radiator NISSAN NOTE 2016 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2824 of 3641

SQUEAK AND RATTLE TROUBLE DIAGNOSESSE-11

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

SE

N

O P

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component installed to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator installation pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine rpm or

load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3023 of 3641

SRC-6

< SYSTEM DESCRIPTION >

COMPONENT PARTS

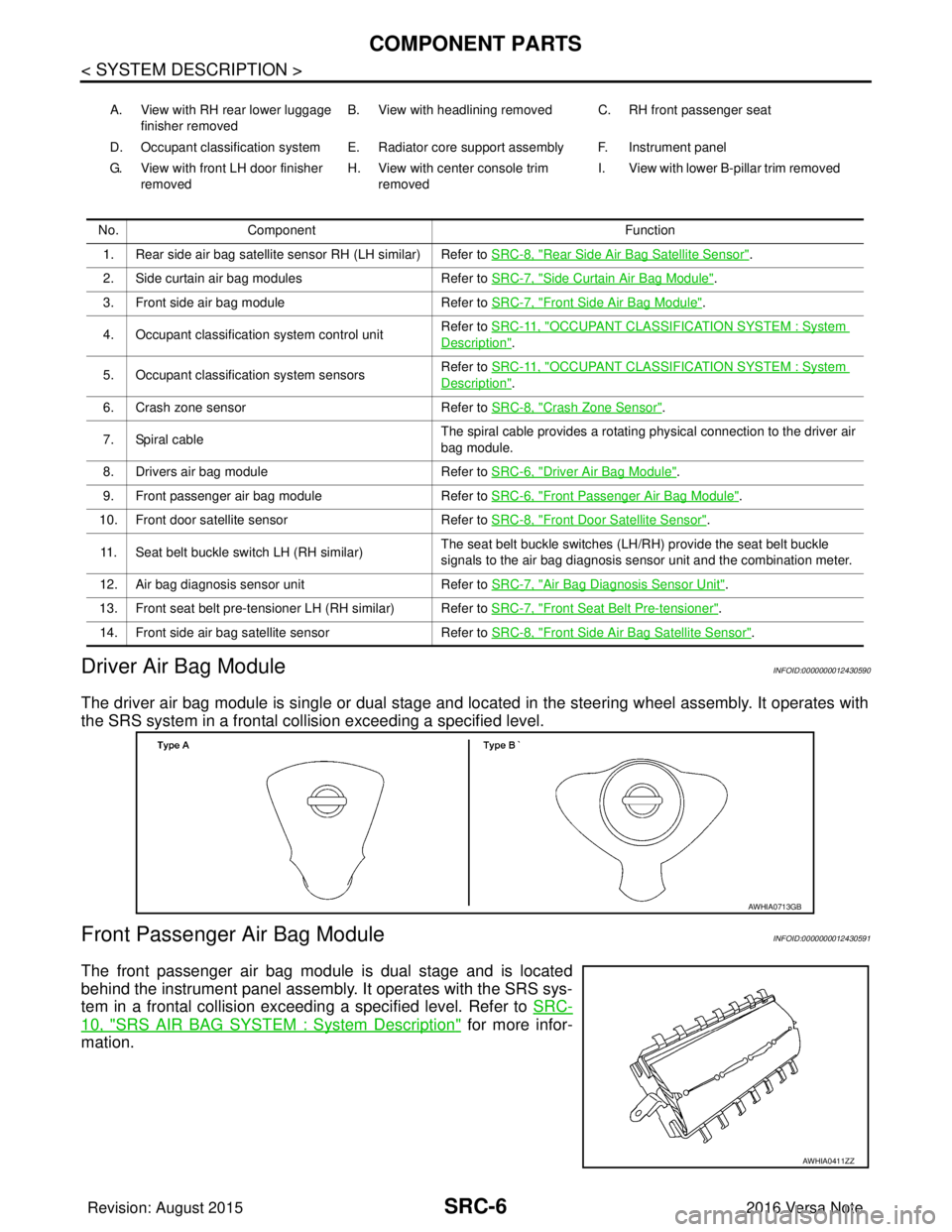

Driver Air Bag Module

INFOID:0000000012430590

The driver air bag module is single or dual stage and located in the steering wheel assembly. It operates with

the SRS system in a frontal collision exceeding a specified level.

Front Passenger Air Bag ModuleINFOID:0000000012430591

The front passenger air bag module is dual stage and is located

behind the instrument panel assembly. It operates with the SRS sys-

tem in a frontal collision exceeding a specified level. Refer to SRC-

10, "SRS AIR BAG SYSTEM : System Description" for more infor-

mation.

A. View with RH rear lower luggage

finisher removed B. View with headlining removed C. RH front passenger seat

D. Occupant classification system E. Radiator core support assembly F. Instrument panel

G. View with front LH door finisher removed H. View with center console trim

removed I. View with lower B-pillar trim removed

No. Component Function

1. Rear side air bag satellite sensor RH (LH similar) Refer to SRC-8, "

Rear Side Air Bag Satellite Sensor".

2. Side curtain air bag modules Refer to SRC-7, "

Side Curtain Air Bag Module".

3. Front side air bag module Refer to SRC-7, "

Front Side Air Bag Module".

4. Occupant classification system control unit Refer to SRC-11, "

OCCUPANT CLASSIFICATION SYSTEM : System

Description".

5. Occupant classification system sensors Refer to SRC-11, "

OCCUPANT CLASSIFICATION SYSTEM : System

Description".

6. Crash zone sensor Refer to SRC-8, "

Crash Zone Sensor".

7. Spiral cable The spiral cable provides a rotating physical connection to the driver air

bag module.

8. Drivers air bag module Refer to SRC-6, "

Driver Air Bag Module".

9. Front passenger air bag module Refer to SRC-6, "

Front Passenger Air Bag Module".

10. Front door satellite sensor Refer to SRC-8, "

Front Door Satellite Sensor".

11. Seat belt buckle switch LH (RH similar) The seat belt buckle switches (LH/RH) provide the seat belt buckle

signals to the air bag diagnosis sensor unit and the combination meter.

12. Air bag diagnosis sensor unit Refer to SRC-7, "

Air Bag Diagnosis Sensor Unit".

13. Front seat belt pre-tensioner LH (RH similar) Refer to SRC-7, "

Front Seat Belt Pre-tensioner".

14. Front side air bag satellite sensor Refer to SRC-8, "

Front Side Air Bag Satellite Sensor".

AWHIA0713GB

AWHIA0411ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3025 of 3641

SRC-8

< SYSTEM DESCRIPTION >

COMPONENT PARTS

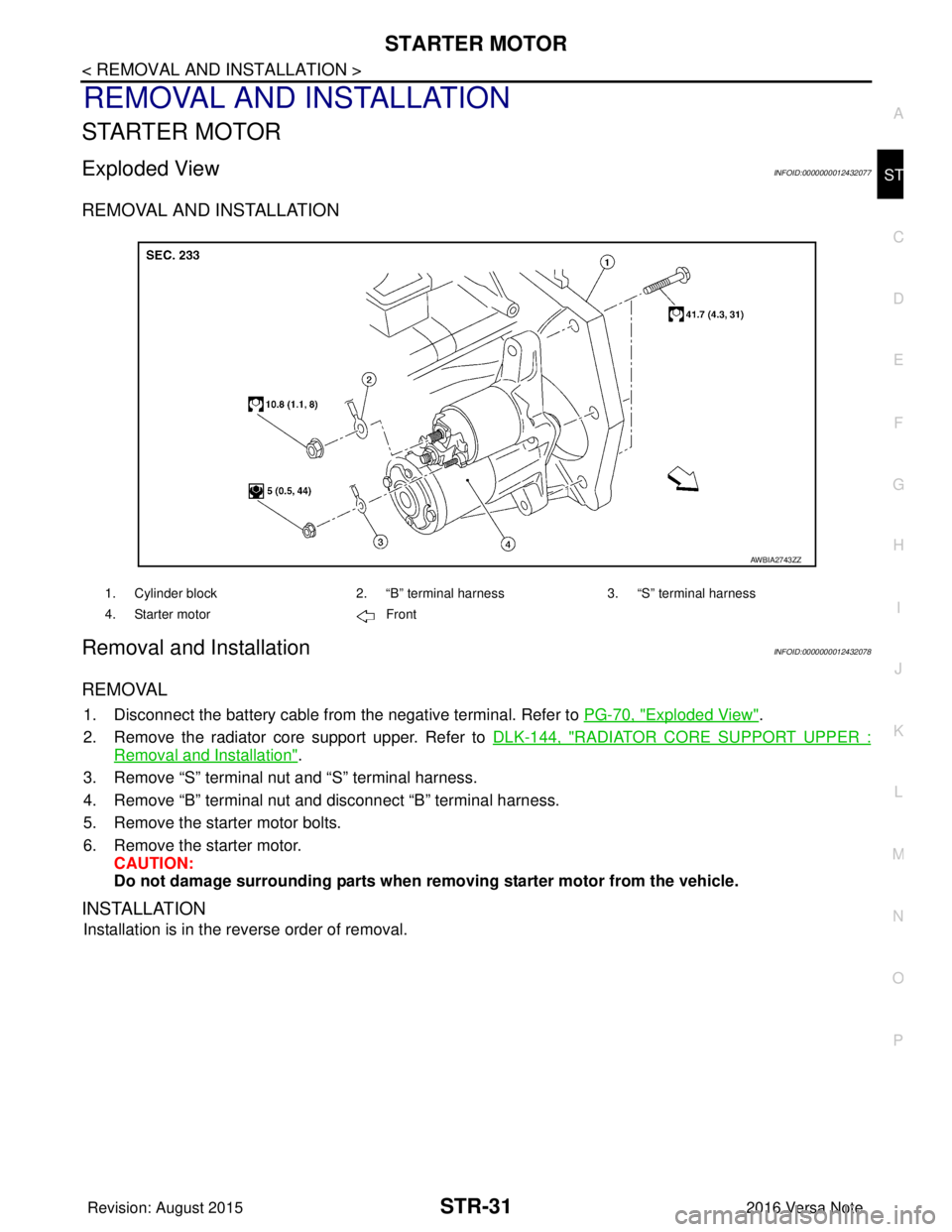

Crash Zone Sensor

INFOID:0000000012430596

The crash zone sensor is located in front of the radiator. The crash

zone sensor sends signals to the air bag diagnosis sensor unit dur-

ing a frontal collision. This sensor may be identified by a yellow con-

nector.

Front Side Air Bag Satellite SensorINFOID:0000000012430597

The front side air bag satellite sensors are located on the front center

pillar LH and RH next to the seat belt pretensioners. The front side

air bag satellite sensors send signals to the air bag diagnosis sensor

unit during a side collision. These sensors may be identified by yel-

low connectors.

Rear Side Air Bag Satellite SensorINFOID:0000000012430598

The rear side air bag satellite sensors are located behind the lug-

gage side lower finisher LH and RH. The rear side air bag satellite

sensors send signals to the air bag diagnosis sensor unit during a

side collision. These sensors may be identified by yellow connec-

tors.

Front Door Satellite SensorINFOID:0000000012430599

The front door satellite sensors are located in the driver and passen-

ger doors. The front door satellite sensors send signals to the air bag

diagnosis sensor unit during a side collision. These sensors may be

identified by yellow connectors.

SRS Component ConnectorsINFOID:0000000012430600

DIRECT CONNECT

The following SRS components use direct-connect style harness connectors.

AWHIA0537ZZ

AWHIA0544ZZ

AWHIA0543ZZ

AWHIA0546ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3183 of 3641

STARTER MOTORSTR-31

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

STR

NP

O

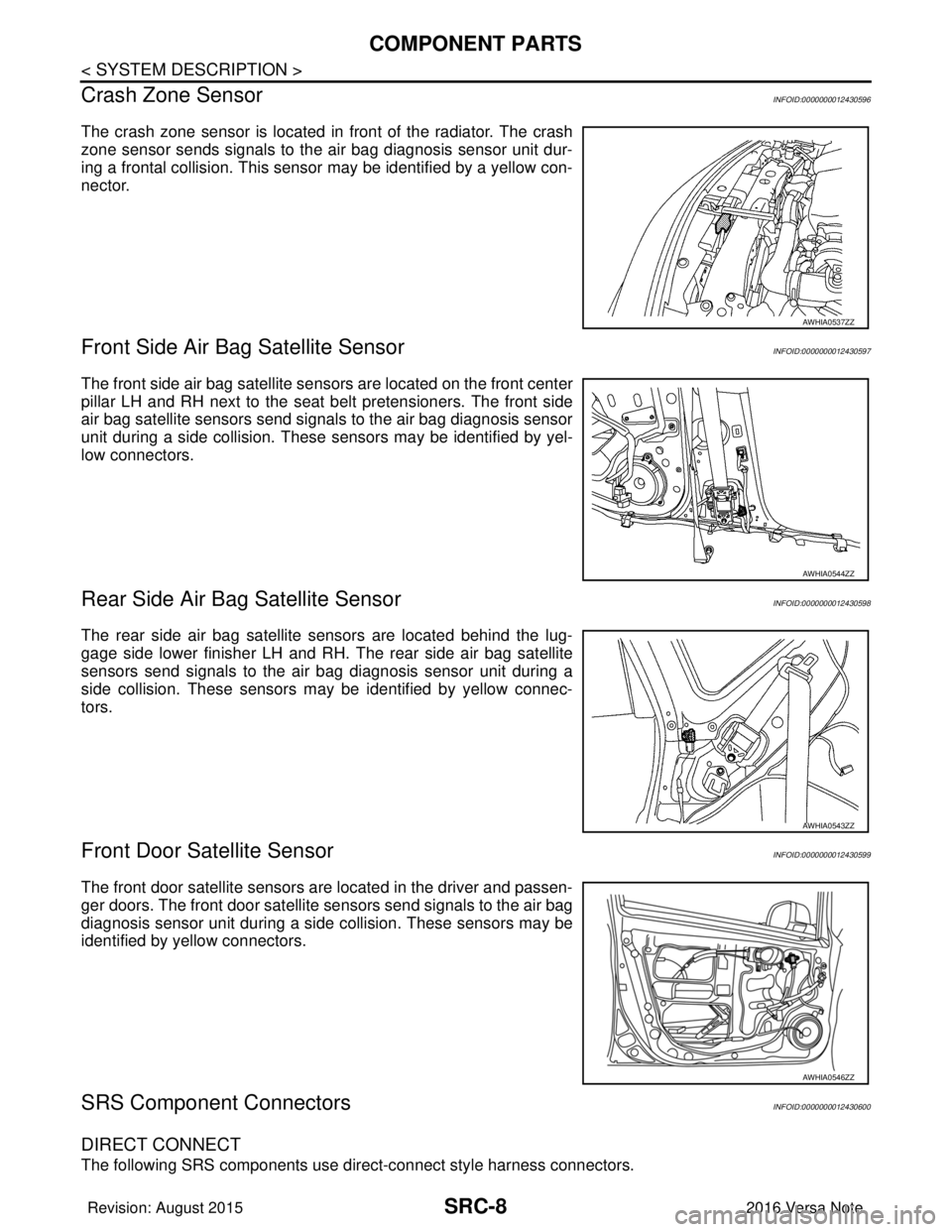

REMOVAL AND INSTALLATION

STARTER MOTOR

Exploded ViewINFOID:0000000012432077

REMOVAL AND INSTALLATION

Removal and InstallationINFOID:0000000012432078

REMOVAL

1. Disconnect the battery cable from

the negative terminal. Refer to PG-70, "Exploded View".

2. Remove the radiator core support upper. Refer to DLK-144, "

RADIATOR CORE SUPPORT UPPER :

Removal and Installation".

3. Remove “S” terminal nut and “S” terminal harness.

4. Remove “B” terminal nut and disconnect “B” terminal harness.

5. Remove the starter motor bolts.

6. Remove the starter motor. CAUTION:

Do not damage surrounding parts when re moving starter motor from the vehicle.

INSTALLATION

Installation is in the reverse order of removal.

1. Cylinder block2. “B” terminal harness3. “S” terminal harness

4. Starter motor Front

AWBIA2743ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3265 of 3641

![NISSAN NOTE 2016 Service Manual PDF TM-24

< UNIT REMOVAL AND INSTALLATION >[5MT: RS5F91R]

TRANSAXLE ASSEMBLY

UNIT REMOVAL AND INSTALLATION

TRANSAXLE ASSEMBLY

Exploded ViewINFOID:0000000012430961

Removal and InstallationINFOID:0000000012 NISSAN NOTE 2016 Service Manual PDF TM-24

< UNIT REMOVAL AND INSTALLATION >[5MT: RS5F91R]

TRANSAXLE ASSEMBLY

UNIT REMOVAL AND INSTALLATION

TRANSAXLE ASSEMBLY

Exploded ViewINFOID:0000000012430961

Removal and InstallationINFOID:0000000012](/img/5/57363/w960_57363-3264.png)

TM-24

< UNIT REMOVAL AND INSTALLATION >[5MT: RS5F91R]

TRANSAXLE ASSEMBLY

UNIT REMOVAL AND INSTALLATION

TRANSAXLE ASSEMBLY

Exploded ViewINFOID:0000000012430961

Removal and InstallationINFOID:0000000012430962

WARNING:

Do not remove the radiator cap when the engine is

hot. Serious burns could occur from high pressure

coolant escaping from the radiator. Wrap a thick clot h around the cap. Slowly turn it a quarter turn to

allow built-up pressure to escape. Carefully remove the cap by turning it all the way.

CAUTION:

Do not reuse CSC (Concentric Slave Cylinder). The CSC slides back to the orig inal position every time

the transaxle assembly is removed. This action may allow dust or contaminants to gather on the slid-

ing parts and damage a seal of CSC causing clutch fluid leakage.

NOTE:

When removing components such as hoses, tubes/lines, etc. , cap or plug openings to prevent fluid from spill-

ing.

REMOVAL

1. Remove the engine and transaxle assembly. Refer to EM-87, "Removal and Installation".

2. Disconnect the reverse lamp switch harness connector.

3. Remove the bolts that fasten the transaxle assembly and engine assembly.

4. Remove transaxle assembly from the engine assembly.

5. Remove engine mounting bracket (LH). Refer to EM-86, "

Exploded View".

6. Remove CSC (Concentric Slave Cylinder). Refer to CL-17, "

Removal and Installation".

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Secure transaxle assembly to a suitable jack.

• The transaxle assembly must not interfere with the wire harnesses and clutch tube.

• When installing transaxle assembly, do not bring input shaft into contact with clutch cover.

• Bolt hole is not threaded on new clutch housing. Self-tapping bolt is used to attach lock plate to

clutch housing.

1. Transaxle assembly

: Refer to "INSTALLATION" in TM-24, "

Removal and Installation" for the locations and tightening torque.

JPDIC0478ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3315 of 3641

![NISSAN NOTE 2016 Service Manual PDF TM-74

< SYSTEM DESCRIPTION >[CVT: RE0F11A]

STRUCTURE AND OPERATION

FLUID COOLER & FL

UID WARMER SYSTEM

FLUID COOLER & FLUID WARMER SYSTEM : System DescriptionINFOID:0000000012431015

CVT FLUID COOLER NISSAN NOTE 2016 Service Manual PDF TM-74

< SYSTEM DESCRIPTION >[CVT: RE0F11A]

STRUCTURE AND OPERATION

FLUID COOLER & FL

UID WARMER SYSTEM

FLUID COOLER & FLUID WARMER SYSTEM : System DescriptionINFOID:0000000012431015

CVT FLUID COOLER](/img/5/57363/w960_57363-3314.png)

TM-74

< SYSTEM DESCRIPTION >[CVT: RE0F11A]

STRUCTURE AND OPERATION

FLUID COOLER & FL

UID WARMER SYSTEM

FLUID COOLER & FLUID WARMER SYSTEM : System DescriptionINFOID:0000000012431015

CVT FLUID COOLER SCHEMATIC

COMPONENT DESCRIPTION

CVT Oil Warmer

• The CVT oil warmer (1) is installed on the front part of transaxle

assembly.

• When engine is started while engine and CVT are cold, engine coolant temperature rises more quickly than CVT fluid tempera-

ture. CVT oil warmer is provided with two circuits for CVT and

engine coolant respectively so that warmed engine coolant warms

CVT quickly. This helps shorten CVT warming up time, improving

fuel economy.

• A cooling effect is obtained when CVT fluid temperature is high.

CVT Fluid Cooler (Water-cooling)

• The CVT fluid cooler (water-cooling) is installed in the radiator side tank (right side).

• CVT fluid is cooled by engine coolant.

SHIFT LOCK SYSTEM

Manual valve Distributes the clutch and brake operation pressures (pilot pressure) corresponding to

each shift position.

High clutch/reverse brake switching valve Switches the circuit for the high clutch and the reverse brake.

Torque converter clutch control valve It is operated with the torque converter clutch solenoid valve and it adjusts the tighten-

ing pressure and non-tightening pressure of the torque converter clutch piston of the

torque converter.

Primary pressure control valve It is operated with the primary pressure solenoid valve and adjusts the feed pressure to

the primary pulley.

Primary pressure solenoid valve TM-65, "

CVT CONTROL SYSTEM : Primary Pressure Solenoid Valve"

Low brake solenoid valve TM-65, "CVT CONTROL SYSTEM : Low Brake Solenoid Valve"

High clutch & reverse brake solenoid valveTM-66, "CVT CONTROL SYSTEM : High Clutch & Reverse Brake Solenoid Valve"

Torque converter clutch solenoid valve TM-66, "CVT CONTROL SYSTEM : Torque Converter Clutch Solenoid Valve"

Line pressure solenoid valve TM-66, "CVT CONTROL SYSTEM : Line Pressure Solenoid Valve"

Part name Function

JSDIA4074GB

JSDIA2586ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3492 of 3641

![NISSAN NOTE 2016 Service Manual PDF WATER HOSETM-251

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

WATER HOSE

Exploded ViewINFOID:0000000012431207

Removal and InstallationINFOID:0000000012431208

REMOVAL

WAR NISSAN NOTE 2016 Service Manual PDF WATER HOSETM-251

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

WATER HOSE

Exploded ViewINFOID:0000000012431207

Removal and InstallationINFOID:0000000012431208

REMOVAL

WAR](/img/5/57363/w960_57363-3491.png)

WATER HOSETM-251

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

WATER HOSE

Exploded ViewINFOID:0000000012431207

Removal and InstallationINFOID:0000000012431208

REMOVAL

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could occur from high-pressure

engine coolant escaping from the radiator. Wrap a thick cloth around the cap. Slowly push down and

turn it a quarter turn to allow built-up pressure to escape. Carefully remove the cap by pushing it down

and turning it all the way.

CAUTION:

Perform these steps after the engine cool ant temperature has cooled sufficiently.

NOTE:

When removing components such as hoses, tubes/lines, etc. , cap or plug openings to prevent fluid from spill-

ing.

1. Remove the hose clamp and pull out the water hose A.

2. Remove the hose clamp and pull out the water hose B.

3. Remove the hose clamp and pull out the water hose C.

4. Pull out the heater hose and remove the water bypass pipe.

5. Remove the heater thermostat assembly.

1. Hose clamp 2. Water hose A3. Clip

4. Bracket A 5. Bracket B6. CVT oil warner

7. Water hose B 8. Water bypass pipe9. Hose clamp

10. Water hose C 11. Water outlet

A. To heater core : Always replace after every disassembly.

: N·m (kg-m, in-lb)

JSDIA4111GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3497 of 3641

![NISSAN NOTE 2016 Service Manual PDF TM-256

< REMOVAL AND INSTALLATION >[CVT: RE0F11A]

CVT OIL WARMER

CVT OIL WARMER

Exploded ViewINFOID:0000000012431217

Removal and InstallationINFOID:0000000012431218

REMOVAL

WARNING:

Never remove the r NISSAN NOTE 2016 Service Manual PDF TM-256

< REMOVAL AND INSTALLATION >[CVT: RE0F11A]

CVT OIL WARMER

CVT OIL WARMER

Exploded ViewINFOID:0000000012431217

Removal and InstallationINFOID:0000000012431218

REMOVAL

WARNING:

Never remove the r](/img/5/57363/w960_57363-3496.png)

TM-256

< REMOVAL AND INSTALLATION >[CVT: RE0F11A]

CVT OIL WARMER

CVT OIL WARMER

Exploded ViewINFOID:0000000012431217

Removal and InstallationINFOID:0000000012431218

REMOVAL

WARNING:

Never remove the radiator cap when the engine is hot. Serious burns coul

d occur from high pressure

engine coolant escaping from the radiator. Wrap a thick cloth ar ound the cap. Slowly turn it a quarter

turn to allow built-up pressure to escape. Carefully remove the cap by turning it all the way.

CAUTION:

Perform these steps after the coolant temperature has cooled sufficiently.

1. Pull out water hose from CVT oil warmer. Refer to TM-251, "

Removal and Installation".

2. Pull out fluid cooler hose from CVT oil warmer. Refer to TM-254, "

Removal and Installation".

3. Remove CVT oil warmer.

4. Remove O-ring from CVT oil warmer.

INSTALLATION

Note the followings and install in the reverse order of removal.

CAUTION:

• Never reuse O-ring.

• Apply CVT fluid to O-ring.

InspectionINFOID:0000000012431219

INSPECTION AFTER INSTALLATION

Start the engine and check visually that ther e is no leakage of CVT fluid and engine coolant.

ADJUSTMENT AFTER INSTALLATION

Adjust CVT fluid level. Refer to TM-229, "Adjustment".

1. Transaxle assembly 2. CVT oil warmer 3. O-ring

: Always replace after every disassembly.

: N·m (kg-m, in-lb)

: Apply CVT fluid

JSDIA5447GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3500 of 3641

![NISSAN NOTE 2016 Service Manual PDF TRANSMISSION ASSEMBLYTM-259

< UNIT REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

UNIT REMOVAL AND INSTALLATION

TRANSMISSION ASSEMBLY

Exploded ViewINFOID:0000000012431223

Re NISSAN NOTE 2016 Service Manual PDF TRANSMISSION ASSEMBLYTM-259

< UNIT REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

UNIT REMOVAL AND INSTALLATION

TRANSMISSION ASSEMBLY

Exploded ViewINFOID:0000000012431223

Re](/img/5/57363/w960_57363-3499.png)

TRANSMISSION ASSEMBLYTM-259

< UNIT REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

UNIT REMOVAL AND INSTALLATION

TRANSMISSION ASSEMBLY

Exploded ViewINFOID:0000000012431223

Removal and InstallationINFOID:0000000012431224

WARNING:

Do not remove the radiator cap when the engine is hot. Serious burns could occur from high-pressure

engine coolant escaping from the radiator. Wrap a thick cloth around the cap. Slowly push down and

turn it a quarter turn to allow built-up pressure to escape. Carefully remove the cap by pushing it down

and turning it all the way.

CAUTION:

• Perform these steps after the coolant temperature has cooled sufficiently.

• When replacing the transaxle, perform "ADDI TIONAL SERVICE WHEN REPLACING TRANSAXLE

ASSEMBLY". Refer to TM-127, "

Description".

NOTE:

When removing components such as hoses, tubes/line, etc. , cap or plug openings to prevent fluid from spill-

ing.

REMOVAL

1. Remove the engine and transaxle assembly. Refer to EM-87, "Removal and Installation".

2. Disconnect the harness connectors and harnesses. • For CVT unit harness connector.

• Transmission position switch harness connector

1. Transaxle assembly

A : For the tightening torque, refer to TM-259, "

Removal and Installation".

JSDIA1890ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com