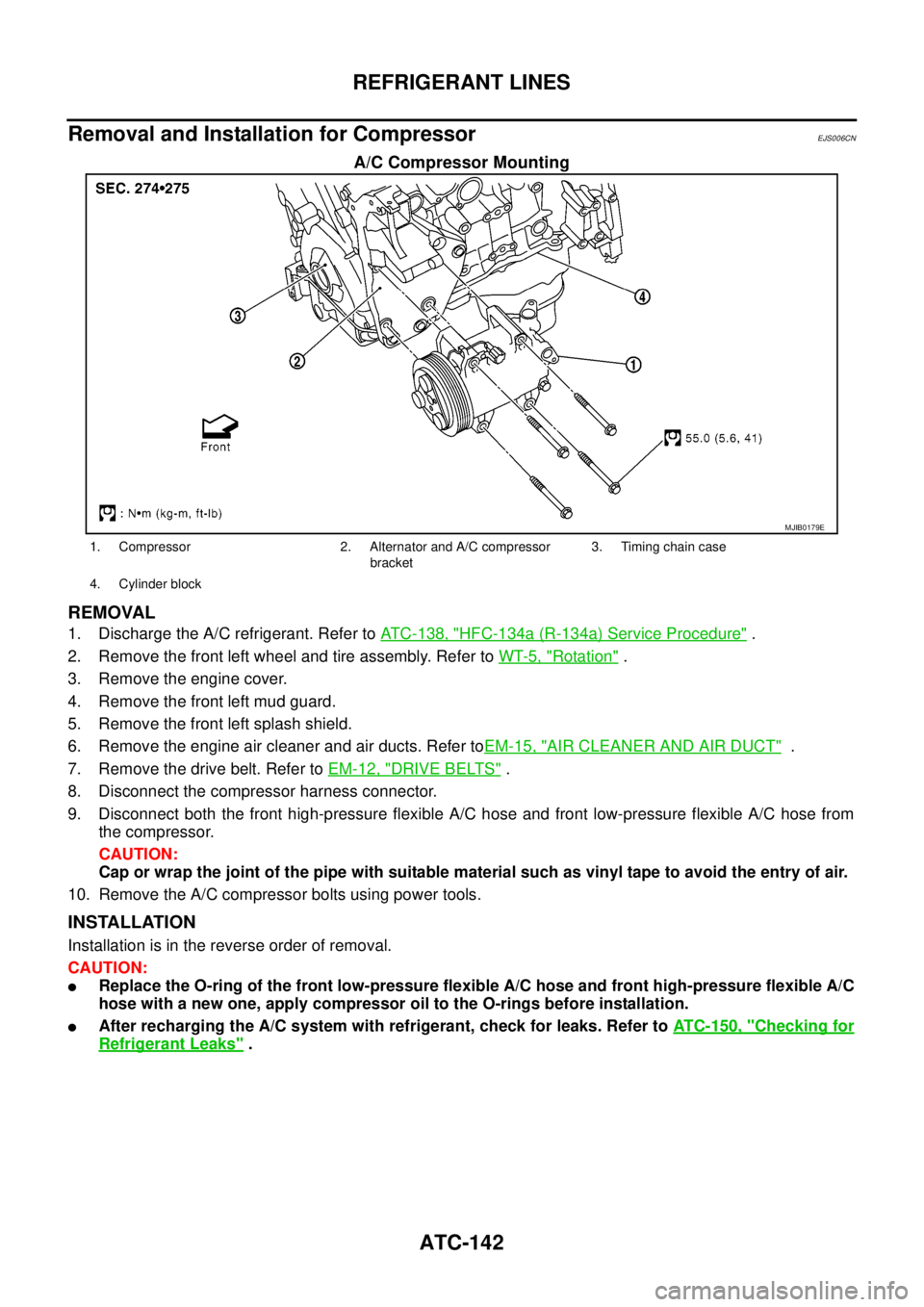

Removal and Installation for Compressor

EJS006CN

A/C Compressor Mounting

REMOVAL

1. Discharge the A/C refrigerant. Refer toATC-138, "HFC-134a (R-134a) Service Procedure".

2. Remove the front left wheel and tire assembly. Refer toWT-5, "

Rotation".

3. Remove the engine cover.

4. Remove the front left mud guard.

5. Remove the front left splash shield.

6. Remove the engine air cleaner and air ducts. Refer toEM-15, "

AIR CLEANER AND AIR DUCT".

7. Remove the drive belt. Refer toEM-12, "

DRIVE BELTS".

8. Disconnect the compressor harness connector.

9. Disconnect both the front high-pressure flexible A/C hose and front low-pressure flexible A/C hose from

the compressor.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

10. Remove the A/C compressor bolts using power tools.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

lReplace the O-ring of the front low-pressure flexible A/C hose and front high-pressure flexible A/C

hose with a new one, apply compressor oil to the O-rings before installation.

lAfter recharging the A/C system with refrigerant, check for leaks. Refer toATC-150, "Checking for

Refrigerant Leaks".

MJIB0179E

1. Compressor 2. Alternator and A/C compressor

bracket3. Timing chain case

4. Cylinder block

Page 480 of 3171

ATC-146

REFRIGERANT LINES

BREAK-IN OPERATION

When replacing compressor clutch assembly, always conduct the break-in operation. This is done by engag-

ing and disengaging the clutch about 30 times. Break-in operation raises the level of transmitted torque.

Removal and Installation for High-pressure Flexible A/C HoseEJS006CP

REMOVAL

1. Remove the front left wheel and tire assembly. Refer toWT-5, "Rotation".

2. Remove the front left mud guard.

3. Remove the front left splash shield.

4. Discharge the refrigerant. Refer toATC-138, "

HFC-134a (R-134a) Service Procedure".

5. Remove the high-pressure flexible A/C hose. Refer toATC-140, "

Components".

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

Refer toATC-140, "

Components".

CAUTION:

lReplace the O-ring of the high-pressure flexible A/C hose with a new one, then apply compressor

oil to it for installation.

lAfter charging refrigerant, check for leaks.

Removal and Installation for High-pressure A/C PipeEJS006CQ

REMOVAL

1. Remove the front right wheel and tire assembly. Refer toWT-5, "Rotation".

2. Remove the front right mud guard.

3. Remove the front right splash shield.

4. Discharge the refrigerant. Refer toATC-138, "

HFC-134a (R-134a) Service Procedure".

5. Remove the low pressure A/C pipe. Refer toATC-147, "

Removal and Installation for Low-pressure A/C

Pipe".

6. Remove the high-pressure A/C pipe. Refer toATC-146, "

Removal and Installation for High-pressure A/C

Pipe".

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

Refer toATC-140, "

Components".

CAUTION:

lReplace the O-ring of the high-pressure A/C pipe with a new one, then apply compressor oil to it

for installation.

lAfter charging refrigerant, check for leaks.

Removal and Installation for Low-pressure Flexible A/C HoseEJS006CR

REMOVAL

1. Remove the front right wheel and tire assembly. Refer toWT-5, "Rotation".

2. Remove the front right mud guard.

3. Remove the front right splash shield.

4. Discharge the refrigerant. Refer toATC-138, "

HFC-134a (R-134a) Service Procedure".

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

5. Remove the low-pressure flexible A/C hose. Refer toATC-140, "

Components".

INSTALLATION

Installation is in the reverse order of removal.

Refer toATC-140, "

Components".

Page 481 of 3171

REFRIGERANT LINES

ATC-147

C

D

E

F

G

H

I

K

L

MA

B

AT C

CAUTION:

lReplace the O-ring of the low-pressure flexible A/C hose with a new one, then apply compressor

oil to it for installation.

lAfter charging refrigerant, check for leaks.

Removal and Installation for Low-pressure A/C PipeEJS006CS

REMOVAL

1. Discharge the refrigerant. Refer toATC-138, "HFC-134a (R-134a) Service Procedure".

2. Disconnect the heater pump connector.

3. Remove the heater pump from the bracket and reposition out of the way. Do not disconnect the heater

hoses from the heater pump.

4. Remove the low-pressure A/C pipe. Refer toATC-140, "

Components".

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

Refer toATC-140, "

Components".

CAUTION:

lReplace the O-ring of the low-pressure A/C pipe with a new one, then apply compressor oil to it for

installation.

lAfter charging refrigerant, check for leaks.

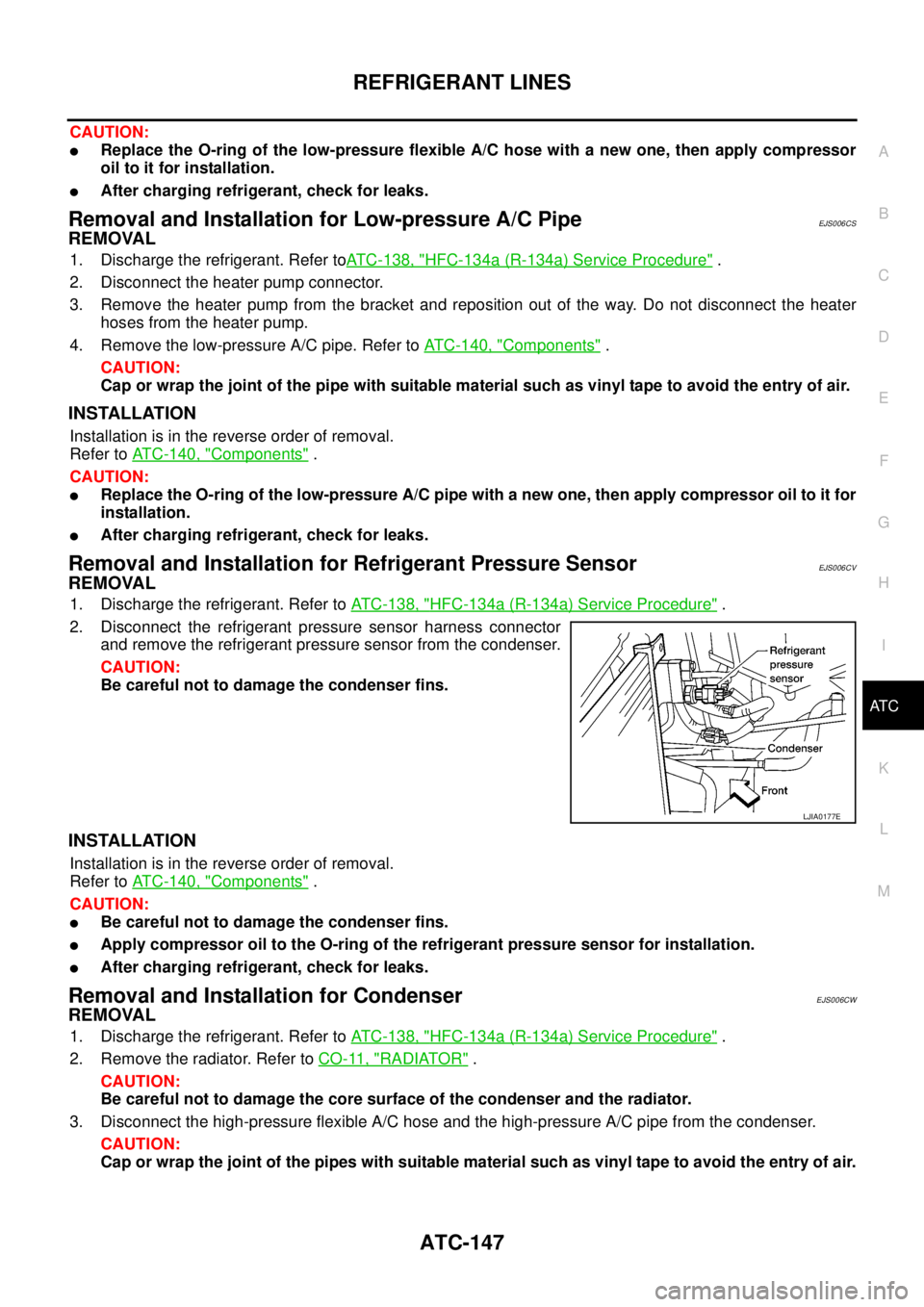

Removal and Installation for Refrigerant Pressure SensorEJS006CV

REMOVAL

1. Discharge the refrigerant. Refer toATC-138, "HFC-134a (R-134a) Service Procedure".

2. Disconnect the refrigerant pressure sensor harness connector

and remove the refrigerant pressure sensor from the condenser.

CAUTION:

Be careful not to damage the condenser fins.

INSTALLATION

Installation is in the reverse order of removal.

Refer toATC-140, "

Components".

CAUTION:

lBe careful not to damage the condenser fins.

lApply compressor oil to the O-ring of the refrigerant pressure sensor for installation.

lAfter charging refrigerant, check for leaks.

Removal and Installation for CondenserEJS006CW

REMOVAL

1. Discharge the refrigerant. Refer toATC-138, "HFC-134a (R-134a) Service Procedure".

2. Remove the radiator. Refer toCO-11, "

RADIATOR".

CAUTION:

Be careful not to damage the core surface of the condenser and the radiator.

3. Disconnect the high-pressure flexible A/C hose and the high-pressure A/C pipe from the condenser.

CAUTION:

Cap or wrap the joint of the pipes with suitable material such as vinyl tape to avoid the entry of air.

LJIA0177E

Page 482 of 3171

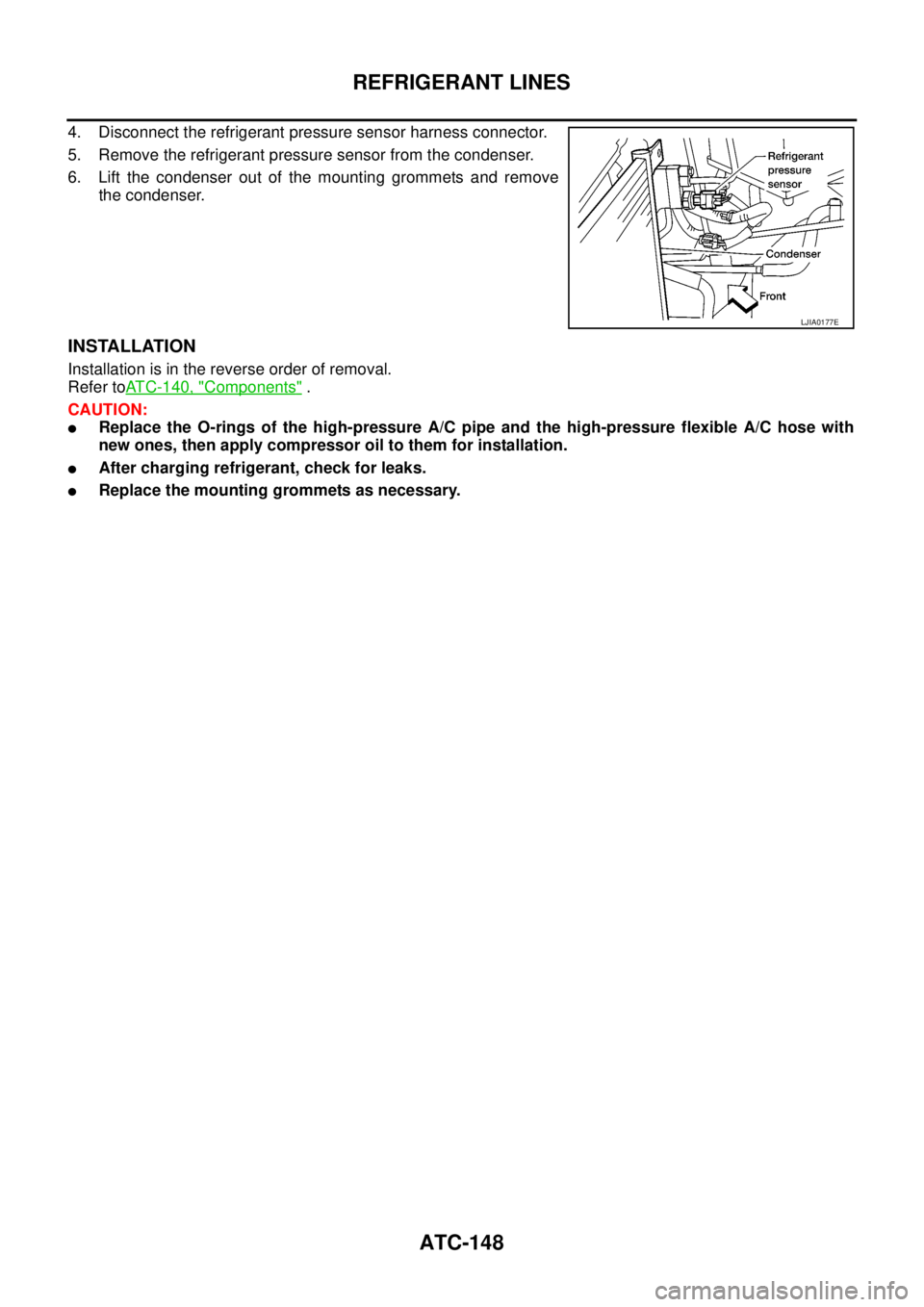

ATC-148

REFRIGERANT LINES

4. Disconnect the refrigerant pressure sensor harness connector.

5. Remove the refrigerant pressure sensor from the condenser.

6. Lift the condenser out of the mounting grommets and remove

the condenser.

INSTALLATION

Installation is in the reverse order of removal.

Refer toATC-140, "

Components".

CAUTION:

lReplace the O-rings of the high-pressure A/C pipe and the high-pressure flexible A/C hose with

new ones, then apply compressor oil to them for installation.

lAfter charging refrigerant, check for leaks.

lReplace the mounting grommets as necessary.

LJIA0177E

Page 484 of 3171

ATC-150

REFRIGERANT LINES

CAUTION:

Replace the O-rings on the A/C low-pressure flexible A/C hose and the high-pressure A/C pipe with

new ones. Apply compressor oil to the O-rings for installation.

Removal and Installation for Expansion ValveEJS006CZ

REMOVAL

1. Discharge the refrigerant. Refer toATC-138, "HFC-134a (R-134a) Service Procedure".

2. Remove the heater and cooling unit assembly. Refer toATC-126, "

REMOVAL".

3. Remove the heater core and evaporator pipes grommet.

4. Remove the expansion valve.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

lReplace the O-rings on then expansion valve and the A/C refrigerant pipes with new ones, then

apply compressor oil to them for installation.

lAfter charging refrigerant, check for leaks.

Checking for Refrigerant LeaksEJS006D1

Perform a visual inspection of all refrigeration parts, fittings, hoses and components for signs of A/C lubricant

leakage, damage and corrosion. A/C lubricant leakage may indicate an area of refrigerant leakage. Allow

extra inspection time in these areas when using either an electronic refrigerant leak detector or fluorescent

dye leak detector.

If dye is observed, confirm the leak with an electronic refrigerant leak detector. It is possible a prior leak was

repaired and not properly cleaned.

When searching for leaks, do not stop when one leak is found but continue to check for additional leaks at all

system components and connections.

When searching for refrigerant leaks using an electronic leak detector, move the probe along the suspected

leak area at 1 to 2 inches per second and no further than 1/4 inch from the component.

CAUTION:

Moving the electronic leak detector probe slower and closer to the suspected leak area will improve

the chances of finding a leak.

Checking System for Leaks Using the Fluorescent Leak DetectorEJS006D2

1. Check A/C system for leaks using the UV lamp and safety goggles [SST: J-42220] in a low sunlight area

(area without windows preferable). Illuminate all components, fittings and lines. The dye will appear as a

bright green/yellow area at the point of leakage. Fluorescent dye observed at the evaporator drain open-

ing indicates an evaporator core assembly (tubes, core or expansion valve) leak.

2. If the suspected area is difficult to see, use an adjustable mirror or wipe the area with a clean shop rag or

cloth, with the UV lamp for dye residue.

3. After the leak is repaired, remove any residual dye using dye cleaner [SST: J-43872] to prevent future mis-

diagnosis.

4. Perform a system performance check and verify the leak repair with an approved electronic refrigerant

leak detector.

NOTE:

Other gases in the work area or substances on the A/C components, for example, anti-freeze, windshield

washer fluid, solvents and lubricants, may falsely trigger the leak detector. Make sure the surfaces to be

checked are clean.

Cleanwithadryclothorblowoffwithshopair.

Do not allow the sensor tip of the detector to contact with any substance. This can also cause false readings

and may damage the detector.Expansion valve bolts : 4 N·m (0.41 kg-m, 35 in-lb)

A/C refrigerant pipe to expansion valve bolt : Refer toATC-140, "

Components"

.

Page 485 of 3171

REFRIGERANT LINES

ATC-151

C

D

E

F

G

H

I

K

L

MA

B

AT C

Dye InjectionEJS006D3

(This procedure is only necessary when recharging the system or when the compressor has seized and was

replaced.)

1. Check A/C system static (at rest) pressure. Pressure must be at least 345 kPa (3.45 bar, 3.52 kg/cm

2,50

psi).

2. Pour one bottle (1/4 ounce / 7.4 cc) of the A/C refrigerant dye into the injector tool [SST: J-41459].

3. Connect the injector tool to the A/C Low-pressure side service fitting.

4. Start engine and switch A/C ON.

5. When the A/C operating (compressor running), inject one bottle (1/4 ounce / 7.4 cc) of fluorescent dye

through the low-pressure service valve using dye injector tool J-41459 (refer to the manufacture’s operat-

ing instructions).

6. With the engine still running, disconnect the injector tool from the service fitting.

CAUTION:

Be careful the A/C system or replacing a component, pour the dye directly into the open system

connection and proceed with the service procedures.

7. Operate the A/C system for a minimum of 20 minutes to mix the dye with the system oil. Depending on the

leak size, operating conditions and location of the leak, it may take from minutes to days for the dye to

penetrate a leak and become visible.

Electronic Refrigerant Leak DetectorEJS006D4

PRECAUTIONS FOR HANDLING LEAK DETECTOR

When performing a refrigerant leak check, use an A/C electrical leak

detector (SST) or equivalent. Ensure that the instrument is calibrated

and set properly per the operating instructions.

The leak detector is a delicate device. In order to use the leak detec-

tor properly, read the operating instructions and perform any speci-

fied maintenance.

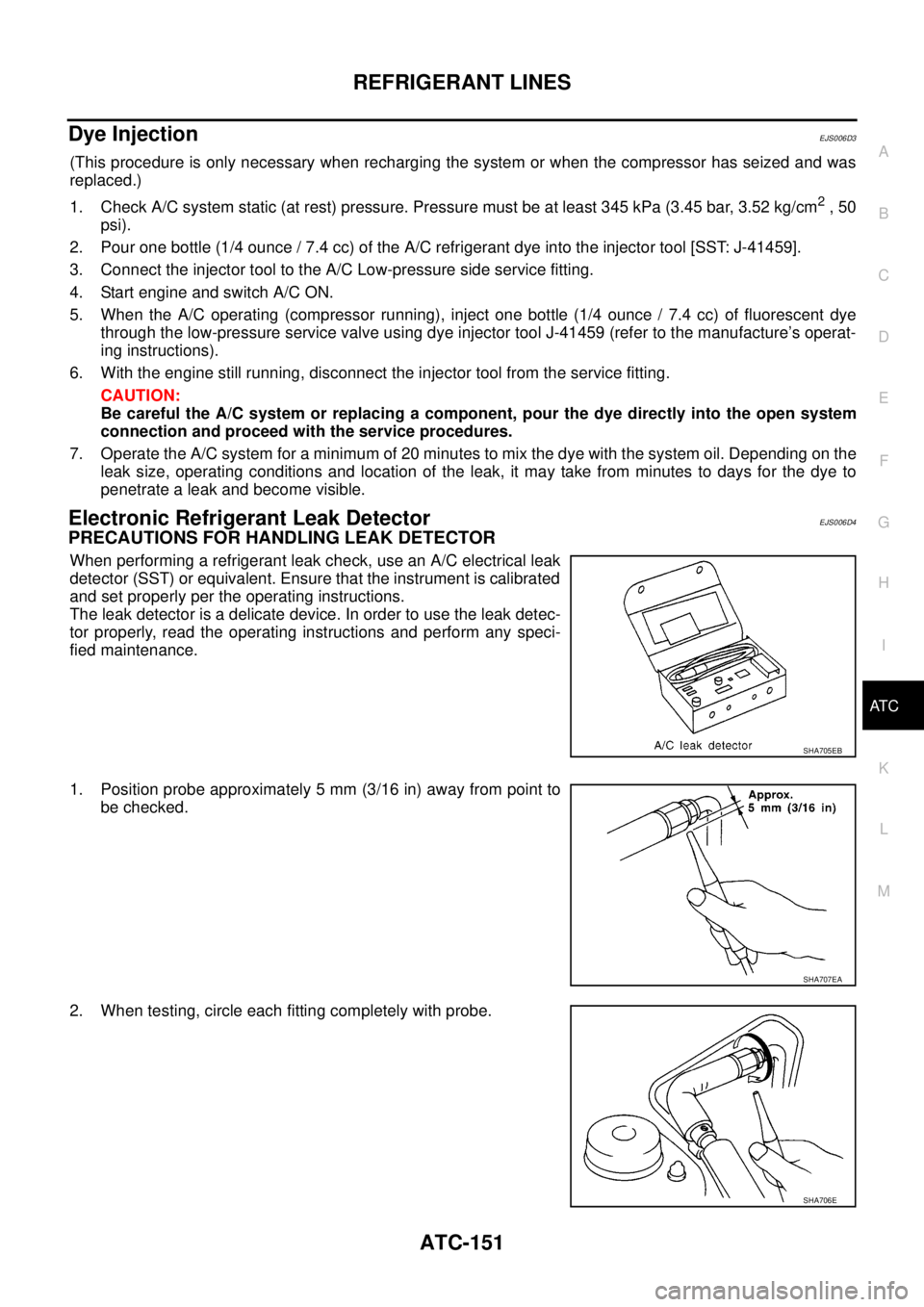

1. Position probe approximately 5 mm (3/16 in) away from point to

be checked.

2. When testing, circle each fitting completely with probe.

SHA705EB

SHA707EA

SHA706E