ELECTRICAL NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 3692 of 3745

TROUBLE DIAGNOSESWT-15

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

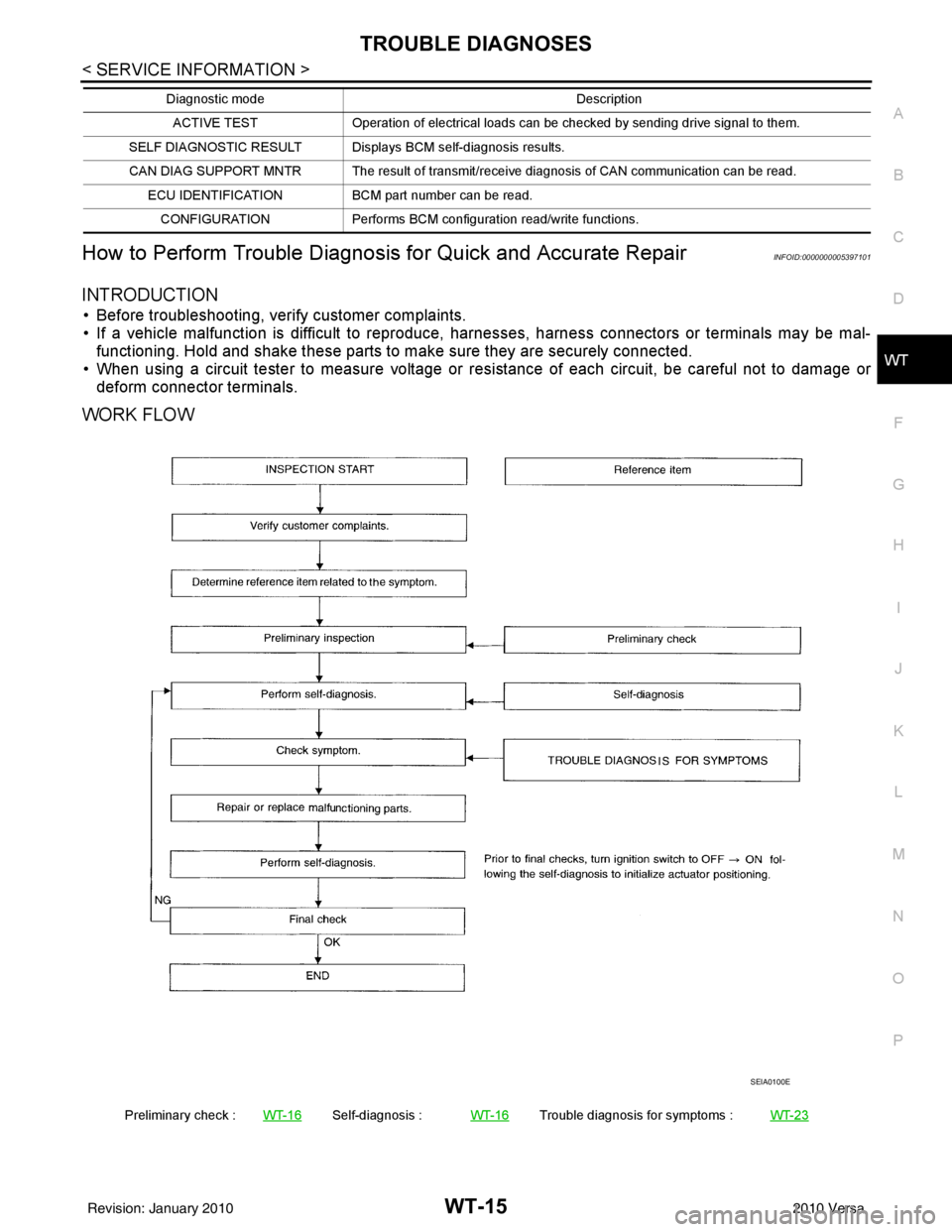

How to Perform Trouble Diagnosis for Quick and Accurate RepairINFOID:0000000005397101

INTRODUCTION

• Before troubleshooting, verify customer complaints.

• If a vehicle malfunction is difficult to reproduce, harnesses, harness connectors or terminals may be mal- functioning. Hold and shake these parts to make sure they are securely connected.

• When using a circuit tester to measure voltage or re sistance of each circuit, be careful not to damage or

deform connector terminals.

WORK FLOW

ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF DIAGNOSTIC RESULT Displays BCM self-diagnosis results.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read. ECU IDENTIFICATION BCM part number can be read.

CONFIGURATION Performs BCM configuration read/write functions.

Diagnostic mode

Description

Preliminary check :WT-16Self-diagnosis :WT-16Trouble diagnosis for symptoms : WT-23

SEIA0100E

Revision: January 20102010 Versa

Page 3706 of 3745

WW-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION WW

A

B

WW

N

O P

CONTENTS

WIPER, WASHER & HORN

SERVICE INFORMATION .. ..........................2

PRECAUTION ................................................ .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution for Procedure without Cowl Top Cover ......3

PREPARATION ...................................................4

Special Service Tool ........................................... ......4

FRONT WIPER AND WASHER SYSTEM ..........5

Component Parts and Harness Connector Loca-

tion ...................................................................... ......

5

System Description ...................................................5

CAN Communication System Description .................7

Schematic .................................................................8

Wiring Diagram - WIPER - ........................................9

Terminal and Reference Value for BCM .................12

Terminal and Reference Value for IPDM E/R .........12

How to Proceed with Trouble Diagnosis .................12

Preliminary Check ...................................................12

CONSULT-III Function (BCM) .................................12

CONSULT-III Function (IPDM E/R) .........................13

Front Wiper Does Not Operate ...............................14

Front Wiper Does Not Return to Stop Position (Af-

ter Front Wiper Operates for 10 Seconds, They

Stop for 20 Seconds, and After Repeating the Op-

eration Five Times, They Become Inoperative) ......

16

Only Front Wiper Low Does Not Operate ...............17

Only Front Wiper High Does Not Operate ...............18

Only Front Wiper Intermittent Does Not Operate ....19

Front Wiper Intermittent Operation Switch Posi-

tion Cannot Be Adjusted .........................................

19

Wiper Does Not Wipe When Front Washer Oper-

ates .........................................................................

20

Front Wiper Does Not Stop .....................................20

Removal and Installation of Front Wiper Arms ........20

Adjustment of Wiper Arm Stop Location .............. ....21

Removal and Installation of Front Wiper Drive As-

sembly .....................................................................

21

Removal and Installation of Front Washer Nozzle ....22

Inspection for Washer Nozzle ..................................22

Washer Nozzle Adjustment ................................. ....23

Washer Tube Layout ...............................................23

Removal and Installation of Front Wiper and

Washer Switch .........................................................

24

Inspection of Front Wiper and Washer Switch Cir-

cuit ...........................................................................

24

Removal and Installation of Washer Tank ...............24

Removal and Installation of Front Washer Motor ....25

REAR WIPER AND WASHER SYSTEM ..........26

Component Parts and Harness Connector Loca-

tion ....................................................................... ....

26

System Description ..................................................26

Wiring Diagram - WIP/R - ........................................28

Terminal and Reference Value for BCM ..................30

How to Proceed with Trou ble Diagnosis ..................30

Preliminary Check ............................................... ....30

CONSULT-III Function (BCM) .................................30

Rear Wiper Does Not Operate ............................ ....30

Rear Wiper Stop Position Is Incorrect .....................31

Only Rear Wiper Does Not Operate ........................33

Only Rear Wiper Intermittent Does Not Operate .....33

Wiper Does Not Wipe When Rear Washer Oper-

ates ..........................................................................

33

Removal and Installation .........................................33

Washer Nozzle Adjustment .....................................36

POWER SOCKET .............................................37

Wiring Diagram - P/SCKT - .....................................37

Removal and Installation .........................................37

HORN ................................................................39

Wiring Diagram - HORN - ........................................39

Removal and Installation .........................................39

Revision: January 20102010 Versa

Page 3707 of 3745

WW-2

< SERVICE INFORMATION >

PRECAUTION

SERVICE INFORMATION

PRECAUTION

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005777027

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005988552

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa

Page 3718 of 3745

FRONT WIPER AND WASHER SYSTEMWW-13

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

WW

N

O P

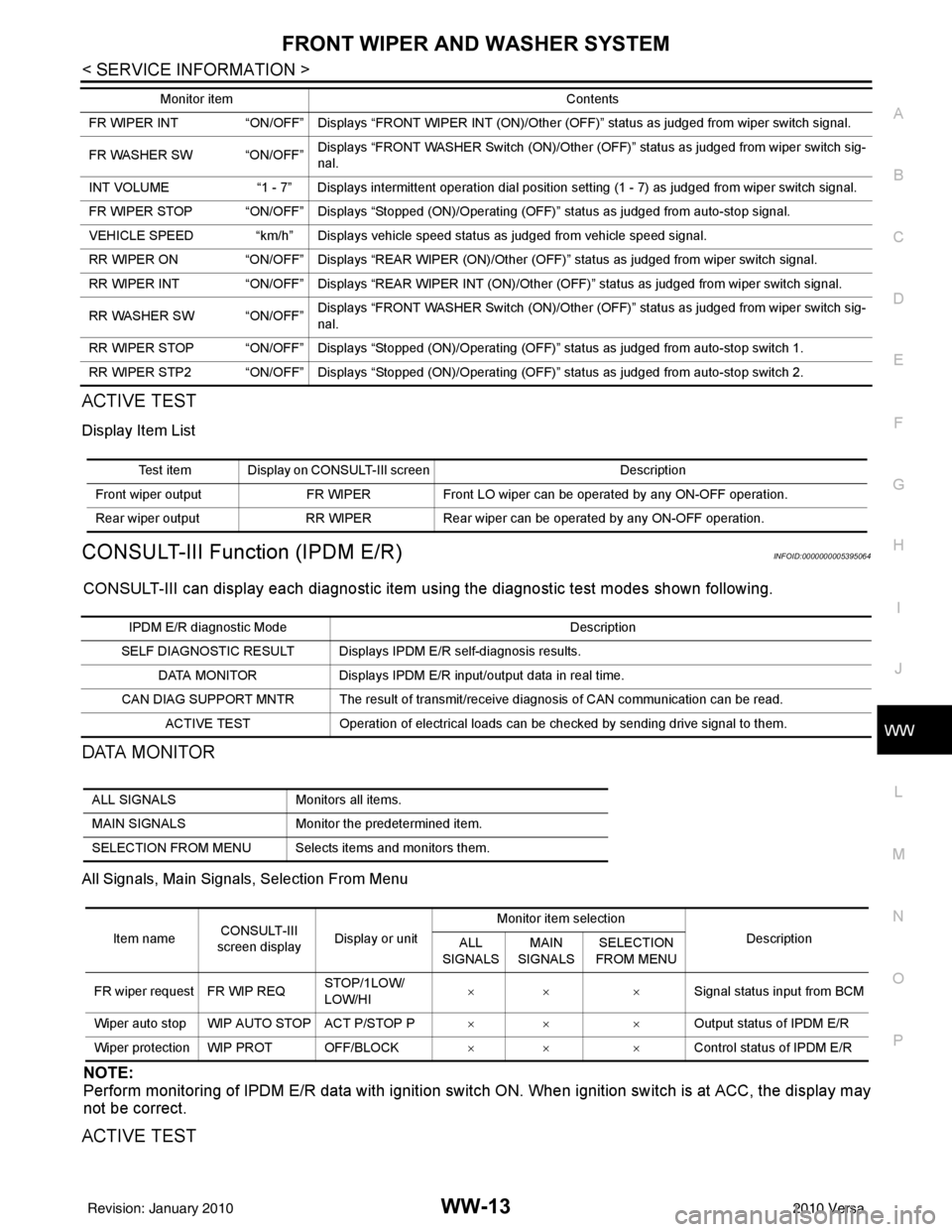

ACTIVE TEST

Display Item List

CONSULT-III Function (IPDM E/R)INFOID:0000000005395064

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

DATA MONITOR

All Signals, Main Signals, Selection From Menu

NOTE:

Perform monitoring of IPDM E/R data with ignition switch ON. When ignition switch is at ACC, the display may

not be correct.

ACTIVE TEST

FR WIPER INT “ON/OFF” Displays “FRONT WIPER INT (ON)/Other (OFF)” status as judged from wiper switch signal.

FR WASHER SW “ON/OFF” Displays “FRONT WASHER Switch

(ON)/Other (OFF)” status as judged from wiper switch sig-

nal.

INT VOLUME “1 - 7” Displays intermittent operation dial position setting (1 - 7) as judged from wiper switch signal.

FR WIPER STOP “ON/OFF” Displays “Stopped (ON)/Operati ng (OFF)” status as judged from auto-stop signal.

VEHICLE SPEED “km/h” Displays vehicle speed stat us as judged from vehicle speed signal.

RR WIPER ON “ON/OFF” Displays “REAR WIPER (ON)/Other (O FF)” status as judged from wiper switch signal.

RR WIPER INT “ON/OFF” Displays “REAR WIPER INT (ON)/Other (OFF)” status as judged from wiper switch signal.

RR WASHER SW “ON/OFF” Displays “FRONT WASHER Switch

(ON)/Other (OFF)” status as judged from wiper switch sig-

nal.

RR WIPER STOP “ON/OFF” Displays “Stopp ed (ON)/Operating (OFF)” status as judged from auto-stop switch 1.

RR WIPER STP2 “ON/OFF” Displays “Stopp ed (ON)/Operating (OFF)” status as judged from auto-stop switch 2.

Monitor item

Contents

Test item Display on CONSULT-III screen Description

Front wiper output FR WIPERFront LO wiper can be operated by any ON-OFF operation.

Rear wiper output RR WIPERRear wiper can be operated by any ON-OFF operation.

IPDM E/R diagnostic Mode Description

SELF DIAGNOSTIC RESULT Displays IPDM E/R self-diagnosis results.

DATA MONITOR Displays IPDM E/R input/output data in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read. ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

ALL SIGNALS Monitors all items.

MAIN SIGNALS Monitor the predetermined item.

SELECTION FROM MENU Selects items and monitors them.

Item name CONSULT-III

screen display Display or unit Monitor item selection

Description

ALL

SIGNALS MAIN

SIGNALS SELECTION

FROM MENU

FR wiper request FR WIP REQ STOP/1LOW/

LOW/HI×× ×

Signal status input from BCM

Wiper auto stop WIP AUTO STOP ACT P/STOP P ×× ×Output status of IPDM E/R

Wiper protection WIP PROT OFF/BLOCK ×× ×Control status of IPDM E/R

Revision: January 20102010 Versa