reset NISSAN NAVARA 2005 Repair User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 609 of 3171

POWERDOORLOCKSYSTEM

BL-25

C

D

E

F

G

H

J

K

L

MA

B

BL

Door lock indicator timer

Door lock indicator timer is designed to reacts and shut down the indicator. The default timer values are 1

minute and 30 minutes.

lWhen the lock operation is activated by keyfob or auto door lock (for further details, refer toBL-92, "Auto

Re-lock Function"), then the illuminate time is set to 1 minute.

lWhen the lock operation is activated by door lock/unlock switch, then the timer is set to 30 minutes.

NOTE:

When the 30 minutes timer is active and ignition switch is turned ON, the indicator illuminate for perma-

nently, unless ignition switch is turned OFF then timer will be reset back to 30 minutes.

CAN Communication System DescriptionEIS00D7T

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

CAN Communication UnitEIS00D7U

Refer toLAN-23, "CAN COMMUNICATION".

Page 643 of 3171

POWER DOOR LOCK — SUPER LOCK —

BL-59

C

D

E

F

G

H

J

K

L

MA

B

BL

Door Lock Warning Function

Under following conditions lock actuators will not response and buzzer warning will beeps while pressing door

lock/unlock switch in LOCK direction.

lIgnition switch is turned OFF

lMechanical key is out of ignition key cylinder

lAny door is opened (except driver side door)

Key Reminder Function

Under following conditions lock actuators will lock the door once, but then immediately unlock all doors and

buzzer warning will beeps while pressing door lock/unlock switch in LOCK direction.

lIgnition switch is turned OFF

lMechanical key is inserted in ignition key cylinder

lDriver side door is opened

Door Lock/Unlock Switch Indicator

The Door lock/unlock switch indicates door lock status. The indicator will illuminate when a lock operation is

accomplish, during this state, if any door is open, the indicator will turn OFF.

Door Lock Indicator Timer

Door lock indicator timer is designed to reacts and shut down the indicator. The default timer values are 1

minute and 30 minutes.

lWhen the lock operation is activated by keyfob or auto door lock (for further details refer toBL-92, "Auto

Re-lock Function"), then the illuminate time is set to 1 minute.

lWhen the lock operation is activated by door lock/unlock switch, then the timer is set to 30 minutes.

NOTE:

When the 30 minutes timer is active and ignition switch is turned ON, then the indicator illuminate for per-

manently unless ignition switch is turned OFF then timer will be reset back to 30 minutes.

CAN Communication System DescriptionEIS00DX1

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

CAN Communication UnitEIS00DX2

Refer toLAN-23, "CAN COMMUNICATION".

Page 676 of 3171

BL-92

MULTI-REMOTE CONTROL SYSTEM

Auto Re-lock Function

The BCM is equipped with an auto re-lock function, when no further user action occurs after an full or partial

unlock, the doors will automatically re-lock after 2 minutes (default value).

The auto re-lock function will not be activated under the following state.

lKeyswitchisOn

lMechanical key is inserted

lAny door is opened

NOTE:

The 2 minutes timer of auto re-lock will be reset if unlock button from the key fob is pressed.

Auto relock function can be changed using “WORK SUPPORT” mode in “AUTO LOCK SET”.

Refer toBL-104, "

Work Support".

Room Lamp Operation

When the following conditions are met:

lcondition of room lamp switch is DOOR position;

ldoor switch OFF (when all the doors are closed);

With input of UNLOCK signal from keyfob multi-remote control system turns on interior lamp (for 30 seconds).

CAN Communication System DescriptionEIS00DBF

Refer toLAN-23, "CAN COMMUNICATION".

Page 915 of 3171

COMBINATION METERS

DI-5

C

D

E

F

G

H

I

J

L

MA

B

DI

FUEL GAUGE

The fuel gauge indicates the approximate fuel level in the fuel tank.

Combination meter reads a resistor signal from fuel level sensor unit.

Signal is supplied

lto combination meter terminal 9

lthrough fuel level sensor unit terminal 1 and 2

lfrom combination meter terminal 4.

ODO/TRIP METER

lABS actuator and electric unit (control unit) converses a pulse signal from wheel sensor to vehicle speed

signal, and transmits vehicle speed signal to combination meter with CAN communication.

lCombination meter uses the vehicle speed signal to calculate the mileage, and it displays.

How to Change/ Reset Indication

lIndication can be changed in the following order by momentarily

pressing the odo/trip meter switch (1).

–Trip A®Trip B®DTE®Average fuel economy®Average

vehicle speed®Running time®Trip A ···.

lHolding the switch for more than 1 second resets displayed

mode (except DTE).

lHolding the switch for more than 3 seconds resets all functions

(except trip A and DTE).

NOTE:

lAfter the display changes automatically, the indication can be

changed to the next mode by pressing the odo/trip meter switch.

lThe record of the odometer is kept even if the battery cable is disconnected.

TRIP COMPUTER

Function

The trip computer can indicate the following items.

lDTE (distance to empty)

lAverage fuel economy

lAverage vehicle speed

lRunning time

DTE (Distance to Empty) Indication

The DTE indication provides the driver with the distance estimation that can be driven before refueling. The

DTE is calculated by signals from the fuel level sensor unit (fuel remaining), ECM (fuel consumption) and ABS

actuator and electric unit (control unit) (vehicle speed). The indication is refreshed every 30 seconds. When

fuel remaining is less than approximately 11.6 (2 1/2 Imp gal), the indication blinks as a warning. If the fuel

remaining is less than approximately 9.6 (2 1/8 Imp gal), the indication shows “---”. In this case, the display

changes to the DTE mode from the different mode. When the battery cable is disconnected and reconnected,

DTE mode displays “---” until the vehicle is driven 0.5 km.

Average Vehicle Speed Indication

Average vehicle speed indication is calculated by running distance and running time. The indication is

refreshed every 30 seconds. If average vehicle speed is reset, average fuel consumption is reset at the same

time. At about 0.5 km and for 30 seconds after resetting, the display shows “- ”®“- ”®“-”®“ -”.

Average Fuel Economy Indication

Average fuel consumption indication is calculated by signals from ABS actuator and electric unit (vehicle

speed) and the ECM (fuel consumption). The indication is refreshed every 30 seconds. At about 0.5 km and

for 30 seconds after resetting, the display shows “- ”®“- ”®“-”®“ -”.

Running Time Indication

Trip time displays ignition switch ON time cumulatively. If trip time is reset, trip distance is reset at the same

time.

SKIB4848E

Page 998 of 3171

EC-18

ENGINE CONTROL SYSTEM

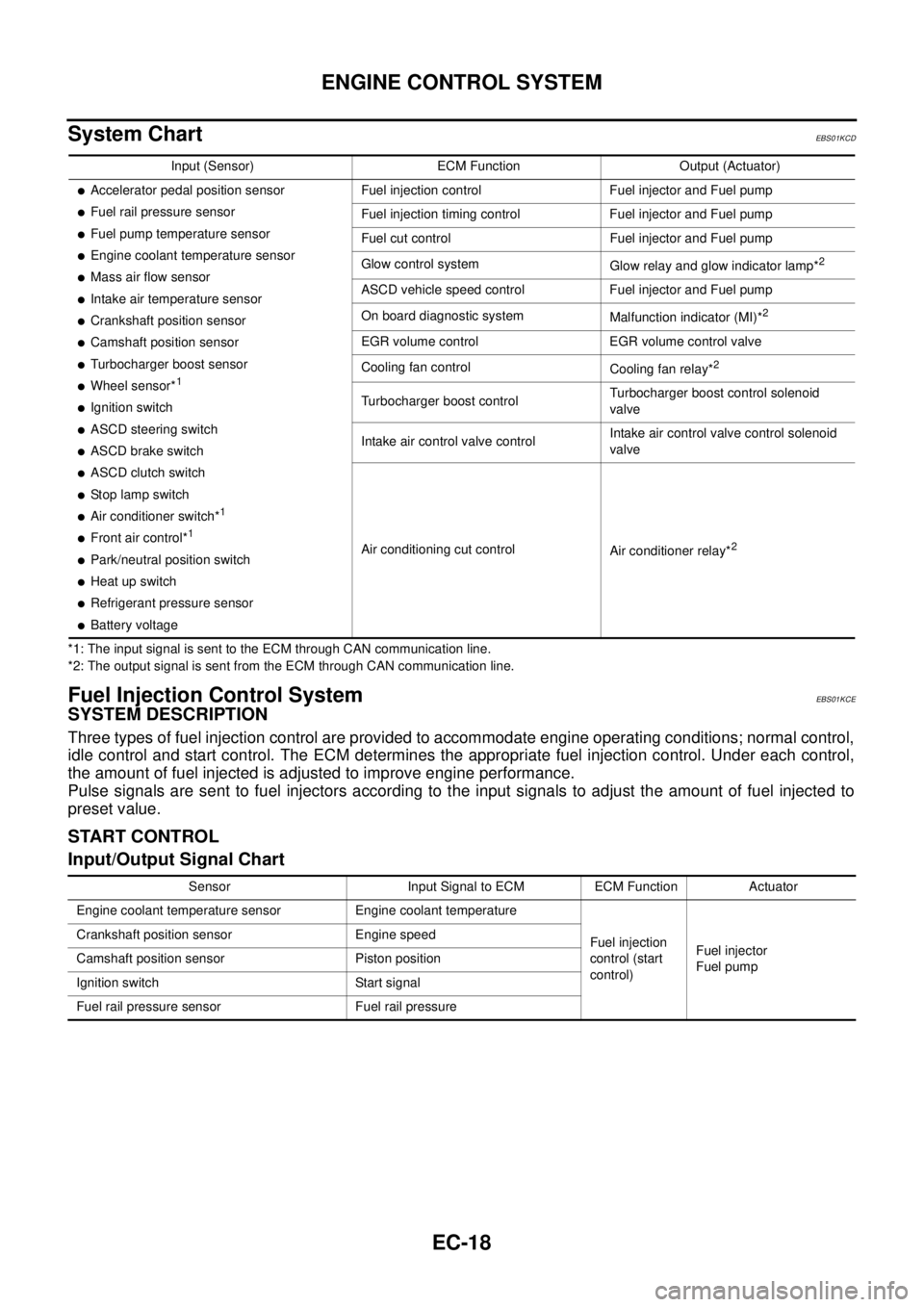

System Chart

EBS01KCD

*1: The input signal is sent to the ECM through CAN communication line.

*2: The output signal is sent from the ECM through CAN communication line.

Fuel Injection Control SystemEBS01KCE

SYSTEM DESCRIPTION

Three types of fuel injection control are provided to accommodate engine operating conditions; normal control,

idle control and start control. The ECM determines the appropriate fuel injection control. Under each control,

the amount of fuel injected is adjusted to improve engine performance.

Pulse signals are sent to fuel injectors according to the input signals to adjust the amount of fuel injected to

preset value.

START CONTROL

Input/Output Signal Chart

Input (Sensor) ECM Function Output (Actuator)

lAccelerator pedal position sensor

lFuel rail pressure sensor

lFuel pump temperature sensor

lEngine coolant temperature sensor

lMass air flow sensor

lIntake air temperature sensor

lCrankshaft position sensor

lCamshaft position sensor

lTurbocharger boost sensor

lWheel sensor*1

lIgnition switch

lASCD steering switch

lASCD brake switch

lASCD clutch switch

lSt o p l a m p s w it c h

lAir conditioner switch*1

lFront air control*1

lPark/neutral position switch

lHeat up switch

lRefrigerant pressure sensor

lBattery voltageFuel injection control Fuel injector and Fuel pump

Fuel injection timing control Fuel injector and Fuel pump

Fuel cut control Fuel injector and Fuel pump

Glow control system

Glow relay and glow indicator lamp*

2

ASCD vehicle speed control Fuel injector and Fuel pump

On board diagnostic system

Malfunction indicator (MI)*

2

EGR volume control EGR volume control valve

Cooling fan control

Cooling fan relay*

2

Turbocharger boost controlTurbocharger boost control solenoid

valve

Intake air control valve controlIntake air control valve control solenoid

valve

Air conditioning cut control

Air conditioner relay*

2

Sensor Input Signal to ECM ECM Function Actuator

Engine coolant temperature sensor Engine coolant temperature

Fuel injection

control (start

control)Fuel injector

Fuel pump Crankshaft position sensor Engine speed

Camshaft position sensor Piston position

Ignition switch Start signal

Fuel rail pressure sensor Fuel rail pressure

Page 999 of 3171

ENGINE CONTROL SYSTEM

EC-19

C

D

E

F

G

H

I

J

K

L

MA

EC

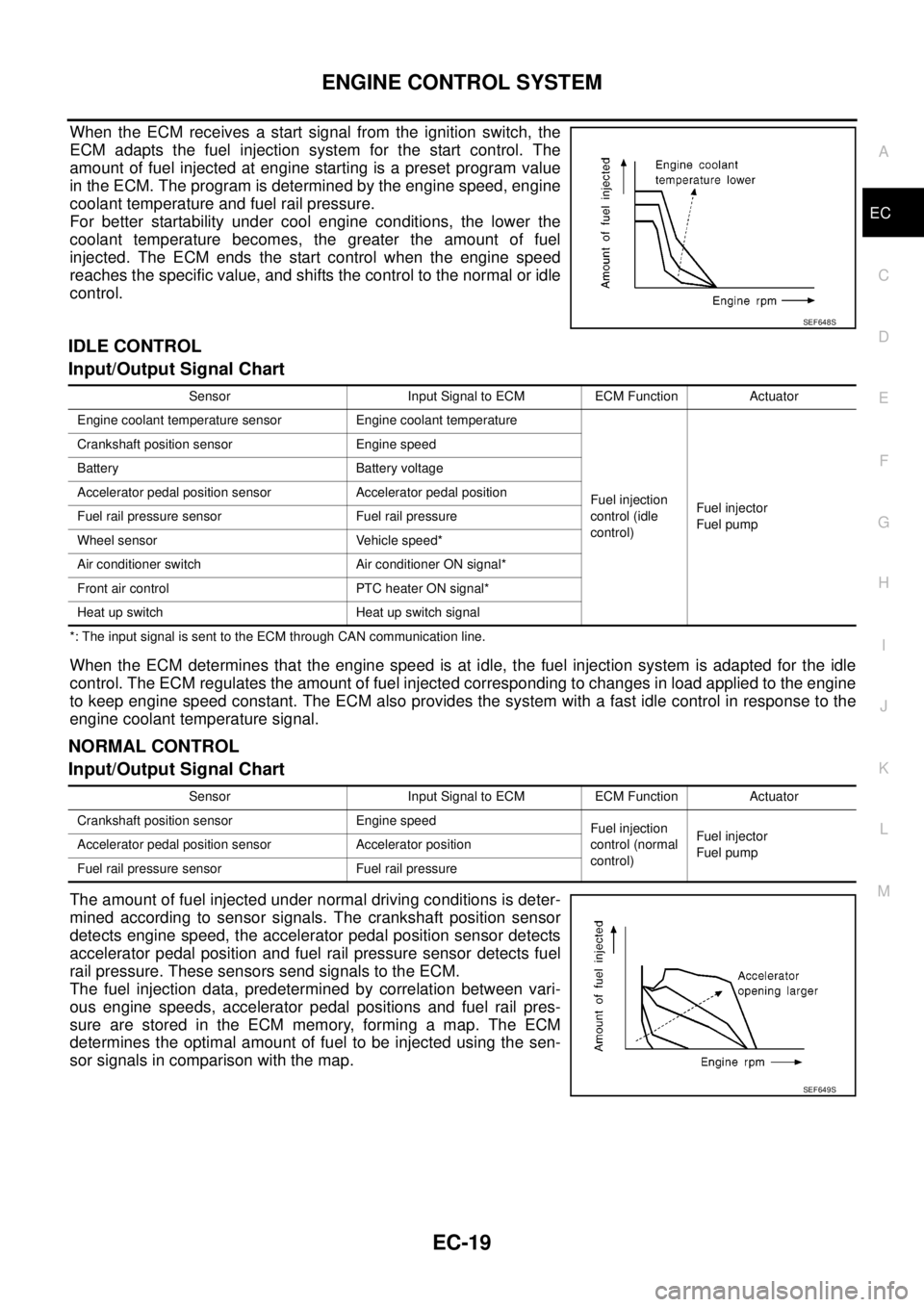

When the ECM receives a start signal from the ignition switch, the

ECM adapts the fuel injection system for the start control. The

amount of fuel injected at engine starting is a preset program value

in the ECM. The program is determined by the engine speed, engine

coolant temperature and fuel rail pressure.

For better startability under cool engine conditions, the lower the

coolant temperature becomes, the greater the amount of fuel

injected. The ECM ends the start control when the engine speed

reaches the specific value, and shifts the control to the normal or idle

control.

IDLE CONTROL

Input/Output Signal Chart

*: The input signal is sent to the ECM through CAN communication line.

When the ECM determines that the engine speed is at idle, the fuel injection system is adapted for the idle

control. The ECM regulates the amount of fuel injected corresponding to changes in load applied to the engine

to keep engine speed constant. The ECM also provides the system with a fast idle control in response to the

engine coolant temperature signal.

NORMAL CONTROL

Input/Output Signal Chart

The amount of fuel injected under normal driving conditions is deter-

mined according to sensor signals. The crankshaft position sensor

detects engine speed, the accelerator pedal position sensor detects

accelerator pedal position and fuel rail pressure sensor detects fuel

rail pressure. These sensors send signals to the ECM.

The fuel injection data, predetermined by correlation between vari-

ous engine speeds, accelerator pedal positions and fuel rail pres-

sure are stored in the ECM memory, forming a map. The ECM

determines the optimal amount of fuel to be injected using the sen-

sor signals in comparison with the map.

SEF648S

Sensor Input Signal to ECM ECM Function Actuator

Engine coolant temperature sensor Engine coolant temperature

Fuel injection

control (idle

control)Fuel injector

Fuel pump Crankshaft position sensor Engine speed

Battery Battery voltage

Accelerator pedal position sensor Accelerator pedal position

Fuel rail pressure sensor Fuel rail pressure

Wheel sensor Vehicle speed*

Air conditioner switch Air conditioner ON signal*

Front air control PTC heater ON signal*

Heat up switch Heat up switch signal

Sensor Input Signal to ECM ECM Function Actuator

Crankshaft position sensor Engine speed

Fuel injection

control (normal

control)Fuel injector

Fuel pump Accelerator pedal position sensor Accelerator position

Fuel rail pressure sensor Fuel rail pressure

SEF649S

Page 1046 of 3171

EC-66

TROUBLE DIAGNOSIS

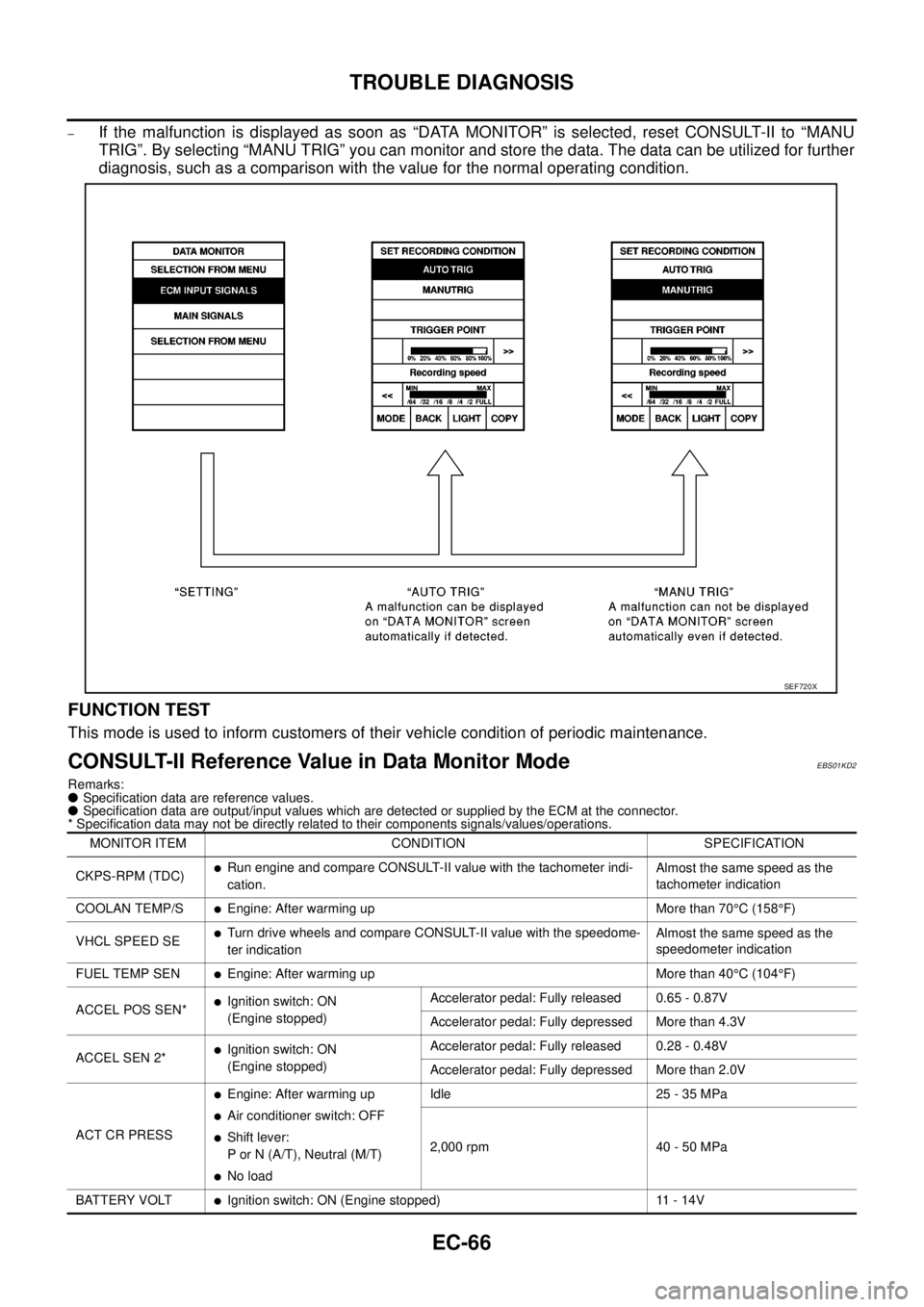

–If the malfunction is displayed as soon as “DATA MONITOR” is selected, reset CONSULT-II to “MANU

TRIG”. By selecting “MANU TRIG” you can monitor and store the data. The data can be utilized for further

diagnosis, such as a comparison with the value for the normal operating condition.

FUNCTION TEST

This mode is used to inform customers of their vehicle condition of periodic maintenance.

CONSULT-II Reference Value in Data Monitor ModeEBS01KD2

Remarks:

lSpecification data are reference values.

lSpecification data are output/input values which are detected or supplied by the ECM at the connector.

* Specification data may not be directly related to their components signals/values/operations.

SEF720X

MONITOR ITEM CONDITION SPECIFICATION

CKPS-RPM (TDC)

lRun engine and compare CONSULT-II value with the tachometer indi-

cation.Almost the same speed as the

tachometer indication

COOLAN TEMP/S

lEngine: After warming up More than 70°C(158°F)

VHCL SPEED SE

lTurn drive wheels and compare CONSULT-II value with the speedome-

ter indicationAlmost the same speed as the

speedometer indication

FUEL TEMP SEN

lEngine: After warming up More than 40°C(104°F)

ACCEL POS SEN*

lIgnition switch: ON

(Engine stopped)Accelerator pedal: Fully released 0.65 - 0.87V

Accelerator pedal: Fully depressed More than 4.3V

ACCEL SEN 2*

lIgnition switch: ON

(Engine stopped)Accelerator pedal: Fully released 0.28 - 0.48V

Accelerator pedal: Fully depressed More than 2.0V

ACT CR PRESS

lEngine: After warming up

lAir conditioner switch: OFF

lShift lever:

P or N (A/T), Neutral (M/T)

lNo loadIdle 25 - 35 MPa

2,000 rpm 40 - 50 MPa

BATTERY VOLT

lIgnition switch: ON (Engine stopped) 11 - 14V

Page 1660 of 3171

GI-38

CONTROL UNIT CONFIGURATION PROCEDURE

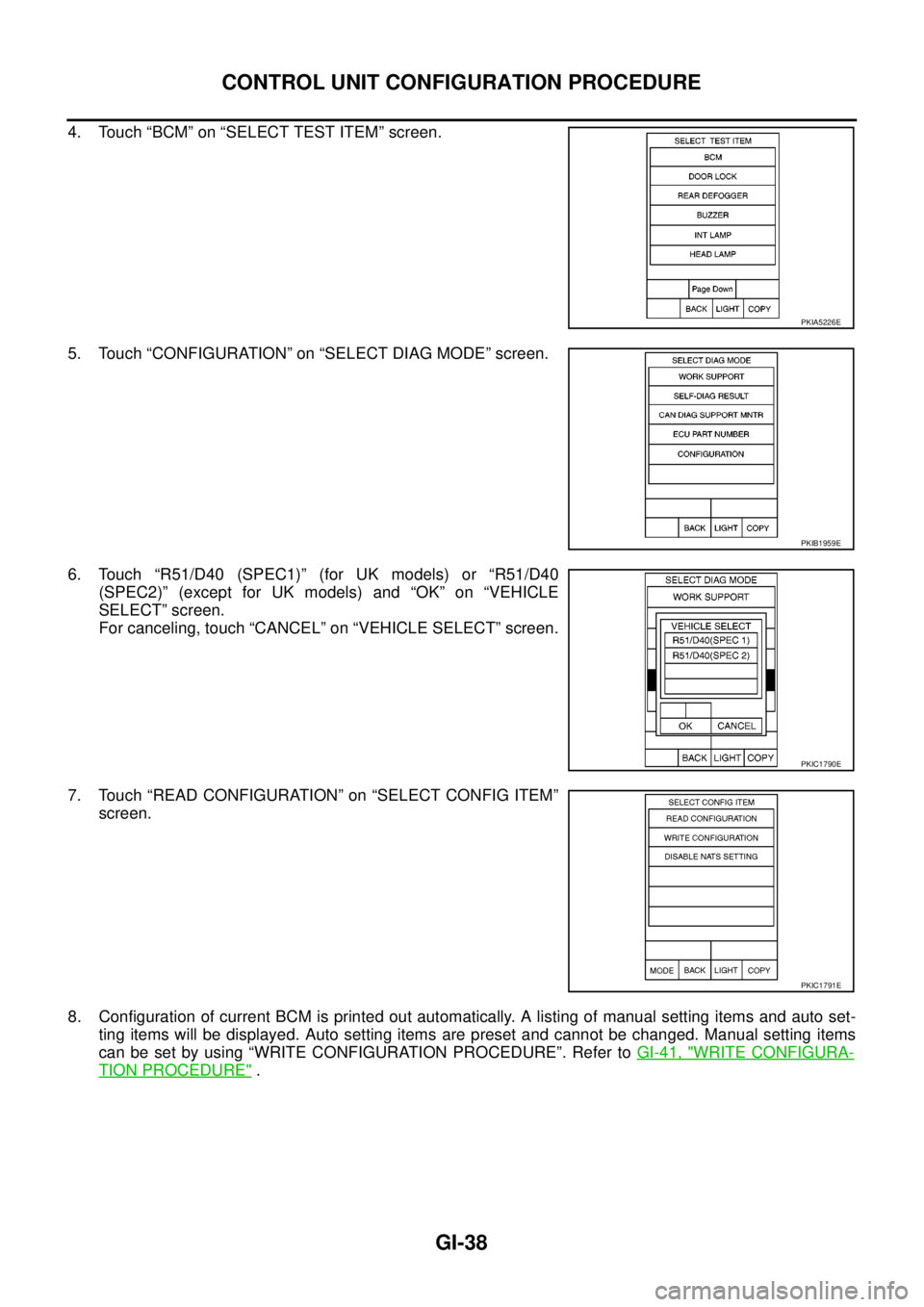

4. Touch “BCM” on “SELECT TEST ITEM” screen.

5. Touch “CONFIGURATION” on “SELECT DIAG MODE” screen.

6. Touch “R51/D40 (SPEC1)” (for UK models) or “R51/D40

(SPEC2)” (except for UK models) and “OK” on “VEHICLE

SELECT” screen.

For canceling, touch “CANCEL” on “VEHICLE SELECT” screen.

7. Touch “READ CONFIGURATION” on “SELECT CONFIG ITEM”

screen.

8. Configuration of current BCM is printed out automatically. A listing of manual setting items and auto set-

ting items will be displayed. Auto setting items are preset and cannot be changed. Manual setting items

can be set by using “WRITE CONFIGURATION PROCEDURE”. Refer toGI-41, "

WRITE CONFIGURA-

TION PROCEDURE".

PKIA5226E

PKIB1959E

PKIC1790E

PKIC1791E

Page 1687 of 3171

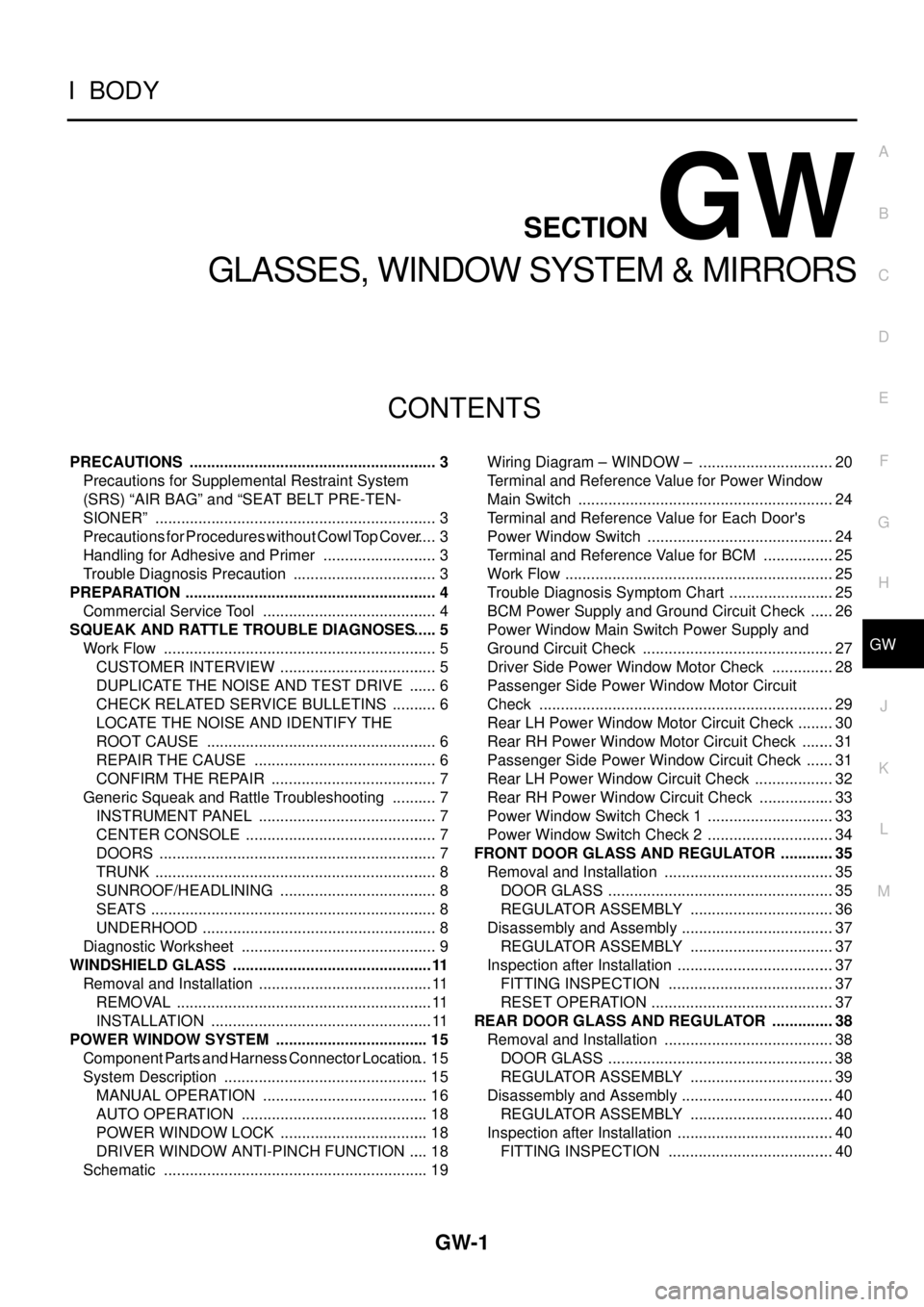

GW-1

GLASSES, WINDOW SYSTEM & MIRRORS

IBODY

CONTENTS

C

D

E

F

G

H

J

K

L

M

SECTIONGW

A

B

GW

GLASSES, WINDOW SYSTEM & MIRRORS

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

Precautions for Procedures without Cowl Top Cover..... 3

Handling for Adhesive and Primer ........................... 3

Trouble Diagnosis Precaution .................................. 3

PREPARATION ........................................................... 4

Commercial Service Tool ......................................... 4

SQUEAK AND RATTLE TROUBLE DIAGNOSES..... 5

Work Flow ................................................................ 5

CUSTOMER INTERVIEW ..................................... 5

DUPLICATE THE NOISE AND TEST DRIVE ....... 6

CHECK RELATED SERVICE BULLETINS ........... 6

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE ...................................................... 6

REPAIR THE CAUSE ........................................... 6

CONFIRM THE REPAIR ....................................... 7

Generic Squeak and Rattle Troubleshooting ........... 7

INSTRUMENT PANEL .......................................... 7

CENTER CONSOLE ............................................. 7

DOORS ................................................................. 7

TRUNK .................................................................. 8

SUNROOF/HEADLINING ..................................... 8

SEATS ................................................................... 8

UNDERHOOD ....................................................... 8

Diagnostic Worksheet .............................................. 9

WINDSHIELD GLASS ...............................................11

Removal and Installation ......................................... 11

REMOVAL ............................................................ 11

INSTALLATION .................................................... 11

POWER WINDOW SYSTEM .................................... 15

Component Parts and Harness Connector Location... 15

System Description ................................................ 15

MANUAL OPERATION ....................................... 16

AUTO OPERATION ............................................ 18

POWER WINDOW LOCK ................................... 18

DRIVER WINDOW ANTI-PINCH FUNCTION ..... 18

Schematic .............................................................. 19Wiring Diagram – WINDOW – ................................ 20

Terminal and Reference Value for Power Window

Main Switch ............................................................ 24

Terminal and Reference Value for Each Door's

Power Window Switch ............................................ 24

Terminal and Reference Value for BCM ................. 25

Work Flow ............................................................... 25

Trouble Diagnosis Symptom Chart ......................... 25

BCM Power Supply and Ground Circuit Check ...... 26

Power Window Main Switch Power Supply and

Ground Circuit Check ............................................. 27

Driver Side Power Window Motor Check ............... 28

Passenger Side Power Window Motor Circuit

Check ..................................................................... 29

Rear LH Power Window Motor Circuit Check ......... 30

Rear RH Power Window Motor Circuit Check ........ 31

Passenger Side Power Window Circuit Check ....... 31

Rear LH Power Window Circuit Check ................... 32

Rear RH Power Window Circuit Check .................. 33

Power Window Switch Check 1 .............................. 33

Power Window Switch Check 2 .............................. 34

FRONT DOOR GLASS AND REGULATOR ............. 35

Removal and Installation ........................................ 35

DOOR GLASS ..................................................... 35

REGULATOR ASSEMBLY .................................. 36

Disassembly and Assembly .................................... 37

REGULATOR ASSEMBLY .................................. 37

Inspection after Installation ..................................... 37

FITTING INSPECTION ....................................... 37

RESET OPERATION ........................................... 37

REAR DOOR GLASS AND REGULATOR ............... 38

Removal and Installation ........................................ 38

DOOR GLASS ..................................................... 38

REGULATOR ASSEMBLY .................................. 39

Disassembly and Assembly .................................... 40

REGULATOR ASSEMBLY .................................. 40

Inspection after Installation ..................................... 40

FITTING INSPECTION ....................................... 40

Page 1723 of 3171

FRONT DOOR GLASS AND REGULATOR

GW-37

C

D

E

F

G

H

J

K

L

MA

B

GW

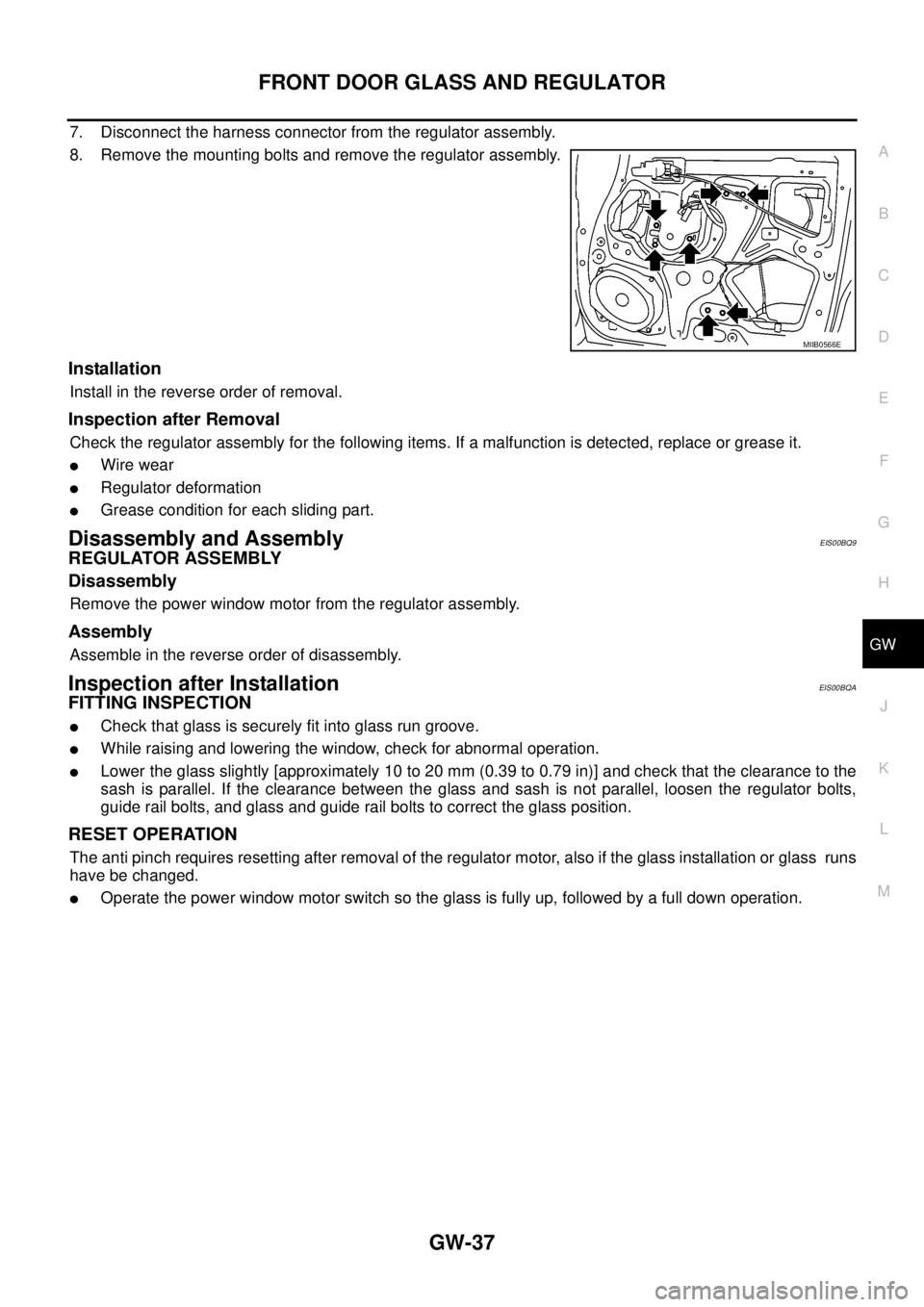

7. Disconnect the harness connector from the regulator assembly.

8. Remove the mounting bolts and remove the regulator assembly.

Installation

Install in the reverse order of removal.

Inspection after Removal

Check the regulator assembly for the following items. If a malfunction is detected, replace or grease it.

lWire wear

lRegulator deformation

lGrease condition for each sliding part.

Disassembly and AssemblyEIS00BQ9

REGULATOR ASSEMBLY

Disassembly

Remove the power window motor from the regulator assembly.

Assembly

Assemble in the reverse order of disassembly.

Inspection after InstallationEIS00BQA

FITTING INSPECTION

lCheck that glass is securely fit into glass run groove.

lWhile raising and lowering the window, check for abnormal operation.

lLower the glass slightly [approximately 10 to 20 mm (0.39 to 0.79 in)] and check that the clearance to the

sash is parallel. If the clearance between the glass and sash is not parallel, loosen the regulator bolts,

guide rail bolts, and glass and guide rail bolts to correct the glass position.

RESET OPERATION

The anti pinch requires resetting after removal of the regulator motor, also if the glass installation or glass runs

have be changed.

lOperate the power window motor switch so the glass is fully up, followed by a full down operation.

MIIB0566E