radiator cap NISSAN TIIDA 2007 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 3327 of 5883

CONDENSER

HA-45

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

CONDENSER

Removal and Installation of Condenser - MR18DE, HR16DEINFOID:0000000001527646

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant. Refer to HA-21, "HFC-134a (R-134a)

Service Procedure".

2. Remove the three upper headlamp bolts to reposition the headlamps out of the way

3. Remove the radiator core support upper.

4. Disconnect the high-pressure flexible hose and high-pressure pipe from condenser.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

5. Disconnect refrigerant pressure sensor connector.

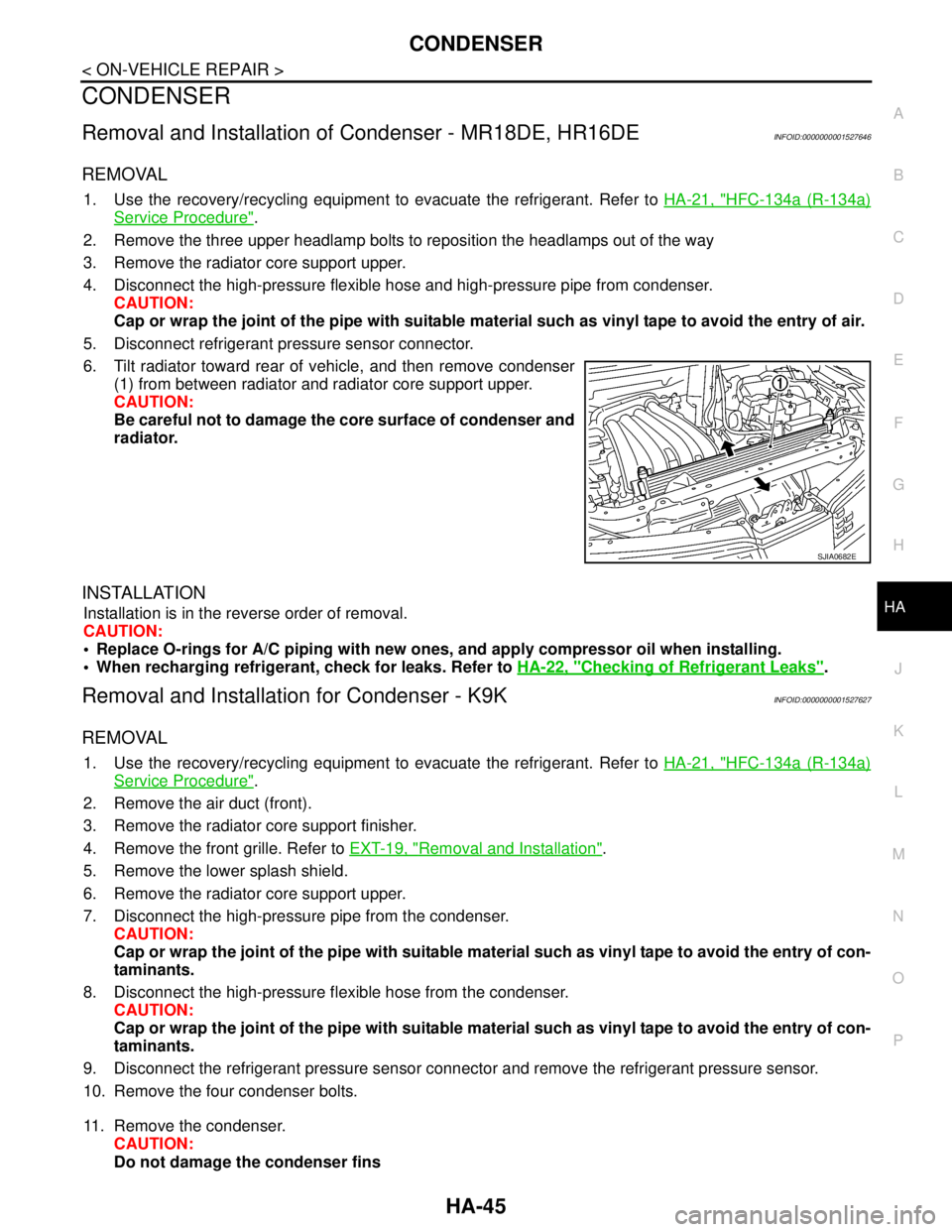

6. Tilt radiator toward rear of vehicle, and then remove condenser

(1) from between radiator and radiator core support upper.

CAUTION:

Be careful not to damage the core surface of condenser and

radiator.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Replace O-rings for A/C piping with new ones, and apply compressor oil when installing.

When recharging refrigerant, check for leaks. Refer to HA-22, "

Checking of Refrigerant Leaks".

Removal and Installation for Condenser - K9KINFOID:0000000001527627

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant. Refer to HA-21, "HFC-134a (R-134a)

Service Procedure".

2. Remove the air duct (front).

3. Remove the radiator core support finisher.

4. Remove the front grille. Refer to EXT-19, "

Removal and Installation".

5. Remove the lower splash shield.

6. Remove the radiator core support upper.

7. Disconnect the high-pressure pipe from the condenser.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of con-

taminants.

8. Disconnect the high-pressure flexible hose from the condenser.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of con-

taminants.

9. Disconnect the refrigerant pressure sensor connector and remove the refrigerant pressure sensor.

10. Remove the four condenser bolts.

11. Remove the condenser.

CAUTION:

Do not damage the condenser fins

SJIA0682E

Page 3414 of 5883

![NISSAN TIIDA 2007 Service Service Manual INSUFFICIENT HEATING

HAC-81

< SYMPTOM DIAGNOSIS >[MANUAL AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

INSUFFICIENT HEATING

Component Function CheckINFOID:0000000001547078

SYMPTOM: Insufficient he NISSAN TIIDA 2007 Service Service Manual INSUFFICIENT HEATING

HAC-81

< SYMPTOM DIAGNOSIS >[MANUAL AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

INSUFFICIENT HEATING

Component Function CheckINFOID:0000000001547078

SYMPTOM: Insufficient he](/img/5/57395/w960_57395-3413.png)

INSUFFICIENT HEATING

HAC-81

< SYMPTOM DIAGNOSIS >[MANUAL AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

INSUFFICIENT HEATING

Component Function CheckINFOID:0000000001547078

SYMPTOM: Insufficient heating

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OPERATIONAL CHECK - TEMPERATURE DECREASE

1. Turn temperature control dial clockwise to maximum heat position.

2. Check for hot air at discharge air outlets.

Can the symptom be duplicated?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK FOR ANY SYMPTOMS

Perform a complete operational check for any symptoms. Refer to HAC-6, "

Operational Check".

Does another symptom exist?

YES >> Refer to HAC-5, "How to Perform Trouble Diagnosis For Quick and Accurate Repair" .

NO >> System OK.

3.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 4.

4.CHECK COOLANT SYSTEM

1. Check engine coolant level. Refer to XX-XX, "*****" .

2. Check hoses for leaks or kinks.

3. Check Radiator cap. Refer to XX-XX, "*****" .

OK or NG

OK >> GO TO 5.

NG >> Repair/replace as necessary.

5.CHECK AIR MIX DOOR CABLE

Check air mix door cable operation. Refer to XXXX AIR MIX DOOR CABLE ADJUSTMENT .

OK or NG

YES >> GO TO 6.

NO >> Adjust or replace air mix door cable. Refer to XXXX AIR MIX DOOR CABLE ADJUST. .

6.CHECK AIR DUCTS

Check ducts for air leaks.

OK or NG

OK >> GO TO 7.

NG >> Repair air leaks.

7.CHECK HEATER HOSE TEMPERATURES

1. Start engine and warm it up to normal operating temperature.

2. Touch both the inlet and outlet heater hoses.

Is the inlet hose hot and the outlet hose warm?

YES >> GO TO 8.

NO >> Both hoses warm: GO TO 9.

8.CHECK ENGINE COOLANT TEMPERATURE SENSOR

Check engine control temperature sensor. Refer to XX-XX, "*****" .

OK or NG

OK >> System OK.

Page 3526 of 5883

![NISSAN TIIDA 2007 Service Service Manual INSUFFICIENT HEATING

HAC-193

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/O NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

INSUFFICIENT HEATING

Component Function CheckINFOID:0000000001547457

SYMPTOM: Insuf NISSAN TIIDA 2007 Service Service Manual INSUFFICIENT HEATING

HAC-193

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/O NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

INSUFFICIENT HEATING

Component Function CheckINFOID:0000000001547457

SYMPTOM: Insuf](/img/5/57395/w960_57395-3525.png)

INSUFFICIENT HEATING

HAC-193

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/O NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

INSUFFICIENT HEATING

Component Function CheckINFOID:0000000001547457

SYMPTOM: Insufficient heating

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OPERATIONAL CHECK - TEMPERATURE INCREASE

1. Press the AUTO switch.

2. Turn the temperature control dial (driver) clockwise until 32° C (90° F) is displayed.

3. Check for hot air at discharge air outlets.

Can this symptom be duplicated?

YES >> GO TO 2.

NO >> Perform complete system operational check. Refer to HAC-87, "

Operational Check".

2.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 3.

3.PERFORM SELF-DIAGNOSIS

Perform self-diagnosis. Refer to HAC-98, "

Front Air Control Self-Diagnosis".

Is the inspection results normal?

YES >> GO TO 4.

NO >> Refer to HAC-197, "

Self-Diagnosis".

4.CHECK ENGINE COOLING SYSTEM

1. Check for proper engine coolant level. Refer to XX-XX, "*****"

.

2. Check hoses for leaks or kinks.

3. Check radiator cap. Refer to XX-XX, "*****"

.

4. Check for air in cooling system.

>> GO TO 5.

5.CHECK AIR MIX DOOR OPERATION

Check the operation of the air mix door.

Is the inspection result normal?

YES >> GO TO 6.

NO >> Check the air mix door motor circuit. Refer to HAC-112, "

Air Mix Door Motor Diagnosis Proce-

dure".

6.CHECK AIR DUCTS

Check for disconnected or leaking air ducts.

Is the inspection result normal?

YES >> GO TO 7.

NO >> Repair all disconnected or leaking air ducts.

7.CHECK HEATER HOSE TEMPERATURES

1. Start engine and warm it up to normal operating temperature.

2. Touch both the inlet and outlet heater hoses.

Is the inspection result normal?

YES >> Hot inlet hose and a warm outlet hose: GO TO 8.

NO >> Both hoses warm: GO TO 9.

8.CHECK ENGINE COOLANT SYSTEM

Check engine control temperature sensor. Refer to XX-XX, "*****"

.

Is the inspection result normal?

Page 3640 of 5883

![NISSAN TIIDA 2007 Service Service Manual INSUFFICIENT HEATING

HAC-307

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

INSUFFICIENT HEATING

Component Function CheckINFOID:0000000001547379

SYMPTOM: Insuffi NISSAN TIIDA 2007 Service Service Manual INSUFFICIENT HEATING

HAC-307

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

INSUFFICIENT HEATING

Component Function CheckINFOID:0000000001547379

SYMPTOM: Insuffi](/img/5/57395/w960_57395-3639.png)

INSUFFICIENT HEATING

HAC-307

< SYMPTOM DIAGNOSIS >[AUTO AIR CONDITIONER (W/NAVI)]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

INSUFFICIENT HEATING

Component Function CheckINFOID:0000000001547379

SYMPTOM: Insufficient heating

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OPERATIONAL CHECK - TEMPERATURE INCREASE

1. Press the AUTO switch.

2. Turn the temperature control dial (driver) clockwise until 32° C (90° F) is displayed.

3. Check for hot air at discharge air outlets.

Can this symptom be duplicated?

YES >> GO TO 2.

NO >> Perform complete system operational check. Refer to HAC-202, "

Operational Check".

2.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 3.

3.PERFORM SELF-DIAGNOSIS

Perform self-diagnosis. Refer to HAC-213, "

Front Air Control Self-Diagnosis".

Is the inspection results normal?

YES >> GO TO 4.

NO >> Refer to HAC-218, "

Front Air Control Self-Diagnosis Code Chart".

4.CHECK ENGINE COOLING SYSTEM

1. Check for proper engine coolant level. Refer to CO-11, "

Inspection" (HR16DE) or CO-35, "Inspection"

(HR18DE) or CO-58, "Inspection" (K9K).

2. Check hoses for leaks or kinks.

3. Check radiator cap. Refer to CO-14, "

Checking Radiator Cap" (HR16DE) CO-38, "Checking Radiator

Cap" or (HR18DE) or CO-60, "Checking Radiator Cap" (K9K).

4. Check for air in cooling system.

>> GO TO 5.

5.CHECK AIR MIX DOOR OPERATION

Check the operation of the air mix door. Refer to HAC-225, "

Air Mix Door Motor Component Function Check".

Is the inspection result normal?

YES >> GO TO 6.

NO >> Check the air mix door motor circuit. Refer to HAC-226, "

Air Mix Door Motor Diagnosis Proce-

dure".

6.CHECK AIR DUCTS

Check for disconnected or leaking air ducts.

Is the inspection result normal?

YES >> GO TO 7.

NO >> Repair all disconnected or leaking air ducts.

7.CHECK HEATER HOSE TEMPERATURES

1. Start engine and warm it up to normal operating temperature.

2. Touch both the inlet and outlet heater hoses.

Is the inspection result normal?

YES >> Hot inlet hose and a warm outlet hose: GO TO 8.

NO >> Inlet hose cold: GO TO 11.

Both hoses warm: GO TO 9.

Page 4241 of 5883

MA-1

MAINTENANCE

C

D

E

F

G

H

I

J

K

L

MB

MA

SECTION MA

N

OA

CONTENTS

MAINTENANCE

PRECAUTION ...............................................3

PRECAUTIONS ...................................................3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

3

PREPARATION ............................................4

PREPARATION ...................................................4

Special Service Tool .................................................4

Commercial Service Tool ..........................................4

Pre-Delivery Inspection Item .....................................5

ON-VEHICLE MAINTENANCE .....................6

GENERAL MAINTENANCE ................................6

General Maintenance ................................................6

PERIODIC MAINTENANCE ................................7

Periodic Maintenance ................................................7

RECOMMENDED FLUIDS AND LUBRI-

CANTS ................................................................

19

Fluids and Lubricants ..............................................19

SAE Viscosity Number ............................................20

Engine Coolant Mixture Ratio .................................21

ENGINE MAINTENANCE (HR16DE) .................22

DRIVE BELTS ...........................................................22

DRIVE BELTS : Checking .......................................22

DRIVE BELTS : Tension Adjustment ......................22

ENGINE COOLANT ...................................................23

ENGINE COOLANT : Inspection .............................23

ENGINE COOLANT : Changing Engine Coolant ....23

RADIATOR ................................................................25

RADIATOR : Checking Radiator .............................25

FUEL LINES ..............................................................25

FUEL LINES : Inspection ........................................25

AIR CLEANER FILTER .............................................25

AIR CLEANER FILTER : Removal and Installation

....

26

ENGINE OIL ...............................................................26

ENGINE OIL : Draining ............................................27

ENGINE OIL : Refilling ............................................27

OIL FILTER ................................................................27

OIL FILTER : Removal and Installation ...................27

OIL FILTER : Inspection ..........................................28

SPARK PLUG ............................................................28

SPARK PLUG : Removal and Installation ...............28

SPARK PLUG : Inspection ......................................29

EVAP VAPOR LINES ................................................30

EVAP VAPOR LINES : Inspection ...........................30

ENGINE MAINTENANCE (MR18DE) ...............31

DRIVE BELTS ............................................................31

DRIVE BELTS : Component ....................................31

DRIVE BELTS : Checking Drive Belts .....................31

DRIVE BELTS : Tension Adjustment ......................31

ENGINE COOLANT ...................................................31

ENGINE COOLANT : Inspection .............................31

ENGINE COOLANT : Changing Engine Coolant ....32

RADIATOR .................................................................33

RADIATOR : Checking Radiator Cap ......................34

RADIATOR : Checking Radiator .............................34

FUEL LINES ...............................................................34

FUEL LINES : Inspection .........................................35

AIR CLEANER FILTER .............................................35

AIR CLEANER FILTER : Removal and Installation

....

35

ENGINE OIL ...............................................................36

ENGINE OIL : Inspection .........................................36

ENGINE OIL : Changing Engine Oil ........................37

Page 4242 of 5883

MA-2

OIL FILTER ...............................................................38

OIL FILTER : Removal and Installation ..................38

OIL FILTER : Inspection .........................................39

SPARK PLUG ...........................................................39

SPARK PLUG : Component ...................................40

SPARK PLUG : Removal and Installation ..............40

EVAP VAPOR LINES ................................................41

EVAP VAPOR LINES : Inspection ..........................41

ENGINE MAINTENANCE (K9K) .......................42

DRIVE BELTS ...........................................................42

DRIVE BELTS : Exploded View .............................42

DRIVE BELTS : Inspection and Adjustment ...........42

ENGINE COOLANT ..................................................42

ENGINE COOLANT : Inspection ............................42

ENGINE COOLANT : Draining ...............................43

ENGINE COOLANT : Refilling ................................43

ENGINE COOLANT : Flushing ...............................44

RADIATOR ................................................................44

RADIATOR : Checking Radiator Cap .....................44

RADIATOR : Checking Radiator ............................45

FUEL LINES ..............................................................45

FUEL LINES : Inspection ........................................45

AIR CLEANER FILTER .............................................46

AIR CLEANER FILTER : Removal and Installation

...

46

ENGINE OIL ..............................................................46

ENGINE OIL : Inspection ........................................47

ENGINE OIL : Draining ...........................................47

ENGINE OIL : Refilling ............................................48

OIL FILTER ...............................................................48

OIL FILTER : Replacement .....................................48

CHASSIS AND BODY MAINTENANCE ...........50

Air Conditioner Filter ...............................................50

Checking Exhaust System ......................................50

Checking Clutch Fluid Level and Leaks ..................50

Checking Clutch System .........................................50

Checking M/T Oil ....................................................50

Changing M/T Oil ....................................................51

Checking A/T Fluid: RE4F03B ................................51

Changing A/T Fluid: RE4F03B ................................52

Checking A/T Fluid: RSF91R ..................................52

Changing A/T Fluid: RS9F94R ...............................52

Balancing Wheels ...................................................53

Rotation ...................................................................53

Checking Brake Fluid Level and Leaks ...................54

Checking Brake Line and Cables ............................54

Changing Brake Fluid .............................................54

Drain and Refill .......................................................54

Checking Disc Brake ...............................................55

Axle and Suspension Parts .....................................56

Drive Shaft ..............................................................56

Lubricating Locks, Hinges and Hood Latch ............57

Checking Seat Belts, Buckles, Retractors, An-

chors and Adjusters ................................................

57

Page 4244 of 5883

MA-4

< PREPARATION >

PREPARATION

PREPARATION

PREPARATION

Special Service ToolINFOID:0000000001277594

Commercial Service ToolINFOID:0000000001277595

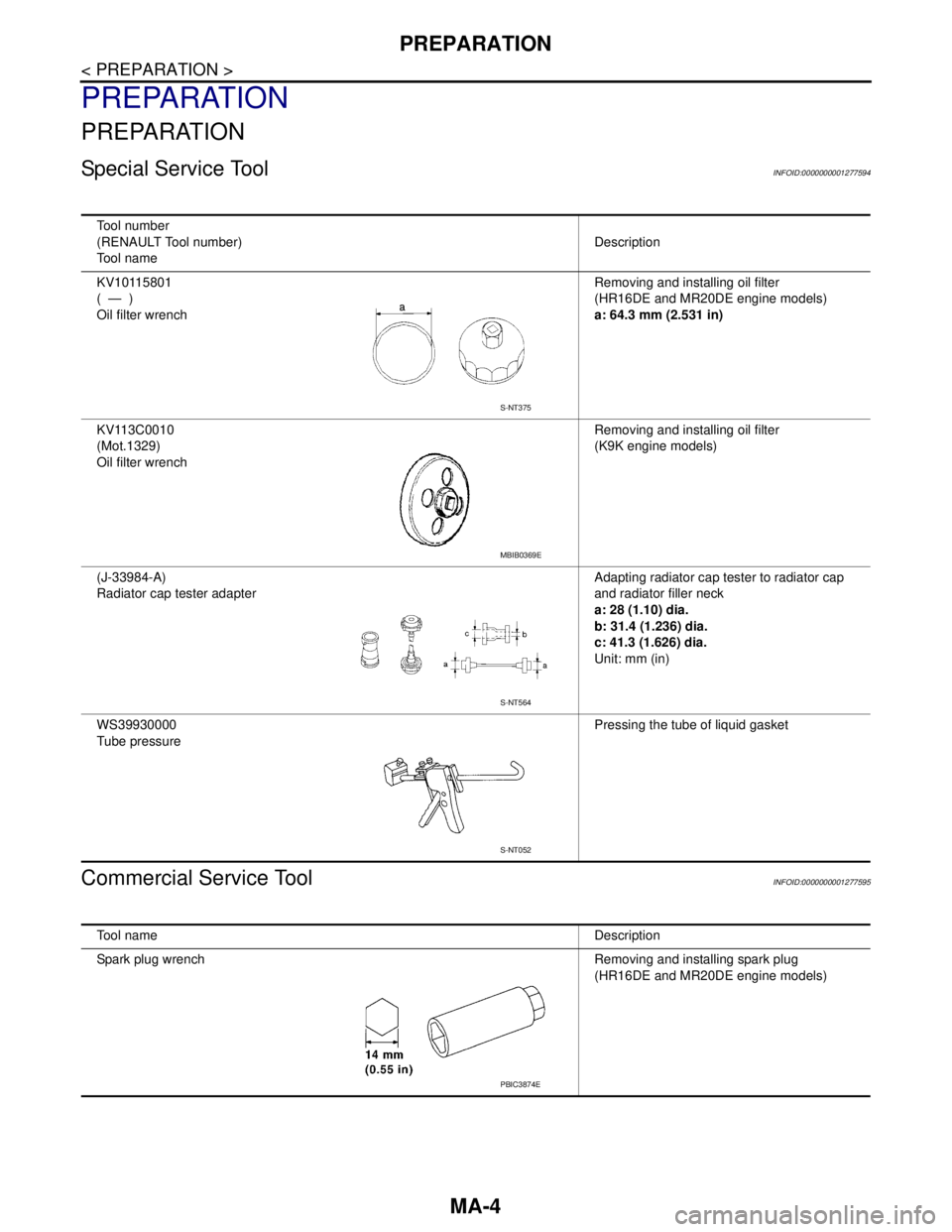

Tool number

(RENAULT Tool number)

Tool nameDescription

KV10115801

( — )

Oil filter wrenchRemoving and installing oil filter

(HR16DE and MR20DE engine models)

a: 64.3 mm (2.531 in)

KV113C0010

(Mot.1329)

Oil filter wrenchRemoving and installing oil filter

(K9K engine models)

(J-33984-A)

Radiator cap tester adapterAdapting radiator cap tester to radiator cap

and radiator filler neck

a: 28 (1.10) dia.

b: 31.4 (1.236) dia.

c: 41.3 (1.626) dia.

Unit: mm (in)

WS39930000

Tube pressurePressing the tube of liquid gasket

S-NT375

MBIB0369E

S-NT564

S-NT052

Tool nameDescription

Spark plug wrench Removing and installing spark plug

(HR16DE and MR20DE engine models)

PBIC3874E

Page 4261 of 5883

RECOMMENDED FLUIDS AND LUBRICANTS

MA-21

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

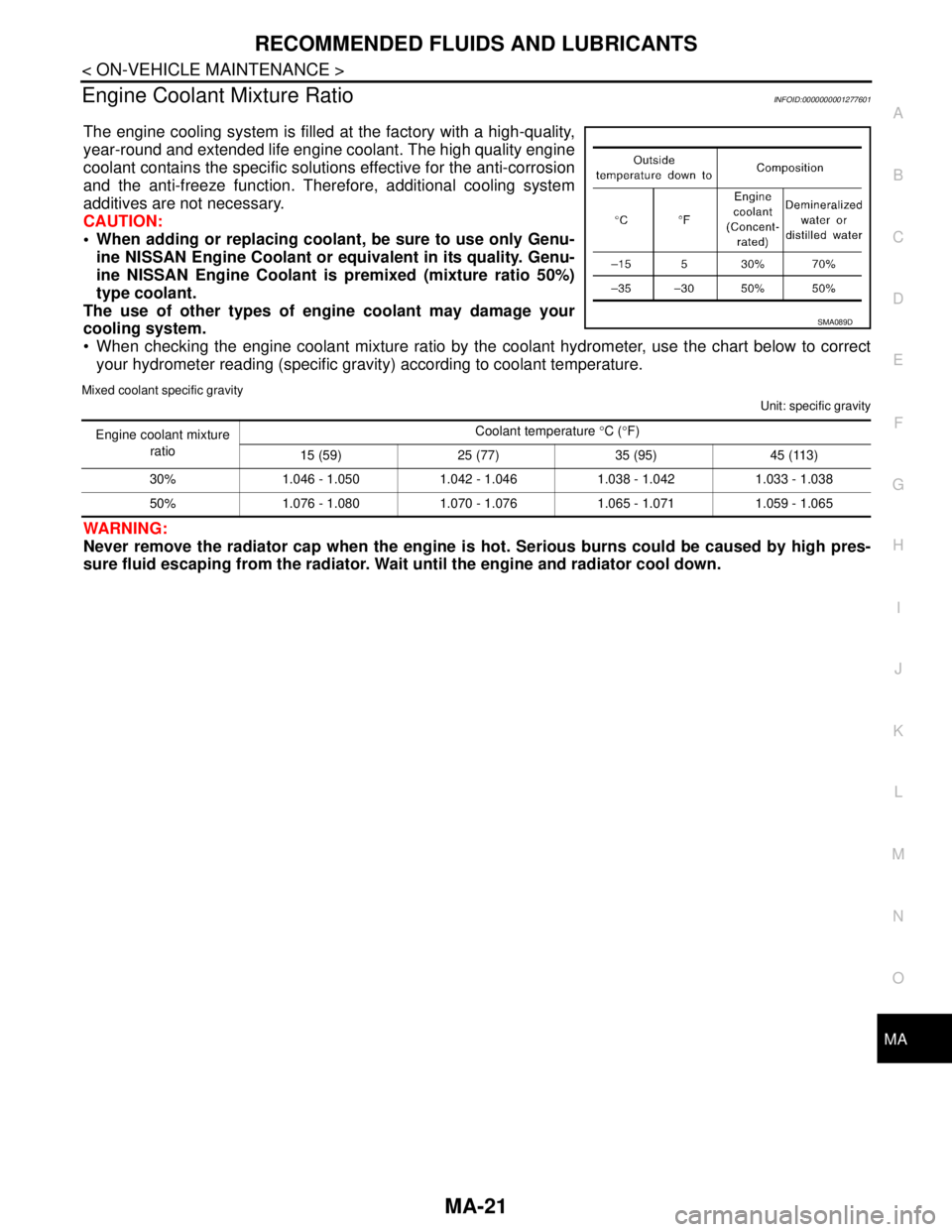

Engine Coolant Mixture RatioINFOID:0000000001277601

The engine cooling system is filled at the factory with a high-quality,

year-round and extended life engine coolant. The high quality engine

coolant contains the specific solutions effective for the anti-corrosion

and the anti-freeze function. Therefore, additional cooling system

additives are not necessary.

CAUTION:

When adding or replacing coolant, be sure to use only Genu-

ine NISSAN Engine Coolant or equivalent in its quality. Genu-

ine NISSAN Engine Coolant is premixed (mixture ratio 50%)

type coolant.

The use of other types of engine coolant may damage your

cooling system.

When checking the engine coolant mixture ratio by the coolant hydrometer, use the chart below to correct

your hydrometer reading (specific gravity) according to coolant temperature.

Mixed coolant specific gravity

Unit: specific gravity

WARNING:

Never remove the radiator cap when the engine is hot. Serious burns could be caused by high pres-

sure fluid escaping from the radiator. Wait until the engine and radiator cool down.

SMA089D

Engine coolant mixture

ratioCoolant temperature °C (°F)

15 (59) 25 (77) 35 (95) 45 (113)

30% 1.046 - 1.050 1.042 - 1.046 1.038 - 1.042 1.033 - 1.038

50% 1.076 - 1.080 1.070 - 1.076 1.065 - 1.071 1.059 - 1.065

Page 4263 of 5883

ENGINE MAINTENANCE (HR16DE)

MA-23

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

When the lock nut is loosened excessively, the idler pulley tilts and the correct tension adjust-

ment cannot be performed. Never loosen it excessively (more than 45 degrees).

Put a matching mark on the lock nut, and check turning angle with a protractor. Never visually

check the tightening angle.

2. Adjust the belt tension by turning the adjusting bolt.

CAUTION:

When checking immediately after installation, first adjust it to the specified value. Then, after

turning crankshaft two turns or more, re-adjust to the specified value to avoid variation in deflec-

tion between pulleys.

When the tension adjustment is performed, the lock nut should be in the condition at step“2”. If

the tension adjustment is performed when the lock nut is loosened more than the standard, the

idler pulley tilts and the correct tension adjustment cannot be performed.

3. Tighten the idler pulley lock nut.

ENGINE COOLANT

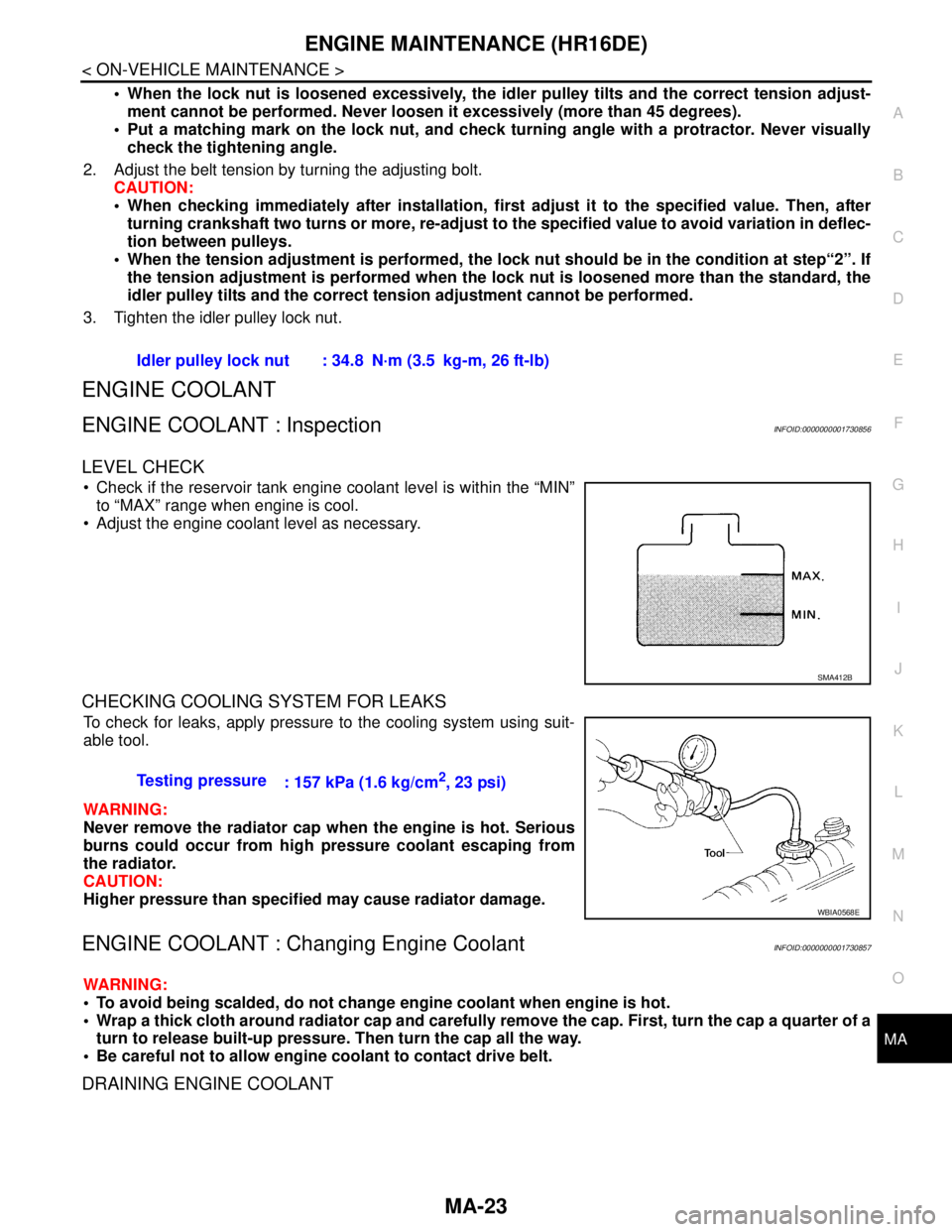

ENGINE COOLANT : InspectionINFOID:0000000001730856

LEVEL CHECK

Check if the reservoir tank engine coolant level is within the “MIN”

to “MAX” range when engine is cool.

Adjust the engine coolant level as necessary.

CHECKING COOLING SYSTEM FOR LEAKS

To check for leaks, apply pressure to the cooling system using suit-

able tool.

WARNING:

Never remove the radiator cap when the engine is hot. Serious

burns could occur from high pressure coolant escaping from

the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage.

ENGINE COOLANT : Changing Engine CoolantINFOID:0000000001730857

WARNING:

To avoid being scalded, do not change engine coolant when engine is hot.

Wrap a thick cloth around radiator cap and carefully remove the cap. First, turn the cap a quarter of a

turn to release built-up pressure. Then turn the cap all the way.

Be careful not to allow engine coolant to contact drive belt.

DRAINING ENGINE COOLANT

Idler pulley lock nut : 34.8 N·m (3.5 kg-m, 26 ft-lb)

SMA412B

Testing pressure

: 157 kPa (1.6 kg/cm2, 23 psi)

WBIA0568E

Page 4264 of 5883

MA-24

< ON-VEHICLE MAINTENANCE >

ENGINE MAINTENANCE (HR16DE)

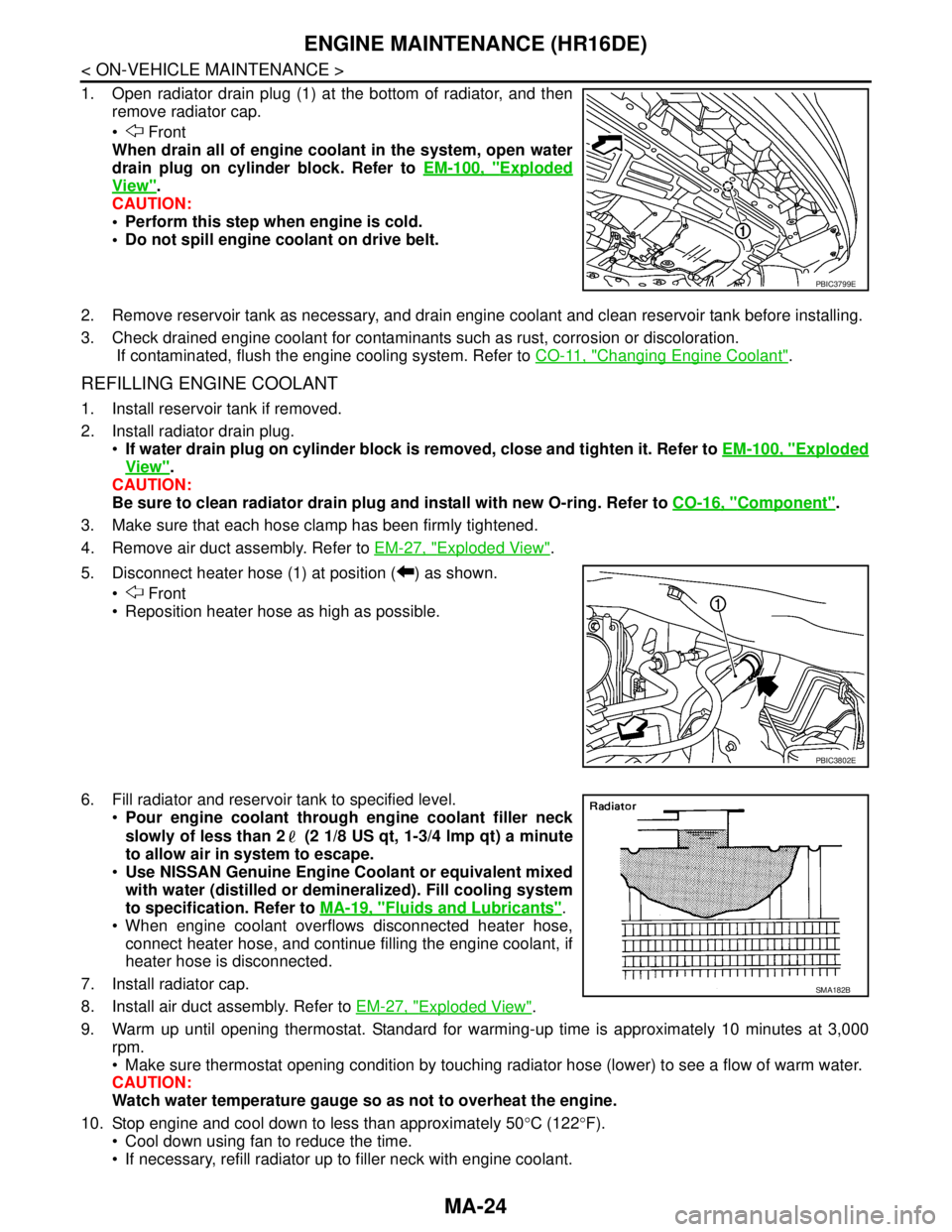

1. Open radiator drain plug (1) at the bottom of radiator, and then

remove radiator cap.

Front

When drain all of engine coolant in the system, open water

drain plug on cylinder block. Refer to EM-100, "

Exploded

View".

CAUTION:

Perform this step when engine is cold.

Do not spill engine coolant on drive belt.

2. Remove reservoir tank as necessary, and drain engine coolant and clean reservoir tank before installing.

3. Check drained engine coolant for contaminants such as rust, corrosion or discoloration.

If contaminated, flush the engine cooling system. Refer to CO-11, "

Changing Engine Coolant".

REFILLING ENGINE COOLANT

1. Install reservoir tank if removed.

2. Install radiator drain plug.

If water drain plug on cylinder block is removed, close and tighten it. Refer to EM-100, "

Exploded

View".

CAUTION:

Be sure to clean radiator drain plug and install with new O-ring. Refer to CO-16, "

Component".

3. Make sure that each hose clamp has been firmly tightened.

4. Remove air duct assembly. Refer to EM-27, "

Exploded View".

5. Disconnect heater hose (1) at position ( ) as shown.

Front

Reposition heater hose as high as possible.

6. Fill radiator and reservoir tank to specified level.

Pour engine coolant through engine coolant filler neck

slowly of less than 2 (2 1/8 US qt, 1-3/4 lmp qt) a minute

to allow air in system to escape.

Use NISSAN Genuine Engine Coolant or equivalent mixed

with water (distilled or demineralized). Fill cooling system

to specification. Refer to MA-19, "

Fluids and Lubricants".

When engine coolant overflows disconnected heater hose,

connect heater hose, and continue filling the engine coolant, if

heater hose is disconnected.

7. Install radiator cap.

8. Install air duct assembly. Refer to EM-27, "

Exploded View".

9. Warm up until opening thermostat. Standard for warming-up time is approximately 10 minutes at 3,000

rpm.

Make sure thermostat opening condition by touching radiator hose (lower) to see a flow of warm water.

CAUTION:

Watch water temperature gauge so as not to overheat the engine.

10. Stop engine and cool down to less than approximately 50°C (122°F).

Cool down using fan to reduce the time.

If necessary, refill radiator up to filler neck with engine coolant.

PBIC3799E

PBIC3802E

SMA182B