sensor NISSAN PATROL 1998 Y61 / 5.G Brake System User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 75, PDF Size: 3.89 MB

Page 54 of 75

![NISSAN PATROL 1998 Y61 / 5.G Brake System User Guide SELF-DIAGNOSTIC RESULTS MODE

Diagnostic item Diagnostic item is detected when ...Diagnostic

procedure

FR RH SENSOR .1

[OPEN] +

Circuit for front right wheel sensor is open.

(An abnormally high input v NISSAN PATROL 1998 Y61 / 5.G Brake System User Guide SELF-DIAGNOSTIC RESULTS MODE

Diagnostic item Diagnostic item is detected when ...Diagnostic

procedure

FR RH SENSOR .1

[OPEN] +

Circuit for front right wheel sensor is open.

(An abnormally high input v](/img/5/614/w960_614-53.png)

SELF-DIAGNOSTIC RESULTS MODE

Diagnostic item Diagnostic item is detected when ...Diagnostic

procedure

FR RH SENSOR .1

[OPEN] +

Circuit for front right wheel sensor is open.

(An abnormally high input voltage is entered.) 1

FR LH SENSOR .1

[OPEN] +

Circuit for front left wheel sensor is open.

(An abnormally high input voltage is entered.) 1

RR RH SENSOR .1

[OPEN] +

Circuit for rear right sensor is open.

(An abnormally high input voltage is entered.) 1

RR LH SENSOR .1

[OPEN] +

Circuit for rear left sensor is open.

(An abnormally high input voltage is entered.) 1

FR RH SENSOR .1

[SHORT] +

Circuit for front right wheel sensor is shorted.

(An abnormally low input voltage is entered.) 1

FR LH SENSOR .1

[SHORT] +

Circuit for front left wheel sensor is shorted.

(An abnormally low input voltage is entered.) 1

RR RH SENSOR .1

[SHORT] +

Circuit for rear right sensor is shorted.

(An abnormally low input voltage is entered.) 1

RR LH SENSOR .1

[SHORT] +

Circuit for rear left sensor is shorted.

(An abnormally low input voltage is entered.) 1

ABS SENSOR .1

[ABNORMAL SIGNAL] +

Teeth damage on sensor rotor or improper installation of wheel sensor.

(Abnormal wheel sensor signal is entered.) 1

FR RH IN ABS SOL

[OPEN] +

Circuit for front right inlet solenoid valve is open.

(An abnormally low output voltage is entered.) 2

FR LH IN ABS SOL

[OPEN] +

Circuit for front left inlet solenoid valve is open.

(An abnormally low output voltage is entered.) 2

RR IN ABS SOL

[OPEN] +

Circuit for rear inlet solenoid valve is open.

(An abnormally low output voltage is entered.) 2

FR RH IN ABS SOL

[SHORT] +

Circuit for front right inlet solenoid valve is shorted.

(An abnormally high output voltage is entered.) 2

FR LH IN ABS SOL

[SHORT] +

Circuit for front left inlet solenoid valve is shorted.

(An abnormally high output voltage is entered.) 2

RR IN ABS SOL

[SHORT] +

Circuit for rear inlet solenoid valve is shorted.

(An abnormally high output voltage is entered.) 2

FR RH OUT ABS SOL

[OPEN] +

Circuit for front right outlet solenoid valve is open.

(An abnormally low output voltage is entered.) 2

FR LH OUT ABS SOL

[OPEN] +

Circuit for front left outlet solenoid valve is open.

(An abnormally low output voltage is entered.) 2

RR OUT ABS SOL

[OPEN] +

Circuit for rear outlet solenoid valve is open.

(An abnormally low output voltage is entered.) 2

FR RH OUT ABS SOL

[SHORT] +

Circuit for front right outlet solenoid valve is shorted.

(An abnormally high output voltage is entered.) 2

FR LH OUT ABS SOL

[SHORT] +

Circuit for front left outlet solenoid valve is shorted.

(An abnormally high output voltage is entered.) 2

RR OUT ABS SOL

[SHORT] +

Circuit for rear outlet solenoid valve is shorted.

(An abnormally high output voltage is entered.) 2

ABS ACTUATOR RELAY

[ABNORMAL] +

Actuator solenoid valve relay is ON, even if control unit sends off signal.

+ Actuator solenoid valve relay is OFF, even if control unit sends on signal. 2

ABS MOTOR RELAY

[ABNORMAL] +

Circuit for ABS motor relay is open or shorted.

+ Circuit for actuator motor is open or shorted.

+ Actuator motor relay is stuck. 3

BATTERY VOLT

[VB-LOW] +

Power source voltage supplied to ABS control unit is abnormally low. 4

CONTROL UNIT +Function of calculation in ABS control unit has failed. 6

G-SENSOR

[ABNORMAL] +

G sensor circuit is open or shorted. 5

. 1: If one or more wheels spin on a rough or slippery road for 40 seconds or more, the ABS warning lamp will illuminate. This does

not indicate a malfunction. Only in the case of the short-circuit (Code Nos. 26, 22, 32 and 36), after repair the ABS warning

lamp also illuminates when the ignition switch is turned ``ON''. In this case, drive the vehicle at speeds greater than 30 km/h (19

MPH) for approximately 1 minute as speci®ed in ``SELF-DIAGNOSIS PROCEDURE'', BR-47. Check to ensure that the ABS

warning lamp goes out while the vehicle is being driven.

TROUBLE DIAGNOSES

CONSULT Inspection Procedure (Cont'd)

BR-52

Page 57 of 75

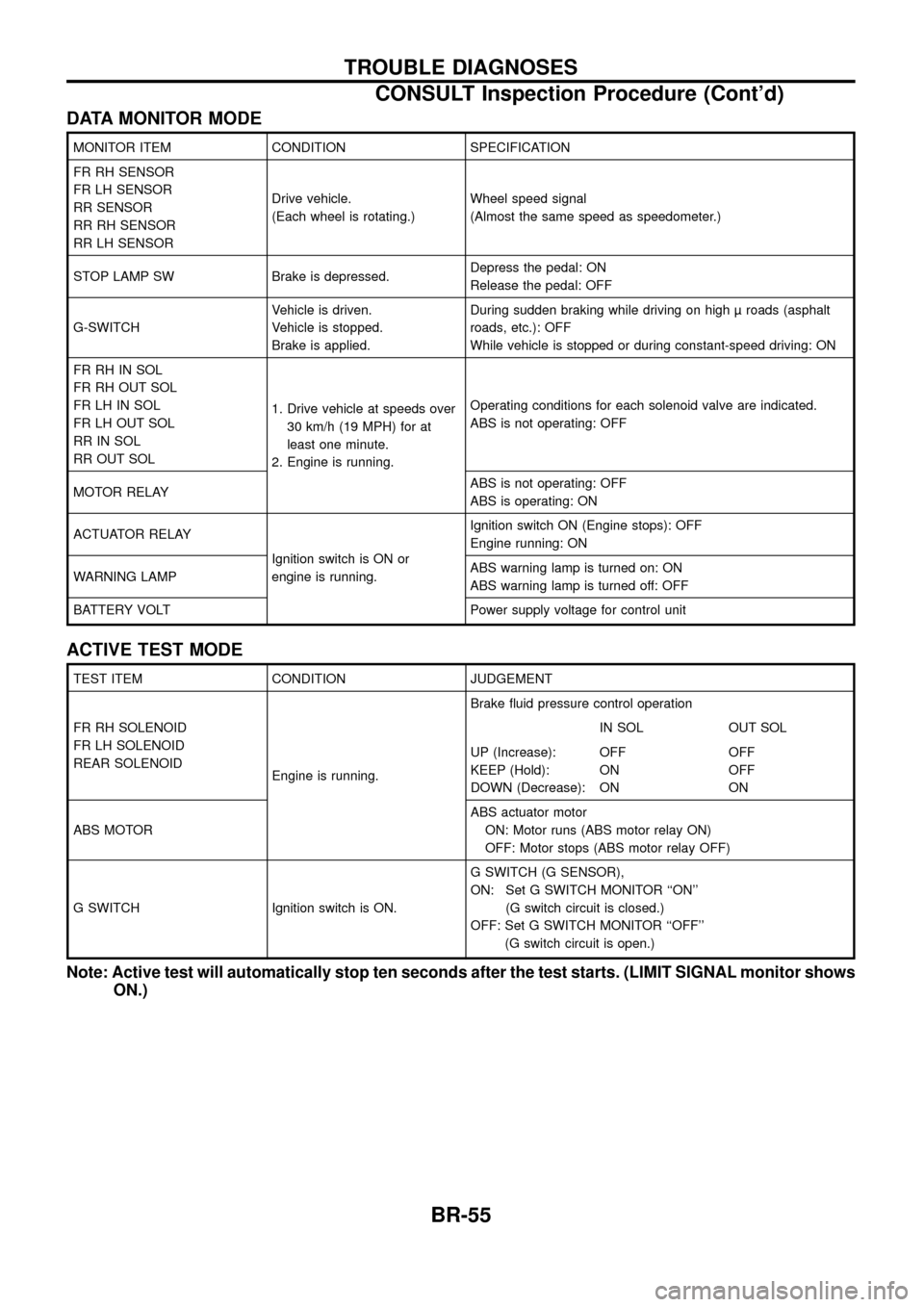

DATA MONITOR MODE

MONITOR ITEM CONDITION SPECIFICATION

FR RH SENSOR

FR LH SENSOR

RR SENSOR

RR RH SENSOR

RR LH SENSORDrive vehicle.

(Each wheel is rotating.)

Wheel speed signal

(Almost the same speed as speedometer.)

STOP LAMP SW Brake is depressed. Depress the pedal: ON

Release the pedal: OFF

G-SWITCH Vehicle is driven.

Vehicle is stopped.

Brake is applied.During sudden braking while driving on high roads (asphalt

roads, etc.): OFF

While vehicle is stopped or during constant-speed driving: ON

FR RH IN SOL

FR RH OUT SOL

FR LH IN SOL

FR LH OUT SOL

RR IN SOL

RR OUT SOL 1. Drive vehicle at speeds over

30 km/h (19 MPH) for at

least one minute.

2. Engine is running. Operating conditions for each solenoid valve are indicated.

ABS is not operating: OFF

MOTOR RELAY ABS is not operating: OFF

ABS is operating: ON

ACTUATOR RELAY Ignition switch is ON or

engine is running.Ignition switch ON (Engine stops): OFF

Engine running: ON

WARNING LAMP ABS warning lamp is turned on: ON

ABS warning lamp is turned off: OFF

BATTERY VOLT Power supply voltage for control unit

ACTIVE TEST MODE

TEST ITEM CONDITION JUDGEMENT

FR RH SOLENOID

FR LH SOLENOID

REAR SOLENOID Engine is running.Brake ¯uid pressure control operation

IN SOL OUT SOL

UP (Increase):

KEEP (Hold):

DOWN (Decrease): OFF

ON

ONOFF

OFF

ON

ABS MOTOR ABS actuator motor

ON: Motor runs (ABS motor relay ON)

OFF: Motor stops (ABS motor relay OFF)

G SWITCH Ignition switch is ON. G SWITCH (G SENSOR),

ON: Set G SWITCH MONITOR ``ON''

(G switch circuit is closed.)

OFF: Set G SWITCH MONITOR ``OFF'' (G switch circuit is open.)

Note: Active test will automatically stop ten seconds after the test starts. (LIMIT SIGNAL monitor shows ON.)

TROUBLE DIAGNOSES

CONSULT Inspection Procedure (Cont'd)

BR-55

Page 59 of 75

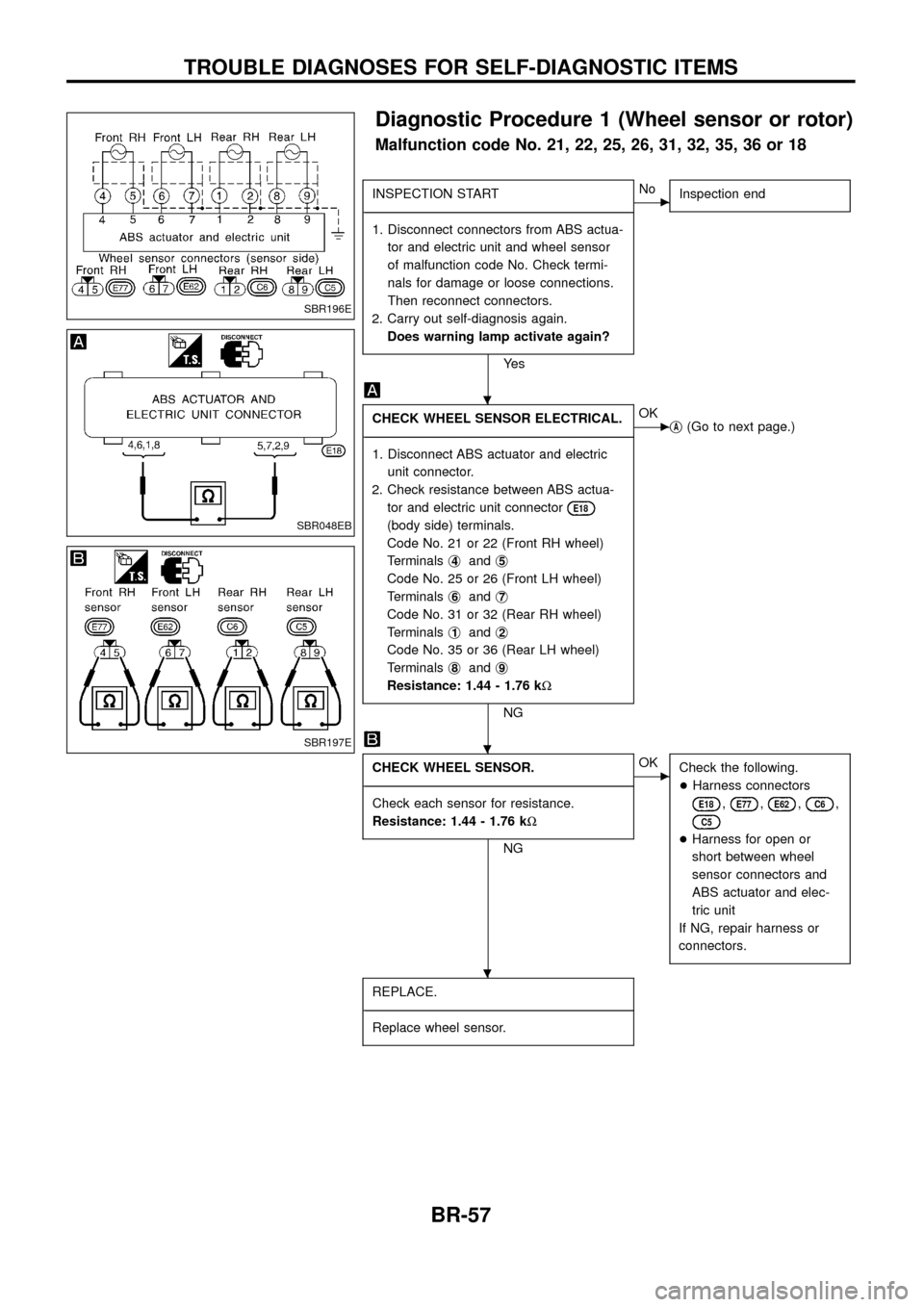

Diagnostic Procedure 1 (Wheel sensor or rotor)

Malfunction code No. 21, 22, 25, 26, 31, 32, 35, 36 or 18

INSPECTION START

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Disconnect connectors from ABS actua- tor and electric unit and wheel sensor

of malfunction code No. Check termi-

nals for damage or loose connections.

Then reconnect connectors.

2. Carry out self-diagnosis again. Does warning lamp activate again?

Ye s

cNo Inspection end

CHECK WHEEL SENSOR ELECTRICAL.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Disconnect ABS actuator and electric unit connector.

2. Check resistance between ABS actua- tor and electric unit connector

E18

(body side) terminals.

Code No. 21 or 22 (Front RH wheel)

Terminals j

4andj5

Code No. 25 or 26 (Front LH wheel)

Terminals j

6andj7

Code No. 31 or 32 (Rear RH wheel)

Terminals j

1andj2

Code No. 35 or 36 (Rear LH wheel)

Terminals j

8andj9

Resistance: 1.44 - 1.76 k

W

NG

cOK

jA(Go to next page.)

CHECK WHEEL SENSOR.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check each sensor for resistance.

Resistance: 1.44 - 1.76 k W

NG

cOK

Check the following.

+Harness connectors

E18,E77,E62,C6,

C5

+Harness for open or

short between wheel

sensor connectors and

ABS actuator and elec-

tric unit

If NG, repair harness or

connectors.

REPLACE.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Replace wheel sensor.

SBR196E

SBR048EB

SBR197E

.

.

.

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMS

BR-57

Page 60 of 75

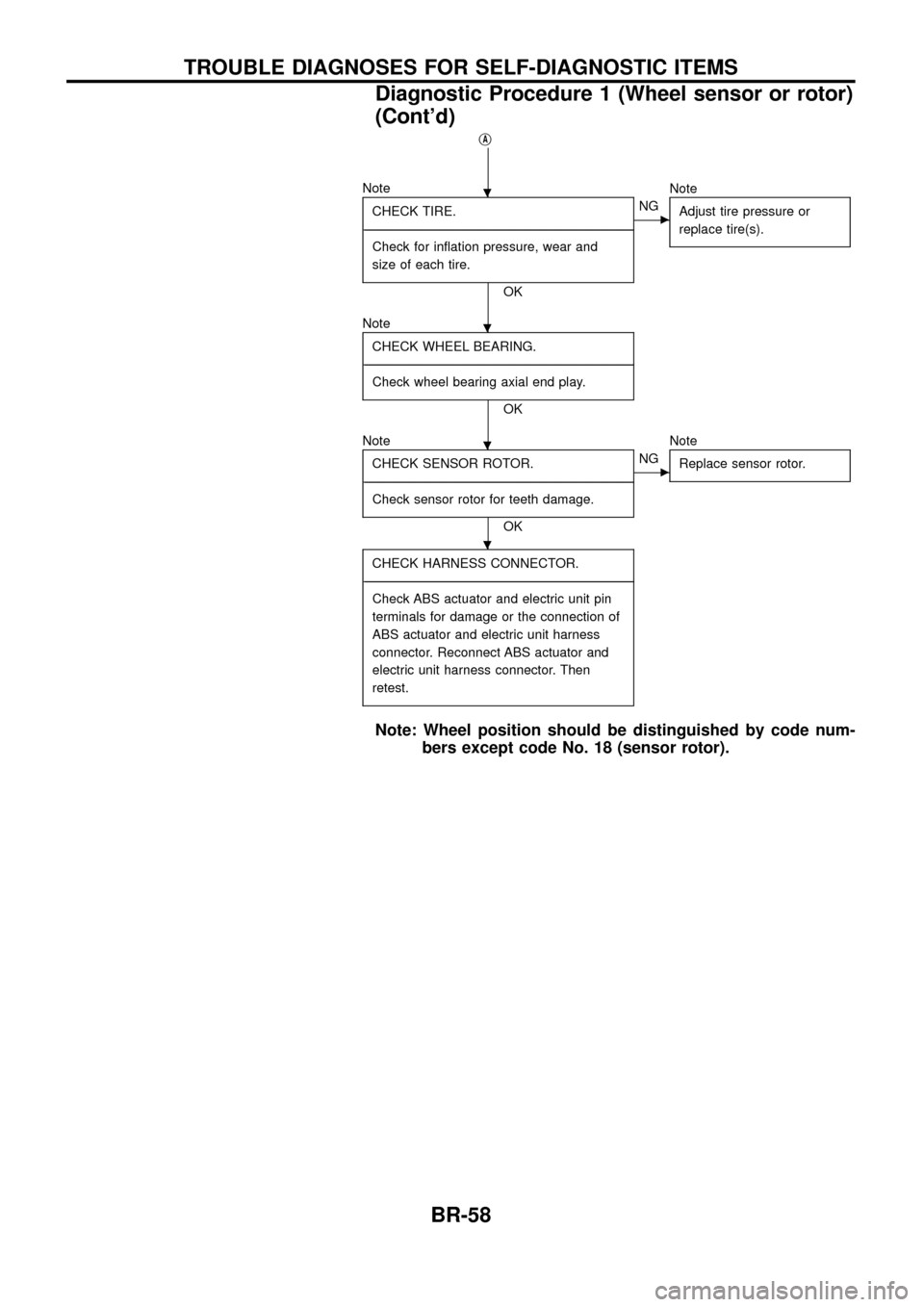

jA

NoteCHECK TIRE.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check for in¯ation pressure, wear and

size of each tire.

OK

cNG Note

Adjust tire pressure or

replace tire(s).

NoteCHECK WHEEL BEARING.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check wheel bearing axial end play.

OK

Note CHECK SENSOR ROTOR.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check sensor rotor for teeth damage.

OK

cNG Note

Replace sensor rotor.

CHECK HARNESS CONNECTOR.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check ABS actuator and electric unit pin

terminals for damage or the connection of

ABS actuator and electric unit harness

connector. Reconnect ABS actuator and

electric unit harness connector. Then

retest.

Note: Wheel position should be distinguished by code num- bers except code No. 18 (sensor rotor).

.

.

.

.

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMS

Diagnostic Procedure 1 (Wheel sensor or rotor)

(Cont'd)

BR-58

Page 66 of 75

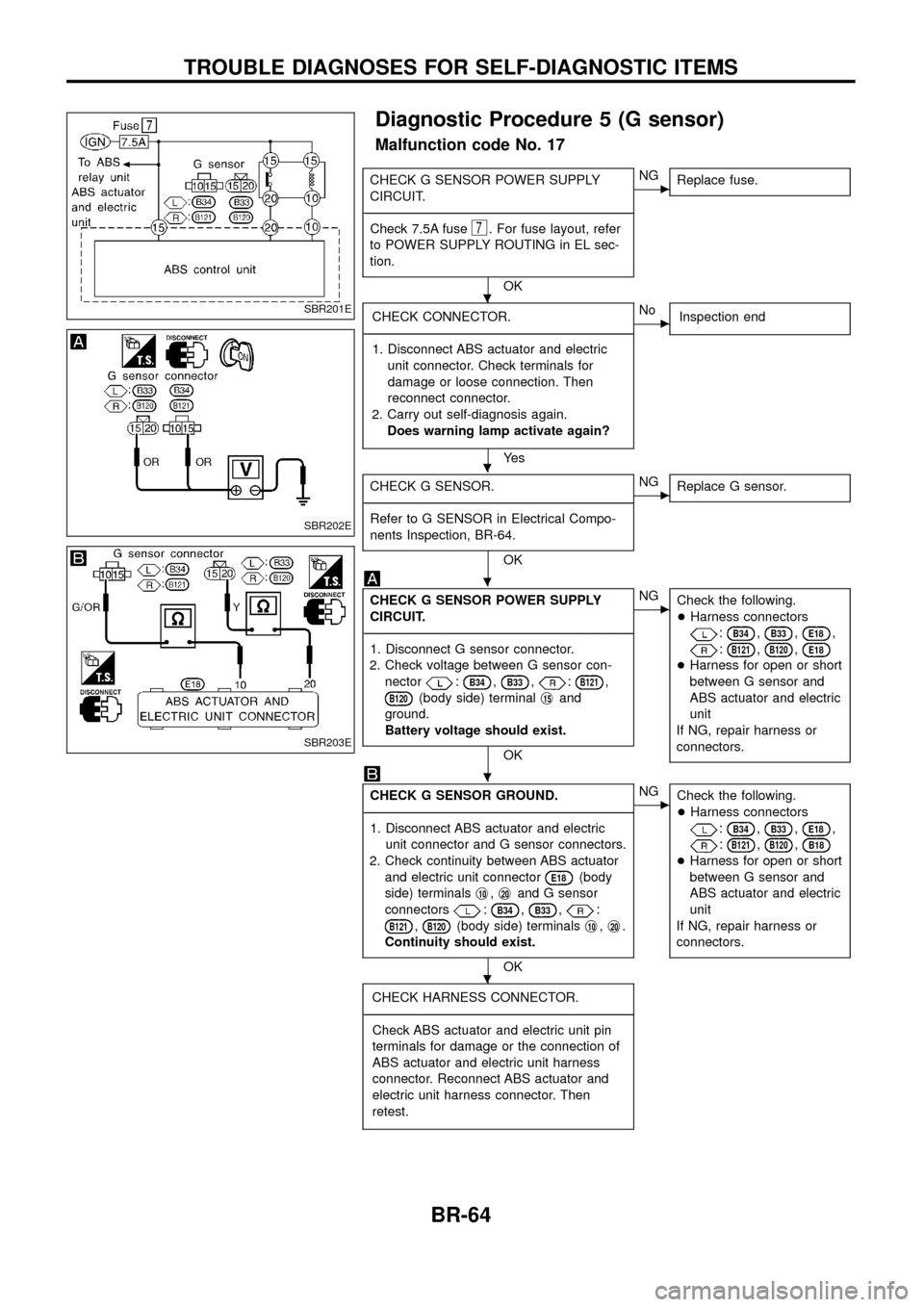

Diagnostic Procedure 5 (G sensor)

Malfunction code No. 17

CHECK G SENSOR POWER SUPPLY

CIRCUIT.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check 7.5A fuse

7. For fuse layout, refer

to POWER SUPPLY ROUTING in EL sec-

tion.

OK

cNG Replace fuse.

CHECK CONNECTOR.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Disconnect ABS actuator and electric unit connector. Check terminals for

damage or loose connection. Then

reconnect connector.

2. Carry out self-diagnosis again. Does warning lamp activate again?

Ye s

cNo Inspection end

CHECK G SENSOR.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Refer to G SENSOR in Electrical Compo-

nents Inspection, BR-64.

OK

cNG Replace G sensor.

CHECK G SENSOR POWER SUPPLY

CIRCUIT.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Disconnect G sensor connector.

2. Check voltage between G sensor con- nector

:B34,B33,:B121,

B120(body side) terminal j15and

ground.

Battery voltage should exist.

OK

cNG Check the following.

+Harness connectors

:B34,B33,E18,

:B121,B120,E18

+Harness for open or short

between G sensor and

ABS actuator and electric

unit

If NG, repair harness or

connectors.

CHECK G SENSOR GROUND.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Disconnect ABS actuator and electric unit connector and G sensor connectors.

2. Check continuity between ABS actuator and electric unit connector

E18(body

side) terminals j

10,j20and G sensor

connectors

:B34,B33,:

B121,B120(body side) terminals j10,j20.

Continuity should exist.

OK

cNG Check the following.

+Harness connectors

:B34,B33,E18,

:B121,B120,B18

+Harness for open or short

between G sensor and

ABS actuator and electric

unit

If NG, repair harness or

connectors.

CHECK HARNESS CONNECTOR.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check ABS actuator and electric unit pin

terminals for damage or the connection of

ABS actuator and electric unit harness

connector. Reconnect ABS actuator and

electric unit harness connector. Then

retest.

SBR201E

SBR202E

SBR203E

.

.

.

.

.

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMS

BR-64

Page 67 of 75

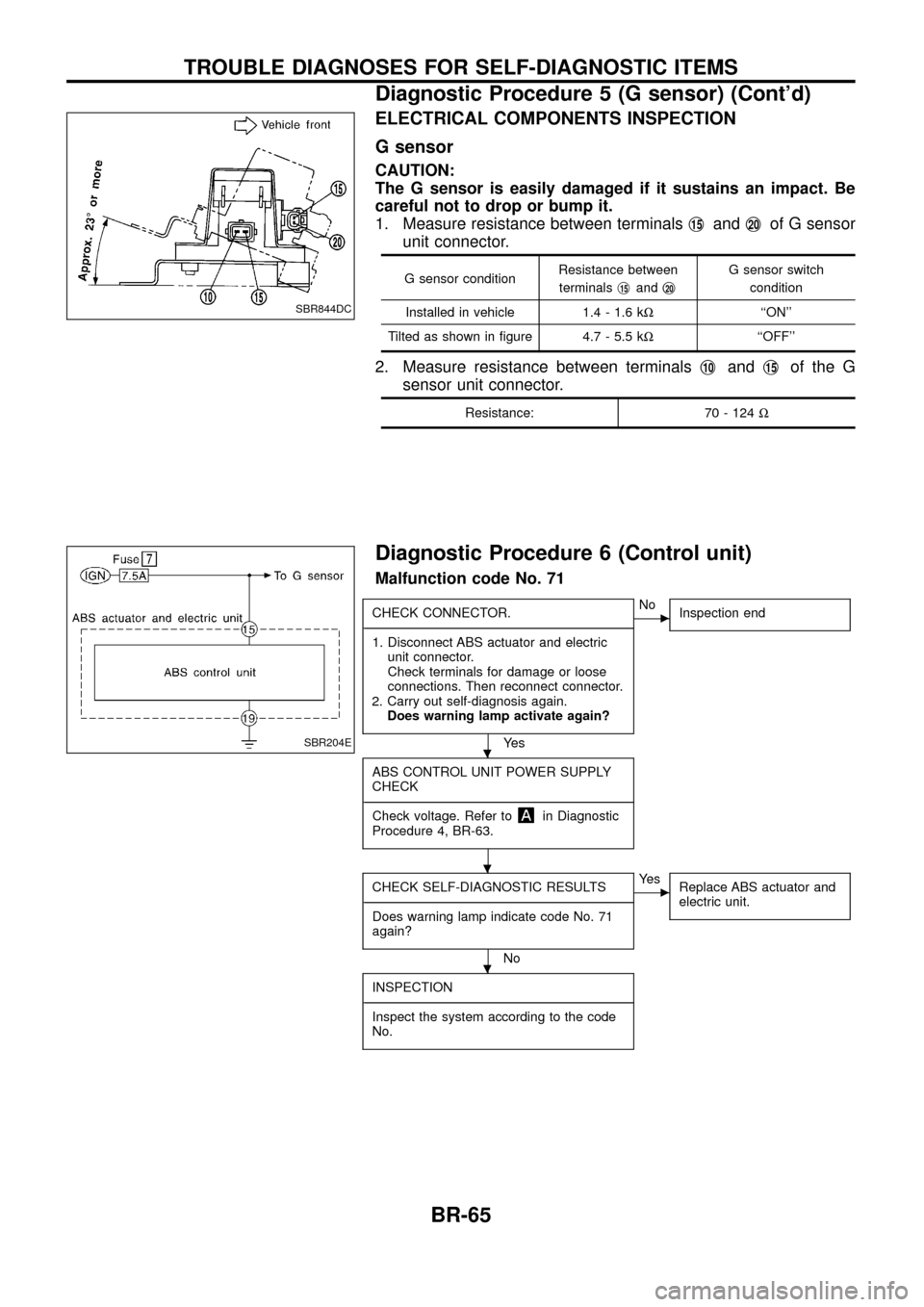

ELECTRICAL COMPONENTS INSPECTION

G sensor

CAUTION:

The G sensor is easily damaged if it sustains an impact. Be

careful not to drop or bump it.

1. Measure resistance between terminalsj

15andj20of G sensor

unit connector.

G sensor condition Resistance between

terminals j15andj20

G sensor switch

condition

Installed in vehicle 1.4 - 1.6 k W``ON''

Tilted as shown in ®gure 4.7 - 5.5 k W``OFF''

2. Measure resistance between terminals j10andj15of the G

sensor unit connector.

Resistance: 70 - 124 W

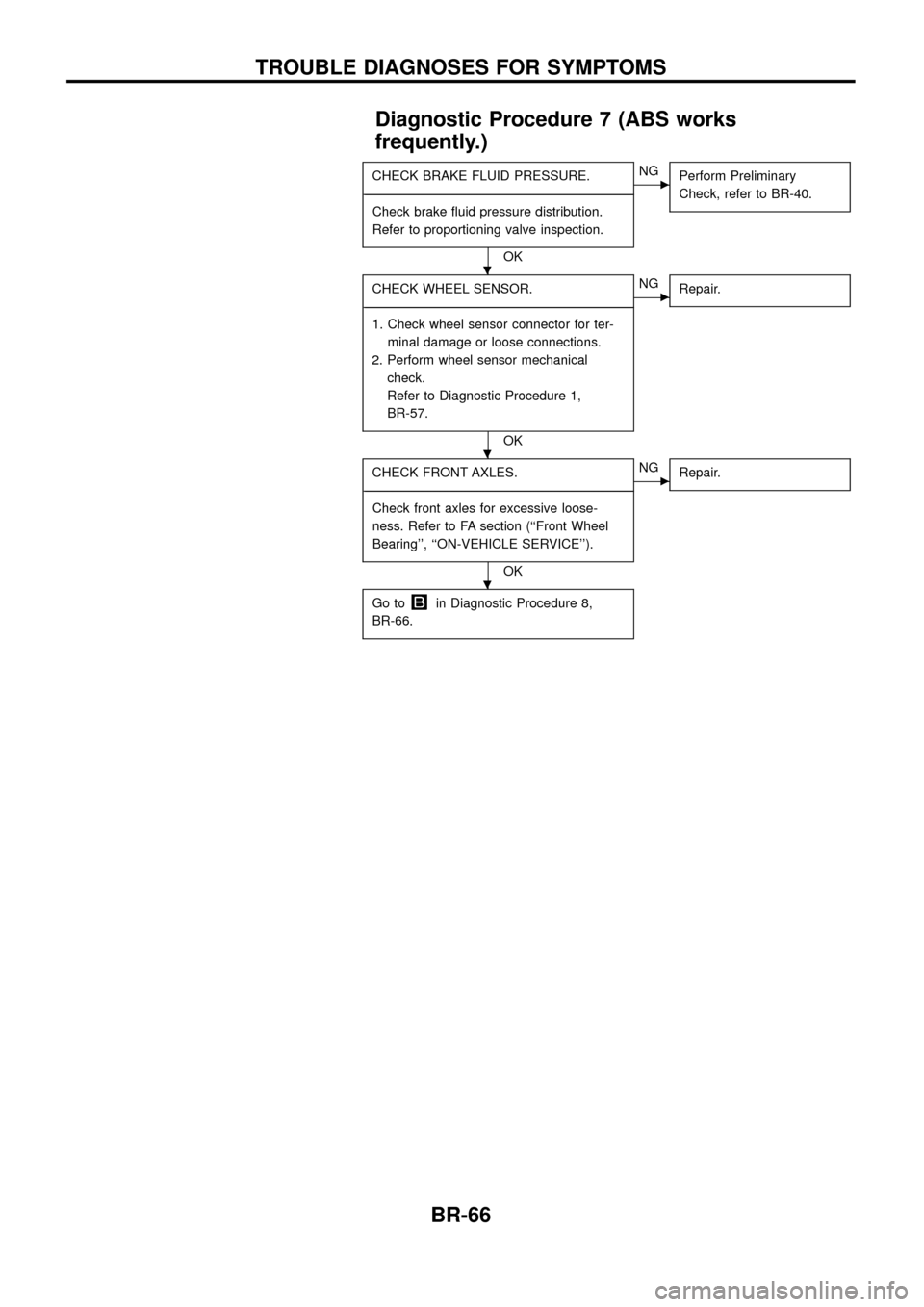

Diagnostic Procedure 6 (Control unit)

Malfunction code No. 71

CHECK CONNECTOR.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Disconnect ABS actuator and electric unit connector.

Check terminals for damage or loose

connections. Then reconnect connector.

2. Carry out self-diagnosis again. Does warning lamp activate again?

Ye s

cNo Inspection end

ABS CONTROL UNIT POWER SUPPLY

CHECK

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check voltage. Refer to

in Diagnostic

Procedure 4, BR-63.

CHECK SELF-DIAGNOSTIC RESULTS

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Does warning lamp indicate code No. 71

again?

No

cYe s Replace ABS actuator and

electric unit.

INSPECTION

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Inspect the system according to the code

No.

SBR844DC

SBR204E.

.

.

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMS

Diagnostic Procedure 5 (G sensor) (Cont'd)

BR-65

Page 68 of 75

Diagnostic Procedure 7 (ABS works

frequently.)

CHECK BRAKE FLUID PRESSURE.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check brake ¯uid pressure distribution.

Refer to proportioning valve inspection.

OK

cNG Perform Preliminary

Check, refer to BR-40.

CHECK WHEEL SENSOR.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Check wheel sensor connector for ter- minal damage or loose connections.

2. Perform wheel sensor mechanical check.

Refer to Diagnostic Procedure 1,

BR-57.

OK

cNG Repair.

CHECK FRONT AXLES.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check front axles for excessive loose-

ness. Refer to FA section (``Front Wheel

Bearing'', ``ON-VEHICLE SERVICE'').

OK

cNG Repair.

Go toin Diagnostic Procedure 8,

BR-66.

.

.

.

TROUBLE DIAGNOSES FOR SYMPTOMS

BR-66

Page 69 of 75

Diagnostic Procedure 8 (Unexpected pedal

action)

CHECK BRAKE PEDAL STROKE.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check brake pedal stroke. Is stroke

excessively large?

No

cYe s Perform Preliminary

Check, refer to BR-40.

CHECK BRAKE PERFORMANCE.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Disconnect ABS actuator and electric unit

connector and check whether brake is

effective.

Ye s

cNo Perform Preliminary

Check, refer to BR-40.

CHECK WARNING LAMP ACTIVATE.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Ensure warning lamp remains off while

driving.

OK

cNG Carry out self-diagnosis.

Refer to BR-47, 51.

CHECK WHEEL SENSOR.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Check wheel sensor connector for ter- minal damage or loose connection.

2. Perform wheel sensor mechanical check.

Refer to Diagnostic Procedure 1,

BR-57.

OK

cNG Repair.

CHECK HARNESS CONNECTOR.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check ABS actuator and electric unit pin

terminals for damage or the connection of

ABS actuator and electric unit harness

connector.

Reconnect ABS actuator and electric unit

harness connector. Then retest.

Diagnostic Procedure 9 (Long stopping

distance)

CHECK ABS PERFORMANCE.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Disconnect ABS actuator and electric unit

connector and check whether stopping

distance is still long.

Ye s

cNo Go toin Diagnostic

Procedure 8, BR-67.

Perform Preliminary Check and air bleed-

ing.

Note: Stopping distance may be larger than vehicles without ABS when road condition is slippery.

SBR540A

SBR186E

.

.

.

.

.

TROUBLE DIAGNOSES FOR SYMPTOMS

BR-67

Page 70 of 75

Diagnostic Procedure 10 (ABS does not work.)

CHECK WARNING LAMP ACTIVATE.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Does the ABS warning lamp activate?

No

cYe s Carry out self-diagnosis.

Refer to BR-47, 51.

Go toin Diagnostic Procedure 8,

BR-67.

Note: ABS does not work when vehicle speed is under 10 km/h (6 MPH).

Diagnostic Procedure 11 (Pedal vibration and

noise)

INSPECTION START

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Apply brake.

2. Start engine.

3. Does the symptom appear only when engine is started?

No

cYe s Carry out self-diagnosis.

Refer to BR-47, 51.

CHECK IF SYMPTOM APPEARS.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Does the symptom appear when electrical

equipment switches (such as headlamp)

are operated?

Ye s

cNo Go toin Diagnostic

Procedure 8, BR-67.

CHECK WHEEL SENSOR.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check wheel sensor shield ground. For

location of shield ground, refer to wiring

diagram and ``HARNESS LAYOUT'' in EL

section.

OK

cNG Repair wheel sensor.

CHECK HARNESS CONNECTOR.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check ABS actuator and electric unit pin

terminals for damage or the connection of

ABS actuator and electric unit harness

connector.

Reconnect ABS actuator and electric unit

harness connector. Then retest.

SAT797A

.

.

.

.

TROUBLE DIAGNOSES FOR SYMPTOMS

BR-68