NISSAN NAVARA 2005 Repair Workshop Manual

NAVARA 2005

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57362/w960_57362-0.png

NISSAN NAVARA 2005 Repair Workshop Manual

Trending: lug pattern, ignition, center console, oil filter, coolant level, hood release, radiator cap

Page 2201 of 3171

LT-118

COMBINATION SWITCH

Combination Switch Inspection

EKS00P9Y

1.SYSTEM CHECK

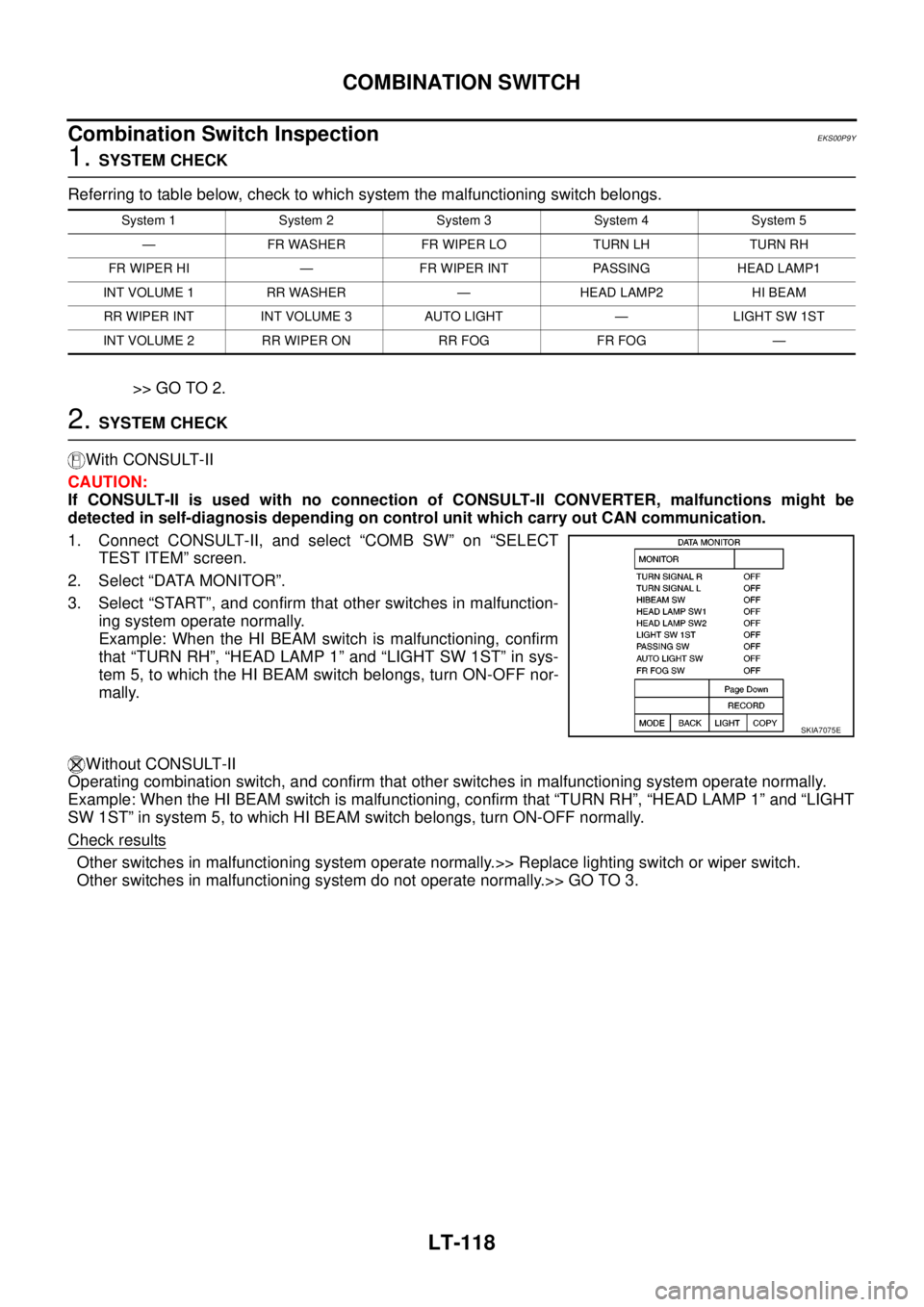

Referring to table below, check to which system the malfunctioning switch belongs.

>> GO TO 2.

2.SYSTEM CHECK

With CONSULT-II

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

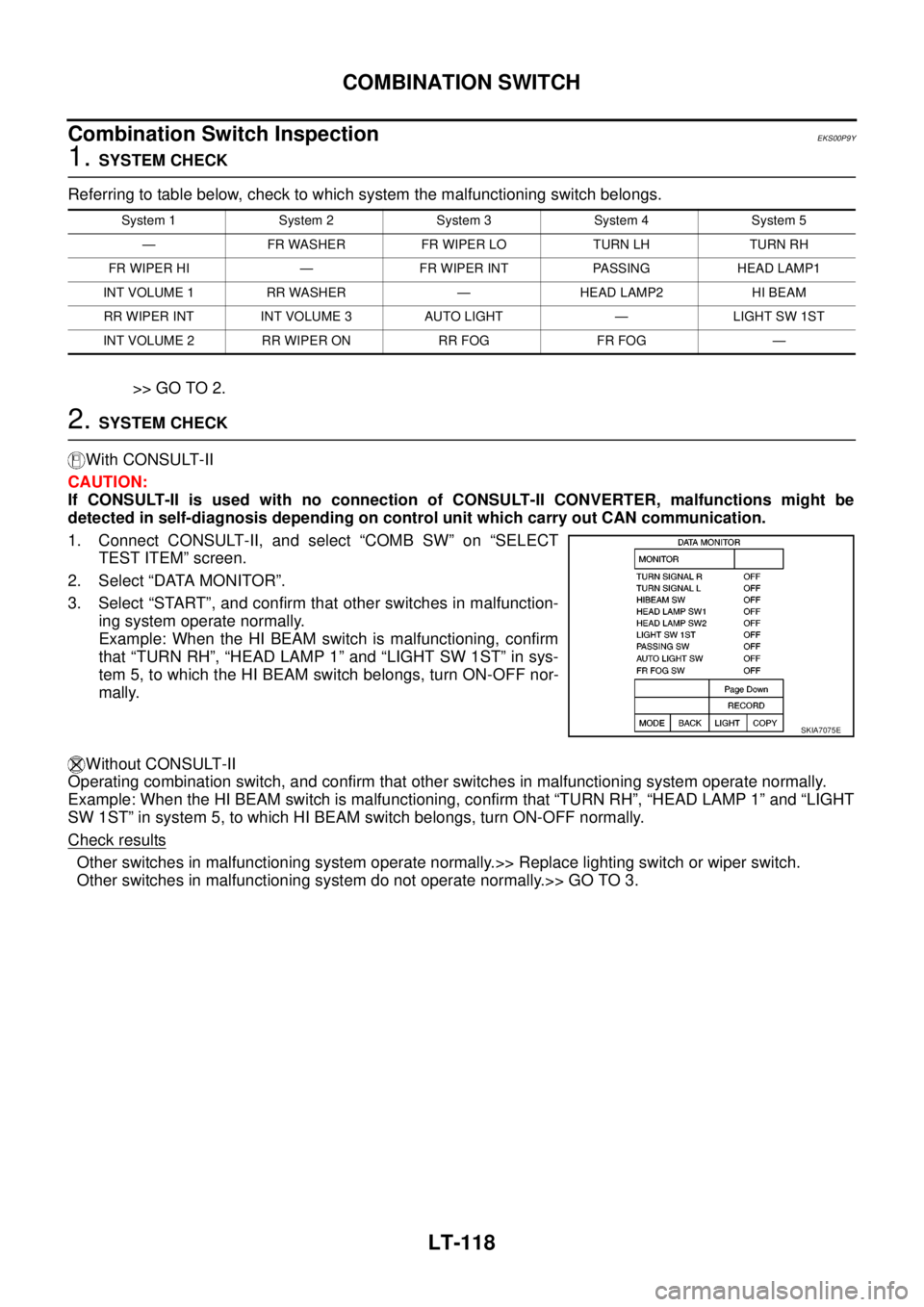

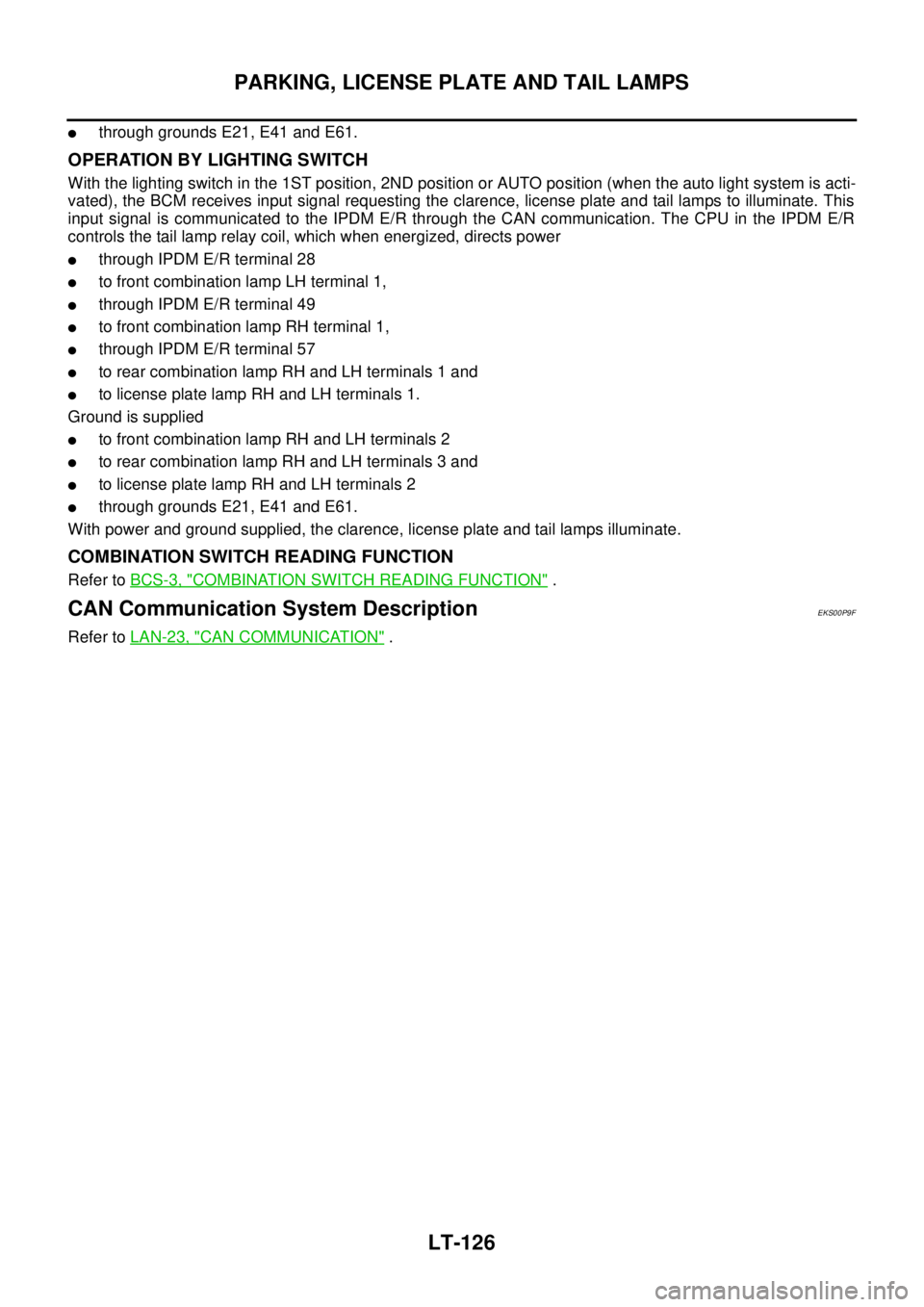

1. Connect CONSULT-II, and select “COMB SW” on “SELECT

TEST ITEM” screen.

2. Select “DATA MONITOR”.

3. Select “START”, and confirm that other switches in malfunction-

ing system operate normally.

Example: When the HI BEAM switch is malfunctioning, confirm

that “TURN RH”, “HEAD LAMP 1” and “LIGHT SW 1ST” in sys-

tem 5, to which the HI BEAM switch belongs, turn ON-OFF nor-

mally.

Without CONSULT-II

Operating combination switch, and confirm that other switches in malfunctioning system operate normally.

Example: When the HI BEAM switch is malfunctioning, confirm that “TURN RH”, “HEAD LAMP 1” and “LIGHT

SW 1ST” in system 5, to which HI BEAM switch belongs, turn ON-OFF normally.

Check results

Other switches in malfunctioning system operate normally.>> Replace lighting switch or wiper switch.

Other switches in malfunctioning system do not operate normally.>> GO TO 3.

System 1 System 2 System 3 System 4 System 5

— FR WASHER FR WIPER LO TURN LH TURN RH

FR WIPER HI — FR WIPER INT PASSING HEAD LAMP1

INT VOLUME 1 RR WASHER — HEAD LAMP2 HI BEAM

RR WIPER INT INT VOLUME 3 AUTO LIGHT — LIGHT SW 1ST

INT VOLUME 2 RR WIPER ON RR FOG FR FOG —

SKIA7075E

Page 2202 of 3171

COMBINATION SWITCH

LT-119

C

D

E

F

G

H

I

J

L

MA

B

LT

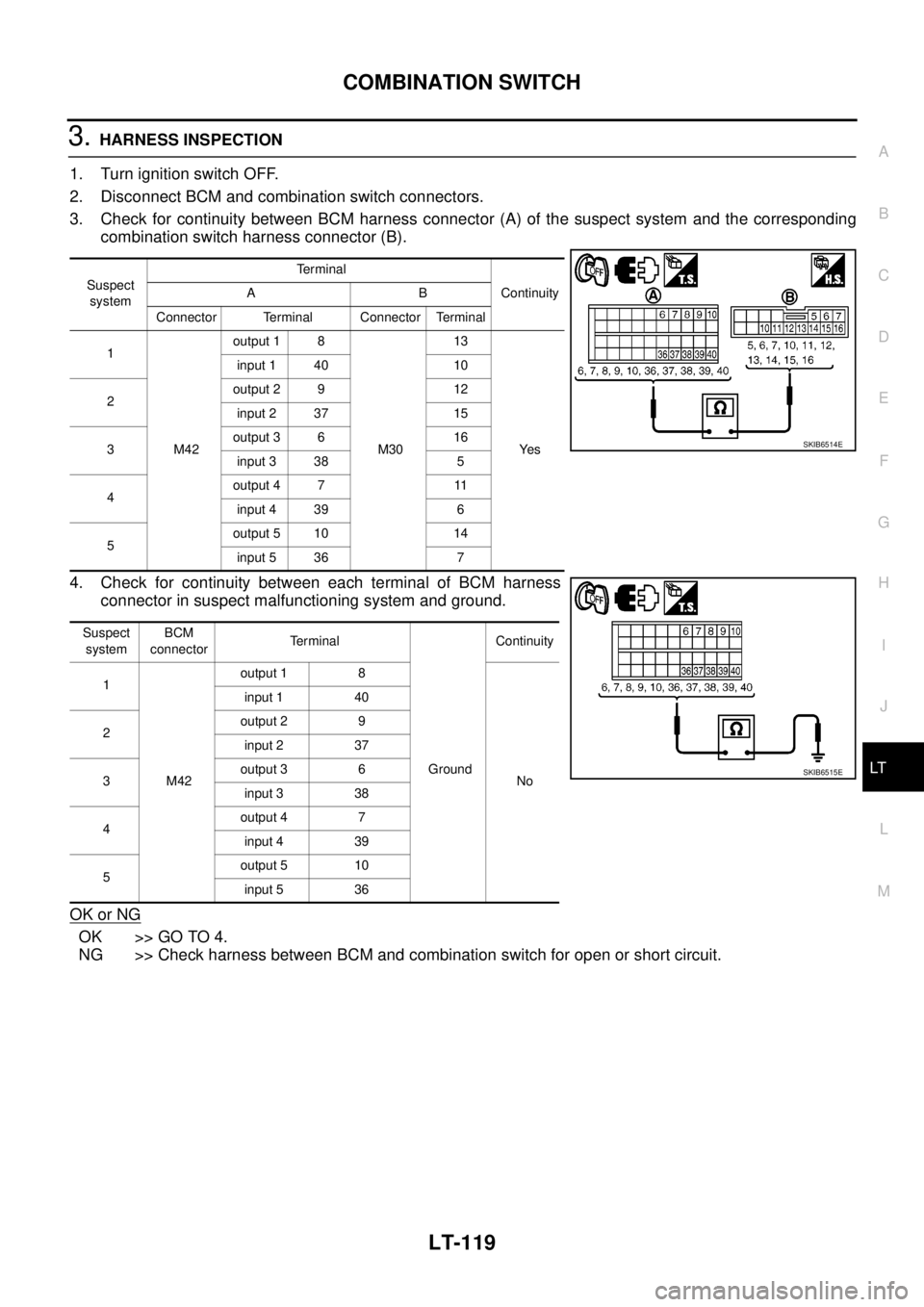

3.HARNESS INSPECTION

1. Turn ignition switch OFF.

2. Disconnect BCM and combination switch connectors.

3. Check for continuity between BCM harness connector (A) of the suspect system and the corresponding

combination switch harness connector (B).

4. Check for continuity between each terminal of BCM harness

connector in suspect malfunctioning system and ground.

OK or NG

OK >> GO TO 4.

NG >> Check harness between BCM and combination switch for open or short circuit.

Suspect

systemTerminal

Continuity AB

Connector Terminal Connector Terminal

1

M42output 1 8

M3013

Ye s input 1 40 10

2output 2 9 12

input 2 37 15

3output 3 6 16

input 3 38 5

4output 4 7 11

input 4 39 6

5output 5 10 14

input 5 36 7

Suspect

systemBCM

connectorTerminal

GroundContinuity

1

M42output 1 8

No input 1 40

2output 2 9

input 2 37

3output 3 6

input 3 38

4output 4 7

input 4 39

5output 5 10

input 5 36

SKIB6514E

SKIB6515E

Page 2203 of 3171

LT-120

COMBINATION SWITCH

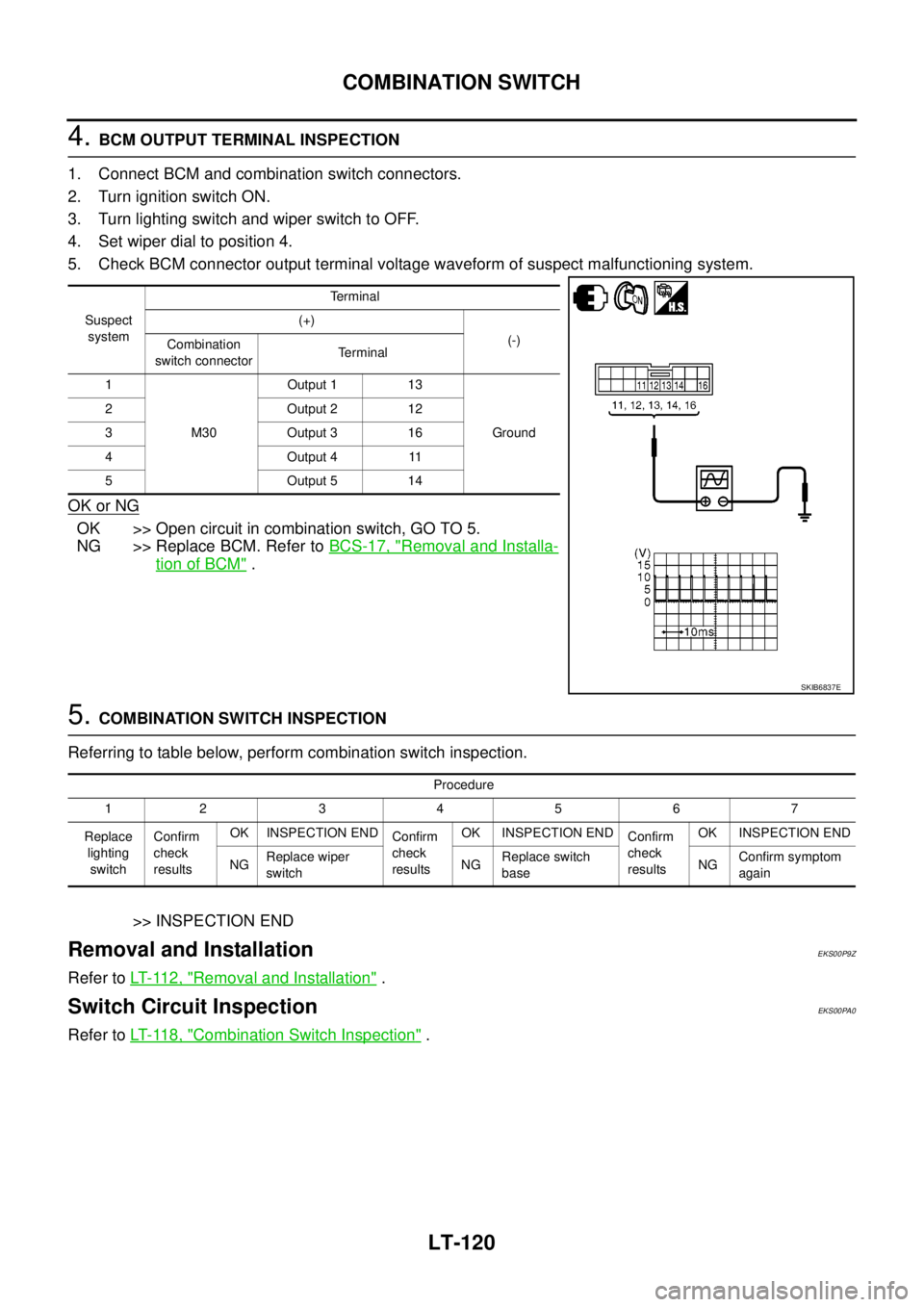

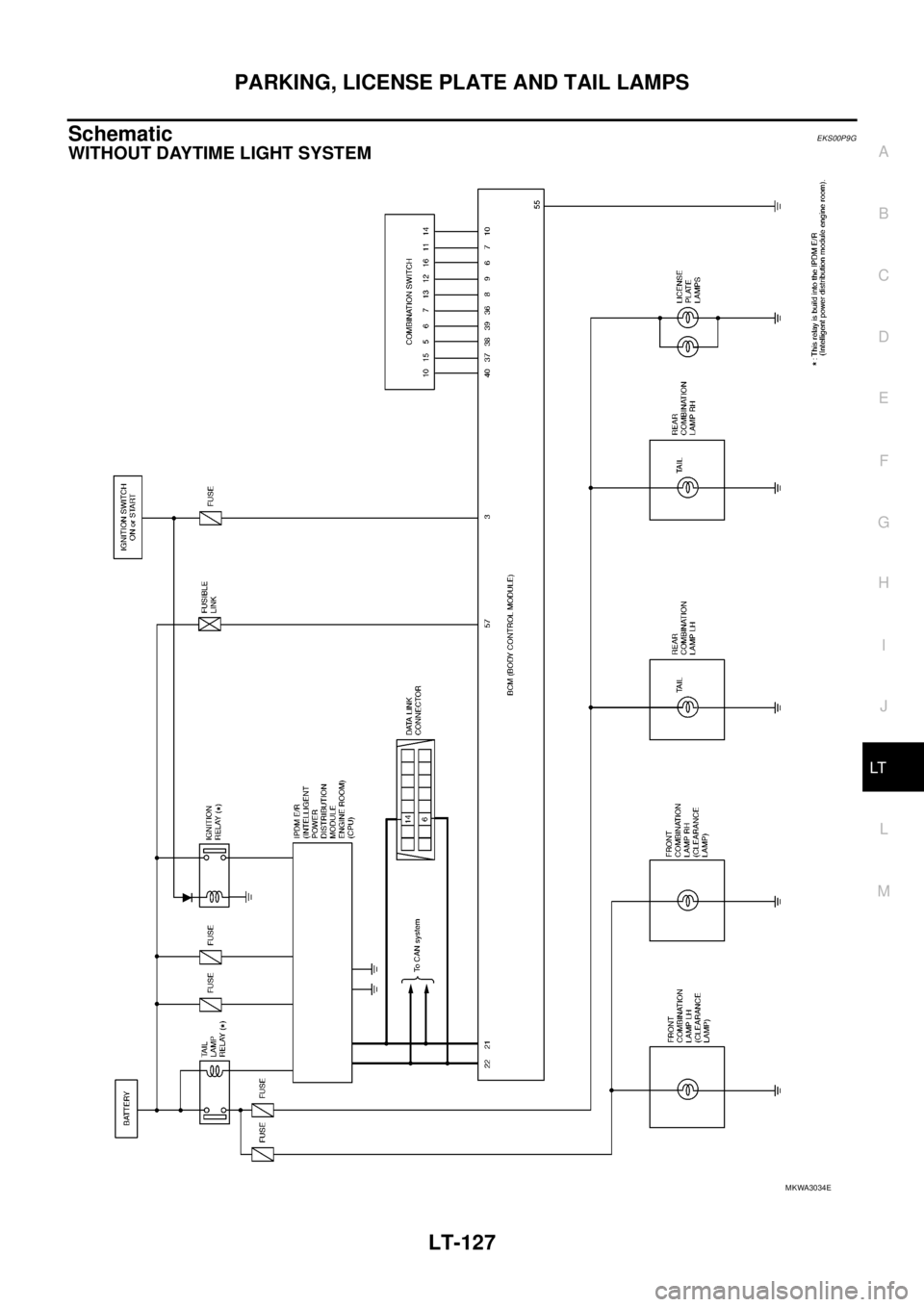

4.BCM OUTPUT TERMINAL INSPECTION

1. Connect BCM and combination switch connectors.

2. Turn ignition switch ON.

3. Turn lighting switch and wiper switch to OFF.

4. Set wiper dial to position 4.

5. Check BCM connector output terminal voltage waveform of suspect malfunctioning system.

OK or NG

OK >> Open circuit in combination switch, GO TO 5.

NG >> Replace BCM. Refer toBCS-17, "

Removal and Installa-

tion of BCM".

5.COMBINATION SWITCH INSPECTION

Referring to table below, perform combination switch inspection.

>> INSPECTION END

Removal and InstallationEKS00P9Z

Refer toLT- 11 2 , "Removal and Installation".

Switch Circuit InspectionEKS00PA0

Refer toLT- 11 8 , "Combination Switch Inspection".

Suspect

systemTerminal

(+)

(-)

Combination

switch connectorTerminal

1

M30Output 1 13

Ground 2 Output 2 12

3 Output 3 16

4Output411

5 Output 5 14

SKIB6837E

Procedure

12 34567

Replace

lighting

switchConfirm

check

resultsOK INSPECTION END

Confirm

check

resultsOK INSPECTION END

Confirm

check

resultsOK INSPECTION END

NGReplace wiper

switchNGReplace switch

baseNGConfirm symptom

again

Page 2204 of 3171

STOP LAMP

LT-121

C

D

E

F

G

H

I

J

L

MA

B

LT

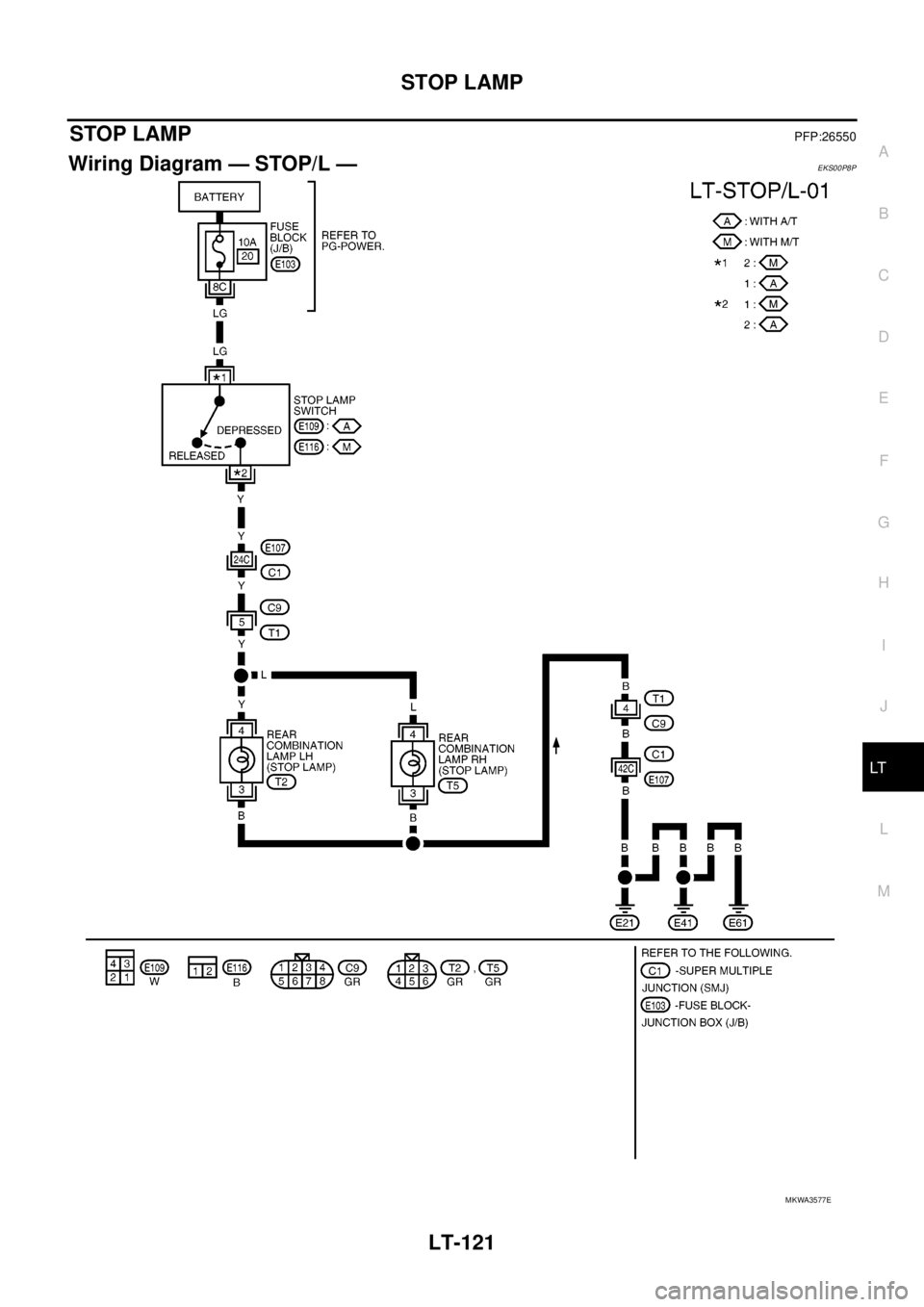

STOP LAMPPFP:26550

Wiring Diagram — STOP/L —EKS00P8P

MKWA3577E

Page 2205 of 3171

LT-122

STOP LAMP

Bulb Replacement

EKS00Q8A

Refer toLT- 1 4 3 , "Bulb Replacement".

Removal and InstallationEKS00Q8B

Refer toLT- 1 4 4 , "Removal and Installation".

Page 2206 of 3171

BACK-UP LAMP

LT-123

C

D

E

F

G

H

I

J

L

MA

B

LT

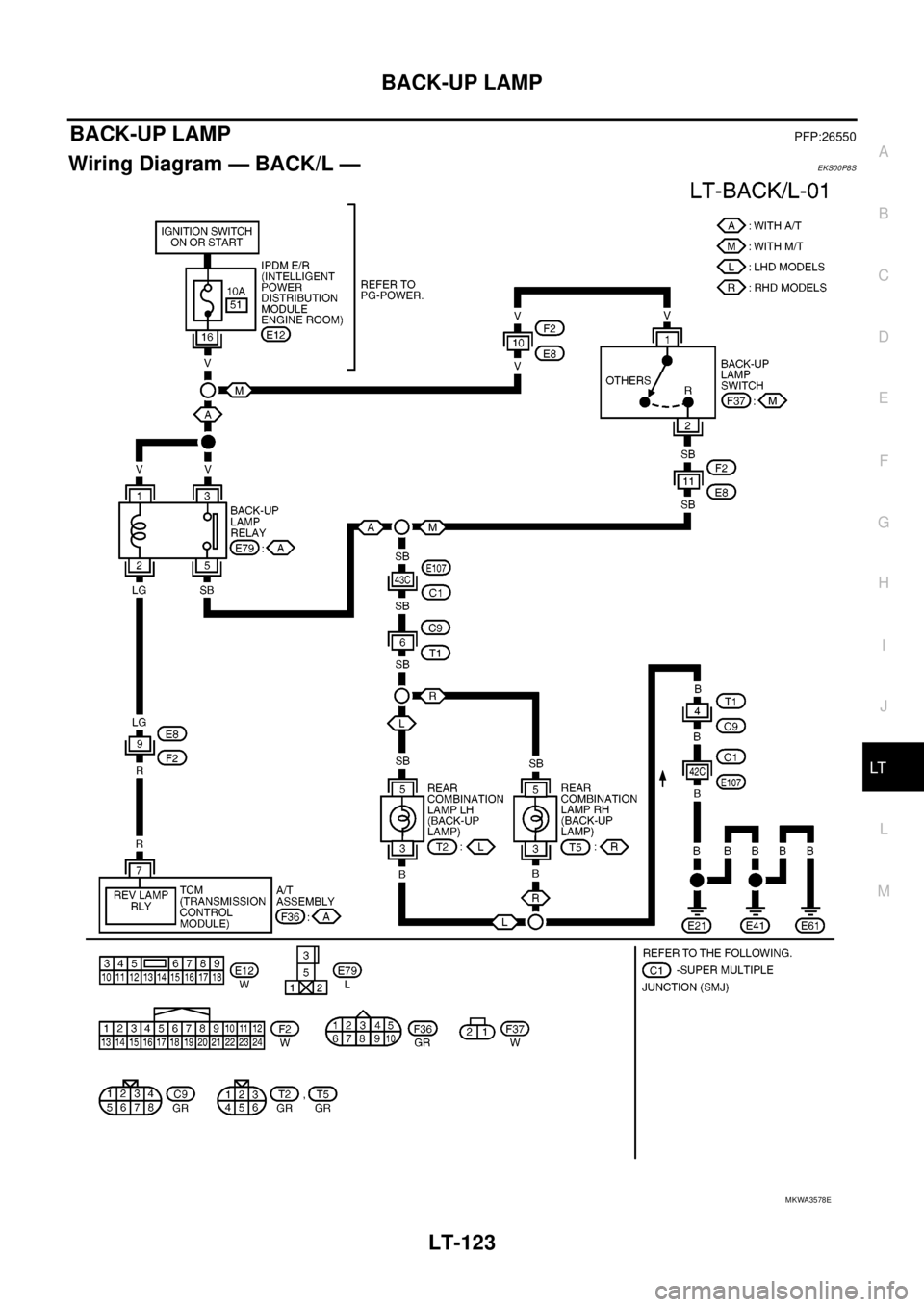

BACK-UP LAMPPFP:26550

Wiring Diagram — BACK/L —EKS00P8S

MKWA3578E

Page 2207 of 3171

LT-124

BACK-UP LAMP

Bulb Replacement

EKS00P8T

Refer toLT- 1 4 3 , "Bulb Replacement".

Removal and InstallationEKS00P8U

Refer toLT- 1 4 4 , "Removal and Installation".

Page 2208 of 3171

PARKING, LICENSE PLATE AND TAIL LAMPS

LT-125

C

D

E

F

G

H

I

J

L

MA

B

LT

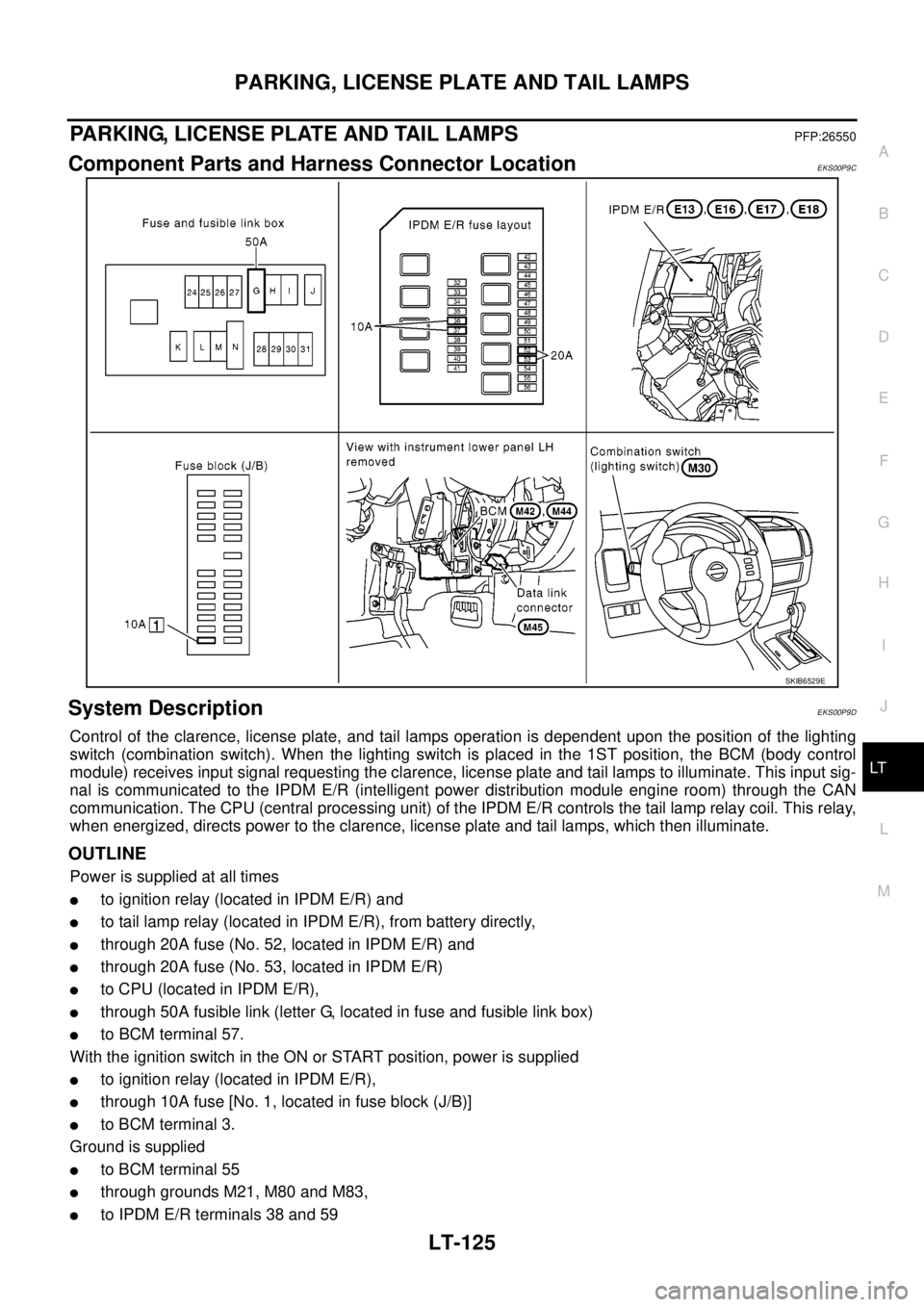

PARKING, LICENSE PLATE AND TAIL LAMPSPFP:26550

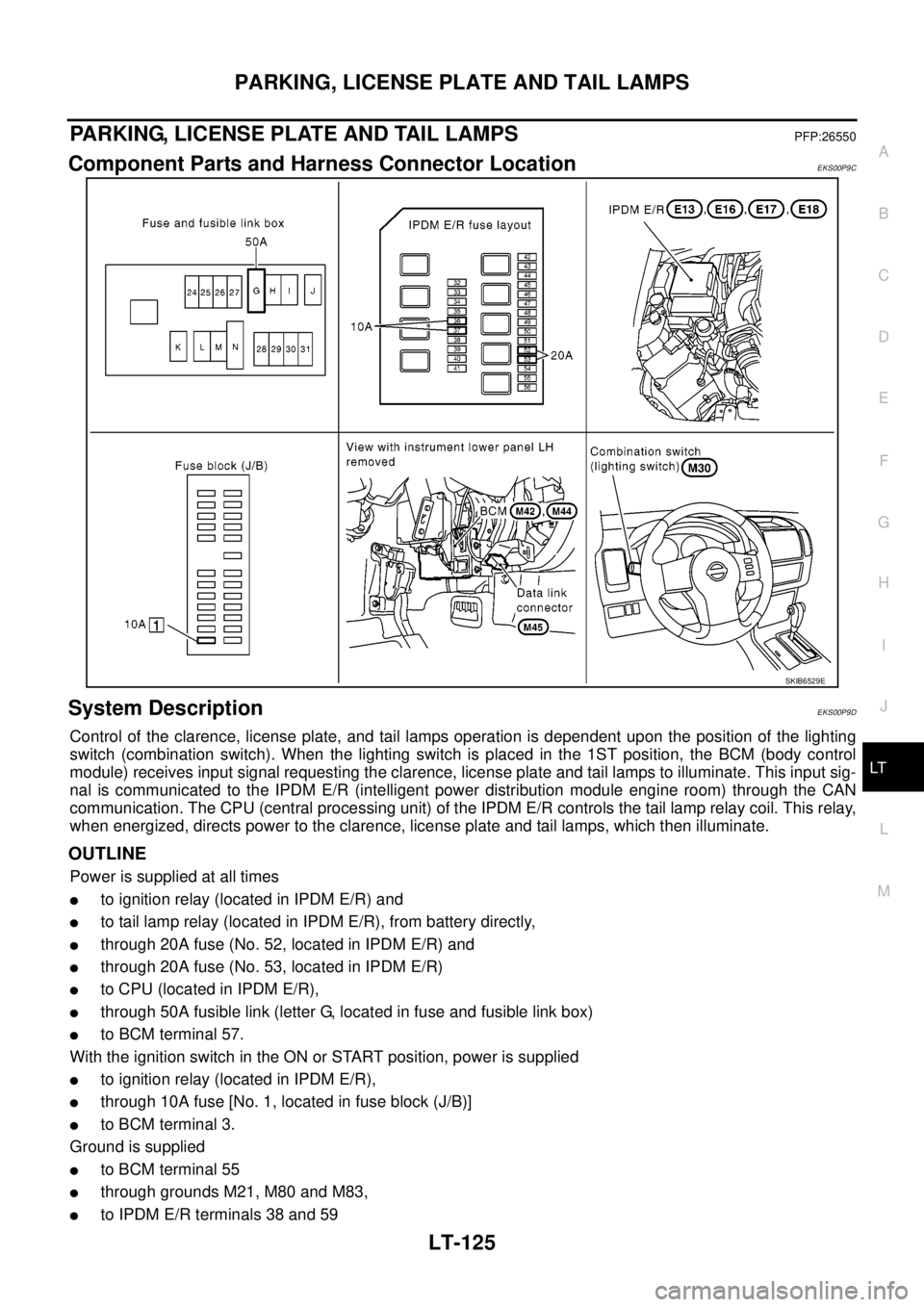

Component Parts and Harness Connector LocationEKS00P9C

System DescriptionEKS00P9D

Control of the clarence, license plate, and tail lamps operation is dependent upon the position of the lighting

switch (combination switch). When the lighting switch is placed in the 1ST position, the BCM (body control

module) receives input signal requesting the clarence, license plate and tail lamps to illuminate. This input sig-

nal is communicated to the IPDM E/R (intelligent power distribution module engine room) through the CAN

communication. The CPU (central processing unit) of the IPDM E/R controls the tail lamp relay coil. This relay,

when energized, directs power to the clarence, license plate and tail lamps, which then illuminate.

OUTLINE

Power is supplied at all times

lto ignition relay (located in IPDM E/R) and

lto tail lamp relay (located in IPDM E/R), from battery directly,

lthrough 20A fuse (No. 52, located in IPDM E/R) and

lthrough 20A fuse (No. 53, located in IPDM E/R)

lto CPU (located in IPDM E/R),

lthrough 50A fusible link (letter G, located in fuse and fusible link box)

lto BCM terminal 57.

With the ignition switch in the ON or START position, power is supplied

lto ignition relay (located in IPDM E/R),

lthrough 10A fuse [No. 1, located in fuse block (J/B)]

lto BCM terminal 3.

Ground is supplied

lto BCM terminal 55

lthrough grounds M21, M80 and M83,

lto IPDM E/R terminals 38 and 59

SKIB6529E

Page 2209 of 3171

LT-126

PARKING, LICENSE PLATE AND TAIL LAMPS

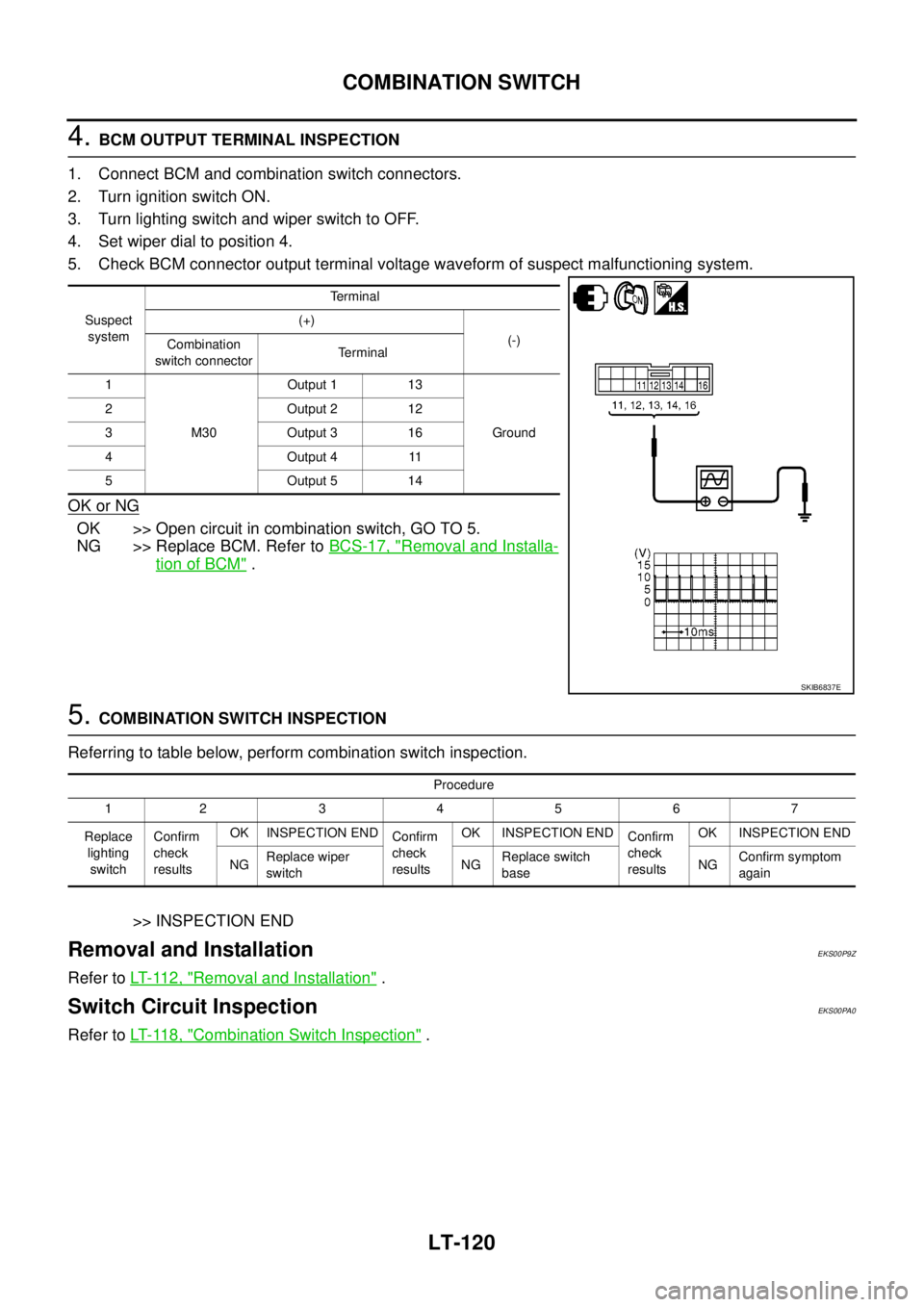

lthrough grounds E21, E41 and E61.

OPERATION BY LIGHTING SWITCH

With the lighting switch in the 1ST position, 2ND position or AUTO position (when the auto light system is acti-

vated), the BCM receives input signal requesting the clarence, license plate and tail lamps to illuminate. This

input signal is communicated to the IPDM E/R through the CAN communication. The CPU in the IPDM E/R

controls the tail lamp relay coil, which when energized, directs power

lthrough IPDM E/R terminal 28

lto front combination lamp LH terminal 1,

lthrough IPDM E/R terminal 49

lto front combination lamp RH terminal 1,

lthrough IPDM E/R terminal 57

lto rear combination lamp RH and LH terminals 1 and

lto license plate lamp RH and LH terminals 1.

Ground is supplied

lto front combination lamp RH and LH terminals 2

lto rear combination lamp RH and LH terminals 3 and

lto license plate lamp RH and LH terminals 2

lthrough grounds E21, E41 and E61.

With power and ground supplied, the clarence, license plate and tail lamps illuminate.

COMBINATION SWITCH READING FUNCTION

Refer toBCS-3, "COMBINATION SWITCH READING FUNCTION".

CAN Communication System DescriptionEKS00P9F

Refer toLAN-23, "CAN COMMUNICATION".

Page 2210 of 3171

PARKING, LICENSE PLATE AND TAIL LAMPS

LT-127

C

D

E

F

G

H

I

J

L

MA

B

LT

SchematicEKS00P9G

WITHOUT DAYTIME LIGHT SYSTEM

MKWA3034E

Trending: length, bolt pattern, automatic transmission fluid, service reset, AUX, alternator, gas mileage