turn signal NISSAN NAVARA 2005 Repair Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 403 of 3171

TROUBLE DIAGNOSIS

ATC-69

C

D

E

F

G

H

I

K

L

MA

B

AT C

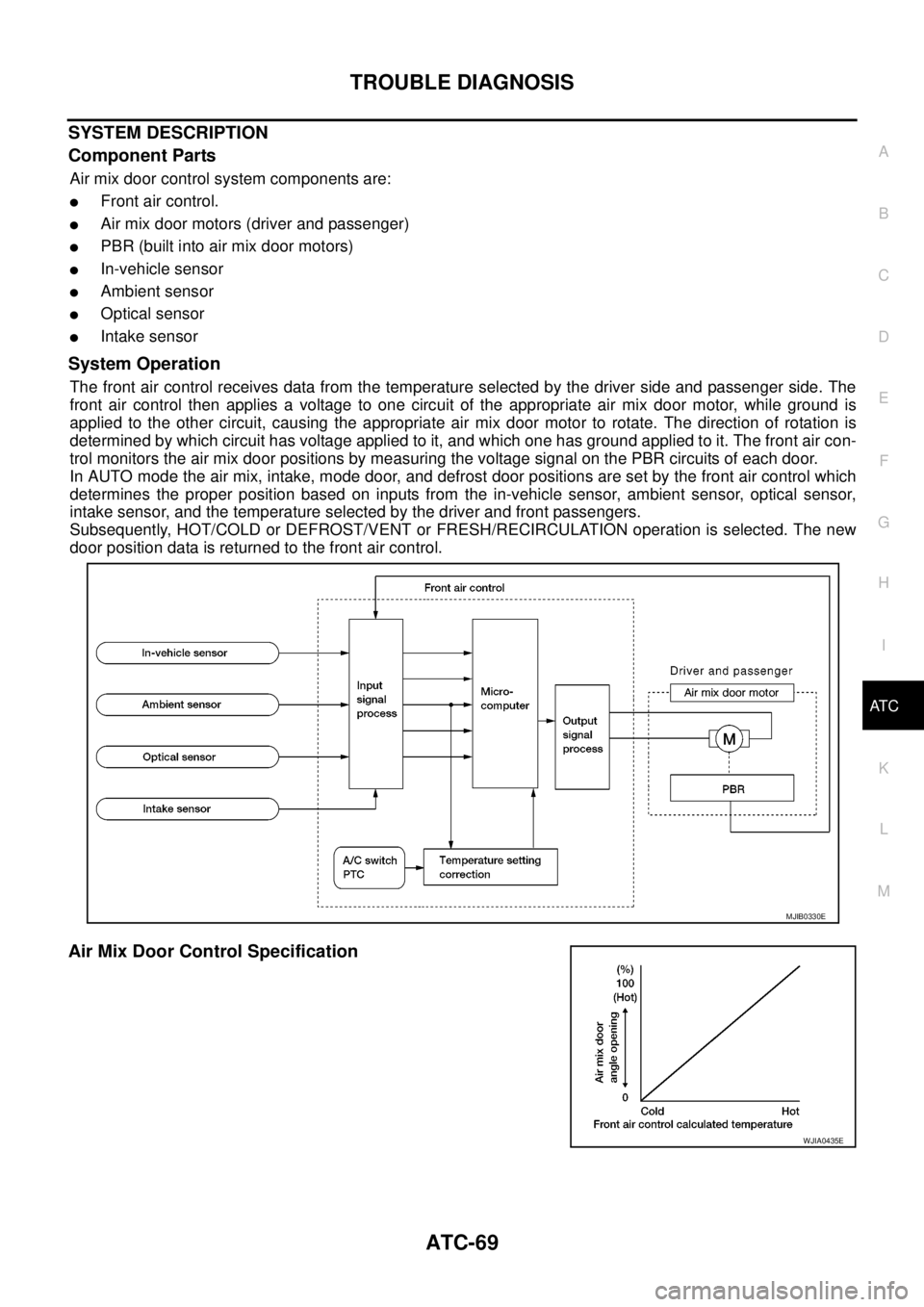

SYSTEM DESCRIPTION

Component Parts

Air mix door control system components are:

lFront air control.

lAir mix door motors (driver and passenger)

lPBR (built into air mix door motors)

lIn-vehicle sensor

lAmbient sensor

lOptical sensor

lIntake sensor

System Operation

The front air control receives data from the temperature selected by the driver side and passenger side. The

front air control then applies a voltage to one circuit of the appropriate air mix door motor, while ground is

applied to the other circuit, causing the appropriate air mix door motor to rotate. The direction of rotation is

determined by which circuit has voltage applied to it, and which one has ground applied to it. The front air con-

trol monitors the air mix door positions by measuring the voltage signal on the PBR circuits of each door.

In AUTO mode the air mix, intake, mode door, and defrost door positions are set by the front air control which

determines the proper position based on inputs from the in-vehicle sensor, ambient sensor, optical sensor,

intake sensor, and the temperature selected by the driver and front passengers.

Subsequently, HOT/COLD or DEFROST/VENT or FRESH/RECIRCULATION operation is selected. The new

door position data is returned to the front air control.

Air Mix Door Control Specification

MJIB0330E

WJIA0435E

Page 405 of 3171

TROUBLE DIAGNOSIS

ATC-71

C

D

E

F

G

H

I

K

L

MA

B

AT C

DIAGNOSTIC PROCEDURE FOR AIR MIX DOOR MOTOR (DRIVER)

1.CHECK RESULT FROM FRONT AIR CONTROL SELF-DIAGNOSIS

Self-diagnosis code 22 is present. Refer toAT C - 5 5 , "

A/C System Self-diagnosis Function".

YES or NO

YES >> GO TO 2.

NO >> GO TO 3.

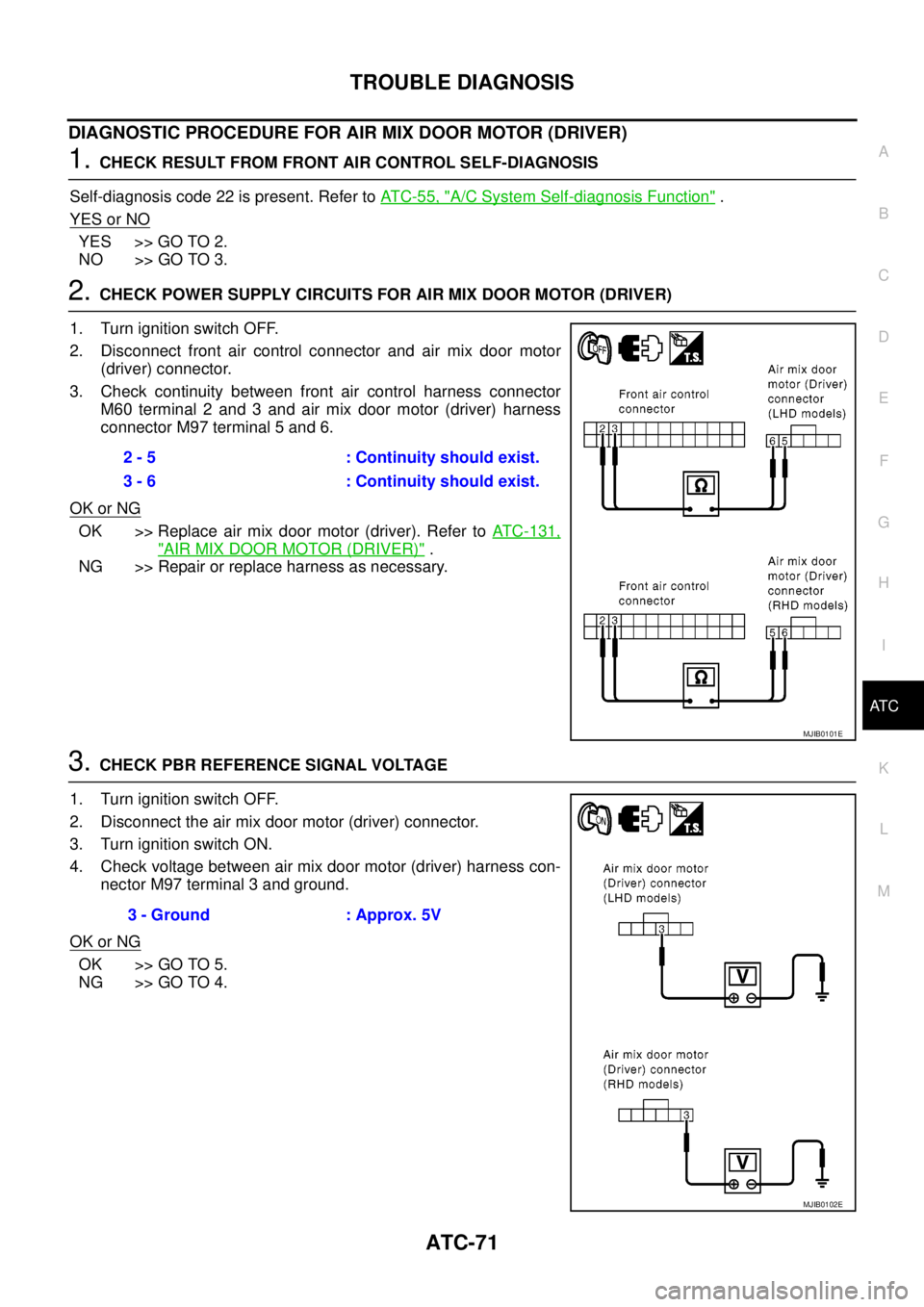

2.CHECK POWER SUPPLY CIRCUITS FOR AIR MIX DOOR MOTOR (DRIVER)

1. Turn ignition switch OFF.

2. Disconnect front air control connector and air mix door motor

(driver) connector.

3. Check continuity between front air control harness connector

M60 terminal 2 and 3 and air mix door motor (driver) harness

connector M97 terminal 5 and 6.

OK or NG

OK >> Replace air mix door motor (driver). Refer toATC-131,

"AIR MIX DOOR MOTOR (DRIVER)".

NG >> Repair or replace harness as necessary.

3.CHECK PBR REFERENCE SIGNAL VOLTAGE

1. Turn ignition switch OFF.

2. Disconnect the air mix door motor (driver) connector.

3. Turn ignition switch ON.

4. Check voltage between air mix door motor (driver) harness con-

nector M97 terminal 3 and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.2 - 5 : Continuity should exist.

3 - 6 : Continuity should exist.

MJIB0101E

3 - Ground : Approx. 5V

MJIB0102E

Page 407 of 3171

TROUBLE DIAGNOSIS

ATC-73

C

D

E

F

G

H

I

K

L

MA

B

AT C

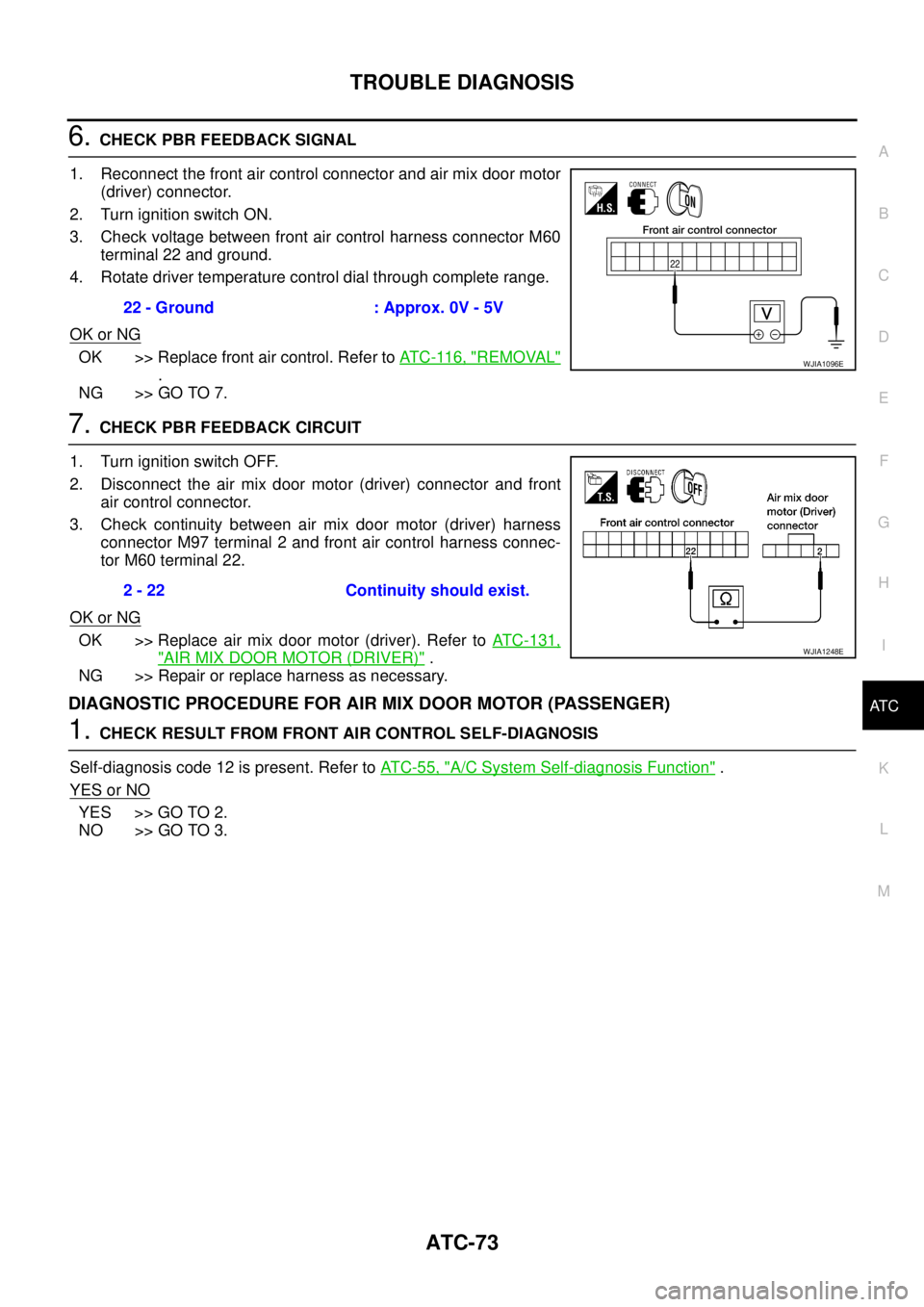

6.CHECK PBR FEEDBACK SIGNAL

1. Reconnect the front air control connector and air mix door motor

(driver) connector.

2. Turn ignition switch ON.

3. Check voltage between front air control harness connector M60

terminal 22 and ground.

4. Rotate driver temperature control dial through complete range.

OK or NG

OK >> Replace front air control. Refer toAT C - 11 6 , "REMOVAL"

.

NG >> GO TO 7.

7.CHECK PBR FEEDBACK CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect the air mix door motor (driver) connector and front

air control connector.

3. Check continuity between air mix door motor (driver) harness

connector M97 terminal 2 and front air control harness connec-

tor M60 terminal 22.

OK or NG

OK >> Replace air mix door motor (driver). Refer toATC-131,

"AIR MIX DOOR MOTOR (DRIVER)".

NG >> Repair or replace harness as necessary.

DIAGNOSTIC PROCEDURE FOR AIR MIX DOOR MOTOR (PASSENGER)

1.CHECK RESULT FROM FRONT AIR CONTROL SELF-DIAGNOSIS

Self-diagnosis code 12 is present. Refer toAT C - 5 5 , "

A/C System Self-diagnosis Function".

YES or NO

YES >> GO TO 2.

NO >> GO TO 3.22 - Ground : Approx. 0V - 5V

WJIA1096E

2 - 22 Continuity should exist.

WJIA1248E

Page 408 of 3171

ATC-74

TROUBLE DIAGNOSIS

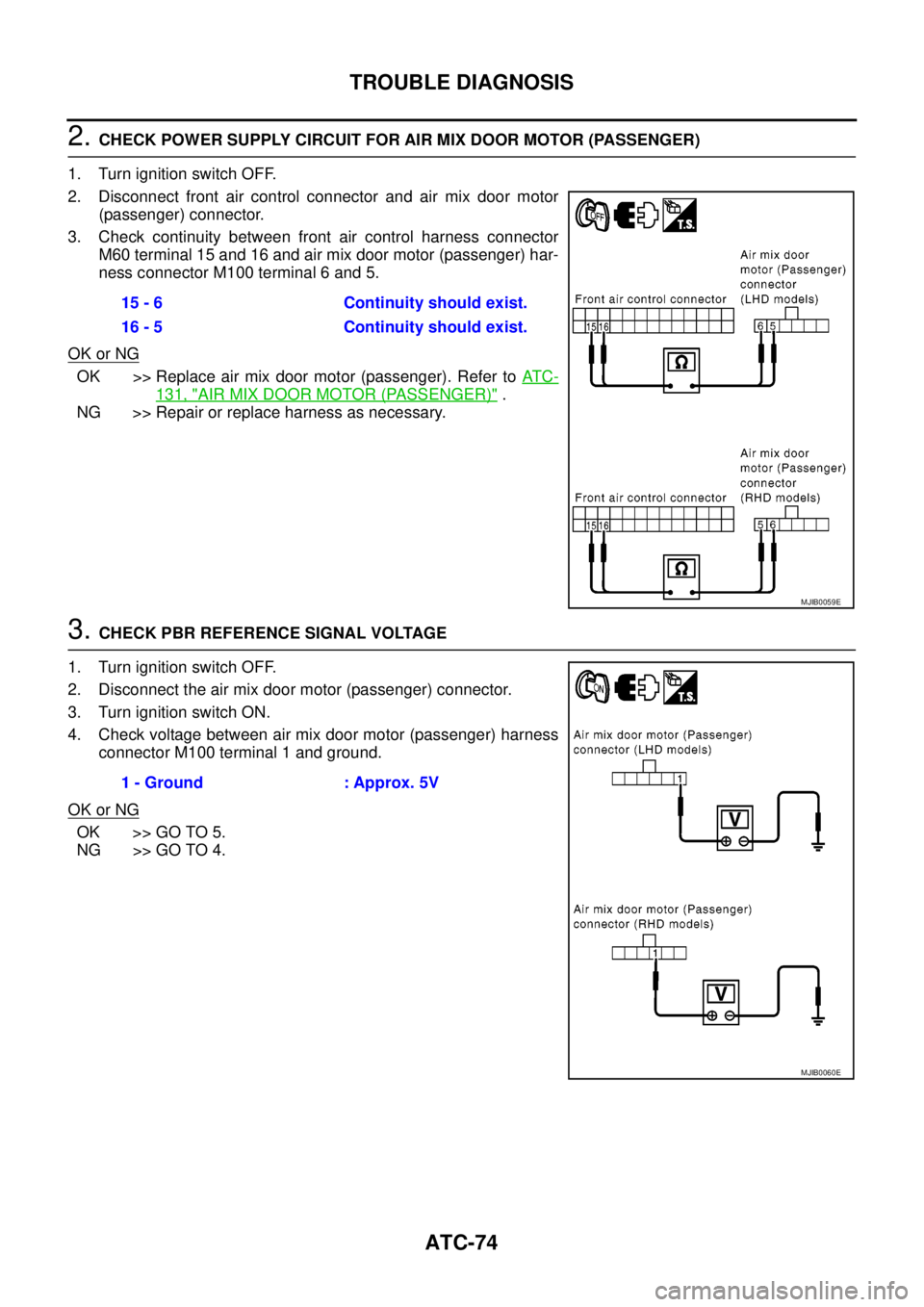

2.CHECK POWER SUPPLY CIRCUIT FOR AIR MIX DOOR MOTOR (PASSENGER)

1. Turn ignition switch OFF.

2. Disconnect front air control connector and air mix door motor

(passenger) connector.

3. Check continuity between front air control harness connector

M60 terminal 15 and 16 and air mix door motor (passenger) har-

ness connector M100 terminal 6 and 5.

OK or NG

OK >> Replace air mix door motor (passenger). Refer toAT C -

131, "AIR MIX DOOR MOTOR (PASSENGER)".

NG >> Repair or replace harness as necessary.

3.CHECK PBR REFERENCE SIGNAL VOLTAGE

1. Turn ignition switch OFF.

2. Disconnect the air mix door motor (passenger) connector.

3. Turn ignition switch ON.

4. Check voltage between air mix door motor (passenger) harness

connector M100 terminal 1 and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.15 - 6 Continuity should exist.

16 - 5 Continuity should exist.

MJIB0059E

1 - Ground : Approx. 5V

MJIB0060E

Page 410 of 3171

ATC-76

TROUBLE DIAGNOSIS

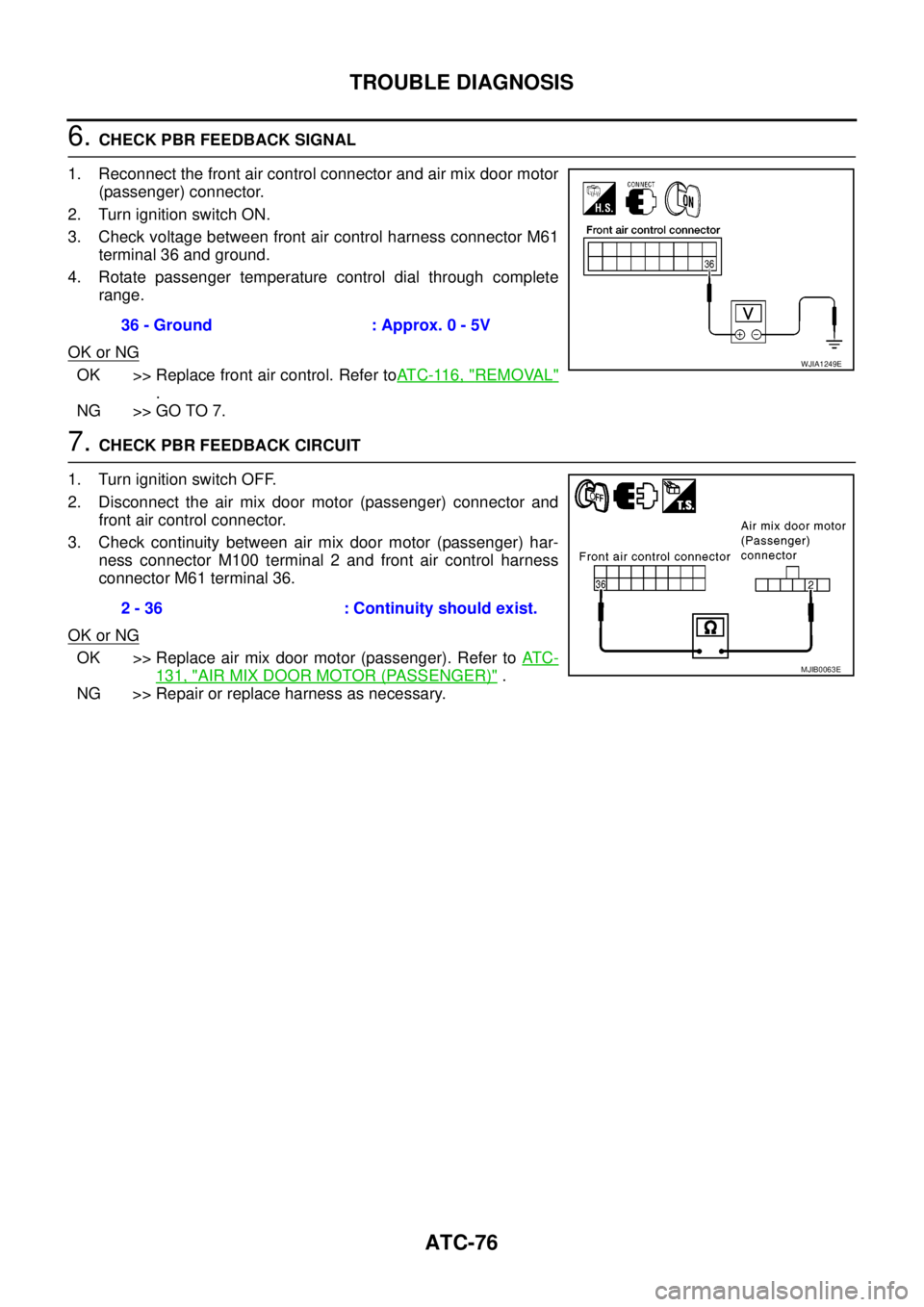

6.CHECK PBR FEEDBACK SIGNAL

1. Reconnect the front air control connector and air mix door motor

(passenger) connector.

2. Turn ignition switch ON.

3. Check voltage between front air control harness connector M61

terminal 36 and ground.

4. Rotate passenger temperature control dial through complete

range.

OK or NG

OK >> Replace front air control. Refer toAT C - 11 6 , "REMOVAL"

.

NG >> GO TO 7.

7.CHECK PBR FEEDBACK CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect the air mix door motor (passenger) connector and

front air control connector.

3. Check continuity between air mix door motor (passenger) har-

ness connector M100 terminal 2 and front air control harness

connector M61 terminal 36.

OK or NG

OK >> Replace air mix door motor (passenger). Refer toAT C -

131, "AIR MIX DOOR MOTOR (PASSENGER)".

NG >> Repair or replace harness as necessary.36 - Ground : Approx. 0 - 5V

WJIA1249E

2 - 36 : Continuity should exist.

MJIB0063E

Page 418 of 3171

ATC-84

TROUBLE DIAGNOSIS

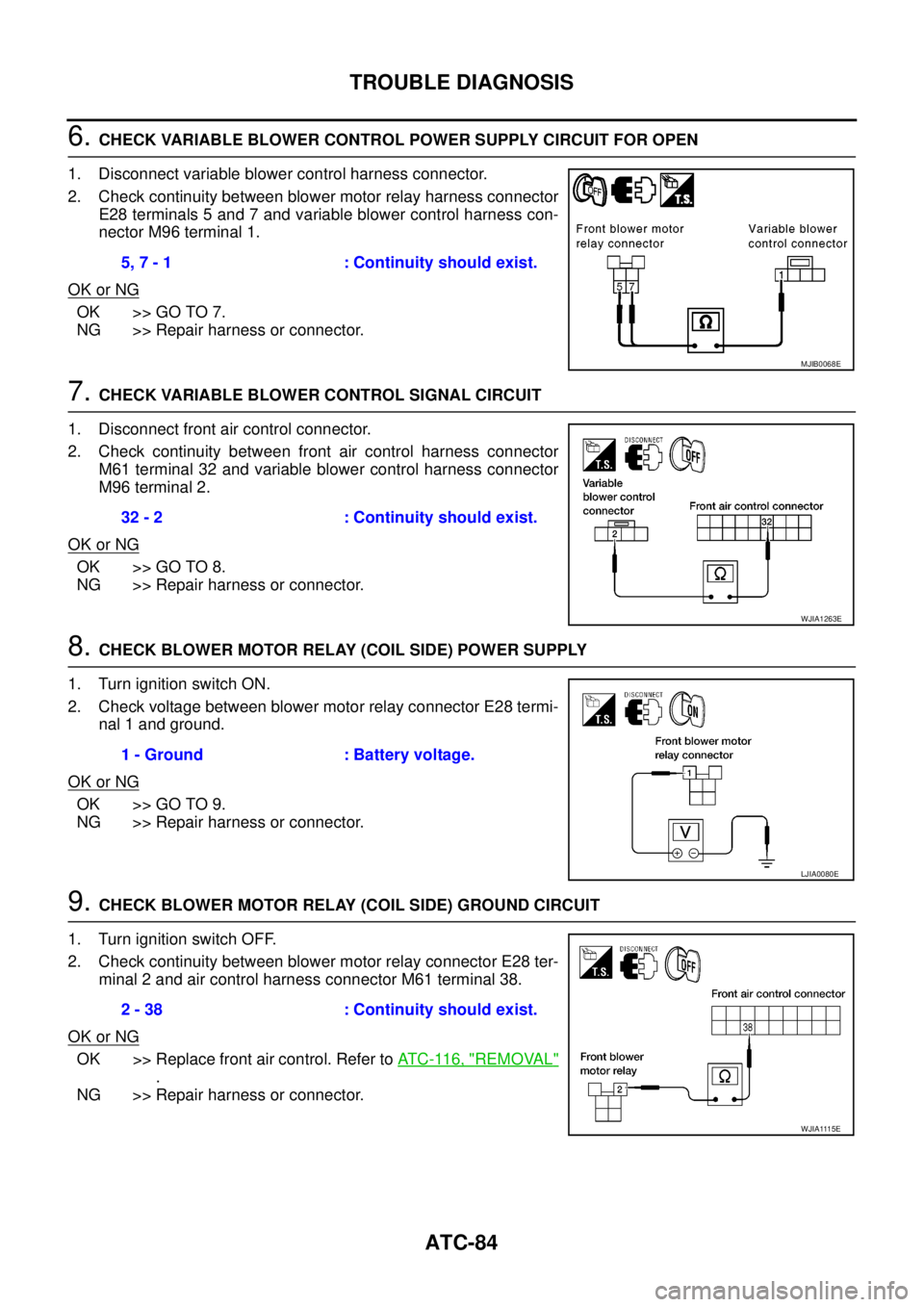

6.CHECK VARIABLE BLOWER CONTROL POWER SUPPLY CIRCUIT FOR OPEN

1. Disconnect variable blower control harness connector.

2. Check continuity between blower motor relay harness connector

E28 terminals 5 and 7 and variable blower control harness con-

nector M96 terminal 1.

OK or NG

OK >> GO TO 7.

NG >> Repair harness or connector.

7.CHECK VARIABLE BLOWER CONTROL SIGNAL CIRCUIT

1. Disconnect front air control connector.

2. Check continuity between front air control harness connector

M61 terminal 32 and variable blower control harness connector

M96 terminal 2.

OK or NG

OK >> GO TO 8.

NG >> Repair harness or connector.

8.CHECK BLOWER MOTOR RELAY (COIL SIDE) POWER SUPPLY

1. Turn ignition switch ON.

2. Check voltage between blower motor relay connector E28 termi-

nal 1 and ground.

OK or NG

OK >> GO TO 9.

NG >> Repair harness or connector.

9.CHECK BLOWER MOTOR RELAY (COIL SIDE) GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between blower motor relay connector E28 ter-

minal 2 and air control harness connector M61 terminal 38.

OK or NG

OK >> Replace front air control. Refer toAT C - 11 6 , "REMOVAL"

.

NG >> Repair harness or connector.5, 7 - 1 : Continuity should exist.

MJIB0068E

32 - 2 : Continuity should exist.

WJIA1263E

1 - Ground : Battery voltage.

LJIA0080E

2 - 38 : Continuity should exist.

WJIA1115E

Page 419 of 3171

TROUBLE DIAGNOSIS

ATC-85

C

D

E

F

G

H

I

K

L

MA

B

AT C

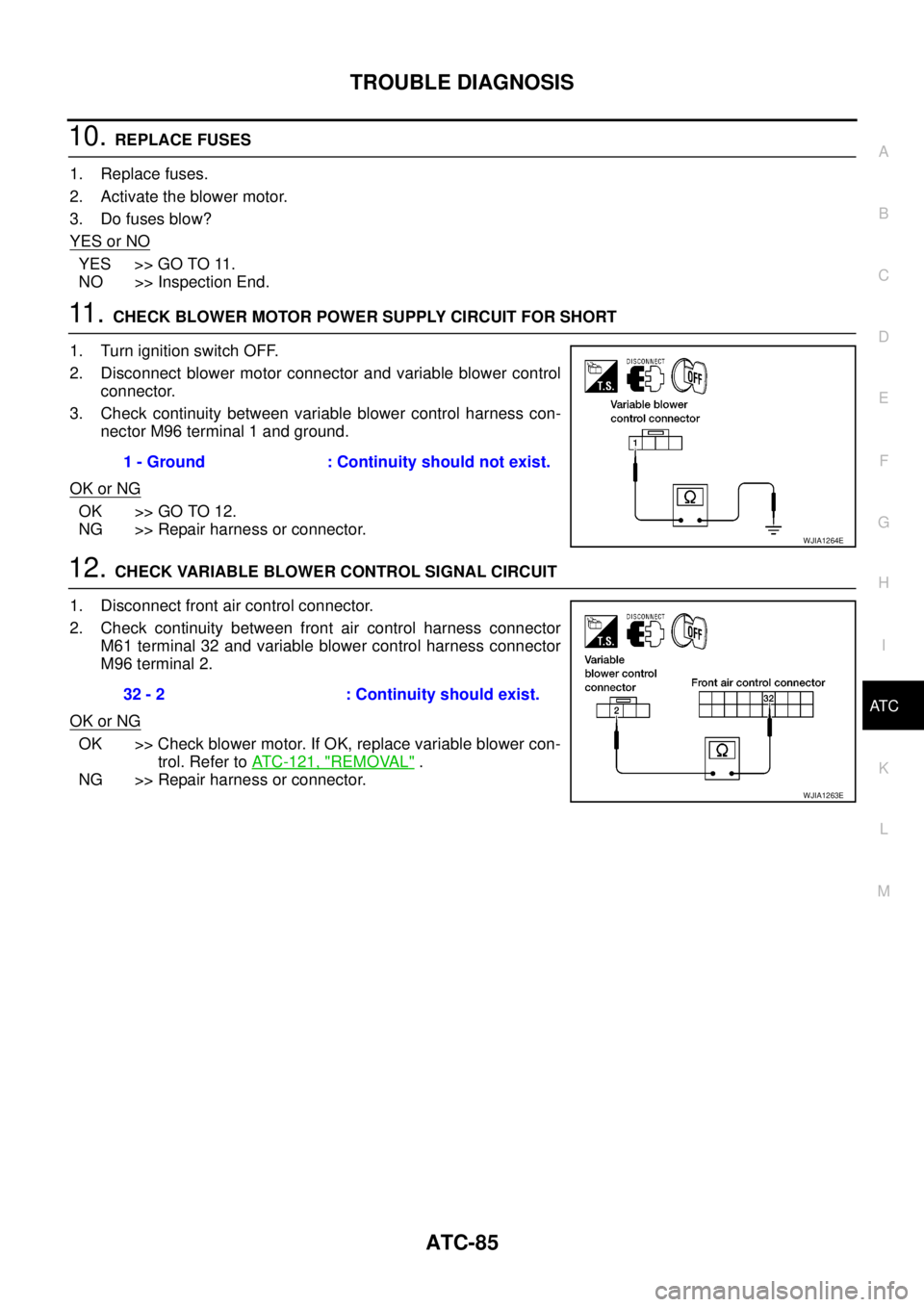

10.REPLACE FUSES

1. Replace fuses.

2. Activate the blower motor.

3. Do fuses blow?

YES or NO

YES >> GO TO 11.

NO >> Inspection End.

11 .CHECK BLOWER MOTOR POWER SUPPLY CIRCUIT FOR SHORT

1. Turn ignition switch OFF.

2. Disconnect blower motor connector and variable blower control

connector.

3. Check continuity between variable blower control harness con-

nector M96 terminal 1 and ground.

OK or NG

OK >> GO TO 12.

NG >> Repair harness or connector.

12.CHECK VARIABLE BLOWER CONTROL SIGNAL CIRCUIT

1. Disconnect front air control connector.

2. Check continuity between front air control harness connector

M61 terminal 32 and variable blower control harness connector

M96 terminal 2.

OK or NG

OK >> Check blower motor. If OK, replace variable blower con-

trol. Refer toATC-121, "

REMOVAL".

NG >> Repair harness or connector.1 - Ground : Continuity should not exist.

WJIA1264E

32 - 2 : Continuity should exist.

WJIA1263E

Page 422 of 3171

ATC-88

TROUBLE DIAGNOSIS

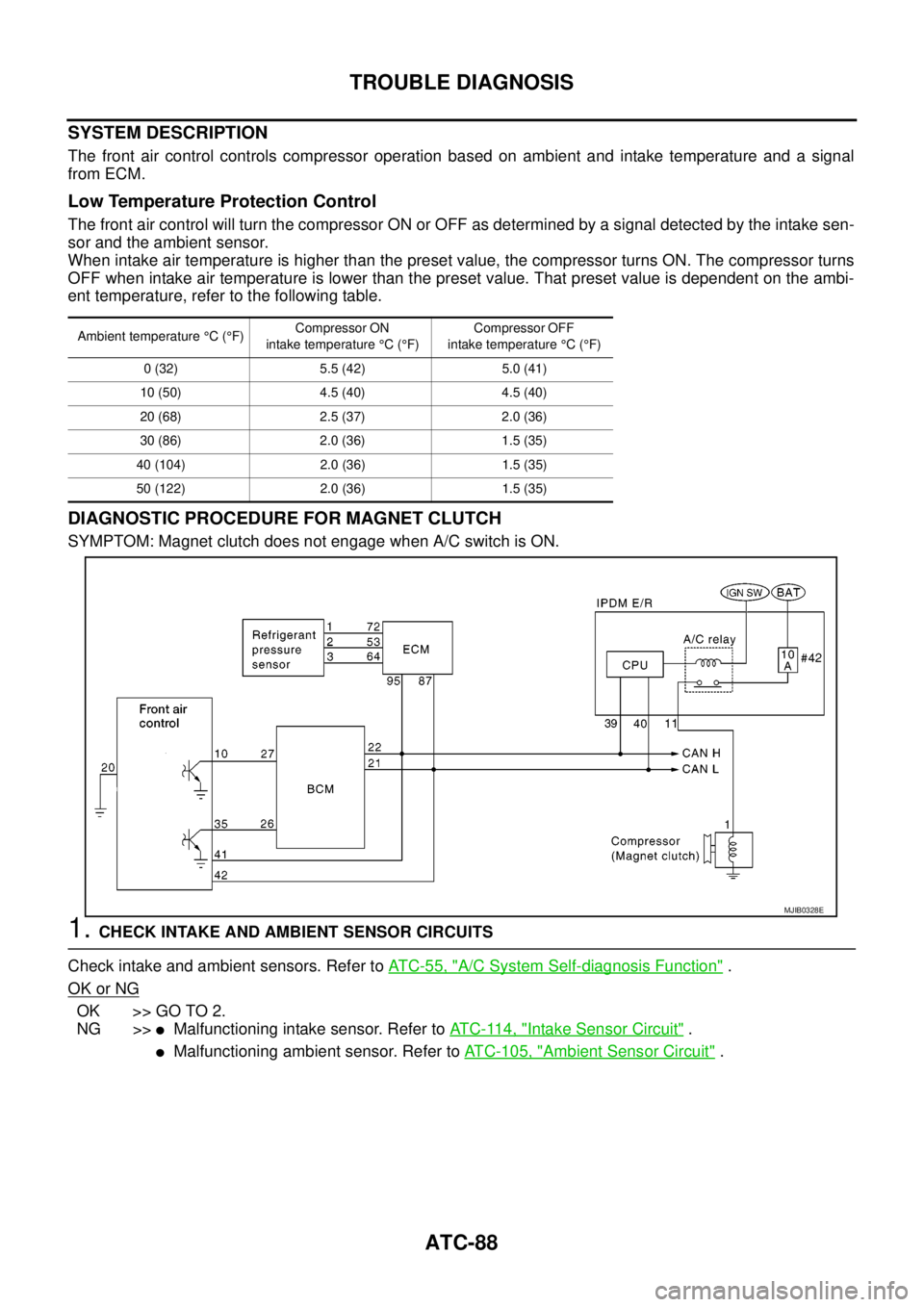

SYSTEM DESCRIPTION

The front air control controls compressor operation based on ambient and intake temperature and a signal

from ECM.

Low Temperature Protection Control

The front air control will turn the compressor ON or OFF as determined by a signal detected by the intake sen-

sor and the ambient sensor.

When intake air temperature is higher than the preset value, the compressor turns ON. The compressor turns

OFF when intake air temperature is lower than the preset value. That preset value is dependent on the ambi-

ent temperature, refer to the following table.

DIAGNOSTIC PROCEDURE FOR MAGNET CLUTCH

SYMPTOM: Magnet clutch does not engage when A/C switch is ON.

1.CHECK INTAKE AND AMBIENT SENSOR CIRCUITS

Check intake and ambient sensors. Refer toAT C - 5 5 , "

A/C System Self-diagnosis Function".

OK or NG

OK >> GO TO 2.

NG >>

lMalfunctioning intake sensor. Refer toAT C - 11 4 , "Intake Sensor Circuit".

lMalfunctioning ambient sensor. Refer toATC-105, "Ambient Sensor Circuit".

Ambient temperature°C(°F)Compressor ON

intake temperature°C(°F)Compressor OFF

intake temperature°C(°F)

0 (32) 5.5 (42) 5.0 (41)

10 (50) 4.5 (40) 4.5 (40)

20 (68) 2.5 (37) 2.0 (36)

30 (86) 2.0 (36) 1.5 (35)

40 (104) 2.0 (36) 1.5 (35)

50 (122) 2.0 (36) 1.5 (35)

MJIB0328E

Page 423 of 3171

TROUBLE DIAGNOSIS

ATC-89

C

D

E

F

G

H

I

K

L

MA

B

AT C

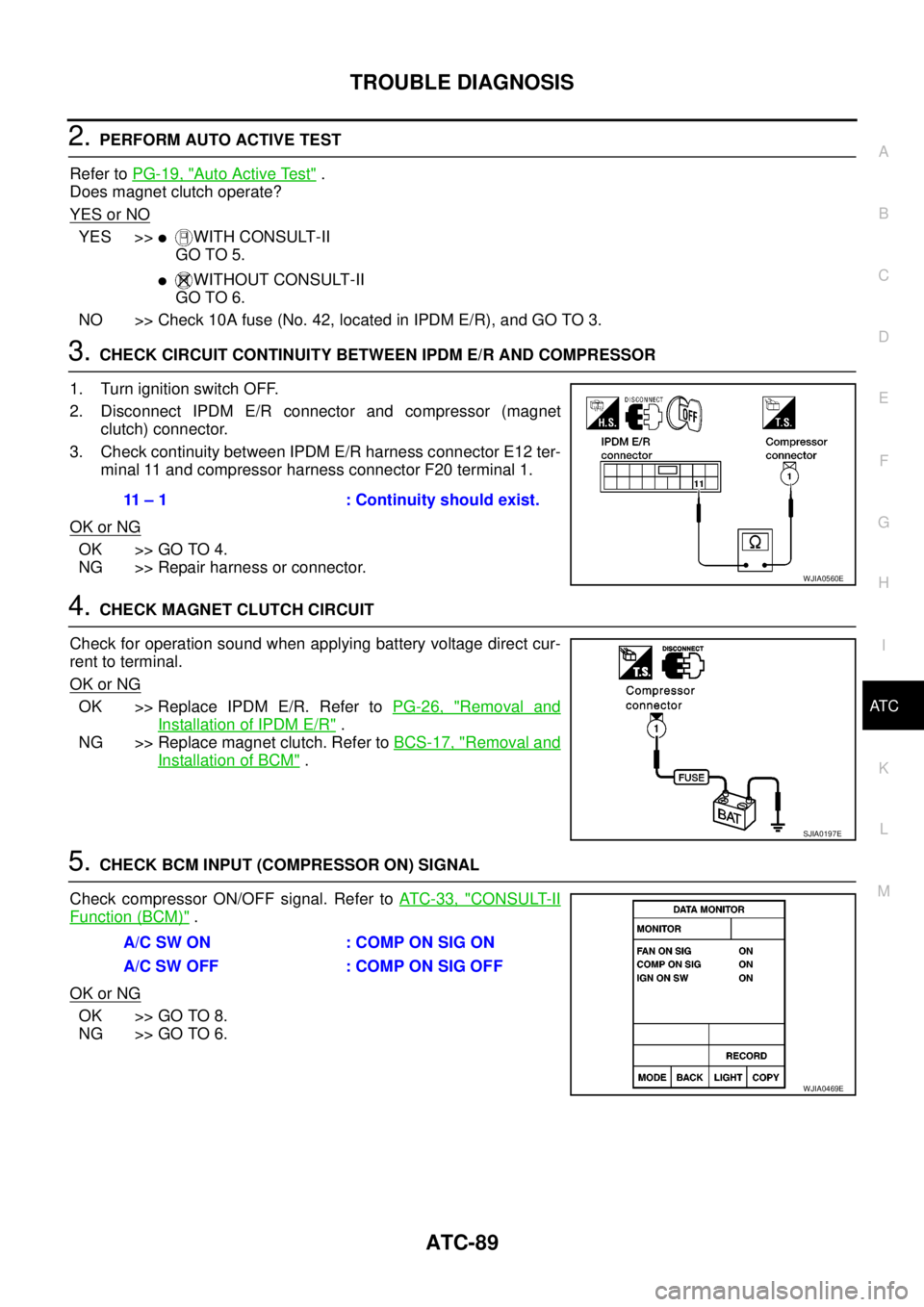

2.PERFORM AUTO ACTIVE TEST

Refer toPG-19, "

Auto Active Test".

Does magnet clutch operate?

YES or NO

YES >>lWITH CONSULT-II

GO TO 5.

lWITHOUT CONSULT-II

GO TO 6.

NO >> Check 10A fuse (No. 42, located in IPDM E/R), and GO TO 3.

3.CHECK CIRCUIT CONTINUITY BETWEEN IPDM E/R AND COMPRESSOR

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector and compressor (magnet

clutch) connector.

3. Check continuity between IPDM E/R harness connector E12 ter-

minal 11 and compressor harness connector F20 terminal 1.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.

4.CHECK MAGNET CLUTCH CIRCUIT

Check for operation sound when applying battery voltage direct cur-

rent to terminal.

OK or NG

OK >> Replace IPDM E/R. Refer toPG-26, "Removal and

Installation of IPDM E/R".

NG >> Replace magnet clutch. Refer toBCS-17, "

Removal and

Installation of BCM".

5.CHECK BCM INPUT (COMPRESSOR ON) SIGNAL

Check compressor ON/OFF signal. Refer toAT C - 3 3 , "

CONSULT-II

Function (BCM)".

OK or NG

OK >> GO TO 8.

NG >> GO TO 6.

11 – 1 : Continuity should exist.

WJIA0560E

SJIA0197E

A/C SW ON : COMP ON SIG ON

A/CSWOFF :COMPONSIGOFF

WJIA0469E

Page 424 of 3171

ATC-90

TROUBLE DIAGNOSIS

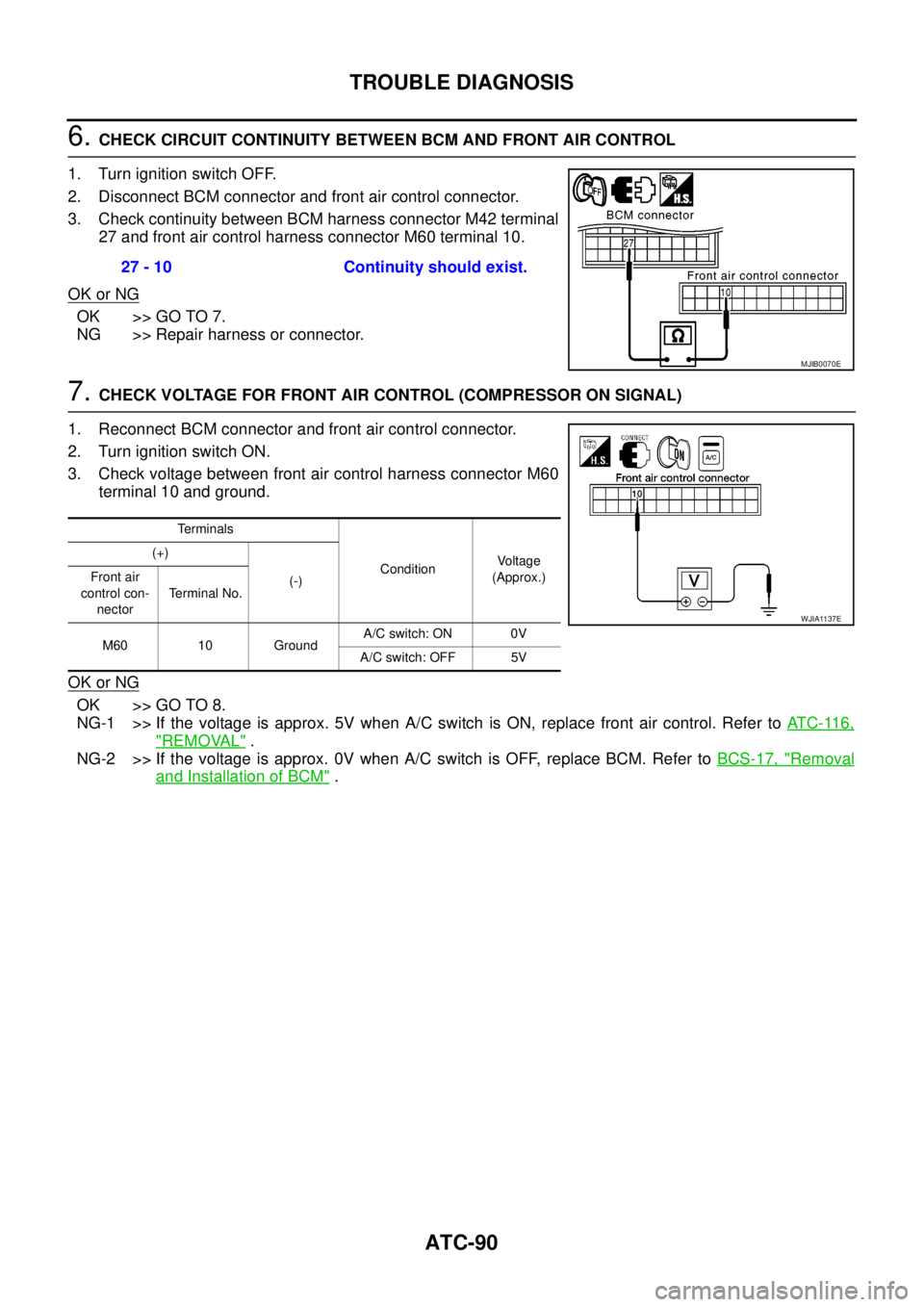

6.CHECK CIRCUIT CONTINUITY BETWEEN BCM AND FRONT AIR CONTROL

1. Turn ignition switch OFF.

2. Disconnect BCM connector and front air control connector.

3. Check continuity between BCM harness connector M42 terminal

27 and front air control harness connector M60 terminal 10.

OK or NG

OK >> GO TO 7.

NG >> Repair harness or connector.

7.CHECK VOLTAGE FOR FRONT AIR CONTROL (COMPRESSOR ON SIGNAL)

1. Reconnect BCM connector and front air control connector.

2. Turn ignition switch ON.

3. Check voltage between front air control harness connector M60

terminal 10 and ground.

OK or NG

OK >> GO TO 8.

NG-1 >> If the voltage is approx. 5V when A/C switch is ON, replace front air control. Refer toAT C - 11 6 ,

"REMOVAL".

NG-2 >> If the voltage is approx. 0V when A/C switch is OFF, replace BCM. Refer toBCS-17, "

Removal

and Installation of BCM". 27 - 10 Continuity should exist.

MJIB0070E

Terminals

ConditionVoltage

(Approx.) (+)

(-) Front air

control con-

nectorTerminal No.

M60 10 GroundA/C switch: ON 0V

A/C switch: OFF 5V

WJIA1137E