torque NISSAN TEANA 2008 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 1908 of 5121

INTAKE MANIFOLD

EM-33

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

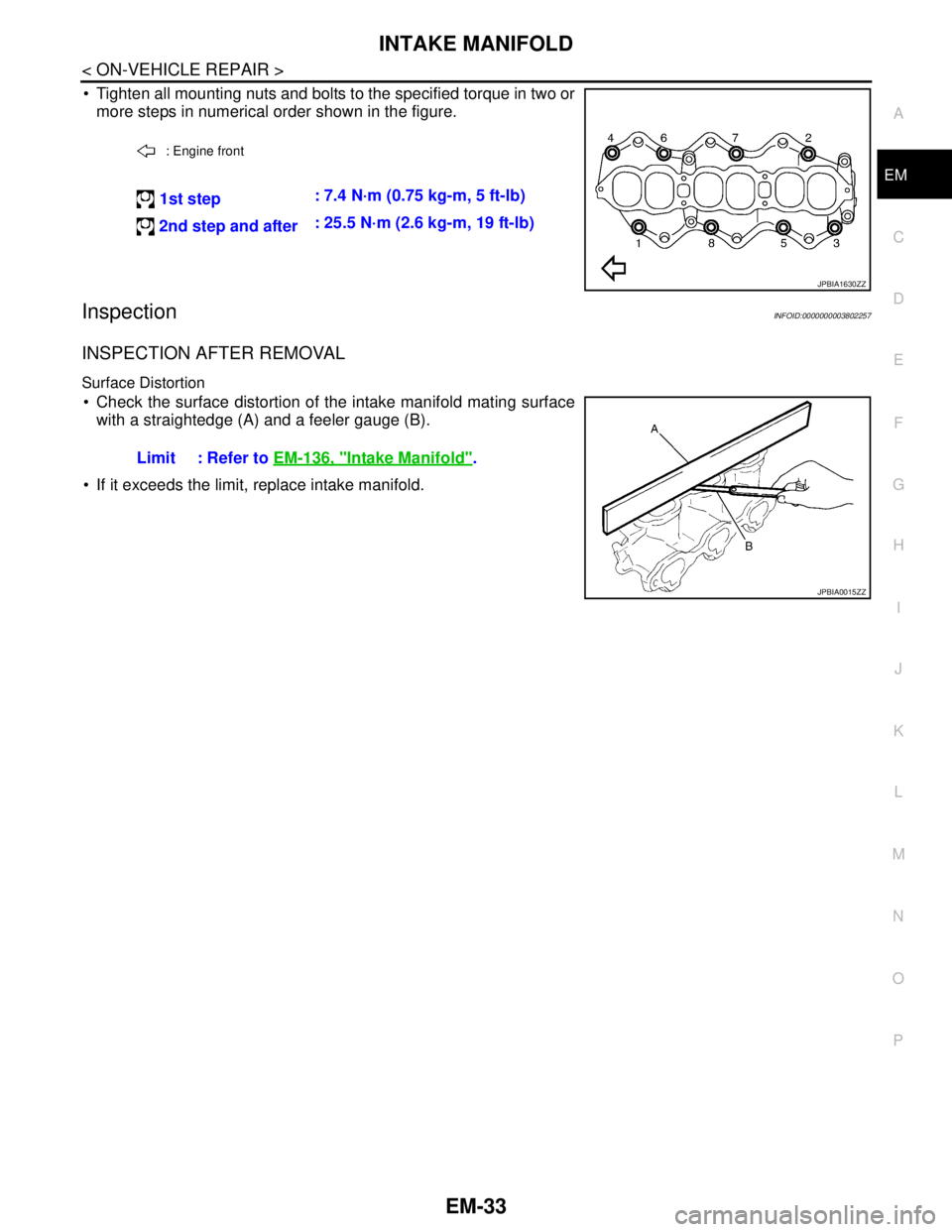

Tighten all mounting nuts and bolts to the specified torque in two or

more steps in numerical order shown in the figure.

InspectionINFOID:0000000003802257

INSPECTION AFTER REMOVAL

Surface Distortion

Check the surface distortion of the intake manifold mating surface

with a straightedge (A) and a feeler gauge (B).

If it exceeds the limit, replace intake manifold.

: Engine front

1st step: 7.4 N·m (0.75 kg-m, 5 ft-lb)

2nd step and after: 25.5 N·m (2.6 kg-m, 19 ft-lb)

JPBIA1630ZZ

Limit : Refer to EM-136, "Intake Manifold".

JPBIA0015ZZ

Page 1911 of 5121

EM-36

< ON-VEHICLE REPAIR >

EXHAUST MANIFOLD AND THREE WAY CATALYST

Cover engine openings to avoid entry of foreign materials.

INSTALLATION

Note the following, and install in the reverse order of removal.

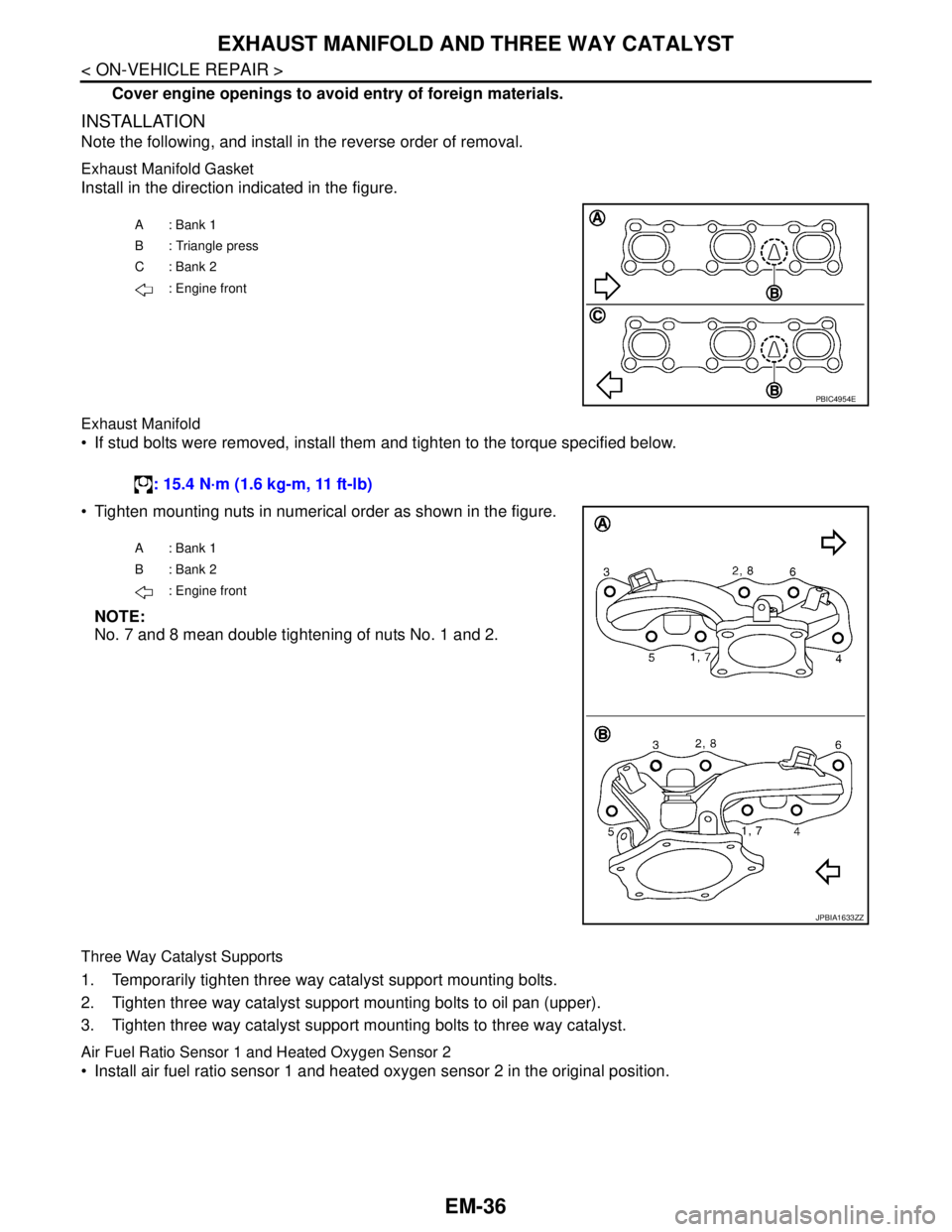

Exhaust Manifold Gasket

Install in the direction indicated in the figure.

Exhaust Manifold

If stud bolts were removed, install them and tighten to the torque specified below.

Tighten mounting nuts in numerical order as shown in the figure.

NOTE:

No. 7 and 8 mean double tightening of nuts No. 1 and 2.

Three Way Catalyst Supports

1. Temporarily tighten three way catalyst support mounting bolts.

2. Tighten three way catalyst support mounting bolts to oil pan (upper).

3. Tighten three way catalyst support mounting bolts to three way catalyst.

Air Fuel Ratio Sensor 1 and Heated Oxygen Sensor 2

Install air fuel ratio sensor 1 and heated oxygen sensor 2 in the original position.

A: Bank 1

B : Triangle press

C: Bank 2

: Engine front

PBIC4954E

: 15.4 N·m (1.6 kg-m, 11 ft-lb)

A: Bank 1

B: Bank 2

: Engine front

JPBIA1633ZZ

Page 1912 of 5121

EXHAUST MANIFOLD AND THREE WAY CATALYST

EM-37

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Install referring the following if the installation positions cannot be

identified.

CAUTION:

Before installing a new air fuel ratio sensor and a new heated

oxygen sensor, clean exhaust system threads using oxygen

sensor thread cleaner (commercial service tool: J-43897-18 or

J43897-12) and apply anti-seize lubricant (commercial service

tool).

Never over torque air fuel ratio sensor 1 and heated oxygen sensor 2. Doing so may cause damage

to air fuel ratio sensor and heated oxygen sensor, resulting in “MI” coming on.

InspectionINFOID:0000000003802260

INSPECTION AFTER REMOVAL

Surface Distortion

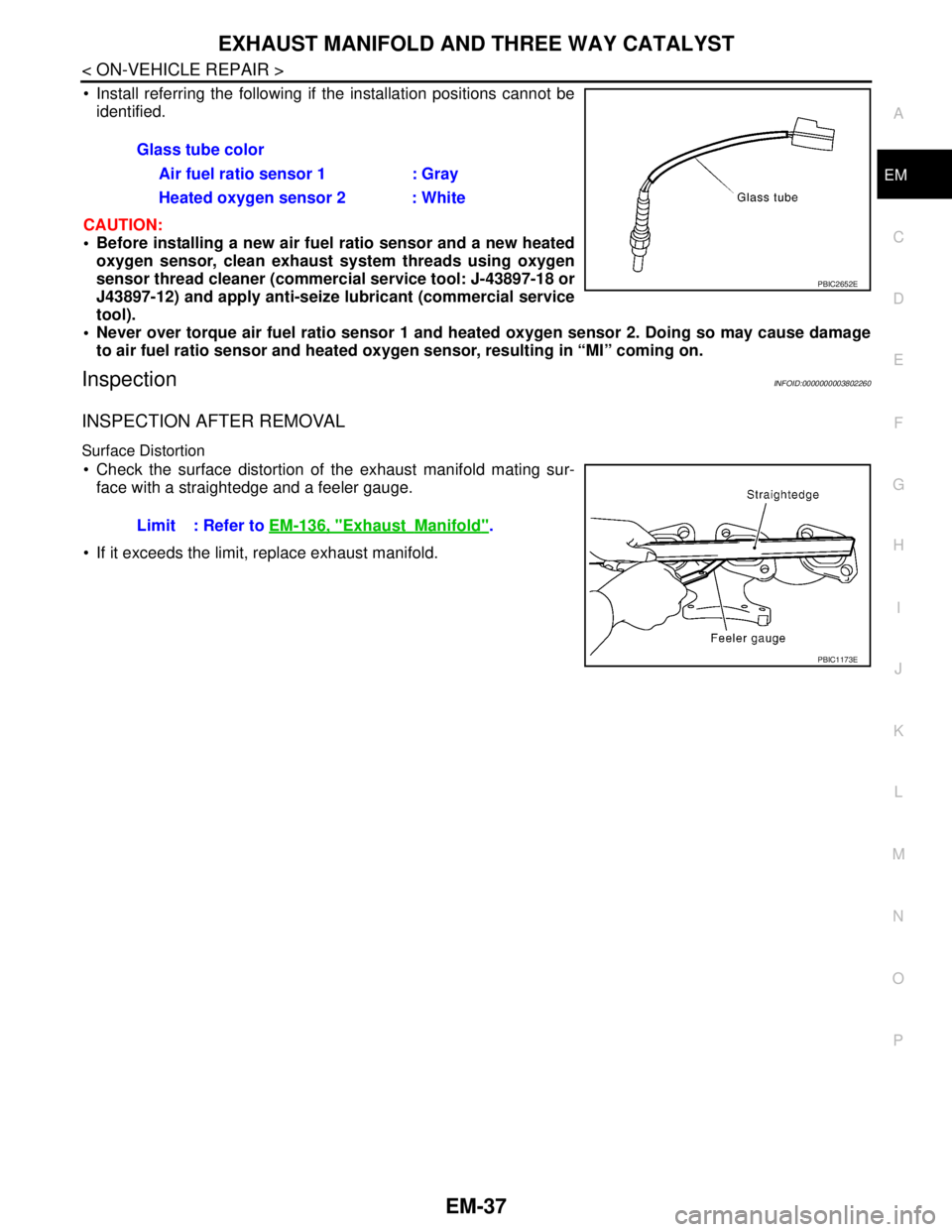

Check the surface distortion of the exhaust manifold mating sur-

face with a straightedge and a feeler gauge.

If it exceeds the limit, replace exhaust manifold.Glass tube color

Air fuel ratio sensor 1 : Gray

Heated oxygen sensor 2 : White

PBIC2652E

Limit : Refer to EM-136, "ExhaustManifold".

PBIC1173E

Page 1914 of 5121

OIL PAN AND OIL STRAINER

EM-39

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

Splash guard (RH and LH): Refer to EXT-22, "FENDER PROTECTOR : Exploded View".

Exhaust front tube: Refer to EX-5, "

Exploded View".

Drive belt: Refer to EM-12, "

Removal and Installation".

4. Remove A/C compressor with piping connected, and temporarily secure it to aside. Refer to HA-36,

"Exploded View".

5. Remove oil level gauge. Refer to EM-96, "

Exploded View".

6. Remove front drive shaft (RH). Refer to FAX-16, "

Exploded View".

7. Remove three way catalyst (bank 1 and bank 2) from exhaust manifolds (bank 1 and bank 2). Refer to

EM-34, "

Exploded View".

8. Remove oil pressure switch.

9. Remove oil filter. Refer to LU-10, "

Removal and Installation".

10. Remove oil cooler and water pipes. Refer to LU-11, "

Exploded View".

11. Support transaxle assembly with a suitable jack.

CAUTION:

When setting the transmission jack, be careful not to allow it to collide against the drain plug.

12. Support front suspension member with a suitable jack.

13. Remove engine mounting insulator (rear). Refer to EM-67, "

Exploded View".

14. Remove engine mounting insulator (LH) mounting bolts from transaxle. Refer to EM-67, "

Exploded View".

15. Remove rear torque rod through bolts from rear torque rod bracket. Refer to EM-67, "

Exploded View".

16. Remove member stay, front suspension member fixing bolts and nuts. Refer to FSU-16, "

Exploded View".

17. Lower the jack for the front suspension member to the height.

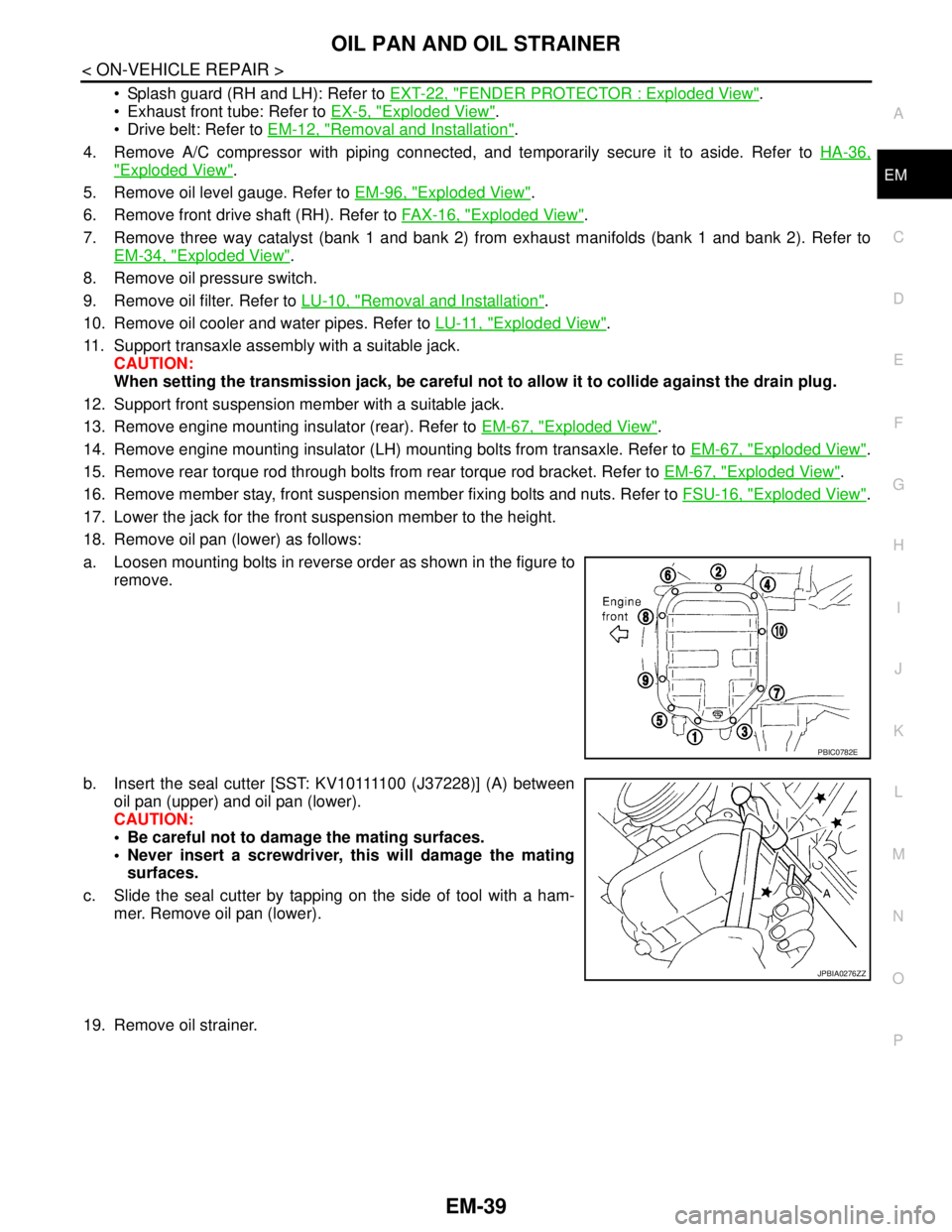

18. Remove oil pan (lower) as follows:

a. Loosen mounting bolts in reverse order as shown in the figure to

remove.

b. Insert the seal cutter [SST: KV10111100 (J37228)] (A) between

oil pan (upper) and oil pan (lower).

CAUTION:

Be careful not to damage the mating surfaces.

Never insert a screwdriver, this will damage the mating

surfaces.

c. Slide the seal cutter by tapping on the side of tool with a ham-

mer. Remove oil pan (lower).

19. Remove oil strainer.

PBIC0782E

JPBIA0276ZZ

Page 1939 of 5121

EM-64

< ON-VEHICLE REPAIR >

TIMING CHAIN

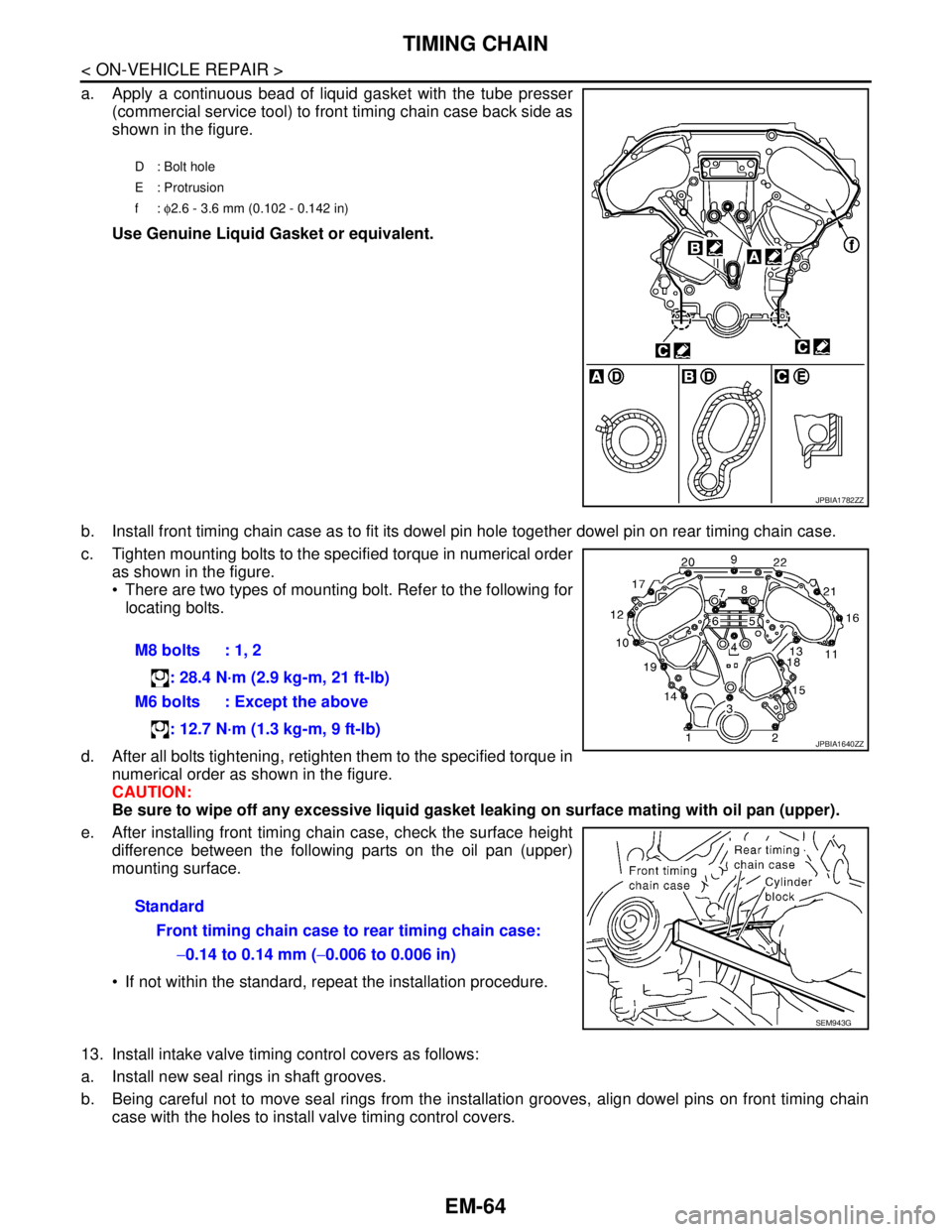

a. Apply a continuous bead of liquid gasket with the tube presser

(commercial service tool) to front timing chain case back side as

shown in the figure.

Use Genuine Liquid Gasket or equivalent.

b. Install front timing chain case as to fit its dowel pin hole together dowel pin on rear timing chain case.

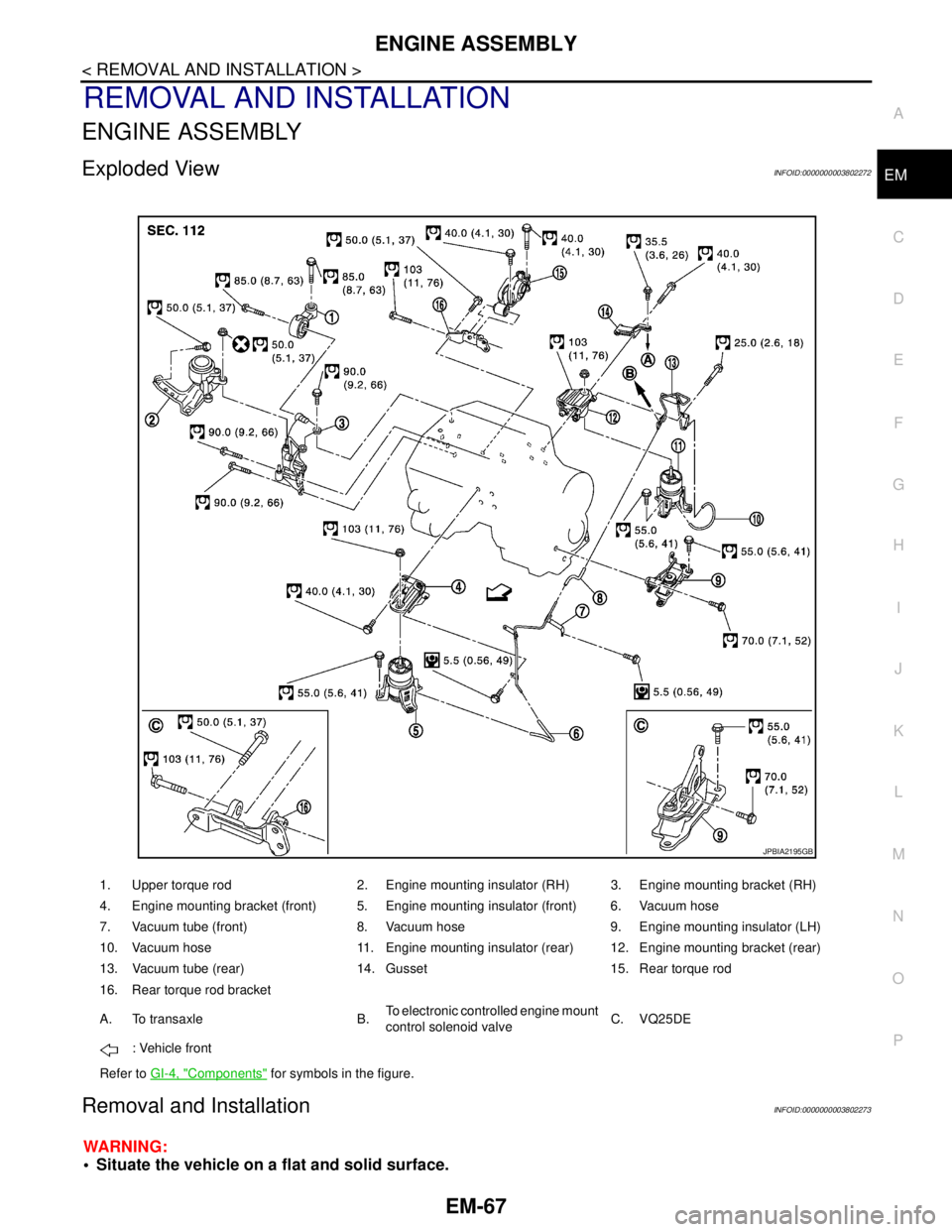

c. Tighten mounting bolts to the specified torque in numerical order

as shown in the figure.

There are two types of mounting bolt. Refer to the following for

locating bolts.

d. After all bolts tightening, retighten them to the specified torque in

numerical order as shown in the figure.

CAUTION:

Be sure to wipe off any excessive liquid gasket leaking on surface mating with oil pan (upper).

e. After installing front timing chain case, check the surface height

difference between the following parts on the oil pan (upper)

mounting surface.

If not within the standard, repeat the installation procedure.

13. Install intake valve timing control covers as follows:

a. Install new seal rings in shaft grooves.

b. Being careful not to move seal rings from the installation grooves, align dowel pins on front timing chain

case with the holes to install valve timing control covers.

D: Bolt hole

E : Protrusion

f: φ2.6 - 3.6 mm (0.102 - 0.142 in)

JPBIA1782ZZ

M8 bolts : 1, 2

: 28.4 N·m (2.9 kg-m, 21 ft-lb)

M6 bolts : Except the above

: 12.7 N·m (1.3 kg-m, 9 ft-lb)

Standard

Front timing chain case to rear timing chain case:

−0.14 to 0.14 mm (−0.006 to 0.006 in)

JPBIA1640ZZ

SEM943G

Page 1942 of 5121

ENGINE ASSEMBLY

EM-67

< REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

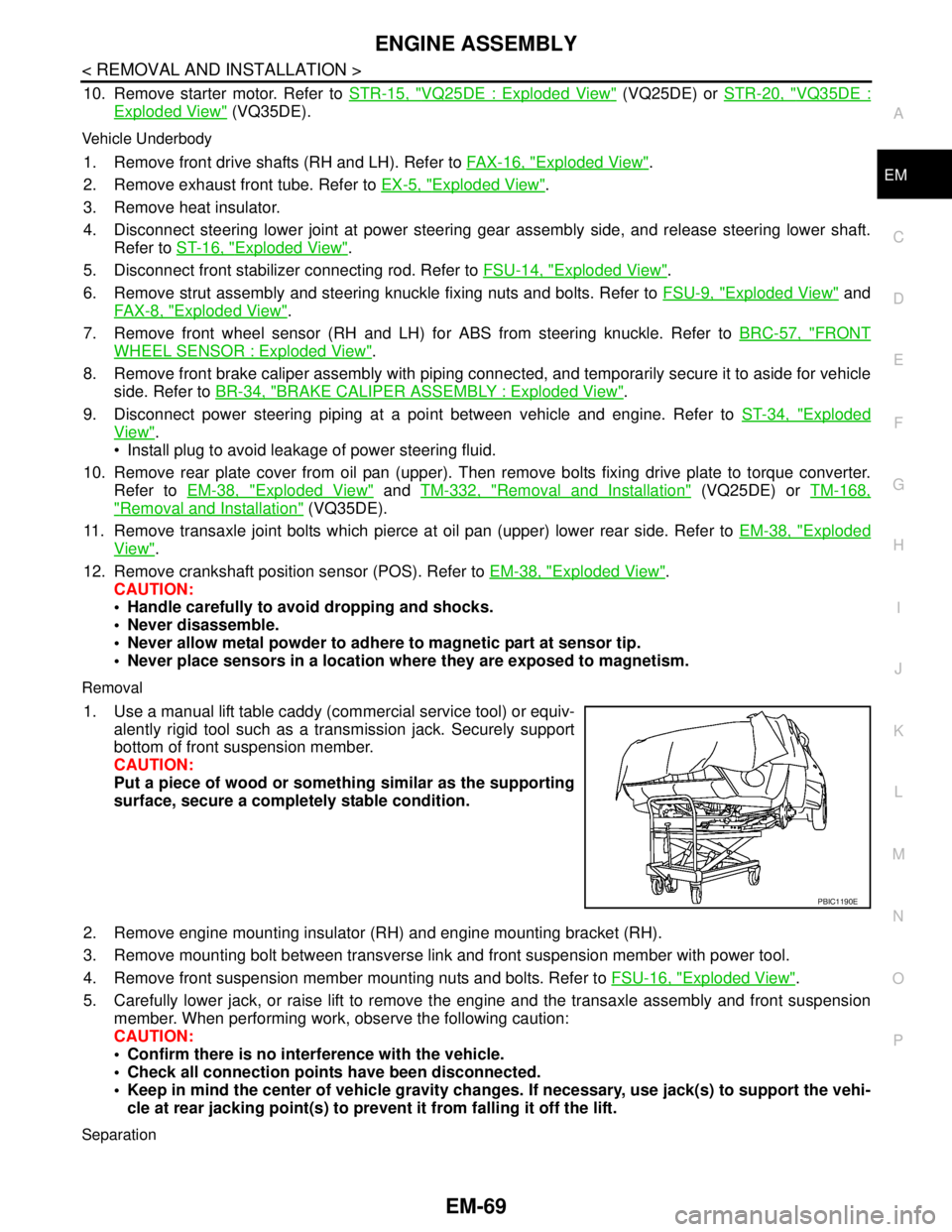

REMOVAL AND INSTALLATION

ENGINE ASSEMBLY

Exploded ViewINFOID:0000000003802272

Removal and InstallationINFOID:0000000003802273

WARNING:

Situate the vehicle on a flat and solid surface.

1. Upper torque rod 2. Engine mounting insulator (RH) 3. Engine mounting bracket (RH)

4. Engine mounting bracket (front) 5. Engine mounting insulator (front) 6. Vacuum hose

7. Vacuum tube (front) 8. Vacuum hose 9. Engine mounting insulator (LH)

10. Vacuum hose 11. Engine mounting insulator (rear) 12. Engine mounting bracket (rear)

13. Vacuum tube (rear) 14. Gusset 15. Rear torque rod

16. Rear torque rod bracket

A. To transaxle B.To electronic controlled engine mount

control solenoid valveC. VQ25DE

: Vehicle front

Refer to GI-4, "

Components" for symbols in the figure.

JPBIA2195GB

Page 1944 of 5121

ENGINE ASSEMBLY

EM-69

< REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

10. Remove starter motor. Refer to STR-15, "VQ25DE : Exploded View" (VQ25DE) or STR-20, "VQ35DE :

Exploded View" (VQ35DE).

Vehicle Underbody

1. Remove front drive shafts (RH and LH). Refer to FAX-16, "Exploded View".

2. Remove exhaust front tube. Refer to EX-5, "

Exploded View".

3. Remove heat insulator.

4. Disconnect steering lower joint at power steering gear assembly side, and release steering lower shaft.

Refer to ST-16, "

Exploded View".

5. Disconnect front stabilizer connecting rod. Refer to FSU-14, "

Exploded View".

6. Remove strut assembly and steering knuckle fixing nuts and bolts. Refer to FSU-9, "

Exploded View" and

FA X - 8 , "

Exploded View".

7. Remove front wheel sensor (RH and LH) for ABS from steering knuckle. Refer to BRC-57, "

FRONT

WHEEL SENSOR : Exploded View".

8. Remove front brake caliper assembly with piping connected, and temporarily secure it to aside for vehicle

side. Refer to BR-34, "

BRAKE CALIPER ASSEMBLY : Exploded View".

9. Disconnect power steering piping at a point between vehicle and engine. Refer to ST-34, "

Exploded

View".

Install plug to avoid leakage of power steering fluid.

10. Remove rear plate cover from oil pan (upper). Then remove bolts fixing drive plate to torque converter.

Refer to EM-38, "

Exploded View" and TM-332, "Removal and Installation" (VQ25DE) or TM-168,

"Removal and Installation" (VQ35DE).

11. Remove transaxle joint bolts which pierce at oil pan (upper) lower rear side. Refer to EM-38, "

Exploded

View".

12. Remove crankshaft position sensor (POS). Refer to EM-38, "

Exploded View".

CAUTION:

Handle carefully to avoid dropping and shocks.

Never disassemble.

Never allow metal powder to adhere to magnetic part at sensor tip.

Never place sensors in a location where they are exposed to magnetism.

Removal

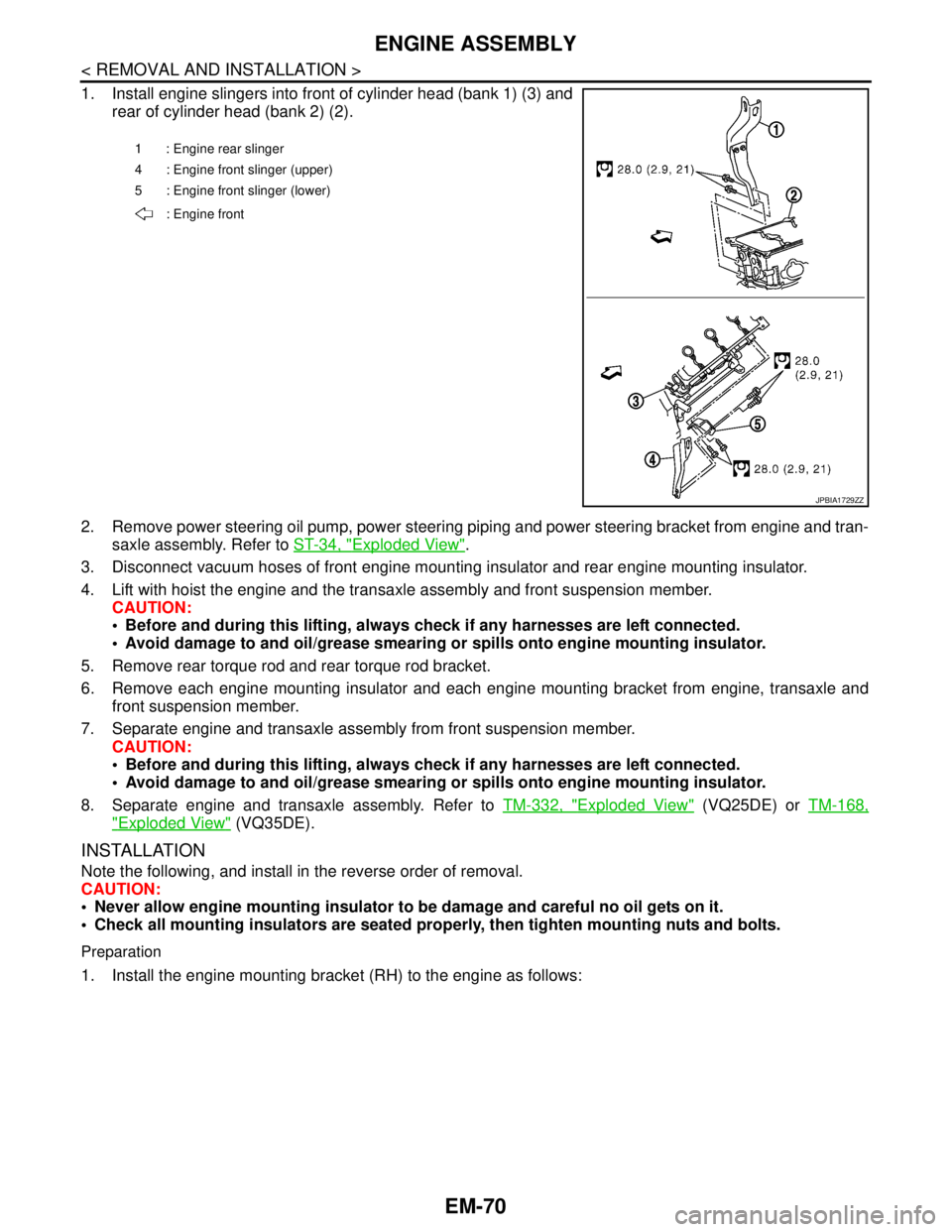

1. Use a manual lift table caddy (commercial service tool) or equiv-

alently rigid tool such as a transmission jack. Securely support

bottom of front suspension member.

CAUTION:

Put a piece of wood or something similar as the supporting

surface, secure a completely stable condition.

2. Remove engine mounting insulator (RH) and engine mounting bracket (RH).

3. Remove mounting bolt between transverse link and front suspension member with power tool.

4. Remove front suspension member mounting nuts and bolts. Refer to FSU-16, "

Exploded View".

5. Carefully lower jack, or raise lift to remove the engine and the transaxle assembly and front suspension

member. When performing work, observe the following caution:

CAUTION:

Confirm there is no interference with the vehicle.

Check all connection points have been disconnected.

Keep in mind the center of vehicle gravity changes. If necessary, use jack(s) to support the vehi-

cle at rear jacking point(s) to prevent it from falling it off the lift.

Separation

PBIC1190E

Page 1945 of 5121

EM-70

< REMOVAL AND INSTALLATION >

ENGINE ASSEMBLY

1. Install engine slingers into front of cylinder head (bank 1) (3) and

rear of cylinder head (bank 2) (2).

2. Remove power steering oil pump, power steering piping and power steering bracket from engine and tran-

saxle assembly. Refer to ST-34, "

Exploded View".

3. Disconnect vacuum hoses of front engine mounting insulator and rear engine mounting insulator.

4. Lift with hoist the engine and the transaxle assembly and front suspension member.

CAUTION:

Before and during this lifting, always check if any harnesses are left connected.

Avoid damage to and oil/grease smearing or spills onto engine mounting insulator.

5. Remove rear torque rod and rear torque rod bracket.

6. Remove each engine mounting insulator and each engine mounting bracket from engine, transaxle and

front suspension member.

7. Separate engine and transaxle assembly from front suspension member.

CAUTION:

Before and during this lifting, always check if any harnesses are left connected.

Avoid damage to and oil/grease smearing or spills onto engine mounting insulator.

8. Separate engine and transaxle assembly. Refer to TM-332, "

Exploded View" (VQ25DE) or TM-168,

"Exploded View" (VQ35DE).

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

Never allow engine mounting insulator to be damage and careful no oil gets on it.

Check all mounting insulators are seated properly, then tighten mounting nuts and bolts.

Preparation

1. Install the engine mounting bracket (RH) to the engine as follows:

1 : Engine rear slinger

4 : Engine front slinger (upper)

5 : Engine front slinger (lower)

: Engine front

JPBIA1729ZZ

Page 1946 of 5121

ENGINE ASSEMBLY

EM-71

< REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

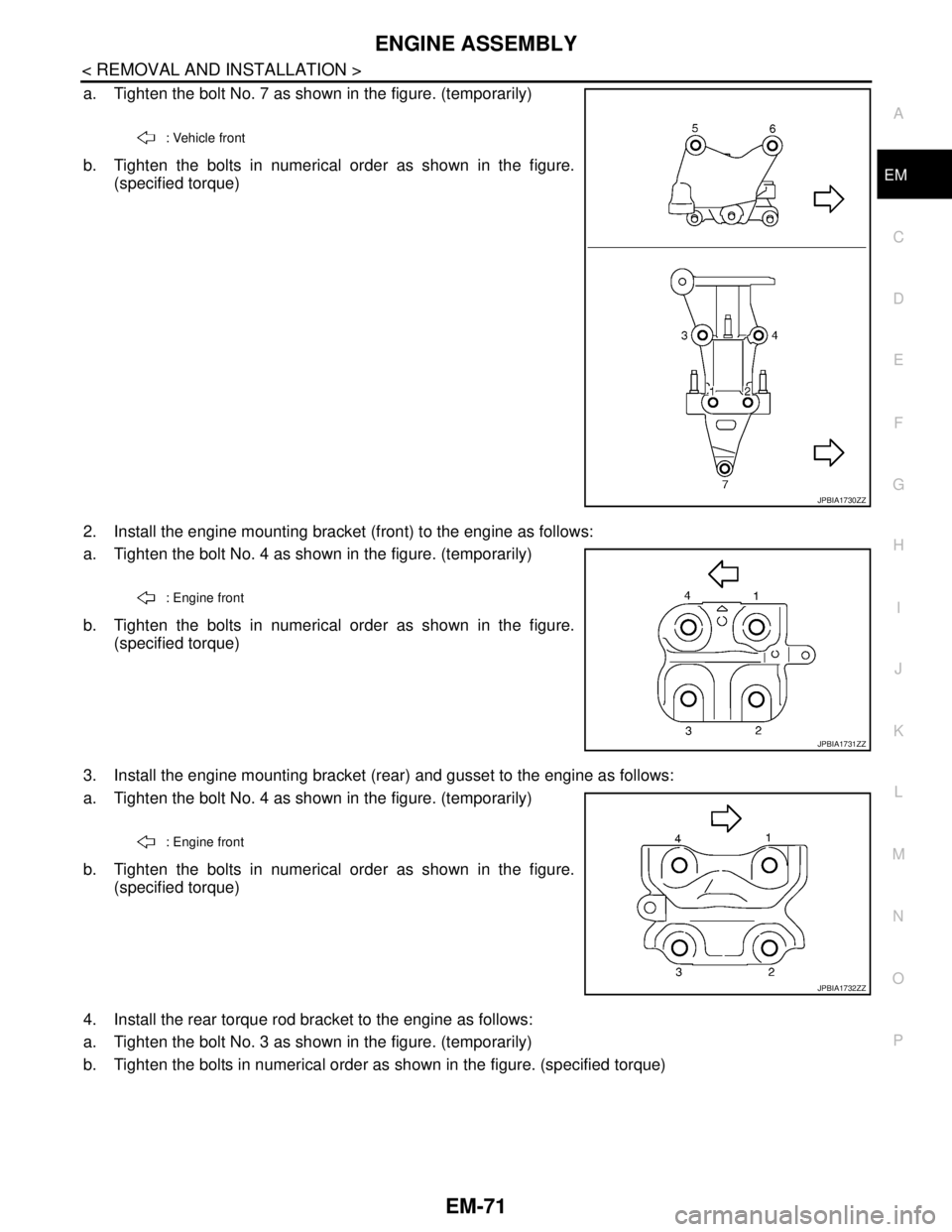

a. Tighten the bolt No. 7 as shown in the figure. (temporarily)

b. Tighten the bolts in numerical order as shown in the figure.

(specified torque)

2. Install the engine mounting bracket (front) to the engine as follows:

a. Tighten the bolt No. 4 as shown in the figure. (temporarily)

b. Tighten the bolts in numerical order as shown in the figure.

(specified torque)

3. Install the engine mounting bracket (rear) and gusset to the engine as follows:

a. Tighten the bolt No. 4 as shown in the figure. (temporarily)

b. Tighten the bolts in numerical order as shown in the figure.

(specified torque)

4. Install the rear torque rod bracket to the engine as follows:

a. Tighten the bolt No. 3 as shown in the figure. (temporarily)

b. Tighten the bolts in numerical order as shown in the figure. (specified torque)

: Vehicle front

JPBIA1730ZZ

: Engine front

JPBIA1731ZZ

: Engine front

JPBIA1732ZZ

Page 1947 of 5121

EM-72

< REMOVAL AND INSTALLATION >

ENGINE ASSEMBLY

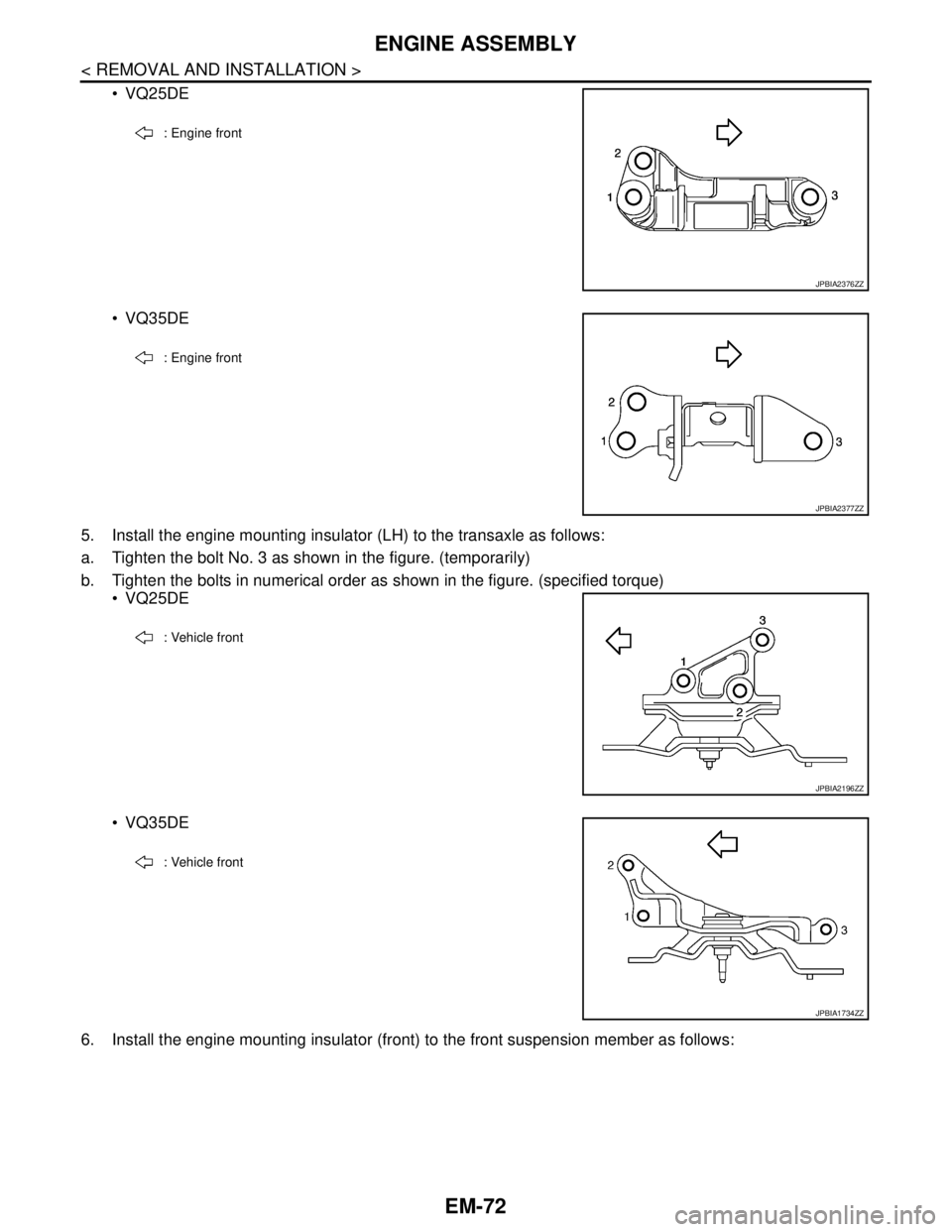

VQ25DE

VQ35DE

5. Install the engine mounting insulator (LH) to the transaxle as follows:

a. Tighten the bolt No. 3 as shown in the figure. (temporarily)

b. Tighten the bolts in numerical order as shown in the figure. (specified torque)

VQ25DE

VQ35DE

6. Install the engine mounting insulator (front) to the front suspension member as follows:

: Engine front

JPBIA2376ZZ

: Engine front

JPBIA2377ZZ

: Vehicle front

JPBIA2196ZZ

: Vehicle front

JPBIA1734ZZ