turn signal NISSAN NAVARA 2005 Repair Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 178 of 3171

AT-170

1ST POSITION SWITCH

1ST POSITION SWITCH

PFP:31918

CONSULT-II Reference ValueECS00I5W

Diagnostic ProcedureECS00I5X

1.CHECK CAN COMMUNICATION LINE

Perform the self-diagnosis. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE".

Is any malfunction in the CAN communication indicated in the results?

YES >> Check CAN communication line. Refer toAT-91, "DTC U1000 CAN COMMUNICATION LINE".

NO >> GO TO 2.

2.CHECK 1ST POSITION SWITCH CIRCUIT

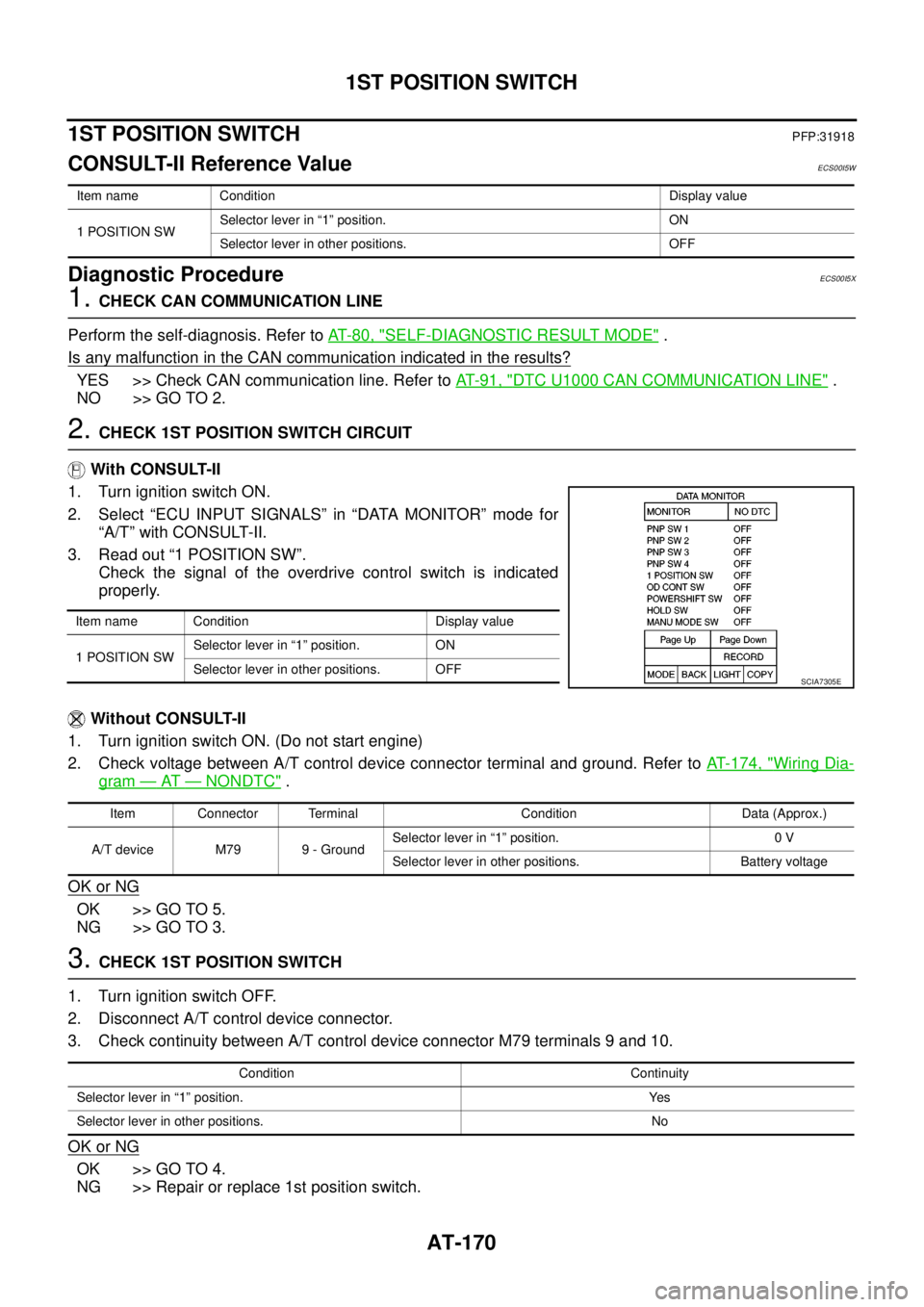

With CONSULT-II

1. Turn ignition switch ON.

2. Select “ECU INPUT SIGNALS” in “DATA MONITOR” mode for

“A/T” with CONSULT-II.

3. Read out “1 POSITION SW”.

Check the signal of the overdrive control switch is indicated

properly.

Without CONSULT-II

1. Turn ignition switch ON. (Do not start engine)

2. Check voltage between A/T control device connector terminal and ground. Refer toAT- 1 7 4 , "

Wiring Dia-

gram—AT—NONDTC".

OK or NG

OK >> GO TO 5.

NG >> GO TO 3.

3.CHECK 1ST POSITION SWITCH

1. Turn ignition switch OFF.

2. Disconnect A/T control device connector.

3. Check continuity between A/T control device connector M79 terminals 9 and 10.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace 1st position switch.

Item name Condition Display value

1 POSITION SWSelector lever in “1” position. ON

Selector lever in other positions. OFF

Item name Condition Display value

1 POSITION SWSelector lever in “1” position. ON

Selector lever in other positions. OFF

SCIA7305E

Item Connector Terminal Condition Data (Approx.)

A/T device M79 9 - GroundSelector lever in “1” position. 0 V

Selector lever in other positions. Battery voltage

Condition Continuity

Selector lever in “1” position. Yes

Selector lever in other positions. No

Page 180 of 3171

AT-172

OVERDRIVE CONTROL SWITCH

OVERDRIVE CONTROL SWITCH

PFP:25130

CONSULT-II Reference ValueECS00HQY

Diagnostic ProcedureECS00HQZ

1.CHECK CAN COMMUNICATION LINE

Perform the self-diagnosis. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE".

Is any malfunction in the CAN communication indicated in the results?

YES >> Check CAN communication line. Refer toAT-91, "DTC U1000 CAN COMMUNICATION LINE".

NO >> GO TO 2.

2.CHECK OVERDRIVE CONTOROL SWITCH CIRCUIT

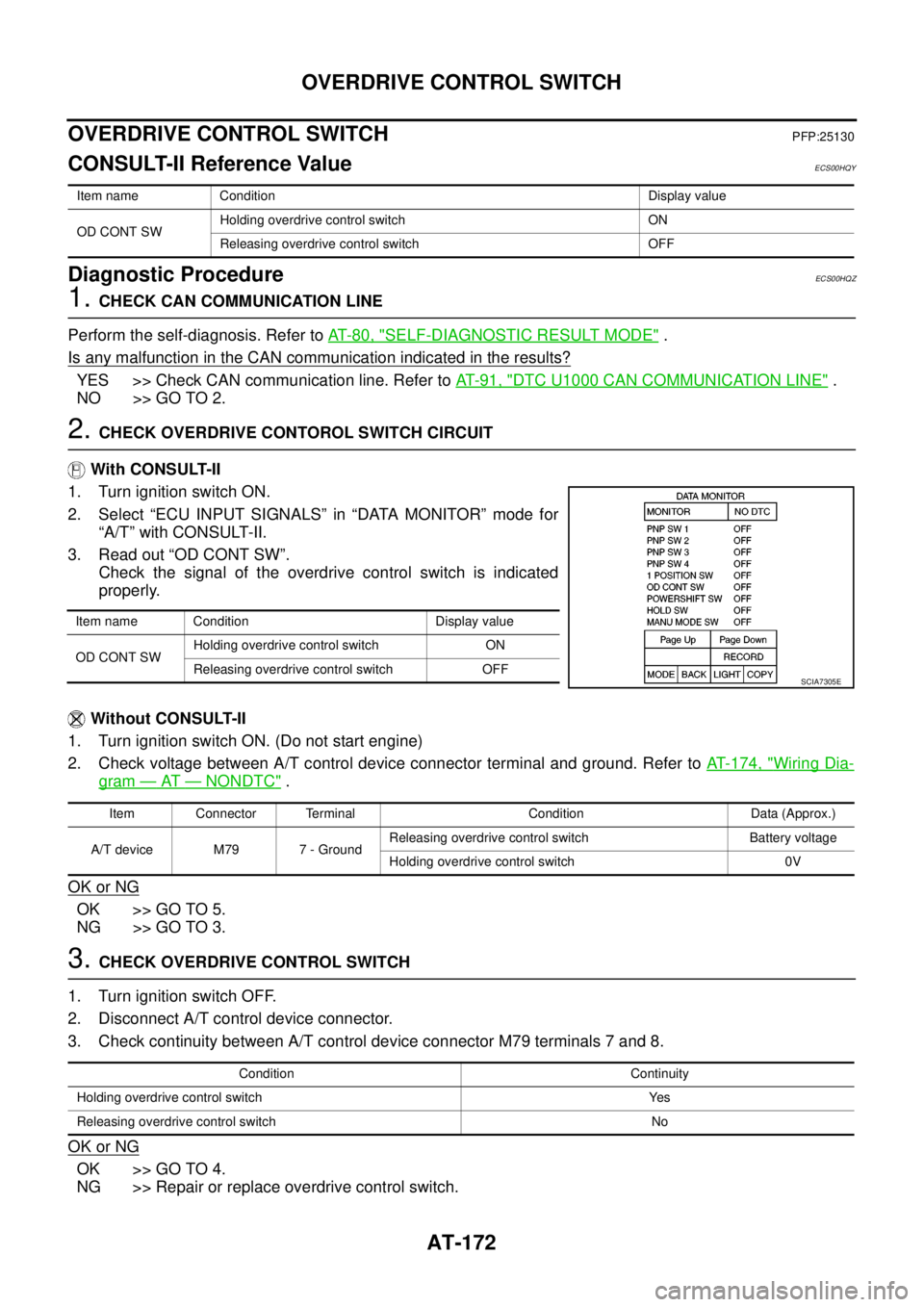

With CONSULT-II

1. Turn ignition switch ON.

2. Select “ECU INPUT SIGNALS” in “DATA MONITOR” mode for

“A/T” with CONSULT-II.

3. Read out “OD CONT SW”.

Check the signal of the overdrive control switch is indicated

properly.

Without CONSULT-II

1. Turn ignition switch ON. (Do not start engine)

2. Check voltage between A/T control device connector terminal and ground. Refer toAT- 1 7 4 , "

Wiring Dia-

gram—AT—NONDTC".

OK or NG

OK >> GO TO 5.

NG >> GO TO 3.

3.CHECK OVERDRIVE CONTROL SWITCH

1. Turn ignition switch OFF.

2. Disconnect A/T control device connector.

3. Check continuity between A/T control device connector M79 terminals 7 and 8.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace overdrive control switch.

Item name Condition Display value

OD CONT SWHolding overdrive control switch ON

Releasing overdrive control switch OFF

Item name Condition Display value

OD CONT SWHolding overdrive control switch ON

Releasing overdrive control switch OFF

SCIA7305E

Item Connector Terminal Condition Data (Approx.)

A/T device M79 7 - GroundReleasing overdrive control switch Battery voltage

Holding overdrive control switch 0V

Condition Continuity

Holding overdrive control switch Yes

Releasing overdrive control switch No

Page 185 of 3171

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-177

D

E

F

G

H

I

J

K

L

MA

B

AT

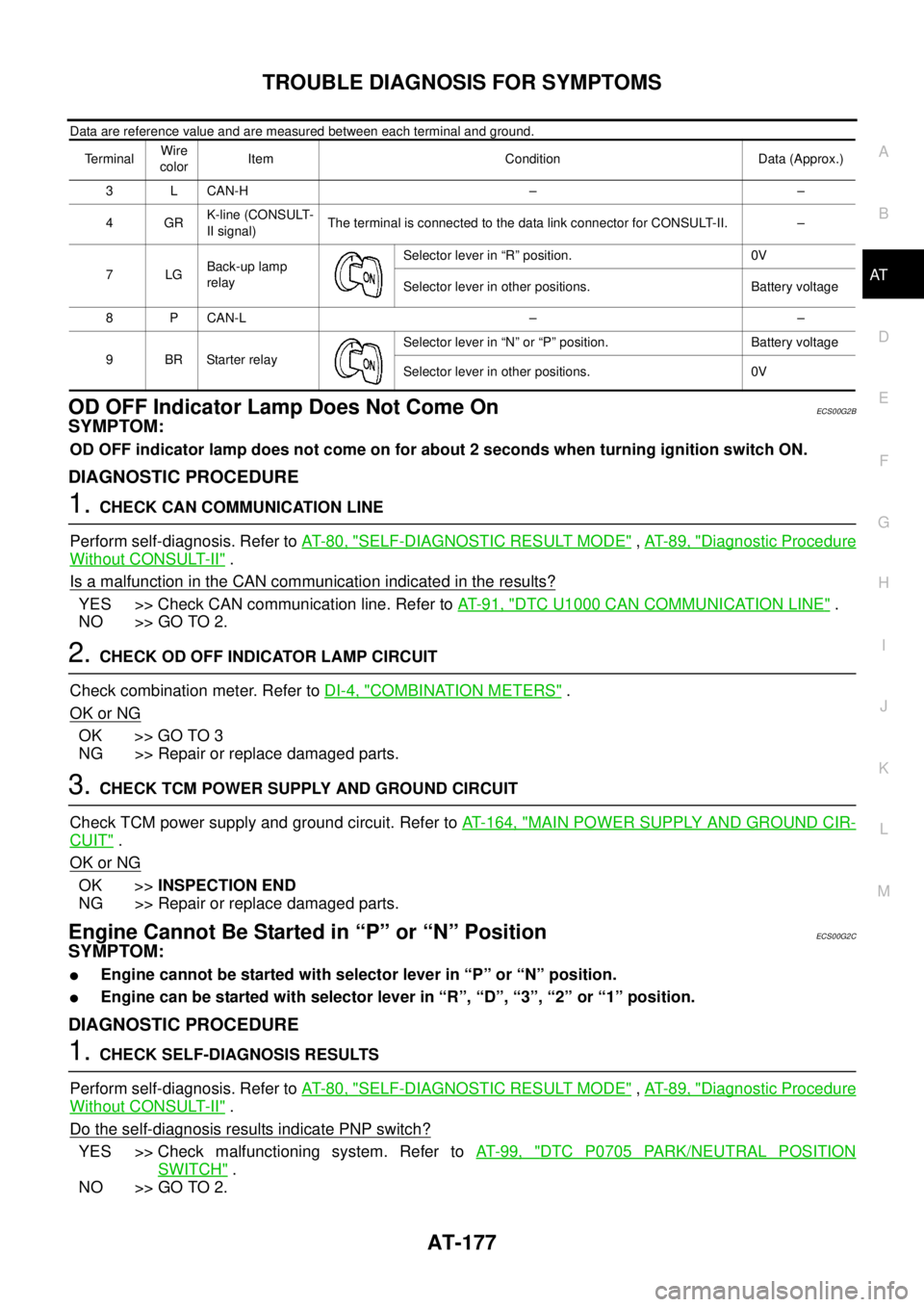

Data are reference value and are measured between each terminal and ground.

OD OFF Indicator Lamp Does Not Come OnECS00G2B

SYMPTOM:

OD OFF indicator lamp does not come on for about 2 seconds when turning ignition switch ON.

DIAGNOSTIC PROCEDURE

1.CHECK CAN COMMUNICATION LINE

Perform self-diagnosis. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE",AT-89, "Diagnostic Procedure

Without CONSULT-II".

Is a malfunction in the CAN communication indicated in the results?

YES >> Check CAN communication line. Refer toAT-91, "DTC U1000 CAN COMMUNICATION LINE".

NO >> GO TO 2.

2.CHECK OD OFF INDICATOR LAMP CIRCUIT

Check combination meter. Refer toDI-4, "

COMBINATION METERS".

OK or NG

OK >> GO TO 3

NG >> Repair or replace damaged parts.

3.CHECK TCM POWER SUPPLY AND GROUND CIRCUIT

Check TCM power supply and ground circuit. Refer toAT- 1 6 4 , "

MAIN POWER SUPPLY AND GROUND CIR-

CUIT".

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

Engine Cannot Be Started in “P” or “N” PositionECS00G2C

SYMPTOM:

lEngine cannot be started with selector lever in “P” or “N” position.

lEngine can be started with selector lever in “R”, “D”, “3”, “2” or “1” position.

DIAGNOSTIC PROCEDURE

1.CHECK SELF-DIAGNOSIS RESULTS

Perform self-diagnosis. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE",AT-89, "Diagnostic Procedure

Without CONSULT-II".

Do the self-diagnosis results indicate PNP switch?

YES >> Check malfunctioning system. Refer toAT-99, "DTC P0705 PARK/NEUTRAL POSITION

SWITCH".

NO >> GO TO 2.

TerminalWire

colorItem Condition Data (Approx.)

3 L CAN-H – –

4GRK-line (CONSULT-

II signal)The terminal is connected to the data link connector for CONSULT-II. –

7LGBack-up lamp

relaySelector lever in “R” position. 0V

Selector lever in other positions. Battery voltage

8 P CAN-L – –

9BRStarterrelaySelector lever in “N” or “P” position. Battery voltage

Selector lever in other positions. 0V

Page 207 of 3171

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-199

D

E

F

G

H

I

J

K

L

MA

B

AT

Lock-up Is Not ReleasedECS00G2P

SYMPTOM:

The lock-up condition cannot be cancelled even after releasing accelerator pedal.

DIAGNOSTIC PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE",AT-89, "Diagnostic Procedure

Without CONSULT-II".

Is any malfunction detected by self-diagnostic results?

YES >> Check malfunctioning system. Refer toAT-80, "SELF-DIAGNOSTIC RESULT MODE",AT- 9 0 ,

"Judgement Self-diagnosis Code".

NO >> GO TO 2.

2.CHECK SYMPTOM

Check again. Refer toAT-48, "

Cruise Test - Part 1".

OK or NG

OK >>INSPECTION END

NG >> GO TO 3.

3.CHECK TCM

1. Check TCM input/output signals. Refer toAT-76, "

TCM Input/Output Signal Reference Values".

2. If NG, recheck A/T assembly harness connector terminals for damage or loose connection with harness

connector.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

Engine Speed Does Not Return to IdleECS00G2Q

SYMPTOM:

When a shift-down is performed, the engine speed does not smoothly return to the idling speed.

DIAGNOSTIC PROCEDURE

1.CHECK A/T FLUID LEVEL

Check A/T fluid level. Refer toAT-12, "

Checking A/T Fluid".

OK or NG

OK >> GO TO 2.

NG >> Refill ATF.

2.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE",AT-89, "Diagnostic Procedure

Without CONSULT-II".

Is any malfunction detected by self-diagnostic results?

YES >> Check malfunctioning system. Refer toAT-80, "SELF-DIAGNOSTIC RESULT MODE",AT- 9 0 ,

"Judgement Self-diagnosis Code".

NO >> GO TO 3.

Page 360 of 3171

ATC-26

AIR CONDITIONER CONTROL

AIR CONDITIONER CONTROL

PFP:27500

DescriptionEJS006B0

The front air control provides automatic regulation of the vehicle's interior temperature. The system is based

on the driver's and passenger's selected “set temperature”, regardless of the outside temperature changes.

This is done by utilizing a microcomputer, also referred to as the front air control, which receives input signals

from the following six sensors:

lAmbient sensor

lIn-vehicle sensor

lIntake sensor

lOptical sensor (one sensor for driver and passenger side)

lPBR (Position Balanced Resistor).

lVehicle speed sensor

The front air control uses these signals (including the set temperature) to automatically control:

lOutlet air volume

lAir temperature

lAir distribution

The front air control is used to select:

lOutlet air volume

lAir temperature/distribution

OperationEJS006B1

AIR MIX DOORS CONTROL

The air mix doors are automatically controlled so that in-vehicle temperature is maintained at a predetermined

value by the temperature setting, ambient temperature, in-vehicle temperature and amount of sunload.

BLOWER SPEED CONTROL

Blower speed is automatically controlled by the temperature setting, ambient temperature, in-vehicle tempera-

ture, intake temperature, amount of sunload and air mix door position.

When AUTO switch is pressed, the blower motor starts to gradually increase air flow volume (if required).

When engine coolant temperature is low, the blower motor operation is delayed to prevent cool air from flow-

ing.

INTAKE DOOR CONTROL

The intake door is automatically controlled by the temperature setting, ambient temperature, in-vehicle tem-

perature, intake temperature, amount of sunload and the ON-OFF operation of the compressor.

MODE DOOR CONTROL

The mode door is automatically controlled by the temperature setting, ambient temperature, in-vehicle temper-

ature, intake temperature and amount of sunload.

DEFROSTER DOOR CONTROL

The defroster door is controlled by: Turning the defroster dial to front defroster.

Page 361 of 3171

AIR CONDITIONER CONTROL

ATC-27

C

D

E

F

G

H

I

K

L

MA

B

AT C

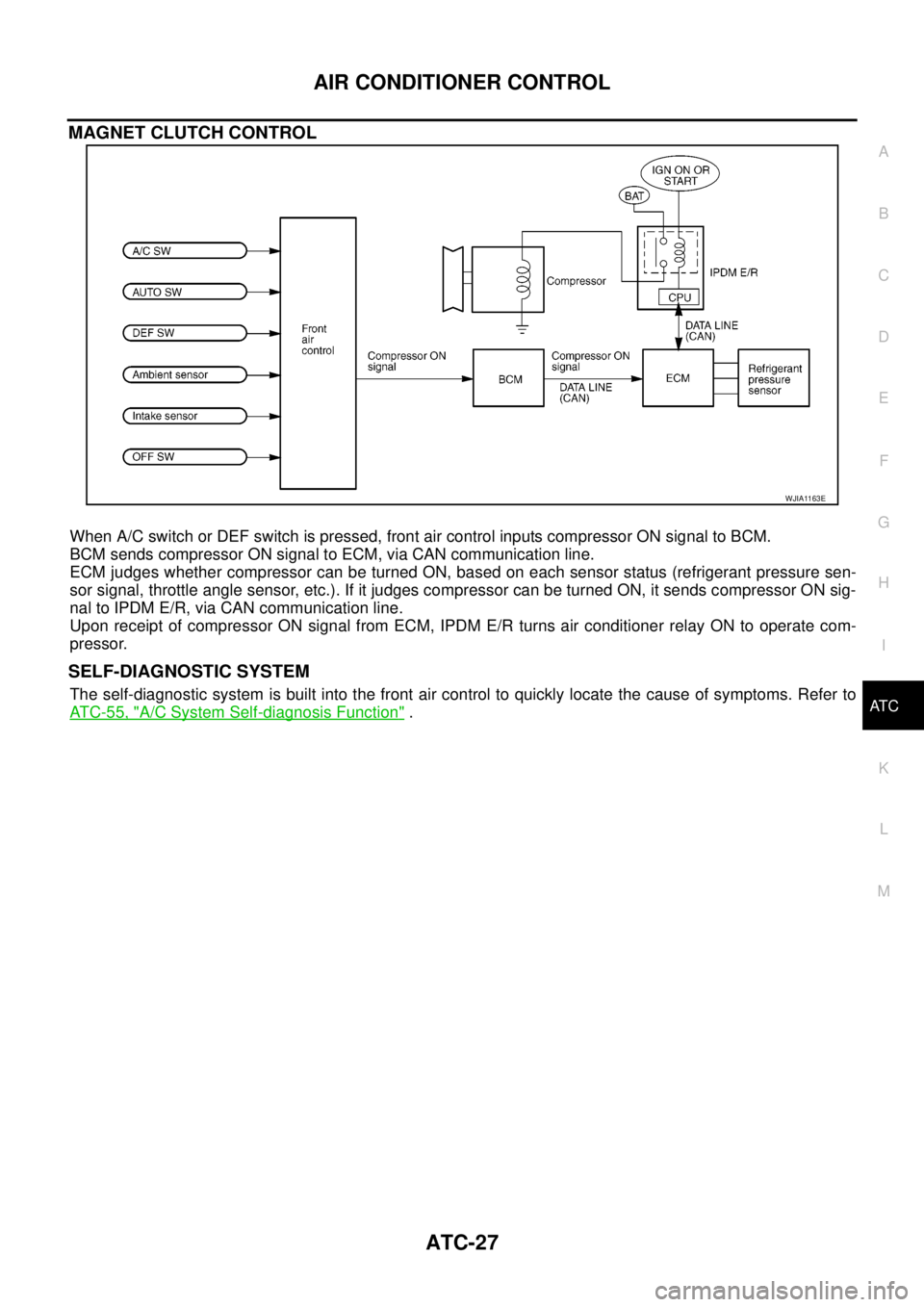

MAGNET CLUTCH CONTROL

When A/C switch or DEF switch is pressed, front air control inputs compressor ON signal to BCM.

BCM sends compressor ON signal to ECM, via CAN communication line.

ECM judges whether compressor can be turned ON, based on each sensor status (refrigerant pressure sen-

sor signal, throttle angle sensor, etc.). If it judges compressor can be turned ON, it sends compressor ON sig-

nal to IPDM E/R, via CAN communication line.

Upon receipt of compressor ON signal from ECM, IPDM E/R turns air conditioner relay ON to operate com-

pressor.

SELF-DIAGNOSTIC SYSTEM

The self-diagnostic system is built into the front air control to quickly locate the cause of symptoms. Refer to

AT C - 5 5 , "

A/C System Self-diagnosis Function".

WJIA1163E

Page 367 of 3171

TROUBLE DIAGNOSIS

ATC-33

C

D

E

F

G

H

I

K

L

MA

B

AT C

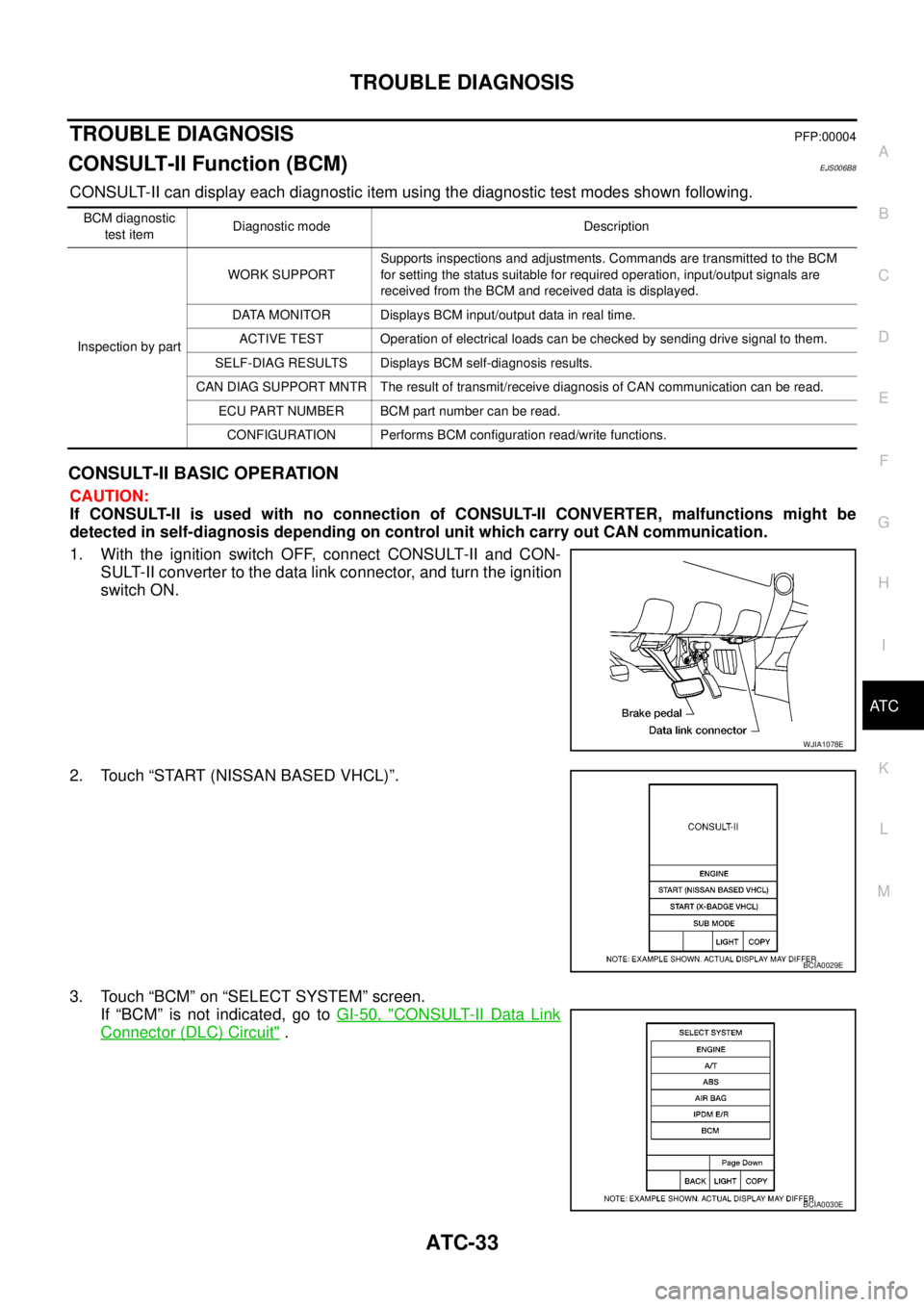

TROUBLE DIAGNOSISPFP:00004

CONSULT-II Function (BCM)EJS006B8

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

CONSULT-II BASIC OPERATION

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

1. With the ignition switch OFF, connect CONSULT-II and CON-

SULT-II converter to the data link connector, and turn the ignition

switch ON.

2. Touch “START (NISSAN BASED VHCL)”.

3. Touch “BCM” on “SELECT SYSTEM” screen.

If “BCM” is not indicated, go toGI-50, "

CONSULT-II Data Link

Connector (DLC) Circuit".

BCM diagnostic

test itemDiagnostic mode Description

Inspection by partWORK SUPPORTSupports inspections and adjustments. Commands are transmitted to the BCM

for setting the status suitable for required operation, input/output signals are

received from the BCM and received data is displayed.

DATA MONITOR Displays BCM input/output data in real time.

ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF-DIAG RESULTS Displays BCM self-diagnosis results.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

ECU PART NUMBER BCM part number can be read.

CONFIGURATION Performs BCM configuration read/write functions.

WJIA1078E

BCIA0029E

BCIA0030E

Page 388 of 3171

ATC-54

TROUBLE DIAGNOSIS

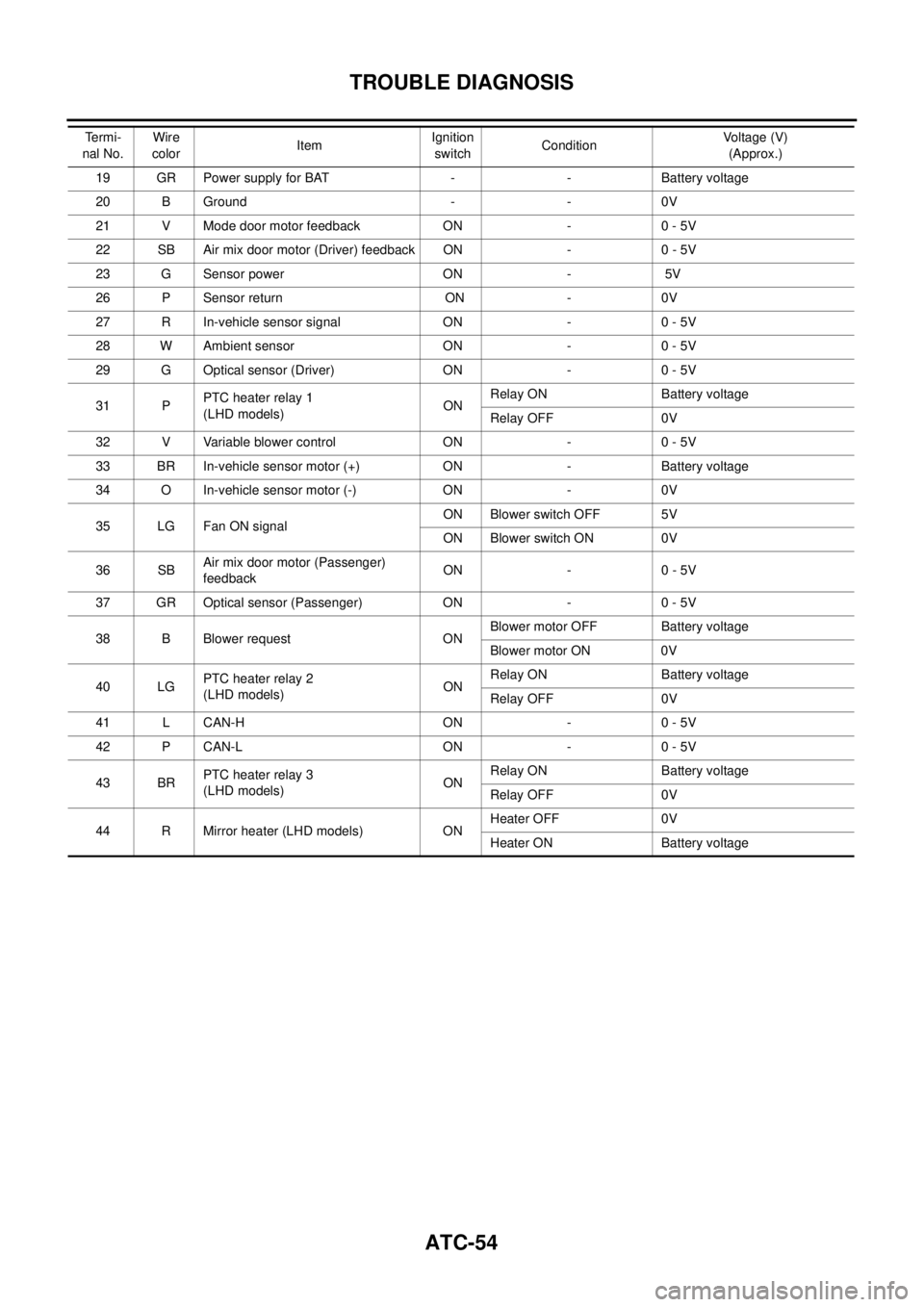

19 GR Power supply for BAT - - Battery voltage

20 B Ground - - 0V

21 V Mode door motor feedback ON - 0 - 5V

22 SB Air mix door motor (Driver) feedback ON - 0 - 5V

23 G Sensor power ON - 5V

26 P Sensor return ON - 0V

27 R In-vehicle sensor signal ON - 0 - 5V

28 W Ambient sensor ON - 0 - 5V

29 G Optical sensor (Driver) ON - 0 - 5V

31 PPTC heater relay 1

(LHD models)ONRelay ON Battery voltage

Relay OFF 0V

32 V Variable blower control ON - 0 - 5V

33 BR In-vehicle sensor motor (+) ON - Battery voltage

34 O In-vehicle sensor motor (-) ON - 0V

35 LG Fan ON signalON Blower switch OFF 5V

ON Blower switch ON 0V

36 SBAir mix door motor (Passenger)

feedbackON - 0 - 5V

37 GR Optical sensor (Passenger) ON - 0 - 5V

38 B Blower request ONBlower motor OFF Battery voltage

Blower motor ON 0V

40 LGPTC heater relay 2

(LHD models)ONRelay ON Battery voltage

Relay OFF 0V

41 L CAN-H ON - 0 - 5V

42 P CAN-L ON - 0 - 5V

43 BRPTC heater relay 3

(LHD models)ONRelay ON Battery voltage

Relay OFF 0V

44 R Mirror heater (LHD models) ONHeater OFF 0V

Heater ON Battery voltage Te r m i -

nal No.Wire

colorItemIgnition

switchConditionVoltage (V)

(Approx.)

Page 400 of 3171

ATC-66

TROUBLE DIAGNOSIS

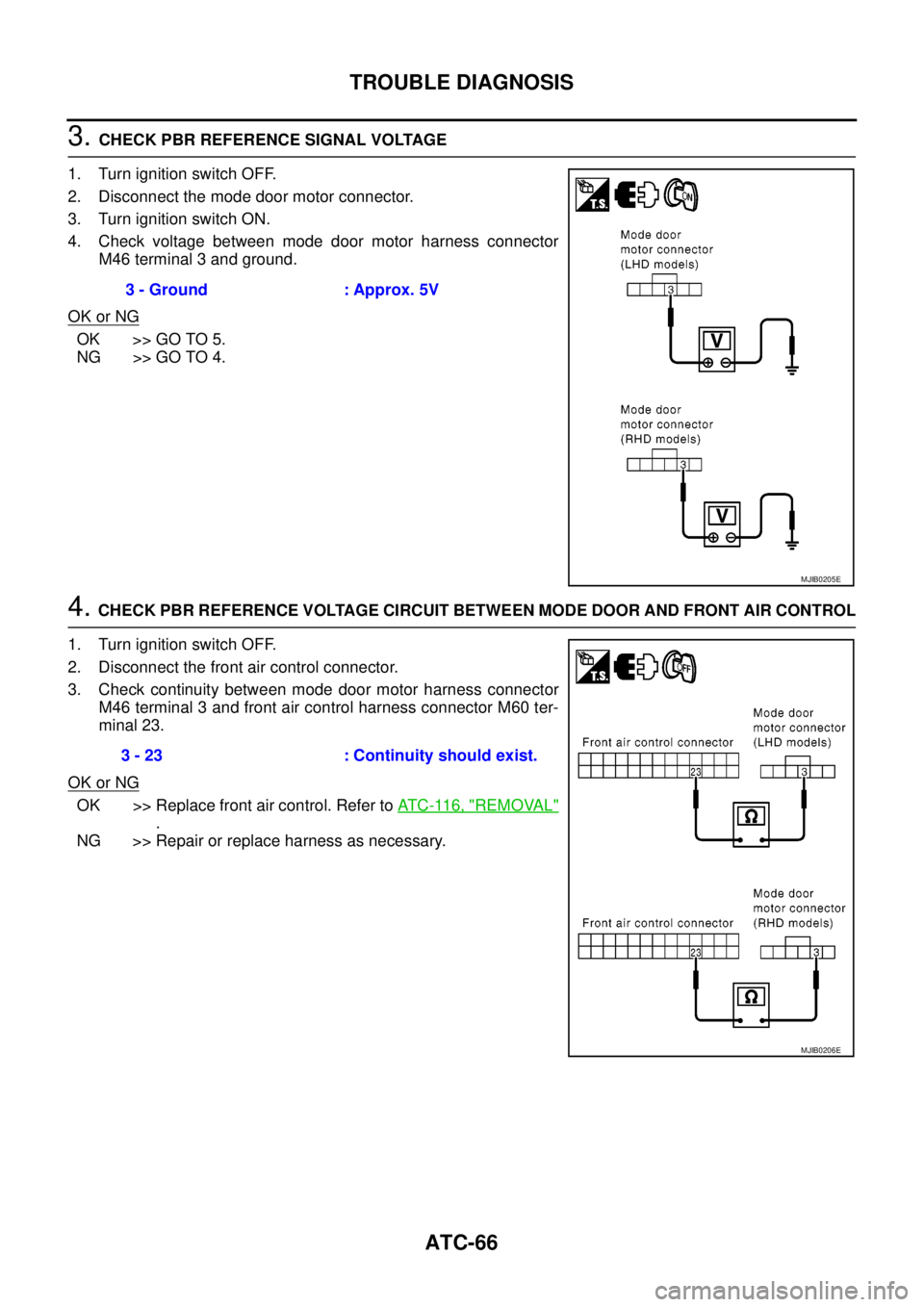

3.CHECK PBR REFERENCE SIGNAL VOLTAGE

1. Turn ignition switch OFF.

2. Disconnect the mode door motor connector.

3. Turn ignition switch ON.

4. Check voltage between mode door motor harness connector

M46 terminal 3 and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.CHECK PBR REFERENCE VOLTAGE CIRCUIT BETWEEN MODE DOOR AND FRONT AIR CONTROL

1. Turn ignition switch OFF.

2. Disconnect the front air control connector.

3. Check continuity between mode door motor harness connector

M46 terminal 3 and front air control harness connector M60 ter-

minal 23.

OK or NG

OK >> Replace front air control. Refer toAT C - 11 6 , "REMOVAL"

.

NG >> Repair or replace harness as necessary.3 - Ground : Approx. 5V

MJIB0205E

3 - 23 : Continuity should exist.

MJIB0206E

Page 401 of 3171

TROUBLE DIAGNOSIS

ATC-67

C

D

E

F

G

H

I

K

L

MA

B

AT C

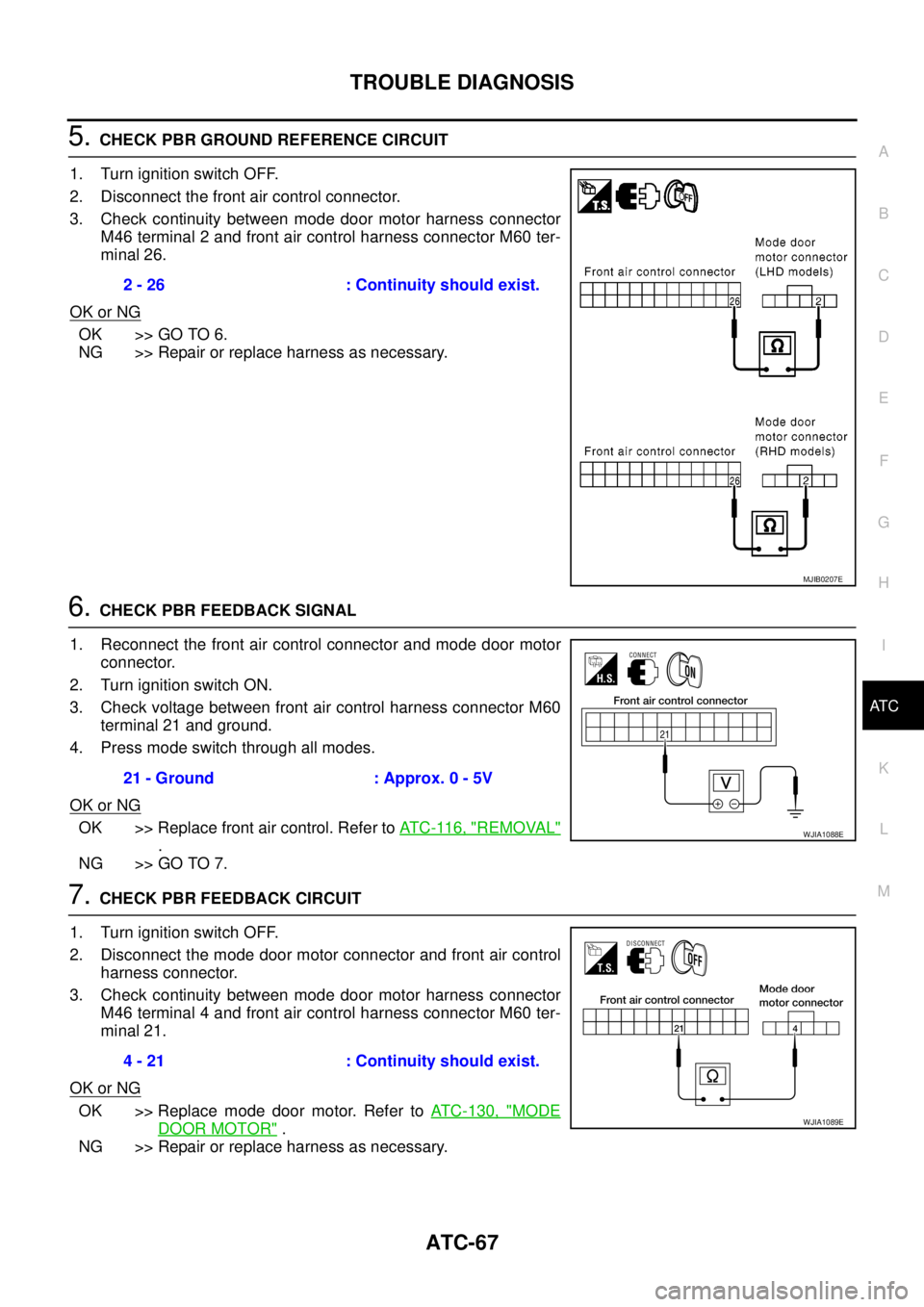

5.CHECK PBR GROUND REFERENCE CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect the front air control connector.

3. Check continuity between mode door motor harness connector

M46 terminal 2 and front air control harness connector M60 ter-

minal 26.

OK or NG

OK >> GO TO 6.

NG >> Repair or replace harness as necessary.

6.CHECK PBR FEEDBACK SIGNAL

1. Reconnect the front air control connector and mode door motor

connector.

2. Turn ignition switch ON.

3. Check voltage between front air control harness connector M60

terminal 21 and ground.

4. Press mode switch through all modes.

OK or NG

OK >> Replace front air control. Refer toAT C - 11 6 , "REMOVAL"

.

NG >> GO TO 7.

7.CHECK PBR FEEDBACK CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect the mode door motor connector and front air control

harness connector.

3. Check continuity between mode door motor harness connector

M46 terminal 4 and front air control harness connector M60 ter-

minal 21.

OK or NG

OK >> Replace mode door motor. Refer toATC-130, "MODE

DOOR MOTOR".

NG >> Repair or replace harness as necessary.2 - 26 : Continuity should exist.

MJIB0207E

21 - Ground : Approx. 0 - 5V

WJIA1088E

4 - 21 : Continuity should exist.

WJIA1089E