check engine light NISSAN PICK-UP 1998 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 216 of 1659

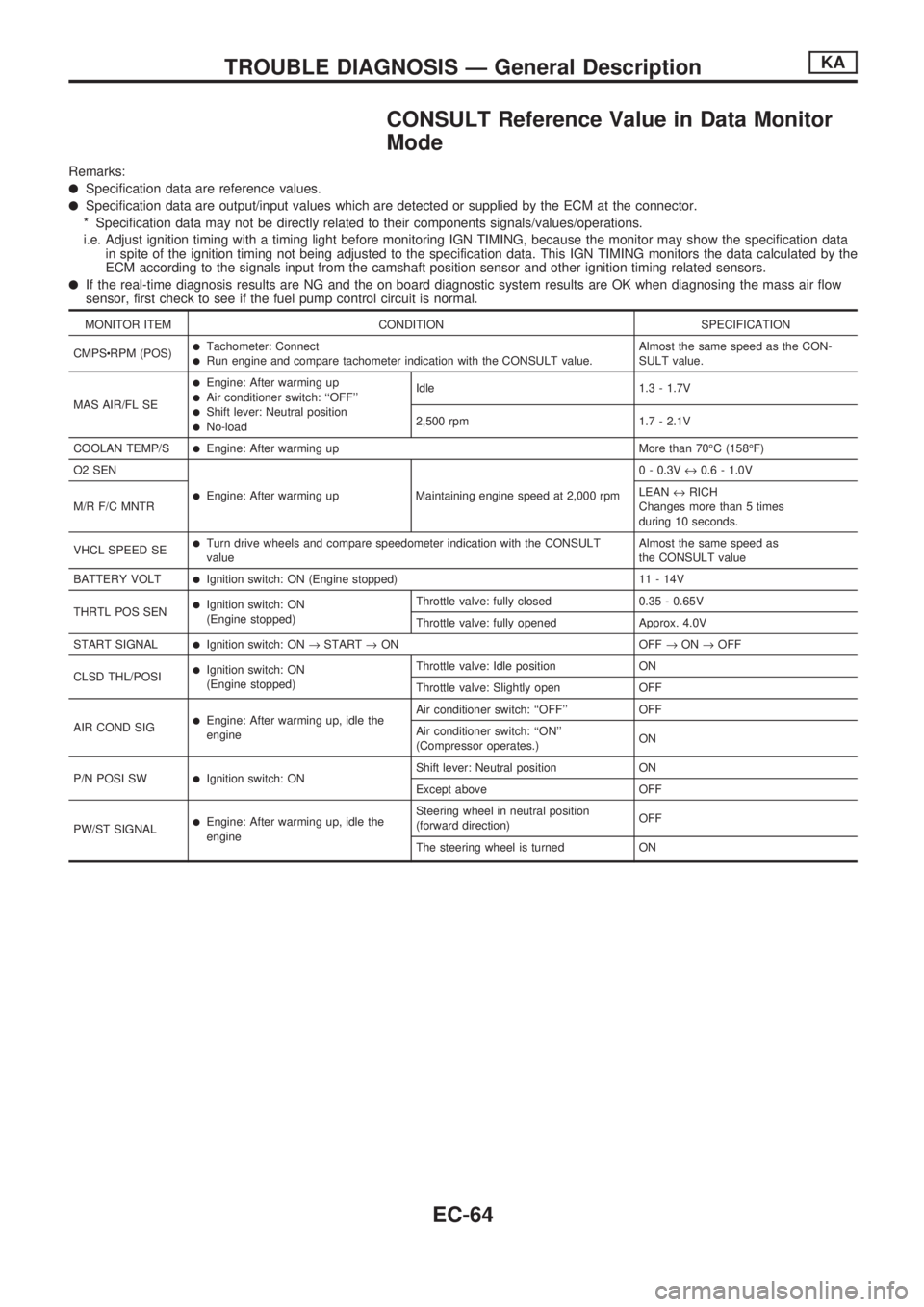

CONSULT Reference Value in Data Monitor

Mode

Remarks:

lSpecification data are reference values.

lSpecification data are output/input values which are detected or supplied by the ECM at the connector.

* Specification data may not be directly related to their components signals/values/operations.

i.e. Adjust ignition timing with a timing light before monitoring IGN TIMING, because the monitor may show the specification data

in spite of the ignition timing not being adjusted to the specification data. This IGN TIMING monitors the data calculated by the

ECM according to the signals input from the camshaft position sensor and other ignition timing related sensors.

lIf the real-time diagnosis results are NG and the on board diagnostic system results are OK when diagnosing the mass air flow

sensor, first check to see if the fuel pump control circuit is normal.

MONITOR ITEM CONDITION SPECIFICATION

CMPScRPM (POS)

lTachometer: ConnectlRun engine and compare tachometer indication with the CONSULT value.Almost the same speed as the CON-

SULT value.

MAS AIR/FL SE

lEngine: After warming uplAir conditioner switch: ``OFF''lShift lever: Neutral positionlNo-loadIdle 1.3 - 1.7V

2,500 rpm 1.7 - 2.1V

COOLAN TEMP/S

lEngine: After warming up More than 70ÉC (158ÉF)

O2 SEN

lEngine: After warming up Maintaining engine speed at 2,000 rpm0 - 0.3V«0.6 - 1.0V

M/R F/C MNTRLEAN«RICH

Changes more than 5 times

during 10 seconds.

VHCL SPEED SE

lTurn drive wheels and compare speedometer indication with the CONSULT

valueAlmost the same speed as

the CONSULT value

BATTERY VOLT

lIgnition switch: ON (Engine stopped) 11 - 14V

THRTL POS SEN

lIgnition switch: ON

(Engine stopped)Throttle valve: fully closed 0.35 - 0.65V

Throttle valve: fully opened Approx. 4.0V

START SIGNAL

lIgnition switch: ON®START®ON OFF®ON®OFF

CLSD THL/POSI

lIgnition switch: ON

(Engine stopped)Throttle valve: Idle position ON

Throttle valve: Slightly open OFF

AIR COND SIG

lEngine: After warming up, idle the

engineAir conditioner switch: ``OFF'' OFF

Air conditioner switch: ``ON''

(Compressor operates.)ON

P/N POSI SW

lIgnition switch: ONShift lever: Neutral position ON

Except above OFF

PW/ST SIGNAL

lEngine: After warming up, idle the

engineSteering wheel in neutral position

(forward direction)OFF

The steering wheel is turned ON

TROUBLE DIAGNOSIS Ð General DescriptionKA

EC-64

Page 388 of 1659

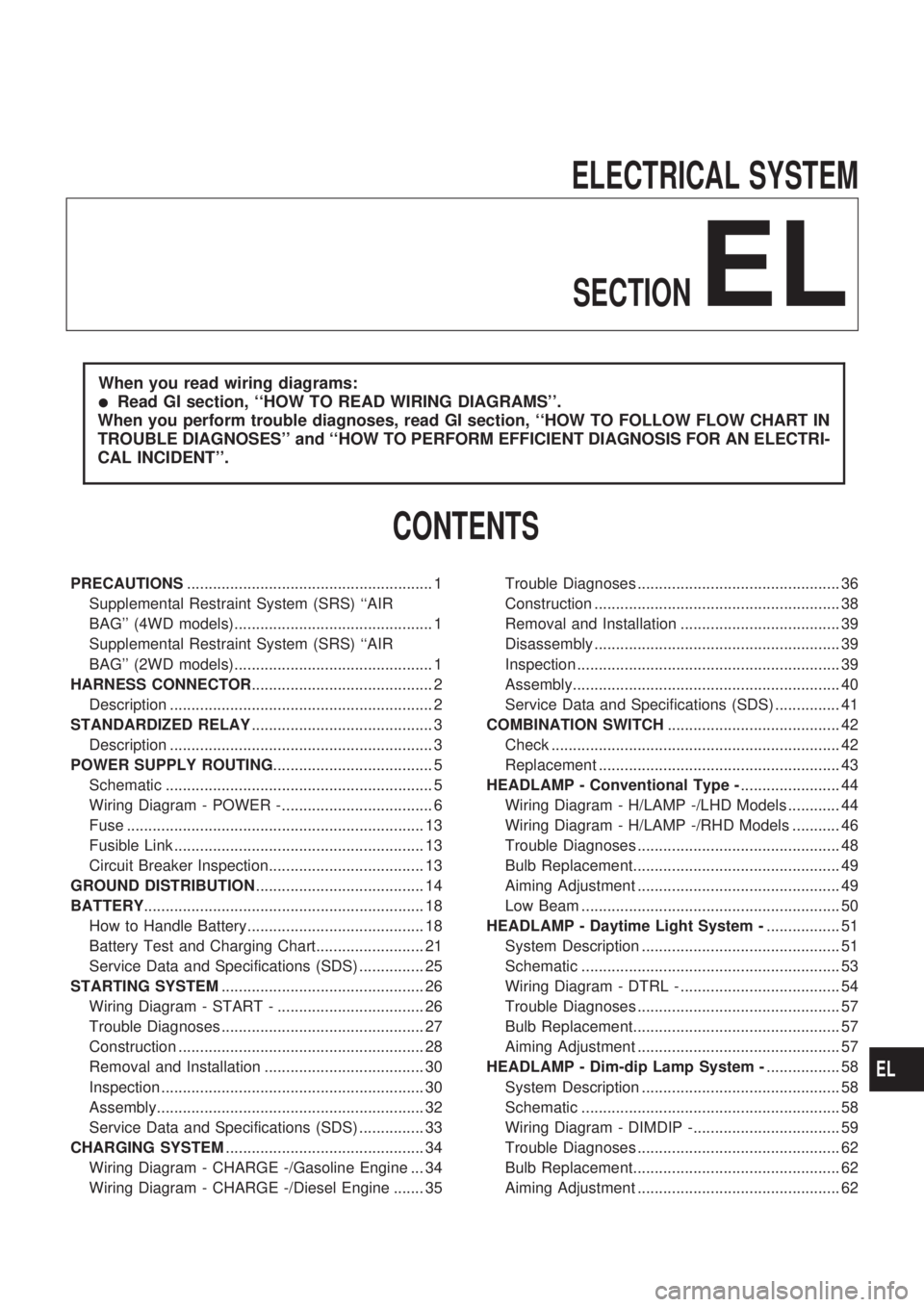

ELECTRICAL SYSTEM

SECTION

EL

When you read wiring diagrams:

lRead GI section, ``HOW TO READ WIRING DIAGRAMS''.

When you perform trouble diagnoses, read GI section, ``HOW TO FOLLOW FLOW CHART IN

TROUBLE DIAGNOSES'' and ``HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRI-

CAL INCIDENT''.

CONTENTS

PRECAUTIONS......................................................... 1

Supplemental Restraint System (SRS) ``AIR

BAG'' (4WD models).............................................. 1

Supplemental Restraint System (SRS) ``AIR

BAG'' (2WD models).............................................. 1

HARNESS CONNECTOR.......................................... 2

Description ............................................................. 2

STANDARDIZED RELAY.......................................... 3

Description ............................................................. 3

POWER SUPPLY ROUTING..................................... 5

Schematic .............................................................. 5

Wiring Diagram - POWER -................................... 6

Fuse ..................................................................... 13

Fusible Link .......................................................... 13

Circuit Breaker Inspection.................................... 13

GROUND DISTRIBUTION....................................... 14

BATTERY................................................................. 18

How to Handle Battery......................................... 18

Battery Test and Charging Chart......................... 21

Service Data and Specifications (SDS) ............... 25

STARTING SYSTEM............................................... 26

Wiring Diagram - START - .................................. 26

Trouble Diagnoses ............................................... 27

Construction ......................................................... 28

Removal and Installation ..................................... 30

Inspection ............................................................. 30

Assembly.............................................................. 32

Service Data and Specifications (SDS) ............... 33

CHARGING SYSTEM.............................................. 34

Wiring Diagram - CHARGE -/Gasoline Engine ... 34

Wiring Diagram - CHARGE -/Diesel Engine ....... 35Trouble Diagnoses ............................................... 36

Construction ......................................................... 38

Removal and Installation ..................................... 39

Disassembly ......................................................... 39

Inspection ............................................................. 39

Assembly.............................................................. 40

Service Data and Specifications (SDS) ............... 41

COMBINATION SWITCH........................................ 42

Check ................................................................... 42

Replacement ........................................................ 43

HEADLAMP - Conventional Type -....................... 44

Wiring Diagram - H/LAMP -/LHD Models ............ 44

Wiring Diagram - H/LAMP -/RHD Models ........... 46

Trouble Diagnoses ............................................... 48

Bulb Replacement................................................ 49

Aiming Adjustment ............................................... 49

Low Beam ............................................................ 50

HEADLAMP - Daytime Light System -................. 51

System Description .............................................. 51

Schematic ............................................................ 53

Wiring Diagram - DTRL - ..................................... 54

Trouble Diagnoses ............................................... 57

Bulb Replacement................................................ 57

Aiming Adjustment ............................................... 57

HEADLAMP - Dim-dip Lamp System -................. 58

System Description .............................................. 58

Schematic ............................................................ 58

Wiring Diagram - DIMDIP -.................................. 59

Trouble Diagnoses ............................................... 62

Bulb Replacement................................................ 62

Aiming Adjustment ............................................... 62

EL

Page 404 of 1659

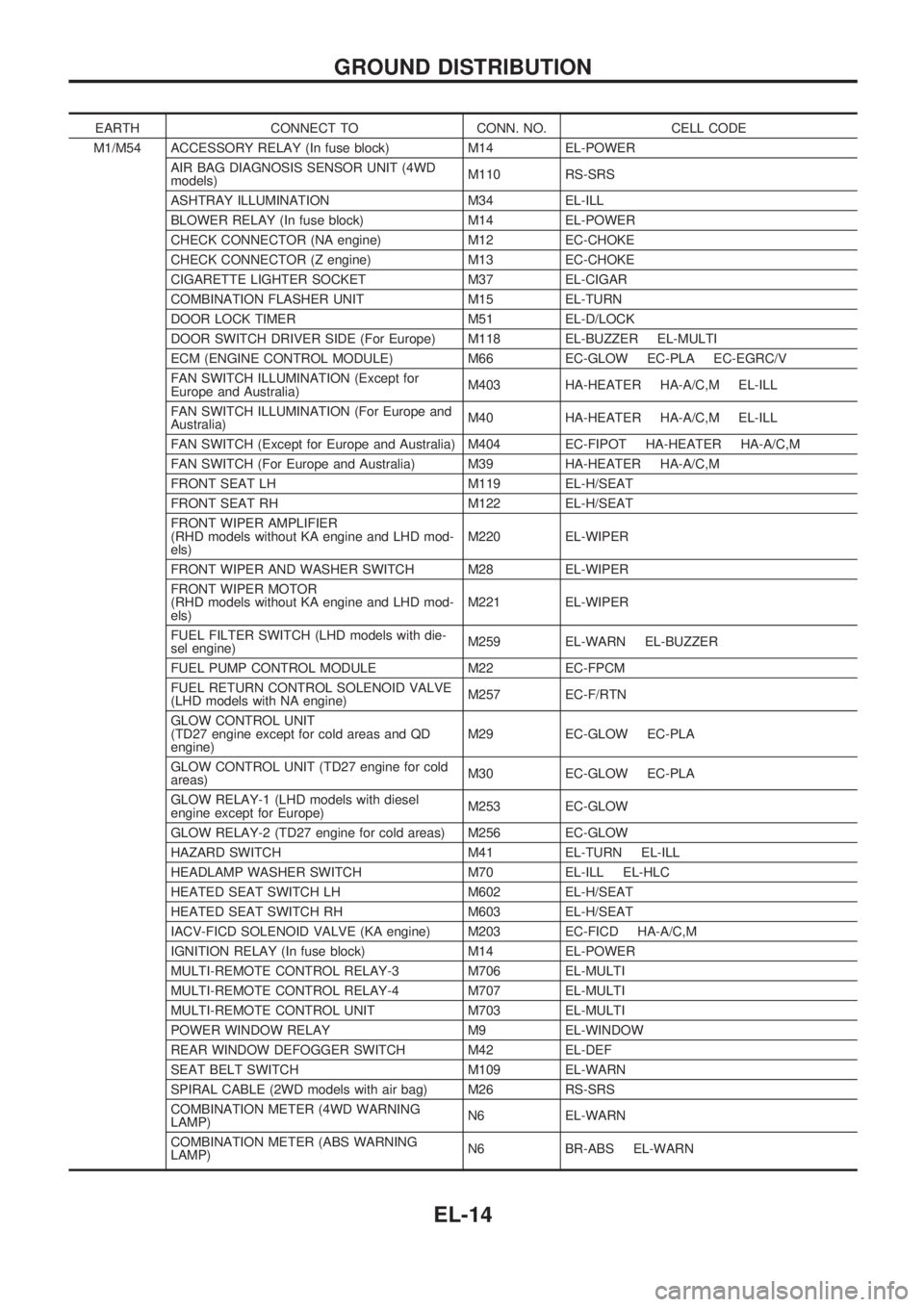

EARTH CONNECT TO CONN. NO. CELL CODE

M1/M54 ACCESSORY RELAY (In fuse block) M14 EL-POWER

AIR BAG DIAGNOSIS SENSOR UNIT (4WD

models)M110 RS-SRS

ASHTRAY ILLUMINATION M34 EL-ILL

BLOWER RELAY (In fuse block) M14 EL-POWER

CHECK CONNECTOR (NA engine) M12 EC-CHOKE

CHECK CONNECTOR (Z engine) M13 EC-CHOKE

CIGARETTE LIGHTER SOCKET M37 EL-CIGAR

COMBINATION FLASHER UNIT M15 EL-TURN

DOOR LOCK TIMER M51 EL-D/LOCK

DOOR SWITCH DRIVER SIDE (For Europe) M118 EL-BUZZER EL-MULTI

ECM (ENGINE CONTROL MODULE) M66 EC-GLOW EC-PLA EC-EGRC/V

FAN SWITCH ILLUMINATION (Except for

Europe and Australia)M403 HA-HEATER HA-A/C,M EL-ILL

FAN SWITCH ILLUMINATION (For Europe and

Australia)M40 HA-HEATER HA-A/C,M EL-ILL

FAN SWITCH (Except for Europe and Australia) M404 EC-FIPOT HA-HEATER HA-A/C,M

FAN SWITCH (For Europe and Australia) M39 HA-HEATER HA-A/C,M

FRONT SEAT LH M119 EL-H/SEAT

FRONT SEAT RH M122 EL-H/SEAT

FRONT WIPER AMPLIFIER

(RHD models without KA engine and LHD mod-

els)M220 EL-WIPER

FRONT WIPER AND WASHER SWITCH M28 EL-WIPER

FRONT WIPER MOTOR

(RHD models without KA engine and LHD mod-

els)M221 EL-WIPER

FUEL FILTER SWITCH (LHD models with die-

sel engine)M259 EL-WARN EL-BUZZER

FUEL PUMP CONTROL MODULE M22 EC-FPCM

FUEL RETURN CONTROL SOLENOID VALVE

(LHD models with NA engine)M257 EC-F/RTN

GLOW CONTROL UNIT

(TD27 engine except for cold areas and QD

engine)M29 EC-GLOW EC-PLA

GLOW CONTROL UNIT (TD27 engine for cold

areas)M30 EC-GLOW EC-PLA

GLOW RELAY-1 (LHD models with diesel

engine except for Europe)M253 EC-GLOW

GLOW RELAY-2 (TD27 engine for cold areas) M256 EC-GLOW

HAZARD SWITCH M41 EL-TURN EL-ILL

HEADLAMP WASHER SWITCH M70 EL-ILL EL-HLC

HEATED SEAT SWITCH LH M602 EL-H/SEAT

HEATED SEAT SWITCH RH M603 EL-H/SEAT

IACV-FICD SOLENOID VALVE (KA engine) M203 EC-FICD HA-A/C,M

IGNITION RELAY (In fuse block) M14 EL-POWER

MULTI-REMOTE CONTROL RELAY-3 M706 EL-MULTI

MULTI-REMOTE CONTROL RELAY-4 M707 EL-MULTI

MULTI-REMOTE CONTROL UNIT M703 EL-MULTI

POWER WINDOW RELAY M9 EL-WINDOW

REAR WINDOW DEFOGGER SWITCH M42 EL-DEF

SEAT BELT SWITCH M109 EL-WARN

SPIRAL CABLE (2WD models with air bag) M26 RS-SRS

COMBINATION METER (4WD WARNING

LAMP)N6 EL-WARN

COMBINATION METER (ABS WARNING

LAMP)N6 BR-ABS EL-WARN

GROUND DISTRIBUTION

EL-14

Page 506 of 1659

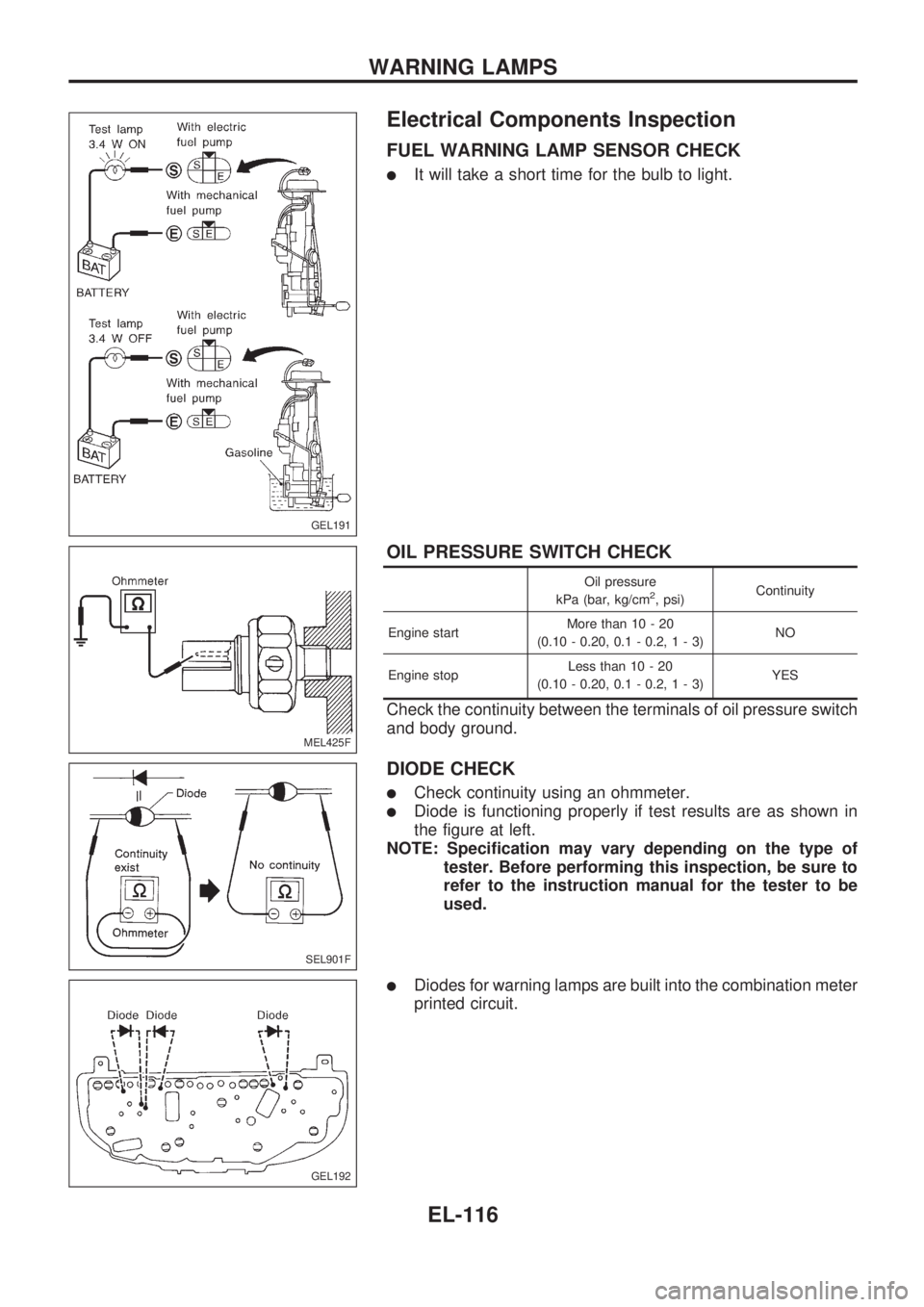

Electrical Components Inspection

FUEL WARNING LAMP SENSOR CHECK

lIt will take a short time for the bulb to light.

OIL PRESSURE SWITCH CHECK

Oil pressure

kPa (bar, kg/cm2, psi)Continuity

Engine startMore than 10 - 20

(0.10 - 0.20, 0.1 - 0.2,1-3)NO

Engine stopLess than 10 - 20

(0.10 - 0.20, 0.1 - 0.2,1-3)YES

Check the continuity between the terminals of oil pressure switch

and body ground.

DIODE CHECK

lCheck continuity using an ohmmeter.

lDiode is functioning properly if test results are as shown in

the figure at left.

NOTE: Specification may vary depending on the type of

tester. Before performing this inspection, be sure to

refer to the instruction manual for the tester to be

used.

lDiodes for warning lamps are built into the combination meter

printed circuit.

GEL191

MEL425F

SEL901F

GEL192

WARNING LAMPS

EL-116

Page 578 of 1659

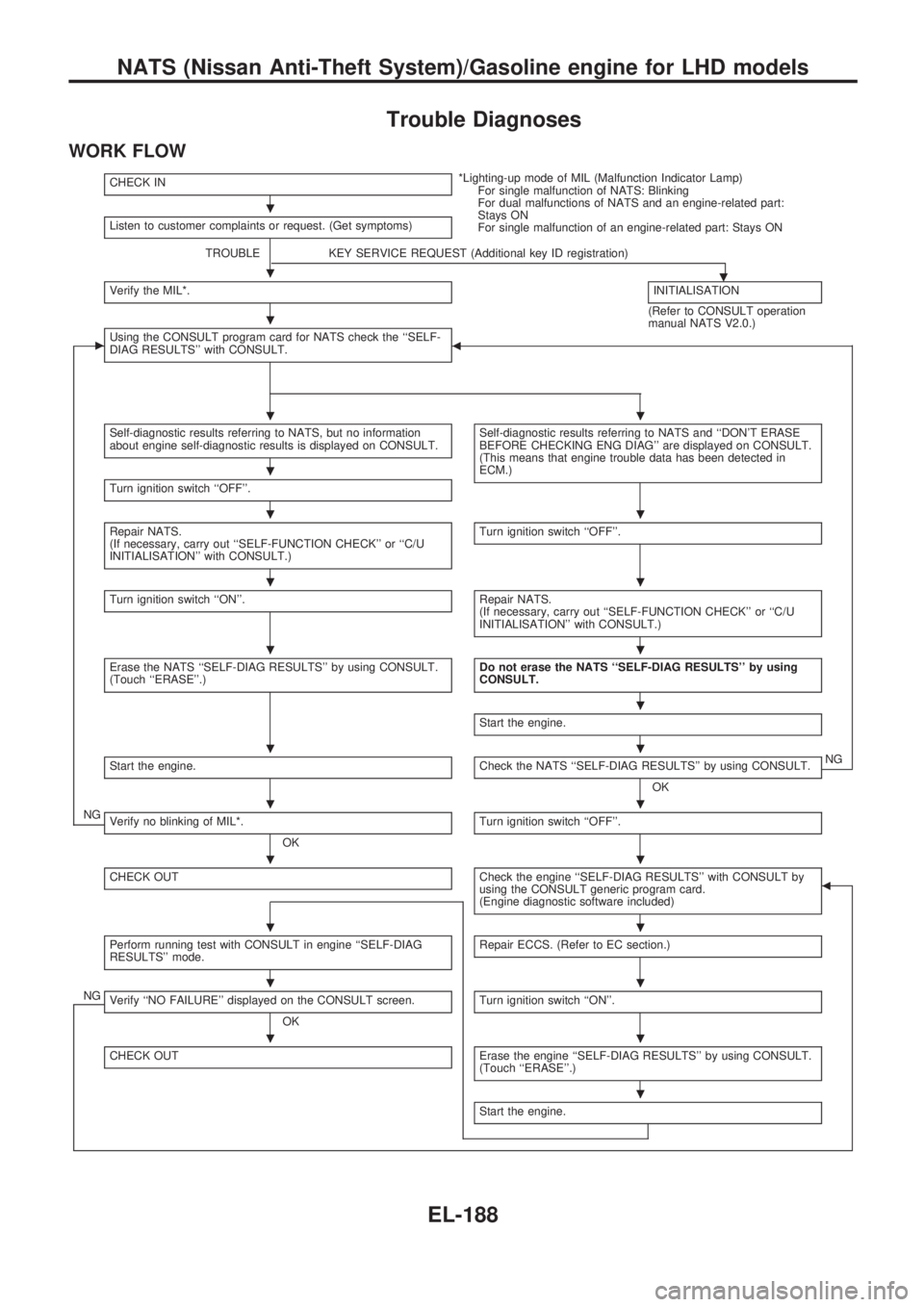

Trouble Diagnoses

WORK FLOW

CHECK IN*Lighting-up mode of MIL (Malfunction Indicator Lamp)

For single malfunction of NATS: Blinking

For dual malfunctions of NATS and an engine-related part:

Stays ON

For single malfunction of an engine-related part: Stays ON Listen to customer complaints or request. (Get symptoms)

TROUBLE KEY SERVICE REQUEST (Additional key ID registration)

.Verify the MIL*.INITIALISATION

(Refer to CONSULT operation

manual NATS V2.0.)

cUsing the CONSULT program card for NATS check the ``SELF-

DIAG RESULTS'' with CONSULT.b

Self-diagnostic results referring to NATS, but no information

about engine self-diagnostic results is displayed on CONSULT.Self-diagnostic results referring to NATS and ``DON'T ERASE

BEFORE CHECKING ENG DIAG'' are displayed on CONSULT.

(This means that engine trouble data has been detected in

ECM.)

Turn ignition switch ``OFF''.

Repair NATS.

(If necessary, carry out ``SELF-FUNCTION CHECK'' or ``C/U

INITIALISATION'' with CONSULT.)Turn ignition switch ``OFF''.

Turn ignition switch ``ON''.Repair NATS.

(If necessary, carry out ``SELF-FUNCTION CHECK'' or ``C/U

INITIALISATION'' with CONSULT.)

Erase the NATS ``SELF-DIAG RESULTS'' by using CONSULT.

(Touch ``ERASE''.)Do not erase the NATS ``SELF-DIAG RESULTS'' by using

CONSULT.

Start the engine.

Start the engine.Check the NATS ``SELF-DIAG RESULTS'' by using CONSULT.

OKNG

NGVerify no blinking of MIL*.

OKTurn ignition switch ``OFF''.

CHECK OUTCheck the engine ``SELF-DIAG RESULTS'' with CONSULT by

using the CONSULT generic program card.

(Engine diagnostic software included)b

Perform running test with CONSULT in engine ``SELF-DIAG

RESULTS'' mode.Repair ECCS. (Refer to EC section.)

NGVerify ``NO FAILURE'' displayed on the CONSULT screen.

OKTurn ignition switch ``ON''.

CHECK OUTErase the engine ``SELF-DIAG RESULTS'' by using CONSULT.

(Touch ``ERASE''.)

Start the engine.

.

.

.

..

.

..

..

..

.

..

..

..

..

..

..

.

NATS (Nissan Anti-Theft System)/Gasoline engine for LHD models

EL-188

Page 579 of 1659

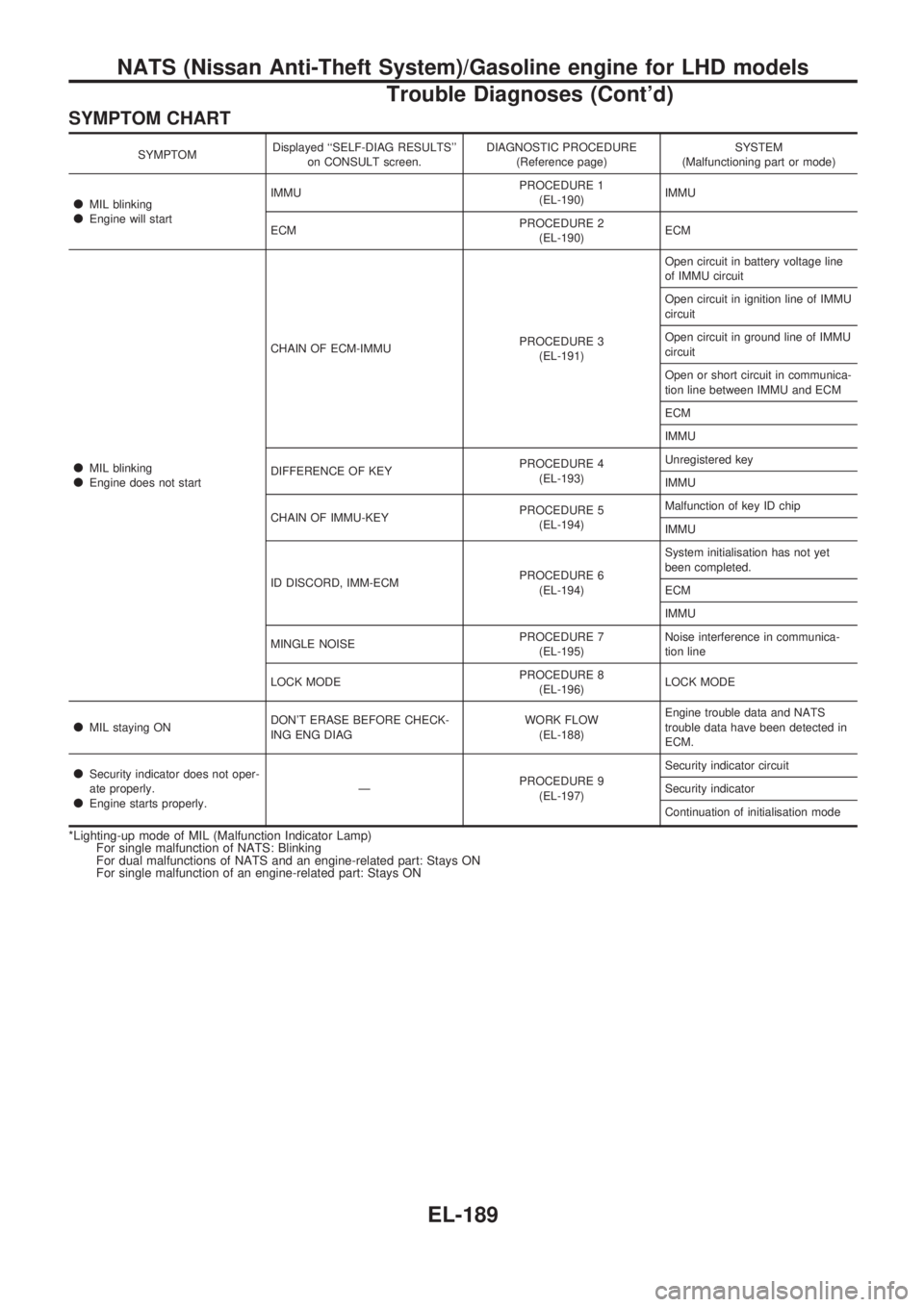

SYMPTOM CHART

SYMPTOMDisplayed ``SELF-DIAG RESULTS''

on CONSULT screen.DIAGNOSTIC PROCEDURE

(Reference page)SYSTEM

(Malfunctioning part or mode)

lMIL blinkinglEngine will startIMMUPROCEDURE 1

(EL-190)IMMU

ECMPROCEDURE 2

(EL-190)ECM

lMIL blinkinglEngine does not startCHAIN OF ECM-IMMUPROCEDURE 3

(EL-191)Open circuit in battery voltage line

of IMMU circuit

Open circuit in ignition line of IMMU

circuit

Open circuit in ground line of IMMU

circuit

Open or short circuit in communica-

tion line between IMMU and ECM

ECM

IMMU

DIFFERENCE OF KEYPROCEDURE 4

(EL-193)Unregistered key

IMMU

CHAIN OF IMMU-KEYPROCEDURE 5

(EL-194)Malfunction of key ID chip

IMMU

ID DISCORD, IMM-ECMPROCEDURE 6

(EL-194)System initialisation has not yet

been completed.

ECM

IMMU

MINGLE NOISEPROCEDURE 7

(EL-195)Noise interference in communica-

tion line

LOCK MODEPROCEDURE 8

(EL-196)LOCK MODE

lMIL staying ONDON'T ERASE BEFORE CHECK-

ING ENG DIAGWORK FLOW

(EL-188)Engine trouble data and NATS

trouble data have been detected in

ECM.

lSecurity indicator does not oper-

ate properly.

lEngine starts properly.ÐPROCEDURE 9

(EL-197)Security indicator circuit

Security indicator

Continuation of initialisation mode

*Lighting-up mode of MIL (Malfunction Indicator Lamp)

For single malfunction of NATS: Blinking

For dual malfunctions of NATS and an engine-related part: Stays ON

For single malfunction of an engine-related part: Stays ON

NATS (Nissan Anti-Theft System)/Gasoline engine for LHD models

Trouble Diagnoses (Cont'd)

EL-189

Page 595 of 1659

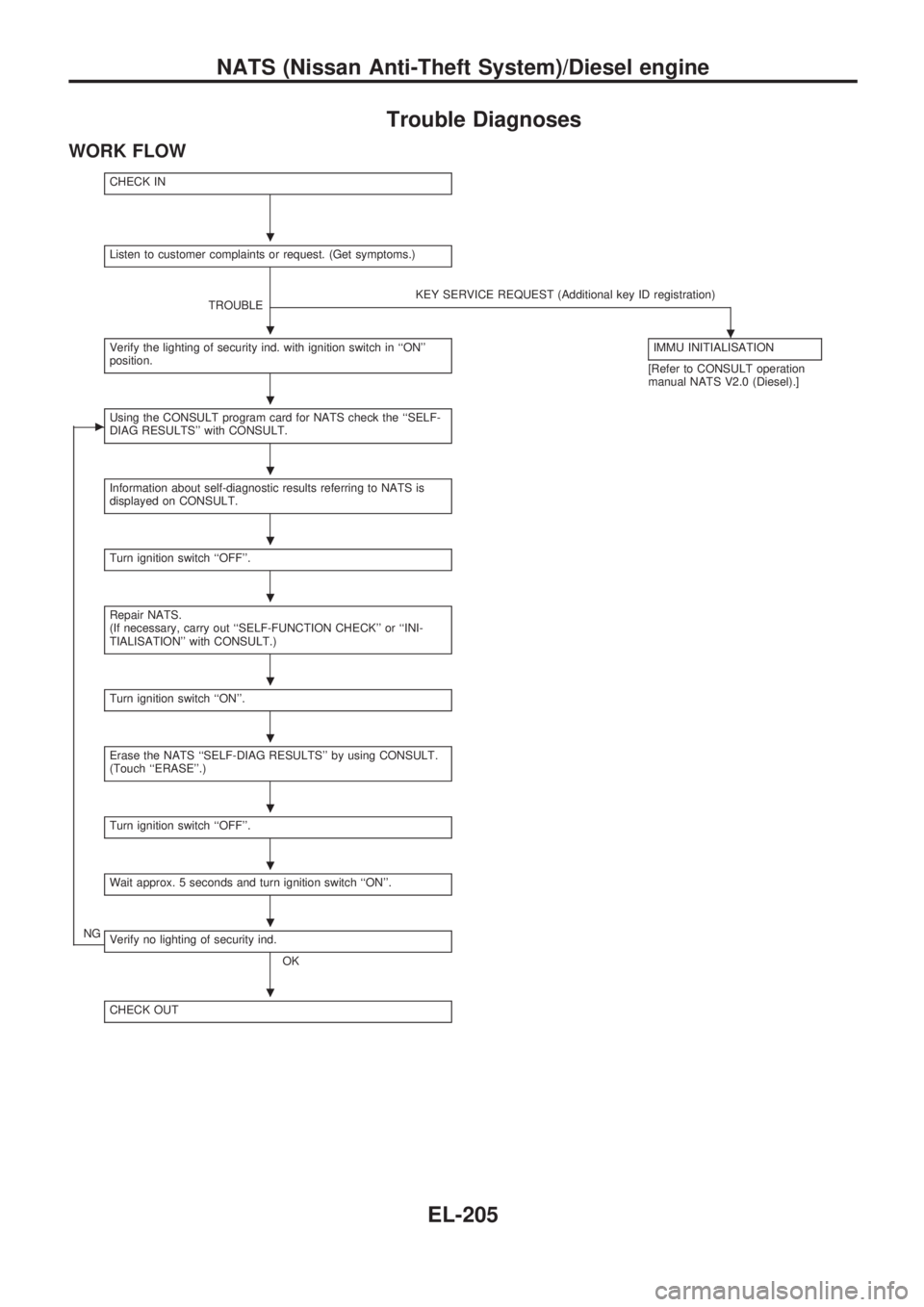

Trouble Diagnoses

WORK FLOW

CHECK IN

Listen to customer complaints or request. (Get symptoms.)

TROUBLEKEY SERVICE REQUEST (Additional key ID registration)

.Verify the lighting of security ind. with ignition switch in ``ON''

position.IMMU INITIALISATION

[Refer to CONSULT operation

manual NATS V2.0 (Diesel).]

cUsing the CONSULT program card for NATS check the ``SELF-

DIAG RESULTS'' with CONSULT.

Information about self-diagnostic results referring to NATS is

displayed on CONSULT.

Turn ignition switch ``OFF''.

Repair NATS.

(If necessary, carry out ``SELF-FUNCTION CHECK'' or ``INI-

TIALISATION'' with CONSULT.)

Turn ignition switch ``ON''.

Erase the NATS ``SELF-DIAG RESULTS'' by using CONSULT.

(Touch ``ERASE''.)

Turn ignition switch ``OFF''.

Wait approx. 5 seconds and turn ignition switch ``ON''.

NGVerify no lighting of security ind.

OK

CHECK OUT

.

.

.

.

.

.

.

.

.

.

.

.

NATS (Nissan Anti-Theft System)/Diesel engine

EL-205

Page 606 of 1659

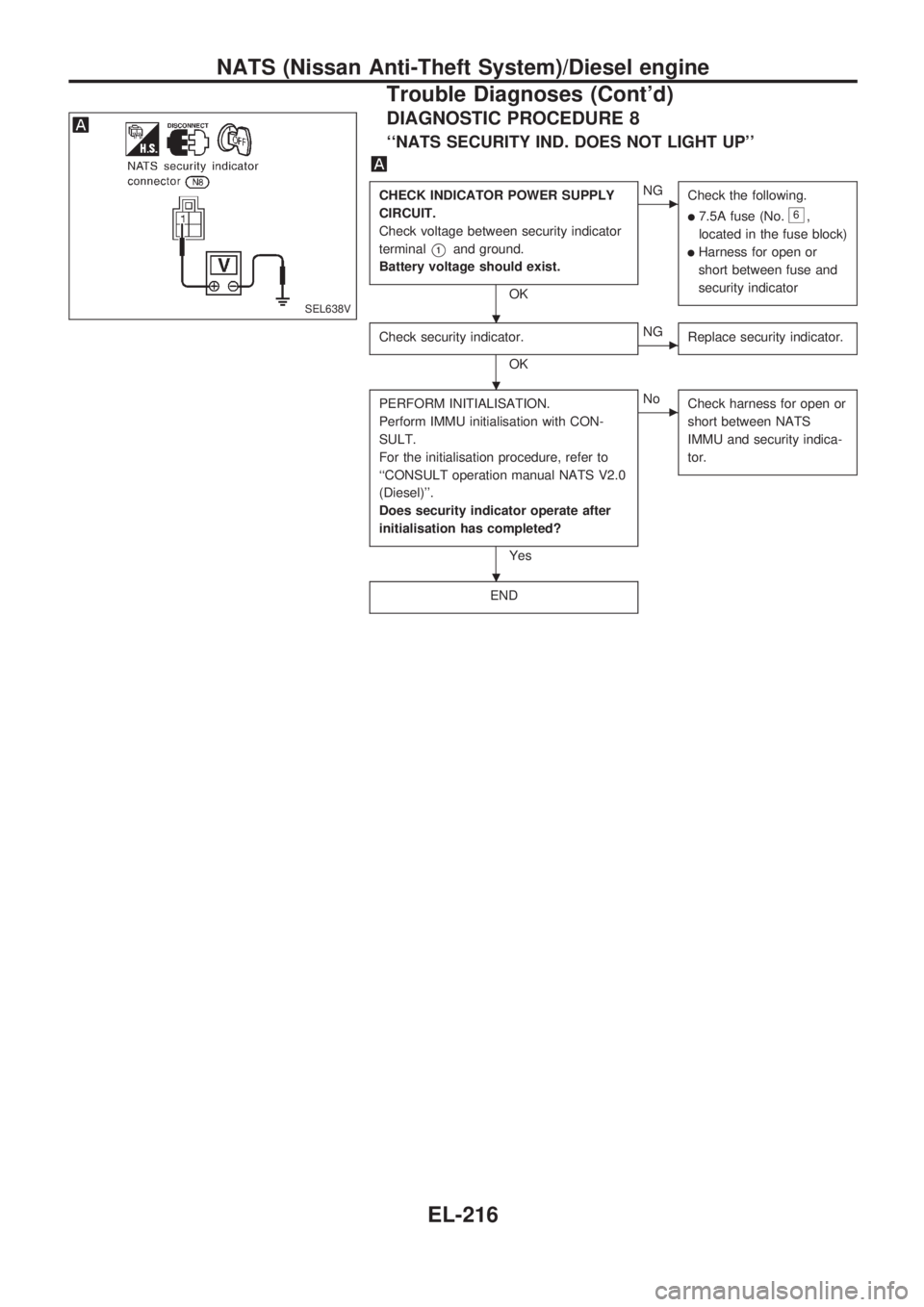

DIAGNOSTIC PROCEDURE 8

``NATS SECURITY IND. DOES NOT LIGHT UP''

CHECK INDICATOR POWER SUPPLY

CIRCUIT.

Check voltage between security indicator

terminal

V1and ground.

Battery voltage should exist.

OK

cNG

Check the following.

l7.5A fuse (No.6,

located in the fuse block)

lHarness for open or

short between fuse and

security indicator

Check security indicator.

OK

cNG

Replace security indicator.

PERFORM INITIALISATION.

Perform IMMU initialisation with CON-

SULT.

For the initialisation procedure, refer to

``CONSULT operation manual NATS V2.0

(Diesel)''.

Does security indicator operate after

initialisation has completed?

Yes

cNo

Check harness for open or

short between NATS

IMMU and security indica-

tor.

END

SEL638V.

.

.

NATS (Nissan Anti-Theft System)/Diesel engine

Trouble Diagnoses (Cont'd)

EL-216

Page 826 of 1659

Incident Simulation Tests

INTRODUCTION

Sometimes the symptom is not present when the vehicle is brought in for service. If possible, re-create the

conditions present at the time of the incident. Doing so may help avoid a No Trouble Found Diagnosis. The

following section illustrates ways to simulate the conditions/environment under which the owner experiences

an electrical incident.

The section is broken into the six following topics:

lVehicle vibration

lHeat sensitive

lFreezing

lWater intrusion

lElectrical load

lCold or hot start up

Get a thorough description of the incident from the customer. It is important for simulating the conditions of

the problem.

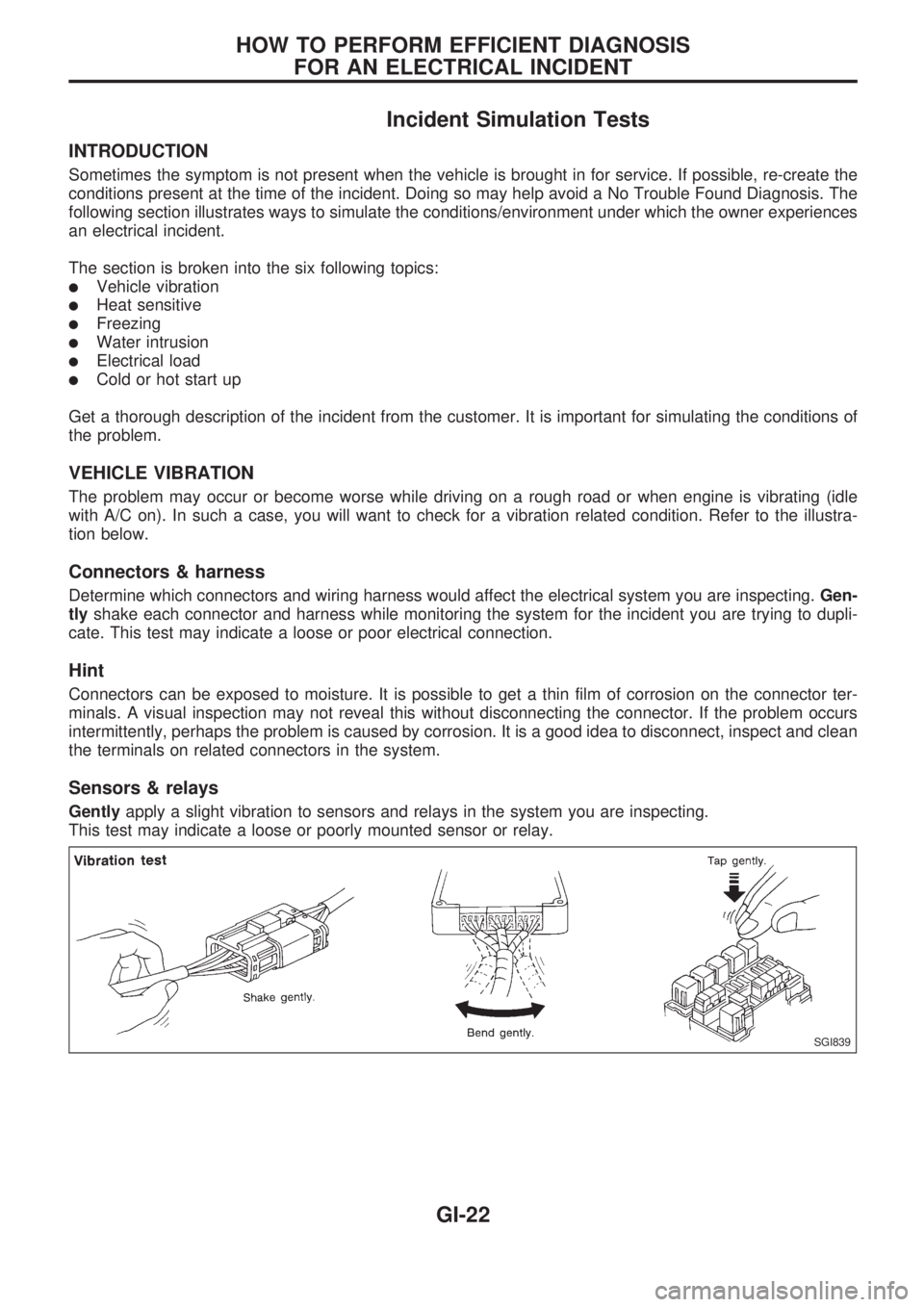

VEHICLE VIBRATION

The problem may occur or become worse while driving on a rough road or when engine is vibrating (idle

with A/C on). In such a case, you will want to check for a vibration related condition. Refer to the illustra-

tion below.

Connectors & harness

Determine which connectors and wiring harness would affect the electrical system you are inspecting.Gen-

tlyshake each connector and harness while monitoring the system for the incident you are trying to dupli-

cate. This test may indicate a loose or poor electrical connection.

Hint

Connectors can be exposed to moisture. It is possible to get a thin film of corrosion on the connector ter-

minals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs

intermittently, perhaps the problem is caused by corrosion. It is a good idea to disconnect, inspect and clean

the terminals on related connectors in the system.

Sensors & relays

Gentlyapply a slight vibration to sensors and relays in the system you are inspecting.

This test may indicate a loose or poorly mounted sensor or relay.

SGI839

HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT

GI-22

Page 860 of 1659

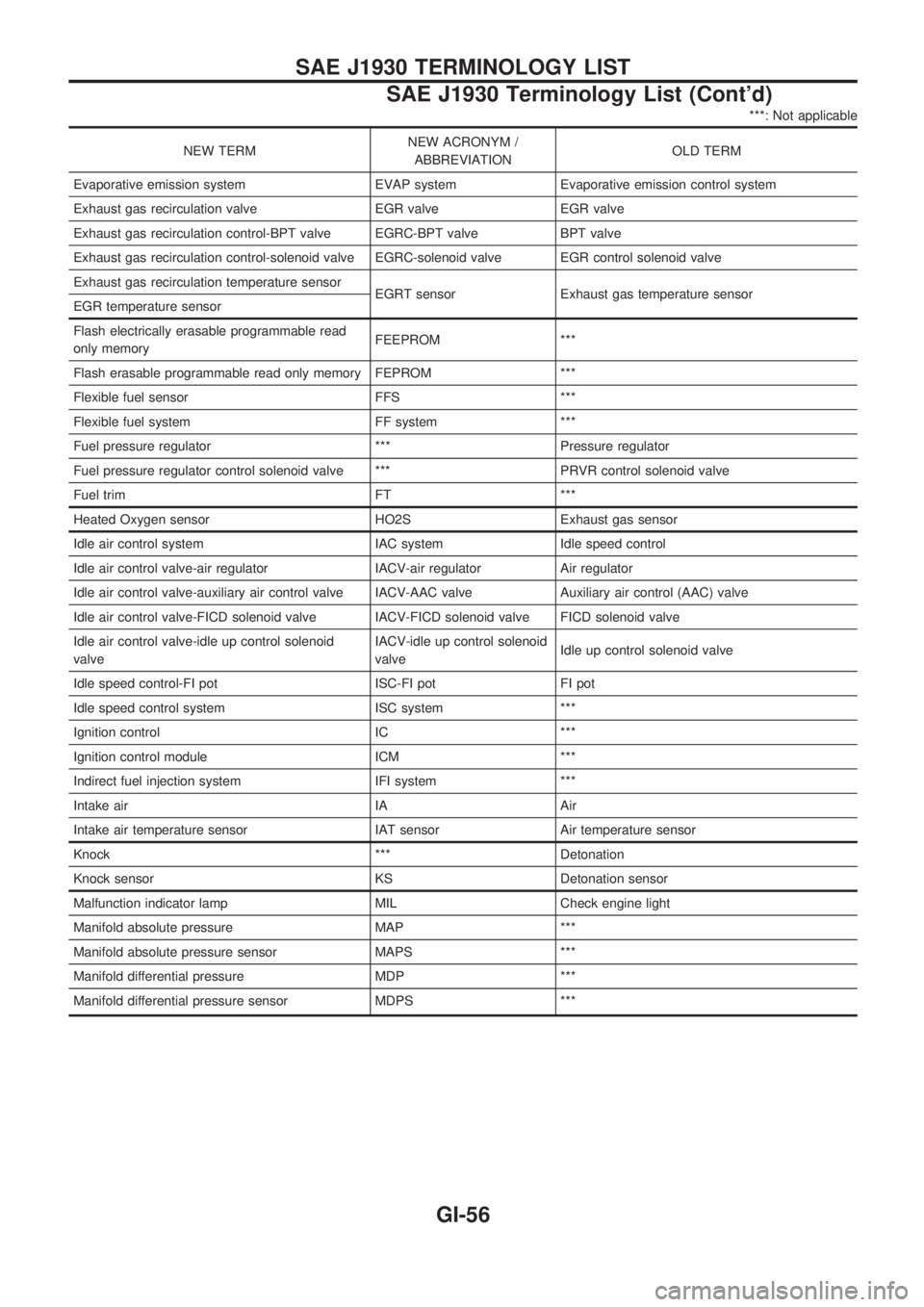

***: Not applicable

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Evaporative emission system EVAP system Evaporative emission control system

Exhaust gas recirculation valve EGR valve EGR valve

Exhaust gas recirculation control-BPT valve EGRC-BPT valve BPT valve

Exhaust gas recirculation control-solenoid valve EGRC-solenoid valve EGR control solenoid valve

Exhaust gas recirculation temperature sensor

EGRT sensor Exhaust gas temperature sensor

EGR temperature sensor

Flash electrically erasable programmable read

only memoryFEEPROM ***

Flash erasable programmable read only memory FEPROM ***

Flexible fuel sensor FFS ***

Flexible fuel system FF system ***

Fuel pressure regulator *** Pressure regulator

Fuel pressure regulator control solenoid valve *** PRVR control solenoid valve

Fuel trim FT ***

Heated Oxygen sensor HO2S Exhaust gas sensor

Idle air control system IAC system Idle speed control

Idle air control valve-air regulator IACV-air regulator Air regulator

Idle air control valve-auxiliary air control valve IACV-AAC valve Auxiliary air control (AAC) valve

Idle air control valve-FICD solenoid valve IACV-FICD solenoid valve FICD solenoid valve

Idle air control valve-idle up control solenoid

valveIACV-idle up control solenoid

valveIdle up control solenoid valve

Idle speed control-FI pot ISC-FI pot FI pot

Idle speed control system ISC system ***

Ignition control IC ***

Ignition control module ICM ***

Indirect fuel injection system IFI system ***

Intake air IA Air

Intake air temperature sensor IAT sensor Air temperature sensor

Knock *** Detonation

Knock sensor KS Detonation sensor

Malfunction indicator lamp MIL Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

SAE J1930 TERMINOLOGY LIST

SAE J1930 Terminology List (Cont'd)

GI-56