NISSAN PRIMERA 1999 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 751 of 2267

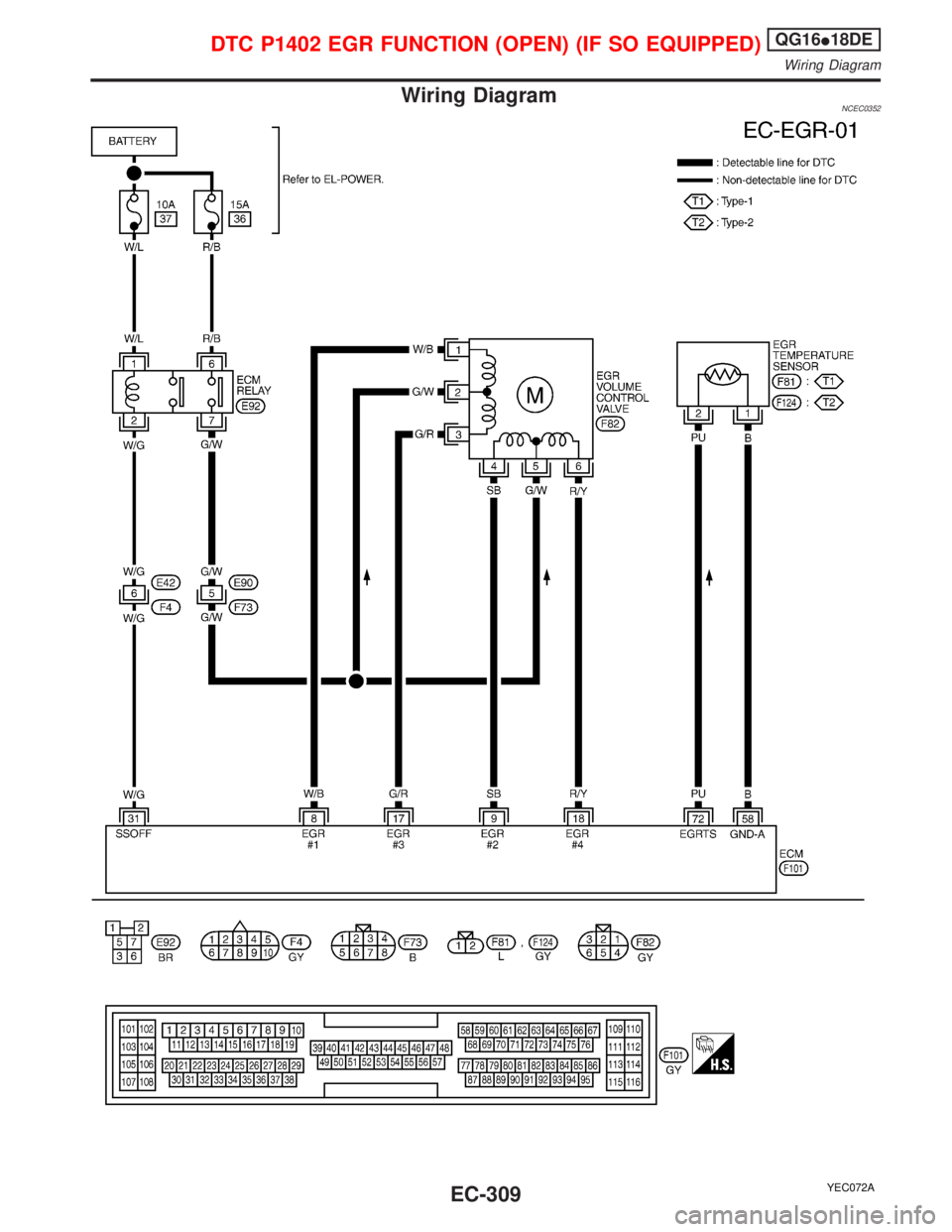

Wiring DiagramNCEC0352

YEC072A

DTC P1402 EGR FUNCTION (OPEN) (IF SO EQUIPPED)QG16I18DE

Wiring Diagram

EC-309

Page 752 of 2267

Diagnostic ProcedureNCEC0353

1 CHECK POWER SUPPLY

1. Disconnect EGR volume control valve harness connector.

2. Turn ignition switch ªONº.

3. Check voltage between terminals 2, 5 and ground with CONSULT-II or tester.

SEF556WVoltage: Battery voltage

OK or NG

OK©GO TO 2.

NG©Check the following.

IHarness or connectors E90, F73

IHarness for open or short between EGR volume control valve and engine control

module relay

If NG, repair harness or connectors.

2 CHECK OUTPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between

ECM terminal 8 and EGR volume control valve terminal 1,

ECM terminal 9 and EGR volume control valve terminal 4,

ECM terminal 17 and EGR volume control valve terminal 3,

ECM terminal 18 and EGR volume control valve terminal 6.

Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short to ground and short to power.

OK or NG

OK©GO TO 3.

NG©Repair open circuit, short to ground or short to power in harness connectors.

3 CHECK EGR TEMPERATURE SENSOR

Refer to ªComponent Inspectionº, EC-QG-304.

OK or NG

OK©GO TO 4.

NG©Replace EGR temperature sensor.

4 CHECK EGR VOLUME CONTROL VALVE

Refer to ªComponent Inspectionº, EC-QG-251.

OK or NG

OK©GO TO 5.

NG©Replace EGR volume control valve.

DTC P1402 EGR FUNCTION (OPEN) (IF SO EQUIPPED)QG16I18DE

Diagnostic Procedure

EC-310

Page 753 of 2267

5 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-QG-102.

©INSPECTION END

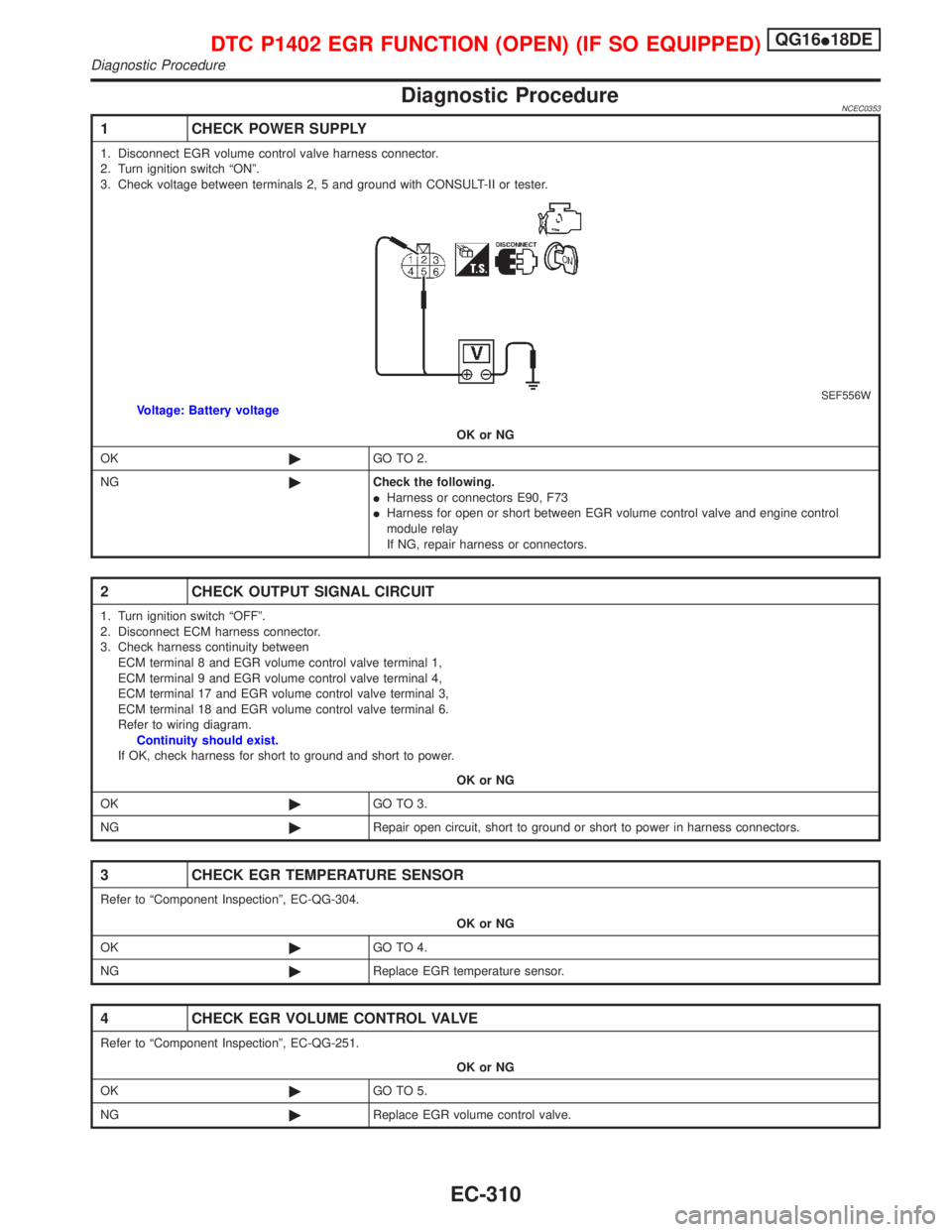

Component InspectionNCEC0354EGR TEMPERATURE SENSORNCEC0354S01Check resistance change and resistance value.

EGR temperature

ÉC (ÉF)Voltage

VResistance

MW

0 (32) 4.56 0.62 - 1.05

50 (122) 2.25 0.065 - 0.094

100 (212) 0.59 0.011 - 0.015

If NG, replace EGR temperature sensor.

SEF643Q

SEF068X

DTC P1402 EGR FUNCTION (OPEN) (IF SO EQUIPPED)QG16I18DE

Diagnostic Procedure (Cont'd)

EC-311

Page 754 of 2267

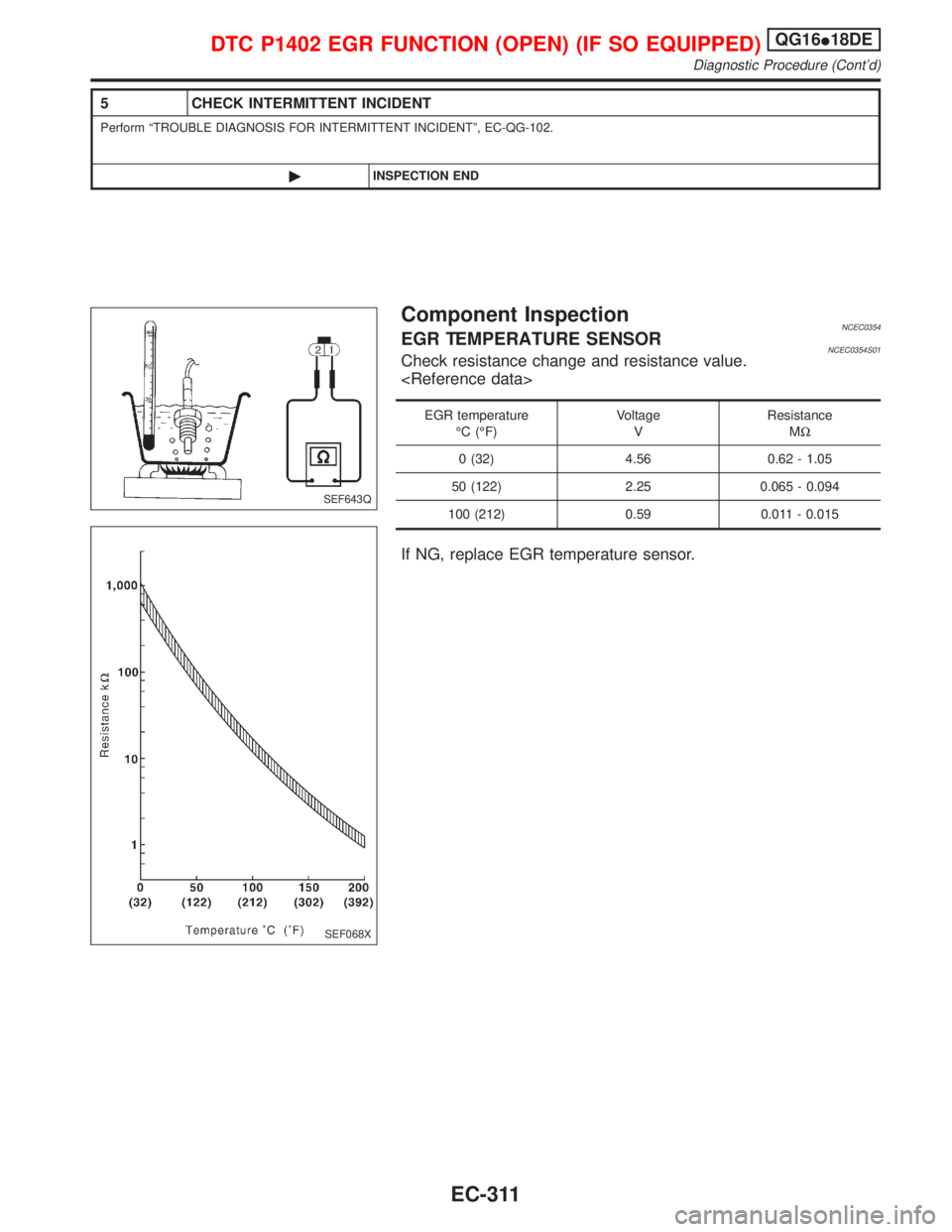

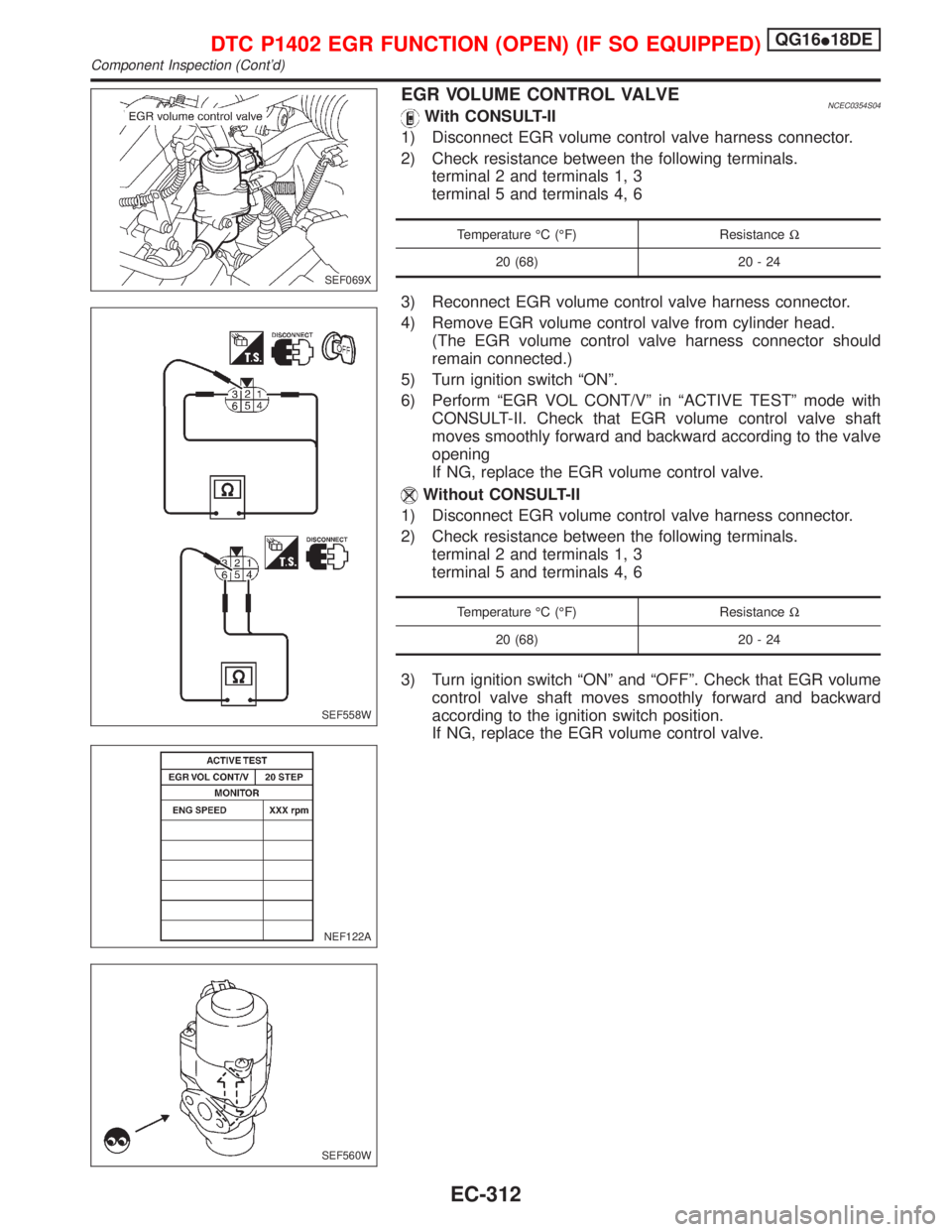

EGR VOLUME CONTROL VALVENCEC0354S04With CONSULT-II

1) Disconnect EGR volume control valve harness connector.

2) Check resistance between the following terminals.

terminal 2 and terminals 1, 3

terminal 5 and terminals 4, 6

Temperature ÉC (ÉF) ResistanceW

20 (68) 20 - 24

3) Reconnect EGR volume control valve harness connector.

4) Remove EGR volume control valve from cylinder head.

(The EGR volume control valve harness connector should

remain connected.)

5) Turn ignition switch ªONº.

6) Perform ªEGR VOL CONT/Vº in ªACTIVE TESTº mode with

CONSULT-II. Check that EGR volume control valve shaft

moves smoothly forward and backward according to the valve

opening

If NG, replace the EGR volume control valve.

Without CONSULT-II

1) Disconnect EGR volume control valve harness connector.

2) Check resistance between the following terminals.

terminal 2 and terminals 1, 3

terminal 5 and terminals 4, 6

Temperature ÉC (ÉF) ResistanceW

20 (68) 20 - 24

3) Turn ignition switch ªONº and ªOFFº. Check that EGR volume

control valve shaft moves smoothly forward and backward

according to the ignition switch position.

If NG, replace the EGR volume control valve.

SEF069X

SEF558W

NEF122A

SEF560W

DTC P1402 EGR FUNCTION (OPEN) (IF SO EQUIPPED)QG16I18DE

Component Inspection (Cont'd)

EC-312

Page 755 of 2267

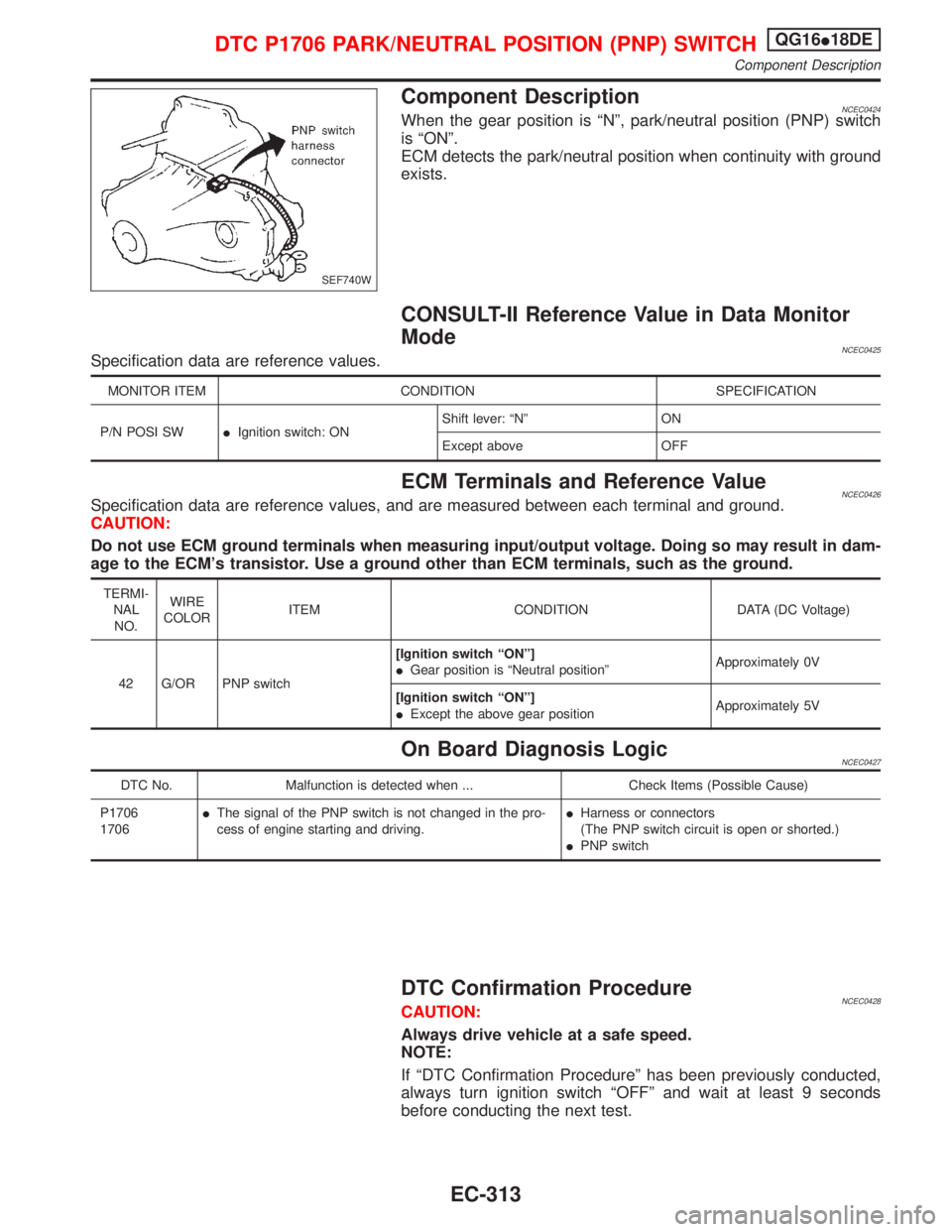

Component DescriptionNCEC0424When the gear position is ªNº, park/neutral position (PNP) switch

is ªONº.

ECM detects the park/neutral position when continuity with ground

exists.

CONSULT-II Reference Value in Data Monitor

Mode

NCEC0425Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

P/N POSI SWIIgnition switch: ONShift lever: ªNº ON

Except above OFF

ECM Terminals and Reference ValueNCEC0426Specification data are reference values, and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

42 G/OR PNP switch[Ignition switch ªONº]

IGear position is ªNeutral positionºApproximately 0V

[Ignition switch ªONº]

IExcept the above gear positionApproximately 5V

On Board Diagnosis LogicNCEC0427

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P1706

1706IThe signal of the PNP switch is not changed in the pro-

cess of engine starting and driving.IHarness or connectors

(The PNP switch circuit is open or shorted.)

IPNP switch

DTC Confirmation ProcedureNCEC0428CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

SEF740W

DTC P1706 PARK/NEUTRAL POSITION (PNP) SWITCHQG16I18DE

Component Description

EC-313

Page 756 of 2267

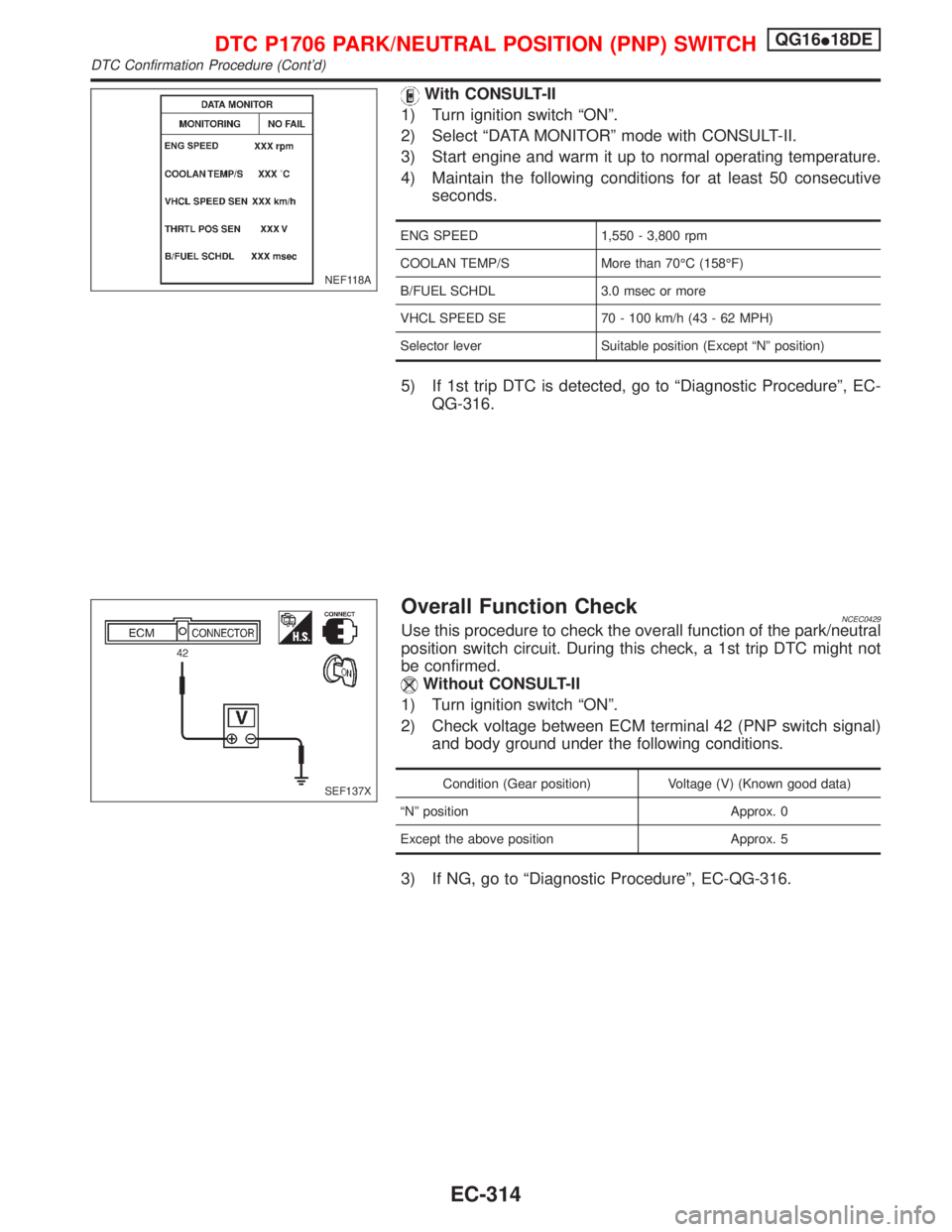

With CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and warm it up to normal operating temperature.

4) Maintain the following conditions for at least 50 consecutive

seconds.

ENG SPEED 1,550 - 3,800 rpm

COOLAN TEMP/S More than 70ÉC (158ÉF)

B/FUEL SCHDL 3.0 msec or more

VHCL SPEED SE 70 - 100 km/h (43 - 62 MPH)

Selector lever Suitable position (Except ªNº position)

5) If 1st trip DTC is detected, go to ªDiagnostic Procedureº, EC-

QG-316.

Overall Function CheckNCEC0429Use this procedure to check the overall function of the park/neutral

position switch circuit. During this check, a 1st trip DTC might not

be confirmed.

Without CONSULT-II

1) Turn ignition switch ªONº.

2) Check voltage between ECM terminal 42 (PNP switch signal)

and body ground under the following conditions.

Condition (Gear position) Voltage (V) (Known good data)

ªNº position Approx. 0

Except the above position Approx. 5

3) If NG, go to ªDiagnostic Procedureº, EC-QG-316.

NEF118A

SEF137X

DTC P1706 PARK/NEUTRAL POSITION (PNP) SWITCHQG16I18DE

DTC Confirmation Procedure (Cont'd)

EC-314

Page 757 of 2267

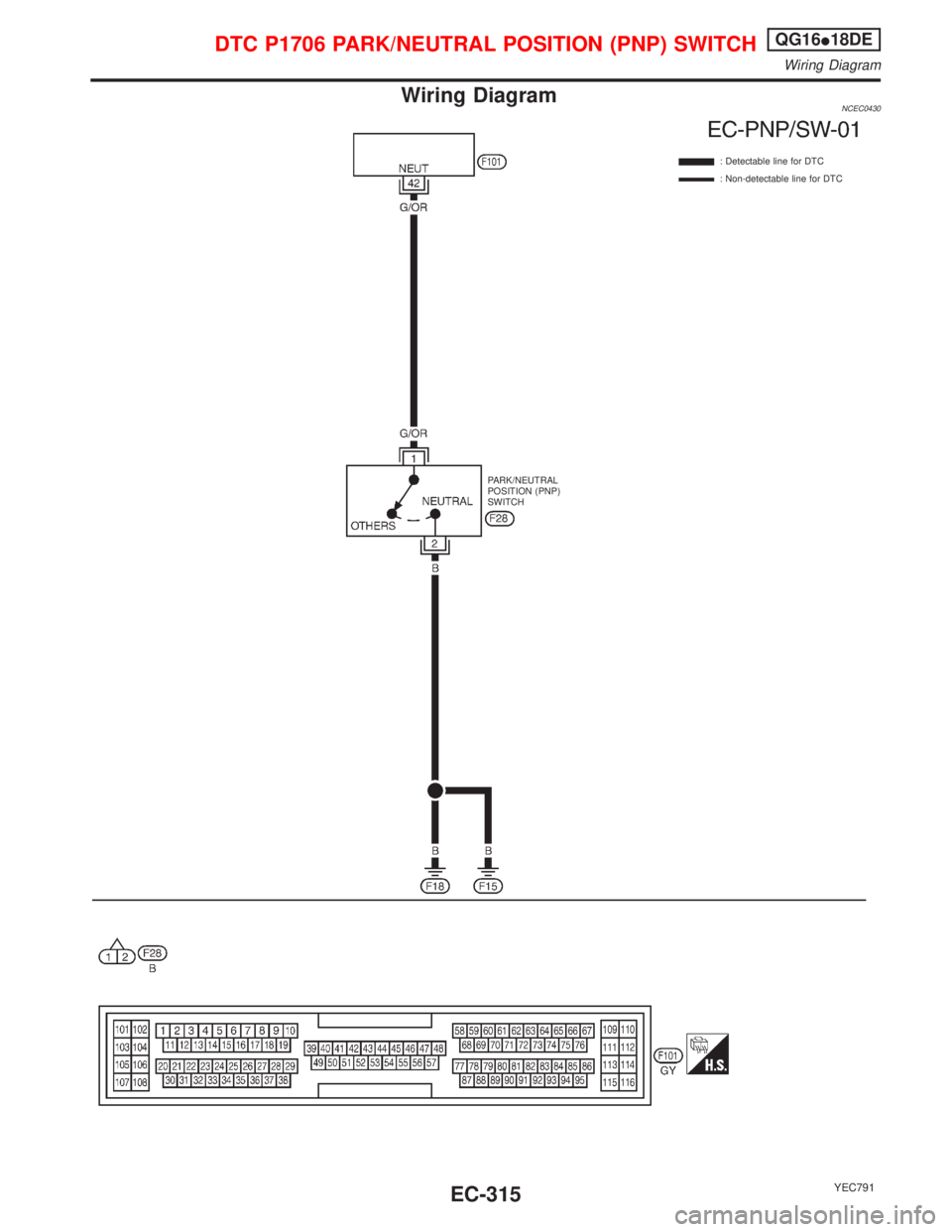

Wiring DiagramNCEC0430

YEC791

: Detectable line for DTC

: Non-detectable line for DTC

PARK/NEUTRAL

POSITION (PNP)

SWITCH

DTC P1706 PARK/NEUTRAL POSITION (PNP) SWITCHQG16I18DE

Wiring Diagram

EC-315

Page 758 of 2267

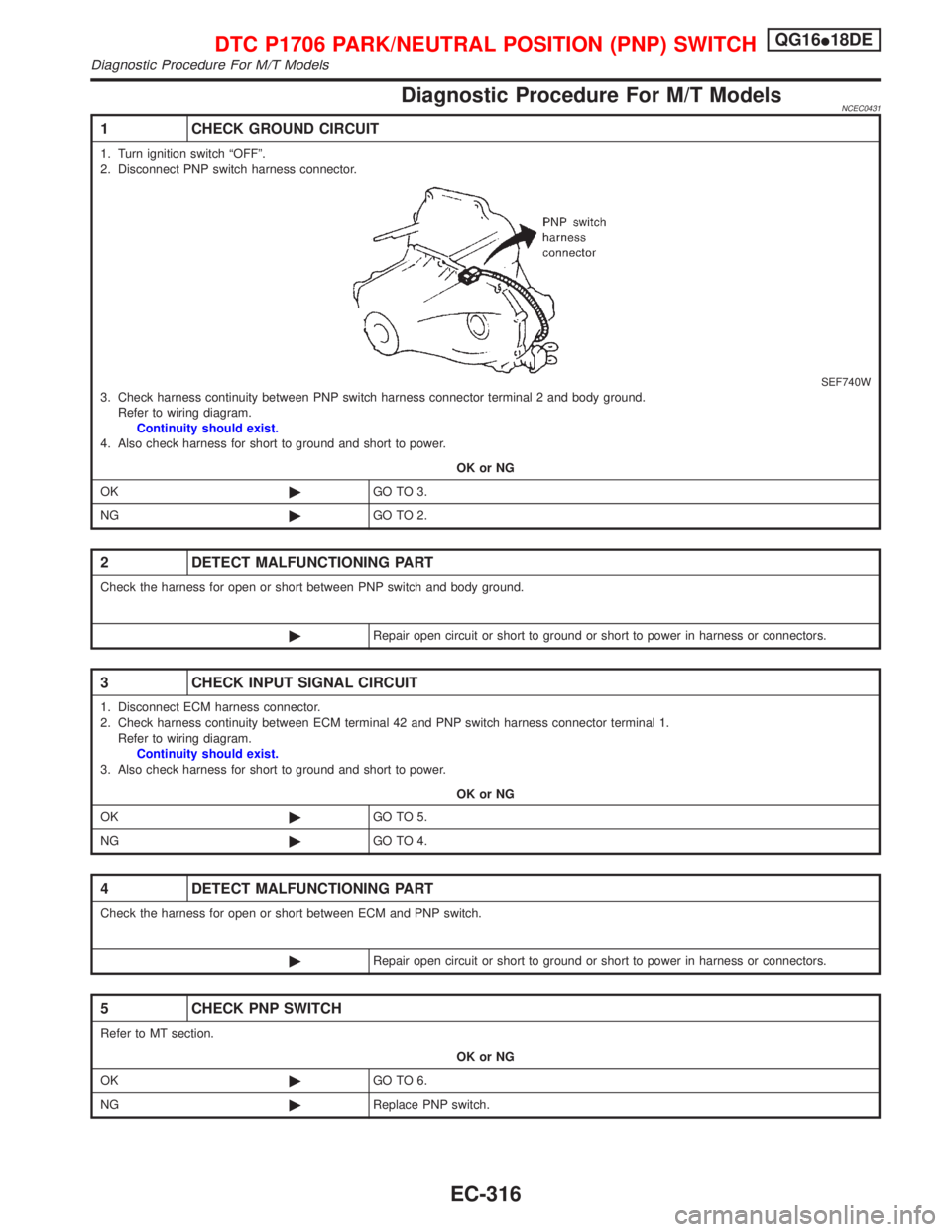

Diagnostic Procedure For M/T ModelsNCEC0431

1 CHECK GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect PNP switch harness connector.

SEF740W3. Check harness continuity between PNP switch harness connector terminal 2 and body ground.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the harness for open or short between PNP switch and body ground.

©Repair open circuit or short to ground or short to power in harness or connectors.

3 CHECK INPUT SIGNAL CIRCUIT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 42 and PNP switch harness connector terminal 1.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©GO TO 4.

4 DETECT MALFUNCTIONING PART

Check the harness for open or short between ECM and PNP switch.

©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK PNP SWITCH

Refer to MT section.

OK or NG

OK©GO TO 6.

NG©Replace PNP switch.

DTC P1706 PARK/NEUTRAL POSITION (PNP) SWITCHQG16I18DE

Diagnostic Procedure For M/T Models

EC-316

Page 759 of 2267

6 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-QG-102.

©INSPECTION END

DTC P1706 PARK/NEUTRAL POSITION (PNP) SWITCHQG16I18DE

Diagnostic Procedure For M/T Models (Cont'd)

EC-317

Page 760 of 2267

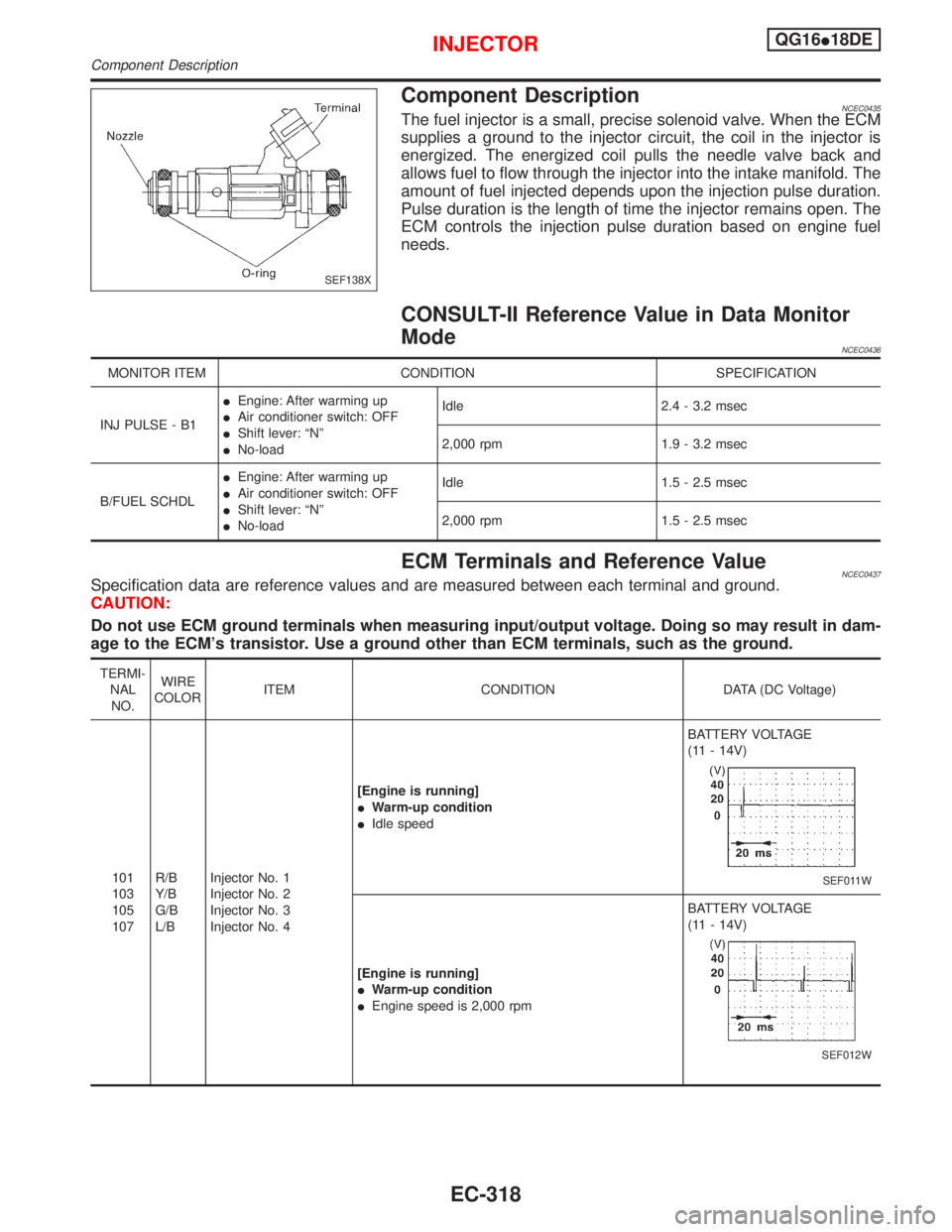

Component DescriptionNCEC0435The fuel injector is a small, precise solenoid valve. When the ECM

supplies a ground to the injector circuit, the coil in the injector is

energized. The energized coil pulls the needle valve back and

allows fuel to flow through the injector into the intake manifold. The

amount of fuel injected depends upon the injection pulse duration.

Pulse duration is the length of time the injector remains open. The

ECM controls the injection pulse duration based on engine fuel

needs.

CONSULT-II Reference Value in Data Monitor

Mode

NCEC0436

MONITOR ITEM CONDITION SPECIFICATION

INJ PULSE - B1IEngine: After warming up

IAir conditioner switch: OFF

IShift lever: ªNº

INo-loadIdle 2.4 - 3.2 msec

2,000 rpm 1.9 - 3.2 msec

B/FUEL SCHDLIEngine: After warming up

IAir conditioner switch: OFF

IShift lever: ªNº

INo-loadIdle 1.5 - 2.5 msec

2,000 rpm 1.5 - 2.5 msec

ECM Terminals and Reference ValueNCEC0437Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

101

103

105

107R/B

Y/B

G/B

L/BInjector No. 1

Injector No. 2

Injector No. 3

Injector No. 4[Engine is running]

IWarm-up condition

IIdle speedBATTERY VOLTAGE

(11 - 14V)

SEF011W

[Engine is running]

IWarm-up condition

IEngine speed is 2,000 rpmBATTERY VOLTAGE

(11 - 14V)

SEF012W

SEF138X

INJECTORQG16I18DE

Component Description

EC-318