check engine NISSAN PATROL 1998 Y61 / 5.G Heather And Air Conditioner User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 128, PDF Size: 3.77 MB

Page 122 of 128

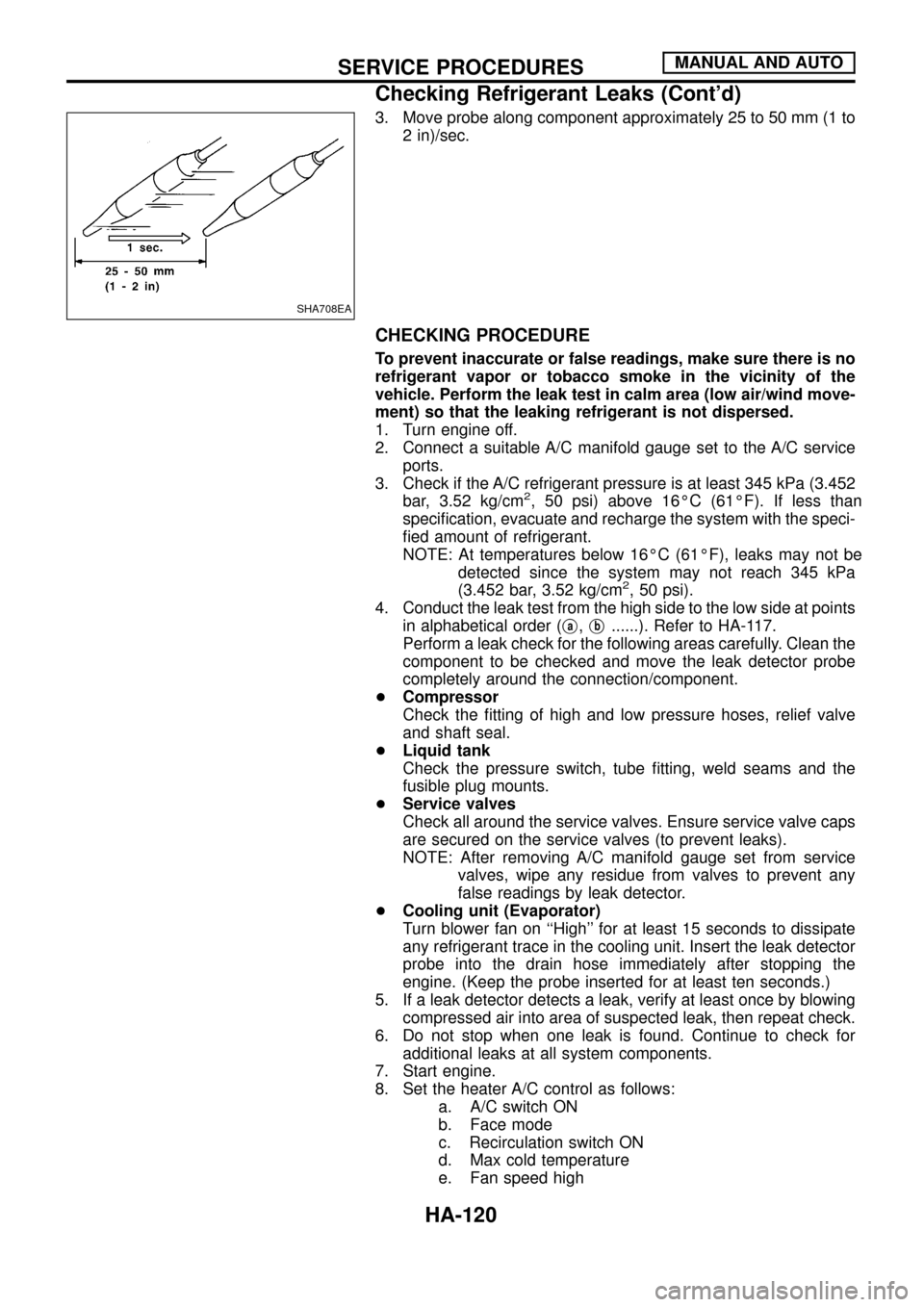

3. Move probe along component approximately 25 to 50 mm (1 to

2 in)/sec.

CHECKING PROCEDURE

To prevent inaccurate or false readings, make sure there is no

refrigerant vapor or tobacco smoke in the vicinity of the

vehicle. Perform the leak test in calm area (low air/wind move-

ment) so that the leaking refrigerant is not dispersed.

1. Turn engine off.

2. Connect a suitable A/C manifold gauge set to the A/C service

ports.

3. Check if the A/C refrigerant pressure is at least 345 kPa (3.452

bar, 3.52 kg/cm

2, 50 psi) above 16ÉC (61ÉF). If less than

speci®cation, evacuate and recharge the system with the speci-

®ed amount of refrigerant.

NOTE: At temperatures below 16ÉC (61ÉF), leaks may not be

detected since the system may not reach 345 kPa

(3.452 bar, 3.52 kg/cm

2, 50 psi).

4. Conduct the leak test from the high side to the low side at points

in alphabetical order (j

a,jb......). Refer to HA-117.

Perform a leak check for the following areas carefully. Clean the

component to be checked and move the leak detector probe

completely around the connection/component.

+Compressor

Check the ®tting of high and low pressure hoses, relief valve

and shaft seal.

+Liquid tank

Check the pressure switch, tube ®tting, weld seams and the

fusible plug mounts.

+Service valves

Check all around the service valves. Ensure service valve caps

are secured on the service valves (to prevent leaks).

NOTE: After removing A/C manifold gauge set from service

valves, wipe any residue from valves to prevent any

false readings by leak detector.

+Cooling unit (Evaporator)

Turn blower fan on ``High'' for at least 15 seconds to dissipate

any refrigerant trace in the cooling unit. Insert the leak detector

probe into the drain hose immediately after stopping the

engine. (Keep the probe inserted for at least ten seconds.)

5. If a leak detector detects a leak, verify at least once by blowing

compressed air into area of suspected leak, then repeat check.

6. Do not stop when one leak is found. Continue to check for

additional leaks at all system components.

7. Start engine.

8. Set the heater A/C control as follows:

a. A/C switch ON

b. Face mode

c. Recirculation switch ON

d. Max cold temperature

e. Fan speed high

SHA708EA

SERVICE PROCEDURESMANUAL AND AUTO

Checking Refrigerant Leaks (Cont'd)

HA-120

Page 123 of 128

9. Run engine at 1,500 rpm for at least 2 minutes.

10. Turn engine off and perform leak check again following steps 4

through 6 above.

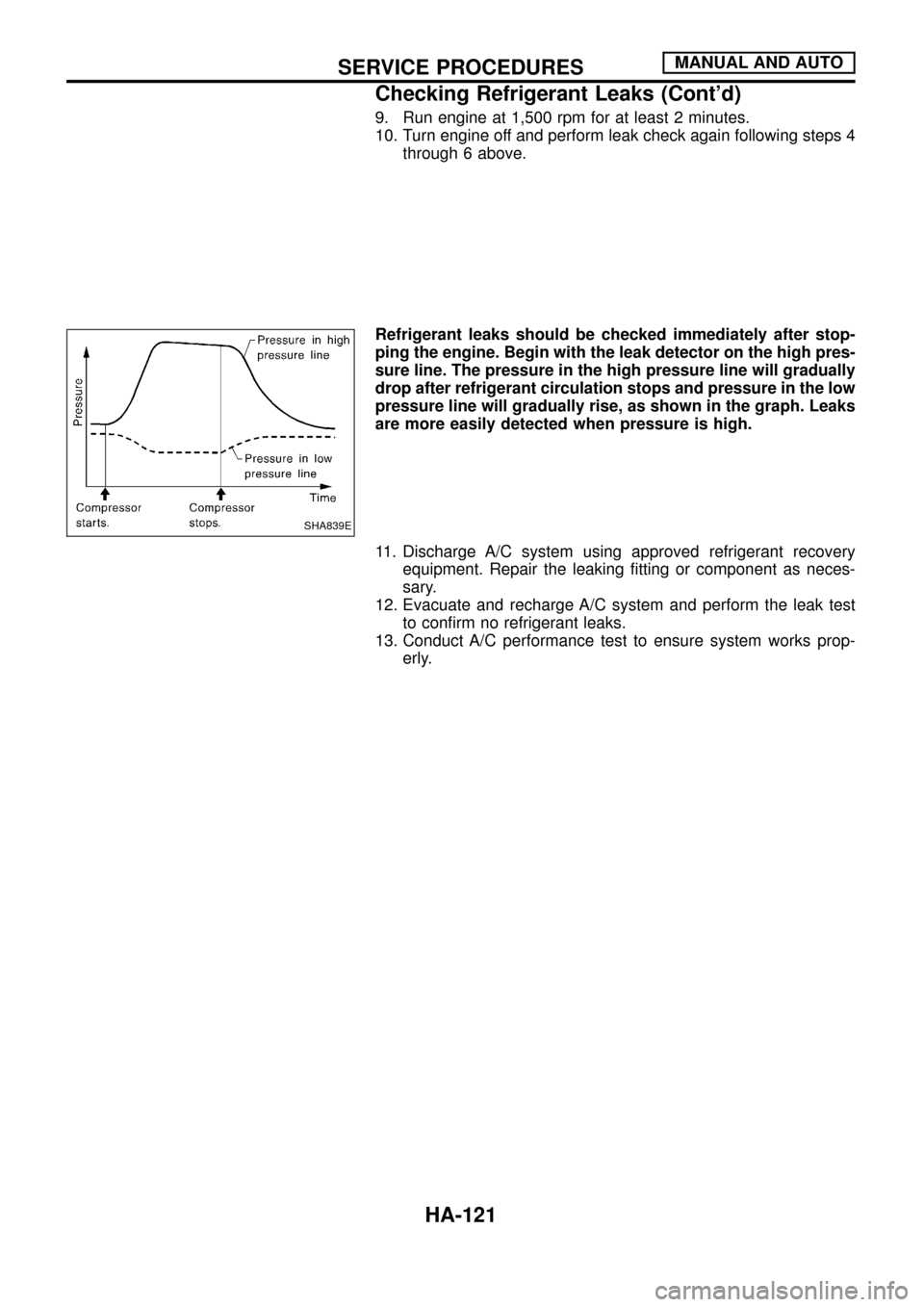

Refrigerant leaks should be checked immediately after stop-

ping the engine. Begin with the leak detector on the high pres-

sure line. The pressure in the high pressure line will gradually

drop after refrigerant circulation stops and pressure in the low

pressure line will gradually rise, as shown in the graph. Leaks

are more easily detected when pressure is high.

11. Discharge A/C system using approved refrigerant recovery

equipment. Repair the leaking ®tting or component as neces-

sary.

12. Evacuate and recharge A/C system and perform the leak test

to con®rm no refrigerant leaks.

13. Conduct A/C performance test to ensure system works prop-

erly.

SHA839E

SERVICE PROCEDURESMANUAL AND AUTO

Checking Refrigerant Leaks (Cont'd)

HA-121

Page 128 of 128

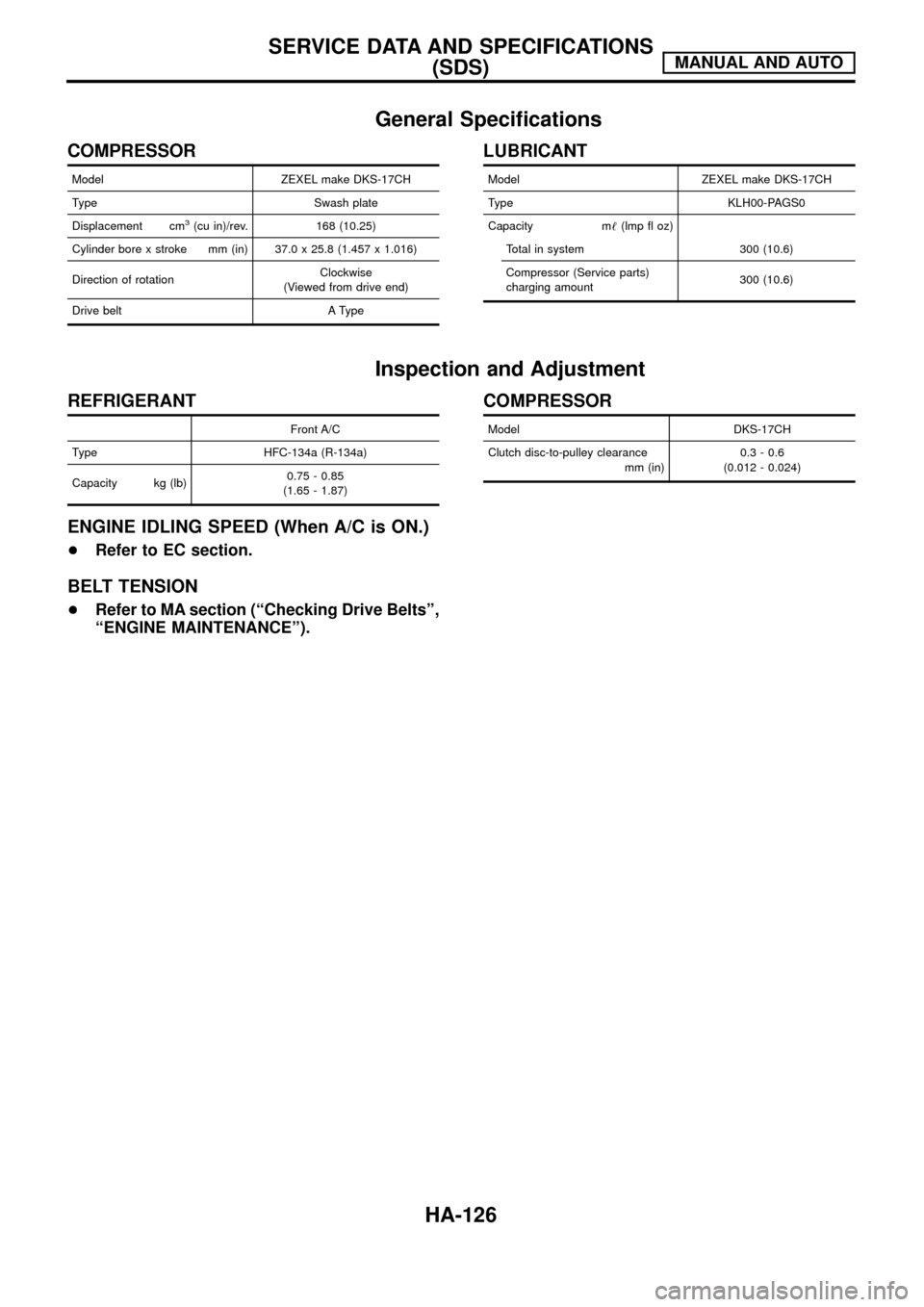

General Speci®cations

COMPRESSOR

Model ZEXEL make DKS-17CH

Type Swash plate

Displacement cm

3(cu in)/rev. 168 (10.25)

Cylinder bore x stroke mm (in) 37.0 x 25.8 (1.457 x 1.016)

Direction of rotationClockwise

(Viewed from drive end)

Drive belt A Type

LUBRICANT

Model ZEXEL make DKS-17CH

Type KLH00-PAGS0

Capacity m!(lmp ¯ oz)

Total in system 300 (10.6)

Compressor (Service parts)

charging amount300 (10.6)

Inspection and Adjustment

REFRIGERANT

Front A/C

Type HFC-134a (R-134a)

Capacity kg (lb)0.75 - 0.85

(1.65 - 1.87)

ENGINE IDLING SPEED (When A/C is ON.)

+Refer to EC section.

BELT TENSION

+Refer to MA section (``Checking Drive Belts'',

``ENGINE MAINTENANCE'').

COMPRESSOR

Model DKS-17CH

Clutch disc-to-pulley clearance

mm (in)0.3 - 0.6

(0.012 - 0.024)

SERVICE DATA AND SPECIFICATIONS

(SDS)MANUAL AND AUTO

HA-126