glove box NISSAN TIIDA 2007 Service Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 3727 of 5883

![NISSAN TIIDA 2007 Service Workshop Manual IP-12

< SERVICE INFORMATION >

INSTRUMENT PANEL ASSEMBLY

[ ]: Number indicates step in removal procedures.

INSTRUMENT PANEL ASSEMBLY

Removal

1. Pull instrument finisher E backward by approximately 30

d NISSAN TIIDA 2007 Service Workshop Manual IP-12

< SERVICE INFORMATION >

INSTRUMENT PANEL ASSEMBLY

[ ]: Number indicates step in removal procedures.

INSTRUMENT PANEL ASSEMBLY

Removal

1. Pull instrument finisher E backward by approximately 30

d](/img/5/57395/w960_57395-3726.png)

IP-12

< SERVICE INFORMATION >

INSTRUMENT PANEL ASSEMBLY

[ ]: Number indicates step in removal procedures.

INSTRUMENT PANEL ASSEMBLY

Removal

1. Pull instrument finisher E backward by approximately 30

degrees while disengaging the instrument finisher E metal clips

and pawl.

Glove box assembly"GLOVE

BOX AS-

SEMBLY"[ 15 ]

Side ventilator assembly (RH)IP-10

[ 16 ] [ 4 ]

Passenger air bag module assemblySR-9

[ 17 ] [ 5 ]

Instrument upper maskIP-10

[ 18 ]

Instrument finisher DIP-10

[ 19 ]

Controller TM-674

[ 20 ]

Instrument upper panel assembly IP-11

[ 21 ]

Console mask"Remov-

al"[ 22 ] [ 1 ]

CVT, A/T console finisherIP-23

[ 23 ] [ 2 ]

M/T console bootIP-23

[ 23 ] [ 2 ]

Console rear finisherIP-23

[ 24 ] [ 3 ]

Console mask cover (with arm rest)IP-23

[ 25 ] [ 4 ]

Rear cup holder (without arm rest)IP-23

[ 25 ] [ 4 ]

Console body assemblyIP-23

[ 26 ] [ 5 ]

Instrument lower cover (LH/RH)"INSTRU-

MENT

LOWER

FINISH-

ER"[ 27 ] [ 6 ]

Center console assembly"CEN-

TER

CON-

SOLE AS-

SEMBLY"[ 28 ] [ 7 ]

Fuse block lidIP-10

[ 29 ]

Lighting and turn signal switchEXL-101

[ 30 ]

Wiper & washer switchWW-76

[ 31 ]

Instrument panel & padIP-10

[ 32 ] PartsReference

pageInstrument

panel and padCluster lid A Cluster lid C Passenger air

bag module

assemblyCenter con-

sole assembly

WIIA1224E

Page 3730 of 5883

INSTRUMENT PANEL ASSEMBLY

IP-15

< SERVICE INFORMATION >

C

D

E

F

G

H

I

K

L

MA

B

IP

N

O

P

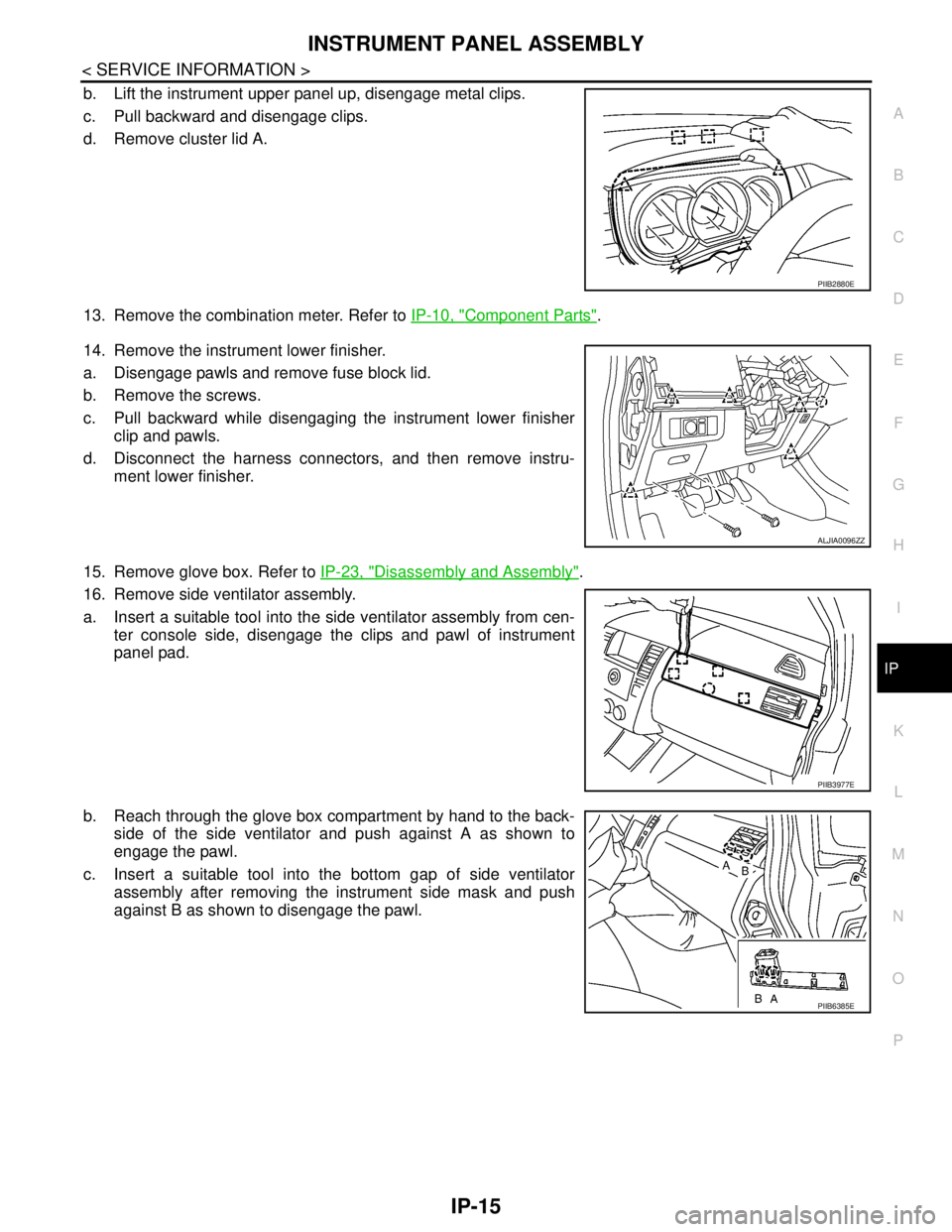

b. Lift the instrument upper panel up, disengage metal clips.

c. Pull backward and disengage clips.

d. Remove cluster lid A.

13. Remove the combination meter. Refer to IP-10, "

Component Parts".

14. Remove the instrument lower finisher.

a. Disengage pawls and remove fuse block lid.

b. Remove the screws.

c. Pull backward while disengaging the instrument lower finisher

clip and pawls.

d. Disconnect the harness connectors, and then remove instru-

ment lower finisher.

15. Remove glove box. Refer to IP-23, "

Disassembly and Assembly".

16. Remove side ventilator assembly.

a. Insert a suitable tool into the side ventilator assembly from cen-

ter console side, disengage the clips and pawl of instrument

panel pad.

b. Reach through the glove box compartment by hand to the back-

side of the side ventilator and push against A as shown to

engage the pawl.

c. Insert a suitable tool into the bottom gap of side ventilator

assembly after removing the instrument side mask and push

against B as shown to disengage the pawl.

PIIB2880E

ALJIA0096ZZ

PIIB3977E

PIIB6385E

Page 3736 of 5883

INSTRUMENT PANEL ASSEMBLY

IP-21

< SERVICE INFORMATION >

C

D

E

F

G

H

I

K

L

MA

B

IP

N

O

P

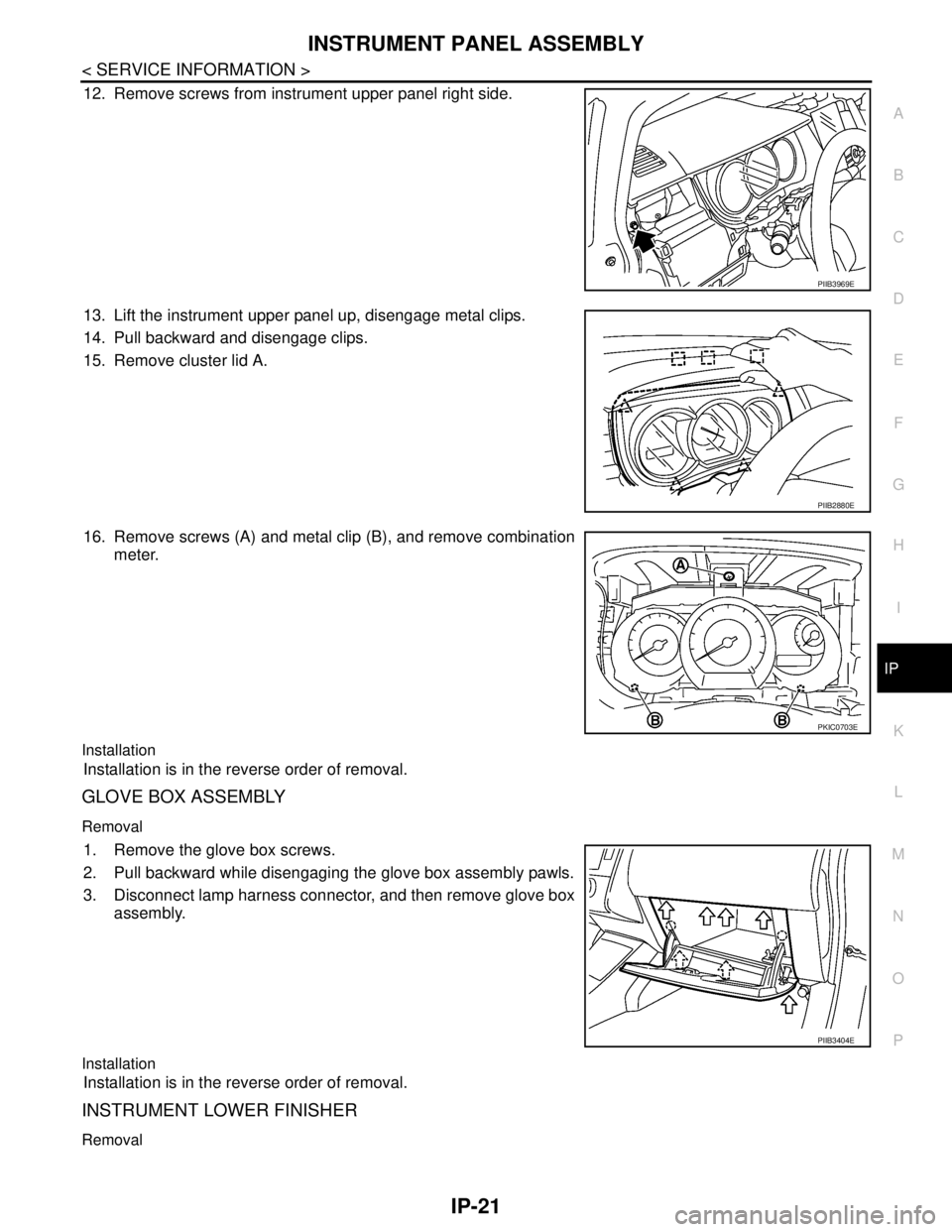

12. Remove screws from instrument upper panel right side.

13. Lift the instrument upper panel up, disengage metal clips.

14. Pull backward and disengage clips.

15. Remove cluster lid A.

16. Remove screws (A) and metal clip (B), and remove combination

meter.

Installation

Installation is in the reverse order of removal.

GLOVE BOX ASSEMBLY

Removal

1. Remove the glove box screws.

2. Pull backward while disengaging the glove box assembly pawls.

3. Disconnect lamp harness connector, and then remove glove box

assembly.

Installation

Installation is in the reverse order of removal.

INSTRUMENT LOWER FINISHER

Removal

PIIB3969E

PIIB2880E

PKIC0703E

PIIB3404E

Page 3738 of 5883

INSTRUMENT PANEL ASSEMBLY

IP-23

< SERVICE INFORMATION >

C

D

E

F

G

H

I

K

L

MA

B

IP

N

O

P

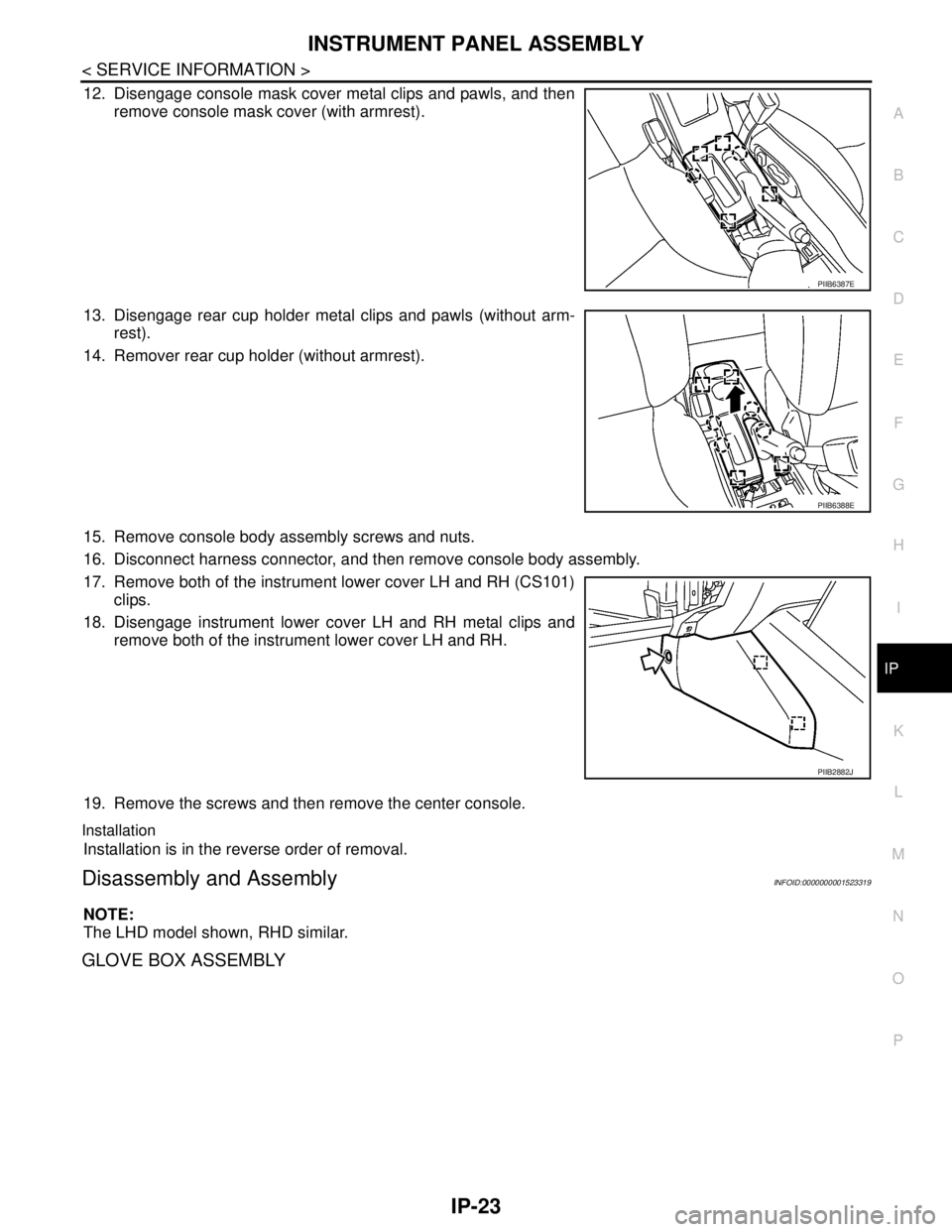

12. Disengage console mask cover metal clips and pawls, and then

remove console mask cover (with armrest).

13. Disengage rear cup holder metal clips and pawls (without arm-

rest).

14. Remover rear cup holder (without armrest).

15. Remove console body assembly screws and nuts.

16. Disconnect harness connector, and then remove console body assembly.

17. Remove both of the instrument lower cover LH and RH (CS101)

clips.

18. Disengage instrument lower cover LH and RH metal clips and

remove both of the instrument lower cover LH and RH.

19. Remove the screws and then remove the center console.

Installation

Installation is in the reverse order of removal.

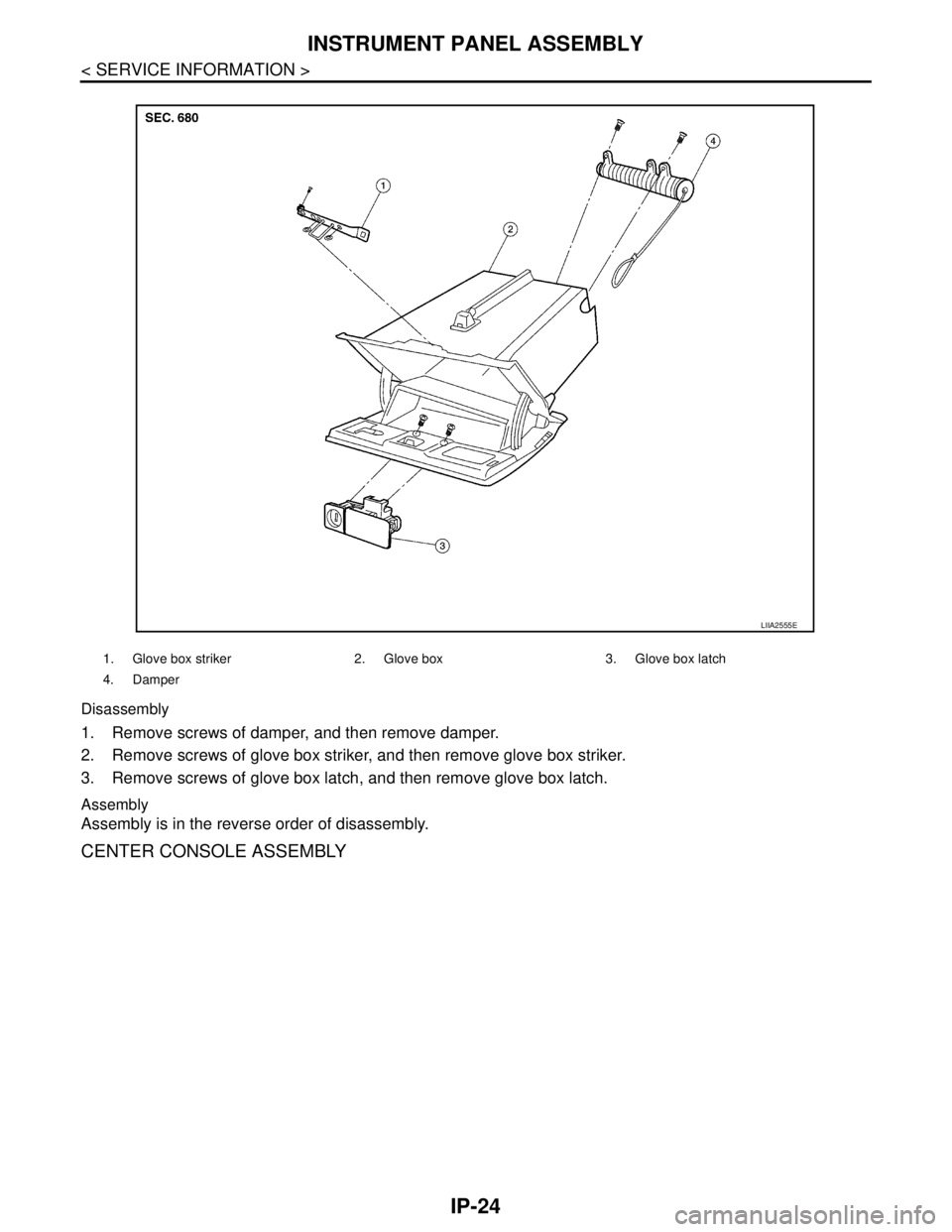

Disassembly and AssemblyINFOID:0000000001523319

NOTE:

The LHD model shown, RHD similar.

GLOVE BOX ASSEMBLY

PIIB6387E

PIIB6388E

PIIB2882J

Page 3739 of 5883

IP-24

< SERVICE INFORMATION >

INSTRUMENT PANEL ASSEMBLY

Disassembly

1. Remove screws of damper, and then remove damper.

2. Remove screws of glove box striker, and then remove glove box striker.

3. Remove screws of glove box latch, and then remove glove box latch.

Assembly

Assembly is in the reverse order of disassembly.

CENTER CONSOLE ASSEMBLY

1. Glove box striker 2. Glove box 3. Glove box latch

4. Damper

LIIA2555E

Page 4290 of 5883

MA-50

< ON-VEHICLE MAINTENANCE >

CHASSIS AND BODY MAINTENANCE

CHASSIS AND BODY MAINTENANCE

Air Conditioner FilterINFOID:0000000001730893

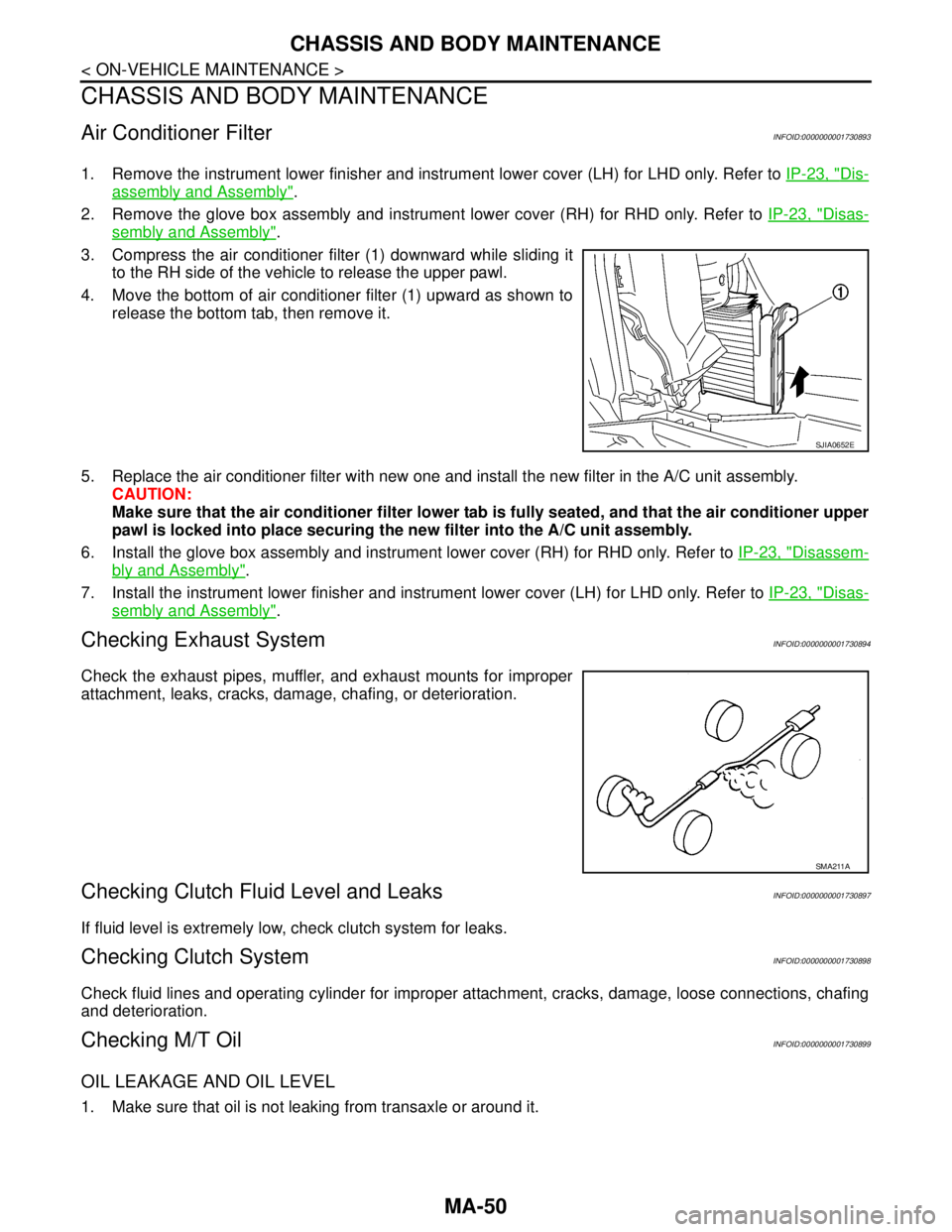

1. Remove the instrument lower finisher and instrument lower cover (LH) for LHD only. Refer to IP-23, "Dis-

assembly and Assembly".

2. Remove the glove box assembly and instrument lower cover (RH) for RHD only. Refer to IP-23, "

Disas-

sembly and Assembly".

3. Compress the air conditioner filter (1) downward while sliding it

to the RH side of the vehicle to release the upper pawl.

4. Move the bottom of air conditioner filter (1) upward as shown to

release the bottom tab, then remove it.

5. Replace the air conditioner filter with new one and install the new filter in the A/C unit assembly.

CAUTION:

Make sure that the air conditioner filter lower tab is fully seated, and that the air conditioner upper

pawl is locked into place securing the new filter into the A/C unit assembly.

6. Install the glove box assembly and instrument lower cover (RH) for RHD only. Refer to IP-23, "

Disassem-

bly and Assembly".

7. Install the instrument lower finisher and instrument lower cover (LH) for LHD only. Refer to IP-23, "

Disas-

sembly and Assembly".

Checking Exhaust SystemINFOID:0000000001730894

Check the exhaust pipes, muffler, and exhaust mounts for improper

attachment, leaks, cracks, damage, chafing, or deterioration.

Checking Clutch Fluid Level and LeaksINFOID:0000000001730897

If fluid level is extremely low, check clutch system for leaks.

Checking Clutch SystemINFOID:0000000001730898

Check fluid lines and operating cylinder for improper attachment, cracks, damage, loose connections, chafing

and deterioration.

Checking M/T OilINFOID:0000000001730899

OIL LEAKAGE AND OIL LEVEL

1. Make sure that oil is not leaking from transaxle or around it.

SJIA0652E

SMA211A

Page 4469 of 5883

PWC-8

< FUNCTION DIAGNOSIS >

POWER WINDOW SYSTEM

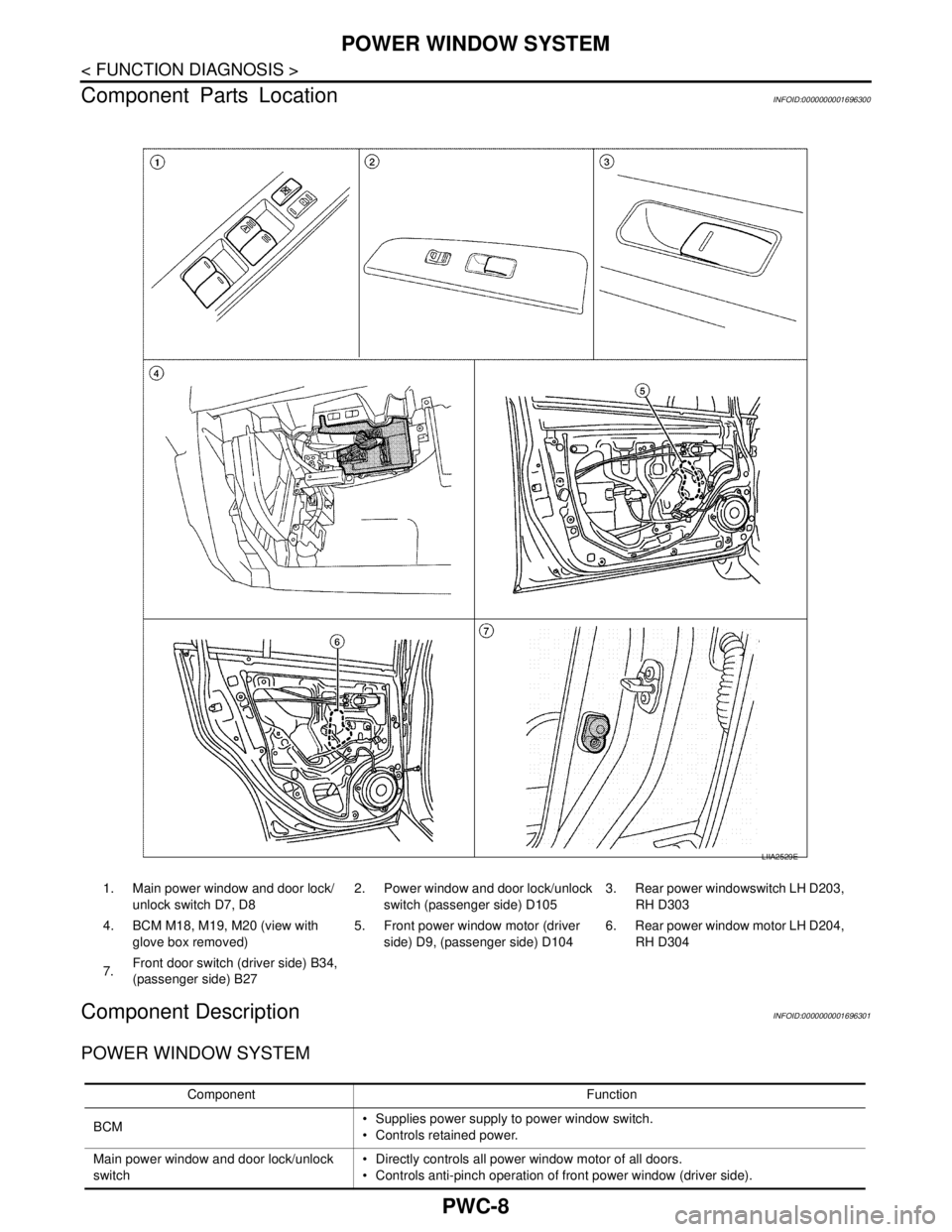

Component Parts Location

INFOID:0000000001696300

Component DescriptionINFOID:0000000001696301

POWER WINDOW SYSTEM

LIIA2529E

1. Main power window and door lock/

unlock switch D7, D82. Power window and door lock/unlock

switch (passenger side) D1053. Rear power windowswitch LH D203,

RH D303

4. BCM M18, M19, M20 (view with

glove box removed)5. Front power window motor (driver

side) D9, (passenger side) D1046. Rear power window motor LH D204,

RH D304

7.Front door switch (driver side) B34,

(passenger side) B27

Component Function

BCM Supplies power supply to power window switch.

Controls retained power.

Main power window and door lock/unlock

switch Directly controls all power window motor of all doors.

Controls anti-pinch operation of front power window (driver side).

Page 4543 of 5883

SUNROOF SYSTEM

RF-9

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

L

MA

B

RF

N

O

P

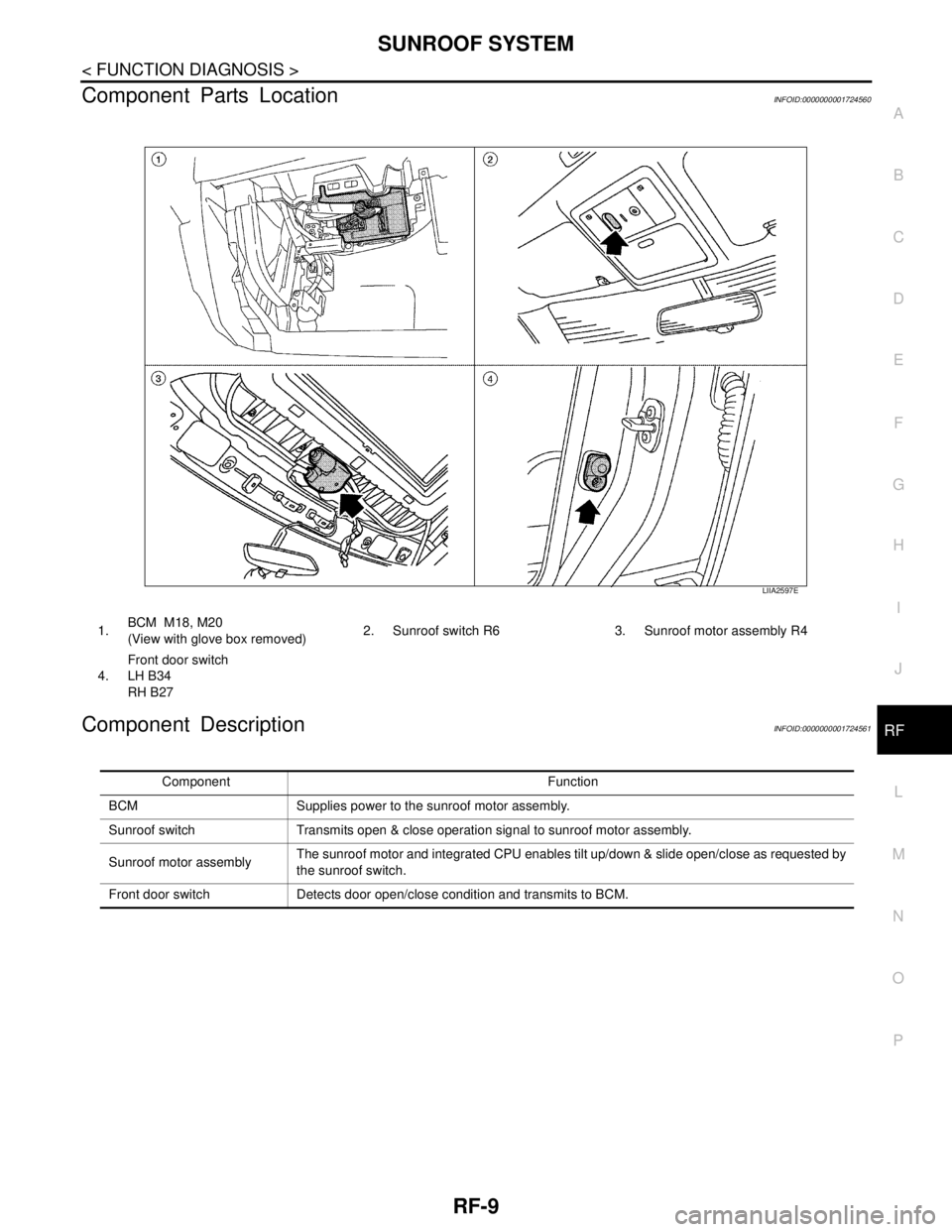

Component Parts LocationINFOID:0000000001724560

Component DescriptionINFOID:0000000001724561

LIIA2597E

1.BCM M18, M20

(View with glove box removed)2. Sunroof switch R6 3. Sunroof motor assembly R4

4.Front door switch

LH B34

RH B27

Component Function

BCM Supplies power to the sunroof motor assembly.

Sunroof switch Transmits open & close operation signal to sunroof motor assembly.

Sunroof motor assemblyThe sunroof motor and integrated CPU enables tilt up/down & slide open/close as requested by

the sunroof switch.

Front door switch Detects door open/close condition and transmits to BCM.

Page 4634 of 5883

![NISSAN TIIDA 2007 Service Workshop Manual INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

SEC-9

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

SEC

N

O

P

Intelligent Key has 2 IDs (for Intelligent Key and for NATS). NISSAN TIIDA 2007 Service Workshop Manual INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

SEC-9

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

SEC

N

O

P

Intelligent Key has 2 IDs (for Intelligent Key and for NATS).](/img/5/57395/w960_57395-4633.png)

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

SEC-9

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

SEC

N

O

P

Intelligent Key has 2 IDs (for Intelligent Key and for NATS). It can perform the door lock/unlock operation and

the engine start operation when the registered Intelligent Key is carried.

When the Intelligent Key battery is discharged, it can be used as emergency back-up by inserting the

mechanical key set in the Intelligent Key to the ignition key cylinder. At that time, perform the NATS ID verifi-

cation. If it is used when the Intelligent Key is carried, perform the Intelligent Key ID verification.

If the ID is successfully verified, and when the ignition knob switch is pressed, steering lock will be released

and initiating the engine will be possible.

The door lock/unlock operation can be performed when the Intelligent Key battery is discharged, by operat-

ing the driver door key cylinder using the mechanical key set in the Intelligent Key.

Up to 4 Intelligent Keys can be registered (including the standard Intelligent Key) on request from the owner.

NOTE:

Refer to XX-XX, "*****"

for any functions other than engine start function of Intelligent Key system.

PRECAUTIONS FOR INTELLIGENT KEY SYSTEM

In the Intelligent Key system, the transponder [the chip for NATS ID verification] is integrated into the

Intelligent Key. (For non-Intelligent Key systems, it is integrated into the mechanical key.) Therefore,

the mechanical key cannot perform the ID verification, and thus it cannot start the engine. Instead,

the NATS ID verification can be performed by inserting the mechanical key into the key cylinder, and

then it can start the engine.

OPERATION WHEN INTELLIGENT KEY IS CARRIED

1. When the ignition knob switch and brake switch are ON, and Intelligent Key unit is transmitting the request

signal to the Intelligent Key.

2. The Intelligent Key receives the request signal and transmits the Intelligent Key ID signal to the Intelligent

Key unit.

3. The Intelligent Key unit receives the Intelligent Key ID signal and verifies it with the registered ID.

4. Intelligent Key unit transmits the steering lock unlock signal to steering lock unit and turn on the key warn-

ing lamp (green) if the verification results are OK. (The detail of key warning lamp operation, refer to XX-

XX, "*****")

5. Release of the steering lock.

6. BCM transmits the starter request signal via CAN communication to IPDM E/R and turns the starter relay

in IPDM E/R ON if BCM judges that the engine start condition is satisfied.

7. IPDM E/R turns the starter control relay ON when receiving the starter request signal.

8. When shift position is in P or N position, battery power is supplied through the starter relay and operate

the starter motor and to start the cranking.

CAUTION:

If a malfunction is detected in the Intelligent Key system, the “KEY” warning lamp in the combina-

tion meter illuminates. At that time, the engine cannot be started.

OPERATION RANGE

Engine can be started when Intelligent Key is inside the vehicle. However, sometimes engine might not start

when Intelligent Key is on instrument panel or in glove box.

OPERATION WHEN MECHANICAL KEY IS USED

When the Intelligent Key battery is discharged, performs the NATS ID verification between the integrated tran-

sponder and BCM by inserting the mechanical key into the key cylinder, and then the engine can be started.

For details relating to starting the engine using mechanical key, refer to SEC-12, "

System Description".

STEERING LOCK OPERATION

Steering is locked by steering lock unit when ignition switch is in the OFF position (the ignition knob is

released) and key switch is OFF (key is removed from ignition key cylinder).

KEY INTERLOCK OPERATION (ONLY FOR M/T MODELS)

In case of a M/T vehicle is in motion and ignition is turned into LOCK position, steering lock unit causes a risk

by activating the steering lock actuator. The key interlock operation is designed to override the steering lock

system and prevent the situation mentioned above from occuring.

LOCK condition

When the following conditions are fulfilled, key interlock solenoid will be locked. (Steering lock inactive)

1 second passes after ignition switch is in ON position and engine revolution speed goes above 500 rpm.

UNLOCK condition

Page 4635 of 5883

![NISSAN TIIDA 2007 Service Workshop Manual SEC-10

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

When any of the following condition are fulfilled key interlock solenoid will be unlocked. (Stee NISSAN TIIDA 2007 Service Workshop Manual SEC-10

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

When any of the following condition are fulfilled key interlock solenoid will be unlocked. (Stee](/img/5/57395/w960_57395-4634.png)

SEC-10

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

When any of the following condition are fulfilled key interlock solenoid will be unlocked. (Steering lock active)

When vehicle speed is below 4km/h (2mph) and the ignition switch is turned from ON to OFF.

When vehicle speed is over 4km/h (2mph) but less than 10km/h (6mph) in LOCK condition, and 3 second

passes after the ignition switch is turned from ON to OFF.

Component Parts LocationINFOID:0000000001404036

Component DescriptionINFOID:0000000001404037

1. BCM M18, M19, M20

(view with glove box removed)2. Intelligent Key Unit M52 3. Steering lock solenoid M6

(bottom view of steering column)

4. Security indicator lamp M31 5. ECM E16 6. Intelligent key warning buzzer (driver side) D6

(LHD: view with front door finisher removed)

7. Intelligent key warning buzzer (driver

side) D6

(RHD: view with front door finisher

removed)8. Intelligent Key warning buzzer

(trunk) B82 (sedan)

(view with trunk finisher LH re-

moved)

ALKIA0844ZZ

Component Reference

Intelligent Key unitSEC-34

BCMXX-XX, "*****"