Release Bonnet NISSAN QASHQAI 2016 Owner´s Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: QASHQAI, Model: NISSAN QASHQAI 2016Pages: 338, PDF Size: 4.87 MB

Page 247 of 338

In case of a flat tyre, follow the instructions as de-

scribed below:

STOPPING THE VEHICLE

WARNING

•Make sure that the parking brake is securely

applied.

•For Manual Transmission (MT) models: Make

sure the shift lever is in the R (Reverse) posi-

tion.

For XTRONIC models: Make sure that the shift

lever is in the P (Park) position.

•Never change tyres when the vehicle is on a

slope, ice or a slippery area. This is hazard-

ous.

•Never change tyres if oncoming traffic is close

to your vehicle. Wait for professional road as-

sistance.

1. Safely move the vehicle off the road, away from

traffic.

2. Switch on the hazard warning flashers.

3. Park on a level surface.

4. Apply the parking brake.

5. Shift the shift lever (MT models) into the R (Re-

verse) position [XTRONIC models, move the shift

lever to the P (Park) position].

6. Turn off the engine.7. Open the bonnet (for details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section) in order to:

•Warn other traffic.

•Signal to professional road assistance that

you require assistance.

8. Have all passengers exit the vehicle and stand in

a safe place, away from traffic and clear of the

vehicle.

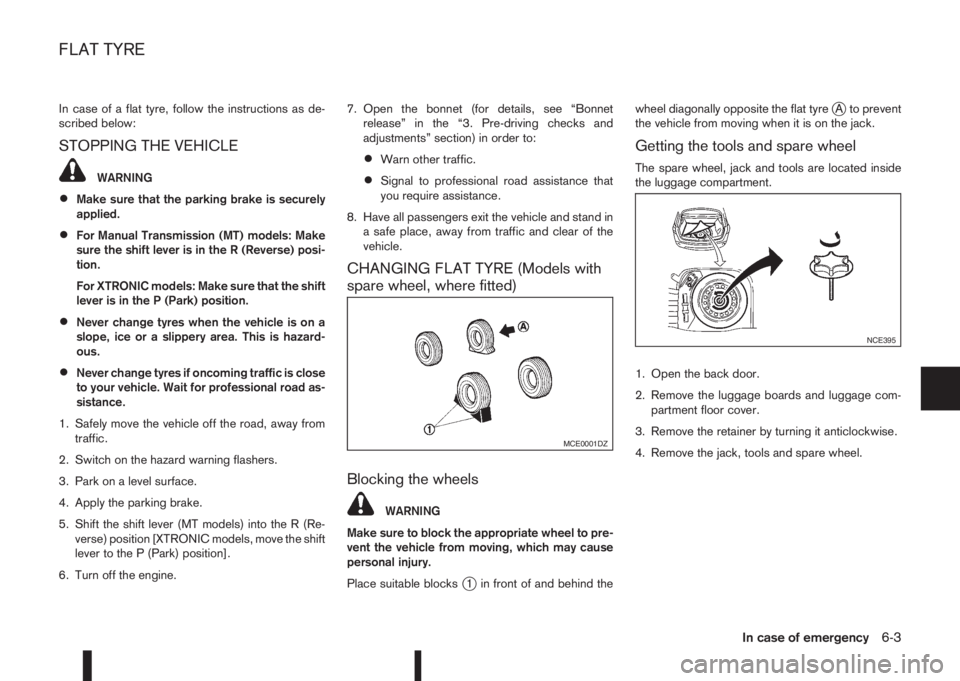

CHANGING FLAT TYRE (Models with

spare wheel, where fitted)

Blocking the wheels

WARNING

Make sure to block the appropriate wheel to pre-

vent the vehicle from moving, which may cause

personal injury.

Place suitable blocks

j1 in front of and behind thewheel diagonally opposite the flat tyre

jA to prevent

the vehicle from moving when it is on the jack.

Getting the tools and spare wheel

The spare wheel, jack and tools are located inside

the luggage compartment.

1. Open the back door.

2. Remove the luggage boards and luggage com-

partment floor cover.

3. Remove the retainer by turning it anticlockwise.

4. Remove the jack, tools and spare wheel.

MCE0001DZ

NCE395

FLAT TYRE

In case of emergency6-3

Page 256 of 338

4. Switch off all unnecessary electrical systems

(headlights, hazard lights etc,).

5. Ensure that the ignition switch of the vehicle be-

ing jump-started is in the LOCK position.

6. Open the bonnet. For details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section.

7. Remove the vent caps (where fitted) on the bat-

tery and cover the battery with an old cloth.

8. Connect the jump leads in the sequence (

j1→j2→j3→j4 ) as illustrated.

CAUTION

•Always connect positivej+ to positivej+

and negativej- to body ground (for ex-

ample, engine mount, etc.) – not to the

battery’s negative

j-.

•An incorrect connection could damage the

charging system.

•Be sure that the jumper cables do not

touch moving parts in the engine compart-

ment.

•Be careful not to allow contact between

the positive jump lead connector and the

vehicle or the negative lead during con-

nection and disconnection.

9. Start the engine of the other vehicle

jA and let it

run for a few minutes. Keep the engine speed at

about 2,000 rpm.10. Start the engine of your vehicle

jB in the nor-

mal way.

CAUTION

Do not keep the starter motor engaged for

more than 10 seconds. If the engine does not

start immediately, turn the ignition switch to

“OFF” and wait 10 seconds before trying

again.

11. After starting the engine of your vehicle, care-

fully disconnect the negative lead and then the

positive lead (

j4→j3→j2→j1).

12. Remove and dispose of the cloth that was used

to cover the vent holes as it may be contami-

nated with corrosive acid.

13. Install the vent caps (where fitted).

14. Close the bonnet.

NOTE

For models which incorporate the Stop/Start

System:

•Ensure that the battery fitted is the special

battery that is enhanced with regard to the

charge-discharge capacity and life perfor-

mance. Avoid using any other battery for the

Stop/Start System, as this may cause early

deterioration of the battery or a malfunction

of the Stop/Start System. It is recommended

that a Genuine NISSAN battery is fitted. For

more information, contact a NISSAN dealer or

qualified workshop

•If the battery terminal is disconnected (for bat-

tery replacement, etc.) and then reconnected,

there may be some delay before the Stop/

Start System reactivates.

6-12In case of emergency

Page 257 of 338

CAUTION

•Three-way catalyst equipped models (where

fitted) should not be started by pushing the

vehicle as the three-way catalyst may be dam-

aged.

•XTRONIC transmission (CVT) models cannot

be started by pushing the vehicle. This may

cause transmission damage.

•Never try to start the vehicle by towing it; when

the engine starts, the forward surge could

cause the vehicle to collide with the tow ve-

hicle.

WARNING

•Never continue driving if the engine of your

vehicle overheats. Doing so could cause a ve-

hicle fire.

•Never open the bonnet if steam is coming

out.

•Never remove engine coolant reservoir cap

when the engine is hot. If the engine coolant

reservoir cap is removed while the engine is

hot, pressurised hot water will spurt out and

possibly cause burning, scalding or serious

injury.

•If steam or coolant is coming out of the en-

gine, stand clear of the vehicle to prevent get-

ting injured.

•The engine cooling fan will start whenever the

coolant temperature exceeds preset degrees.

•Be careful not to allow your hands, hair, jewel-

lery or clothing to come into contact with, or

get caught in, the cooling fan or drive belts.

If the engine of your vehicle is overheating (indi-

cated by the engine coolant temperature gauge) or

if you feel a lack of engine power, detect unusual

noise, etc., proceed as follows:

1. Move and park the vehicle safely off the road and

away from traffic.

2. Turn on the hazard warning flasher lights.

3. Apply the parking brake.4. Shift the shift lever (MT models) into the N (Neu-

tral) position, XTRONIC transmission (CVT)

models: move the shift lever to the P (Park) posi-

tion.

DO NOT STOP THE ENGINE.

5. Open all windows.

6. Switch off the air conditioner system (where fit-

ted).

7. Set the heater or air conditioner temperature

control to maximum “HOT” and fan speed con-

trol to maximum speed.

8. Exit the vehicle.

9. Visually inspect and listen for steam or coolant

escaping from the radiator before opening the

bonnet. Wait until no steam or coolant can be

seen before proceeding.

10. Open the bonnet. For details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section.

11. Visually check if the cooling fan is running.

12. Visually check the radiator and radiator hoses

for leakage.

WARNING

If coolant is leaking, the cooling fan belt is

missing or loose or the cooling fan is not run-

ning, stop the engine.

PUSH-STARTING ENGINE OVERHEAT

In case of emergency6-13

Page 258 of 338

13. After the engine cools down, check the coolant

level in the engine coolant reservoir with the

engine running.

14. If the level is low, remove the engine coolant

reservoir cap and add coolant slowly into the

reservoir. After refilling the reservoir to the MAX

level, install the reservoir cap.

WARNING

Before removing the engine coolant reservoir

cap and to avoid the danger of being scalded,

cover the reservoir cap with a rag and loosen

the reservoir cap to the first notch to allow the

steam to escape.

15. Close the bonnet.

Have your vehicle inspected or repaired by a

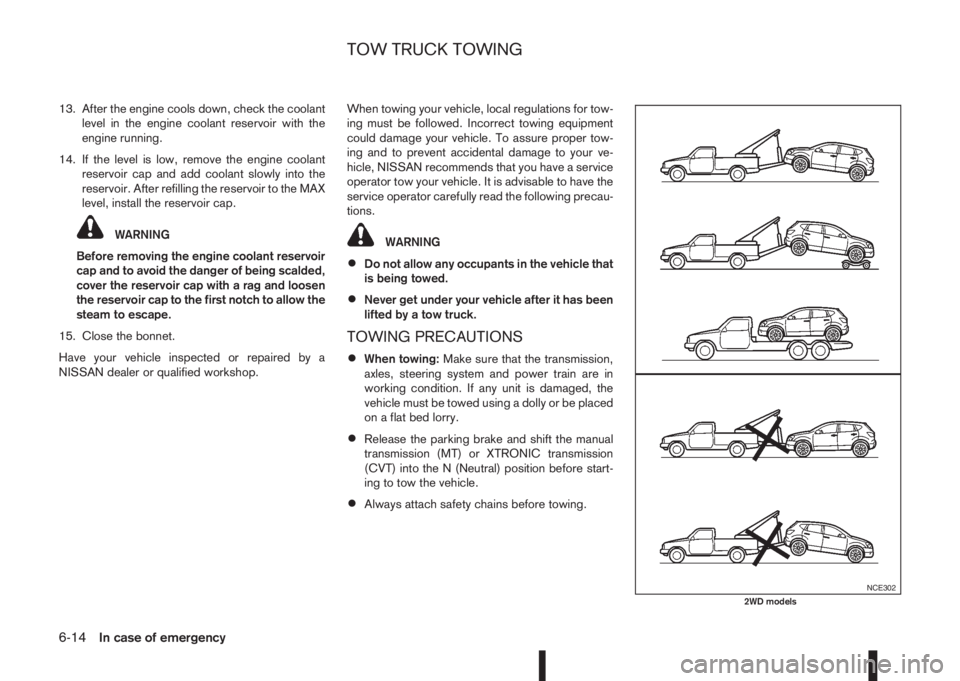

NISSAN dealer or qualified workshop.When towing your vehicle, local regulations for tow-

ing must be followed. Incorrect towing equipment

could damage your vehicle. To assure proper tow-

ing and to prevent accidental damage to your ve-

hicle, NISSAN recommends that you have a service

operator tow your vehicle. It is advisable to have the

service operator carefully read the following precau-

tions.WARNING

•Do not allow any occupants in the vehicle that

is being towed.

•Never get under your vehicle after it has been

lifted by a tow truck.

TOWING PRECAUTIONS

•When towing:Make sure that the transmission,

axles, steering system and power train are in

working condition. If any unit is damaged, the

vehicle must be towed using a dolly or be placed

on a flat bed lorry.

•Release the parking brake and shift the manual

transmission (MT) or XTRONIC transmission

(CVT) into the N (Neutral) position before start-

ing to tow the vehicle.

•Always attach safety chains before towing.

NCE3022WD models

TOW TRUCK TOWING

6-14In case of emergency

Page 270 of 338

Some day-to-day and regular maintenance is essen-

tial to maintain your NISSAN’s good mechanical

condition, as well as its emission and engine perfor-

mance.

It is the owner’s responsibility to make sure that the

specified maintenance, as well as general mainte-

nance, is performed.

As the vehicle owner, you are the only one who can

ensure that your vehicle receives the proper mainte-

nance care.

SCHEDULED MAINTENANCE

For your convenience, the required scheduled main-

tenance items are described and listed in the sepa-

rate Warranty Information and Maintenance book-

let. You must refer to that booklet to ensure that

necessary maintenance is performed on your

NISSAN vehicle at regular intervals.

GENERAL MAINTENANCE

General maintenance includes those items which

should be checked during normal day-to-day opera-

tion of the vehicle. They are essential if your vehicle

is to continue to operate properly. It is your respon-

sibility to perform these procedures regularly as pre-

scribed.

Performing general maintenance checks requires

minimal mechanical skill and a few general automo-

tive tools.

These checks or inspections can be done by your-

self, a qualified technician or, if you prefer, your

NISSAN dealer or qualified workshop.

WHERE TO GO FOR SERVICE

If maintenance service is required or your vehicle

appears to malfunction, have the systems checked

and tuned by an authorised NISSAN dealer or quali-

fied workshop.During the normal day-to-day operation of the ve-

hicle, general maintenance should be performed

regularly as prescribed in this section. If you detect

any unusual sounds, vibrations or smell, be sure to

check for the cause or have a NISSAN dealer or

qualified workshop do it promptly. In addition, you

should notify a NISSAN dealer or qualified work-

shop if repairs are required.

When performing any checks or maintenance work,

closely observe the “Maintenance precautions” later

in this section.

EXPLANATION OF GENERAL

MAINTENANCE ITEMS

Additional information on the following items with

an asterisk (*) is found later in this section.

The maintenance items listed here should be per-

formed from time to time, unless otherwise speci-

fied.

Outside the vehicle

Back door, doors and bonnet:

Check that the back door, all doors and the bonnet

operate properly. Also ensure that all latches lock

securely. Lubricate hinges and latches if necessary.

Make sure that the secondary latch keeps the bon-

net from opening when the primary latch is released.

When driving in areas using road salt or other cor-

rosive materials, check for lubrication frequently.

MAINTENANCE REQUIREMENTS GENERAL MAINTENANCE

8-2Maintenance and do-it-yourself

Page 275 of 338

MR20DD, MR16DE or R9M engine

1. Set the heater or air conditioner temperature

control to the maximum “HOT” position.

2. Open the bonnet. For details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section.

3. Open the engine coolant reservoir cap

j1to

help drain the coolant.

4. Loosen the engine coolant radiator drain plug

j3

to help drain the coolant.

5. Disconnect the end of the hose

j2 to drain the

coolant.

6. Flush the cooling system by running clean water

through the engine coolant reservoir.

7. Install the hose

j2.

8. Tighten the engine coolant radiator drain plug

j3.

9. Fill the coolant reservoir up to the MAX level.

See “Capacities and recommended fuel/

lubricants” in the “9. Technical information” sec-

tion for cooling system capacity.

10. Install the engine coolant reservoir cap.

11. Start the engine, and rev the engine two or

three times under no load.

12. Touch the radiator hose and feel if the water

flows.

13. Keep racing the engine at a speed of 3,000 rpm

for about 10 minutes.14. Observe the coolant temperature gauge for

signs of overheating.

15. Stop the engine and check coolant level, allow

to cool and refill up to the MAX level.

16. Check radiator lower hose for any signs of leak-

age.

17. Close the bonnet.HRA2DDT or K9K engine

1. Set the heater or air conditioner temperature

control to the maximum “HOT” position.

2. Open the bonnet. For details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section.

3. Loosen the engine coolant radiator drain plug

j1

to help drain the coolant.

4. Disconnect the radiator lower hose

j2 and open

the drain plugj3 on the engine block.5. Open the engine coolant reservoir cap to help to

drain the coolant.

6. Flush the cooling system by running fresh water

through the engine coolant reservoir.

7. Install the hose

j2 and securely tighten the en-

gine block drain plugj3.

8. Tighten the engine coolant radiator drain plug

j1.

9. Fill the reservoir up to the MAX level with cool-

ant. See “Capacities and recommended

fuel/lubricants” in the “9. Technical information”

section for cooling system capacity.

10. Install the engine coolant reservoir cap.

11. Start the engine, and rev the engine two or

three times under no load.

12. Touch the radiator hose and feel if the water

flows.

13. Keep racing the engine at a speed of 2,000 –

2,500 rpm for about 10 minutes.

14. Observe the coolant temperature gauge for

signs of overheating.

15. Stop the engine and check coolant level, allow

to cool and refill up to the MAX level.

16. Check the radiator lower hose for any signs of

leakage.

17. Close the bonnet.

NDI1491

Maintenance and do-it-yourself8-7

Page 277 of 338

5. Open the bonnet. For details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section.

6. Remove the dipstick and wipe it clean.

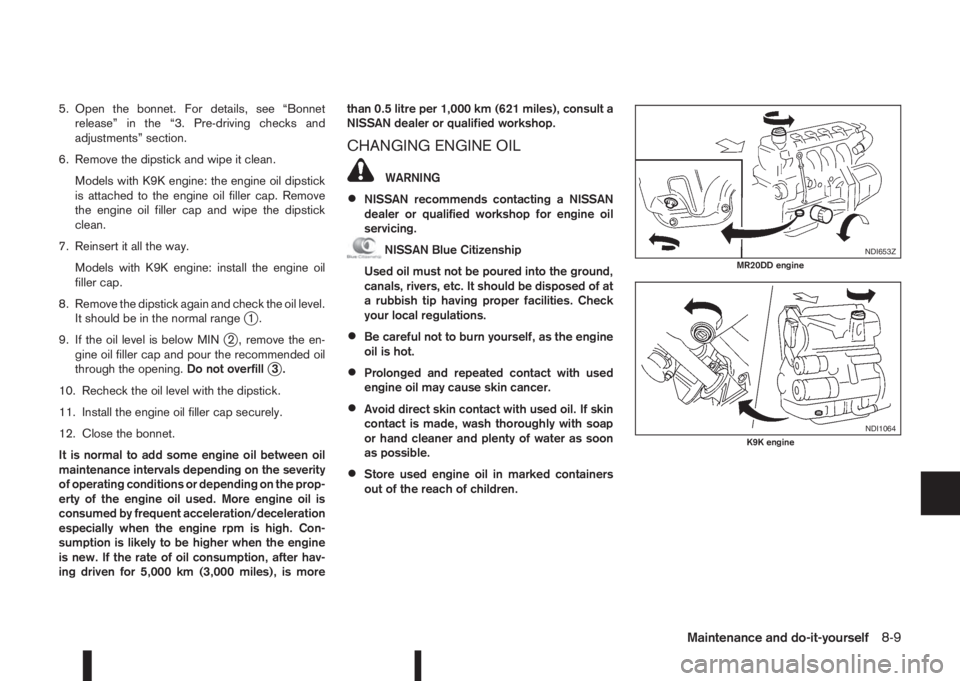

Models with K9K engine: the engine oil dipstick

is attached to the engine oil filler cap. Remove

the engine oil filler cap and wipe the dipstick

clean.

7. Reinsert it all the way.

Models with K9K engine: install the engine oil

filler cap.

8. Remove the dipstick again and check the oil level.

It should be in the normal range

j1.

9. If the oil level is below MIN

j2 , remove the en-

gine oil filler cap and pour the recommended oil

through the opening.Do not overfill

j3.

10. Recheck the oil level with the dipstick.

11. Install the engine oil filler cap securely.

12. Close the bonnet.

It is normal to add some engine oil between oil

maintenance intervals depending on the severity

of operating conditions or depending on the prop-

erty of the engine oil used. More engine oil is

consumed by frequent acceleration/deceleration

especially when the engine rpm is high. Con-

sumption is likely to be higher when the engine

is new. If the rate of oil consumption, after hav-

ing driven for 5,000 km (3,000 miles), is morethan 0.5 litre per 1,000 km (621 miles), consult a

NISSAN dealer or qualified workshop.

CHANGING ENGINE OIL

WARNING

•NISSAN recommends contacting a NISSAN

dealer or qualified workshop for engine oil

servicing.

NISSAN Blue Citizenship

Used oil must not be poured into the ground,

canals, rivers, etc. It should be disposed of at

a rubbish tip having proper facilities. Check

your local regulations.

•Be careful not to burn yourself, as the engine

oil is hot.

•Prolonged and repeated contact with used

engine oil may cause skin cancer.

•Avoid direct skin contact with used oil. If skin

contact is made, wash thoroughly with soap

or hand cleaner and plenty of water as soon

as possible.

•Store used engine oil in marked containers

out of the reach of children.

NDI653ZMR20DD engine

NDI1064K9K engine

Maintenance and do-it-yourself8-9

Page 278 of 338

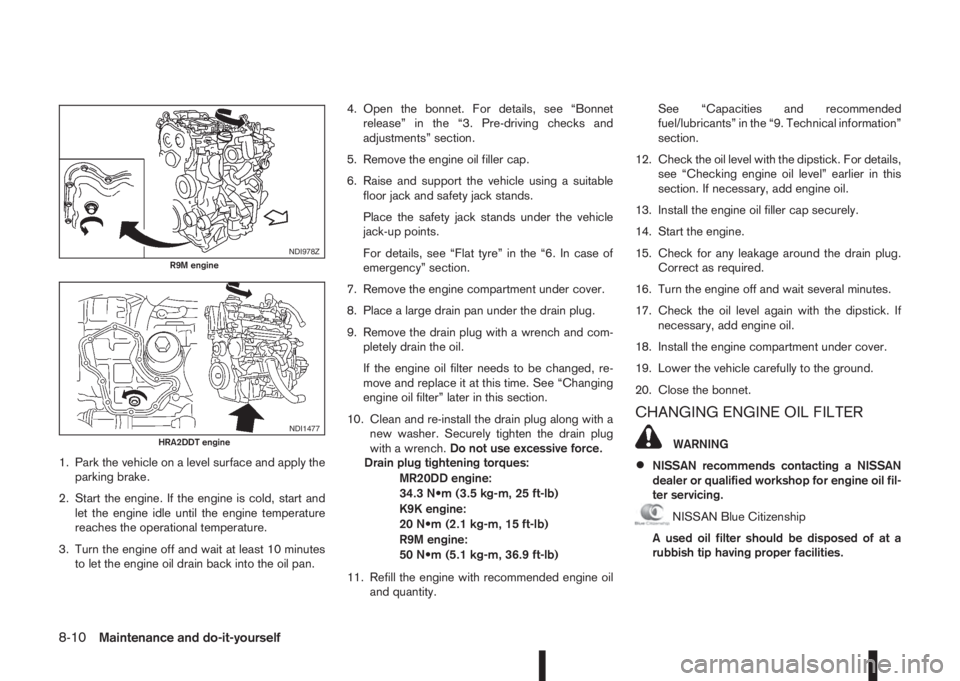

1. Park the vehicle on a level surface and apply the

parking brake.

2. Start the engine. If the engine is cold, start and

let the engine idle until the engine temperature

reaches the operational temperature.

3. Turn the engine off and wait at least 10 minutes

to let the engine oil drain back into the oil pan.4. Open the bonnet. For details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section.

5. Remove the engine oil filler cap.

6. Raise and support the vehicle using a suitable

floor jack and safety jack stands.

Place the safety jack stands under the vehicle

jack-up points.

For details, see “Flat tyre” in the “6. In case of

emergency” section.

7. Remove the engine compartment under cover.

8. Place a large drain pan under the drain plug.

9. Remove the drain plug with a wrench and com-

pletely drain the oil.

If the engine oil filter needs to be changed, re-

move and replace it at this time. See “Changing

engine oil filter” later in this section.

10. Clean and re-install the drain plug along with a

new washer. Securely tighten the drain plug

with a wrench.Do not use excessive force.

Drain plug tightening torques:

MR20DD engine:

34.3 N•m (3.5 kg-m, 25 ft-lb)

K9K engine:

20 N•m (2.1 kg-m, 15 ft-lb)

R9M engine:

50 N•m (5.1 kg-m, 36.9 ft-lb)

11. Refill the engine with recommended engine oil

and quantity.See “Capacities and recommended

fuel/lubricants” in the “9. Technical information”

section.

12. Check the oil level with the dipstick. For details,

see “Checking engine oil level” earlier in this

section. If necessary, add engine oil.

13. Install the engine oil filler cap securely.

14. Start the engine.

15. Check for any leakage around the drain plug.

Correct as required.

16. Turn the engine off and wait several minutes.

17. Check the oil level again with the dipstick. If

necessary, add engine oil.

18. Install the engine compartment under cover.

19. Lower the vehicle carefully to the ground.

20. Close the bonnet.

CHANGING ENGINE OIL FILTER

WARNING

•NISSAN recommends contacting a NISSAN

dealer or qualified workshop for engine oil fil-

ter servicing.

NISSAN Blue Citizenship

A used oil filter should be disposed of at a

rubbish tip having proper facilities.

NDI978ZR9M engine

NDI1477HRA2DDT engine

8-10Maintenance and do-it-yourself

Page 295 of 338

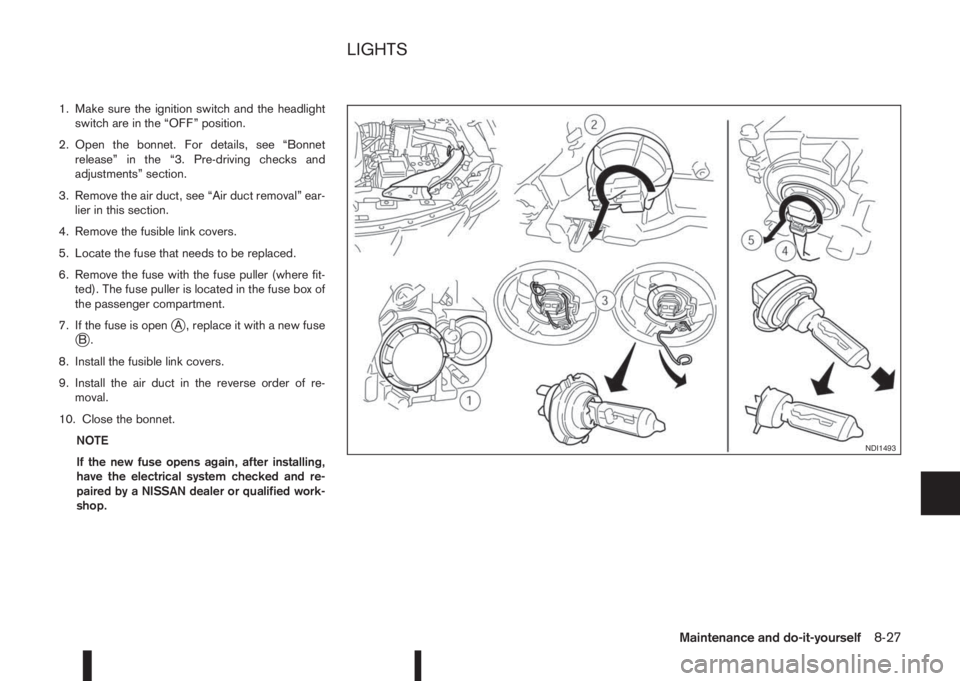

1. Make sure the ignition switch and the headlight

switch are in the “OFF” position.

2. Open the bonnet. For details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section.

3. Remove the air duct, see “Air duct removal” ear-

lier in this section.

4. Remove the fusible link covers.

5. Locate the fuse that needs to be replaced.

6. Remove the fuse with the fuse puller (where fit-

ted). The fuse puller is located in the fuse box of

the passenger compartment.

7. If the fuse is open

jA , replace it with a new fusejB.

8. Install the fusible link covers.

9. Install the air duct in the reverse order of re-

moval.

10. Close the bonnet.

NOTE

If the new fuse opens again, after installing,

have the electrical system checked and re-

paired by a NISSAN dealer or qualified work-

shop.

NDI1493

LIGHTS

Maintenance and do-it-yourself8-27

Page 296 of 338

HEADLIGHTS

LED headlight (where fitted)

The LED headlight is a projector style which uses a

LED module without serviceable parts.

CAUTION

•To prevent an electric shock, never attempt to

modify or disassemble the LED headlights as-

sembly.

•If replacement is required, contact a NISSAN

dealer or qualified workshop.

Replacing the halogen headlight bulb

CAUTION

•High pressure halogen gas is sealed inside

the halogen bulb. The bulb may break if the

glass envelope is scratched or the bulb is

dropped.

•When handling the bulb, DO NOT TOUCH THE

GLASS ENVELOPE.

•Use the same number type and wattage as

originally installed.

•Aiming is usually not necessary after replac-

ing the bulb. When aiming adjustment is nec-

essary, contact a NISSAN dealer or qualified

workshop.

•Do not leave the bulb out of the headlight

reflector for a long period of time as dust,moisture or smoke may enter the headlight

body and affect the performance of the head-

light.

The headlight is a semi-sealed beam type which

uses a replaceable headlight (halogen) bulb. A bulb

can be replaced from inside the engine compart-

ment without removing the headlight assembly.

Contact a NISSAN dealer or qualified workshop, if

you need assistance for bulb replacement.

High beam bulb replacement:

1. Open the bonnet. For details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section.

2. Disconnect the negative (—) battery cable.

3. When the broken bulb is located in the headlight

assembly under the air duct, carefully remove the

air duct, see “Air duct removal” earlier in this

section.

4. Remove the connector from the back of the cover

assembly

j1.

5. Turn the cover assembly 1/4 of a turn in the anti

clockwise direction and remove the cover by dis-

connecting the internal connector

j2.

6. Push and turn the retaining pin to loosen it

j3.

7. Remove the headlight bulb. Do not shake or ro-

tate the bulb when removing it.

8. Install the new bulb in the reverse order of re-

moval.9. Re-install the covers internal connector on the

back of the bulb.

10. Re-install the cover by turning the cover assem-

bly 1/4 of a turn in the clockwise direction.

11. Re-install the connector on the back of the cover

assembly.

12. Where removed (step 3.), re-install the air duct,

bolt and clips in the reverse order of removal.

13. Reconnect the negative (—) battery cable and

close the bonnet.

Low beam bulb replacement:

1. Open the bonnet. For details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section.

2. Disconnect the negative (—) battery cable.

3. When the broken bulb is located in the headlight

assembly under the air duct, carefully remove the

air duct, see “Air duct removal” earlier in this

section.

4. Remove the connector from the back of the bulb

assembly

j4.

5. Turn the bulb assembly 1/8 of a turn in the anti

clockwise direction and remove the headlight

bulb

j5.

6. Install the new bulb in the headlight body by turn-

ing it clockwise until it is securely sealed within

the headlight body.

7. Re-install the connector on the back of the bulb

assembly.

8-28Maintenance and do-it-yourself