display NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 2572 of 5121

DIAGNOSIS AND REPAIR WORK FLOW

HA-3

< BASIC INSPECTION >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORK FLOW

Work FlowINFOID:0000000003795801

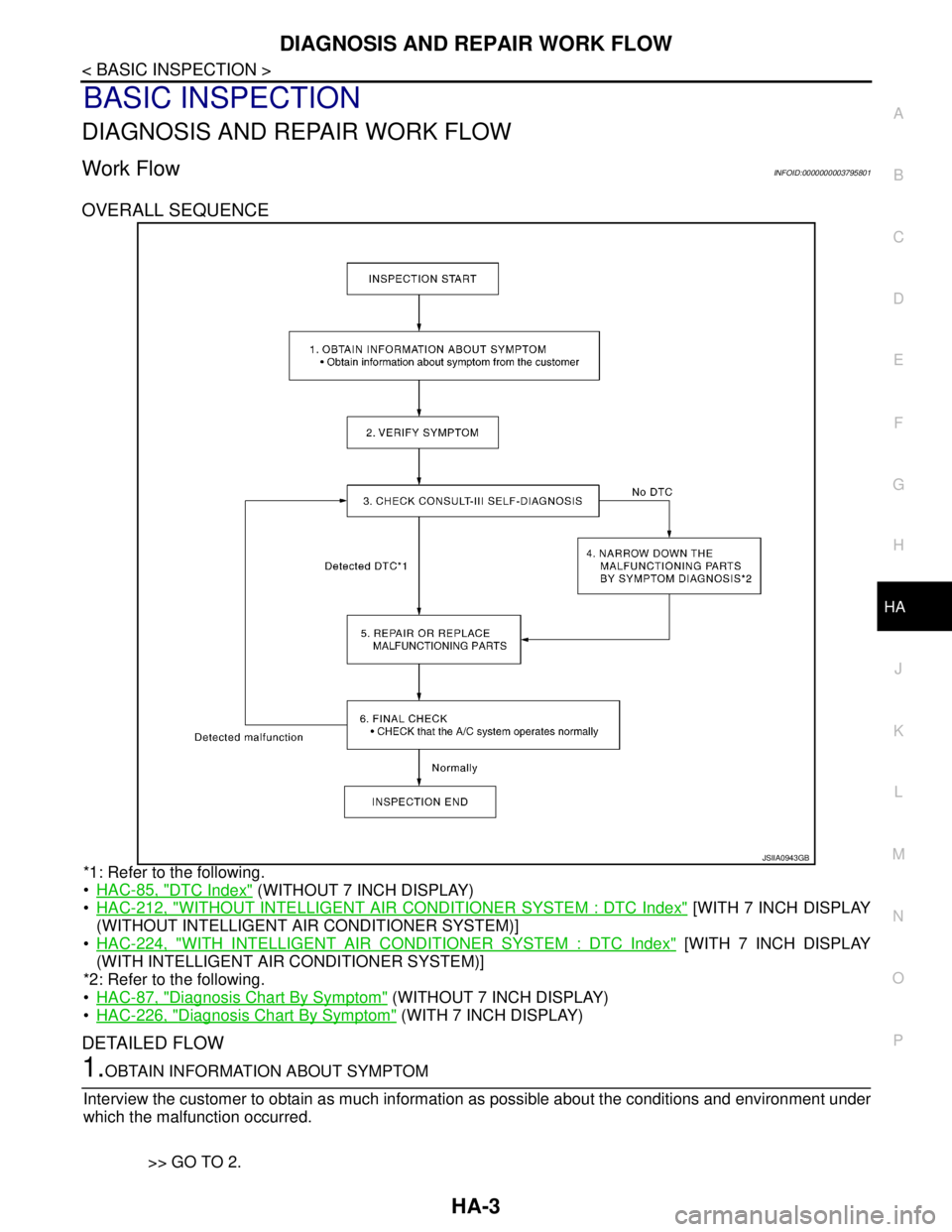

OVERALL SEQUENCE

*1: Refer to the following.

•HAC-85, "

DTC Index" (WITHOUT 7 INCH DISPLAY)

HAC-212, "

WITHOUT INTELLIGENT AIR CONDITIONER SYSTEM : DTC Index" [WITH 7 INCH DISPLAY

(WITHOUT INTELLIGENT AIR CONDITIONER SYSTEM)]

HAC-224, "

WITH INTELLIGENT AIR CONDITIONER SYSTEM : DTC Index" [WITH 7 INCH DISPLAY

(WITH INTELLIGENT AIR CONDITIONER SYSTEM)]

*2: Refer to the following.

HAC-87, "

Diagnosis Chart By Symptom" (WITHOUT 7 INCH DISPLAY)

HAC-226, "

Diagnosis Chart By Symptom" (WITH 7 INCH DISPLAY)

DETAILED FLOW

1.OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain as much information as possible about the conditions and environment under

which the malfunction occurred.

>> GO TO 2.

JSIIA0943GB

Page 2573 of 5121

HA-4

< BASIC INSPECTION >

DIAGNOSIS AND REPAIR WORK FLOW

2.VERIFY SYMPTOM

Verify the symptom with operational check based on the information obtained from the customer. Refer to the

following.

HAC-8, "

Description & Inspection" (WITHOUT 7 INCH DISPLAY)

HAC-108, "

WITHOUT INTELLIGENT AIR CONDITIONER SYSTEM : Description & Inspection" [WITH 7

INCH DISPLAY (WITHOUT INTELLIGENT AIR CONDITIONER SYSTEM)]

HAC-112, "

WITH INTELLIGENT AIR CONDITIONER SYSTEM : Description & Inspection" [WITH 7 INCH

DISPLAY (WITH INTELLIGENT AIR CONDITIONER SYSTEM)]

>> GO TO 3.

3.CHECK WITH SELF-DIAGNOSIS FUNCTION OF CONSULT-III

Using CONSULT-III, perform “SELF-DIAGNOSIS RESULTS” of HVAC. Refer to the following.

HAC-85, "

DTC Index" (WITHOUT 7 INCH DISPLAY)

HAC-212, "

WITHOUT INTELLIGENT AIR CONDITIONER SYSTEM : DTC Index" [WITH 7 INCH DISPLAY

(WITHOUT INTELLIGENT AIR CONDITIONER SYSTEM)]

HAC-224, "

WITH INTELLIGENT AIR CONDITIONER SYSTEM : DTC Index" [WITH 7 INCH DISPLAY

(WITH INTELLIGENT AIR CONDITIONER SYSTEM)]

Are self

-diagnosis results normal?

YES >> GO TO 4.

NO >> GO TO 5.

4.NARROW DOWN THE MALFUNCTIONING PARTS BY SYMPTOM DIAGNOSIS

Perform symptom diagnosis and narrow down the malfunctioning parts. Refer to the following.

HAC-87, "

Diagnosis Chart By Symptom" (WITHOUT 7 INCH DISPLAY)

HAC-226, "

Diagnosis Chart By Symptom" (WITH 7 INCH DISPLAY)

>> GO TO 5.

5.REPAIR OR REPLACE

Repair or replace malfunctioning parts.

NOTE:

If DTC is displayed, erase DTC after repairing or replacing malfunctioning parts.

>> GO TO 6.

6.FINAL CHECK

Check that the A/C system operates normally.

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 3.

Page 2578 of 5121

REFRIGERATION SYSTEM SYMPTOMS

HA-9

< SYMPTOM DIAGNOSIS >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

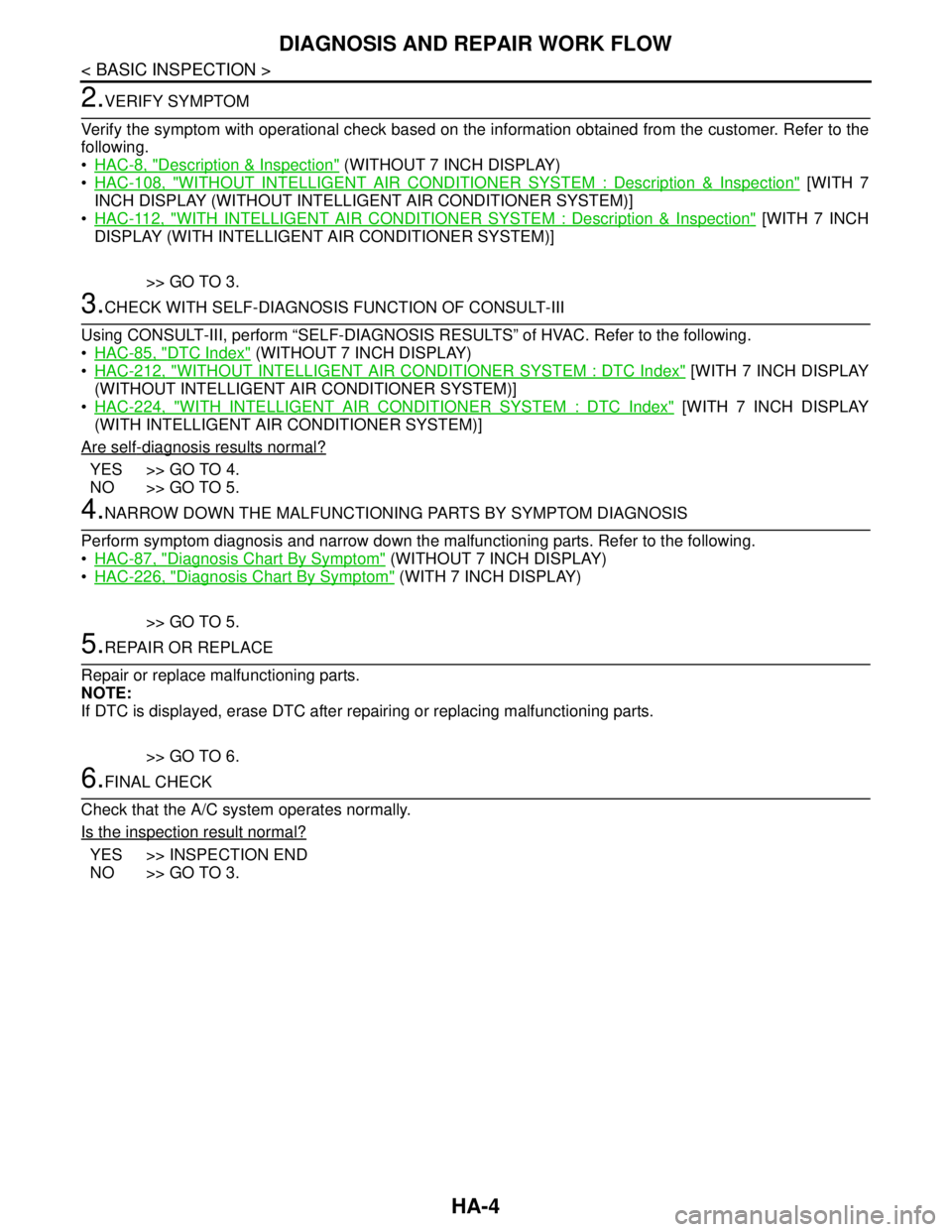

High-pressure side is too low and

low-pressure side is too high.High- and low-pressure sides

become equal soon after

compressor operation stops.Compressor pressure opera-

tion is improper.

↓

Damaged inside compressor

packings.Replace compressor.

No temperature difference be-

tween high- and low-pressure

sides.Compressor pressure opera-

tion is improper.

↓

Damaged inside compressor

packings.Replace compressor.

Both high and low-pressure sides

are too low. There is a big temperature

difference between the liq-

uid tank outlet and inlet.

Outlet temperature is ex-

tremely low.

Liquid tank inlet and expan-

sion valve are frosted.Liquid tank inside is slightly

clogged. Replace liquid tank.

Check lubricant for contami-

nation.

Expansion valve inlet tem-

perature is extremely low

compared with areas near

the liquid tank.

Expansion valve inlet is

frosted.

Temperature difference oc-

curs somewhere in high-

pressure side.High-pressure pipe located be-

tween liquid tank and expan-

sion valve is clogged. Check and repair malfunc-

tioning parts.

Check lubricant for contami-

nation.

Expansion valve and liquid

tank are warm or slightly cool

when touched.Low refrigerant charge.

↓

Leaking fittings or components.Check refrigerant for leakages.

Refer to HA-31, "

Refrigerant

Leakages".

There is a big temperature dif-

ference between the expan-

sion valve inlet and outlet

while the valve itself is frost-

ed.Expansion valve slightly closes

compared with the specifica-

tion.

↓

1. Improper expansion

valve adjustment.

2. Malfunctioning expansion

valve.

3. Outlet and inlet may be

clogged. Remove foreign materials by

using compressed air.

Replace expansion valve.

Check lubricant for contami-

nation.

An area of the low-pressure

pipe is colder than areas near

the evaporator outlet.Low-pressure pipe is clogged

or crushed. Check and repair malfunc-

tioning parts.

Check lubricant for contami-

nation.

Air flow volume is not suffi-

cient or is too low.Evaporator is frozen. Check intake sensor circuit.

Refer to HAC-50, "

Diagnosis

Procedure"(WITHOUT 7

INCH DISPLAY) or HAC-172,

"Diagnosis Proce-

dure"(WITH 7 INCH DIS-

PLAY).

Replace compressor.

Repair evaporator fins.

Replace evaporator.

Check blower motor circuit.

Refer to HAC-68, "

Diagnosis

Procedure"(WITHOUT 7

INCH DISPLAY) or HAC-193,

"Diagnosis Proce-

dure"(WITH 7 INCH DIS-

PLAY). Gauge indication Refrigerant cycle Probable cause Corrective action

AC356A

AC353A

Page 2586 of 5121

PRECAUTIONS

HA-17

< PRECAUTION >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

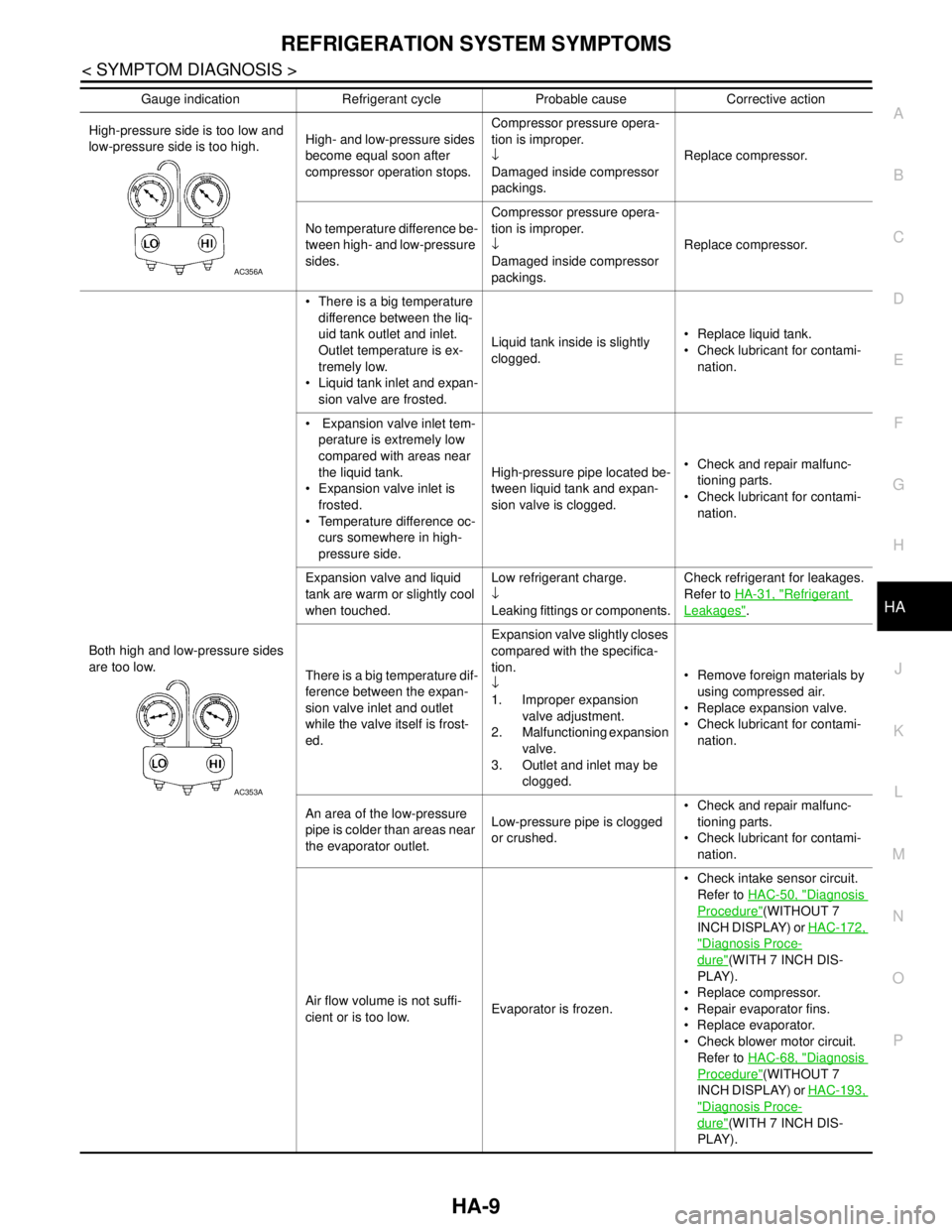

Be certain that the gauge face indicates HFC-134a or R-134a. Be

sure the gauge set has 1/2″-16 ACME threaded connections for ser-

vice hoses. Confirm the set has been used only with refrigerant

HFC-134a (R-134a) and specified lubricants.

SERVICE HOSES

Be certain that the service hoses display the markings described

(colored hose with black stripe). All hoses must equip positive shut-

off devices (either manual or automatic) near the end of the hoses

opposite to the manifold gauge.

SERVICE COUPLERS

Never attempt to connect HFC-134a (R-134a) service couplers to a

CFC-12 (R-12) A/C system. The HFC-134a (R-134a) couplers do

not properly connect to the CFC-12 (R-12) system. However, if an

improper connection is attempted, discharging and contamination

may occur.

REFRIGERANT WEIGHT SCALE

Verify that no refrigerant other than HFC-134a (R-134a) and speci-

fied lubricants have been used with the scale. The hose fitting must

be 1/2″-16 ACME if the scale controls refrigerant flow electronically.

CALIBRATING ACR4 WEIGHT SCALE

Calibrate the scale each three month.

To calibrate the weight scale on the ACR4:

1. Press “Shift/Reset” and “Enter” at the same time.

2. Press “8787”. “A1” is displayed.

3. Remove all weight from the scale.

4. Press “0”, then press “Enter”. “0.00” is displayed and change to “A2”.

SHA533D

RHA272D

Shut-off valve rotation A/C service valve

Clockwise Open

Counterclockwise Close

RHA273D

RHA274D

Page 2587 of 5121

HA-18

< PRECAUTION >

PRECAUTIONS

5. Place a known weight (dumbbell or similar weight), between 4.5 and 8.6 kg (10 and 19 lb.) on the center

of the weight scale.

6. Enter the known weight using four digits. (Example 10 lb. = 10.00, 10.5 lb. = 10.50)

7. Press “Enter”— the display returns to the vacuum mode.

8. Press “Shift/Reset” and “Enter” at the same time.

9. Press “6”— the known weight on the scale is displayed.

10. Remove the known weight from the scale. “0.00” is displayed.

11. Press “Shift/Reset” to return the ACR4 to the program mode.

CHARGING CYLINDER

Using a charging cylinder is not recommended. Refrigerant may be vented into air from cylinder’s top valve

when filling the cylinder with refrigerant. Also, the accuracy of the cylinder is generally less than that of an

electronic scale or of quality recycle/recharge equipment.

Page 2594 of 5121

REFRIGERANT

HA-25

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

WARNING:

Never breath A/C refrigerant and lubricant vapor or mist. Exposure may irritate eyes, nose and throat.

Use only approved recovery/recycling recharging equipment to discharge HFC-134a (R-134a) refriger-

ant. Ventilate work area before resuming service if accidental system discharge occurs. Additional

health and safety information may be obtained from refrigerant and lubricant manufacturers.

1.CHECK A/C SYSTEM

1. Check that A/C system operates normally. Refer to the following.

-HAC-8, "

Description & Inspection" (WITHOUT 7 INCH DISPLAY)

-HAC-108, "

WITHOUT INTELLIGENT AIR CONDITIONER SYSTEM : Description & Inspection" [WITH 7

INCH DISPLAY (WITHOUT INTELLIGENT AIR CONDITIONER SYSTEM)]

-HAC-112, "

WITH INTELLIGENT AIR CONDITIONER SYSTEM : Description & Inspection" [WITH 7 INCH

DISPLAY (WITH INTELLIGENT AIR CONDITIONER SYSTEM)]

2. Check if there is a large amount of leakage of refrigerant or oil.

CAUTION:

Never perform the lubricant return operation if a large amount of leakage of lubricant is detected.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Check for refrigerant leakage. Refer to HA-32, "

Inspection".

2.LUBRICANT RETURN OPERATION

1. Start the engine and run it as follows.

- Engine speed: Idle - 1,200 rpm

- A/C switch: ON

- Blower speed: Max. position

- Air inlet: Recirculation (REC)

- Set temperature: FULL HOT

2. Perform lubricant return operation for approximately 10 minutes.

3. Stop the engine.

>> GO TO 3.

3.CHECK RECOVERY/RECYCLING RECHARGING EQUIPMENT

1. Operate recovery/recycling recharging equipment.

CAUTION:

Follow the instructions of the manufacturer for the handling or maintenance of the equipment.

Never fill the equipment with undesignated refrigerant.

2. Check the gauge pressure of recovery/recycling recharging equipment.

Is there pressure?

YES >> GO TO 4.

NO >> GO TO 5.

4.DISCHARGE REFRIGERANT INSIDE PIPES

Discharge the refrigerant from the high-pressure hose and low-pressure hose of recovery/recycling recharging

equipment.

>> GO TO 5.

5.CONNECT RECOVERY/RECYCLING RECHARGING EQUIPMENT

1. Remove the service valve caps from the vehicle.

2. Connect recovery/recycling recharging equipment to the service valves.

>> GO TO 6.

6.DISCHARGE REFRIGERANT FROM THE VEHICLE

Operate recovery/recycling recharging equipment to discharge the refrigerant from the vehicle.

Page 2598 of 5121

LUBRICANT

HA-29

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

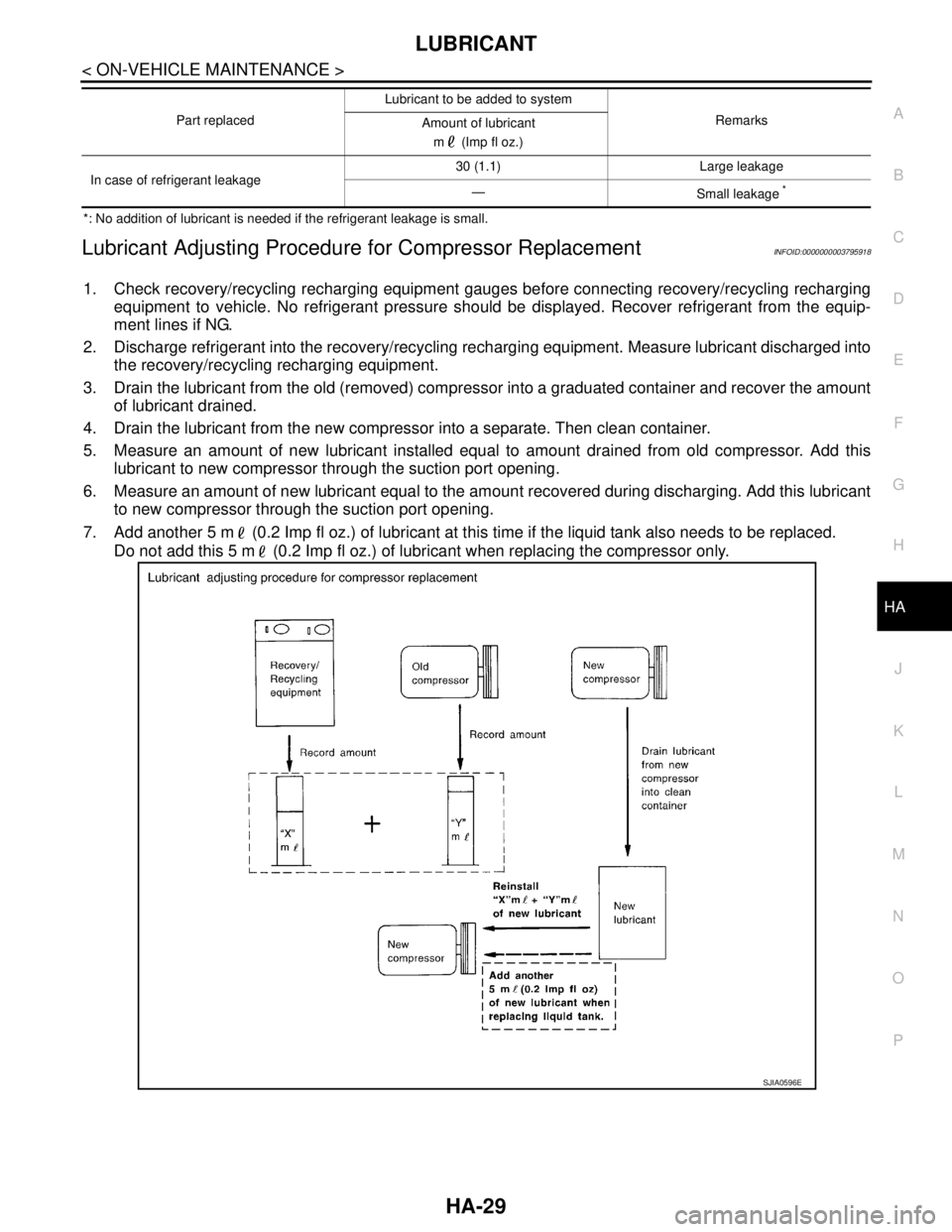

*: No addition of lubricant is needed if the refrigerant leakage is small.

Lubricant Adjusting Procedure for Compressor ReplacementINFOID:0000000003795918

1. Check recovery/recycling recharging equipment gauges before connecting recovery/recycling recharging

equipment to vehicle. No refrigerant pressure should be displayed. Recover refrigerant from the equip-

ment lines if NG.

2. Discharge refrigerant into the recovery/recycling recharging equipment. Measure lubricant discharged into

the recovery/recycling recharging equipment.

3. Drain the lubricant from the old (removed) compressor into a graduated container and recover the amount

of lubricant drained.

4. Drain the lubricant from the new compressor into a separate. Then clean container.

5. Measure an amount of new lubricant installed equal to amount drained from old compressor. Add this

lubricant to new compressor through the suction port opening.

6. Measure an amount of new lubricant equal to the amount recovered during discharging. Add this lubricant

to new compressor through the suction port opening.

7. Add another 5 m (0.2 Imp fl oz.) of lubricant at this time if the liquid tank also needs to be replaced.

Do not add this 5 m (0.2 Imp fl oz.) of lubricant when replacing the compressor only.

In case of refrigerant leakage30 (1.1) Large leakage

—

Small leakage *

Part replacedLubricant to be added to system

Remarks

Amount of lubricant

m (Imp fl oz.)

SJIA0596E

Page 2599 of 5121

HA-30

< ON-VEHICLE MAINTENANCE >

REFRIGERATION SYSTEM

REFRIGERATION SYSTEM

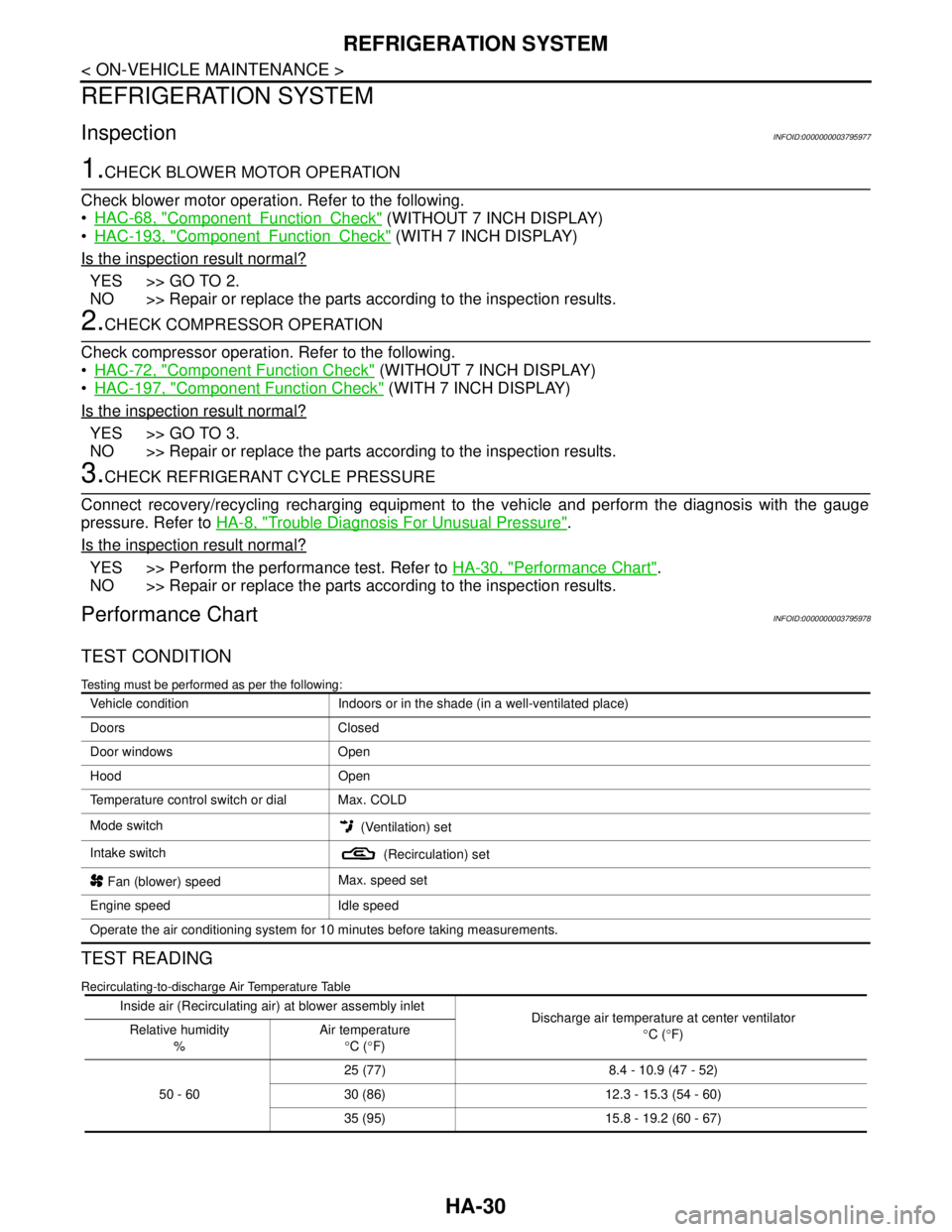

InspectionINFOID:0000000003795977

1.CHECK BLOWER MOTOR OPERATION

Check blower motor operation. Refer to the following.

HAC-68, "

ComponentFunctionCheck" (WITHOUT 7 INCH DISPLAY)

HAC-193, "

ComponentFunctionCheck" (WITH 7 INCH DISPLAY)

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace the parts according to the inspection results.

2.CHECK COMPRESSOR OPERATION

Check compressor operation. Refer to the following.

HAC-72, "

Component Function Check" (WITHOUT 7 INCH DISPLAY)

HAC-197, "

Component Function Check" (WITH 7 INCH DISPLAY)

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace the parts according to the inspection results.

3.CHECK REFRIGERANT CYCLE PRESSURE

Connect recovery/recycling recharging equipment to the vehicle and perform the diagnosis with the gauge

pressure. Refer to HA-8, "

Trouble Diagnosis For Unusual Pressure".

Is the inspection result normal?

YES >> Perform the performance test. Refer to HA-30, "Performance Chart".

NO >> Repair or replace the parts according to the inspection results.

Performance ChartINFOID:0000000003795978

TEST CONDITION

Testing must be performed as per the following:

TEST READING

Recirculating-to-discharge Air Temperature Table

Vehicle condition Indoors or in the shade (in a well-ventilated place)

Doors Closed

Door windows Open

Hood Open

Temperature control switch or dial Max. COLD

Mode switch

(Ventilation) set

Intake switch

(Recirculation) set

Fan (blower) speedMax. speed set

Engine speed Idle speed

Operate the air conditioning system for 10 minutes before taking measurements.

Inside air (Recirculating air) at blower assembly inlet

Discharge air temperature at center ventilator

°C (°F) Relative humidity

%Air temperature

°C (°F)

50 - 6025 (77) 8.4 - 10.9 (47 - 52)

30 (86) 12.3 - 15.3 (54 - 60)

35 (95) 15.8 - 19.2 (60 - 67)

Page 2604 of 5121

ELECTRICAL LEAK DETECTOR

HA-35

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

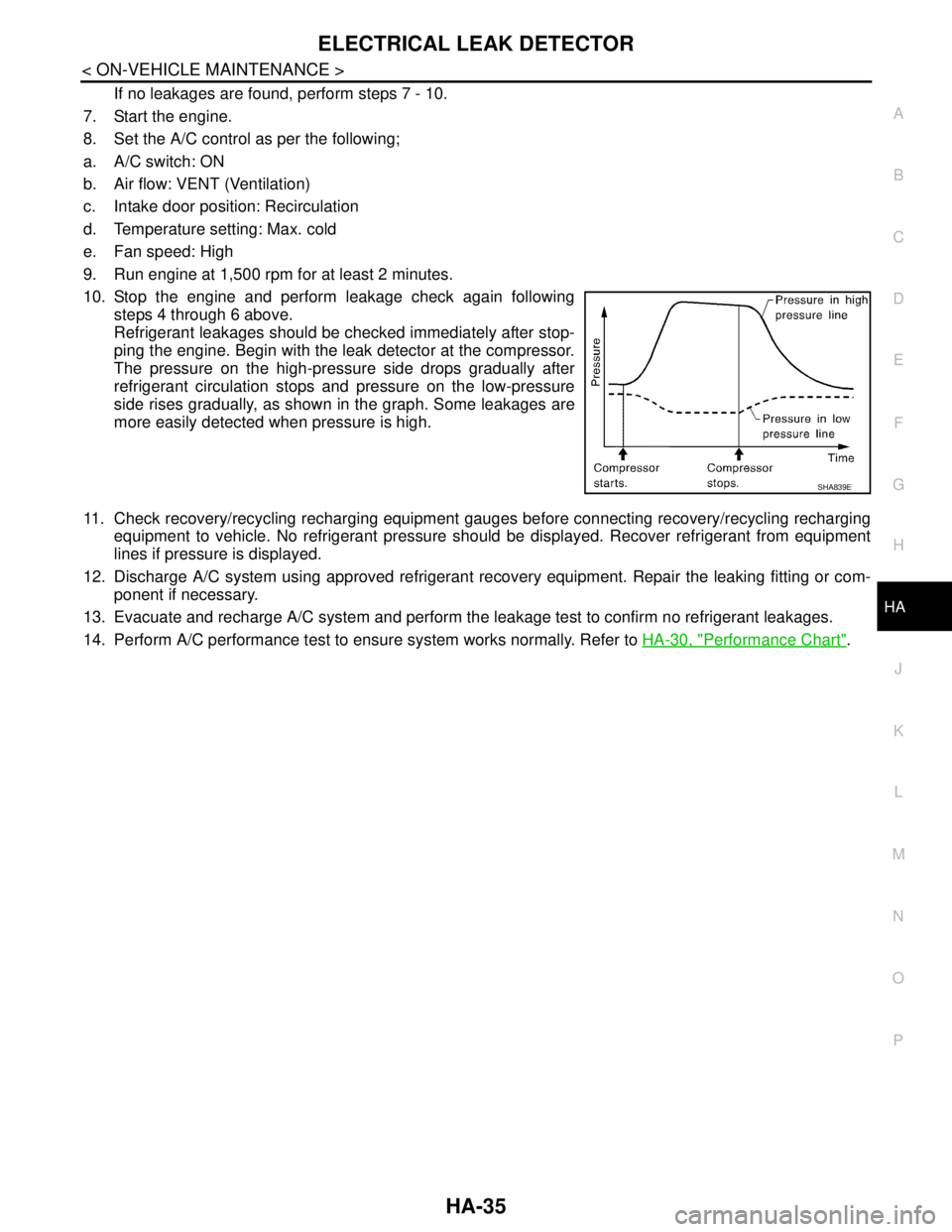

If no leakages are found, perform steps 7 - 10.

7. Start the engine.

8. Set the A/C control as per the following;

a. A/C switch: ON

b. Air flow: VENT (Ventilation)

c. Intake door position: Recirculation

d. Temperature setting: Max. cold

e. Fan speed: High

9. Run engine at 1,500 rpm for at least 2 minutes.

10. Stop the engine and perform leakage check again following

steps 4 through 6 above.

Refrigerant leakages should be checked immediately after stop-

ping the engine. Begin with the leak detector at the compressor.

The pressure on the high-pressure side drops gradually after

refrigerant circulation stops and pressure on the low-pressure

side rises gradually, as shown in the graph. Some leakages are

more easily detected when pressure is high.

11. Check recovery/recycling recharging equipment gauges before connecting recovery/recycling recharging

equipment to vehicle. No refrigerant pressure should be displayed. Recover refrigerant from equipment

lines if pressure is displayed.

12. Discharge A/C system using approved refrigerant recovery equipment. Repair the leaking fitting or com-

ponent if necessary.

13. Evacuate and recharge A/C system and perform the leakage test to confirm no refrigerant leakages.

14. Perform A/C performance test to ensure system works normally. Refer to HA-30, "

Performance Chart".

SHA839E

Page 2624 of 5121

EVAPORATOR PIPE ASSEMBLY

HA-55

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

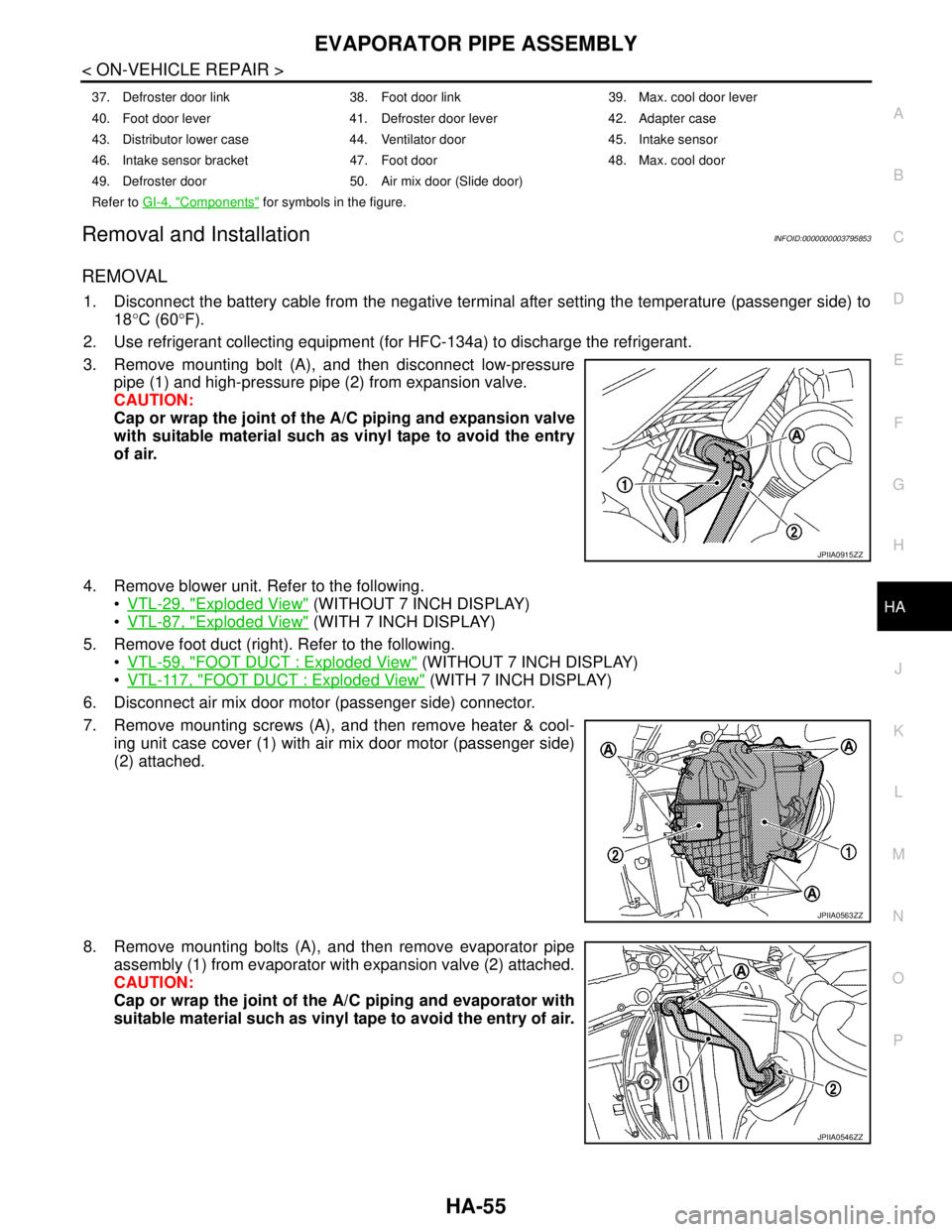

Removal and InstallationINFOID:0000000003795853

REMOVAL

1. Disconnect the battery cable from the negative terminal after setting the temperature (passenger side) to

18°C (60°F).

2. Use refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant.

3. Remove mounting bolt (A), and then disconnect low-pressure

pipe (1) and high-pressure pipe (2) from expansion valve.

CAUTION:

Cap or wrap the joint of the A/C piping and expansion valve

with suitable material such as vinyl tape to avoid the entry

of air.

4. Remove blower unit. Refer to the following.

VTL-29, "

Exploded View" (WITHOUT 7 INCH DISPLAY)

VTL-87, "

Exploded View" (WITH 7 INCH DISPLAY)

5. Remove foot duct (right). Refer to the following.

VTL-59, "

FOOT DUCT : Exploded View" (WITHOUT 7 INCH DISPLAY)

VTL-117, "

FOOT DUCT : Exploded View" (WITH 7 INCH DISPLAY)

6. Disconnect air mix door motor (passenger side) connector.

7. Remove mounting screws (A), and then remove heater & cool-

ing unit case cover (1) with air mix door motor (passenger side)

(2) attached.

8. Remove mounting bolts (A), and then remove evaporator pipe

assembly (1) from evaporator with expansion valve (2) attached.

CAUTION:

Cap or wrap the joint of the A/C piping and evaporator with

suitable material such as vinyl tape to avoid the entry of air.

37. Defroster door link 38. Foot door link 39. Max. cool door lever

40. Foot door lever 41. Defroster door lever 42. Adapter case

43. Distributor lower case 44. Ventilator door 45. Intake sensor

46. Intake sensor bracket 47. Foot door 48. Max. cool door

49. Defroster door 50. Air mix door (Slide door)

Refer to GI-4, "

Components" for symbols in the figure.

JPIIA0915ZZ

JPIIA0563ZZ

JPIIA0546ZZ