ignition NISSAN TIIDA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 5820 of 5883

WW-18

< COMPONENT DIAGNOSIS >

FRONT WIPER MOTOR LO CIRCUIT

FRONT WIPER MOTOR LO CIRCUIT

Component Function CheckINFOID:0000000001366610

1. CHECK FRONT WIPER LO OPERATION

IPDM E/R AUTO ACTIVE TEST

1. Start IPDM E/R auto active test. Refer to PCS-10, "

Diagnosis Description".

2. Check that the front wiper operates at the LO operation.

CONSULT-III ACTIVE TEST

1. Select "FRONT WIPER" of IPDM E/R active test item.

2. While operating the test item, check front wiper operation.

Is front wiper (LO) operation normal?

YES >> Front wiper motor LO circuit is normal.

NO >> Refer to WW-18, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000001366611

1. CHECK FRONT WIPER MOTOR FUSE

1. Turn the ignition switch OFF.

2. Check that the following fuse is not blown.

Is the fuse blown?

YES >> GO TO 2

NO >> GO TO 3

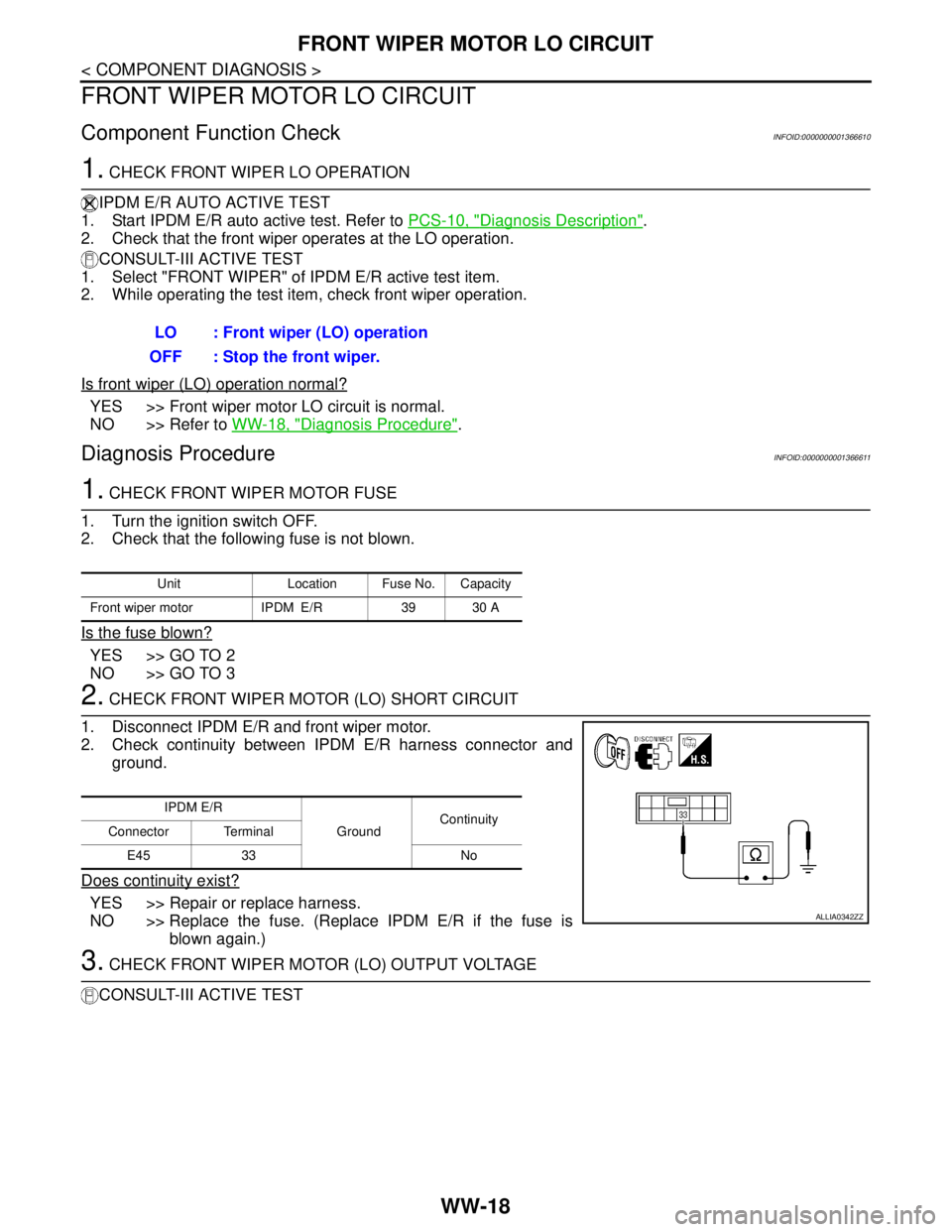

2. CHECK FRONT WIPER MOTOR (LO) SHORT CIRCUIT

1. Disconnect IPDM E/R and front wiper motor.

2. Check continuity between IPDM E/R harness connector and

ground.

Does continuity exist?

YES >> Repair or replace harness.

NO >> Replace the fuse. (Replace IPDM E/R if the fuse is

blown again.)

3. CHECK FRONT WIPER MOTOR (LO) OUTPUT VOLTAGE

CONSULT-III ACTIVE TESTLO : Front wiper (LO) operation

OFF : Stop the front wiper.

Unit Location Fuse No. Capacity

Front wiper motor IPDM E/R 39 30 A

IPDM E/R

GroundContinuity

Connector Terminal

E45 33 No

ALLIA0342ZZ

Page 5821 of 5883

FRONT WIPER MOTOR LO CIRCUIT

WW-19

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

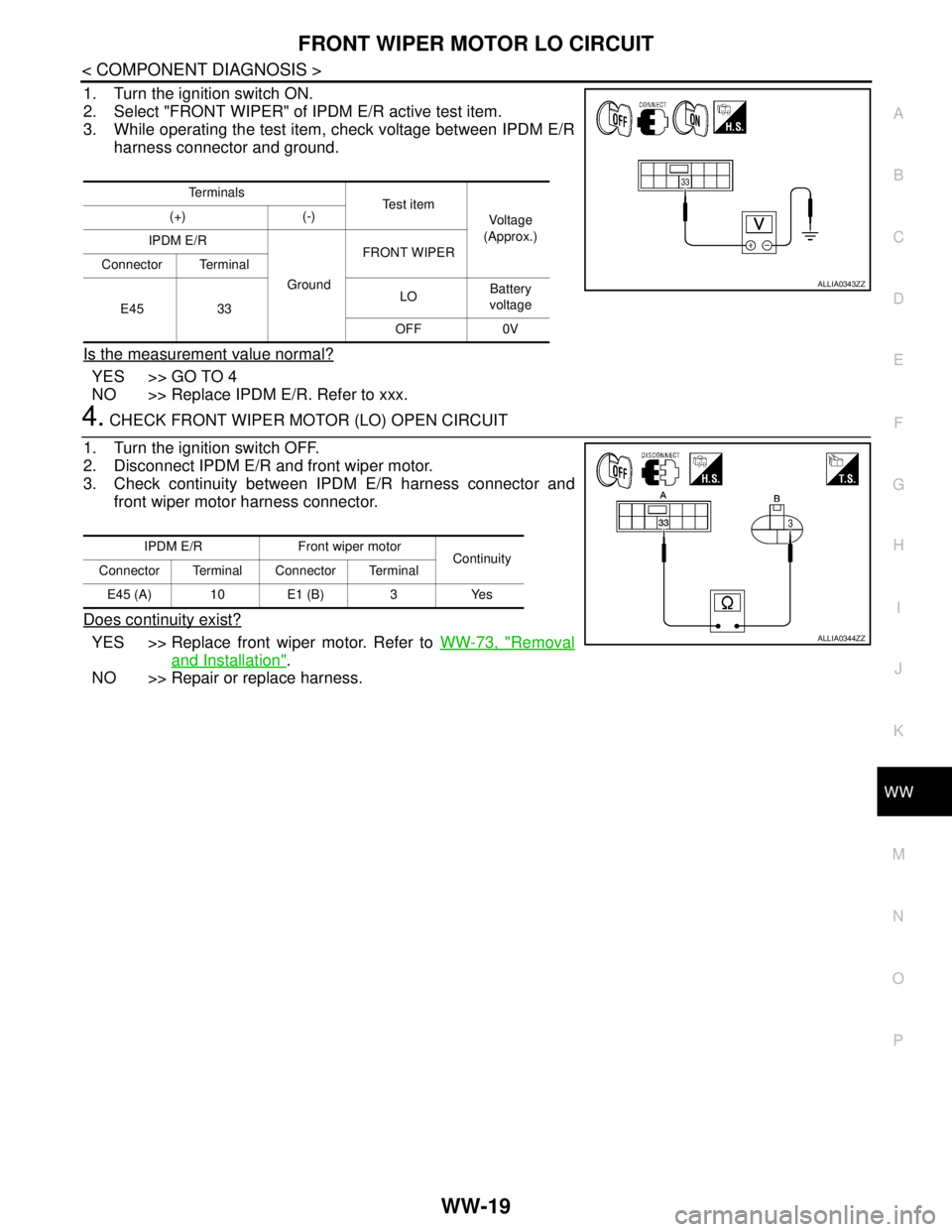

1. Turn the ignition switch ON.

2. Select "FRONT WIPER" of IPDM E/R active test item.

3. While operating the test item, check voltage between IPDM E/R

harness connector and ground.

Is the measurement value normal?

YES >> GO TO 4

NO >> Replace IPDM E/R. Refer to xxx.

4. CHECK FRONT WIPER MOTOR (LO) OPEN CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R and front wiper motor.

3. Check continuity between IPDM E/R harness connector and

front wiper motor harness connector.

Does continuity exist?

YES >> Replace front wiper motor. Refer to WW-73, "Removal

and Installation".

NO >> Repair or replace harness.

Te r m i n a l s

Te s t i t e m

Voltage

(Approx.) (+) (-)

IPDM E/R

GroundFRONT WIPER

Connector Terminal

E45 33LOBattery

voltage

OFF 0V

ALLIA0343ZZ

IPDM E/R Front wiper motor

Continuity

Connector Terminal Connector Terminal

E45 (A) 10 E1 (B) 3 Yes

ALLIA0344ZZ

Page 5822 of 5883

WW-20

< COMPONENT DIAGNOSIS >

FRONT WIPER MOTOR HI CIRCUIT

FRONT WIPER MOTOR HI CIRCUIT

Component Function CheckINFOID:0000000001366612

1. CHECK FRONT WIPER HI OPERATION

IPDM E/R AUTO ACTIVE TEST

1. Start IPDM E/R auto active test. Refer to PCS-10, "

Diagnosis Description".

2. Check that the front wiper operates at the HI operation.

CONSULT-III ACTIVE TEST

1. Select "FRONT WIPER" of IPDM E/R active test item.

2. While operating the test item, check front wiper operation.

Is front wiper (HI) operation normal?

YES >> Front wiper motor HI circuit is normal.

NO >> Refer to WW-20, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000001366613

1. CHECK FRONT WIPER MOTOR FUSE

1. Turn the ignition switch OFF.

2. Check that the following fuse is not blown.

Is the fuse blown?

YES >> GO TO 2

NO >> GO TO 3

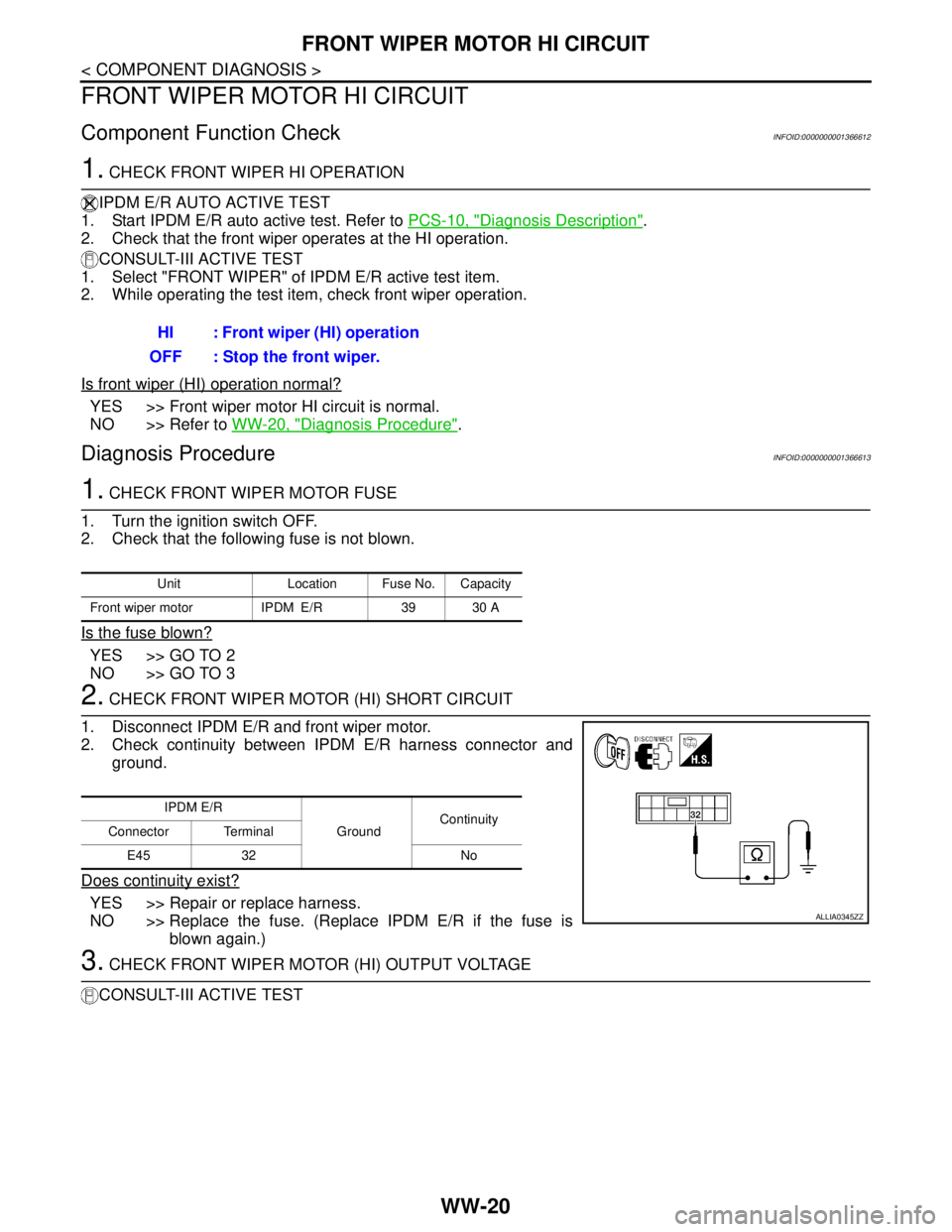

2. CHECK FRONT WIPER MOTOR (HI) SHORT CIRCUIT

1. Disconnect IPDM E/R and front wiper motor.

2. Check continuity between IPDM E/R harness connector and

ground.

Does continuity exist?

YES >> Repair or replace harness.

NO >> Replace the fuse. (Replace IPDM E/R if the fuse is

blown again.)

3. CHECK FRONT WIPER MOTOR (HI) OUTPUT VOLTAGE

CONSULT-III ACTIVE TESTHI : Front wiper (HI) operation

OFF : Stop the front wiper.

Unit Location Fuse No. Capacity

Front wiper motor IPDM E/R 39 30 A

IPDM E/R

GroundContinuity

Connector Terminal

E45 32 No

ALLIA0345ZZ

Page 5823 of 5883

FRONT WIPER MOTOR HI CIRCUIT

WW-21

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

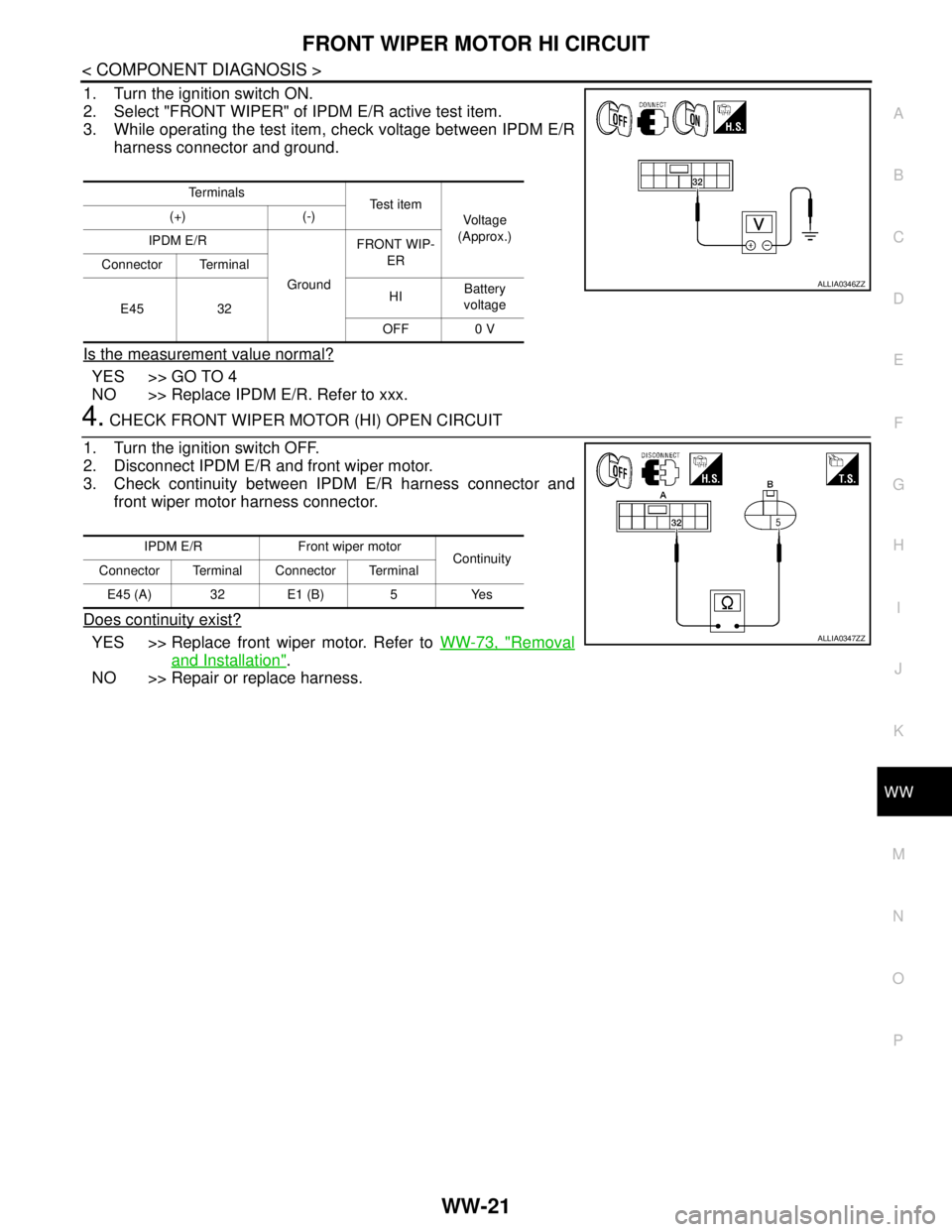

1. Turn the ignition switch ON.

2. Select "FRONT WIPER" of IPDM E/R active test item.

3. While operating the test item, check voltage between IPDM E/R

harness connector and ground.

Is the measurement value normal?

YES >> GO TO 4

NO >> Replace IPDM E/R. Refer to xxx.

4. CHECK FRONT WIPER MOTOR (HI) OPEN CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R and front wiper motor.

3. Check continuity between IPDM E/R harness connector and

front wiper motor harness connector.

Does continuity exist?

YES >> Replace front wiper motor. Refer to WW-73, "Removal

and Installation".

NO >> Repair or replace harness.

Te r m i n a l s

Te s t i t e m

Voltage

(Approx.) (+) (-)

IPDM E/R

GroundFRONT WIP-

ER

Connector Terminal

E45 32HIBattery

voltage

OFF 0 V

ALLIA0346ZZ

IPDM E/R Front wiper motor

Continuity

Connector Terminal Connector Terminal

E45 (A) 32 E1 (B) 5 Yes

ALLIA0347ZZ

Page 5824 of 5883

WW-22

< COMPONENT DIAGNOSIS >

FRONT WIPER AUTO STOP SIGNAL CIRCUIT

FRONT WIPER AUTO STOP SIGNAL CIRCUIT

Component Function CheckINFOID:0000000001366614

1. CHECK FRONT WIPER (AUTO STOP) SIGNAL CHECK

CONSULT-III DATA MONITOR

1. Select "FRONT WIPER STOP" of IPDM E/R data monitor item.

2. Operate the front wiper.

3. Check that "FR WIPER STOP" changes to "STOP P" and "ACT P" linked with the wiper operation.

Is the status of item normal?

YES >> Front wiper auto stop signal circuit is normal.

NO >> Refer to WW-22, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000001366615

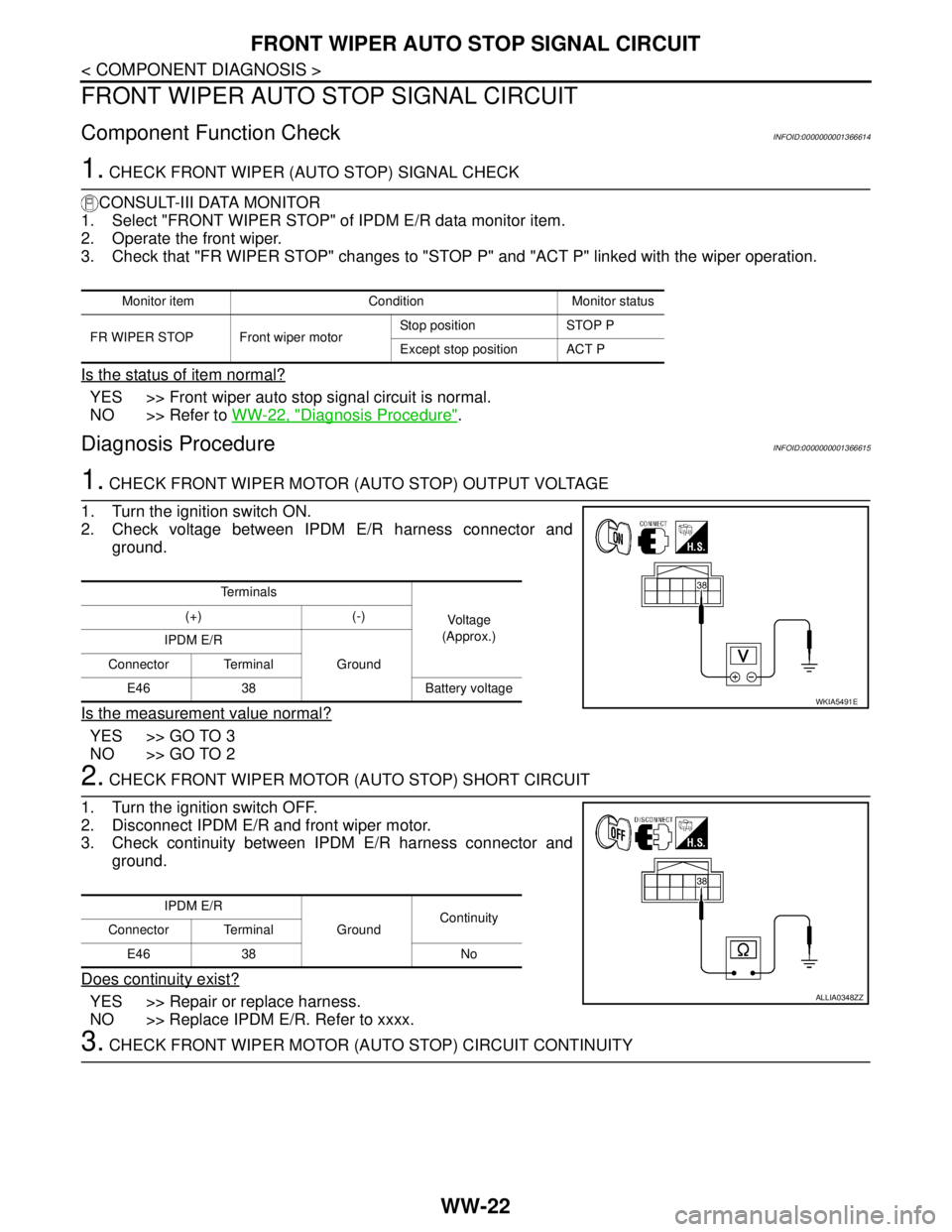

1. CHECK FRONT WIPER MOTOR (AUTO STOP) OUTPUT VOLTAGE

1. Turn the ignition switch ON.

2. Check voltage between IPDM E/R harness connector and

ground.

Is the measurement value normal?

YES >> GO TO 3

NO >> GO TO 2

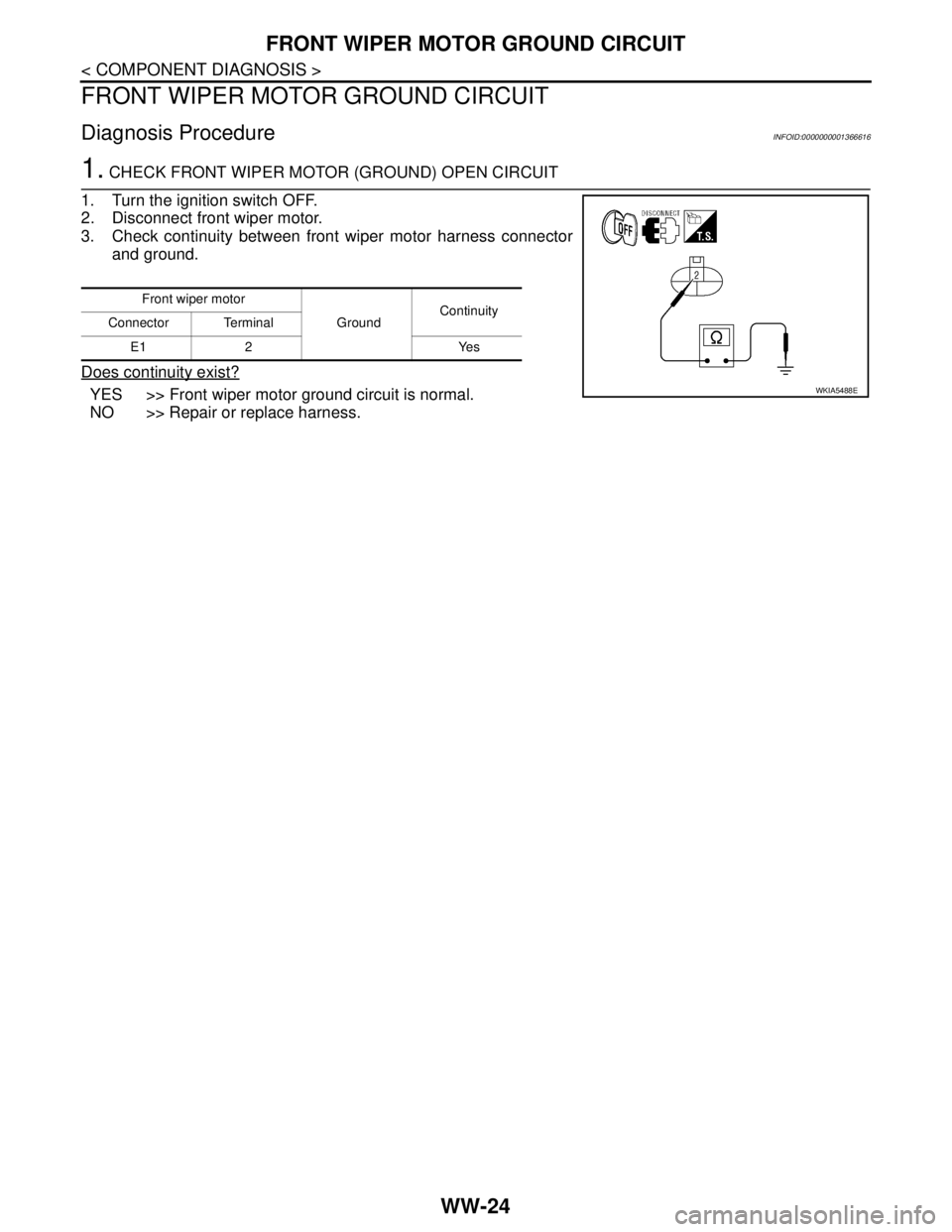

2. CHECK FRONT WIPER MOTOR (AUTO STOP) SHORT CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R and front wiper motor.

3. Check continuity between IPDM E/R harness connector and

ground.

Does continuity exist?

YES >> Repair or replace harness.

NO >> Replace IPDM E/R. Refer to xxxx.

3. CHECK FRONT WIPER MOTOR (AUTO STOP) CIRCUIT CONTINUITY

Monitor item Condition Monitor status

FR WIPER STOP Front wiper motorStop position STOP P

Except stop position ACT P

Te r m i n a l s

Voltage

(Approx.) (+) (-)

IPDM E/R

Ground Connector Terminal

E46 38 Battery voltage

WKIA5491E

IPDM E/R

GroundContinuity

Connector Terminal

E46 38 No

ALLIA0348ZZ

Page 5826 of 5883

WW-24

< COMPONENT DIAGNOSIS >

FRONT WIPER MOTOR GROUND CIRCUIT

FRONT WIPER MOTOR GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000001366616

1. CHECK FRONT WIPER MOTOR (GROUND) OPEN CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect front wiper motor.

3. Check continuity between front wiper motor harness connector

and ground.

Does continuity exist?

YES >> Front wiper motor ground circuit is normal.

NO >> Repair or replace harness.

Front wiper motor

GroundContinuity

Connector Terminal

E1 2 Yes

WKIA5488E

Page 5827 of 5883

WASHER SWITCH

WW-25

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

WASHER SWITCH

DescriptionINFOID:0000000001366617

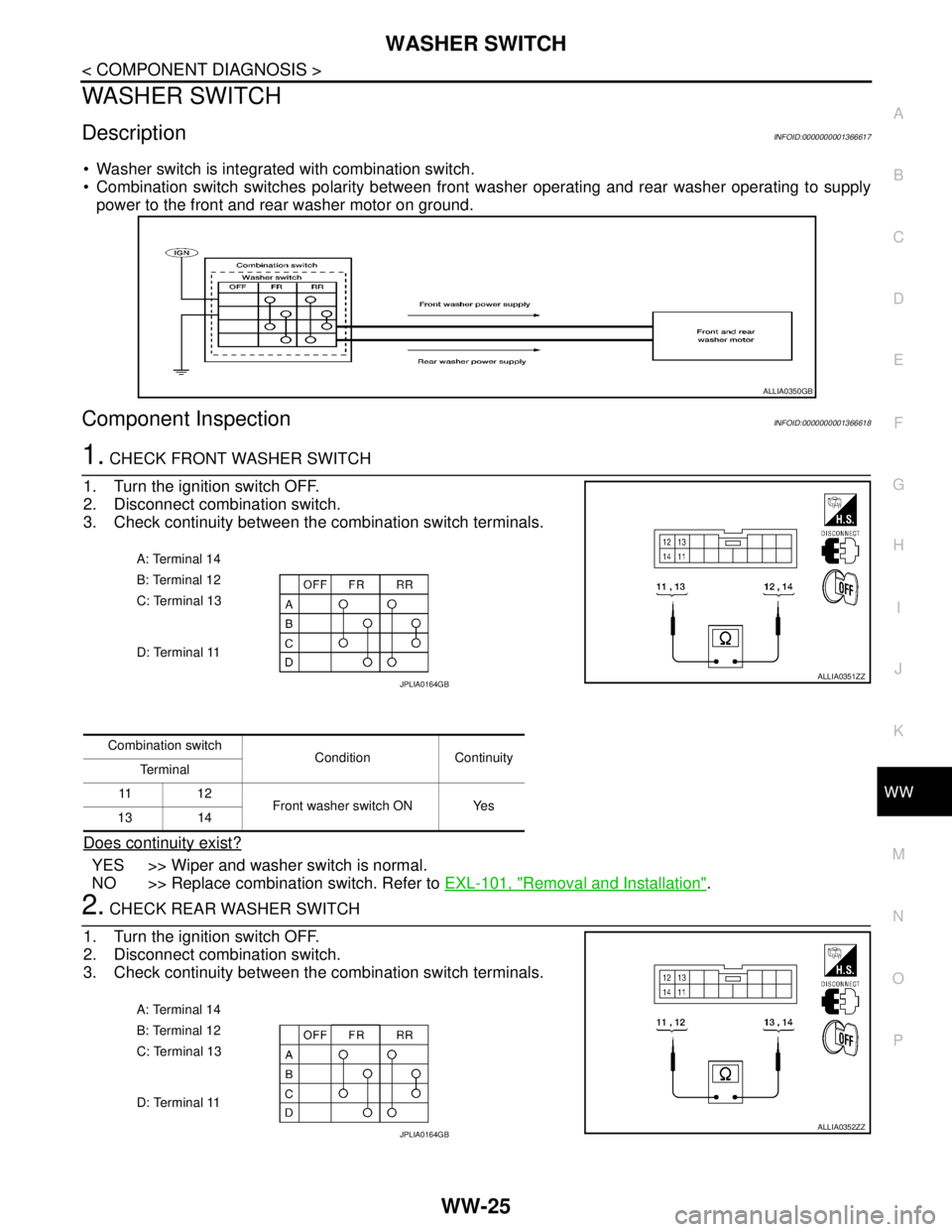

Washer switch is integrated with combination switch.

Combination switch switches polarity between front washer operating and rear washer operating to supply

power to the front and rear washer motor on ground.

Component InspectionINFOID:0000000001366618

1. CHECK FRONT WASHER SWITCH

1. Turn the ignition switch OFF.

2. Disconnect combination switch.

3. Check continuity between the combination switch terminals.

Does continuity exist?

YES >> Wiper and washer switch is normal.

NO >> Replace combination switch. Refer to EXL-101, "

Removal and Installation".

2. CHECK REAR WASHER SWITCH

1. Turn the ignition switch OFF.

2. Disconnect combination switch.

3. Check continuity between the combination switch terminals.

ALLIA0350GB

A: Terminal 14

B: Terminal 12

C: Terminal 13

D: Terminal 11

ALLIA0351ZZJPLIA0164GB

Combination switch

Condition Continuity

Te r m i n a l

11 1 2

Front washer switch ON Yes

13 14

A: Terminal 14

B: Terminal 12

C: Terminal 13

D: Terminal 11

ALLIA0352ZZJPLIA0164GB

Page 5830 of 5883

WW-28

< COMPONENT DIAGNOSIS >

REAR WIPER MOTOR CIRCUIT

REAR WIPER MOTOR CIRCUIT

Component Function CheckINFOID:0000000001366621

1. CHECK REAR WIPER ON OPERATION

CONSULT-III ACTIVE TEST

1. Select "RR WIPER" of BCM active test item.

2. While operating the test item, check rear wiper operation.

Is rear wiper operation normal?

YES >> Rear wiper motor circuit is normal.

NO >> Refer to WW-28, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000001366622

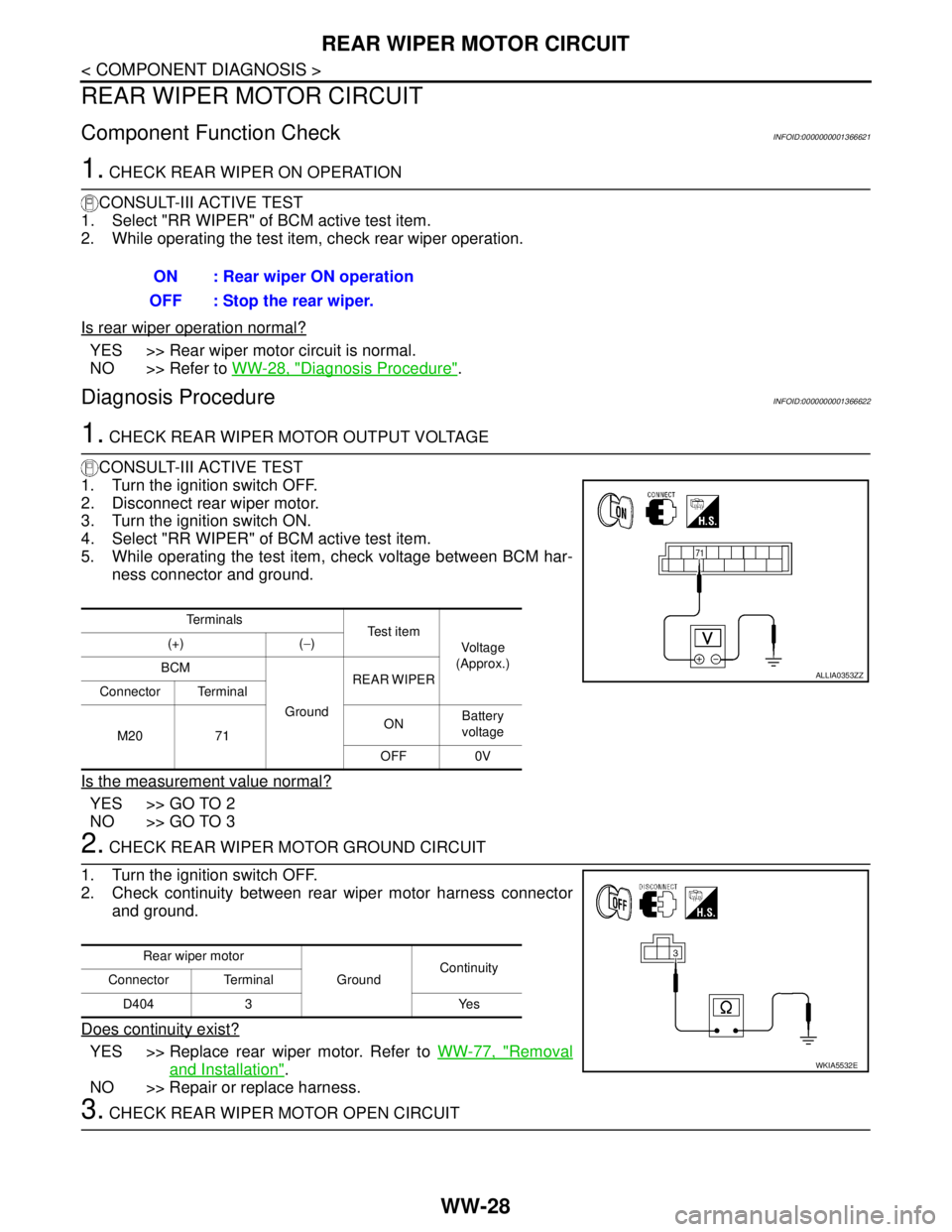

1. CHECK REAR WIPER MOTOR OUTPUT VOLTAGE

CONSULT-III ACTIVE TEST

1. Turn the ignition switch OFF.

2. Disconnect rear wiper motor.

3. Turn the ignition switch ON.

4. Select "RR WIPER" of BCM active test item.

5. While operating the test item, check voltage between BCM har-

ness connector and ground.

Is the measurement value normal?

YES >> GO TO 2

NO >> GO TO 3

2. CHECK REAR WIPER MOTOR GROUND CIRCUIT

1. Turn the ignition switch OFF.

2. Check continuity between rear wiper motor harness connector

and ground.

Does continuity exist?

YES >> Replace rear wiper motor. Refer to WW-77, "Removal

and Installation".

NO >> Repair or replace harness.

3. CHECK REAR WIPER MOTOR OPEN CIRCUIT ON : Rear wiper ON operation

OFF : Stop the rear wiper.

Te r m i n a l s

Te s t i t e m

Voltage

(Approx.) (+) (−)

BCM

GroundREAR WIPER

Connector Terminal

M20 71ONBattery

voltage

OFF 0V

ALLIA0353ZZ

Rear wiper motor

GroundContinuity

Connector Terminal

D404 3 Yes

WKIA5532E

Page 5831 of 5883

REAR WIPER MOTOR CIRCUIT

WW-29

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

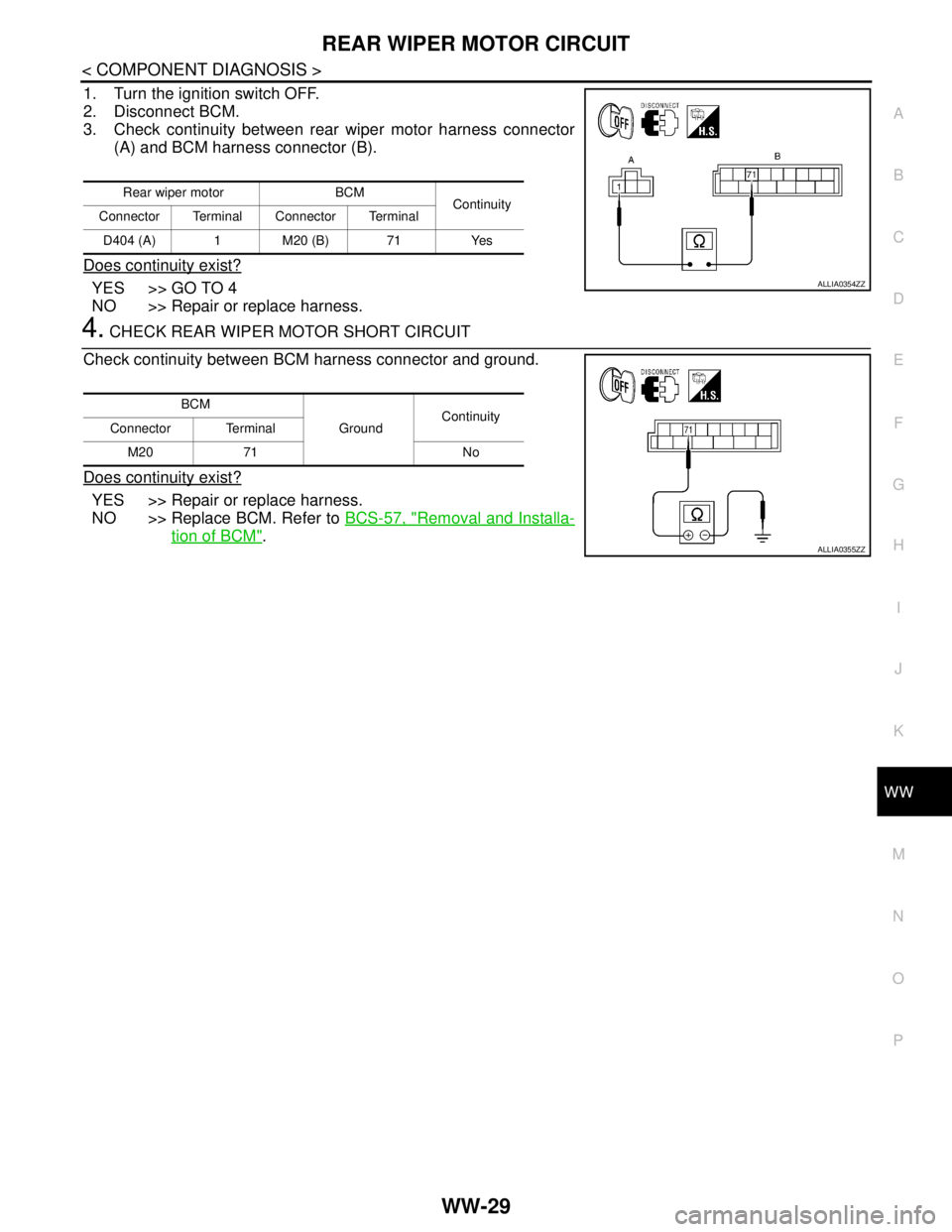

1. Turn the ignition switch OFF.

2. Disconnect BCM.

3. Check continuity between rear wiper motor harness connector

(A) and BCM harness connector (B).

Does continuity exist?

YES >> GO TO 4

NO >> Repair or replace harness.

4. CHECK REAR WIPER MOTOR SHORT CIRCUIT

Check continuity between BCM harness connector and ground.

Does continuity exist?

YES >> Repair or replace harness.

NO >> Replace BCM. Refer to BCS-57, "

Removal and Installa-

tion of BCM".

Rear wiper motor BCM

Continuity

Connector Terminal Connector Terminal

D404 (A) 1 M20 (B) 71 Yes

ALLIA0354ZZ

BCM

GroundContinuity

Connector Terminal

M20 71 No

ALLIA0355ZZ

Page 5832 of 5883

WW-30

< COMPONENT DIAGNOSIS >

REAR WIPER AUTO STOP SIGNAL CIRCUIT

REAR WIPER AUTO STOP SIGNAL CIRCUIT

Component Function CheckINFOID:0000000001366623

1.CHECK REAR WIPER (AUTO STOP) OPERATION

CONSULT-III DATA MONITOR

1. Select "WIPER" of BCM data monitor item.

2. Operate the rear wiper.

3. Check that "RR WIPER STOP" changes to "ON" and "OFF" linked with the wiper operation.

Is the status of item normal?

YES >> Rear wiper auto stop signal circuit is normal.

NO >> Refer to WW-30, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000001366624

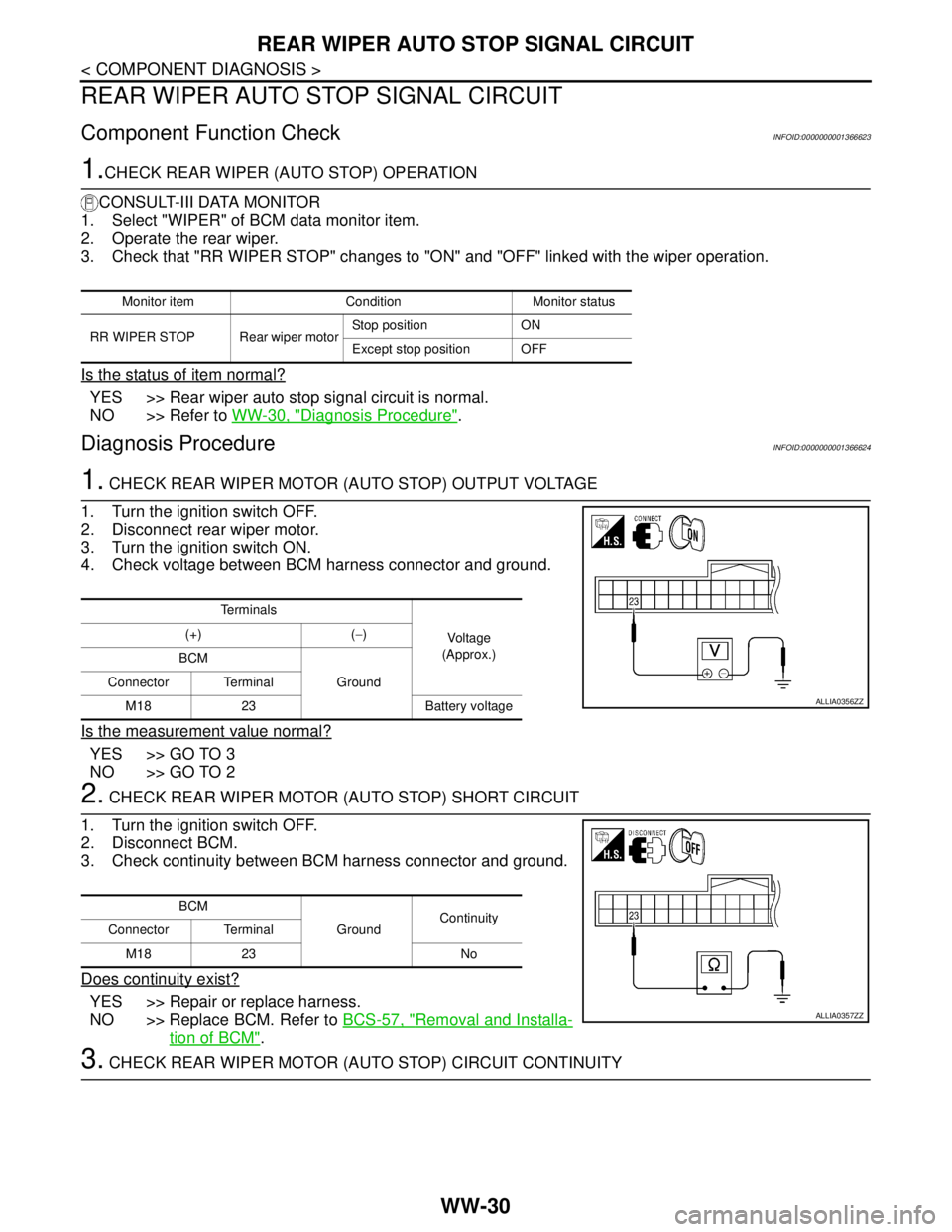

1. CHECK REAR WIPER MOTOR (AUTO STOP) OUTPUT VOLTAGE

1. Turn the ignition switch OFF.

2. Disconnect rear wiper motor.

3. Turn the ignition switch ON.

4. Check voltage between BCM harness connector and ground.

Is the measurement value normal?

YES >> GO TO 3

NO >> GO TO 2

2. CHECK REAR WIPER MOTOR (AUTO STOP) SHORT CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect BCM.

3. Check continuity between BCM harness connector and ground.

Does continuity exist?

YES >> Repair or replace harness.

NO >> Replace BCM. Refer to BCS-57, "

Removal and Installa-

tion of BCM".

3. CHECK REAR WIPER MOTOR (AUTO STOP) CIRCUIT CONTINUITY

Monitor item Condition Monitor status

RR WIPER STOP Rear wiper motorStop position ON

Except stop position OFF

Te r m i n a l s

Voltage

(Approx.) (+) (−)

BCM

Ground Connector Terminal

M18 23 Battery voltage

ALLIA0356ZZ

BCM

GroundContinuity

Connector Terminal

M18 23 No

ALLIA0357ZZ