brake light NISSAN TIIDA 2010 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 934 of 3745

![NISSAN TIIDA 2010 Service User Guide BRC-44

< SERVICE INFORMATION >[VDC/TCS/ABS]

SYSTEM DESCRIPTION

TCS Function

INFOID:0000000005612145

• Spinning of the drive wheels is detected by the A BS/TCS/VDC control unit using inputs from the NISSAN TIIDA 2010 Service User Guide BRC-44

< SERVICE INFORMATION >[VDC/TCS/ABS]

SYSTEM DESCRIPTION

TCS Function

INFOID:0000000005612145

• Spinning of the drive wheels is detected by the A BS/TCS/VDC control unit using inputs from the](/img/5/57397/w960_57397-933.png)

BRC-44

< SERVICE INFORMATION >[VDC/TCS/ABS]

SYSTEM DESCRIPTION

TCS Function

INFOID:0000000005612145

• Spinning of the drive wheels is detected by the A BS/TCS/VDC control unit using inputs from the wheel

speed sensors. If wheel spin occurs, the drive wheel right and left brake fluid pressure control and engine

fuel cut are conducted while the throttle value is restricted to reduce the engine torque and decrease the

amount of wheel spin. In addition, the throttle openi ng is controlled to achieve the optimum engine torque.

• Depending on road condition, the vehicle may have a sluggish feel. This is normal, because optimum trac- tion has the highest priority during TCS operation.

• TCS may be activated during sudden vehicle acceleration, wide open throttle acceleration, sudden transmis- sion shifts or when the vehicle is driven on a road with a varying surface friction coefficient.

• The SLIP indicator lamp flashes to inform the driver of TCS operation.

VDC FunctionINFOID:0000000005612146

• In addition to the ABS/TCS function, the driver steering amount and brake operation amount are detected

from the steering angle sensor, and the vehicle's drivi ng status (amount of under steering/over steering) is

determined using inputs from the yaw rate/side/decel G sensor, wheel speed sensors, etc. and this informa-

tion is used to improve vehicle stability by cont rolling the braking and engine torque application to the

wheels.

• The SLIP indicator lamp flashes to inform the driver of VDC operation.

• During VDC operation, the vehicle body and brake pedal may vibrate lightly and a mechanical noise may be

heard. This is normal.

• The ABS warning lamp, VDC OFF indicator lamp and SLIP indicator lamp may turn on when the vehicle is

subject to strong shaking or large vibration, such as when the vehicle is on a turn table or a ship while the

engine is running or steep slope. In this case, rest art the engine on a normal road and if the ABS warning

lamp, VDC OFF indicator lamp and SLIP indicator lamp turn off, there is no problem.

Wheel SensorsINFOID:0000000005612147

The front sensor units consist of a gear-shaped sensor rotor and a

sensor element. The element contains a magnet around which a coil

is wound. The front wheel sensors are installed on the front of the

wheel knuckles. As the wheel rotates, the sensor generates a

square-wave signal. The frequency in creases as the wheel speed

increases.

The rear sensor units consist of w heel hubs with a series of internal

magnets and a sensor element. The rear wheel sensors are installed

on the inner side of the wheel knuckles. As the wheel rotates, the

sensor generates a square-wave signal. The frequency increases as

the wheel speed increases.

Fail-Safe FunctionINFOID:0000000005612148

ABS/EBD SYSTEM

In case of an electrical malfunction with the ABS, t he ABS warning lamp, VDC OFF indicator lamp and SLIP

indicator lamp will turn on. In case of an electrical malfunction with the EBD system, the BRAKE warning lamp,

ABS warning lamp, VDC OFF indicator lamp and SLIP indicator lamp will turn on.

LBR333

WFIA0033E

Revision: January 20102010 Versa

Page 1042 of 3745

![NISSAN TIIDA 2010 Service User Guide PRECAUTIONSCVT-9

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

6. Turn ignition switch ON. CAUTION:

Never start engine.

7. Select “Self Diagnostic Results” in “TRANSMISSION NISSAN TIIDA 2010 Service User Guide PRECAUTIONSCVT-9

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

6. Turn ignition switch ON. CAUTION:

Never start engine.

7. Select “Self Diagnostic Results” in “TRANSMISSION](/img/5/57397/w960_57397-1041.png)

PRECAUTIONSCVT-9

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

6. Turn ignition switch ON. CAUTION:

Never start engine.

7. Select “Self Diagnostic Results” in “TRANSMISSION”.

8. Shift the selector lever to “R” position.

9. Depress slightly the accelerator pedal (Pedal angle: 2/8) while depressing the brake pedal.

10. Select “Erase” with step 9.

11. Release brake pedal and accelerator pedal.

12. Turn ignition switch OFF while keeping the selector lever in “R” position.

13. Wait approximately 10 seconds.

14. Turn ignition switch ON while keeping the selector lever in “R” position.

15. Select “Special function” in “TRANSMISSION”.

16. Check that the value on “CALIB DATA” in CONSULT-II I is the same as the data listed in the table below.

• Restart the procedure from step 3 if the values are not the same.

CALIB DATA

17. Shift the selector lever to “P” position.

18. Check that the shift position indicator in combinat ion meter turns ON. (It indicates approximately 1 or 2

seconds after shifting the selector lever to “P” position.)

• Check the following items if shift position indicator does not turn ON. Repair or replace accordingly as

necessary.

- The harness between TCM and ROM ASSY in transaxle assembly is open or shorted.

- Terminals disconnected, loose, or bent from connector housing.

- Power supply and ground of TCM. Refer to CVT-113, "

Description".

PATTERN C

1. Replace transaxle assembly first, and then replace TCM.

2. Perform the service of “PATTERN A”.

(Perform the service of “PATTERN B” if TCM is replaced first.)

Removal and Installation Procedure for CVT Unit ConnectorINFOID:0000000005397762

REMOVAL

Rotate bayonet ring counterclockwise, pull out CVT unit harness

connector upward and disconnect it.

INSTALLATION

Item name Display value

UNIT CLB ID 1 00

UNIT CLB ID 2 00

UNIT CLB ID 3 00

UNIT CLB ID 4 00

UNIT CLB ID 5 00

UNIT CLB ID 6 00

SCIA2096E

Revision: January 20102010 Versa

Page 1196 of 3745

![NISSAN TIIDA 2010 Service User Guide SHIFT CONTROL SYSTEMCVT-163

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

• When installing the control cable (1) to the CVT shift selector assembly (2), make sure that the con NISSAN TIIDA 2010 Service User Guide SHIFT CONTROL SYSTEMCVT-163

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

• When installing the control cable (1) to the CVT shift selector assembly (2), make sure that the con](/img/5/57397/w960_57397-1195.png)

SHIFT CONTROL SYSTEMCVT-163

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

• When installing the control cable (1) to the CVT shift selector assembly (2), make sure that the control cable (1) is fully pressed

in with the ribbed surface (A) fa cing downward from the vehicle.

: Vehicle front

• After installation is completed, adjust and check the CVT position.

Refer to CVT-164, "

Adjustment of CVT Position" and CVT-164,

"Checking of CVT Position".

CVT Shift Selector Disassembly and AssemblyINFOID:0000000005398000

DISASSEMBLY

NOTE:

Refer to CVT-160, "

Removal and Installation" to disassemble.

1. Remove shift lever handle from CVT shift selector assembly. Refer to CVT-163, "

Shift Lever Handle

Removal and Installation".

2. Remove position lamp from position indicator plate (1).

3. Insert a suitable tool to (A) (at 4 locations) as shown, and bend each hook slightly to raise position indicator plate (1) and

remove from CVT shift selector assembly (2).

4. Remove bracket from CVT sh ift selector assembly (2).

5. Remove CVT shift selector harness connector from CVT shift selector assembly (2).

6. Release tabs (A) on shift lock solenoid and park position switch assembly from hooks (B) on CVT shift selector assembly to shift

lock solenoid and park position switch assembly.

ASSEMBLY

Assembly is in the reverse order of disassembly.

Shift Lever Handle Removal and InstallationINFOID:0000000005398001

REMOVAL

CAUTION:

Make sure that parking brake is a pplied before removal/installation.

SCIA6253E

SCIA6969E

SCIA6977E

Revision: January 20102010 Versa

Page 1211 of 3745

DI-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION DI

A

B

DI

N

O P

CONTENTS

DRIVER INFORMATION SYSTEM

SERVICE INFORMATION .. ..........................2

PRECAUTION ................................................ .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

COMBINATION METERS ...................................4

Component Parts and Harness Connector Loca-

tion ...................................................................... ......

4

System Description ...................................................4

Arrangement of Combination Meter ..........................6

Internal Circuit ...........................................................7

Wiring Diagram - METER - .......................................8

Combination Meter Harness Connector Terminal

Layout .....................................................................

10

Terminal and Reference Value for Combination

Meter .......................................................................

10

Self-Diagnosis Mode of Combination Meter ........ ....11

CONSULT-III Function (METER/M&A) ............... ....13

Trouble Diagnosis ...................................................14

Symptom Chart .......................................................15

Power Supply and Ground Circuit Inspection .........15

Vehicle Speed Signal Inspection .............................16

Engine Speed Signal Inspection .............................17

Fuel Level Sensor Signal Inspection .......................17

Fuel Gauge Fluctuates, Indicates Wrong Value, or

Varies ......................................................................

19

Fuel Gauge Does Not Move to Full-position ...........19

DTC [U1000] CAN Communication Circuit ......... ....19

Electrical Component Inspection .............................20

Removal and Installation .........................................20

WARNING LAMPS ......................................... ....21

Schematic ........................................................... ....21

Wiring Diagram - WARN - ................................... ....22

Oil Pressure Warning Lamp Stays Off (Ignition

Switch ON) .......................................................... ....

30

Oil Pressure Warning Lamp Does Not Turn Off

(Oil Pressure Is Normal) ...................................... ....

32

Component Inspection .............................................32

A/T INDICATOR ................................................34

System Description ..................................................34

Wiring Diagram - AT/IND - .......................................35

A/T Indicator Does Not Illuminate ............................36

CVT INDICATOR ...............................................38

System Description ..................................................38

Schematic ................................................................38

Wiring Diagram - CVTIND - .....................................39

CVT Indicator Does Not Illuminate ..........................41

WARNING CHIME .............................................43

Component Parts and Harness Connector Loca-

tion ....................................................................... ....

43

System Description ..................................................43

Wiring Diagram - CHIME - .......................................46

Terminal and Reference Value for BCM ..................47

CONSULT-III Function (B CM) .................................47

Trouble Diagnosis ................................................ ....48

Combination Meter Buzzer Circuit Inspection .........49

Front Door Switch LH Signal Inspection .............. ....50

Key Switch Signal Inspection (Without Intelligent

Key) ..................................................................... ....

51

Key Switch and Ignition Knob Switch Signal In-

spection (With Intelligent Key, When Mechanical

Key Is Used) ........................................................ ....

52

Lighting Switch Signal Inspection ............................54

Parking Brake Switch Signal Inspection ..................54

Electrical Component Inspection .............................55

Revision: January 20102010 Versa

Page 1253 of 3745

WARNING CHIMEDI-43

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

WARNING CHIME

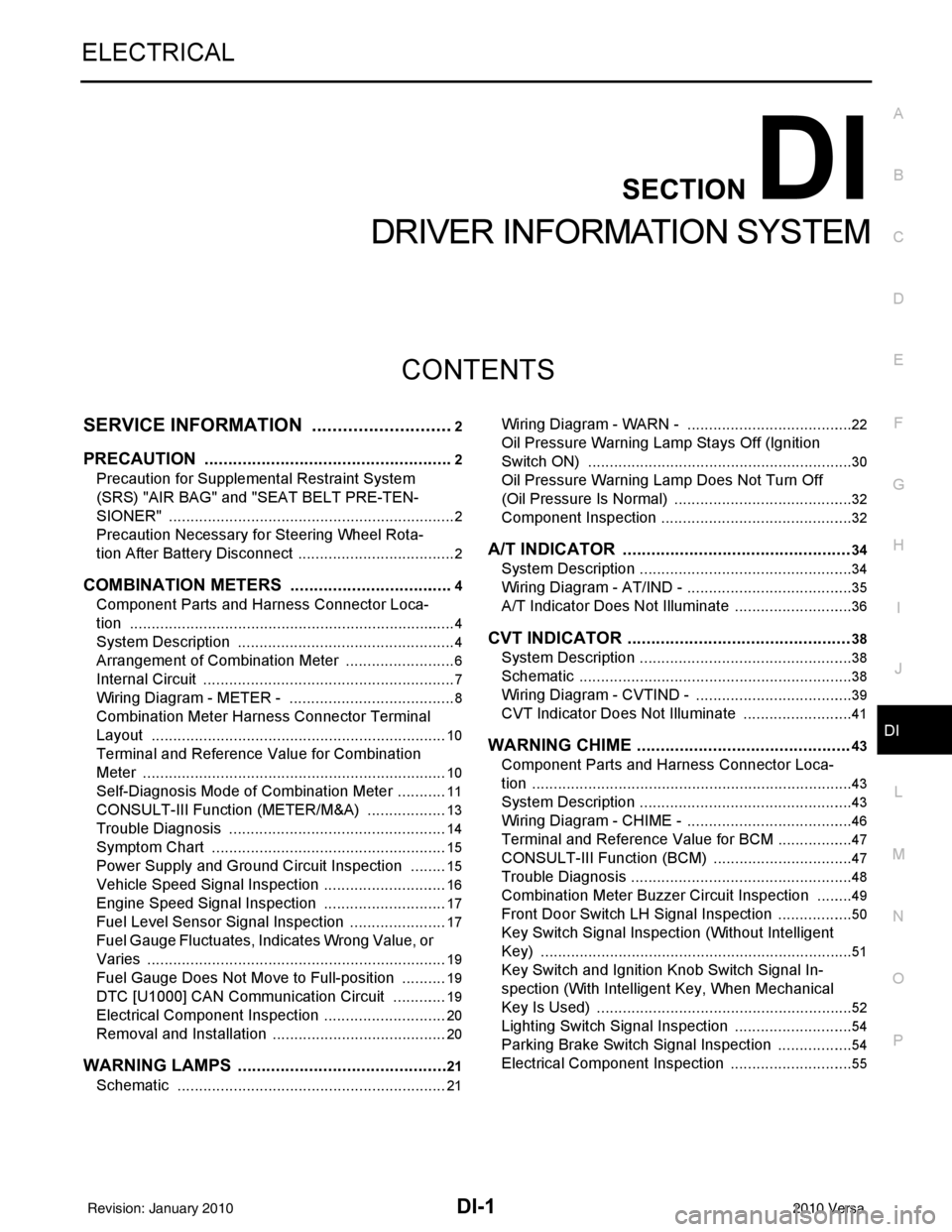

Component Parts and Har ness Connector LocationINFOID:0000000005395039

System DescriptionINFOID:0000000005395040

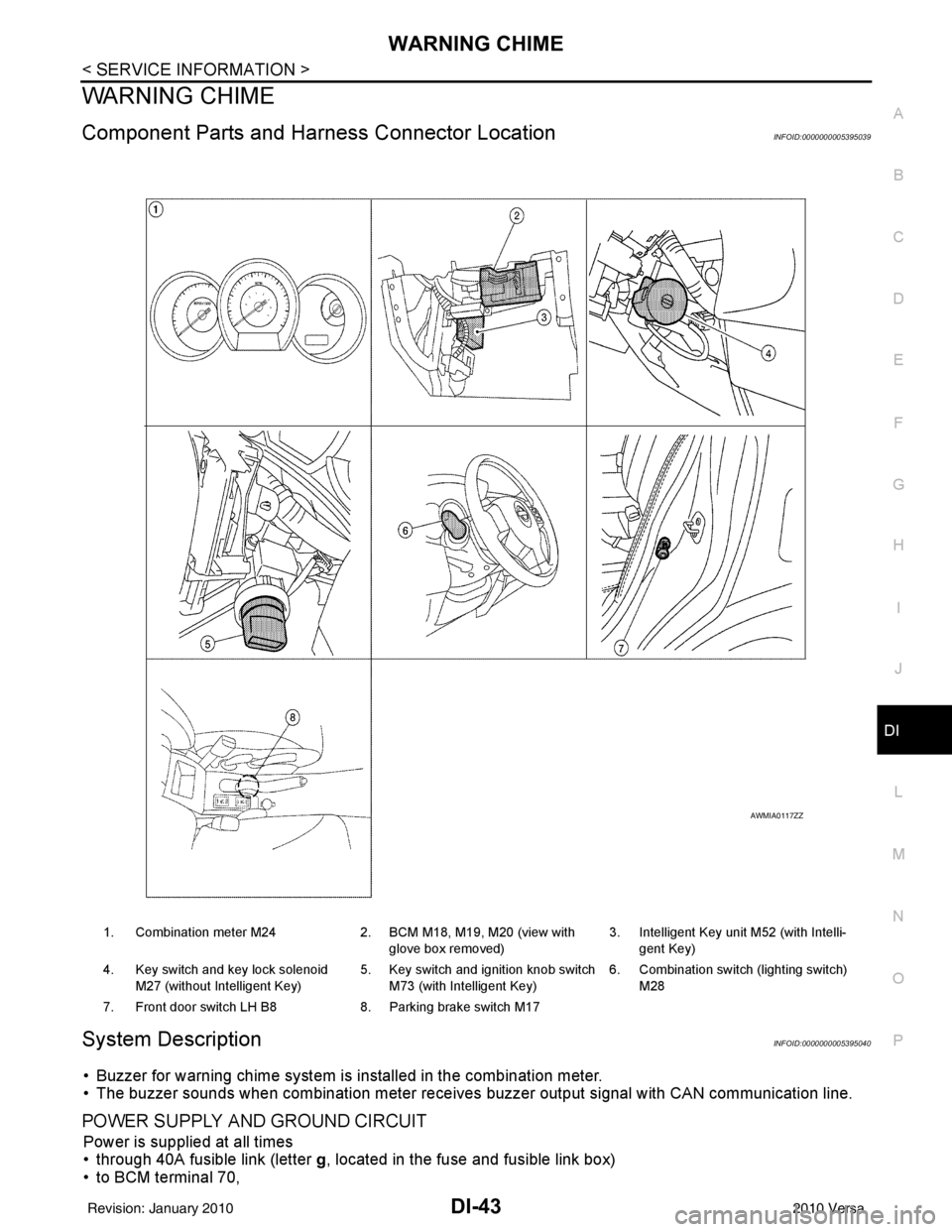

• Buzzer for warning chime system is installed in the combination meter.

• The buzzer sounds when combination meter receives buzzer output signal with CAN communication line.

POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

• through 40A fusible link (letter g, located in the fuse and fusible link box)

• to BCM terminal 70,

1. Combination meter M24 2. BCM M18, M19, M20 (view with

glove box removed) 3. Intelligent Key unit M52 (with Intelli-

gent Key)

4. Key switch and key lock solenoid M27 (without Intelligent Key) 5. Key switch and ignition knob switch

M73 (with Intelligent Key) 6. Combination switch (lighting switch)

M28

7. Front door switch LH B8 8. Parking brake switch M17

AWMIA0117ZZ

Revision: January 20102010 Versa

Page 1255 of 3745

WARNING CHIMEDI-45

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

• When the combination meter receives light warning signal, it sounds warning chime.

PARKING BRAKE WARNING CHIME

The parking brake warning chime sounds when the parking brake is applied and vehicle speed reaches

approximately 2 km/h (1 MPH).

• The combination meter receives a parking brake applied signal from the parking brake switch.

• When the combination meter receives a vehicle speed si gnal from the ABS actuator and electric unit (control

unit) (with ABS), vehicle speed sensor (without ABS or CVT) or the TCM (with CVT, without ABS), it sounds

the buzzer.

WKIA5465E

LKIA0906E

Revision: January 20102010 Versa

Page 1259 of 3745

WARNING CHIMEDI-49

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

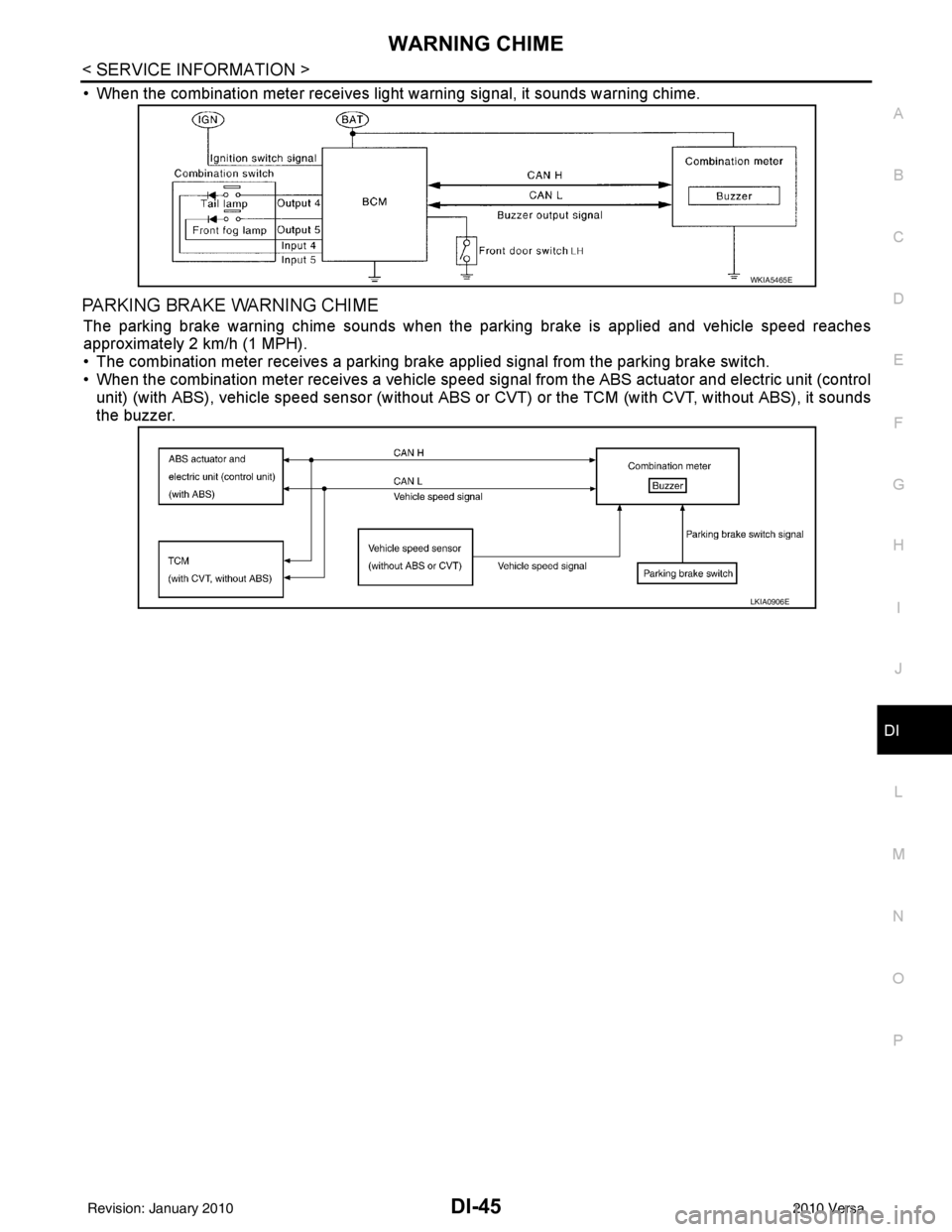

1.CHECK BCM

Perform self-diagnosis of BCM. Refer to DI-47, "

CONSULT-III Function (BCM)".

Self

-diagnostic results content

No malfunction detected>> GO TO 2.

Malfunction detected>> Check applicable parts, and repair or replace corresponding parts.

2.CHECK COMBINATION METER

Perform self-diagnosis of combination meter. Refer to DI-13, "

CONSULT-III Function (METER/M&A)".

Self

-diagnostic results content

No malfunction detected>> Inspection End.

Malfunction detected>> Check applicable parts, and repair or replace corresponding parts.

SYMPTOM CHART

Combination Meter Buzzer Circuit InspectionINFOID:0000000005395045

1.CHECK CHIME OPERATION

1. Select “BUZZER” of “BCM” on CONSULT-III.

2. Perform “LIGHT WARN ALM” or “IGN KEY WARN ALM” of “ACTIVE TEST”.

Does chime sound?

YES >> Combination meter buzzer circuit is OK. Return to DI-48, "Trouble Diagnosis".

NO >> GO TO 2.

2.CHECK COMBINATION METER INPUT SIGNAL

1. Select “METER/M&A” on CONSULT-III.

2. Turn on hazard switch or lighting switch while monitoring “BUZZER” of “DATA MONITOR” and check

operation status.

OK or NG

Symptom Diagnoses/Service procedure

All warning chime systems do not activate. Perform the following inspections.

•

DI-49, "

Combination Meter Buzzer Circuit Inspection"

•DI-50, "Front Door Switch LH Signal Inspection"

If above check is OK, replace BCM. Refer to BCS-19, "Removal

and Installation of BCM".

Key warning chime

does not activate. Without Intelligent Key.

Perform

DI-51, "

Key Switch Signal Inspection (Without Intelligent

Key)".

If above check is OK, replace BCM. Refer to BCS-19, "

Removal

and Installation of BCM".

With Intelligent Key, when mechanical key

is used. Perform

DI-52, "

Key Switch and Ignition Knob Switch Signal In-

spection (With Intelligent Key, When Mechanical Key Is Used)".

If above check is OK, replace BCM. Refer to BCS-19, "

Removal

and Installation of BCM".

With Intelligent Key, when Intelligent Key

is carried with the driver. Refer to BL-119, "

Trouble Diagnosis Symptom Chart".

Light warning chime does not activate. Perform

DI-54, "

Lighting Switch Signal Inspection".

If above check is OK, replace BCM. Refer to BCS-19, "

Removal

and Installation of BCM".

Parking brake warning chime does not activate Perform the following inspections

•

DI-54, "

Parking Brake Switch Signal Inspection"

•DI-16, "Vehicle Speed Signal Inspection"

“BUZZER”

While hazard switch or

lighting switch is ON : ON and OFF repeatedly

Except above : OFF

Revision: January 20102010 Versa

Page 1264 of 3745

DI-54

< SERVICE INFORMATION >

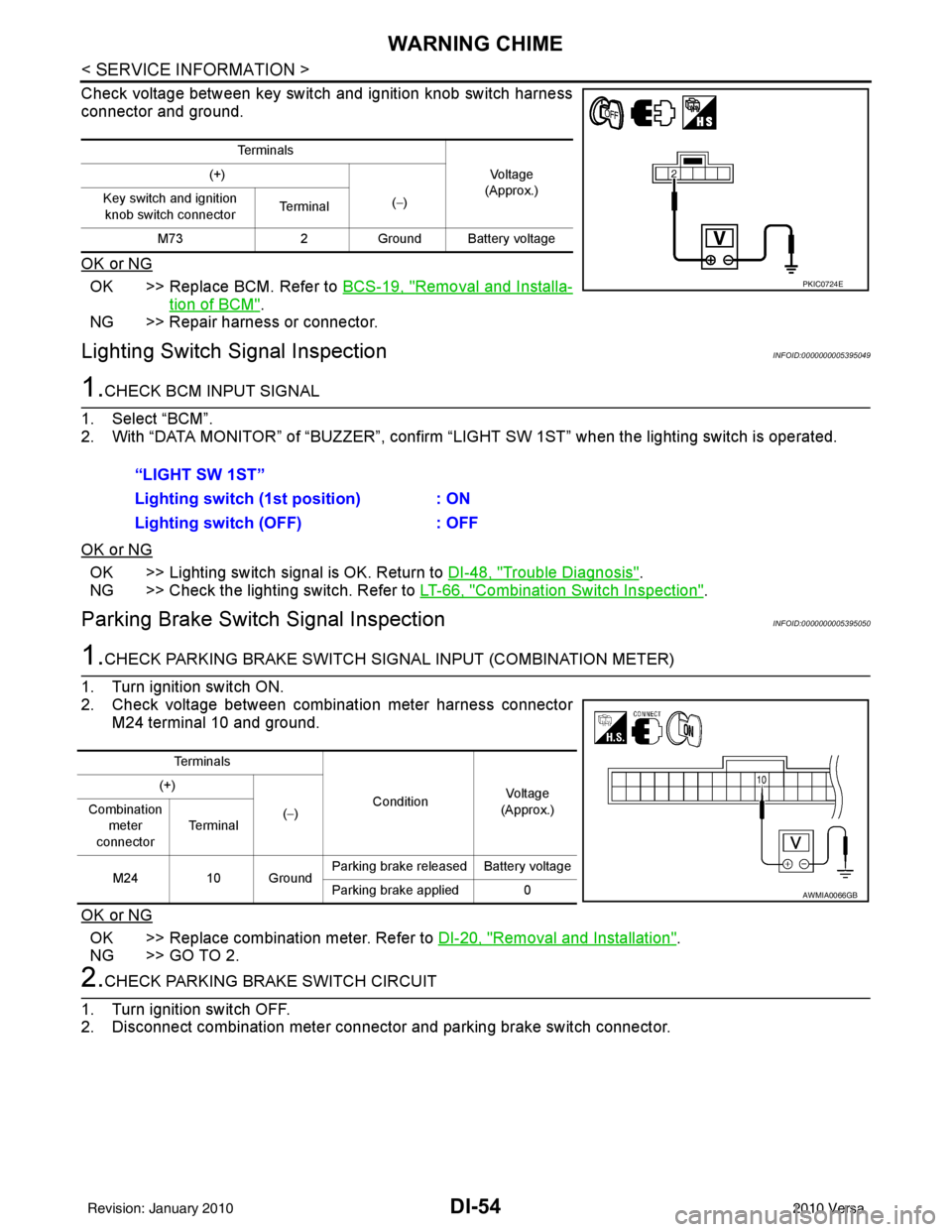

WARNING CHIME

Check voltage between key switch and ignition knob switch harness

connector and ground.

OK or NG

OK >> Replace BCM. Refer to BCS-19, "Removal and Installa-

tion of BCM".

NG >> Repair harness or connector.

Lighting Switch Signal InspectionINFOID:0000000005395049

1.CHECK BCM INPUT SIGNAL

1. Select “BCM”.

2. With “DATA MONITOR” of “BUZZER”, confirm “LIG HT SW 1ST” when the lighting switch is operated.

OK or NG

OK >> Lighting switch signal is OK. Return to DI-48, "Trouble Diagnosis".

NG >> Check the lighting switch. Refer to LT-66, "

Combination Switch Inspection".

Parking Brake Switch Signal InspectionINFOID:0000000005395050

1.CHECK PARKING BRAKE SWITCH SIGNAL INPUT (COMBINATION METER)

1. Turn ignition switch ON.

2. Check voltage between combination meter harness connector M24 terminal 10 and ground.

OK or NG

OK >> Replace combination meter. Refer to DI-20, "Removal and Installation".

NG >> GO TO 2.

2.CHECK PARKING BRAKE SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect combination meter connector and parking brake switch connector.

Te r m i n a l s

Vo l ta g e

(Approx.)

(+)

(−)

Key switch and ignition

knob switch connector Te r m i n a l

M73 2Ground Battery voltage

PKIC0724E

“LIGHT SW 1ST”

Lighting switch ( 1st position) : ON

Lighting switch (OFF) : OFF

Te r m i n a l s

ConditionVoltag e

(Approx.)

(+)

(−)

Combination

meter

connector Te r m i n a l

M24 10 Ground Parking brake released Battery voltage

Parking brake applied 0

AWMIA0066GB

Revision: January 20102010 Versa

Page 1291 of 3745

![NISSAN TIIDA 2010 Service User Guide EC-26

< BASIC INSPECTION >[HR16DE]

INSPECTION AND ADJUSTMENT

• Each time electric throttle control actuator or ECM is replaced.

• Idle speed or ignition timing is out of specification.

IDLE AIR VO NISSAN TIIDA 2010 Service User Guide EC-26

< BASIC INSPECTION >[HR16DE]

INSPECTION AND ADJUSTMENT

• Each time electric throttle control actuator or ECM is replaced.

• Idle speed or ignition timing is out of specification.

IDLE AIR VO](/img/5/57397/w960_57397-1290.png)

EC-26

< BASIC INSPECTION >[HR16DE]

INSPECTION AND ADJUSTMENT

• Each time electric throttle control actuator or ECM is replaced.

• Idle speed or ignition timing is out of specification.

IDLE AIR VOLUME LEARNING

: Special Repair RequirementINFOID:0000000005398245

1.PRECONDITIONING

Make sure that all of the following conditions are satisfied.

Learning will be cancelled if any of the follo wing conditions are missed for even a moment.

• Battery voltage: More than 12.9 V (At idle)

• Engine coolant temperature: 70 - 100 °C (158 - 212° F)

• Selector lever: P or N (A/T), Neutral (M/T)

• Electric load switch: OFF (Air conditioner, headlamp, rear window defogger)

On vehicles equipped with daytime light systems, if the parking brake is applied before the engine is

started the headlamp will not be illuminated.

• Steering wheel: Neutral (Straight-ahead position)

• Vehicle speed: Stopped

• Transmission: Warmed-up

- A/T models

• With CONSULT-III: Drive vehicle until “FLUID TEMP SE” in “DATA MONITOR” mode of “TRANSMISSION”

system indicates less than 0.9 V.

• Without CONSULT-III: Drive vehicle for 10 minutes.

- M/T models

• Drive vehicle for 10 minutes.

Do you have CONSULT-III?

YES >> GO TO 2.

NO >> GO TO 3.

2.IDLE AIR VOLUME LEARNING

With CONSULT-III

1. Perform Accelerator Pedal Released Position Learning. Refer to EC-25, "

ACCELERATOR PEDAL

RELEASED POSITION LEARNING : Special Repair Requirement".

2. Perform Throttle Valve Closed Position Learning. Refer to EC-25, "

THROTTLE VALVE CLOSED POSI-

TION LEARNING : Special Repair Requirement".

3. Start engine and warm it up to normal operating temperature.

4. Select “IDLE AIR VOL LEARN” in “WORK SUPPORT” mode.

5. Touch “START” and wait 20 seconds.

Is

“CMPLT” displayed on CONSULT-III screen?

YES >> GO TO 4.

NO >> GO TO 5.

3.IDLE AIR VOLUME LEARNING

Without CONSULT-III

NOTE:

• It is better to count the ti me accurately with a clock.

• It is impossible to switch the di agnostic mode when an accelerator pedal position sensor circuit has

a malfunction.

1. Perform Accelerator Pedal Released Position Learning. Refer to EC-25, "

ACCELERATOR PEDAL

RELEASED POSITION LEARNING : Special Repair Requirement".

2. Perform Throttle Valve Closed Position Learning. Refer to EC-25, "

THROTTLE VALVE CLOSED POSI-

TION LEARNING : Special Repair Requirement".

3. Start engine and warm it up to normal operating temperature.

4. Turn ignition switch OFF and wait at least 10 seconds.

5. Confirm that accelerator pedal is fully releas ed, turn ignition switch ON and wait 3 seconds.

6. Repeat the following procedure quickly five times within 5 seconds.

- Fully depress the accelerator pedal.

- Fully release the accelerator pedal.

7. Wait 7 seconds, fully depress the accelerator pedal and keep it for approx. 20 seconds until the MIL stops

blinking and turned ON.

8. Fully release the accelerator pedal within 3 seconds after the MIL turned ON.

Revision: January 20102010 Versa

Page 1366 of 3745

![NISSAN TIIDA 2010 Service User Guide ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-101

< FUNCTION DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

HO2S2 MNTR(B1)

RICH/

LEAN • Display of heated oxygen sensor 2 signal:

RICH: means the amount of NISSAN TIIDA 2010 Service User Guide ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-101

< FUNCTION DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

HO2S2 MNTR(B1)

RICH/

LEAN • Display of heated oxygen sensor 2 signal:

RICH: means the amount of](/img/5/57397/w960_57397-1365.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-101

< FUNCTION DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

HO2S2 MNTR(B1)

RICH/

LEAN • Display of heated oxygen sensor 2 signal:

RICH: means the amount of oxygen after three way

catalyst is relatively small.

LEAN: means the amount of oxygen after three way

catalyst is relatively large. • When the engine is stopped, a certain

value is indicated.

VHCL SPEED SE km/h or

mph • The vehicle speed computed from the vehicle speed

signal sent from combination meter is displayed.

BATTERY VOLT V • The power supply voltage of ECM is displayed.

ACCEL SEN 1 V• The accelerator pedal position sensor signal voltage is

displayed. • ACCEL SEN 2 signal is converted by

ECM internally. Thus, it differs from

ECM terminal voltage signal.

ACCEL SEN 2

TP SEN 1-B1

V• The throttle position sensor signal voltage is dis-

played. • TP SEN 2-B1 signal is converted by

ECM internally. Thus, it differs from

ECM terminal voltage signal.

TP SEN 2-B1

FUEL T/TMP SE

°C or °F • The fuel temperature (determined by the signal volt-

age of the fuel tank temperature sensor) is displayed.

INT/A TEMP SE °C or °F • The intake air temperature (determined by the signal

voltage of the intake air temperature sensor) is indicat-

ed.

EVAP SYS PRES V • The signal voltage of EVAP control system pressure

sensor is displayed.

FUEL LEVEL SE V • The signal voltage of the fuel level sensor is displayed.

START SIGNAL ON/OFF • Indicates start signal status [ON/OFF] computed by

the ECM according to the signals of engine speed and

battery voltage. • After starting the engine, [OFF] is dis-

played regardless of the starter sig-

nal.

CLSD THL POS ON/OFF • Indicates idle position [ON/OFF] computed by ECM

according to the accelerator pedal position sensor sig-

nal.

AIR COND SIG ON/OFF • Indicates [ON/OFF] condition of the air conditioner

switch determined by the air conditioner ON signal.

P/N POSI SW ON/OFF • Indicates [ON/OFF] condit

ion from the park/neutral

position (PNP) signal.

PW/ST SIGNAL ON/OFF • [ON/OFF] condition of the power steering system (de-

termined by the signal sent from EPS control unit) is

indicated.

LOAD SIGNAL ON/OFF • Indicates [ON/OFF] condition from the electrical load

signal.

ON: Rear window defogger switch is ON and/or light-

ing switch is in 2nd position.

OFF: Both rear window defogger switch and lighting

switch are OFF.

IGNITION SW ON/OFF • Indicates [ON/OFF] condition from ignition switch sig-

nal.

HEATER FAN SW ON/OFF • Indicates [ON/OFF] condition from the heater fan

switch signal.

BRAKE SW ON/OFF• Indicates [ON/OFF] condition from the stop lamp

switch signal.

INJ PULSE-B1 msec • Indicates the actual fuel injection pulse width compen-

sated by ECM according to the input signals. • When the engine is stopped, a certain

computed value is indicated.

IGN TIMING BTDC• Indicates the ignition timing computed by ECM ac-

cording to the input signals. • When the engine is stopped, a certain

value is indicated.

CAL/LD VALUE %• “Calculated load value” indicates the value of the cur-

rent air flow divided by peak air flow.

MASS AIRFLOW g·m/s • Indicates the mass air flow computed by ECM accord-

ing to the signal voltage of the mass air flow sensor.

Monitored item Unit

DescriptionRemarks

Revision: January 20102010 Versa