set clock NISSAN NOTE 2016 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1185 of 3641

![NISSAN NOTE 2016 Service User Guide EC-58

< SYSTEM DESCRIPTION >[HR16DE]

DIAGNOSIS SYSTEM (ECM)

• ECM blinks MIL for about 10 seconds if all SRT codes are not set.

MALFUNCTION WARNING MODE

Description

In this function ECM turns on or NISSAN NOTE 2016 Service User Guide EC-58

< SYSTEM DESCRIPTION >[HR16DE]

DIAGNOSIS SYSTEM (ECM)

• ECM blinks MIL for about 10 seconds if all SRT codes are not set.

MALFUNCTION WARNING MODE

Description

In this function ECM turns on or](/img/5/57363/w960_57363-1184.png)

EC-58

< SYSTEM DESCRIPTION >[HR16DE]

DIAGNOSIS SYSTEM (ECM)

• ECM blinks MIL for about 10 seconds if all SRT codes are not set.

MALFUNCTION WARNING MODE

Description

In this function ECM turns on or blinks MIL when it detects a malfunction in the emission control system com-

ponents and/or the powertrain control components (which affe

ct vehicle emissions) to inform the driver that a

malfunction has been detected.

Operation Procedure

1. Turn ignition switch ON.

2. Check that MIL illuminates. If it remains OFF, check MIL circuit. Refer to EC-456, "

Diagnosis Procedure".

3. Start engine and let it idle. • For two trip detection logic diagnoses, ECM turns on MIL when it detects the same malfunction twice inthe two consecutive driving cycles.

• For 1st trip detection logic diagnoses, ECM turns on MIL when it detects a malfunction in one driving cycle.

• ECM blinks MIL when it detects a malfunction t hat may damage the three way catalyst (misfire).

SELF-DIAGNOSTIC RESULTS MODE

Description

This function allows to indicate DTCs or 1st trip DT Cs stored in ECM according to the number of times MIL is

blinking.

How to Set Self-diagnostic Results Mode

NOTE:

• It is better to count the time accurately with a clock.

• It is impossible to switch the diagnostic mode when an accelerator pedal position sensor circuit has a mal-

function.

• After ignition switch is turned off, ECM is always released from the “self-diagnostic results” mode.

1. Confirm that accelerator pedal is fully releas ed, turn ignition switch ON and wait 3 seconds.

2. Repeat the following procedure quickly five times within 5 seconds. • Fully depress the accelerator pedal.

• Fully release the accelerator pedal.

3. Wait 7 seconds, fully depress the accelerator pedal and keep it depressed for approx. 10 seconds until the MIL starts blinking.

NOTE:

Do not release the accelerator pedal for 10 seconds if MIL starts blinking during this period. This blinking

is displaying SRT status and is continued for another 10 seconds.

4. Fully release the accelerator pedal. ECM has entered to “Self-diagnostic results” mode.

JMBIA1515GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1257 of 3641

![NISSAN NOTE 2016 Service User Guide EC-130

< BASIC INSPECTION >[HR16DE]

IDLE AIR VOLUME LEARNING

IDLE AIR VOLUME LEARNING

DescriptionINFOID:0000000012431358

Idle Air Volume Learning is a function of ECM to learn the idle air volume that NISSAN NOTE 2016 Service User Guide EC-130

< BASIC INSPECTION >[HR16DE]

IDLE AIR VOLUME LEARNING

IDLE AIR VOLUME LEARNING

DescriptionINFOID:0000000012431358

Idle Air Volume Learning is a function of ECM to learn the idle air volume that](/img/5/57363/w960_57363-1256.png)

EC-130

< BASIC INSPECTION >[HR16DE]

IDLE AIR VOLUME LEARNING

IDLE AIR VOLUME LEARNING

DescriptionINFOID:0000000012431358

Idle Air Volume Learning is a function of ECM to learn the idle air volume that keeps each engine idle speed

within the specific range. It must be performed under any of the following conditions:

• Each time electric throttle control actuator or ECM is replaced.

• Idle speed or ignition timing is out of specification.

Refer to

EC-130, "

Work Procedure".

Work ProcedureINFOID:0000000012431359

1.PRECONDITIONING

Make sure that all of the following conditions are satisfied.

Learning will be cancelled if any of the follo wing conditions are missed for even a moment.

• Battery voltage: More than 12.9 V (At idle)

• Engine coolant temperature: 70 - 100 °C (158 - 212° F)

• Selector lever: P or N (CVT), Neutral (M/T)

• Electric load switch: OFF

(Air conditioner, headlamp, rear window defogger)

- For vehicles equipped with dayt ime light systems, perform one of the following procedures before

starting engine not to illuminate headlamps.

• Apply parking brake

• Set lighting switch to the 1st position

• Steering wheel: Neutral (Straight-ahead position) position

• Vehicle speed: Stopped

• Transmission: Warmed-up

- CVT models

• With CONSULT: Drive vehicle until “FLUID TEMP SE ” in “DATA MONITOR” mode of “TRANSMISSION” sys-

tem indicates less than 0.9 V.

• Without CONSULT: Drive vehicle for 10 minutes.

- M/T models

• Drive vehicle for 10 minutes.

Do you have CONSULT?

YES >> GO TO 2.

NO >> GO TO 3.

2.IDLE AIR VOLUME LEARNING

With CONSULT

1. Perform ACCELERATOR PEDAL RELEAS ED POSITION LEARNING. Refer to EC-128, "

Description".

2. Perform THROTTLE VALVE CLOSED POSITION LEARNING. Refer to EC-129, "

Description".

3. Start engine and warm it up to normal operating temperature.

4. Select “IDLE AIR VOL LEARN” in “WORK SUPPORT” mode with CONSULT.

5. Touch “START” and wait 20 seconds.

Is

“CMPLT” displayed on CONSULT screen?

YES >> GO TO 4.

NO >> GO TO 5.

3.IDLE AIR VOLUME LEARNING

Without CONSULT

NOTE:

• It is better to count the ti me accurately with a clock.

• It is impossible to switch the di agnostic mode when an accelerator pedal position sensor circuit has

a malfunction.

1. Perform ACCELERATOR PEDAL RELEAS ED POSITION LEARNING. Refer to EC-128, "

Description".

2. Perform THROTTLE VALVE CLOSED POSITION LEARNING. Refer to EC-129, "

Description".

3. Start engine and warm it up to normal operating temperature.

4. Turn ignition switch OFF and wait at least 10 seconds.

5. Confirm that accelerator pedal is fully releas ed, turn ignition switch ON and wait 3 seconds.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1830 of 3641

FRONT WHEEL HUB AND KNUCKLEFAX-13

< REMOVAL AND INSTALLATION >

CEF

G H

I

J

K L

M A

B

FA X

N

O P

5. Perform inspection after assembly. Refer to FAX-13, "Inspection".

InspectionINFOID:0000000012431893

INSPECTION AFTER REMOVAL

Check the following items, and replace the part if necessary.

• Check components for deformation, cracks, and other damage.

• Check boots of transverse link and steering outer so cket ball joint for breakage, axial end play, and swing

torque. Refer to FSU-10, "

Inspection" and FSU-20, "Ball Joint".

INSPECTION AFTER DISASSEMBLY

Wheel Hub

• Check wheel hub for cracks (with magnetic exploration or dye testing). Replace if necessary.

Steering Knuckle

• Check steering knuckle for deformation, cracks, and other damage. Replace if any non-standard conditions

are found.

Snap Rings

• Check snap ring for wear or cracks. Replace if necessary.

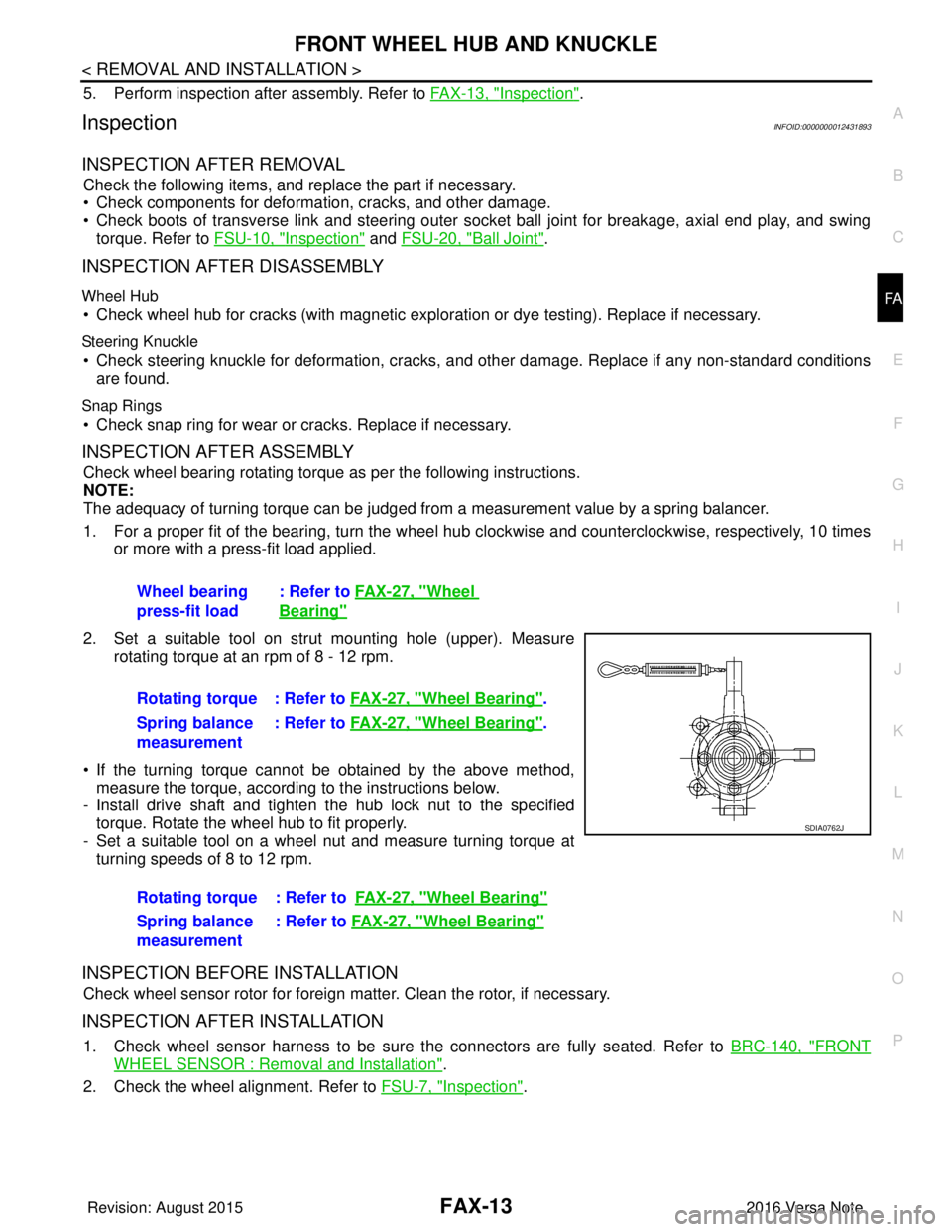

INSPECTION AFTER ASSEMBLY

Check wheel bearing rotating torque as per the following instructions.

NOTE:

The adequacy of turning torque can be judged from a measurement value by a spring balancer.

1. For a proper fit of the bearing, turn the wheel hub clockwise and counterclockwise, respectively, 10 times

or more with a press-fit load applied.

2. Set a suitable tool on strut mounting hole (upper). Measure rotating torque at an rpm of 8 - 12 rpm.

• If the turning torque cannot be obtained by the above method, measure the torque, according to the instructions below.

- Install drive shaft and tighten the hub lock nut to the specified

torque. Rotate the wheel hub to fit properly.

- Set a suitable tool on a wheel nut and measure turning torque at turning speeds of 8 to 12 rpm.

INSPECTION BEFORE INSTALLATION

Check wheel sensor rotor for foreign matter. Clean the rotor, if necessary.

INSPECTION AFTER INSTALLATION

1. Check wheel sensor harness to be sure the connectors are fully seated. Refer to BRC-140, "FRONT

WHEEL SENSOR : Removal and Installation".

2. Check the wheel alignment. Refer to FSU-7, "

Inspection".

Wheel bearing

press-fit load

: Refer to

FAX-27, "

Wheel

Bearing"

Rotating torque : Refer to FAX-27, "Wheel Bearing".

Spring balance

measurement : Refer to

FAX-27, "

Wheel Bearing".

Rotating torque : Refer to FAX-27, "

Wheel Bearing"

Spring balance

measurement: Refer to

FAX-27, "Wheel Bearing"

SDIA0762J

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1975 of 3641

![NISSAN NOTE 2016 Service User Guide PRECAUTIONSHAC-7

< PRECAUTION > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Be certain that the gauge face indicates HFC-134a or R-134a. Be

sure the gauge set has 1/2 ″-16 ACME threa NISSAN NOTE 2016 Service User Guide PRECAUTIONSHAC-7

< PRECAUTION > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Be certain that the gauge face indicates HFC-134a or R-134a. Be

sure the gauge set has 1/2 ″-16 ACME threa](/img/5/57363/w960_57363-1974.png)

PRECAUTIONSHAC-7

< PRECAUTION > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Be certain that the gauge face indicates HFC-134a or R-134a. Be

sure the gauge set has 1/2 ″-16 ACME threaded connections for ser-

vice hoses. Confirm the set has been used only with refrigerant

HFC-134a (R-134a) and specified oils.

SERVICE HOSES

Be certain that the service hoses display the markings described

(colored hose with black stripe) . All hoses must be equipped with

positive shut-off devices (either manual or automatic) near the end of

the hoses opposite to the manifold gauge.

SERVICE COUPLERS

Do not attempt to connect HFC-134a (R-134a) service couplers to

the CFC-12 (R-12) A/C system. The HFC-134a (R-134a) couplers

do not properly connect to the CFC-12 (R-12) system. However, if an

improper connection is attempted, discharging and contamination

may occur.

REFRIGERANT WEIGHT SCALE

Verify that no refrigerant other than HFC-134a (R-134a) and speci-

fied oils have been used with the scale. The hose fitting must be 1/

2 ″-16 ACME if the scale controls refrigerant flow electronically.

CHARGING CYLINDER

Using a charging cylinder is not re commended. Refrigerant may be vented into air from cylinder’s top valve

when filling the cylinder with refrigerant. Also, the accura cy of the cylinder is generally less than that of an

electronic scale or of quality recycle/recharge equipment.

SHA533D

RHA272D

Shut-off valve rotati on A/C service valve

Clockwise Open

Counterclockwise Close

RHA273D

RHA274D

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2329 of 3641

MA-14

< PERIODIC MAINTENANCE >

ENGINE MAINTENANCE

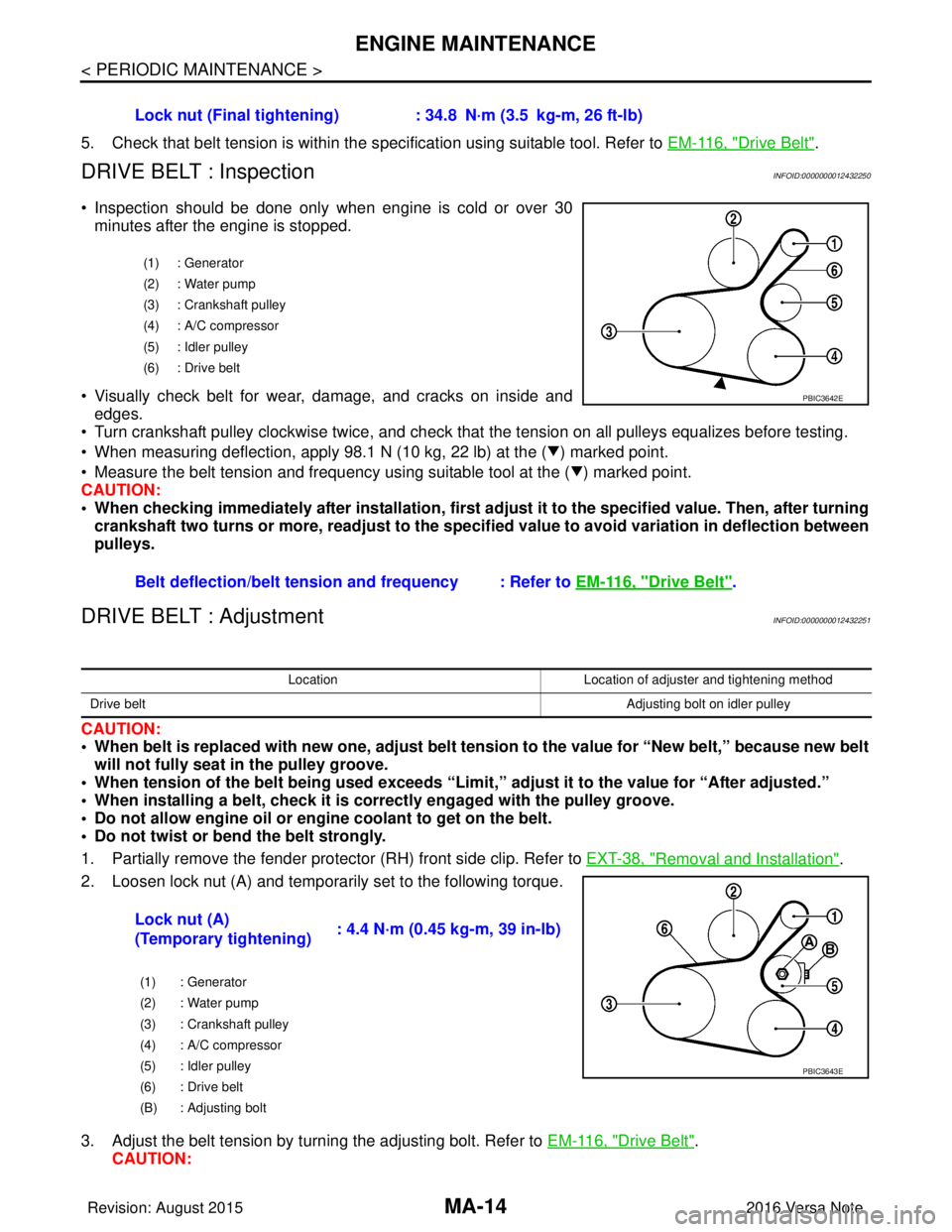

5. Check that belt tension is within the specification using suitable tool. Refer to EM-116, "Drive Belt".

DRIVE BELT : InspectionINFOID:0000000012432250

• Inspection should be done only when engine is cold or over 30

minutes after the engine is stopped.

• Visually check belt for wear, damage, and cracks on inside and edges.

• Turn crankshaft pulley clockwise twice, and check that the tension on all pulleys equalizes before testing.

• When measuring deflection, apply 98.1 N (10 kg, 22 lb) at the ( ) marked point.

• Measure the belt tension and frequency using suitable tool at the ( ) marked point.

CAUTION:

• When checking immediately after installation, first ad just it to the specified value. Then, after turning

crankshaft two turns or more, readjust to the speci fied value to avoid variation in deflection between

pulleys.

DRIVE BELT : AdjustmentINFOID:0000000012432251

CAUTION:

• When belt is replaced with new one, adjust belt tension to the value for “New belt,” because new belt will not fully seat in the pulley groove.

• When tension of the belt being used exceeds “Limit,” adjust it to the value for “After adjusted.”

• When installing a belt, check it is co rrectly engaged with the pulley groove.

• Do not allow engine oil or engine coolant to get on the belt.

• Do not twist or bend the belt strongly.

1. Partially remove the fender protector (RH) front side clip. Refer to EXT-38, "

Removal and Installation".

2. Loosen lock nut (A) and temporarily set to the following torque.

3. Adjust the belt tension by turning the adjusting bolt. Refer to EM-116, "

Drive Belt".

CAUTION: Lock nut (Final tightening) :

34.8 N·m (3.5 kg-m, 26 ft-lb)

(1) : Generator

(2) : Water pump

(3) : Crankshaft pulley

(4) : A/C compressor

(5) : Idler pulley

(6) : Drive belt

Belt deflection/belt tension and frequency : Refer to EM-116, "Drive Belt".

PBIC3642E

LocationLocation of adjuster and tightening method

Drive belt Adjusting bolt on idler pulley

Lock nut (A)

(Temporary tightening): 4.4 N·m (0.45 kg-m, 39 in-lb)

(1) : Generator

(2) : Water pump

(3) : Crankshaft pulley

(4) : A/C compressor

(5) : Idler pulley

(6) : Drive belt

(B) : Adjusting bolt

PBIC3643E

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2727 of 3641

REAR WHEEL HUBRAX-9

< REMOVAL AND INSTALLATION >

CEF

G H

I

J

K L

M A

B

RAX

N

O P

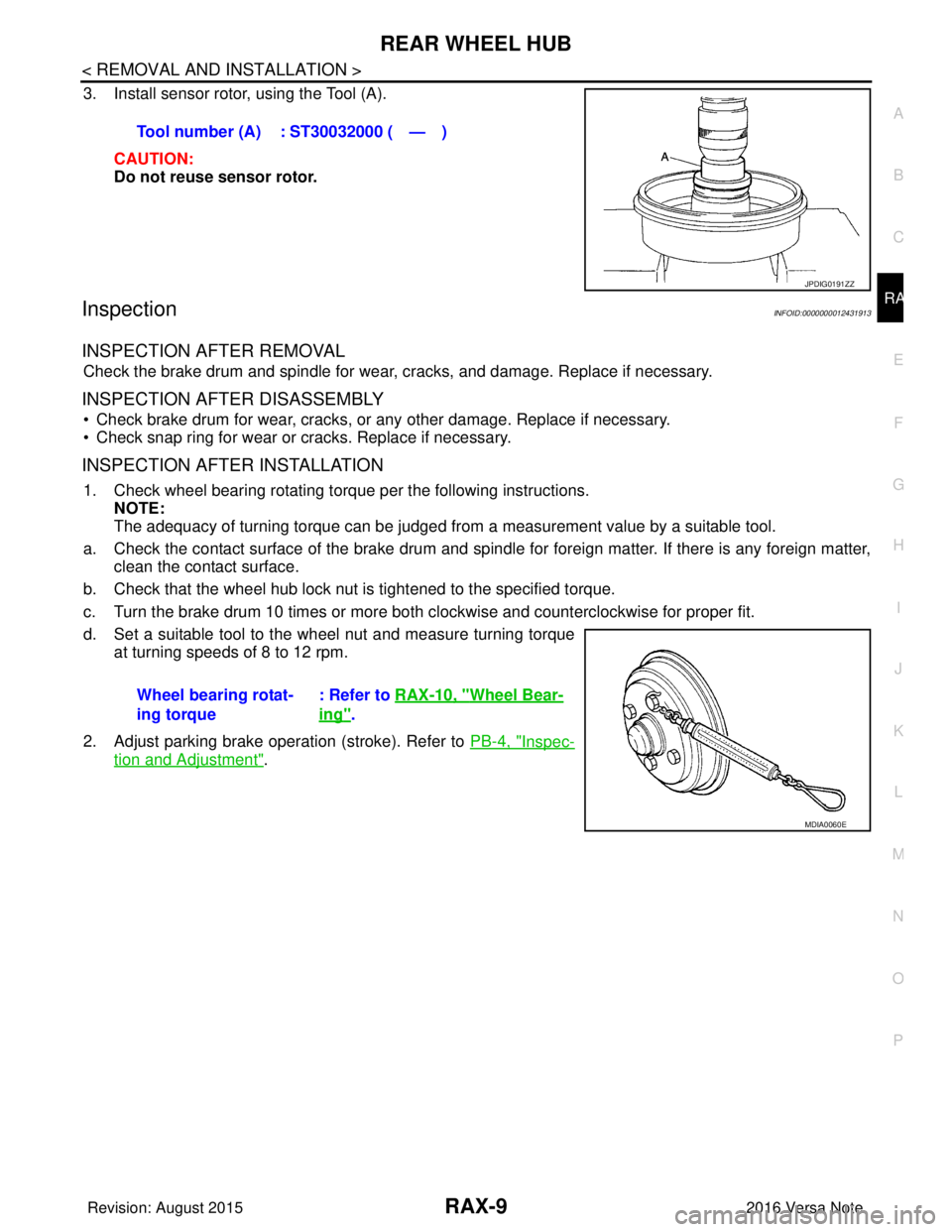

3. Install sensor rotor, using the Tool (A).

CAUTION:

Do not reuse sensor rotor.

InspectionINFOID:0000000012431913

INSPECTION AFTER REMOVAL

Check the brake drum and spindle for wear , cracks, and damage. Replace if necessary.

INSPECTION AFTER DISASSEMBLY

• Check brake drum for wear, cracks, or any other damage. Replace if necessary.

• Check snap ring for wear or cracks. Replace if necessary.

INSPECTION AFTER INSTALLATION

1. Check wheel bearing rotating torque per the following instructions. NOTE:

The adequacy of turning torque can be judged from a measurement value by a suitable tool.

a. Check the contact surface of the brake drum and spindle for foreign matter. If there is any foreign matter, clean the contact surface.

b. Check that the wheel hub lock nut is tightened to the specified torque.

c. Turn the brake drum 10 times or more bot h clockwise and counterclockwise for proper fit.

d. Set a suitable tool to the wheel nut and measure turning torque at turning speeds of 8 to 12 rpm.

2. Adjust parking brake operation (stroke). Refer to PB-4, "

Inspec-

tion and Adjustment".

Tool number (A) : ST30032000 ( — )

JPDIG0191ZZ

Wheel bearing rotat-

ing torque

: Refer to

RAX-10, "Wheel Bear-

ing".

MDIA0060E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3134 of 3641

SR-18

< REMOVAL AND INSTALLATION >

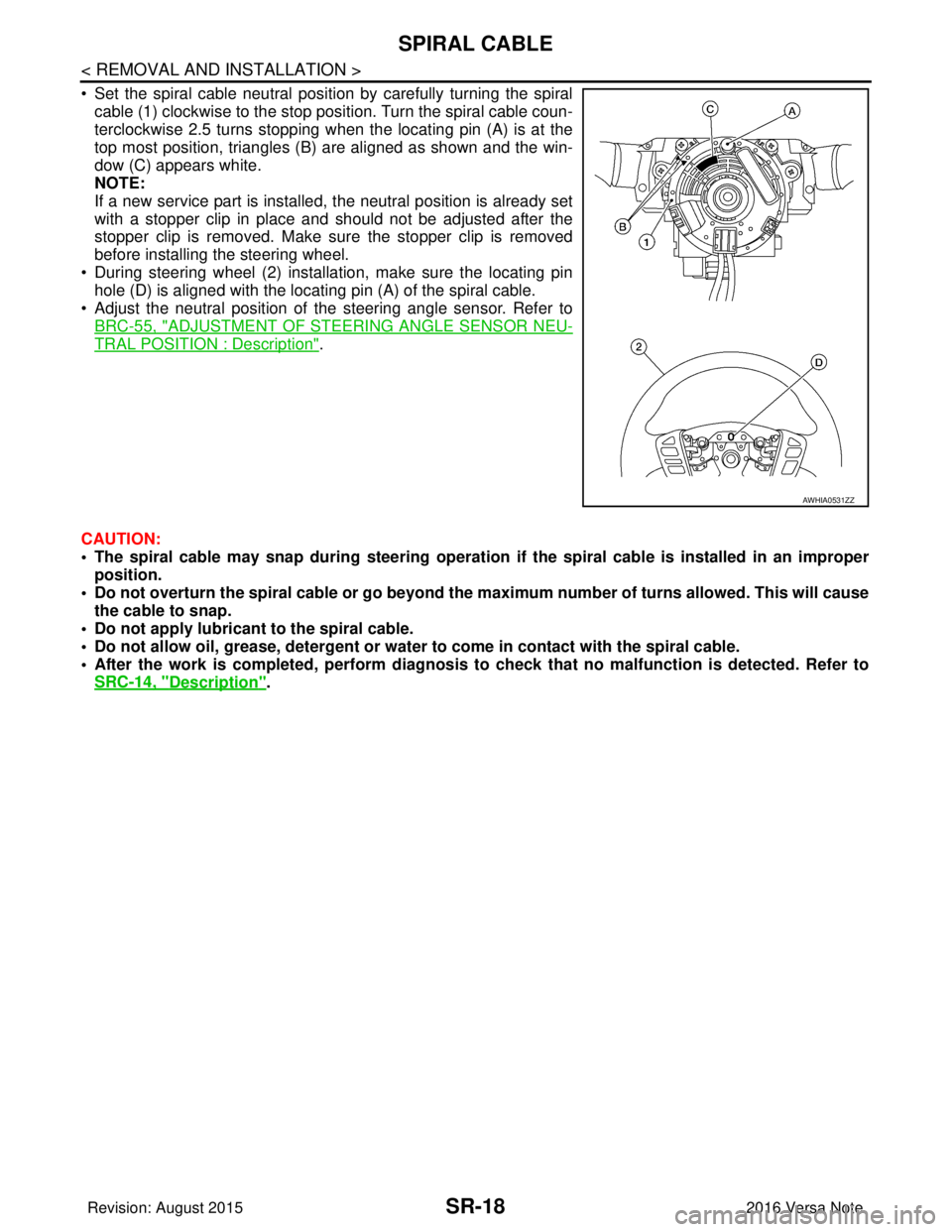

SPIRAL CABLE

• Set the spiral cable neutral position by carefully turning the spiralcable (1) clockwise to the stop position. Turn the spiral cable coun-

terclockwise 2.5 turns stopping when the locating pin (A) is at the

top most position, triangles (B) are aligned as shown and the win-

dow (C) appears white.

NOTE:

If a new service part is installed, the neutral position is already set

with a stopper clip in place and should not be adjusted after the

stopper clip is removed. Make sure the stopper clip is removed

before installing the steering wheel.

• During steering wheel (2) installation, make sure the locating pin hole (D) is aligned with the locating pin (A) of the spiral cable.

• Adjust the neutral position of the steering angle sensor. Refer to

BRC-55, "

ADJUSTMENT OF STEERI NG ANGLE SENSOR NEU-

TRAL POSITION : Description".

CAUTION:

• The spiral cable may snap during steering operation if the spiral cable is installed in an improper

position.

• Do not overturn the spiral cable or go beyond the maximum number of turns allowed. This will cause

the cable to snap.

• Do not apply lubricant to the spiral cable.

• Do not allow oil, grease, detergent or water to come in contact with the spiral cable.

• After the work is completed, perform diagnosis to check that no malfunction is detected. Refer to

SRC-14, "

Description".

AWHIA0531ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3271 of 3641

![NISSAN NOTE 2016 Service User Guide TM-30

< UNIT DISASSEMBLY AND ASSEMBLY >[5MT: RS5F91R]

TRANSAXLE ASSEMBLY

Disassembly

INFOID:0000000012430965

1. Remove drain plug and gasket from clutch housing using suitable tool, and drain gear oil NISSAN NOTE 2016 Service User Guide TM-30

< UNIT DISASSEMBLY AND ASSEMBLY >[5MT: RS5F91R]

TRANSAXLE ASSEMBLY

Disassembly

INFOID:0000000012430965

1. Remove drain plug and gasket from clutch housing using suitable tool, and drain gear oil](/img/5/57363/w960_57363-3270.png)

TM-30

< UNIT DISASSEMBLY AND ASSEMBLY >[5MT: RS5F91R]

TRANSAXLE ASSEMBLY

Disassembly

INFOID:0000000012430965

1. Remove drain plug and gasket from clutch housing using suitable tool, and drain gear oil.

2. Remove filler plug and gasket from transaxle case.

3. Remove rear housing and O-ring. CAUTION:

Remove in direction of input shaft ( ) as shown. Rear

housing oil channel is inserte d to input shaft center hole.

4. Move the shifter lever A (1) to the 3rd gear position. NOTE:

• If it is not moved to the 3rd gear position, transaxle case can-

not be removed from clutch housing.

• The 3rd gear position means that shifter lever A is fully rotated

clockwise and it is returned approximately 10 degrees.

1. Differential side bearing outer race 2. Differential side bearing 3. Final drive

: Replace the parts as a set.

JPDIC0481ZZ

SCIA1709J

PCIB1524E

Revision: August 2015 2016 Versa Note

cardiagn.com