NISSAN PATROL 2006 Service Manual

PATROL 2006

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57368/w960_57368-0.png

NISSAN PATROL 2006 Service Manual

Trending: adding oil, remove seats, tire type, maintenance, front break, weight, Break

Page 1021 of 1226

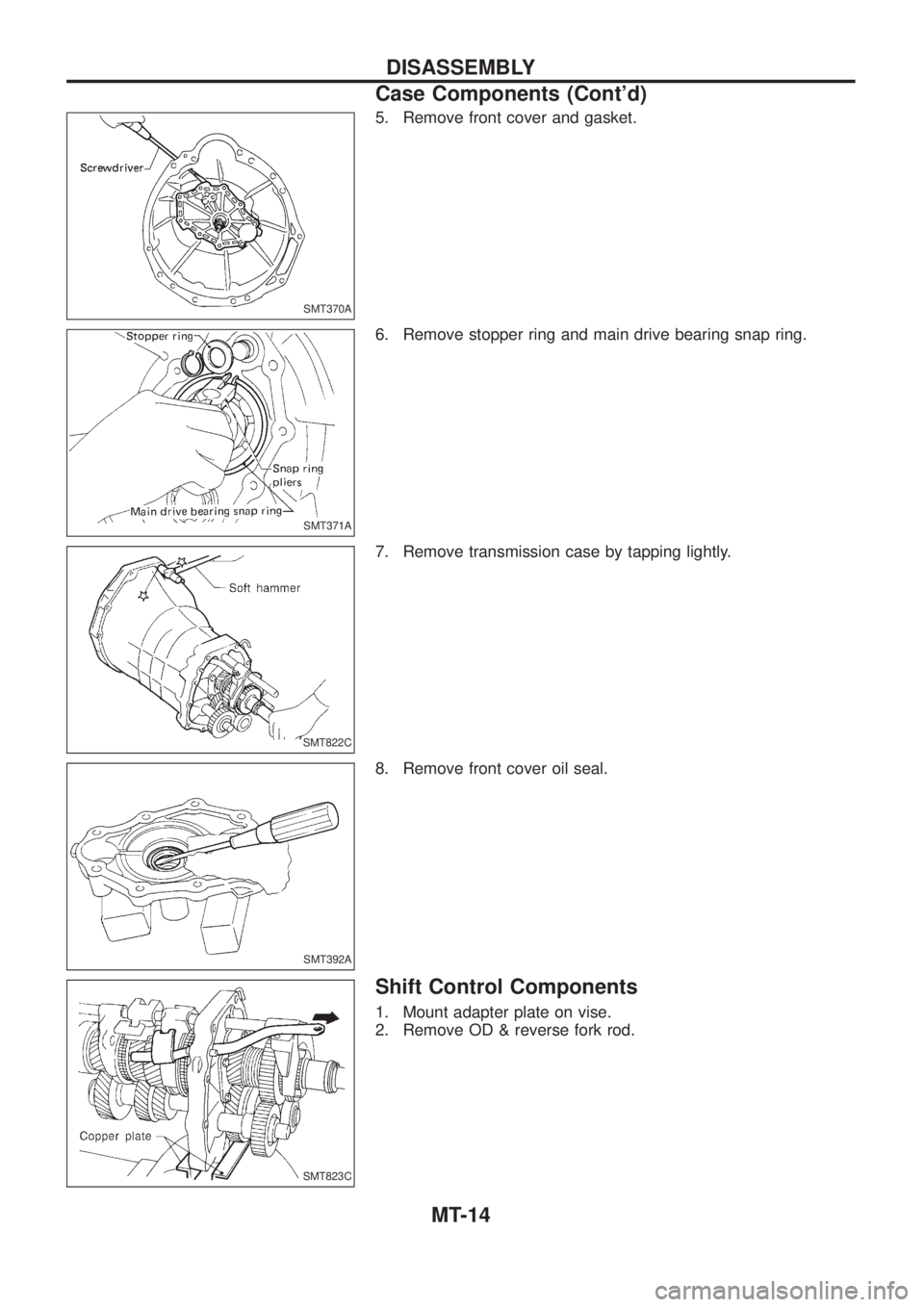

5. Remove front cover and gasket.

6. Remove stopper ring and main drive bearing snap ring.

7. Remove transmission case by tapping lightly.

8. Remove front cover oil seal.

Shift Control Components

1. Mount adapter plate on vise.

2. Remove OD & reverse fork rod.

SMT370A

SMT371A

SMT822C

SMT392A

SMT823C

DISASSEMBLY

Case Components (Cont'd)

MT-14

Page 1022 of 1226

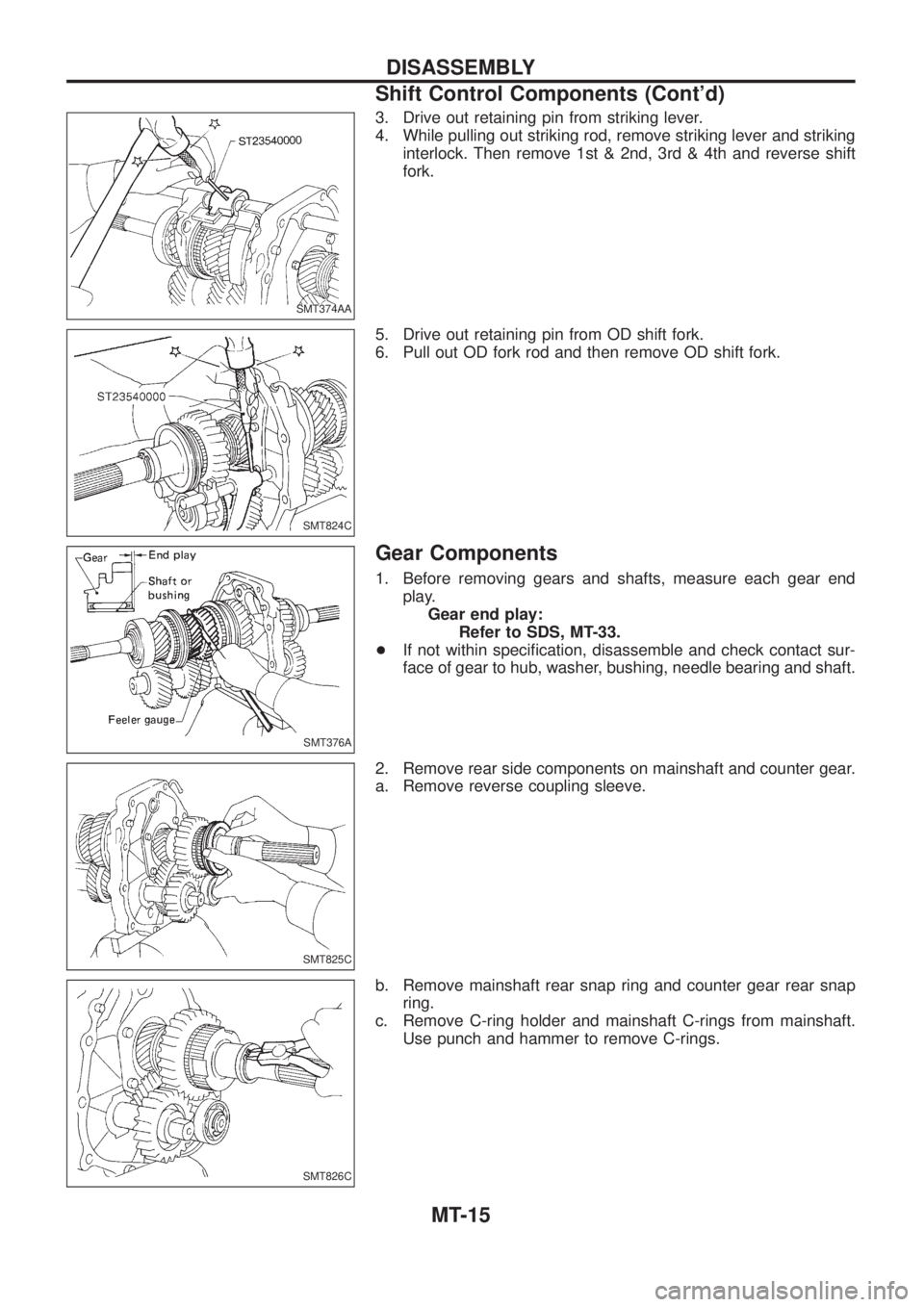

3. Drive out retaining pin from striking lever.

4. While pulling out striking rod, remove striking lever and striking

interlock. Then remove 1st & 2nd, 3rd & 4th and reverse shift

fork.

5. Drive out retaining pin from OD shift fork.

6. Pull out OD fork rod and then remove OD shift fork.

Gear Components

1. Before removing gears and shafts, measure each gear end

play.

Gear end play:

Refer to SDS, MT-33.

+If not within speci®cation, disassemble and check contact sur-

face of gear to hub, washer, bushing, needle bearing and shaft.

2. Remove rear side components on mainshaft and counter gear.

a. Remove reverse coupling sleeve.

b. Remove mainshaft rear snap ring and counter gear rear snap

ring.

c. Remove C-ring holder and mainshaft C-rings from mainshaft.

Use punch and hammer to remove C-rings.

SMT374AA

SMT824C

SMT376A

SMT825C

SMT826C

DISASSEMBLY

Shift Control Components (Cont'd)

MT-15

Page 1023 of 1226

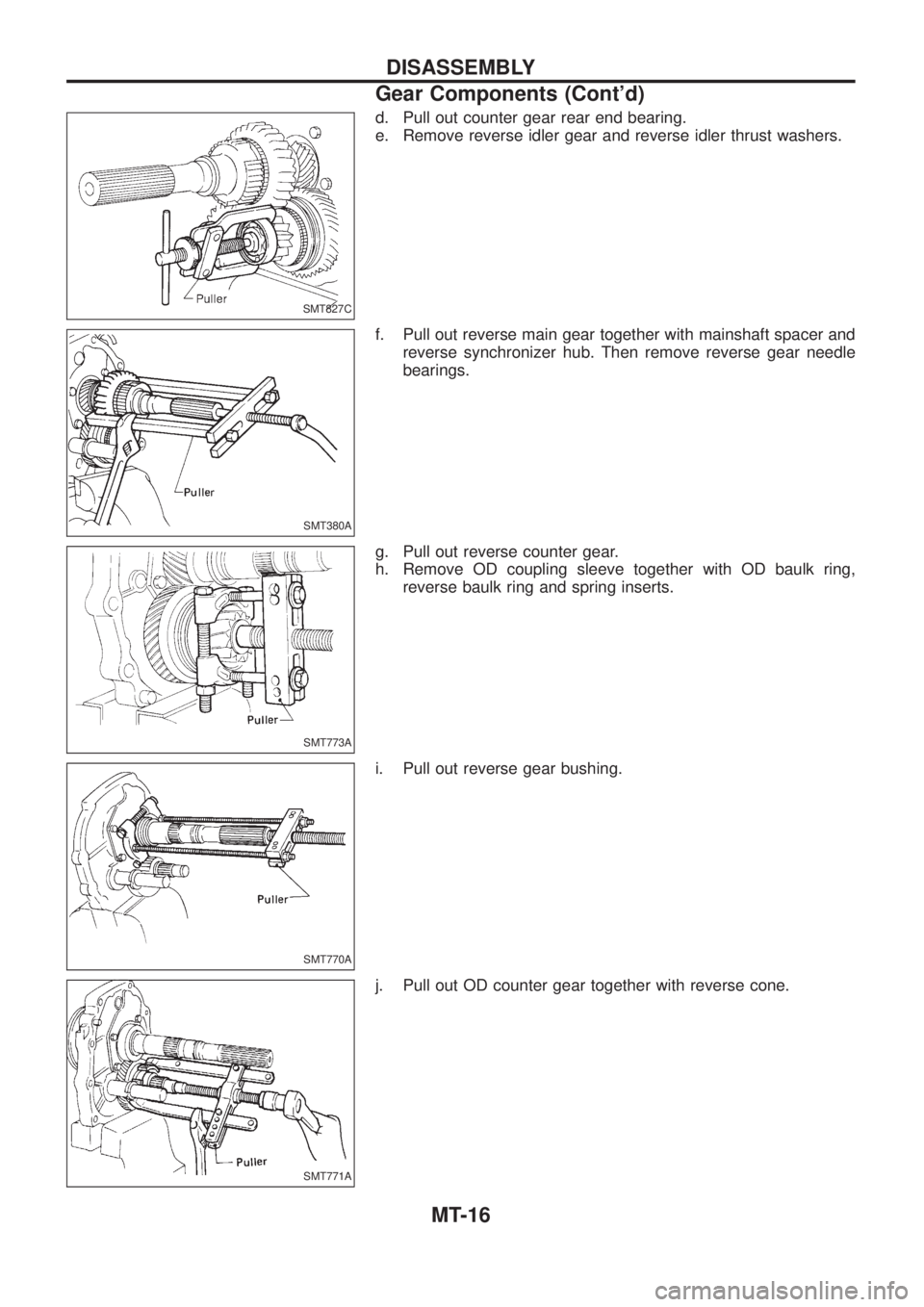

d. Pull out counter gear rear end bearing.

e. Remove reverse idler gear and reverse idler thrust washers.

f. Pull out reverse main gear together with mainshaft spacer and

reverse synchronizer hub. Then remove reverse gear needle

bearings.

g. Pull out reverse counter gear.

h. Remove OD coupling sleeve together with OD baulk ring,

reverse baulk ring and spring inserts.

i. Pull out reverse gear bushing.

j. Pull out OD counter gear together with reverse cone.

SMT827C

SMT380A

SMT773A

SMT770A

SMT771A

DISASSEMBLY

Gear Components (Cont'd)

MT-16

Page 1024 of 1226

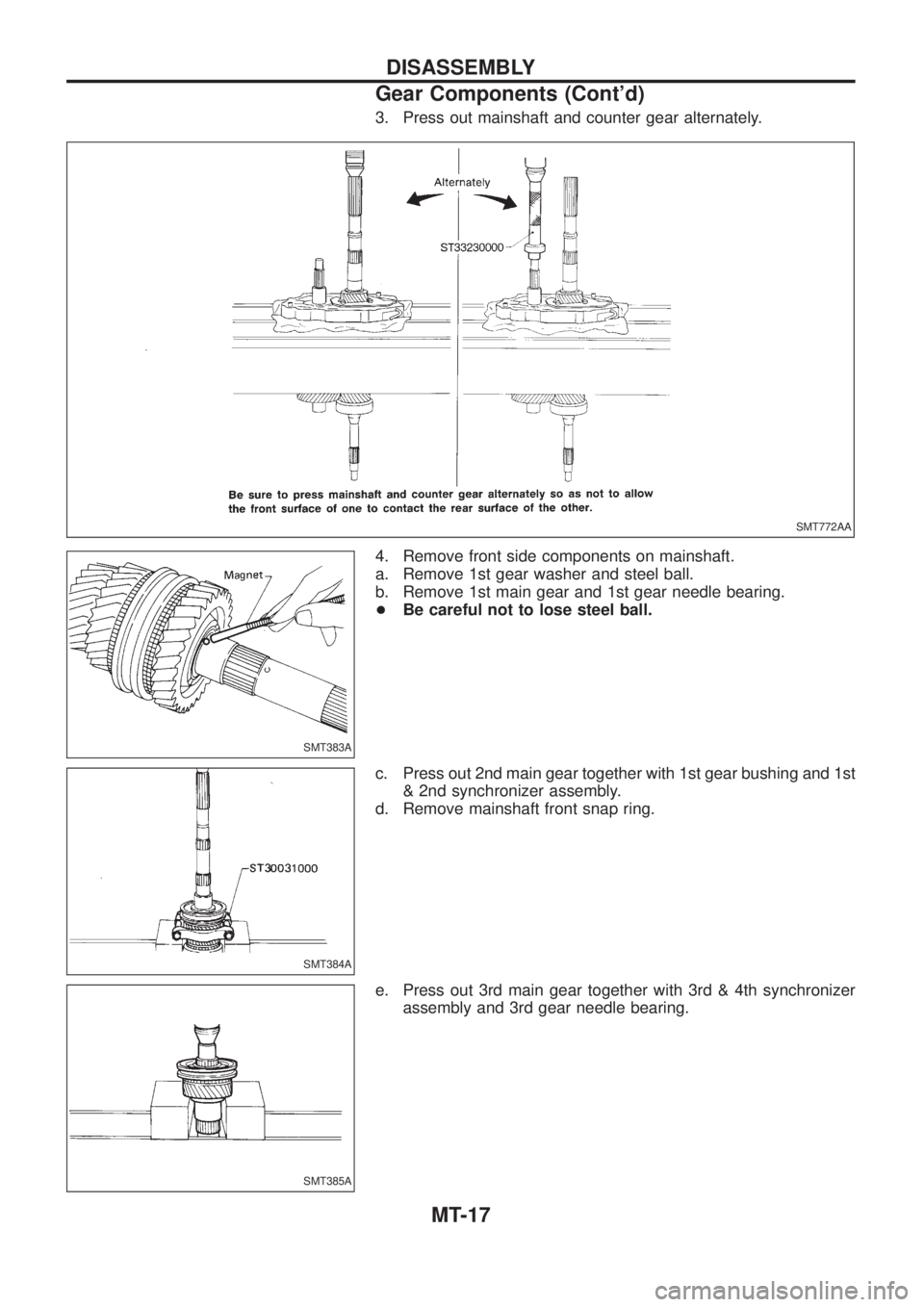

3. Press out mainshaft and counter gear alternately.

4. Remove front side components on mainshaft.

a. Remove 1st gear washer and steel ball.

b. Remove 1st main gear and 1st gear needle bearing.

+Be careful not to lose steel ball.

c. Press out 2nd main gear together with 1st gear bushing and 1st

& 2nd synchronizer assembly.

d. Remove mainshaft front snap ring.

e. Press out 3rd main gear together with 3rd & 4th synchronizer

assembly and 3rd gear needle bearing.

SMT772AA

SMT383A

SMT384A

SMT385A

DISASSEMBLY

Gear Components (Cont'd)

MT-17

Page 1025 of 1226

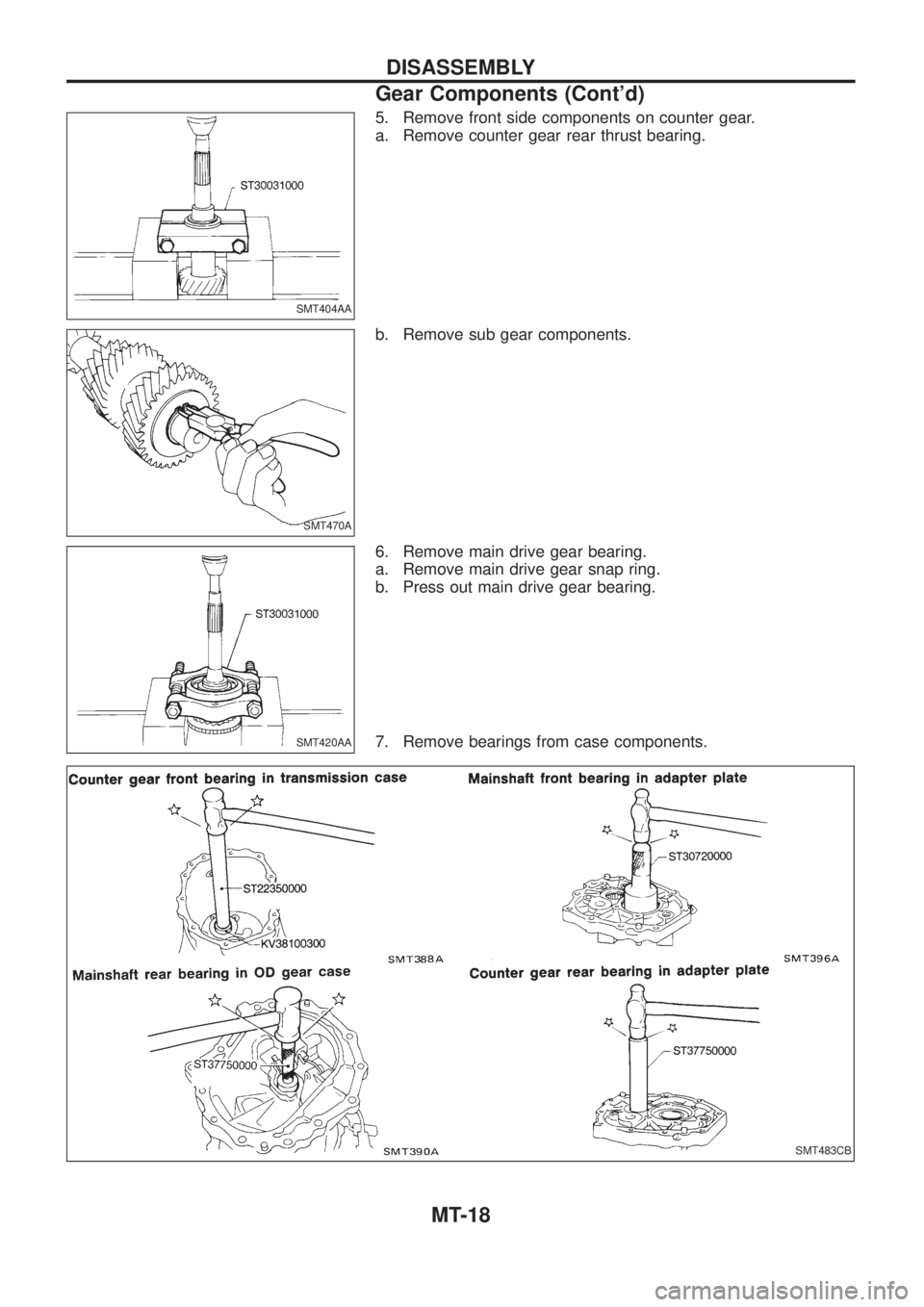

5. Remove front side components on counter gear.

a. Remove counter gear rear thrust bearing.

b. Remove sub gear components.

6. Remove main drive gear bearing.

a. Remove main drive gear snap ring.

b. Press out main drive gear bearing.

7. Remove bearings from case components.

SMT404AA

SMT470A

SMT420AA

SMT483CB

DISASSEMBLY

Gear Components (Cont'd)

MT-18

Page 1026 of 1226

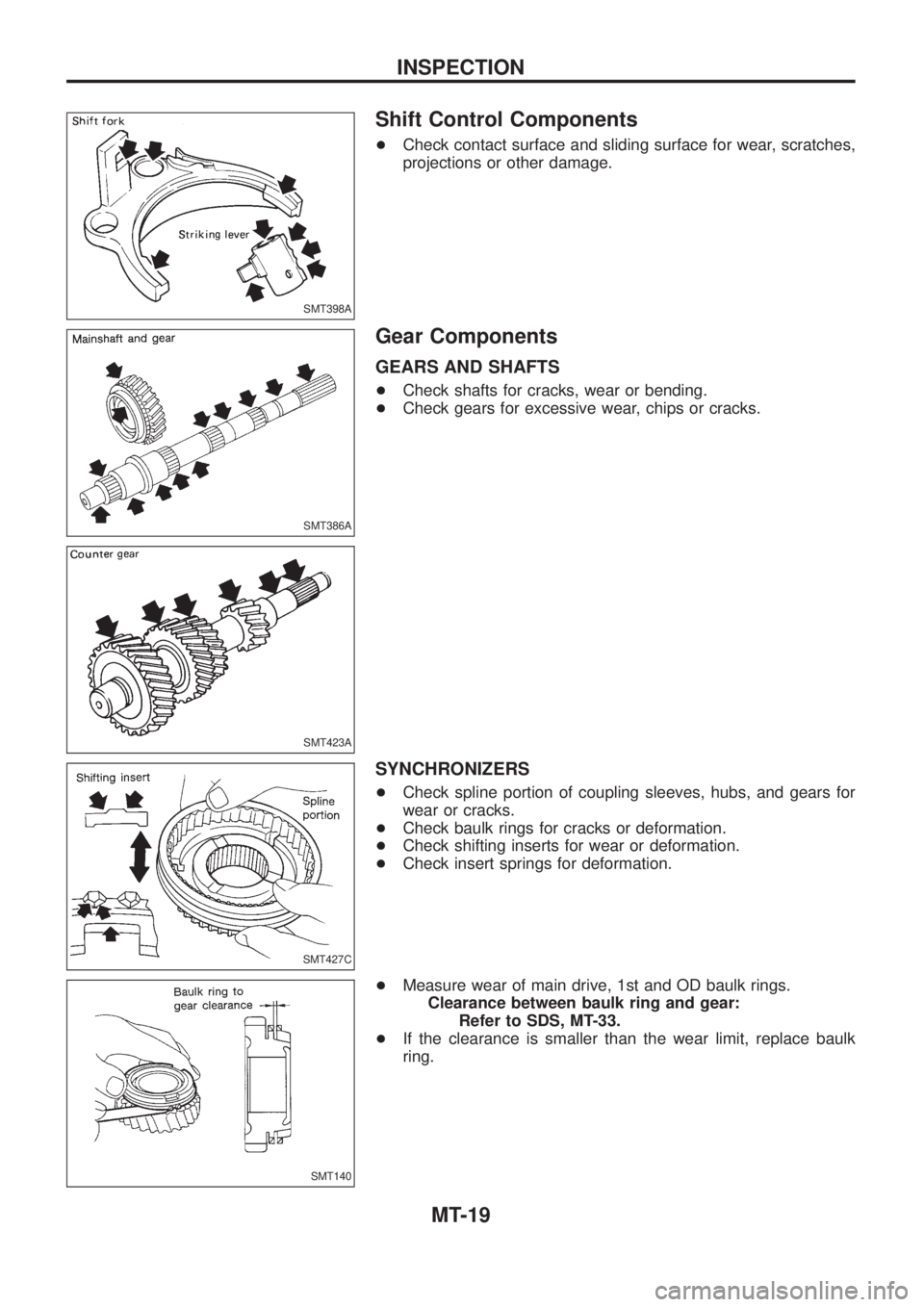

Shift Control Components

+Check contact surface and sliding surface for wear, scratches,

projections or other damage.

Gear Components

GEARS AND SHAFTS

+Check shafts for cracks, wear or bending.

+Check gears for excessive wear, chips or cracks.

SYNCHRONIZERS

+Check spline portion of coupling sleeves, hubs, and gears for

wear or cracks.

+Check baulk rings for cracks or deformation.

+Check shifting inserts for wear or deformation.

+Check insert springs for deformation.

+Measure wear of main drive, 1st and OD baulk rings.

Clearance between baulk ring and gear:

Refer to SDS, MT-33.

+If the clearance is smaller than the wear limit, replace baulk

ring.

SMT398A

SMT386A

SMT423A

SMT427C

SMT140

INSPECTION

MT-19

Page 1027 of 1226

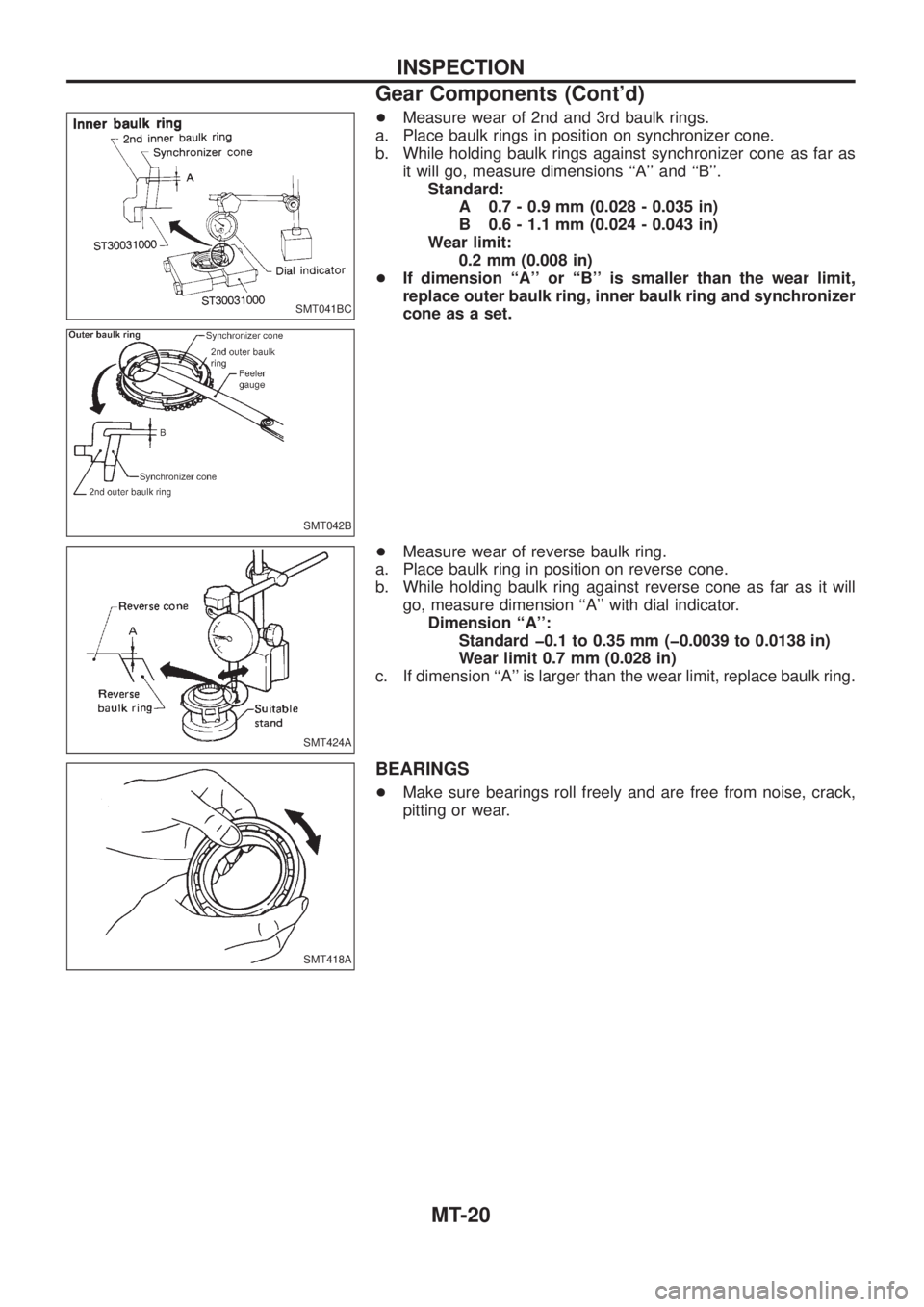

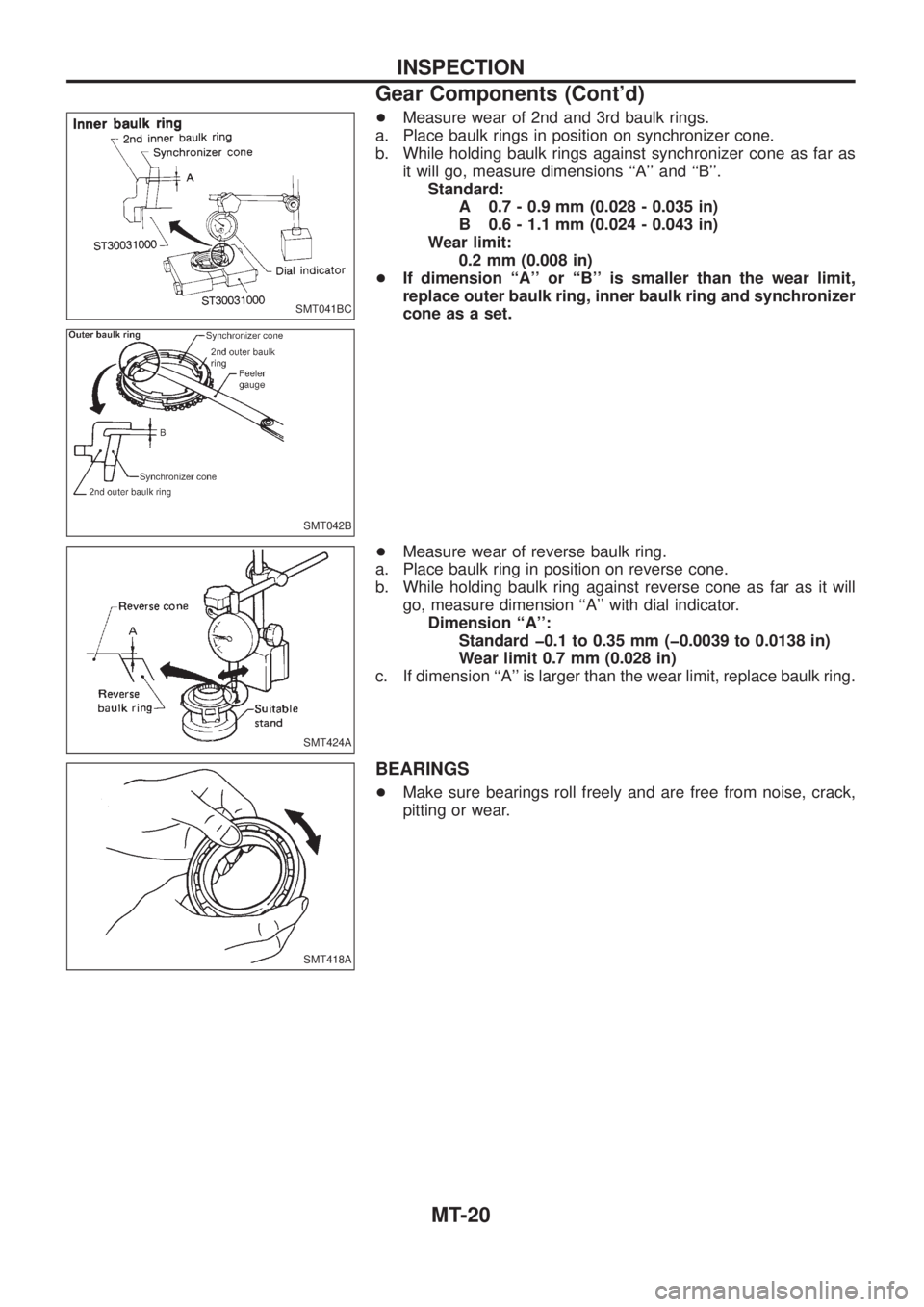

+Measure wear of 2nd and 3rd baulk rings.

a. Place baulk rings in position on synchronizer cone.

b. While holding baulk rings against synchronizer cone as far as

it will go, measure dimensions ``A'' and ``B''.

Standard:

A 0.7 - 0.9 mm (0.028 - 0.035 in)

B 0.6 - 1.1 mm (0.024 - 0.043 in)

Wear limit:

0.2 mm (0.008 in)

+If dimension ``A'' or ``B'' is smaller than the wear limit,

replace outer baulk ring, inner baulk ring and synchronizer

cone as a set.

+Measure wear of reverse baulk ring.

a. Place baulk ring in position on reverse cone.

b. While holding baulk ring against reverse cone as far as it will

go, measure dimension ``A'' with dial indicator.

Dimension ``A'':

Standard þ0.1 to 0.35 mm (þ0.0039 to 0.0138 in)

Wear limit 0.7 mm (0.028 in)

c. If dimension ``A'' is larger than the wear limit, replace baulk ring.

BEARINGS

+Make sure bearings roll freely and are free from noise, crack,

pitting or wear.

SMT041BC

SMT042B

SMT424A

SMT418A

INSPECTION

Gear Components (Cont'd)

MT-20

Page 1028 of 1226

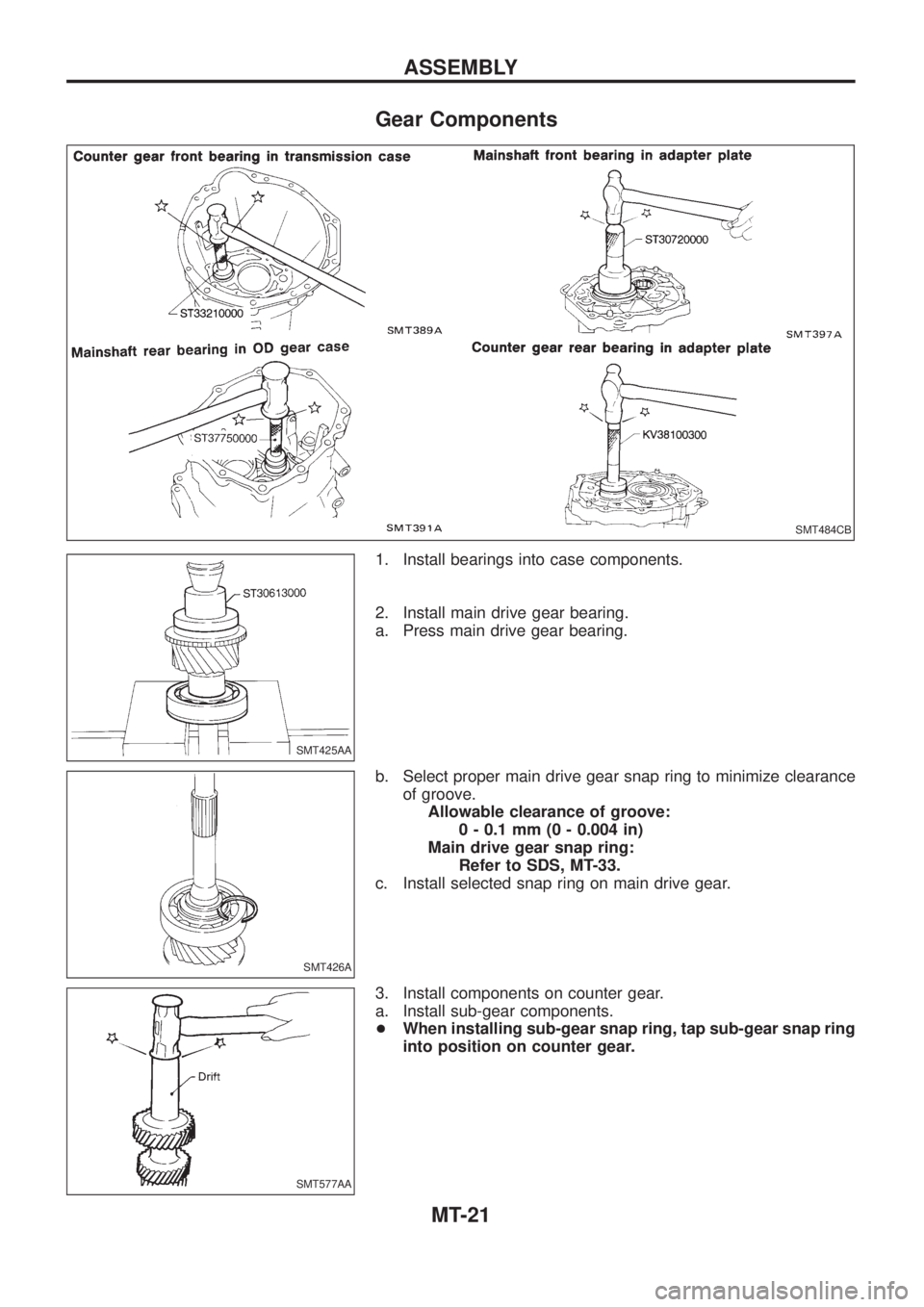

Gear Components

1. Install bearings into case components.

2. Install main drive gear bearing.

a. Press main drive gear bearing.

b. Select proper main drive gear snap ring to minimize clearance

of groove.

Allowable clearance of groove:

0 - 0.1 mm (0 - 0.004 in)

Main drive gear snap ring:

Refer to SDS, MT-33.

c. Install selected snap ring on main drive gear.

3. Install components on counter gear.

a. Install sub-gear components.

+When installing sub-gear snap ring, tap sub-gear snap ring

into position on counter gear.

SMT484CB

SMT425AA

SMT426A

SMT577AA

ASSEMBLY

MT-21

Page 1029 of 1226

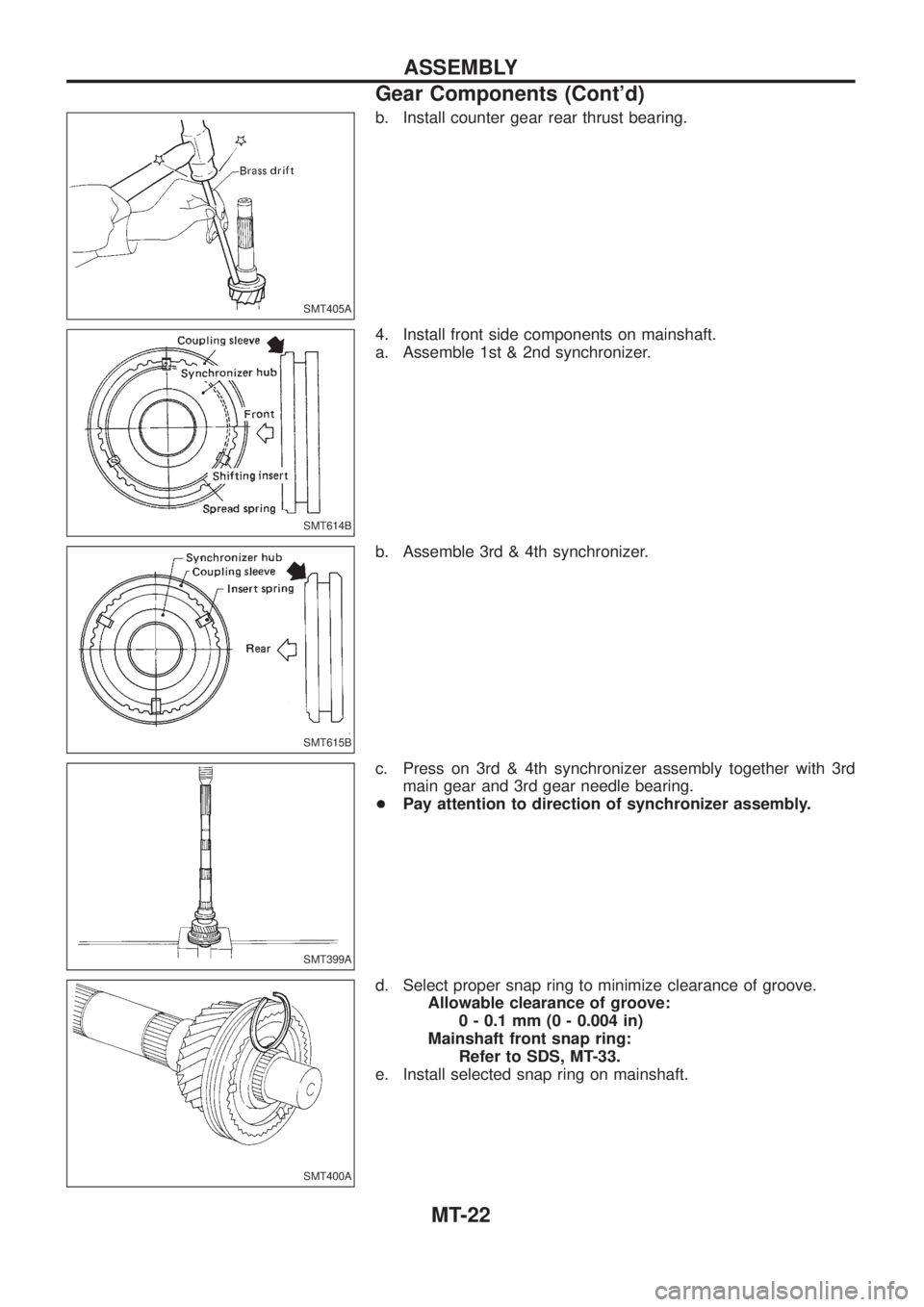

b. Install counter gear rear thrust bearing.

4. Install front side components on mainshaft.

a. Assemble 1st & 2nd synchronizer.

b. Assemble 3rd & 4th synchronizer.

c. Press on 3rd & 4th synchronizer assembly together with 3rd

main gear and 3rd gear needle bearing.

+Pay attention to direction of synchronizer assembly.

d. Select proper snap ring to minimize clearance of groove.

Allowable clearance of groove:

0 - 0.1 mm (0 - 0.004 in)

Mainshaft front snap ring:

Refer to SDS, MT-33.

e. Install selected snap ring on mainshaft.

SMT405A

SMT614B

SMT615B

SMT399A

SMT400A

ASSEMBLY

Gear Components (Cont'd)

MT-22

Page 1030 of 1226

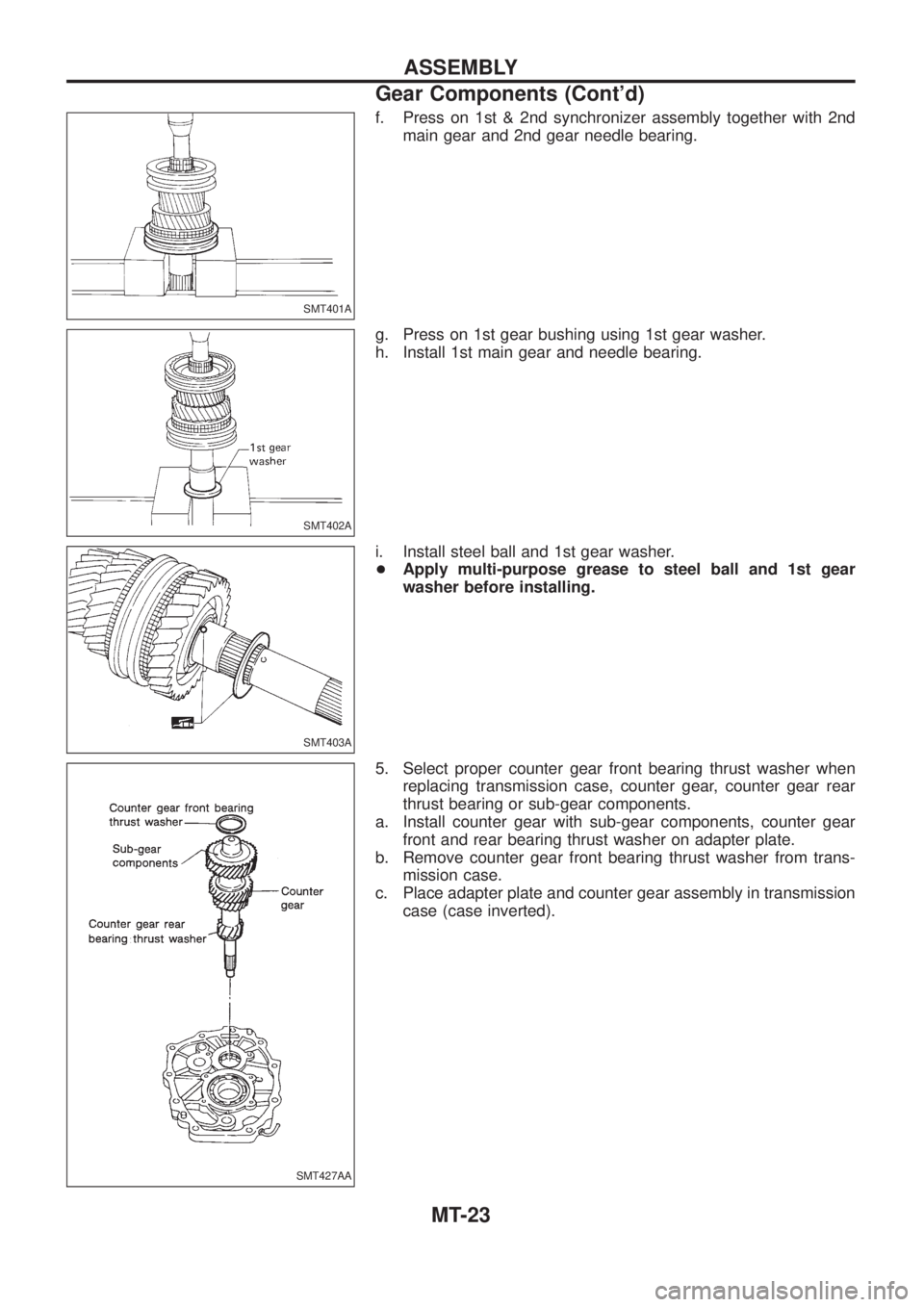

f. Press on 1st & 2nd synchronizer assembly together with 2nd

main gear and 2nd gear needle bearing.

g. Press on 1st gear bushing using 1st gear washer.

h. Install 1st main gear and needle bearing.

i. Install steel ball and 1st gear washer.

+Apply multi-purpose grease to steel ball and 1st gear

washer before installing.

5. Select proper counter gear front bearing thrust washer when

replacing transmission case, counter gear, counter gear rear

thrust bearing or sub-gear components.

a. Install counter gear with sub-gear components, counter gear

front and rear bearing thrust washer on adapter plate.

b. Remove counter gear front bearing thrust washer from trans-

mission case.

c. Place adapter plate and counter gear assembly in transmission

case (case inverted).

SMT401A

SMT402A

SMT403A

SMT427AA

ASSEMBLY

Gear Components (Cont'd)

MT-23

Trending: octane, load capacity, turn signal bulb, transfer case, stop start, catalytic converter, cooling system