light NISSAN QASHQAI 2012 Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2012, Model line: QASHQAI, Model: NISSAN QASHQAI 2012Pages: 297, PDF Size: 4.09 MB

Page 234 of 297

Downloaded from www.Manualslib.com manuals search engine Lights*:

Clean the headlights on a regular basis. Make sure

that the headlights, stop lights, tail lights, turn signal

lights, and other lights are all operating properly and

installed securely. Also check headlight aim.

Tyres*:

Check the pressure with a gauge periodically when

at a service station (including the spare) and adjust

to the specified pressure if necessary. Check care-

fully for damage, cuts or excessive wear.

Tyre rotation*:

Tyres should be rotated every 10,000 km (6,000

miles) for Two-Wheel Drive (2WD) models and

5,000 km (3,000 miles) for Four-Wheel Drive (4WD)

models. However, the timing for tyre rotation may

vary according to your driving habits and road sur-

face conditions.

Wheel alignment and balance:

If the vehicle pull to either side while driving on a

straight and level road, or if you detect uneven or

abnormal tyre wear, there may be a need for wheel

alignment. If the steering wheel or seat vibrates at

normal highway speeds, wheel balancing may be

needed.

Wheel nuts:

When checking the tyres, make sure no wheel nuts

are missing, and check for any loose wheel nuts.

Tighten if necessary.Windscreen:

Clean the windscreen on a regular basis. Check the

windscreen at least every six months for cracks or

other damage. Have a damaged windscreen re-

paired by a qualified repair facility.

Wiper blades*:

Check for cracks or wear if they do not wipe prop-

erly.

Under the bonnet and vehicle

The maintenance items listed here should be

checked periodically, e.g. each time you check the

engine oil or refuel.

Battery*:

Check if the green indicator on the top of the main-

tenance free battery is visible. If it is not visible,

replace the battery as soon as possible.

Vehicles operated in high temperatures or under

severe conditions, check the fluid level frequently.

Brake and clutch fluid level*:

Make sure that the brake and clutch fluid level is

between the MAX and MIN lines on the reservoir.

Engine coolant level*:

Check the coolant level when the engine is cold.

Engine drive belts*:

Make sure that the drive belts are not frayed, worn,

cracked or oily.Engine oil level*:

Check the level after parking the vehicle on a level

surface and turning off the engine.

Fluid leaks:

Check under the vehicle for fuel, oil, water or other

fluid leaks after the vehicle has been parked for a

while. Water dripping from the air conditioner after

use is normal. If you should notice any leaks or if

petrol fumes are evident, check for the cause and

have it corrected immediately.

Window washer fluid*:

Check that there is adequate fluid in the tank.

Inside the vehicle

The maintenance items listed here should be

checked on a regular basis, such as when perform-

ing periodic maintenance, cleaning the vehicle, etc.

Accelerator pedal:

Check the pedal for smooth operation and make

sure that the pedal does not catch or require uneven

effort. Keep the floor mats away from the pedal.

Brake pedal*:

Check the pedal for smooth operation. If the brake

pedal suddenly goes down further than normal, the

pedal feels spongy or the vehicle seems to take

longer to stop, contact a NISSAN dealer or qualified

workshop immediately. Keep the floor mat away

from the pedal.

Maintenance and do-it-yourself8-3

Page 235 of 297

Downloaded from www.Manualslib.com manuals search engine Handbrake*:

Confirm that your vehicle is held securely on a fairly

steep hill with only the handbrake applied.

Seats:

Check seat position controls such as seat adjust-

ers, seatback recliner, etc. to ensure they operate

smoothly and all latches lock securely in every posi-

tion. Check that the head restraints move up and

down smoothly and the locks hold securely in all

latched positions.

Seat belts:

Check that all parts of the seat belt system (e.g.

buckles, anchors, adjusters and retractors) operate

properly and smoothly, and are installed securely.

Check the belt webbing for cuts, fraying, wear or

damage. See “Seat belts” in the “1. Safety — seats,

seat belts and supplemental restraint system” sec-

tion for further details.

Steering wheel:

Check for any change in the steering conditions,

such as excessive free play, hard steering or strange

noises.

Warning lights and audible reminders:

Make sure that all warning/indicator lights and au-

dible reminders are operating properly.

Windscreen defogger:

Check that the air comes out of the defogger outlets

properly when operating the heater or air condi-

tioner.Windscreen wiper and washer*:

Check that the wipers and washer operate properly

and that the wipers do not streak.

When performing any inspection or maintenance

work on your vehicle, always take care to prevent

serious accidental injury to yourself or damage to

the vehicle. The following are general precautions

which should be closely observed.

Park the vehicle on a level surface, apply the

handbrake securely and block the wheels to

prevent the vehicle from moving. For a manual

transmission models, move the gear lever to

N (Neutral) position.[For automatic transmis-

sion or continuously variable transmission

models: move the selector lever to P (Park)

position.]

Do not work under the engine bonnet while

the engine is hot. Turn off the engine and wait

until it cools down.

Be sure to turn the ignition switch to the “OFF”

or LOCK position.

When the ignition switch is in the ON or Acc

position, the cooling fan may start to operate

suddenly even when the engine is not run-

ning. To avoid injury, always disconnect the

negative battery cable before working near

the engine.

If you must work with the engine running,

keep your hands, clothing, hair and tools away

from moving fans, belts and any other moving

parts.

It is advisable to remove ties and any jewel-

lery, such as rings, watches, etc. before work-

ing on your vehicle.

MAINTENANCE PRECAUTIONS

8-4Maintenance and do-it-yourself

Page 242 of 297

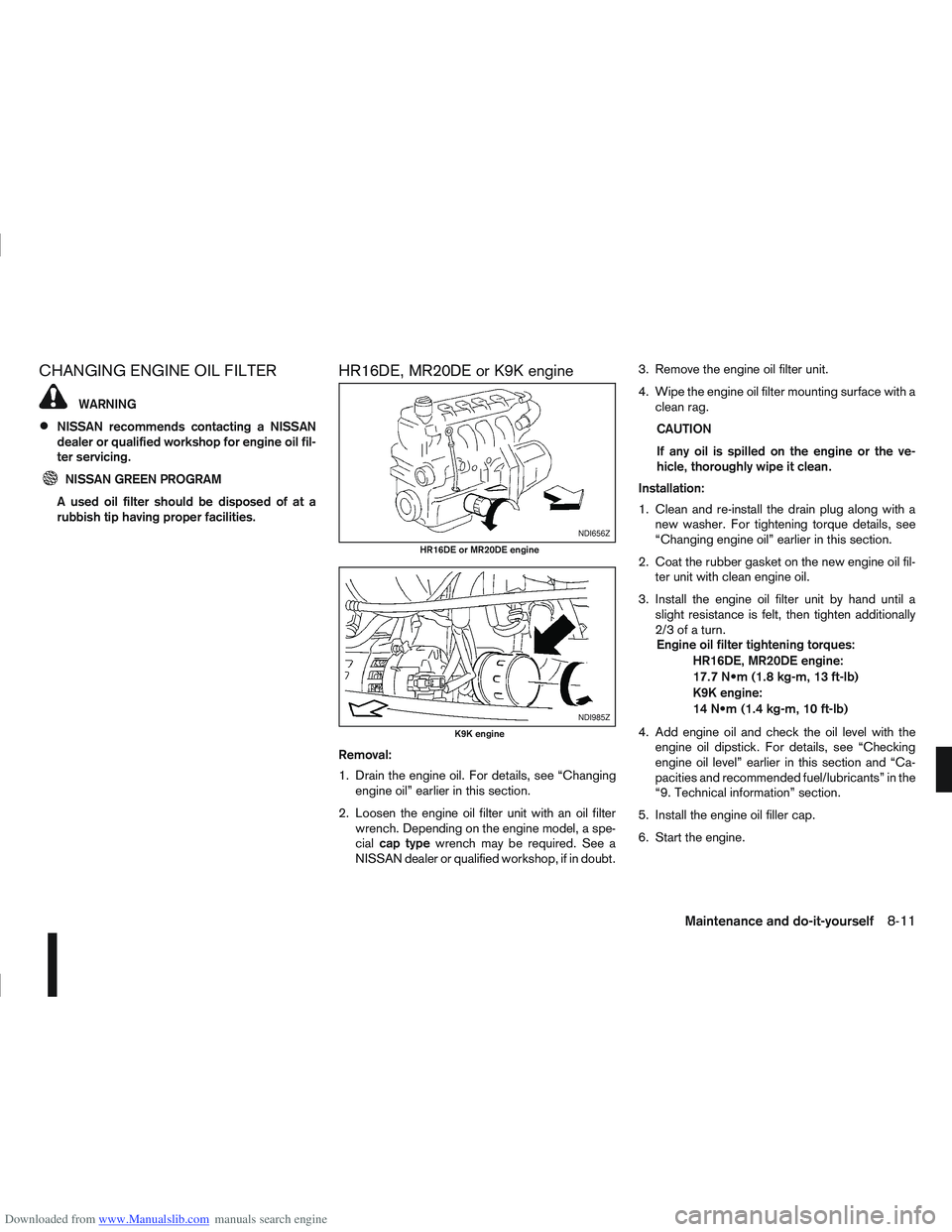

Downloaded from www.Manualslib.com manuals search engine CHANGING ENGINE OIL FILTER

WARNING

NISSAN recommends contacting a NISSAN

dealer or qualified workshop for engine oil fil-

ter servicing.

NISSAN GREEN PROGRAM

A used oil filter should be disposed of at a

rubbish tip having proper facilities.

HR16DE, MR20DE or K9K engine

Removal:

1. Drain the engine oil. For details, see “Changing engine oil” earlier in this section.

2. Loosen the engine oil filter unit with an oil filter wrench. Depending on the engine model, a spe-

cial cap type wrench may be required. See a

NISSAN dealer or qualified workshop, if in doubt. 3. Remove the engine oil filter unit.

4. Wipe the engine oil filter mounting surface with a

clean rag.

CAUTION

If any oil is spilled on the engine or the ve-

hicle, thoroughly wipe it clean.

Installation:

1. Clean and re-install the drain plug along with a new washer. For tightening torque details, see

“Changing engine oil” earlier in this section.

2. Coat the rubber gasket on the new engine oil fil- ter unit with clean engine oil.

3. Install the engine oil filter unit by hand until a slight resistance is felt, then tighten additionally

2/3ofaturn.Engine oil filter tightening torques:

HR16DE, MR20DE engine:

17.7 (1.8 kg-m, 13 ft-lb)

K9K engine:

14 (1.4 kg-m, 10 ft-lb)

4. Add engine oil and check the oil level with the engine oil dipstick. For details, see “Checking

engine oil level” earlier in this section and “Ca-

pacities and recommended fuel/lubricants” in the

“9. Technical information” section.

5. Install the engine oil filler cap.

6. Start the engine.

NDI656Z

HR16DE or MR20DE engine

NDI985Z

K9K engine

Maintenance and do-it-yourself8-11

Page 243 of 297

Downloaded from www.Manualslib.com manuals search engine 7. After the engine has been warmed up, make surethere are no leaks around the engine oil filter unit

and the drain plug. Correct as required.

8. Turn the engine off and wait several minutes. Check the oil level and add engine oil, if neces-

sary.

9. Install the engine compartment under cover.

10. Lower the vehicle carefully to the ground.

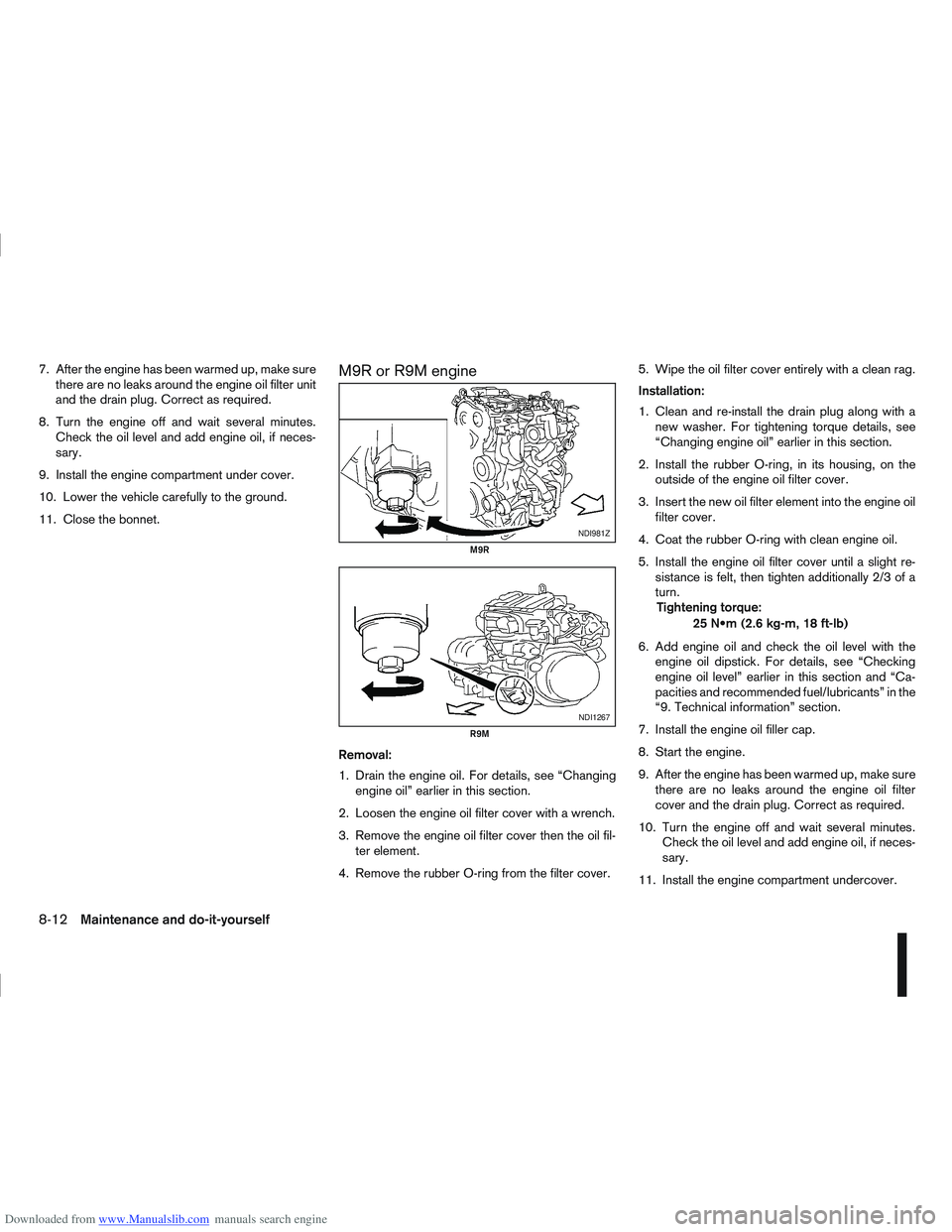

11. Close the bonnet.M9R or R9M engine

Removal:

1. Drain the engine oil. For details, see “Changing engine oil” earlier in this section.

2. Loosen the engine oil filter cover with a wrench.

3. Remove the engine oil filter cover then the oil fil- ter element.

4. Remove the rubber O-ring from the filter cover. 5. Wipe the oil filter cover entirely with a clean rag.

Installation:

1. Clean and re-install the drain plug along with a

new washer. For tightening torque details, see

“Changing engine oil” earlier in this section.

2. Install the rubber O-ring, in its housing, on the outside of the engine oil filter cover.

3. Insert the new oil filter element into the engine oil filter cover.

4. Coat the rubber O-ring with clean engine oil.

5. Install the engine oil filter cover until a slight re- sistance is felt, then tighten additionally 2/3 of a

turn.Tightening torque:

25 (2.6 kg-m, 18 ft-lb)

6. Add engine oil and check the oil level with the engine oil dipstick. For details, see “Checking

engine oil level” earlier in this section and “Ca-

pacities and recommended fuel/lubricants” in the

“9. Technical information” section.

7. Install the engine oil filler cap.

8. Start the engine.

9. After the engine has been warmed up, make sure there are no leaks around the engine oil filter

cover and the drain plug. Correct as required.

10. Turn the engine off and wait several minutes. Check the oil level and add engine oil, if neces-

sary.

11. Install the engine compartment undercover.

NDI981Z

M9R

NDI1267

R9M

8-12Maintenance and do-it-yourself

Page 244 of 297

Downloaded from www.Manualslib.com manuals search engine 12. Lower the vehicle carefully to the ground.

13. Close the bonnet.

PROTECT THE ENVIRONMENT

NISSAN GREEN PROGRAM

It is illegal to pollute drains, water courses and soil.

Use authorised waste collection facilities, including

civic amenity sites and garages providing facilities

for the disposal of used oil and used oil filters. If in

doubt, contact your local authority for advice on dis-

posal.

The regulations concerning the pollution of the

environment will vary from country to country.

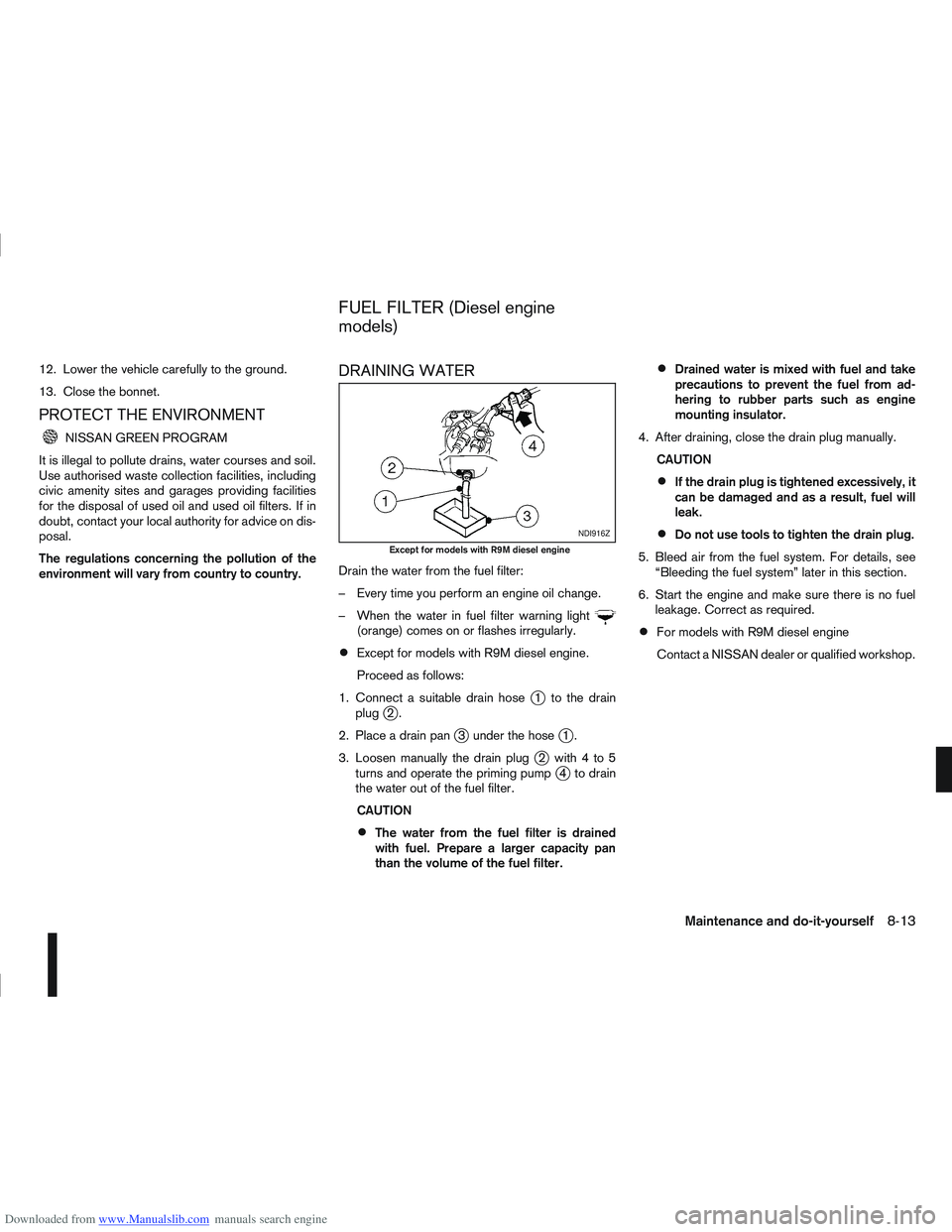

DRAINING WATER

Drain the water from the fuel filter:

– Every time you perform an engine oil change.

– When the water in fuel filter warning light

(orange) comes on or flashes irregularly.

Except for models with R9M diesel engine.

Proceed as follows:

1. Connect a suitable drain hose

j1 to the drain

plugj2.

2. Place a drain pan

j3 under the hosej1.

3. Loosen manually the drain plug

j2 with4to5

turns and operate the priming pumpj4 to drain

the water out of the fuel filter.

CAUTION

The water from the fuel filter is drained

with fuel. Prepare a larger capacity pan

than the volume of the fuel filter.

Drained water is mixed with fuel and take

precautions to prevent the fuel from ad-

hering to rubber parts such as engine

mounting insulator.

4. After draining, close the drain plug manually. CAUTION

If the drain plug is tightened excessively, it

can be damaged and as a result, fuel will

leak.

Do not use tools to tighten the drain plug.

5. Bleed air from the fuel system. For details, see “Bleeding the fuel system” later in this section.

6. Start the engine and make sure there is no fuel leakage. Correct as required.

For models with R9M diesel engine

Contact a NISSAN dealer or qualified workshop.

NDI916Z

Except for models with R9M diesel engine

FUEL FILTER (Diesel engine

models)

Maintenance and do-it-yourself8-13

Page 246 of 297

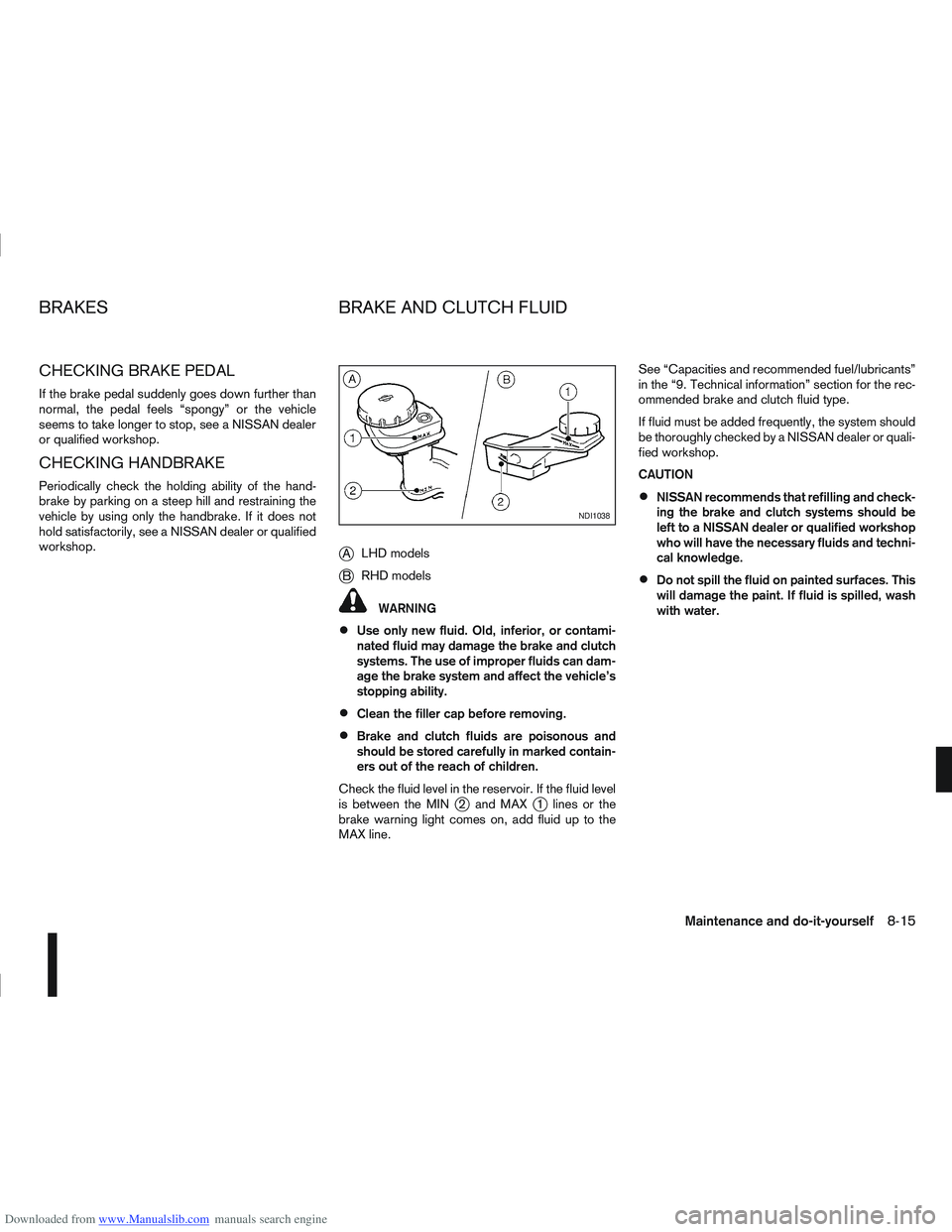

Downloaded from www.Manualslib.com manuals search engine CHECKING BRAKE PEDAL

If the brake pedal suddenly goes down further than

normal, the pedal feels “spongy” or the vehicle

seems to take longer to stop, see a NISSAN dealer

or qualified workshop.

CHECKING HANDBRAKE

Periodically check the holding ability of the hand-

brake by parking on a steep hill and restraining the

vehicle by using only the handbrake. If it does not

hold satisfactorily, see a NISSAN dealer or qualified

workshop.

jALHD models

jB RHD models

WARNING

Use only new fluid. Old, inferior, or contami-

nated fluid may damage the brake and clutch

systems. The use of improper fluids can dam-

age the brake system and affect the vehicle’s

stopping ability.

Clean the filler cap before removing.

Brake and clutch fluids are poisonous and

should be stored carefully in marked contain-

ers out of the reach of children.

Check the fluid level in the reservoir. If the fluid level

is between the MIN

j2 and MAXj1 lines or the

brake warning light comes on, add fluid up to the

MAX line. See “Capacities and recommended fuel/lubricants”

in the “9. Technical information” section for the rec-

ommended brake and clutch fluid type.

If fluid must be added frequently, the system should

be thoroughly checked by a NISSAN dealer or quali-

fied workshop.

CAUTION

NISSAN recommends that refilling and check-

ing the brake and clutch systems should be

left to a NISSAN dealer or qualified workshop

who will have the necessary fluids and techni-

cal knowledge.

Do not spill the fluid on painted surfaces. This

will damage the paint. If fluid is spilled, wash

with water.

NDI1038

BRAKES

BRAKE AND CLUTCH FLUID

Maintenance and do-it-yourself8-15

Page 247 of 297

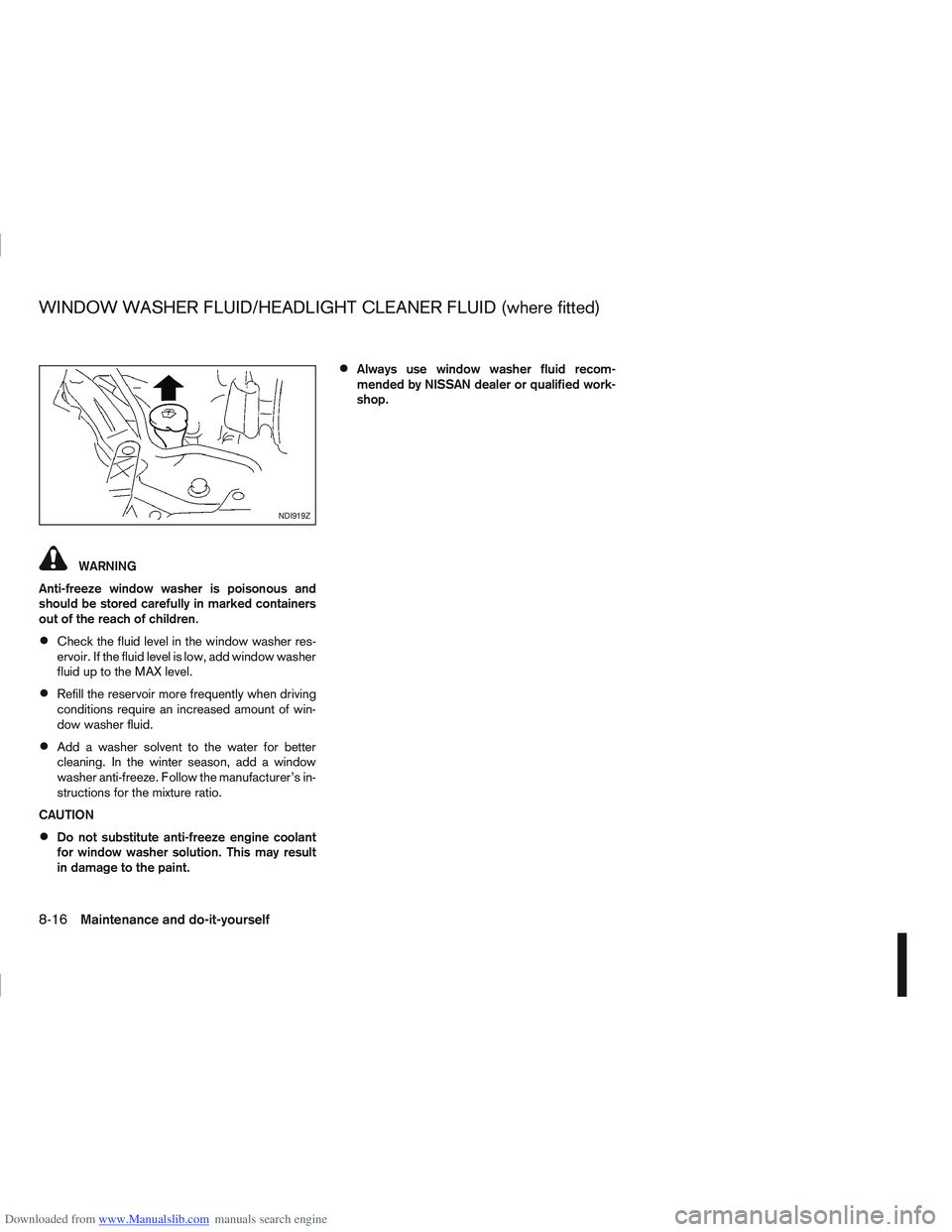

Downloaded from www.Manualslib.com manuals search engine WARNING

Anti-freeze window washer is poisonous and

should be stored carefully in marked containers

out of the reach of children.

Check the fluid level in the window washer res-

ervoir. If the fluid level is low, add window washer

fluid up to the MAX level.

Refill the reservoir more frequently when driving

conditions require an increased amount of win-

dow washer fluid.

Add a washer solvent to the water for better

cleaning. In the winter season, add a window

washer anti-freeze. Follow the manufacturer’s in-

structions for the mixture ratio.

CAUTION

Do not substitute anti-freeze engine coolant

for window washer solution. This may result

in damage to the paint.

Always use window washer fluid recom-

mended by NISSAN dealer or qualified work-

shop.

NDI919Z

WINDOW WASHER FLUID/HEADLIGHT CLEANER FLUID (where fitted)

8-16Maintenance and do-it-yourself

Page 255 of 297

Downloaded from www.Manualslib.com manuals search engine Be careful not to damage the connector sup-

port bracket when disconnecting the connec-

tor.

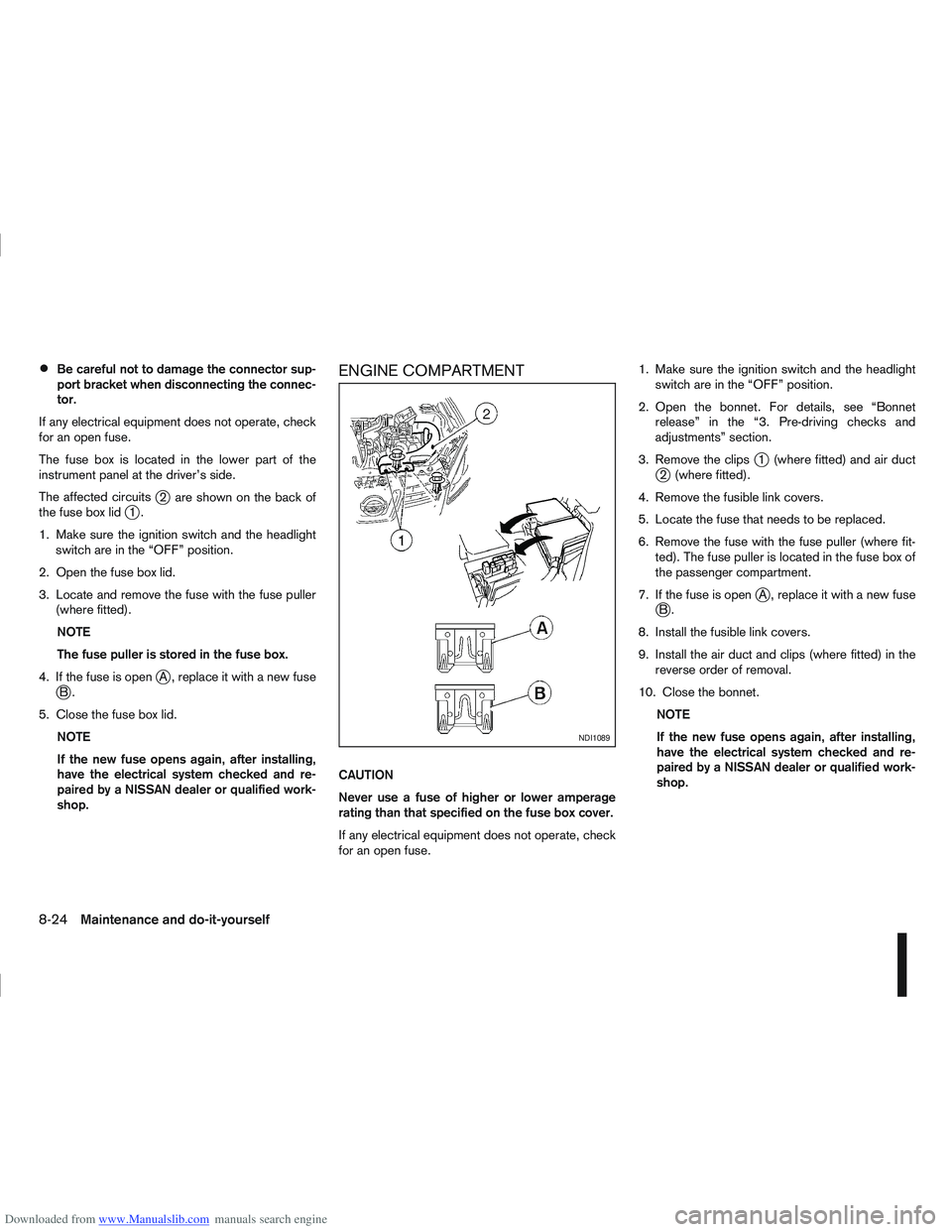

If any electrical equipment does not operate, check

for an open fuse.

The fuse box is located in the lower part of the

instrument panel at the driver’s side.

The affected circuits

j2 are shown on the back of

the fuse box lidj1.

1. Make sure the ignition switch and the headlight switch are in the “OFF” position.

2. Open the fuse box lid.

3. Locate and remove the fuse with the fuse puller (where fitted).

NOTE

The fuse puller is stored in the fuse box.

4. If the fuse is open

jA , replace it with a new fusejB.

5. Close the fuse box lid. NOTE

If the new fuse opens again, after installing,

have the electrical system checked and re-

paired by a NISSAN dealer or qualified work-

shop.

ENGINE COMPARTMENT

CAUTION

Never use a fuse of higher or lower amperage

rating than that specified on the fuse box cover.

If any electrical equipment does not operate, check

for an open fuse. 1. Make sure the ignition switch and the headlight

switch are in the “OFF” position.

2. Open the bonnet. For details, see “Bonnet release” in the “3. Pre-driving checks and

adjustments” section.

3. Remove the clips

j1 (where fitted) and air ductj2 (where fitted).

4. Remove the fusible link covers.

5. Locate the fuse that needs to be replaced.

6. Remove the fuse with the fuse puller (where fit- ted). The fuse puller is located in the fuse box of

the passenger compartment.

7. If the fuse is open

jA , replace it with a new fusejB.

8. Install the fusible link covers.

9. Install the air duct and clips (where fitted) in the reverse order of removal.

10. Close the bonnet. NOTE

If the new fuse opens again, after installing,

have the electrical system checked and re-

paired by a NISSAN dealer or qualified work-

shop.

NDI1089

8-24Maintenance and do-it-yourself

Page 256 of 297

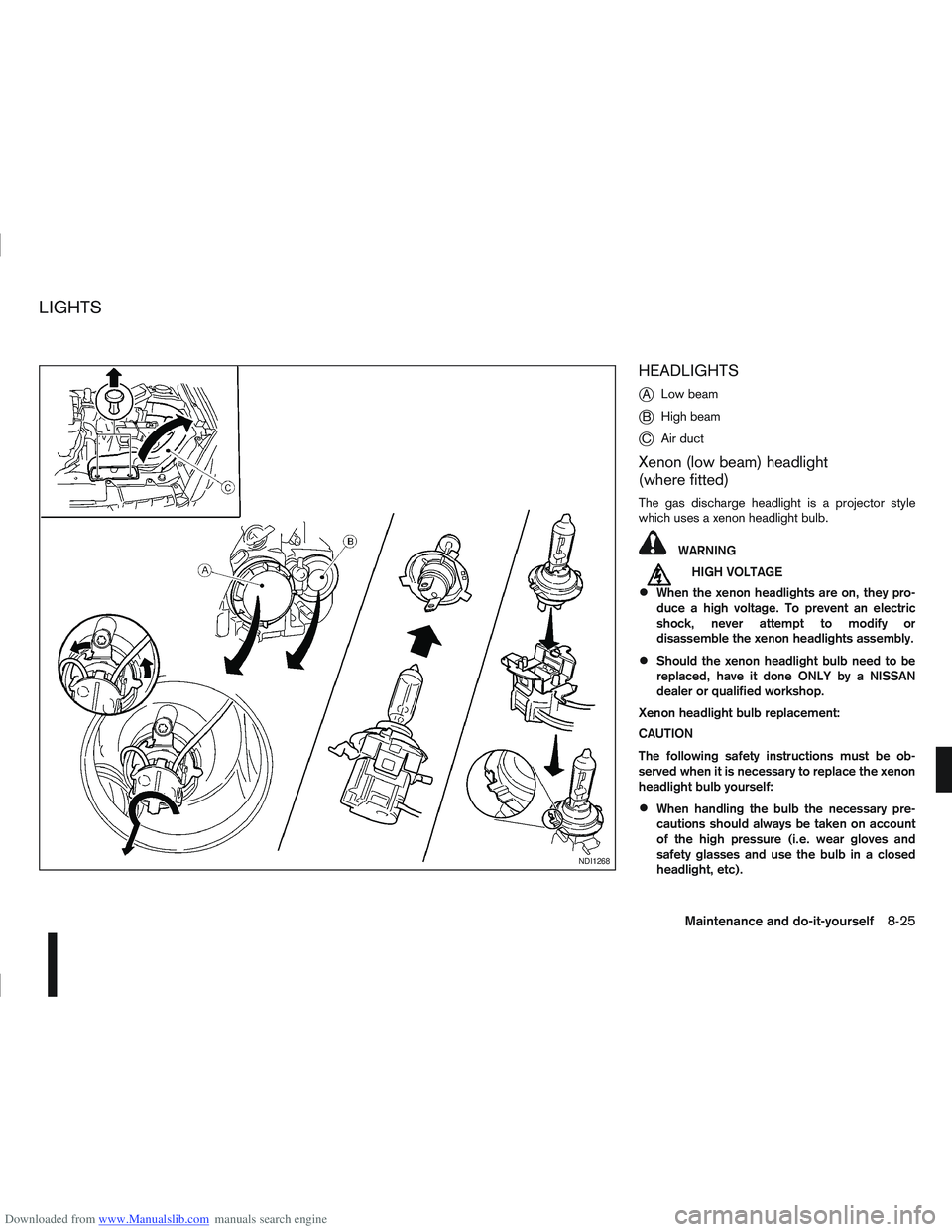

Downloaded from www.Manualslib.com manuals search engine HEADLIGHTS

j

ALow beam

jB High beam

jC Air duct

Xenon (low beam) headlight

(where fitted)

The gas discharge headlight is a projector style

which uses a xenon headlight bulb.

WARNING

mHIGH VOLTAGE

When the xenon headlights are on, they pro-

duce a high voltage. To prevent an electric

shock, never attempt to modify or

disassemble the xenon headlights assembly.

Should the xenon headlight bulb need to be

replaced, have it done ONLY by a NISSAN

dealer or qualified workshop.

Xenon headlight bulb replacement:

CAUTION

The following safety instructions must be ob-

served when it is necessary to replace the xenon

headlight bulb yourself:

When handling the bulb the necessary pre-

cautions should always be taken on account

of the high pressure (i.e. wear gloves and

safety glasses and use the bulb in a closed

headlight, etc).

NDI1268

LIGHTS

Maintenance and do-it-yourself8-25

Page 257 of 297

Downloaded from www.Manualslib.com manuals search engine Only hold the xenon headlight bulb by the

base.

The bulb is manufactured from high-quality

quartz and is under high pressure.

Damage, soiling, and fingerprints should be

avoided and, if necessary, removed with alco-

hol before installing the bulb.

When the headlights are switched on, the

bulbs produce a certain amount of UV radia-

tion. In order to avoid any impairment of health

(burning and conjunctivitis), the bulb should

only be used in closed headlights with appro-

priate UV–absorbing front glass.

Due to the risk of burning, the bulb should be

left to cool down for 3 minutes after switching

off before touching.

Due to the use of mercury and various salts,

the bulb should be treated as special waste

when discarded.

The bulb may only be operated with a suitable

ballast which produces very high voltages

when switched on and during operation.

Contact with bulb and wires should therefore

be avoided and a safe distance of at least 30

mm should be maintained.

Replacing the halogen headlight bulb

CAUTION

High pressure halogen gas is sealed inside

the halogen bulb. The bulb may break if the

glass envelope is scratched or the bulb is

dropped.

When handling the bulb, DO NOT TOUCH THE

GLASS ENVELOPE.

Use the same number type and wattage as

originally installed.

Aiming is usually not necessary after replac-

ing the bulb. When aiming adjustment is nec-

essary, contact a NISSAN dealer or qualified

workshop.

Do not leave the bulb out of the headlight

reflector for a long period of time as dust,

moisture or smoke may enter the headlight

body and affect the performance of the head-

light.

The headlight is a semi-sealed beam type which

uses a replaceable headlight (halogen) bulb. A bulb

can be replaced from inside the engine compart-

ment without removing the headlight assembly.

Contact a NISSAN dealer or qualified workshop, if

you need assistance for bulb replacement.

1. Open the bonnet. For details, see “Bonnet release” in the “3. Pre-driving checks and

adjustments” section.

2. Disconnect the negative (—) battery cable. 3. When the broken bulb is located in the headlight

assembly under the air duct, carefully remove the

clips and rotate the air duct

jc clockwise a 1/4

of a turn.

4. Remove the cap (

jAorjB ) of the headlight as-

sembly.

5. Turn the connector 1/4 of a turn in the anti clock- wise direction and remove the headlight bulb.

6. Install the new bulb in the reverse order of re- moval and make sure that the cap is securely

sealed with the headlight body.

7. Where removed (step 3.), re-install the air duct

jc and clips in the order of removal.

8. Reconnect the negative (—) battery cable and close the bonnet.

NOTE

Fog may temporarily form inside the lens of the

exterior lights in the rain or in a car wash. The fog

is caused by a temperature difference between

the inside and the outside of the lens. This is not

a malfunction. If large droplets can be seen, then

contact a NISSAN dealer or qualified workshop.

8-26Maintenance and do-it-yourself